Etq TG72K12 User Manual

Owner’s Manual Model TG72K12

AIR-COOLED GASOLINE ENGINE GENERATOR SET

PREFACE

Thank you for purchasing products from EASTERN TOOLS & EQUIPMENT, INC. We appreciate your business. The following manual is only a guide to assist you and is not a complete or comprehensive manual of all aspects of maintaining and repairing your generator. The equipment you have purchased is a complex piece of machinery. We recommend that that you consult with a dealer if you have doubts or concerns as to your experience or ability to properly maintain or repair your equipment. You will save time and the inconvenience of having to go back to the store if you choose to write or call us concerning missing parts, service questions, operating advice, and/or assembly questions. Our gasoline generators have some of the following features:

Lightweight construction

Air cooled

Four-stroke gasoline internal combustion engine

Recoil starter

Large fuel tank

Automatic voltage stabilizer

NFB circuit protector

AC outputs

Low oil level sensor

Battery not included: Some brands you can use Champion 94b1, JBS 12N9-4B-1, MOTOCROSS

M2290B, NAPA 740-1869, POWERSONIC CB9-B

The ETQ air-cooled gasoline generators are widely used when electrical power is scarce. Our generators provide a portable mobile solution in supplying power for field operations during project construction.

This manual will explain how to operate and service your generator set.

If you have any questions or suggestions about this manual, please contact your local dealer or us directly. Consumers should notice that this manual might differ slightly from the actual product as more improvements are made to our products. Some of the pictures in this manual may differ slightly from the actual product as well. Eastern Tools and Equipment, Inc. reserves the right to make changes at any time without notice and without incurring any obligation.

