Page 1

Operating and installation instructions - INOA cellar conditioners

March 2009

1

Page 2

CONTENTS

WELCOME TO THE WORLD OF EUROCAVE

1 • CONDITIONER DESCRIPTION

2 • IMPORTANT SAFETY RECOMMENDATIONS

3 • ELECTRICAL POWER SUPPLY

4 • CARE FOR THE ENVIRONMENT AND ENERGY SAVING

5 • TECHNICAL SPECIFICATIONS

6 • CELLAR INSULATION

7 • INSTALLING YOUR CONDITIONER

I- General points

II- Drilling the wall

III- Fitting

IV- Discharging condensate

8 • CONDITIONER OPERATION

9 • INSTALLING THE REMOTE CONTROL

I- Remote control description

II- Installing the remote control inside the cellar

III- Installing the remote control outside the cellar

10 • COMMISSIONING YOUR CONDITIONER

I- Connection

II- Switching on

III- Remote control description

IV- Installing the remote control

V- Setting the temperature

VI- Silent function

VII- “Heating” function

VIII- Changing the remote control batteries

IX- Discharging condensate

11 • MAINTENANCE

12 • OPERATING FAULTS

2

Venting plate and wall mounting bracket dimensions

p.18

p.15

p.15

p.15

p.16

p.18

p.18

p.18

p.19

p.19

p.20

p.20

p.20

p.20

p.21

p.21

p.7

p.8

p.9

p.9

p.10

p.10

p.11

p.13

p.14

p.6

p.6

p.4

p.5

p.6

Page 3

Solutions to meet all your needs

Inoa* Vin au Verre*

* Product not available in cer tain countries.

3

W INE C ABINETS

O rigine Classic Compact

Leather Meuble à Vins Elite

Sommelier

STORAGE SYSTEMS

Modulothèque Modulocube Modulorack

S

C

ELLAR C O N DIT IONERS

YSTEM TO SERVE W INES BY THE GLASS

Page 4

O ur greatest wish is to accompany your enthusiasm for wine throughout the years…

To do so, EuroCave puts all of its know-how into action to bring together the essential factors in optimal wine maturing:

Temperature:

The two worst enemies of your wine are extreme temperatures and sudden uctuations in temperature.

A constant temperature of 10° to 14°C (50 to 57°F) is considered to be ideal for your wine to reach its full potential.

O wing to its electronic regulation system, your EuroCave IN OA conditioner is activated as soon a

s the cellar

temperature rises one degree above the programmed temperature. Furthermore, the presence of a heater built into the

air distributor protects your wine from any signicant fall in temperature.

Humidity:

This is an essential factor, enabling corks to retain their sealing qualities. The level of humidity must be higher than 50%

(i

deally between 60 and 75 %).

By maintaining a constant evaporation temperature, above 0°C , your EuroC ave IN O A conditioner ensures minimal drying

out of the air of your cellar and an ideal level of humidity.

Protection from light:

Light, and more especially its ultra-violet component, will rapidly prove noxious to your wine by irreversible oxidation of

its tannins. For this reason we strongly advise that wines be stored in the dark, far from U.V. light.

Protection fr

om vibration:

Vibration disturbs the slow process of your wine’s biochemical evolution, and is often fatal for the nest wines.

The housing of your EuroCave conditioner is fully sound-proofed (by 20 mm polyethylene foam) and the compressor and

fans are tted with silent blocks to absorb any residual vibration.

Natural aeration:

A constant supply of air from the outside is also indispensable.

All of these specic features can be

found in the EuroC ave INOA conditioner you have bought. W e thank you for the

condence you have placed in us.

French wines

Alsace 10°C

Beaujolais 13°C

Bordeaux Sweet W hite 6°C

Bordeaux D ry W hite 8°C

Bordeaux Red 17°C

Bourgogne W hite 11°C

Burgundy Red 18°C

Champagne 6°C

Jura 10°C

Languedoc-Roussillon 13°C

Provence Rosé 12°C

Savoie 9°C

Vins de Loire Dr y W hite 10°C

Vins de Loire Sweet 7° C

Vins de Loire Red 14°C

Vins du Rhône 15°C

Vins du Sud Ouest Sweet 7°C

Vins du Sud Ouest Red 15°C

Australian wines

Cabernet franc 16°C

Cabernet sauvignon 17°C

Chardonnay 10°C

Merlot 17°C

Muscat à petit gr ain 6°C

Pinot noir 15°C

Sauvignon W hite 8°C

Semillon 8°C

Shiraz 18°C

Verdhelo 7°C

Other wines

C°61 ainrofilaC

C°51 elihC

C°71 niapS

C°61 ylatI

Usual wine serving temperatures

WELCOME TO THE WORLD OF EUROCAVE

4

Page 5

1 - Conditioner / ceiling distance: 200 mm min.

