Ettan IPGphor II User Manual

user manual

2-D electrophoresis and first-dimension IEF

um

80-6505-22/Rev. A0/06-03

Ettan IPGphor II

isoelectric focusing system

Page finder

1. Ettan IPGphor II function and description

1.1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2. Instrument components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3. Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Instrument set up

2.1. Placing the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2. Power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3. Optional: Serial port connector for a printer or computer connection . . . . . . . . . . .7

3. Operating instructions

3.1. Power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2. Creating and editing protocol programs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2.1. Protocol parameters

3.2.2. Ettan IPGphor II Control Software

3.2.3. Editing protocol parameters

3.3. IPG strip rehydration and sample application:

IPGphor Cup Loading Strip Holder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.4. IPG strip rehydration and sample application:

Fixed-length IPGphor Strip Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.5. Running a protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.5.1. Final assembly

3.5.2. Starting isoelectric focusing

3.5.3. Pausing or stopping a protocol

3.5.4. Printing a log of instrument conditions

4. Care and maintenance

4.1. Important!

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2. Cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.3. Replacing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6. Customer service information

6.1. Technical service and repair

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.2. Ordering information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Protocol worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

•

pi

English

Safety warnings and precautions

Important user information

Please read this entire manual to fully understand the safe and effective use of this product.

The lightning symbol within an equilateral triangle is intended to alert the user to the risk of

exposure to high voltages. Should you have any comments on this manual, we will be pleased

to receive them via email at ts-ep@am.amershambiosciences.com or at:

Amersham Biosciences AB

SE-751 84

Uppsala, Sweden

Amersham Biosciences reserves the right to make changes in the specifications without

prior notice.

Warranty and Liability

Amersham Biosciences guarantees that the product delivered has been thoroughly tested to

ensure that it meets its published specifications. The warranty included in the conditions of

delivery is valid only if the product has been installed and used according to the instructions

supplied by Amersham Biosciences.

Amersham Biosciences shall in no event be liable for incidental or consequential damages,

including without limitation, lost profits, loss of income, loss of business opportunities, loss

of use and other related exposures, however caused, arising from the faulty and incorrect use

of the product.

No part of this publication may be reproduced, stored in a retrieval system or transmitted in

any form by any means, without permission in written form from the company.

Renseignements importants d’utilization

Pour une bonne compréhension et une utilisation en sécurité maximale, il convient de lire

entièrement ce manuel. Le symbole de l’éclair dans un triangle équilatéral a pour objet d’attirer l’attention de l’utilisateur sur un danger d’exposition à la haute tension. Tous vos

commentaires sur ce manuel seront les bienvenus et veuillez les adresser à:

Amersham Biosciences AB

SE-751 84

Uppsala, Sweden

Amersham Biosciences se réserve le droit d’effectuer des modifications de ces spécifications

sans aucun préavis.

Garantie et responsabilité

Amersham Biosciences garantit à l’utilisateur que le produit livré a subi avec succès tous les

essais prévus pour s’assurer qu’il est conforme aux spécifications et normes en vigueur. La

garantie incluse dans les conditions de livraison n’est valable que si le produit a été installé

et utilisé conformément aux instructions fournies par Amersham Biosciences.

La société Amersham Biosciences ne sera en aucun cas responsable de tout dommage causé

directement ou indirectement par toute utilisation incorrecte ou non approuvée du produit ou

découlant de cette utilisation, y compris toute perte de bénéfice ou de recettes, toute perte de

perspectives commerciales, tout empêchement d’utilisation et tout autre risques ayant un rapport

avec l’utilisation du produit, mais sans aucune limitation quant à la nature de ces dommages.

La reproduction, le stockage dans un système de récupération d’informations ou la transmission sous quelque forme que ce soit et par quelque moyen que ce soit de la présente publication en totalité ou en partie sont strictement interdits sans autorisation préalable écrite de

la société.

