Eurolite HOOKS AND COUPLERS User manual

HOOKS AND COUPLERS

For your own safety, please read this leaflet carefully before you

initially start-up. You can find the latest update online.

Safety Instructions

This product has left our premises in absolutely perfect condition. In

order to maintain this condition and to ensure a safe operation, it is

absolutely necessary for the user to follow the safety instructions

and warning notes written in this user manual. Damages caused by

the disregard of this user manual are not subject to warranty. The

dealer will not accept liability for any resulting defects or problems.

If the product will be operated in any way different to the one

described in this manual, it may suffer damages and the guarantee

becomes void. Furthermore, any other operation may lead to

dangers like crash etc. Please consider that unauthorized

modifications on the adapter are forbidden due to safety reasons.

Operating Determinations

This hook or half coupler is designed for installing projectors,

lighting effects etc. on a truss system with a tube diameter of 50

mm. The maximum load must never be exceeded. In case the

maximum load of the hook or coupler is too low, you either need to

install two hooks or couplers or a different kind with a higher

maximum load. This product is designed for professional use, e.g.

on stages, in discotheques, theatres etc. Make sure that the area

below the installation place is blocked when rigging, derigging or

servicing.

Installation Instructions

DANGER TO LIFE! Please consider the DIN 15560-27 and the

respective national norms during the installation! The

installation must only be carried out by an authorized dealer!

Before taking into operation for the first time, the installation

has to be approved by an expert.

The installation of the device has to be built and constructed in a

way that it can hold 10 times the weight for 1 hour without any

harming deformation.

The installation must always be secured with a secondary safety

attachment, e.g. an appropriate catch net. This secondary safety

attachment must be constructed in a way that no part of the

installation can fall down if the main attachment fails.

When rigging, derigging or servicing the device staying in the area

below the installation place, on bridges, under high working places

and other endangered areas is forbidden.

The operator has to make sure that safety-relating and machine-

technical installations are approved by: a) an expert before taking

into operation for the first time and after changes before taking

into operation another time. b) an expert after every four year in

the course of an acceptance test. c) a skilled person once a year.

The device should be installed outside areas where persons may

walk by or be seated.

The device has to be installed out of the reach of people.

Overhead rigging requires extensive experience, including (but not

limited to) calculating working load limits, installation material

being used, and periodic safety inspection of all installation

material and the device. If you lack these qualifications, do not

attempt the installation yourself, but instead use a professional

structural rigger. Improper installation can result in bodily injury

and or damage to property.

If the device shall be lowered from the ceiling or high joists,

professional trussing systems have to be used. The device must

never be fixed swinging freely in the room.

Devices in hanging installations may cause severe injuries when

crashing down! If you have doubts concerning the safety of a

possible installation, do not install the device!

Before rigging make sure that the installation area can hold a

minimum point load of 10 times the device's weight.

Mount the device to your truss system via the clamp. For

overhead use, always install an appropriate safety bond. You

must only use safety bonds complying with DIN 56927, quick links

complying with DIN 56926, shackles complying with DIN EN 16771 and BGV C1 carbines. The safety bonds, quick links, shackles

and the carbines must be sufficiently dimensioned and used

correctly in accordance with the latest industrial safety regulations

(e. g. BGV C1, BGI 810-3).

www.eurolite.de

00083390.DOCX, Version 3.2

For overhead rigging in public or industrial areas, a series of

safety instructions have to be followed that this manual can only

give in part. The operator must therefore inform himself on the

current safety instructions and consider them. The manufacturer

cannot be made liable for damages caused by incorrect

installations or insufficient safety precautions!

The maximum drop distance must never exceed 20 cm. A safety

rope which already hold the strain of a crash or which is defective

must not be used again.

Maintenance

The operator has to make sure that safety-relating and machinetechnical installations are inspected by: a) an expert after every four

years in the course of an acceptance test. b) a skilled person once

a year. The following points have to be considered during the

inspection: a) All screws used for installing the devices or parts of

the device have to be tightly connected and must not be corroded.

b) There must not be any deformations on housings, fixations and

installation spots (ceiling, suspension, trussing).

Observe prescribed testing deadlines: a) Once a year by an expert.

b) Every four years by a skilled person. c) Before every use for

breakage and function by the operator.

Should you have further questions, please contact your dealer.