2 - Ceiling

3 - Cellar wall

4 - Metal mounting frame

5 - Flexible ducting

6 - Aesthetic front panel

7 - Grid, to be cleaned regularly (see p.11)

8 - Mounting frame / conditioner seal

9 - Evaporator, to be cleaned regularly

10 -

Condenser, to be cleaned regularly

11 - Inside of cellar

12 - Remote control

13 - Grid securing screws (quantity: 24)

14 - Aesthetic front panel securing screws

(quantity: 4)

15 -

Screws to x frame to the wall (quantity: 4)

16 - Screws to x conditioner to the frame

(quantity: 4)

1 - CONDITIONER DESCRIPTION

HOT AIR

COLD AIR

5

Page 6

2 - IMPORTANT SAFETY RECOMMENDATIONS

Your conditioner’s power lead is supplied without a plug. Installation of a power plug or connection of the conditioner to a junction box must be car ried

out by a qualied electrician.

In all cases, the connection of your conditioner must be carried out on an earthed socket to prevent any risk of electric shock.

Have an electrician carr y out the installation. He will tell you whether or not the socket is correctly earthed and, if necessa

ry, will perform any work required

to br ing your installation in line with standards.

IMPORTANT: any electrical work must be carried out by a qualied electrician.

Electric connection must be carried out by means of a device to ensure isolation from the mains system.The isolating device should open all of the contacts

of all the poles ensuring complete disconnection in line with the conditions in over-voltage category III. In

stallation must be carr ied out in compliance with

national installation regulations.

Should you move to another country, check that the conditioner ’s electrical rating (see grey identication label) complies with the country (voltage,

frequency).

Ensure that the plug (230 V – 13 A*) is correctly earthed and that your installation

is protected by a dierential circuit breaker (30 mA*).

*not valid for some countries

3 - ELECTRICAL POWER SUPPLY

For your personal safety, the conditioner must be correctly earthed.

4 - CARE FOR THE ENVIRONMENT

AND ENERGY SAVING

Never use your conditioner for anything other than its specic purpose as described in this guide.

Never unplug the conditioner by pulling on the supply lead. Take a rm hold on the plug and pull out smoothly in a

straight line from the wall socket.

If the power lead is damaged, it must be replaced by a qualied electrician.

Do not allow children to climb, sit, stand on or hang from the conditioner.They could damage the conditioner, as well

as badly hurting themselves.

Never damage your applianc

e’s refrigeration unit.

W hen using your conditioner, you

should always observe certain

basic precautions, especially:

Warning

Disposal of packaging:

The packaging used by EuroCave is made of recyclable materials.

After unpacking your conditioner, take the packaging to a waste disposal centre. For the most part it will be recycled.

Recycling:A caring gesture

Electrical and electronic equipment have potentially hazardous eects on the environment and public health due to the presence of

noxious substances.

You should therefore never dispose of electrical or electronic equipment with unsorted municipal waste.

W hen buying a new EuroCave product (wine cabinet, cellar

conditioner, Vin au Verre), you can take advice about the recycling of your old appliance from

your EuroCave dealer.

In compliance with legal provisions covering respect and care for the environment, your conditioner does not contain CFCs.

Energy saving:

- Install your conditioner in an appr

opriate place and within the recommended temperature ranges.

- Keep the door open for as short a time as possible.

N.B.: Care for the environment: when replacing your conditioner, consult your local municipal refuse department in order to obser ve the appropr iate

recycling procedure.

For refrigerant gases, substances and some par ts contained in the conditioner, EuroC ave uses recyclable materials which require a special packaging disposal

procedure to be followe

d.

Place unusable appliances out of use by unplugging them.