TABLE OF CONTENTS

|

Page |

TECHNICAL SPECIFICATIONS AND DATA |

1 |

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR |

2 |

PACKAGE CONTENTS |

3 |

Assembly |

4 |

Instruction for the use of lifting bracket. |

5 |

AUTO THROTTLE CONTROL SWITCH |

6 |

Instruction for the use of RV adapter |

6 |

Battery Assembly Procedure |

7 |

SAFETY PRECAUTIONS |

8 |

Electric shock and short circuit |

8 |

Prevention from accidental burns |

8 |

Refueling precautions |

8 |

Engine safety precautions |

9 |

Generator safety |

9 |

PREPARATION BEFORE OPERATION |

9 |

Engine oil |

9 |

Air cleaner |

11 |

GROUNDING THE GENERATOR |

12 |

OPERATING THE GENERATOR |

12 |

Starting the engine |

12 |

Connecting electrical loads and electrical capacity |

13 |

Stopping the engine |

14 |

RECEPTACLES |

15 |

MAINTENANCE |

16 |

Cleaning the generator |

17 |

Spark Plug |

17 |

Storage |

18 |

TROUBLESHOOTING |

19 |

WIRING DIAGRAM |

20 |

PART LISTINGS |

21 |

Exploded Generator View |

21 |

Crankcase |

23 |

Push rod & Valve Rocker |

24 |

Cylinder Head & Cylinder Head Cover Assembly |

25 |

Crankcase Cover Assembly |

26 |

Crankshaft, Piston & Tie-Rod |

27 |

Carburetor Assembly & Air Cleaner Assembly |

29 |

Flywheel & Recoil Starter |

29 |

Ignition Coil |

32 |

Regulating Control System |

32 |

Starting Motor Assy |

33 |

LIMITED WARRANTY |

34 |

PRODUCT REGISTRATION CARD |

34 |

ETQ

|

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

|

|

TECHNICAL SPECIFICATIONS AND DATA |

|||

|

|

|

TG8250/TG72K12 |

|

|

|

|

||

|

|

|

|

|

|

Engine Type |

|

4-stroke, Air-cooled, OHV |

|

|

|

|

|

|

|

Displacement |

|

420 cc(23.74 cu in) |

|

|

|

|

|

|

|

Bore × Stroke |

|

88×64 mm (3.5×2.5 in) |

|

|

|

|

|

|

|

Max.Output |

|

9.56 KW (13Hp)@ 3600 r/min |

|

|

|

|

|

|

|

Max.Torque |

|

2.7 kg-m(19.5 ft 1b)@2500rpm |

|

|

|

|

|

|

|

Fuel |

|

Unleaded |

|

|

|

|

|

|

|

Fuel Tank Capacity |

|

24.32 Liters(6.42 gal) |

|

|

|

|

|

|

|

Operation Hours |

|

10Hrs @ 50% load |

|

|

|

|

|

|

|

Engine Oil |

|

SAE 10W-30 or equivalent motor oil |

|

|

|

|

|

|

|

Engine Oil Capacity |

|

1.0L (33.8 Ounces) |

|

|

|

|

|

|

|

Engine Start Pattern |

|

Manual start / Electric Start |

|

|

|

|

|

|

|

Generator Type |

|

Synchronous generator |

|

|

|

|

|

|

|

Phase |

|

|

Single |

|

|

|

|

|

|

Power Factor |

|

Cos θ = 1.0 |

|

|

|

|

|

|

|

AC Output Voltage |

|

120V/240V |

|

|

|

|

|

|

|

AC Output Frequency |

|

|

60Hz |

|

|

|

|

|

|

AC Output Max Power |

|

8250 ± 10% Watts |

|

|

|

|

|

|

|

AC Output Rated Power |

|

7250 ± 3% Watts |

|

|

|

|

|

|

|

T.H.D |

|

|

< 5% |

|

|

|

|

|

|

Noise Level |

|

70 dB @ 7m |

|

|

|

|

|

|

|

Product Weight |

|

99 kg(218 lbs) |

|

|

|

|

|

|

|

Product Dimensions |

|

78.0×80.5×71.5 cm (30.71 x 31.69 x 28.15 in) |

|

|

|

|

|

|

*Add oil to the engine when the “Oil Warning Light” is on. *Engine might stop and may incur damage if oil is too low.

**Please refer to page 15 for receptacle power ratings.

1

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR

Please read this manual and follow the procedures covered in this manual. Become familiar with the generators functions, applications, and limitations.

Below is a diagram of the locations of the various controls and functions of the generator

ILLUSTRATION OF CONTROLS

(1) |

(2) |

(28) |

|

(27) |

(3) |

|

(4) (5)

(26)

(6)

(7)

(25)

(24) (9) (8)

(10)

(23) |

|

(11) 12 |

|

|

|

|

(22) |

(13) |

|

|

(21)(19) (20) (18) (17) (16) (15) (14)

(1) FUEL TANK CAP |

(15) RUN TIME METER |

|

|

|

|

(2) MUFFLER COMP |

(16) AUTO THROTTLE SWITCH |

|

|

|

|

(3) CIRCUIT BREAKER(30A) |

(17) CAP ASSY,OIL FILLER |

|

|

|

|

(4) CIRCUIT BREAKER(30A) |

(18) BOLT,PLUG,DRAIN |

|

|

|

|

(5) SWITCH ASSY.,PANEL(32A) |

(19) OIL INDICATOR LIGHT ASSY |

|

|

|

|

(6) |

240/120V LOCKING RECEPTACLE L14-30 |

(20) STAY ASSY |

|

|

|

(7) LUG GROUND |

(21) PUSHBUTTON ELECTRICITY STARTUP SWITCH |

|

|

|

|

(8) |

3-POLE RECEPTACLE L5-30R |

(22) STAND ASSY |

|

|

|

(9) |

120V RECEPTACLE 5-20R |

(23) STARTER ASSY,RECOIL |

|

|

|

(10) FROTH WHEEL 10" |

(24) AIR/C ASSY |

|

|

|

|

(11) WASHER,SPRING 12MM |

(25) COCK ASSY.FUEL |

|

|

|

|

(12) NUT,FLANGE M12 |

(26) CHOKE SET ASSY |

|

|

|

|

(13) BATTERY KICKSTAND |

(27) TANK COMP,FUEL |

|

|

|

|

(14) CIRCUIT BREAKER(20A) |

(28) FRAME ASSY |

|

|

|

|

WARNING: DO NOT exceed the generator’s wattage/amperage capacity. Our products are continuously being changed and improved. Every effort has been made to ensure that information in the manual is accurate and up to date. However, we reserve the right to change, alter or otherwise improve the product and this manual at any time without prior notice.

2

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PACKAGE CONTENTS

Your generator comes with the items listed below. Please check to see that all of the following items are included with your generator.

If you are missing components DO NOT RETURN TO STORE, please call (888)908-6200 for customer service.

Order No. |

|

Name |

Qty |

|||

1 |

Air-cooled generator set |

1 |

||||

|

Tool Kit: |

|

||||

|

|

|

Flat Head Screwdriver |

|

|

|

|

|

|

|

|

|

|

|

|

|

Spark Plug Wrench |

|

|

|

|

|

|

|

|

|

|

2 |

|

|

Wrench, 8×10,17×19 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

Bottle Wire |

|

|

|

|

|

|

|

|

|

|

|

|

|

SWITCH PLUG |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Assembly Kit: |

|

||||

3 |

|

|

Wheel (2 pcs) |

|

|

1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

Assembly Kit: |

|

||||

4 |

|

|

Wheel Kit Hardware |

|

|

1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

Assembly Kit: |

|

||||

5 |

|

|

Generator Foot (2 pcs) |

|

|

1 |

|

|

|

|

|

||

|

|

etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Assembly Kit: |

|

||||

6 |

|

|

Handle |

|

|

1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

Suspend |

|

||||

7 |

|

|

|

|

|

1 |

|

|

Conveyance Suspend |

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

8 |

Owner’s manual |

1 |

||||

3

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

ASSEMBLY

Nut

U-Bolt

Washer

Axle

Nut

Wheel

Bolt+Nut

Foot

4

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Handle Bar Assembly

·Secure the bracket bolt and nut. |

BOLT |

|

|

||

·Make sure that the bracket is nicely tightened |

|

|

down. |

ABNORMITY |

|

·Place the handle bar into the bracket. |

||

|

||

·Secure with a bolt and nut |

NUT |

|

|

||

|

IMMOBILITY PIECE |

HANDLE PIPE

Instruction for the use of the lifting bracket.