Ettan IPGphor II Isoelectric Focusing System • safety warnings and precautions

um 80-6505-22

•

pii

Français

Información importante para el usuario

Para comprender el producto y utilizarlo con seguridad es necesario leer este manual en su

totalidad. El símbolo del rayo en un triángulo equilátero alerta al usuario sobre el riesgo de

exposición a altas tensiones. Si desearan hacer algún comentario sobre este manual, tengan

la amabilidad de remitirlo a:

Amersham Biosciences AB

SE-751 84

Uppsala, Sweden

Amersham Biosciences se reserva el derecho a modificar las especificaciones sin previo aviso.

Garantía y responsabilidad

Amersham Biosciences garantiza que el producto entregado ha sido probado a fondo para

comprobar el cumplimiento de las especificaciones publicadas. La garantía incluida en las

condiciones de entrega sólo es válida si el producto se ha instalado y utilizado de acuerdo

con las instrucciones entregadas por Amersham Biosciences.

Amersham Biosciences no será responsable, bajo ningún concepto, de daños directos o indirectos, incluyendo sin limitación la pérdida de beneficios, la pérdida de ingresos, la pérdida de

oportunidades de negocio, la pérdida de utilización y otras consecuencias relacionadas,

cualquiera que sea la causa, que se deban a la utilización defectuosa e incorrecta del producto.

No está permitida la reproducción, ni el almacenaje en un sistema de recuperación, ni la

transmisión de parte alguna de esta publicación sin la autorización por escrito de la empresa.

Wichtige Benutzerinformationen

Für ein vollständiges Verständnis und eine sichere Handhabung dieses Produktes ist es

notwendig, daß der Benutzer dieses Handbuch vollständig durchliest. Ein Blitzsymbol in

einem gleichseitigen Dreieck soll den Benutzer auf die Gefahr anliegender Hochspannungen

hinweisen. Wenn Sie Anmerkungen zu diesem Handbuch haben, dann senden Sie diese

bitte an:

Amersham Biosciences AB

SE-751 84

Uppsala, Sweden

Amersham Biosciences behält sich das Recht vor, die Spezifikationen ohne vorhergehende

Ankündigung zu ändern.

Gewährleistung and Haftung

Amersham Biosciences garantiert, daß das gelieferte Produkt sorgfältig auf die Einhaltung der

veröffentlichten Spezifikationen getestet wurde. Die in den Lieferbedingungen näher

erläuterten Gewährleistungsansprüche gelten nur dann, wenn das Produkt gemäß den von

Amersham Biosciences gelieferten Anweisungen installiert und benutzt wurde.

Amersham Biosciences übernimmt keinerlei Haftung für Schäden oder Folgeschäden,

einschließlich, aber nicht begrenzt auf Gewinneinbußen, Einkommensverluste, entgangene

Geschäftsabschlüsse, Verlust der Gebrauchsfähigkeit oder andere Verluste, die wie auch immer

durch eine fehlerhafte oder unsachgemäße Verwendung des Produkts verursacht wurden.

Die vorliegende Veröffentlichung darf nur mit vorhergehender schriftlicher Genehmigung

durch das Unternehmen vervielfältigt, in einem Abrufsystem gespeichert oder in irgendeiner

Form oder mit irgendwelchen Mitteln übertragen werden.

• safety warnings and precautions

•

piii

Español

Deutsch

Informazioni importanti per l’operatore

Per un utilizzo sicuro del prodotto, leggere attentamente l’intero contenuto del presente

manuale. Il simbolo del fulmine all’interno di un triangolo equilatero indica all’utente la

presenza di un rischio di esposizione ad alte tensioni. Si prega di inviare eventuali commenti

al presente manuale a:

Amersham Biosciences AB

SE-751 84

Uppsala, Sweden

Amersham Biosciences si riserva il diritto di apportare modifiche ai dati tecnici senza preavviso.

Garanzia e responsabilitá

Amersham Biosciences garantisce che prima della consegna il prodotto è stato collaudato a

fondo per soddisfare i requisiti specificati. La garanzia inclusa nelle condizioni di consegna

risulta valida solamente se il prodotto è stato installato ed utilizzato nel rispetto delle

istruzioni fornite da Amersham Biosciences.