6

Page 7

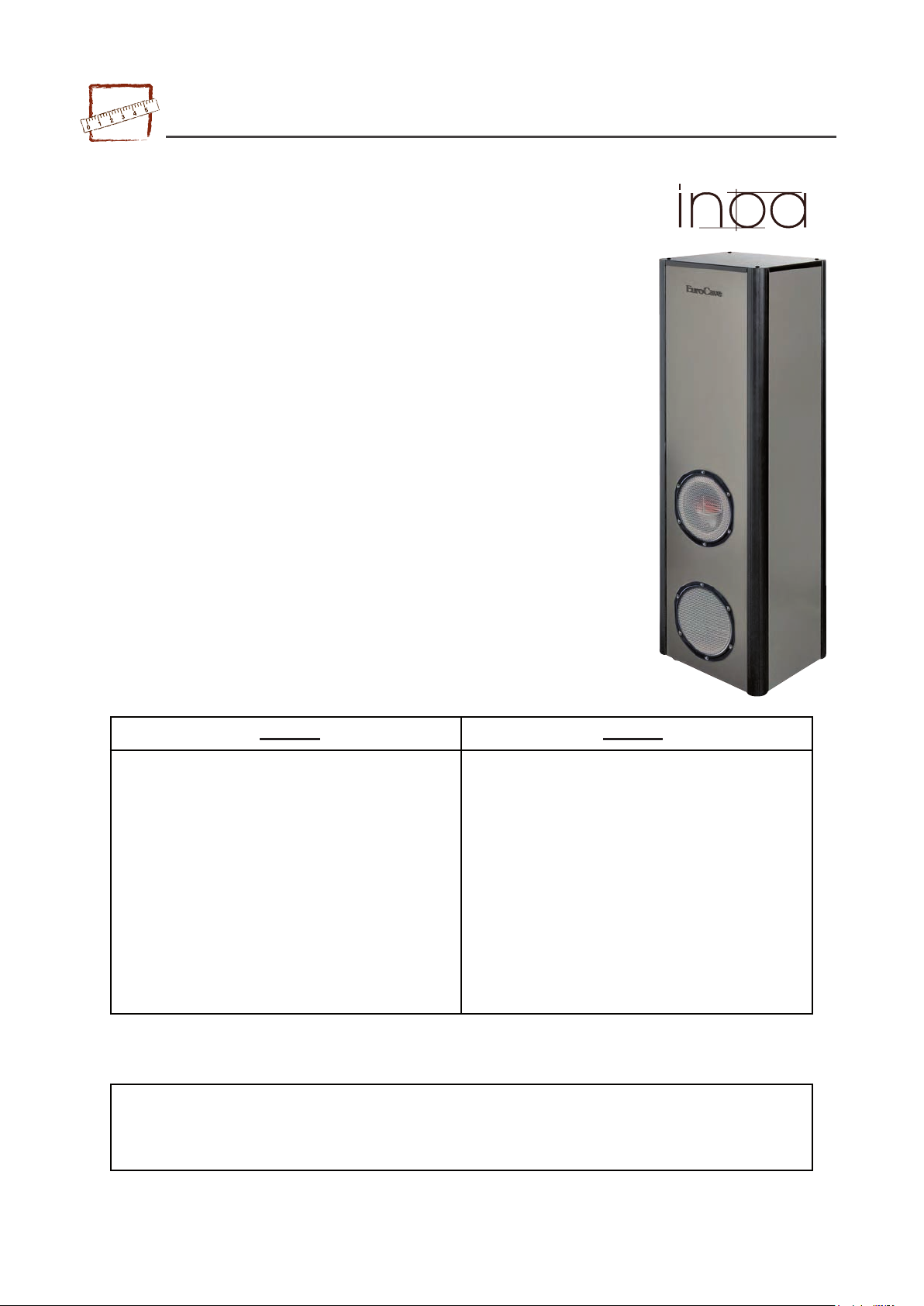

INOA CELLAR CONDITIONER

EuroCave Inoa 25 Cellar conditioner

Dimension W385 x D322 x H1250 mm

Weight: 43 KG

Power supply 230V / 50 Hz

Volume up to 25 m3 (*)

Cooling Capacity 600W

Electrical Power 500W (**)

Heater element 650W

Cooling Gas: R134a

External Temp -5°C to 35°C

Noise level: 44dbA – 50dbA

Supplied with a 3.50 m power lead without plug

Ref: INOA 25

EuroCave Inoa 50 Cellar conditioner

Dimension W385 x D322 x H1250 mm

Weight: 46 KG

Power supply 230V / 50 Hz

Volume up to 50 m3 (*)

Cooling Capacity 1200W

Electrical Power 800W (**)

Heater element 650W

Cooling Gas: R134a

External Temp -5°C to 35°C

Noise level: 44dbA – 50dbA

Supplied with a 3.50 m power lead without plug

Ref: INOA 50

INOA 25 INOA 50

S PECI F ICATIONS

* for an isolated wine cellar following our advice please refer to our insulation guide

** for an internal temperature of 12°C and an external temperature of 32°C

F

UNCTION

The purpose of the cellar conditioner is to climate control any kind of fully

insulated room creating an ideal wine cellar environment by monitoring and

adjusting the temperature and humidity.

T EC H NOLO GY

The conditioner’s housing is dampened against sound and the compressor

and fans are fitted with silent blocks to absorb any residual vibration.

A quiet conditioner: the system automatically adjusts speeds to ambient

temperature conditions, combined with the use of particularly quiet fans,

allows the conditioner to operate very discreetly.

Energy efficiency: Inoa conditioners use the compressor infrequently,

insulation between the condenser and the evaporator minimises any

exchange between the cold and hot sections of the appliance, thus favouring

energy efficiency.

The Inoa come as standard with the hot air discharge opposite the cold air

exit. It can be ordered with the hot air exit on the left or the right side as an

option.

Important information

For insulation, installing, positioning and more please make sure you have read our Installation

guide and our Insulation guide.