The lifting bracket is for lifting the generator which is described in the instruction manual, and it can bear 3 to 3.5 times the net weight of the generator.

Operation process:

Step 1: Take the lifting bracket attachment out of the box and then enter it from the end of the frame (see below picture).

Step 2: Move it towards the middle of the frame (please note it does not interfere with or scratch the fuel tank). (See below picture)

Step 3: Move it to the middle of the frame. (See below picture)

Step 4: Lift the generator slowly.

Step 5: Remove the lifting bracket by following (step 3→step 2→step 1) and then fasten it on the frame as standby.

5

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

AUTO THROTTLE CONTROL SWITCH

When using the generator, leave the AUTO THROTTLE CONTROL SWITCH (ATC) in the “ON” position; as soon as no output is need, engine will go into idle speed thus save fuel. As soon as, power is need, engine will operate as normal again.

Photo of “ON” position:

Auto Throttle Switch

Instruction for the use of RV adapter

To use the attachment, the RV adapter is located in the attachments box. The adaptor should always be coupled to the 3-pin receptacle (L5-30R) for the use of customers.

6

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

|

Battery Assembly Procedure |

STEP 4 |

|

|

STEP 1 |

|

|

(+) |

|

|

|

|

(+) |

( ) |

|

|

BOLT+NUT

STEP 5

BOLT

( )

STEP 2

STEP 6 OK

STEP 3

BOLT

7

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

SAFETY PRECAUTIONS |

ELECTRIC SHOCK AND SHORT CIRCUIT |

|

In order to ensure safety for the consumer, please carefully follow instructions on being careful with the generators.

Operate the generator ONLY outdoors. Never run the generator indoors as the engine gives off poisonous carbon monoxide, an odorless and colorless gas. Inhaling carbon monoxide will cause nausea, fainting or death. Also, keep the generator at least 3 feet away from flammable matter for adequate ventilation.

Be sure to notify the utility company when using the generator for backup power. Use approved transfer equipment to isolate the generator from electric utility. In highly conductive area such as metal decking or steel work, use a ground circuit fault interrupter. Never touch the generator if the generator is wet. Also, never touch the generator if your hand is wet. Never operate your generator if the weather conditions call for any type of precipitation such as rain, snow, or fog.

DANGER

Always properly ground the generator. Failing to do so can result in electrocution, particularly if the generator is equipped with a wheel kit.

PREVENTION FROM ACCIDENTAL BURNS

Never touch the muffler and its cover when the engine is running. Never touch the muffler and cover after the engine has been used, as the muffler remains hot for a good period of time.

REFUELING PRECAUTIONS

Gasoline and its vapors are extremely flammable. Do not smoke near gasoline and keep gasoline away from generator while the generator is running. When adding fuel, turn the generator off and let it cool at least 2 minutes before removing the gas cap. Loosen gas cap slowly to relieve the pressure in the tank.

Fill fuel tank outdoors and never overfill the tank.

8

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

When storing gasoline or equipment with fuel in tank.

Store away from appliances or equipment that have a pilot light or other ignition sources because it can ignite gasoline vapors.

ENGINE SAFETY PRECAUTIONS

Do not touch hot surfaces. Allow equipment to fully cool down before touching.

After the generator has been run, the engine produces heat. The temperature of the muffler and nearby areas can reach or exceed 1600 F. Severe burns will occur on contact with skin. Do not modify the generator in any way. The generator supplies the rated voltage and rated frequency at its governed speed.

GENERATOR SAFETY

Never overload your generator as this can damage your generator or the electrical devices connected to it

Do not start generator with electrical devices connected to it. Start the generator first and after the speed of the generator stabilizes, electrical loads can be applied to it.

When connecting electrical loads, make sure the devices are "OFF" first before connecting them. Keep the same concept when

disconnecting electrical devices; make sure all devices are in the "OFF" position before disconnecting.

Operate the generator on level surfaces only. Inclined surfaces reduce the effective lubrication of the engine.

Do not expose the generator to excessive moisture, dust, dirt, or corrosive vapors.

PREPARATION BEFORE

OPERATION

Before starting the generator, verify the following conditions.