Amersham Biosciences non potrà essere ritenuta responsabile di incidenti o danni consequenziali, inclusi’ma non limitati’a perdite di profitti, mancato guadagno, perdite di affari,

difetti di funzionamento e relative esposizioni, dovuti ad un utilizzo non corretto del prodotto.

Nessuna parte della presente pubblicazione può essere riprodotta, conservata in sistemi di

gestione dati o trasmessa in alcun forma né per nessuno scopo senza autorizzazione scritta

del produttore.

Ettan IPGphor II Isoelectric Focusing System • safety warnings and precautions

um 80-6505-22

•

piv

Italiano

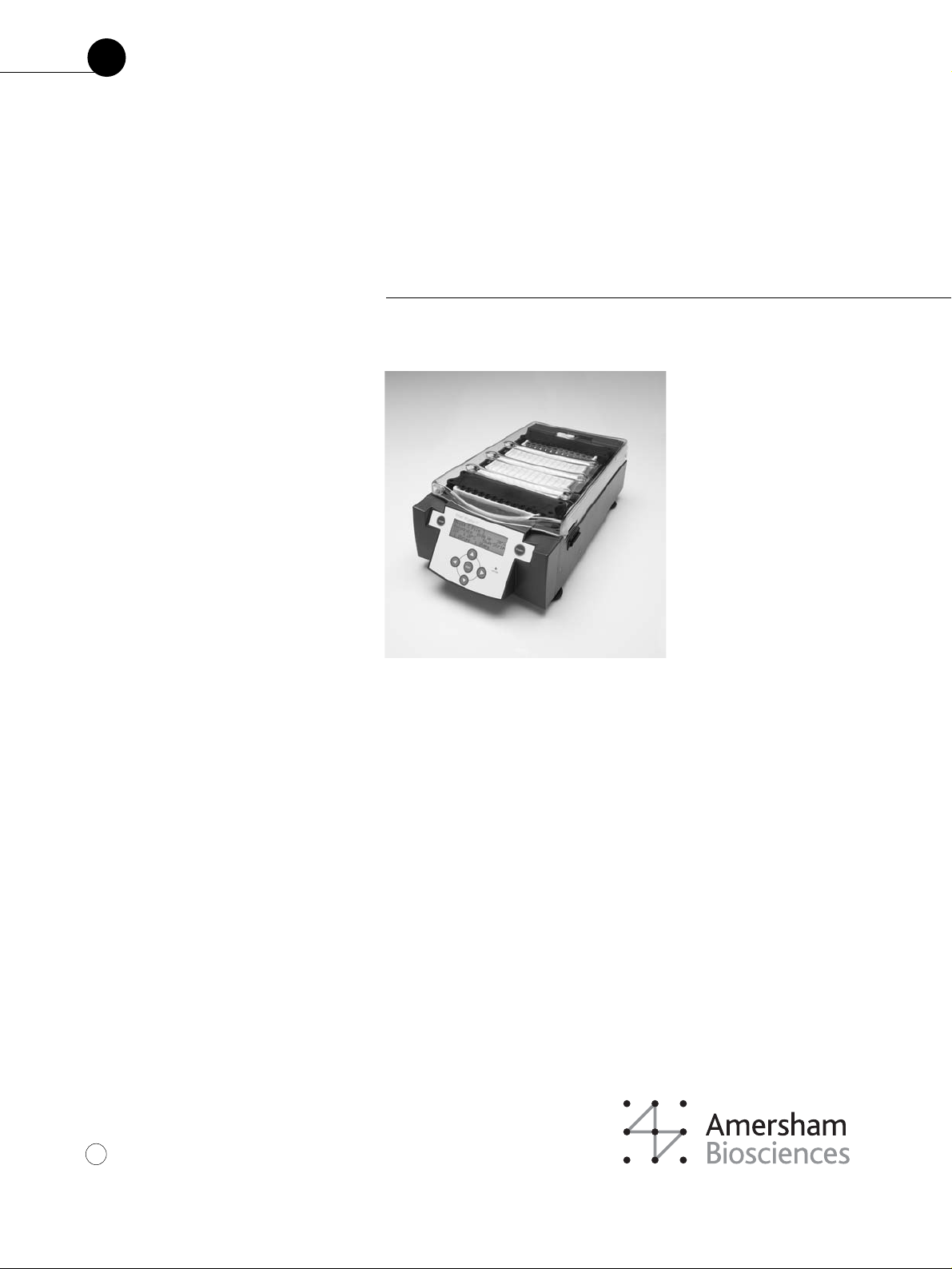

1. Ettan IPGphor II Isoelectric Focusing System

function and description

The Ettan™IPGphor™II Isoelectric Focusing System performs first dimension isoelectric focusing (IEF) in 2-dimensional (2-D) electrophoresis.

The system comprises Immobiline

™

DryStrip gel strips, which contain an

immobilized pH gradient (IPG); strip holders, which serve as both and

IEF chambers for the IPG strips; and the Ettan IPGphor II unit, which

includes a high-voltage DC power supply, solid state temperature control,

and can be programmed with up to ten user-defined IEF protocols.

Programmable functions include:

• rehydration time,

• platform temperature,

• maximum current limit,

• voltage change pattern,

• voltage for each step in the isoelectric focusing program, and

• step duration.

IPG strips are available in five lengths —7, 11, 13, 18, and 24 cm — and a

number of pH ranges, several linear and nonlinear (listed in section 6.2,

Ordering information). Two types of strip holders are available, a fixedlength strip holder and a variable-length cup loading strip holder. Once

the IPG strip is in place in a fixed-length strip holder, no further handling

is required. The holder is placed on the Ettan IPGphor II electrode platform for isoelectric focusing and the sample is introduced either during or

after the rehydration step. Up to 12 strip holders of the same size can be

accommodated for any one protocol.

The cup loading manifold accommodates 3 mm wide strips from 7 to 24 cm

long. After rehydration, strips are placed in the strip holder and the sample

cup positioned as desired for loading in a particular zone. Up to 9 cup