Technical Specifications

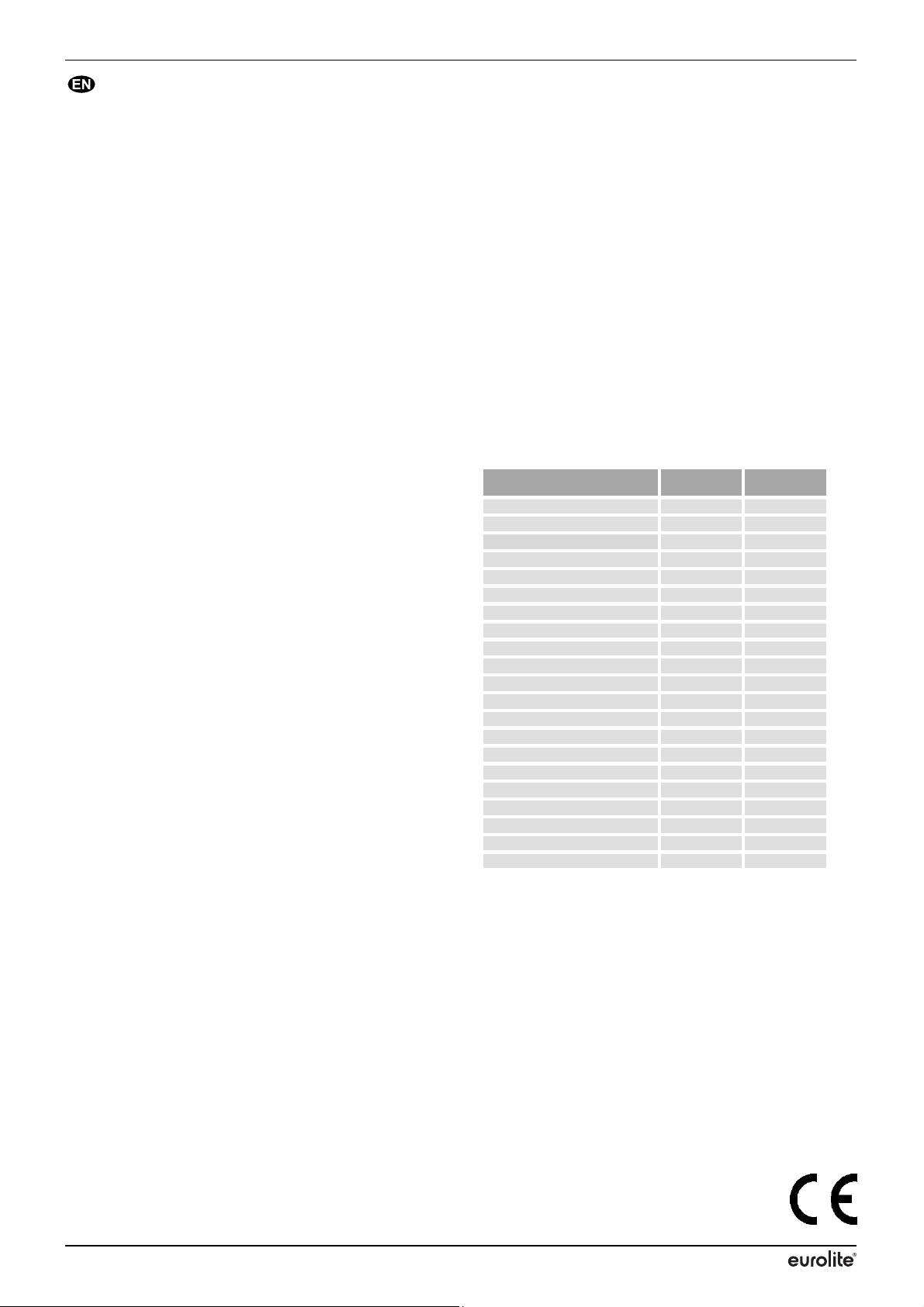

Item

TPC-10 59006856, 59006858

TPC-15 5900685E, 5900685F

TPC-20 59006859

TPC-30 59006860, 59006862

TPC-31 59006865, 59006867

TPC-32 59006868

TPC-35 59006870, 59006872

TPC-36 5900687A

TPC-50 59006800, 59006802

TPC-51 59006848, 59006849

TPC-55 59006845, 59006846

TPC-56 59006850

TH-35 58000705

TH-100N 58000732

TH-150 58000735, 58000736

TH-200 58000740, 58000741

TH-250 58000760

TH-260 58000751

DEC-30 59006905, 59006908

DEC-30D 59006915, 59006917

DEC-30E 59006920, 59006922

Every information is subject to change without prior notice.

07.01.2015 ©

Max. Last WLL

(4-fach)

150 kg 0.3 kg

150 kg 0.3 kg

10 kg 0.03 kg

500 kg 0.5 kg

500 kg 0.6 kg

200 kg 0.4 kg

500 kg 0.9 kg

200 kg 0.5 kg

800 kg 0.7 kg

800 kg 0.8 kg

800 kg 1.3 kg

800 kg 1.3 kg

75 kg 0.2 kg

200 kg 0.5 kg

200 kg 0.4 kg

400 kg 0.6 kg

250 kg 0.5 kg

200 kg 0.5 kg

100 kg 0.1 kg

250 kg 0.2 kg

250 kg 0.2 kg

Weight

Loading...

Loading...