ENGINE OIL

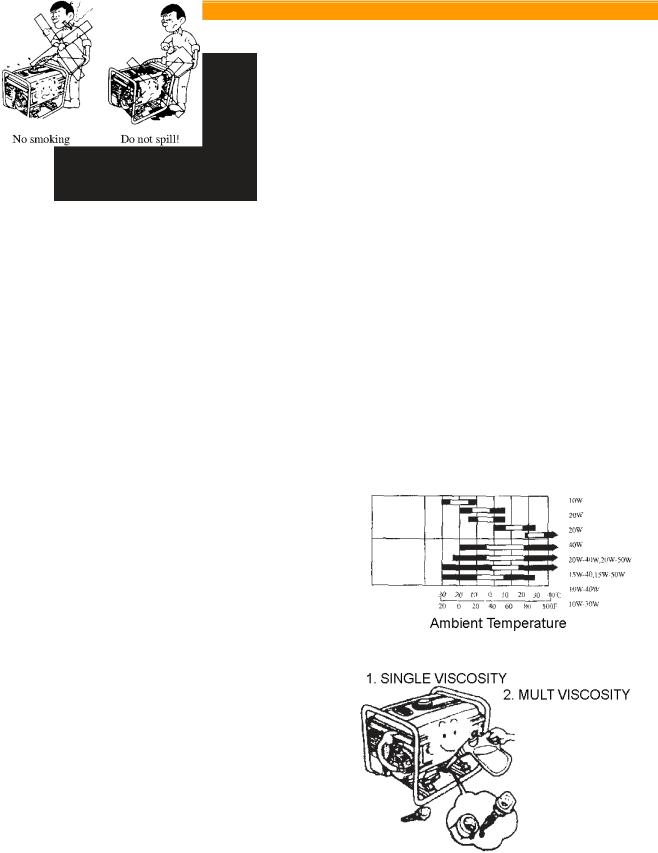

•Fill the engine with SAE 10W-30 engine oil for generator use or follow the table below.

•Make sure the generator is on a level surface and make sure the oil dipstick is on tight.

9

ETQ

EASTERN TOOLS & EQUIPMENT INC |

|

Tel: (888)908-6200 |

Web Site: easterntools.com |

|

GASOLINE |

|

o Wash in solvent |

||

|

o Squeeze |

|

||

|

|

|

o Soak oil |

|

|

|

|

o Squeeze dry |

|

|

|

|

|

|

•Add unleaded gasoline and never fill the fuel tank indoors. Also, be sure to install the fuel tank cap on tight after filling.

•DO NOT overfill the fuel tank. Always allow room for fuel expansion. Never fill the fuel tank when the engine is running or hot.

Allow the unit to cool for two minutes before refueling. DO NOT use light a cigarette or smoke when filling the fuel tank.

AIR CLEANER

•Unsnap the air cleaner cover springs, and remove the air cleaner cover.

•Check the air cleaner element to be sure they are clean and in good condition.

•Reinstall the air cleaner element and secure the cover by setting the cover spring.

BATTERY(only for electric start models)

Charged Storage Batteries

|

Voltage |

20Hour |

|

Normal Charge |

||||

|

|

|

|

|

|

|||

Type |

Ratein |

First Stage |

Second Stage |

|||||

|

(V) |

Amp-hr |

|

|

|

|

|

|

|

Amp |

Hours |

Amp |

Hours |

||||

|

|

|||||||

|

|

|

|

|

|

|

|

|

GFM-21 |

12 |

21 |

|

1.5 |

10 12 |

1.0 |

8 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•If the air filter is dirty, remove and clean the element.

10

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

GROUNDING THE GENERATOR |

OPERATING THE GENERATOR |

|

The National Electric Code requires that the frame of generator and the external electrically conductive parts of the generator be connected to an approved earth ground. Local codes may differ and require other grounding specifications. For this purpose, please use the ground wire that attaches from the frame to the generator unit.

Using a No. 12 AWG (American Wire Gauge) stranded copper wire to the frame and to an earth-driven copper or brass grounding rod provides sufficient safety against shock. However, local codes may differ. Contact a local electrician to find out specifications for grounding your generator.

Note: Note: Grounding your generator is highly recommended. It helps prevent electrical shock if a ground fault condition exists in the generator or in faulty connected electrical devices. Also, because the generator is rotating at high speeds, static electricity tends to buildup within the unit. Grounding helps dissipate the static electricity often building up in underground devices.

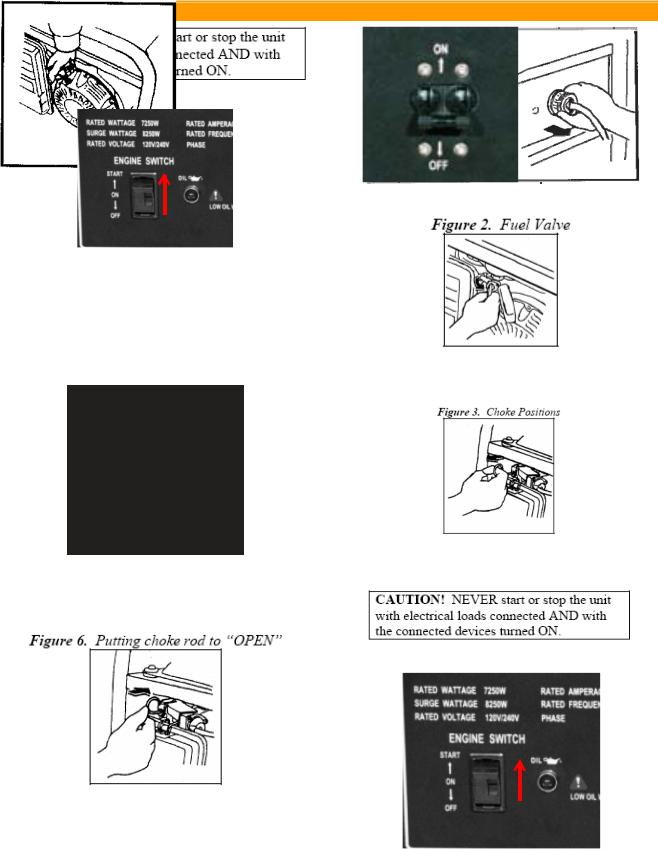

STARTING THE ENGINE

Before starting the engine, verify that the engine oil is full, gasoline is full, and air Filter is in place. Also, disconnect any load from the AC receptacle, and turn the AC circuit breaker OFF (Figure 1)

Figure 1. Disconnecting electrical devices

•Turn the fuel valve to the "On" position (Figure 2).