5 - T ECHNICAL SPECIFICATIONS

7

Page 8

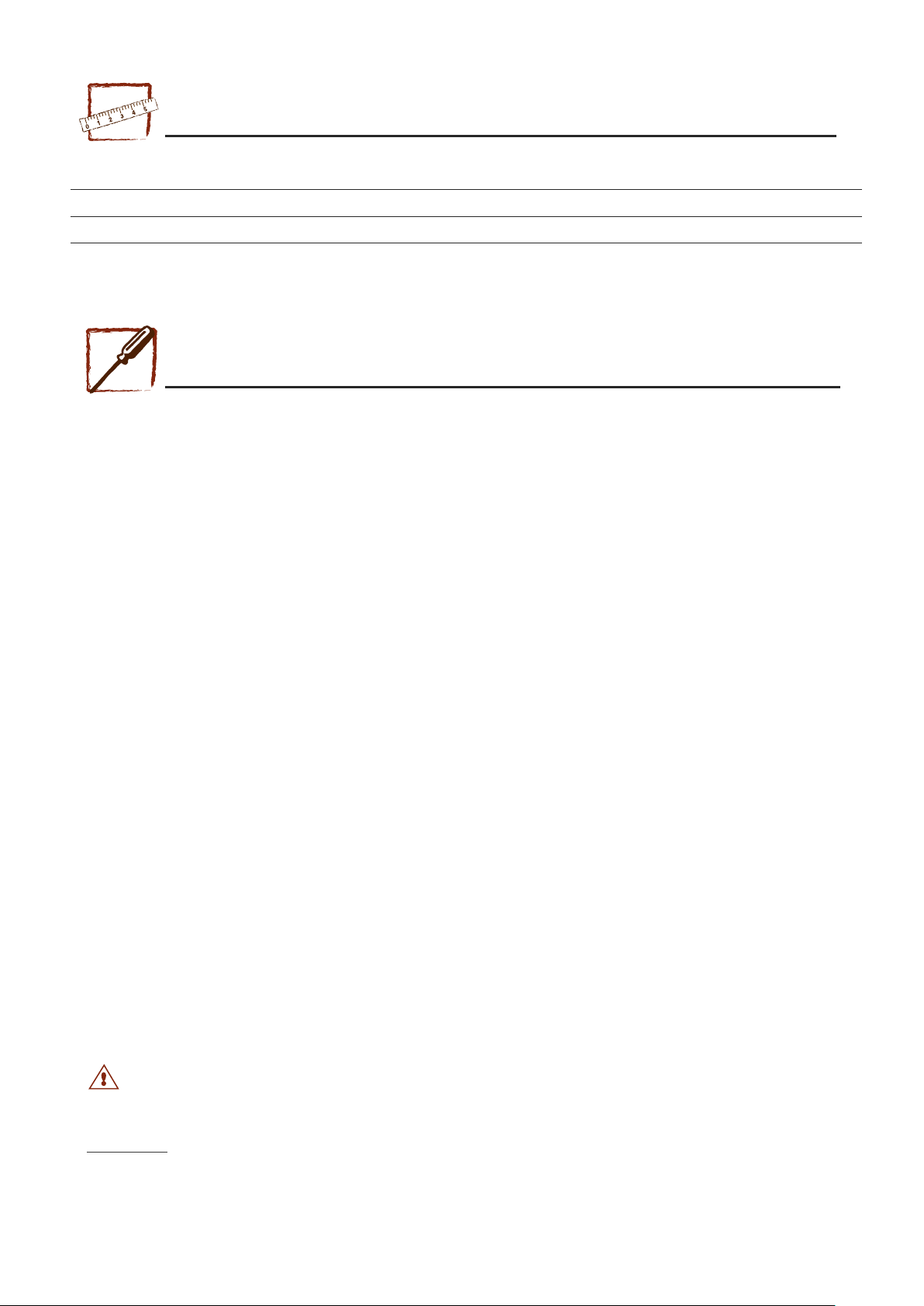

2 - TECHNICAL SPECIFICATIONS

3 - CELLAR INSULATION

Dimensions Power Sample Cooling Weight Electrical Heating Refrigerant External

in mm supply volume m

3

serutarepmetW ecnatsiserW rewopgKW yticapac

Inoa 25 W385 x D322 230 V up to 600 W** 43 Kg 550 W** 650 W R134a -5°C to 35°C

x H1250 / 50 Hz 25 m3 * (without CFCs)

Inoa 50 W385 x D322 230 V up to 1200 W** 46 Kg 800 W** 650 W R134a -5°C to 35°C

x H1250 / 50 Hz 50 m3 * (without CFCs)

* in a very well insulated room - ** for an internal temperature of 12° C and an external temperature of 32° C.

Supplied with a 3.50 m power lead without plug.

Traditional building materials such as stone, concrete and brick are very poor insulators and only underground sections represent any real insulation.

It is therefore essential, in the majority of cases, to insulate the entire room to be conditioned.

Insulate – yes but how?

We recommend that you use extruded polystyrene, currently the most ecient product on the market. It is the least ammable and the most durable

material. It also has the advantage of not being attacked by rodents. Furthermore,extruded polystyrene boards can be layered and therefore prevent thermal

bridges.To increase your conditioner’s lifespan and reduce electricity consumption, we recommend that you use extruded polystyrene which is at least 80

mm thick.

80 mm of extruded polystyrene provides the same amount of insulation as a 5m thick stone wall.

The insulation must be completely continuous (no gaps).

Insulation boards: dierent methods of tting are possible

How can you determine whether or not a material is a good insulator? The insulation performance of a material is established by its R thermal resistance

(m2.°C/W). It determines the material’s ability to conduct heat.

R = e/ λ - The greater the R coecient, the better the insulation. (λ = thermal conductivity coecient)

There are 3 types of insulation boards:

Insulator only, complex (with plaster cover) or sandwich (plaster both sides)

Depending on the type of insulator chosen, several methods of tting are possible:

• Against the walls

- Standard extruded polystyrene board:pre-cut to the dimensions of the area to be conditioned,they are tted using high-bond mortar.For a more acceptable

nish, it is possible to x rails onto which you screw the plaster board panels over the polystyrene.

- Sandwich or complex boards: the polystyrene is already integrated into the plaster board.

Whatever the method used, all kinds of decorative nishes are possible to obtain an attractive wall.

If you

only want to condition a section of your room, install a plaster board dividing wall then insulate the side of the room to be conditioned.