loading strip holders can be accommodated at one time.

1.1. Unpacking

Unwrap all packages carefully and compare contents with the packing

list, making sure all items arrived. If any part is missing, contact your

local Amersham Biosciences sales office. Inspect all components for

damage that may have occurred while the unit was in transit. If any part

appears damaged, contact the carrier immediately. Be sure to keep all

packing material for damage claims or to use should it become necessary

to return the unit.

• Ettan IPGphor II function and description

•

p1

Ettan IPGphor II Isoelectric Focusing System • IPGphor II function and description

um 80-6505-22

•

p2

control panel

negative (cathode)

electrode area

positive (anode)

electrode area

IPGphor cup loading manifold

Ettan IPGphor II control software

(computer not included)

Cover

Pressure

block

Sample

application wells

Base

1.2. Instrument components

Five strip holder lengths are available —

7, 11, 13, 18, and 24 cm — one for each

IPG strip length.

Note: all strips (and holders) used at any

one time must be of the same length.

A cup loading strip holder that accomo-

dates all strip lengths is also available.

The mains power switch is located on

the back panel on the left side.

Serial port (RS232) for a

connection to a PC or printer.

Control panel The Ettan IPGphor II is controlled by a 7-key membrane keypad. Instrument status is indicated on the LCD screen.

LCD screen The main screen is “Protocol #1, Name.” The default location of the cursor is always under the protocol number

“1.” Select any protocol by pressing the up and down arrow keys to display the number of the desired protocol. Once

the selected protocol is started, the LCD screen indicates the parameters of the step currently being carried out.

In “edit mode” the LCD displays the programmable parameters. Place the cursor in the field to be edited using the

right and left arrow keys and adjust the value by pressing the up and down arrow keys.

COMMAND keys The EDIT key switches the display to “edit mode,” in which protocol steps can be programmed. (See section 3.2.)

Pressing the EDIT key in edit mode switches the display back to the identification screen for the protocol being edited.