Figure 2. Fuel Valve

• Place the choke lever in the “CHOKE” position (Figure 3.).

Figure 3. Engine switch on position

• Turn the engine switch to the “ON” position (Figure 4).

11

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Figure 4. Engine switch on position

•Pull the recoil starter grip lightly until resistance is felt, then pull hard.Warning: Do not allow the starter grip to snap back against the engine.Return it gently (Figure 5.).

Figure 45. Recoil starting rope

• Push the choke rod to the “OPEN” position a short distance at a time over several seconds as the engine warms up (Figure 6).

ELECTRIC STARTING

Before starting the engine, verify that the engine oil is full, gasoline is full, and air filter is in place. Also, disconnect any load from the AC receptacle, and turn the AC circuit breaker OFF (Figure 1).

Figure1 .Disconnecting electrical devices

• Turn the fuel valve to the “On” position (Figure 2).

·Place the choke lever in the “CHOKE” position (Figure 3.).

• Turn the engine switch to the “ON” position (Figure 4).

Figure 4. Engine switch on position

• Push the choke rod to the “OPEN” position a short distance at a time over several seconds as the engine warms up (Figure 5).

12

ETQ

EASTERN TOOLS & EQUIPMENT INC

5

CONNECTING ELECTRICAL LOADS AND ELECTRICAL CAPACITY

After starting the generator, let the engine warm up after connecting electrical loads to it. Do not have any electrical loads connected before starting the generator.

Make sure all electrical devices are 60 Hz devices.

Do not connect 50 Hz devices to the generator. Do not connect 3-phase loads to the generator. Do not overload the generator.

Before beginning your work, you must verify that the rated (running) and surge (starting) wattage for the items you will power do not exceed the operating capacity of the generator. Please refer to the following Table (1) for wattage / amperage ratings. Also, in order to prolong the life of your generator, sequentially add loads and allow the generator to stabilize before adding another load. Never exceed the capacity of the generator.

Estimate how many surge (starting) watts you will need. Surge wattage is the short burst of power needed to start electric motor-driven tools or appliances such as a circular saw or refrigerator.

Tel: (888)908-6200 |

|

Web Site: easterntools.com |

||||

|

Table 1. Wattage reference chart |

|

|

|||

|

|

|

|

Rated |

Additional |

|

|

|

|

|

Surge |

|

|

|

Tool or Appliance |

|

(Running) |

|

||

|

|

(Starting) |

|

|||

|

|

|

|

Watts |

|

|

|

|

|

|

Watts |

|

|

|

|

|

|

|

|

|

|

Essentials |

|

|

|

|

|

|

Light Bulb – 75 watt |

|

75 |

- |

|

|

|

Freezer |

|

500 |

500 |

|

|

|

Sump Pump |

|

800 |

1200 |

|

|

|

Refrigerator / Freezer – 18 |

800 |

1600 |

|

||

|

Cu. Ft. |

|

|

|||

|

|

|

|

|

||

|

1/3 HP Water Well Pump |

1000 |

2000 |

|

||

|

Heating/Cooling |

|

|

|

|

|

|

Air conditioner – 10000 BTU |

1200 |

1800 |

|

||

|

Window Fan |

|

300 |

600 |

|

|

|

½ HP Furnace Fan Blower |

800 |

1300 |

|

||

|

Kitchen |

|

|

|

|

|

|

1000 Watt Microwave Oven |

1000 |

- |

|

||

|

Coffee Maker |

|

1500 |

- |

|

|

|

Single element electric stove |

1500 |

- |

|

||

|

Hot plate |

|

2500 |

- |

|

|

|

Family Room |

|

|

|

|

|

|

DVD / CD Player |

|

100 |

- |

|

|

|

VCR |

|

100 |

- |

|

|

|

Stereo Receiver |

|

450 |

- |

|

|

|

27 “ Color Television |

|

500 |

- |

|

|

|

Personal Computer w/17” |

800 |

- |

|

||

|

monitor |

|

|

|||

|

|

|

|

|

||

|

Other |

|

|

|

|

|

|

Security system |

|

180 |

- |

|

|

|

AM / FM clock radio |

|

300 |

- |

|

|

|

½ HP Garage door opener |

480 |

520 |

|

||

|

40 Gallon electric water |

4000 |

- |

|

||

|

heater |

|

|

|||

|

|

|

|

|

||

|

DIY / Job Site |

|

|

|

|

|

|

Halogen work light |

|

1000 |

- |

|

|

|

1/3 HP Airless sprayer |

600 |

1200 |

|

||

|

Reciprocating Saw |

|

960 |

960 |

|

|

|

½ HP Electric Drill |

|

1000 |

1000 |

|

|

|

7 ¼ “ Circular saw |

|

1500 |

1500 |

|

|

|

10” Miter saw |

|

1800 |

1800 |

|

|

|

6” Table Planer |

|

1800 |

1800 |

|

|

|

10” Table saw / Radial arm |

2000 |

2000 |

|

||

|

saw |

|

|

|||

|

|

|

|

|

||

|

1 ½ HP air compressor |

2500 |

2500 |

|

||

Note: wattages listed are only approximates. Check your electrical device for actual wattage.