N.B.: Befor

e being insulated, walls must be clean. If they are too damp, clean them with a wire brush then clean with a high pressure water jet and paint with

an emulsion paint.

• On the ceiling and door

The process for insulating the ceiling and door is identical to that of the walls. We recommend that you use extruded polystyrene.

• On the floor (insulation optional)

- Original clay oor: not insulating favours the passage of humidity, which is good for the wine.

- Concrete oor (for example): Concrete is a very poor insulator.A few centimetres of ne gravel can, in some cases, improve insulation.

It is essential that the surface material used for the oor (whether or not covering

insulation) can support the weight of wine racks and has resistance to compression.

Tools required

- handsaw, tape measure, bricklayer’s ruler, trestles,screwdriver or screw gun, drill, hammer, level, plumb line, wood mallet, spatula, precision knife...

8

Page 9

7 - INSTALLING THE CONDITIONER

I - General points

- Never damage the appliance’s refrigerating circuit.

Your conditioner’s power lead is supplied without a plug. “Fitting a power plug or connecting the conditioner to a junction box must be carried out by a

In all cases, connection of your conditioner must be carried out on an earthed socket to prevent any risk of electric shock.

*not valid for some countries

IMPORTANT : any electrical work must be carried out by a

Electric connection must be carried out by means of a device to ensure isolation from the mains system. The

isolating device should open all of the contacts of all the poles ensuring complete disconnection in line with

the conditions r in over-voltage category III. Installation must be ca ried out in compliance with national

installation regulations.

• Positioning your conditioner:

The conditioner produces cold air inside the cellar and expels hot air outside (see diagram A).

- Do not install the conditioner facing the door of the room (risk of condensation on the door joints).

- Do not place the external section of the conditioner

above a source of heat.

- For insulation reasons, there must be no windows or bay windows in the room to be conditioned.

- Is it not better to state that pipes with hot water must be insulated so that there is no heat loss?

- The exterior of the conditioner must not be located in an area subject to ingress of rain, wind, snow or poor

quality air.

- No heat-producing appliance must be located in the area to be conditioned (e.g. refrigerator,radiator, boiler).

- Do not obstruct the air entry and exit points.

- Never place a container or object containing liquid on top of the conditioner.

- The room where the hot air is expelled must, ideally,be approximately twice as large as the wine cellar and well

ventilated so that the hot air can be properly expelled.

- Wait 48 h

- Never connect several conditioners to a multi-socket.

• Recommendations:

- Fit your conditioner as close as possible to the ceiling in order to ensure uniform dispersal of cold air in the

cellar.

- We recommend that you leave a space of 200 mm between the ceiling and conditioner housing to make it easier

electrician. Power outlet not valid for some countries.

Ventilated

room

Temperature:

Max.: 35°C

Min.: -5°C

Diagram A

Door Conditioner

Door

Conditioner

CELLAR

Bottles

CELLAR

CELLAR

Bottles

Conditioner

- Air outlets (hot and cold) must not be obstructed by any obstacles (minimum distance: 1500 mm).

Direct the cold air outlet so it is facing the bottles (see diagram D).

• Installation: (see B diagrams)

Diagram D

CELLAR

Door

The conditioner was designed to be completely modular and adapt to any type of cellar.

however, installing it at a height for improved air convection).

You also have the option of expelling hot air outside the room by way of extractor piping (standard piping, 160 mm in diameter, not supplied).

Cold air

discharged

Conditioner housed outside the cellar

with extraction facing forwards /

aesthetic front panel on the inside

Conditioner housed inside the cellar,

Conditioner housed inside the cellar

with extraction facing forwards /

aesthetic front panel on the outside

Conditioner housed outside the cellar

with extraction on the left side /

aesthetic front panel on the inside.

Cold air

discharged

Hot air

expelled

Diagram B Diagram B

Diagram B Diagram B

Hot air

expelled

Bottles

4

GB

9

Page 10

7 - INSTALLING THE CONDITIONER

• Fitting: (see C diagrams)

The conditioner comes supplied with a metallic mounting frame which

simplies the process of drilling air entry and exit holes.

It also has extendable ducting to be cut to length (75 cm each) in order to

install the conditioner whatever the thickness of the wall.

Finally, the conditioner is supplied with an aesthetic front panel and 4 grids

for an aesthetic appearance.

II- Drilling the wall

- Determine the location of the conditioner housing (inside or outside the cellar)

- Position the metallic mounting frame:(1)

• in relation to the ceiling if tting the conditioner at a height (maintain a distance of 200

mm between the top of the frame and the ceiling),

• in relation to the oor for a low tting (maintain a distance of 80 mm between the

bottom of the frame and the oor).

- Use the metallic frame to outline the position of the 2 drill holes (2).

- Drill the wall.The holes must be larger than the outline drawn – between 210 mm min. and

280 mm max.

III- Fitting

- Fold the ring’s 4 supports inwards (1).

- Fit the 2 extendable ducts onto the rings of the metallic frame (2).

- Scre

w the securing rings onto the ducts (3).

- Position the metallic frame while passing the exible ducts through the 2 holes drilled into the wall (4).

- Push back the 4 supports towards the outside of the ring (5).