The left arrow key moves the cursor to the left. Moving the cursor off the screen to the left repositions the cursor at

the left side of the next row. At the bottom row the cursor is repositioned at the left side of the top row.

The right arrow key moves the cursor to the right. Moving the cursor off the screen to the right repositions the cursor

at the left of the next row. At the bottom row the cursor is repositioned at the left side of the top row.

The up arrow key increases the value of the selected field or digit, and the down arrow key decreases the value of the

selected field or digit.

The START key begins the selected protocol.

The STOP key pauses the protocol. Pressing the STOP key a second time cancels the protocol in progress.

HV ON indicator lamp The HV ON lamp indicates that the high voltage power supply is on and isoelectric focusing is in progress. This lamp

is not illuminated during the rehydration phase of a protocol.

Platform Up to 12 fixed-length strip holders of the same length or 9 variable-length cup loading strip holders can be placed on

the platform for rehydration and IEF. The embedded electrode areas provide the electrical connection between strip

holder electrodes and the integral power supply. Platform temperature is controlled by Peltier thermoelectric modules.

Electrode areas Both electrode areas are gold-plated copper. Placing a strip holder so that it bridges both electrode areas completes

the electrical circuit (once the safety lid is in place). Each holder must be oriented properly:

Negative (cathode) area: Place the flat end of the holder in the shorter electrode area, visually verifying that there is

metal-to-metal contact between the electrode on the bottom of the holder and the electrode area for the fixed length

strip holders.

Positive (anode) area: The pointed end of the holder points toward the back of the unit, and the electrode must

contact the longer electrode area; the position of the tip should correspond to the guidemarks on the edge of the

platform (7, 11, 13, 18, and 24 cm) for the fixed length strip holders.

Safety lid The safety lid must be properly latched before power can be applied. The pressure pads in the lid secure the strip

holders. A minimum of two pads should contact the cover of each strip holder to ensure an electrical connection.

Strip holders The strip holders and manifold are made of aluminum oxide ceramic of minimal thickness for efficient heat transfer.

This material is very brittle so the holders are fragile and must be handled with care. The ceramic is treated with a

special coating to minimize protein binding and must be cleaned only with the IPGphor Cleaning Solution supplied to

retain that coating.

Fixed-length strip holders Each fixed-length strip holder base holds a single IPG strip throughout rehydration and isoelectric focusing. A match-

ing length holder is available for each size strip. The holders, like IPG strips, have a flat and a pointed and. The

pointed end (“point is positive”) designates the anode, and thus the location of the acidic end of the immobilized

gradient. Embedded electrodes provide electrical connection between electrode areas and the gel.

Sample application wells Each of the two wells can accept up to 15 µl of sample (7.5 µl on either side of the strip) in excess of the rehydra-

tion volume (i.e. 30 µl maximum for both wells). Introduce the sample through the wells if it is not included in the

rehydration solution.

Cover The cover protects the IPG strip during rehydration, and the shape of the underside of the cover ensures electrical

continuity during IEF by pressing strip against the electrode while allowing electrolysis gases to escape. Rehydration

and separation progress can be monitored visually through the clear cover.

Cup loading manifold The cup loading manifold holds up to 12 IPG strips.

The manifold allows for cup loading or bridge loading.

The manifold allows the user to run strips that have been rehydrated into the IPG strip using the reswelling tray.

The manifold itself is not used for rehydration.

Electrodes The cup loading manifold has contact pins on the side of the electrodes.

These contact pins make contact with the power supply electrode areas when placed on the IPGphor

separation platform.

Sample cups Sample cups can be placed almost anywhere along the length of the IPGphor strip holder that is not blocked by

a protrusion. For proper sealing of the cup to the gel, the feet of the sample cup must all rest on the bottom of

the channel.

• Ettan IPGphor II function and description

•

p3

1.3. Important information

Instrument operation

• Caution! Ettan IPGphor II is a high voltage instrument that can cause fatal

electrical shock if the safety features are disabled. The safety lid must be

properly latched before starting a protocol.

• Exceeding the recommended current limit of 50 µA per IPG strip can cause

the strip to burn and may damage the instrument.