13

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

STOPPING THE ENGINE |

• Turn the fuel valve to the "OFF" position |

|

|

(Figure 4). |

|

• Turn the AC circuit breaker to the "OFF" |

|

|

position (Figure 1). |

|

Figure 4. |

Figure 1.

•Unplug all the electrical loads from the generator panel (Figure 2).

•

Figure 2.

•Let the engine run at no-load for several minutes to stabilize the internal temperatures of engine and generator.

•Turn the engine switch to the "OFF" position (Figure 3).

Figure 3.

14

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

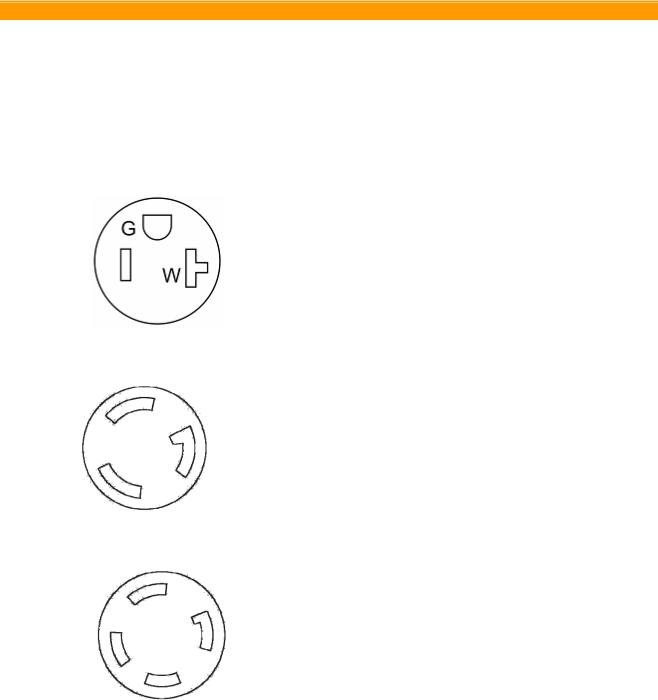

RECEPTACLES

This generator is equipped with the following

Receptacles

Figure 1. NEMA 5-20R: 125 Volt, 20 Amp

GFCI Duplex Receptacle

Figure 2. NEMA L5-30R: 125 Volt, 30 Amp

Receptacle

W

G

Figure 3. NEMA L14-30R: 240/120Volt, 30Amp Twist Lock Receptacle

X

W G y

Note: Please be sure to use electrical cords that support the amount of wattage being used.

The electrical cords should be able to handle 30 Amps of current at 125/250 Volts.

15

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

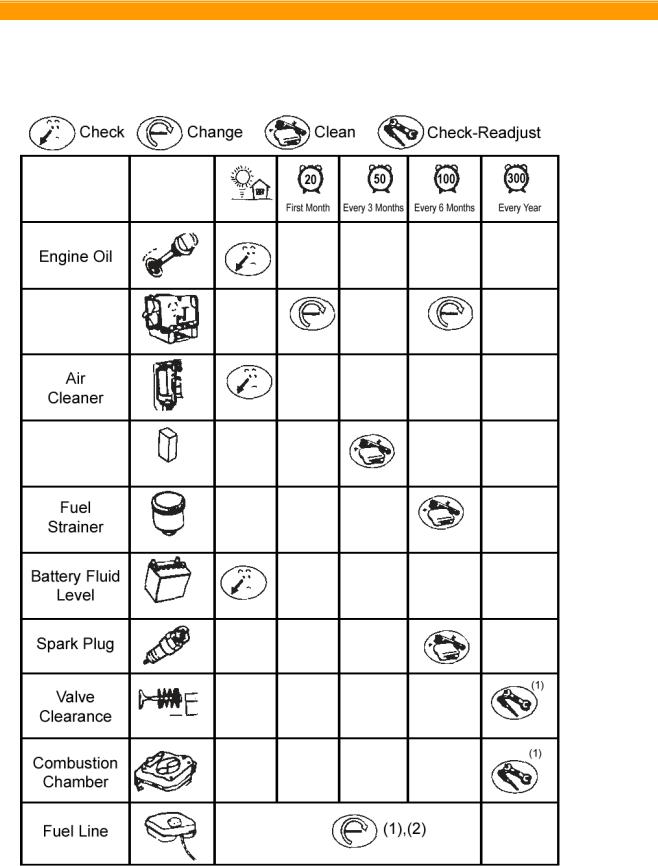

MAINTENANCE

Below is a routine maintenance schedule.

(1): These items should be serviced by a dealer. (2): Every 3 years.