- Screw the metallic frame onto the wall with 2 high screws and two low screws (not supplied).Use screws suitable for the wall material (6).

- We recommend that you put a bead of silicone between the plate and the wall to ensure eective sealing.

- Pull the 2 ducts (xed to the metallic frame) through the other side of the wall (7).

- Stretch the ducts to the maximum in order to make them as smooth as possible (8).

- Cut the ducts ush with the wall using a Stanley knife for the material (9) and pliers for the metallic wiring (10).

(1)

(1) (2) (3) (4) (5)

(2)

(6) (7) (8) (9) (10)

Metallic

mounting

frame

Extendable

ducting

Wall drill

holes

Aesthetic

front panel

Aesthetic

front panel

Grid

Grid

Wall drill

holes

Extendable

ducting

Metallic

mounting

frame

C margaiDC margaiD

Conditioner housed inside the cellar

Conditioner housed outside the cellar

10

Page 11

11

Air-in

Air-in

Page 12

AFTER SALES DEPARTMENT

TECHNICAL NOTE N° 031

Date : 15/11/10 Revision : 0 Page : 1 of 2

Subject: INOA-TECHNICAL DATAS AND TUBING

UNITS AFFECTED: INOA25 et INOA50

SERIAL NUMBER: All

DATE OF PRODUCTION: Since June 2007

Position of the panels :

Maximum pipe lengths recommended:

Two parts, 7 linear meters of pipe diameter 160 mm without elbow.

Or

Two parts, 5 linear meters of pipe diameter 160 mm with 3 90°’s elbows.

Page 13

AFTER SALES DEPARTMENT

TECHNICAL NOTE N° 031

Date : 15/11/10 Revision : 0 Page : 1 of 2

Subject: INOA-TECHNICAL DATAS AND TUBING

Extraction kit: AEVACLM or PEVACLM (not supplied with the air conditioner, option

to be ordered), one kit per hole.

Technical datas: INOA 230 V 50 Hz INOA25 INOA50

Maximum volume of the wine cellar 25 m3 50 m3

Cooling power 600 W 1200 W

Maximum distance for the remote control 10 m 10 m

Quantity of speeds for the condenser fan 4 4

Quantity of speeds of the evaporator fan 3 3

Condenser fan air flow (per speed : 1, 2, 3, 4) in m3/h 230, 335,

431, 563

Evaporator fan air flow (per speed : 1, 2, 3) in m3/h 199, 285,

382

Gas load in R134a 400 grs 400 grs

Pressures BP and HP for 35°c (in bar) 2,3 ; 11,2 2,1 ; 10,5

Type of gas reducer Capillary Capillary

Condenser gas temperature 47°c 45°c

273, 353,

473, 682

227, 352,

445

Page 14

7 - INSTALLING THE CONDITIONER

- Position and t the aesthetic front panel to the wall (screws not supplied). Use screws suitable for the wall material (11).

- We recommend that you put a bead of silicone between the panel and the wall to ensure eective sealing.

- Fold the ange’s 4 supports inwards (12).

- Place the ducts onto the anges ensuring that they are well secured on the supports (13).

- Push the 4 supports towards the outside of the ange (14).

- On the side of the conditioner to be placed against the wall unscrew the 2 grids from the housing using the supplied Hex wrench and retain the screws.) (15).

- Using the screws retained in the last instruction, screw the 2 grids onto the aesthetic front panel (16).

- Unscrew the 2 screws on the top of the conditioner using a Hex wrench (supplied), on the side to be placed against the wall. Retain the two screws (17).

- Fix the conditioner housing to the metallic frame, taking care to press rmly onto the foam (18).

- Sc

rew down the conditioner housing using 2 screws at the top (those retained earlier) and 2 screws at the bottom (supplied in the accessories packet) (19).

• Fitting onto a door:

You can t the conditioner onto a door.

In this case, it is ESSENTIAL to check that the door is capable of supporting a weight of 46 kg and that it does not produce vibration.

The procedure for tting is the same as for the wall.

• Fitting close to the floor:

When the conditioner is tted close to the oor it is ESSENTIAL that it is xed to

the wall.

• Conditioner with air extraction via piping:

Repeat the steps described at the beginning of paragraph III.

Conditioner housed outside the cellar:

- On the conditioner housing, unscrew the 2 grids (openings that will not be placed against the wall) using a Hex wrench (supplied).

- Where the grids were located, position and screw, using a Hex wrench (supplied) the 2 anges* onto the housing (1) and (2).

- Fit together the reducer* (3).

- Position the air extraction piping (standard piping, 160 mm in diameter, not supplied).

*Consult your EuroCave distributor

(11)

(16)

)3()2()1(

(17) (18) (19)

(12) (13) (14) (15)

12

Page 15

7 - INSTALLING THE CONDITIONER

Conditioner housed inside the cellar:

There are 2 methods for attaching the hot air extraction piping:

- Attaching the piping directly to the aesthetic front panel:

- Position and screw, using a Hex wrench (supplied), the two supplied anges* onto the aesthetic front panel (1).

- Fit together the reducer (2).

- Position the air extraction piping (standard piping, 160 mm in diameter, not supplied) (3).