• During isoelectric focusing, do not lean on the safety lid, do not apply excess

pressure or uneven weight to the lid, and do not place any items on the lid.

Such pressure could cause arcing between the strip holder electrodes and the

electrode areas, damaging the instrument.

• Plug the instrument into a properly grounded outlet.

• Always disconnect the power cord before servicing.

• Ensure that the cooling vents at the front, back, and bottom of the instrument

are not obstructed.

• Operate Ettan IPGphor II on a level surface.

• Avoid spilling liquids on the body of the instrument.

• Avoid scratching the electrode areas.

IPG strips, strip holders, and reagents

•

The strip holders and manifold trays are very brittle and fragile.

Handle carefully: Do not bump or drop.

•

Always wear gloves when handling IPG strips and the equipment that comes in

contact with them. This will help minimize protein contamination which can

result in artifactual spots in the silver stained 2-D patterns.

•

Clean strip holders and manifold with the strip holder cleaning solution

provided. Clean all other components that come in contact with the IPG

strip or the sample with a detergent designed for glassware. Rinse well with

distilled water.

•

Use the appropriate rehydration volume for the IPG strip length.

•

Solutions containing urea may be warmed briefly. Do not heat any solutions

containing urea above 30–40 ºC as isocyanate, a urea degradation product, will

carbamylate the proteins in the sample, thus changing their isoelectric points.

•

All chemicals should be of the highest purity. Double distilled water should

be used.

Ettan IPGphor II Isoelectric Focusing System • IPGphor II function and description

um 80-6505-22

•

p4

English

Informations importantes

Précautions d’emploi

• Attention! l’Ettan IPGphor II est un instrument à très haut voltage pouvant

causer un choc électrique mortel si les conditions de sécurité ne sont pas

respectées. Le couvercle de sécurité doit être convenablement verrouillé avant

de démarrer un protocole.

• Dépasser les limites de courant recommandées, 50 µA un bande IPG, peut

amener les bandes à brûler et endommager l’instrument!

• Durant l’isoélectrofocalisation, ne pas s’appuyer sur le couvercle de sécurité, ne

pas exercer de pression excessive ni de poids inutile sur le couvercle, et ne pas

placer d’objets sur le couvercle. Une telle pression pourrait provoquer un arc

électrique entre les électrodes des cassettes et la plate-forme de migration

porte-électrodes, abîmant l’instrument.

• Brancher l’instrument à une prise de terre appropriée.

• Toujours déconnecter le cordon d’alimentation avant la maintenance.

• S’assurer que les ventilations devant et à l’arrière de l’appareil ne sont pas

obstruées.

• Utiliser l’Ettan IPGphor II sur une surface plane.

• Eviter de renverser des liquides sur l’instrument.

• Eviter de rayer la plate-forme de migration porte-électrodes..

Mèches IPG, cassettes et réactifs

• Les cassettes sont très fragiles. Manipulez-les avec précaution: évitez de les

heurter ou de les laisser tomber.

• Toujours mettre des gants pour manipuler les bandes IPG ainsi que

l’équipement en contact avec celles-ci. Ceci aide à minimiser la contamination

protéique qui peut occasionner des spots artefactuels sur le gel 2D après la

coloration à l’argent.

• Nettoyer les sarcophages avec la solution dédiée à cet effet. Nettoyez tous les

composants qui rentrent en contact avec les bandes IPG ou l’échantillon, avec

un détergent pour matériel en verre. Bien rincer avec de l’eau distillée.

• Utilisez le volume approprié de réhydratation.

• Les solutions contenant de l’urée peuvent être chauffées brièvement. Ne pas

chauffer de solution contenant de l’urée à plus de 30–40 ºC car l’isocyanate,

un produit de dégradation de l’urée, produira une carbamylation des protéines

de l’échantillon, changeant ainsi leurs points isoélectriques.

• Tous les produits chimiques doivent être de la plus grande pureté. Veillez à

utiliser de l’eau doublement distillée.

• Ettan IPGphor II function and description

•

p5

Français

Loading...

Loading...