16

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

|

CLEANING THE GENERATOR |

|

|

|

|

|

|

|

Generator maintenance consists of keeping the |

|

|

|

unit clean and dry. Be sure to store the unit in a |

|

|

|

clean and dry environment, where it will not be |

|

|

|

exposed to excessive dust, dirt, moisture or any |

|

|

|

corrosive vapors. Cooling slots should always |

|

|

|

be clean and free from clogs. |

|

|

|

Note: Do not use a garden hose to clean the |

|

|

|

generator. Water can enter the fuel and intake |

|

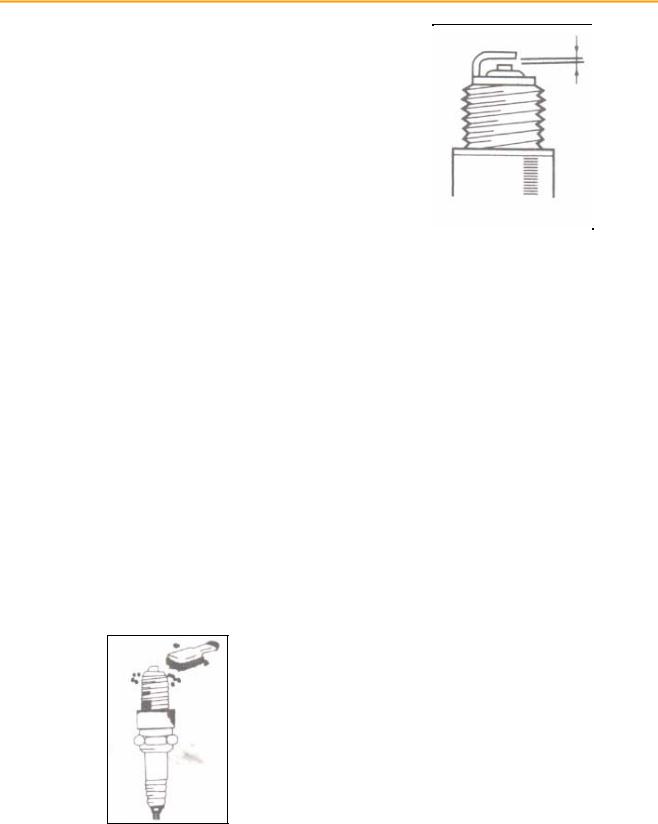

Gap measurements |

|

system, which cause problems. In addition, if |

0.7~0.8 mm (.028~.031 inches) |

||

water and dirt build up on the internal windings |

|

|

|

of the generator, the resistance of these |

NOTE: If spark plug needs to be replaced, use |

||

windings will decrease. |

NGK(or STAR) Brand: BPR6ES or F7(R)TC |

||

• To clean the generator, use a damp cloth to wipe the exterior surfaces.

• Use a soft bristle brush to loosen caked on dirt of oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Compressed air (not to exceed 25 psi) may be used to blow away dirt.

SPARK PLUG

• Remove the spark plug

• Remove the carbon deposits

•Check for discoloration. Standard is tan in color.

•Check spark plug gap

17

ETQ

EASTERN TOOLS & EQUIPMENT INC |

Tel: (888)908-6200 |

Web Site: easterntools.com |

STORAGE |

|

Figure 3. |

The generator should be started at least once every week. If this cannot be done and you must store the unit more than 30 days, please follow the following guidelines.

Close the fuel valve: drain the fuel from the fuel tank (Figure 1).

Figure 1.

•Drain the fuel from the carburetor (Figure 2).

Figure 2.

•Tighten the oil drain plug and fill the engine with new oil to the filter neck (Figure 4).

Figure 4.

•Pull the starter grip carefully until resistance is felt (Figure 5).

Figure 5.

•Remove the oil filter cap and drain plug to drain the oil (Figure 3).

• Store the generator in a clean area.

18

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

TROUBLESHOOTING

IMPORTANT: If trouble persists please call our customer help line at (888) 908-6200 M-F

8-5 Central Time.