- Attaching the piping directly to the conditioner housing (the extraction piping passes through the wall):

If using this method, you must not use the exible ducting supplied with the

conditioner.

- Fit the reducer* directly onto the mounting frame through the wall (1).

- Position the air extraction piping (standard piping, 160 mm in diameter, not supplied) (2) (3).

For this type of fitting, it is necessary to ensure sealing around the piping.

*Consult your EuroCave distributor

IV- Discharging condensate

The conditioner was designed to allow condensate to be discharged (discharge pipe located under the

conditioner’s housing) either inside the cellar

, if the humidity level is too low,or outside the cellar.

Simply pass the pipes through the wall to discharge the condensate into the room next to the conditioner

housing.

Ensure that the piping is not cramped.

(1) (2) (3)

(1) (2) (3)

13

Page 16

8 - CONDITIONER OPERATION

Cold air

Hot air

(heated if necessary)

Hot air

Evaporator

Condenser

Compressor

Fan

Turbine

Heater

The INOA conditioner is tted with a refr igerating unit:

• an evaporator forces cold air inside the room,

• a condenser expels the hot air outside.

14

The evaporator fan operates continuously to ensure that air is constantly mixed and that temperatures

are as uniform as possible,in accordance with speeds automatically adjusted according to requirements.

Page 17

I- Remote control description

Radio frequency remote control (433.92 Mhz)

Each remote control has a personalised code matched to the conditioner.

Power supply: 2 x 3V (CR 2430 battery, supplied)

II- Installing the remote control inside the

cellar

We recommend that you place the remote control as close as possible to the bottles.

Fit the unit close to your

bottles using the supplied

pegs and screws (see

diagram below)

NB: Do not place the remote control in the path of the conditioner’s cold air ow.

Temperature

indicator

Low battery

indicator

Knob

9 - INSTALLING THE REMOTE CONTROL

Temperature

units (according

to the country)

Conrmation and on/o key

Temperature and

setting display

Adjustment keys

On / o indicator

15

Page 18

III- Installing the remote control outside the cellar

The remote control can also be placed outside the cellar.

In this case, it is essential to connect a sensor (supplied with the appliance) to the remote control before installing it.

a- Connecting the sensor to the remote control

- On the back of the remote control, push the 2 batteries downwards using a screwdriver (see diagram below).

- Remove the central knob, unscrew the screw with a small screwdriver and open the unit (see diagram below)

On the back, connect the sensor’s 2 wires (blue and red) to the circuit connector using a small at screwdriver (see diagram below).

You can connect either the blue wire or the red wire to the circuit connector.

Pass the wires through the recess on the top of the unit.

- Close the unit, ensuring that the wires pass through the recess and are not jammed

- Rescrew and replace the central knob

9 - INSTALLING THE REMOTE CONTROL

Battery CR2430

16

Page 19

- Programming the remote control

Where placing the remote control outside the cellar, having connected the external sensor, it is essential to reprogramme the unit

- To turn on the remote control, press and hold down the key for about 8 seconds until the indicator goes o.

- First press and continuously hold down the key, at the same time press and continuously hold down the key for several seconds until three

lines appear. The model number is then displayed and ashes. .

- Press .

- The screen appears indicating IN (IN= internal installation). Press the key to change to OUT external mode.

- The display appears indicating OUT (OUT= external installation). Press to conrm.

- The pictogram appears. Press .

- The screen appears. Press .

- The pictogram appears. Press .

- .appears. Press .

- The pictogram appears. Press .

- The screen appears, then .

If you wish to reprogramme the remote control for an internal sensor,disconnect the wired sensor and reprogramme the remote control in internal mode

(IN) by

repeating the rst two steps described in the paragraph above (see 5-III-b p.11):

The 2nd screen displays indicating OUT (OUT= external installation). Press the key to change to IN internal mode. Press to

conrm.

Then repeat the same steps, as indicated in the above paragraph (see 5-III-b).

c- Fitting

- Fit the remote control and sensor using the screws and pegs supplied (see diagram on page 9, chapter II).

- Place the sensor inside the cellar.

- Place the sensor as close as possible to the bottles

N.B.: the sensor has a range of 3 metres.

9 - INSTALLING THE REMOTE CONTROL

17

Page 20

10 - COMMISSIONING YOUR CONDITIONER

I- Connection

Check that the plug is connected to a power supply (presence of correct amp fuses, functioning 30 mA* dierential circuit breaker - not applicable to certain

countries).W ait 48 hours before plugging in your conditioner.

II- Switching on

- Place the switch, located under the conditioner, in position 1.

- Press and hold down the key on your remote control for about 8 seconds, until the indicator goes o.

To put your conditioner on standby

, press and hold down the key on your remote control for about 5 seconds and release it before the indicator

goes o.

III- Remote control description

Radio frequency remote control (433.92 Mhz).

Each remote control has a personalised code matched to the conditioner.

Temperature

indicator

Low battery

indicator

Knob

Temperature units

(according to the

countr y)

Conr mation and on/o key

Temperature and

setting display

Adjustment keys

O n / o indicator

18

Page 21

10 - COMMISSIONING YOUR CONDITIONER

IV- Installing the remote control

You can install the remote control inside your cellar.

We recommend that you place it as close as possible to the bottles.

Fix the unit close to your bottles using the supplied pegs and screws (see diagram below)

N.B.: D o not place the remote control in the path of the conditioner ’s cold air ow.

It is also possible to place the remote control outside the cellar.

In this case, an external sensor (supplie

d) must be connected to the remote control and then the remote control must be reprogrammed.

For fur ther details, contact your EuroCave retailer.

V- Setting the temperature

Setting the temperature of your conditioner is carried out entirely from the remote control which has the following layout:

- Temper ature display: displays the actual temperature inside

your cellar.

- Setting keys: allow you to select the desired temperature

inside the cellar.

T

o adjust the temperature:

- Press then immediately release the key.

The setting then appears (the temperature ashes).

- - W hen the temperature ashes, you have 7 seconds to change the setting by pressing the or keys, other wise the display automatically returns to

the previous setting.

The recommended setting range for maturing wine: 10 to 14°C .

Temperature

units (according

to the country)

Selection and conrmation key

Cellar

temperature

display

Cellar temperature

setting keys

Temperature

indicator

19

Page 22

10 - COMMISSIONING YOUR CONDITIONER

- Press the key to conrm the new setting, the display then returns to the new setting.

The setting can be adjusted between 9 and 15°C . Beyond this range, the and keys do not work.

WARNING: to operate correctly, your conditioner must be in a location where the ambient

temperature is between -5°C is 35°C.

W hen making signicant modications to temperature settings, it can take several hours for the temperature in your cellar to stabilise and for the conditioner

to display the desired temperature.

VI- Silent function

Your EuroCave conditioner is tted with a silent function which allows the sound level to be reduced when you enter the cellar.

W hen the conditioner is on:

- Press and hold down the key for 3 seconds.

The display then appears. Next the current temperature is displayed.

You will be able to see this function via the pictogr am which ashes for 15 minutes.

The compressor then remains in operation and the fans

change to slow speed for 15 minutes.

After this, the conditioner returns to the default operating speed.

VII- Heating function

The EuroCave INOA conditioner has a heater (650 W ) allowing the internal temperature in your cellar to be maintained at an optimal level.

As soon as the temperature drops below the programmed temperature, the heating function is automatically activated.

VIII- C hanging the remote control batteries

Remote control power supply: 1 x 3 V (CR 2430 batter y) (2 batteries supplied)

Battery life: 2 years approx

The remote control is supplied with 2 batter ies. O nly one battery is required (pull o the plastic strip to make it

useable).The other battery is a spare.

- W hen the battery runs out, the pictogram ashes on the remote control’s display.

- Take the remote control o the wall.

- On the back of the remote control, push the used battery

down using a screwdriver (see diagram opposite).

- Pull the strip from the spare battery, which will then be ready for use.

- Remember to buy a replacement for the spare battery.

IX - Discharging condensate

Your conditioner was designed to allow condensate to be discharged (discharge pipe located under the conditioner ’s

housing) either inside the cellar, if the humidity level is too low, or outside the cellar.

S

imply pass the pipe through the wall to discharge the condensate into the room next to the conditioner housing.

Ensure that the piping is not kinked.

20

Page 23

12 - OPERATING FAULTS

If the conditioner is not working, there may be loss of synchronism between the appliance and the remote control.

Synchronising procedure:

- Remove the conditioner housing upper cover (4 screws) (1).

- To turn on the remote control, press and hold down the key for about 8 seconds, until the indicator goes o.

- Place the switch, located under the conditioner,in position 1.The green LED on the board comes on (2).

- Press and hold down the On/O button (brown button) on the board for more than 6 seconds, then release (3). The green LED will then start to ash

(synchronising mode).

- Simultaneously press the and keys on the remote control until ! is displayed .

- As soon as the green LED on the board stops ashing (end of synchronising mode), the conditioner and remote control are then synchronised.

- Exit "RF" mode by pressing the key on the remote control.

(1) (2) (3)

On/ o button

Green LED

11 - MAINTENANCE

It is necessary to thoroughly clean the conditioner’s internal elements every year.

- Unplug the appliance.

- Place the appliance on the ground to disassemble it (4 screws).

- Vacuum the 4 air entry and exit grids.

- Remove the upper cover (2 screws) (1).

- Snap o from the top the 2 columns in order to access the 8 screws of the 2 front sections (2).

- Disassemble the front sections by removing the screws (square end pieces, not supplied).

- Thoroughly clean the ribs of the 2 exchangers with a vacuum cleaner (3).

- Repeat these instructions in the opposite order to reassemble the appliance.

(1) (2) (3)

Ribs of the

2 exchangers

21

Page 24

12

GB

WARNING

The information in this document is subject to modication without prior notice.

EuroCave oers no guarantee on this equipment item if it is used for any specic purpose other than that for which it was designed. EuroCave cannot be

held responsible for any errors in this manual, nor for any damage linked to or following the provision, performance or use of the equipment item.

All photocopying, reproduction, translation, wether partial or total, are strictly prohibited, without prior written consent from EuroCave.

22

Page 25

Around Wine

57 Chiltern Street

London W1U 6ND

020 7935 4679

eurocave@aroundwine.co.uk

www.eurocave.co.uk - eurocave@aroundwine.co.uk

23

Loading...

Loading...