Problem |

Cause |

Solution |

|

|

Engine switch is set |

Set engine switch to "on". |

|

|

to "off". |

|

|

|

Fuel valve is turned |

Turn fuel valve to "open" position. |

|

|

to "closed". |

|

|

|

Choke is open. |

Close the choke |

|

|

Engine is out of gas. |

Add gas. |

|

Engine will not |

|

|

|

Engine is filled with |

|

||

start |

|

||

contaminated or old |

Change the gas in the engine. |

||

|

|||

|

gas |

|

|

|

Spark plug is dirty. |

Clean spark plug. |

|

|

Spark plug is broken. |

Replace spark plug. |

|

|

Generator is not on |

Move generator to a level surface to prevent low oil shutdown from |

|

|

level surface. |

triggering. |

|

|

Oil is low |

Add or replace oil. |

|

|

Circuit reset button is |

Wait for 2 minutes and push the circuit reset button to the "on" |

|

|

off. |

position. |

|

Engine runs but |

|

|

|

Bad connecting |

If you are using an extension cord, try a different one. |

||

there is no |

|||

wires/cables. |

|||

|

|||

electrical output |

|

||

Bad electrical device |

|

||

|

|

||

|

connected to |

Try connecting a different device. |

|

|

generator. |

|

|

Generator runs but |

Generator is |

Try connecting fewer electrical loads to the generator. |

|

does not support |

overloaded |

||

|

|||

all electrical |

|

|

|

Short in one of the |

Try disconnecting any faulty or short-circuited electrical loads. |

||

devices |

|||

connected devices. |

|||

|

|||

connected. |

|

||

Air cleaner is dirty. |

Clean or replace air cleaner. |

||

|

19

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

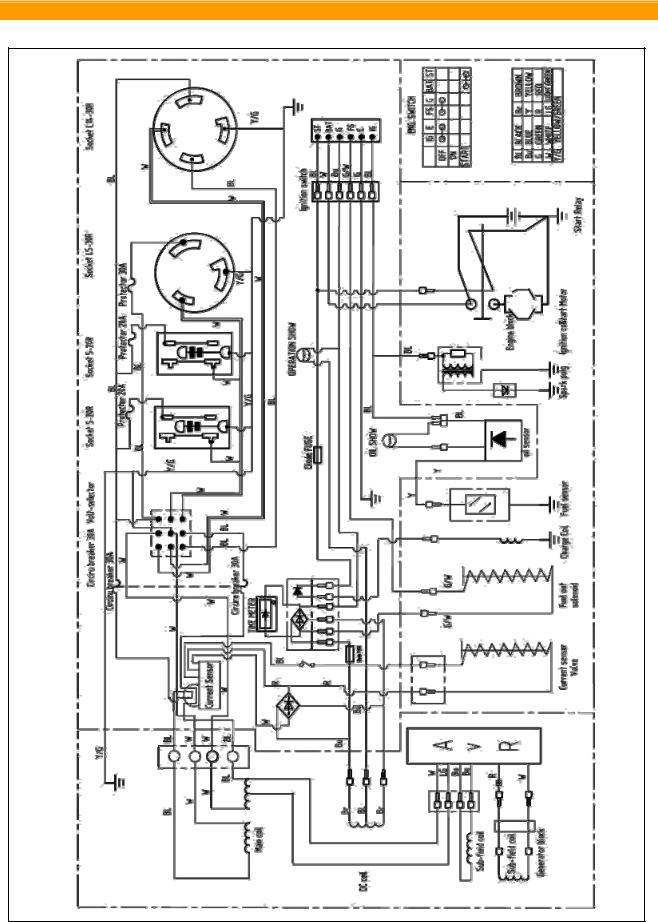

WIRING DIAGRAM

20

ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PART LISTINGS

GENERATOR

NUMBER |

PART NUMBER |

DESCRIPTION |

QTY |

|

|

|

|

1 |

19620-188-00 |

CONNECTION FLAT |

1 |

|

|

|

|

2 |

31120-D70-00 |

STATOR COMP |

1 |

|

|

|

|

3 |

31150-D70-00 |

STATOR COVER |

1 |

|

|

|

|

4 |

31130-D70-00 |

ROTOR,COMP |

1 |

|

|

|

|

5 |

31170-188-00 |

GENERATOR STAY |

1 |

|

|

|

|

6 |

31203-188-00 |

BRACKET,RR.,MOTOR(BLACK) |

1 |

|

|

|

|

7 |

19512-188-00 |

GENERATOR FAN |

1 |

|

|

|

|

8 |

31160-188-00 |

BRUSH ASSY |

1 |

|

|

|

|

9 |

30300-190-00 |

VOLTAGE REGULATOR (7KW) |

1 |

|

|

|

|

10 |

95701-10285-00 |

FASTNESS BOLT(ROTOR)10×285 |

1 |

|

|

|

|

11 |

95701-05016-00 |

BOLT,FLANGE 5×16 |

1 |

|

|

|

|

12 |

95701-05016-00 |

BOLT,FLANGE 5×16 |

2 |

|

|

|

|

13 |

95701-05016-00 |

BOLT,FLANGE 5×16 |

2 |

|

|

|

|

14 |

95701-05016-00 |

BOLT,FLANGE 5×16 |

2 |

|

|

|

|

15 |

92101-05235-00 |

FLANGE BOLT(STATOR) 5×235 |

2 |

|

|

|

|

16 |

94111-05000-00 |

FLANGE BOLT(STATOR) M5 |

2 |

|

|

|

|

17 |

95701-06195-00 |

FLANGE BOLT(STATOR) 6×195 |

4 |

|

|

|

|

18 |

94111-10000-00 |

WASHER,SPRING(ROTOR) 10MM |

1 |

|

|

|

|

19 |

90650-00300-00 |

BAND’WIRE(SINGLE) 300mm |

2 |

|

|

|

|

21 |

91005-188-00 |

BEARING 6205RS |

1 |

|

|

|

|

22 |

90305-05000-00 |

NUT (STATOR) M5 |

2 |

|

|

|

|

23 |

94112-05000-00 |

WASHER,SPRING 5MM |

4 |

|

|

|

|

24 |

90486-05000-00 |

WASHER,PLAIN |

4 |

|

|

|

|

21

Loading...

Loading...