ETQ PG30P11 Owner's Manual

Owner’s Manual Model PG30P1 1

3500 Peak Watts/3000 Running Watts

PORTABLE LPG GENERATOR

Eastern Tools & Equipment, Inc.

Total Harmonic Distortion T.H.D<5%

Thank you for purchasing products from EASTERNTOOLS & EQUIPMENT, INC. We

appreciate your business. The following manual is only a guide to assist you and is not a

complete or comprehensive manual of all aspects of maintaining and repairing your

generator. The equipment you have purchased is a complex piece of machinery. We

recommend that that you consult with a dealer if you have doubts or concerns as to your

experience or ability to properly maintain or repair your equipment. You will save time and

the inconvenience of having to go back to the store if you choose to write or call us

concerning missing parts, service questions, operating advice, and/or assembly questions.

Our LPG generators have some of the following features:

.Light weight construction

.Air cooled

.Four-stroke LPG internal combustion engine

.Recoil starter

.Automatic voltage stabilizer

.NFB circuit protector

.AC outputs

.Low oil level sensor

.T.H.D < 5%

.120V 20A Duplex(GFCI)

The ETQ air-cooled LPG generators are widely used when electrical power is scarce. Our

generators provide a portable mobile solution in supplying power for field operations during

project construction.

This manual will explain how to operate and service your generator set.

If you have any questions or suggestions about this manual, please contact your local

dealer or us directly. Consumers should notice that this manual might differ slightly

from the actual product as more improvements are made to our products. Some of

the pictures in this manual may differ slightly from the actual product as well.

Eastern Tools and Equipment, Inc. reserves the right to make changes at any time

without notice and without incurring any obligation.

PREFACE

Introduction ................................. ....... ........... 1

Portable Power Generator.......... ....... .............1

Accessories................................... ....... ...........1

This Booklet.................................... ....... .........1

Manual Conventions .................... ....... ...........2

Safety Rules .............................. ....... ..............3

Controls and Features................. ....... .............5

Generator......................................................... 5

Power Panel …………………………………….. 6

Parts Included ..................................... ............ 7

Assembly…………………………………………..8

Remove the Generator from the Shipping

Carton ................................................. .............8

Install the Wheel Kit............................. ....... .....8

Install the Support Leg........ ....... ......................8

Install the Handle.................... ....... ..................8

Install the Spark Arrester (optional).... ....... ......8

Add Engine Oil ........................ ....... .................8

Add Fuel............................. ....... .......................9

Grounding.............................. ....... ...................9

Operation ................... ....... ........................... 10

Generator Location.............. .......................... 10

Grounding.......................... ............................ 10

Surge Protection ................ ............................ 10

Starting the Engine................ ........................ 10

Connecting Electrical Loads..... ..................... 10

Stopping the Engine ................... ................... 10

Do Not Overload Generator…………………….11

Capacity…………………………………………..11

Power Management....................... ....... .........11

Wattage Reference Chart............. ...................11

Maintenance............................. ....... ............. 12

Engine Maintenance……………………………12

Oil…………………………………………………12

Spark Plugs………………………………………12

Air Filter... 12

Spark Arrester (if installed)……………………..13

Cleaning…………………………………………..13

Adjustments……………………………………...13

Maintenance Schedule........ ....... .................. 13

Generator Maintenance............. .................... 13

Storage .................................. ....... ............... 14

Engine Storage...................... ......................... 14

Generator Storage.................. ........................ 14

Specifications ..................... ....... ................... 15

Engine Specifications................. .................... 15

Generator Specifications........... ..................... 15

Fuel......................................... ........................ 15

Oil................................ ................................... 15

Spark Plugs ...................... .............................. 15

Valve Clearance............. ................................. 15

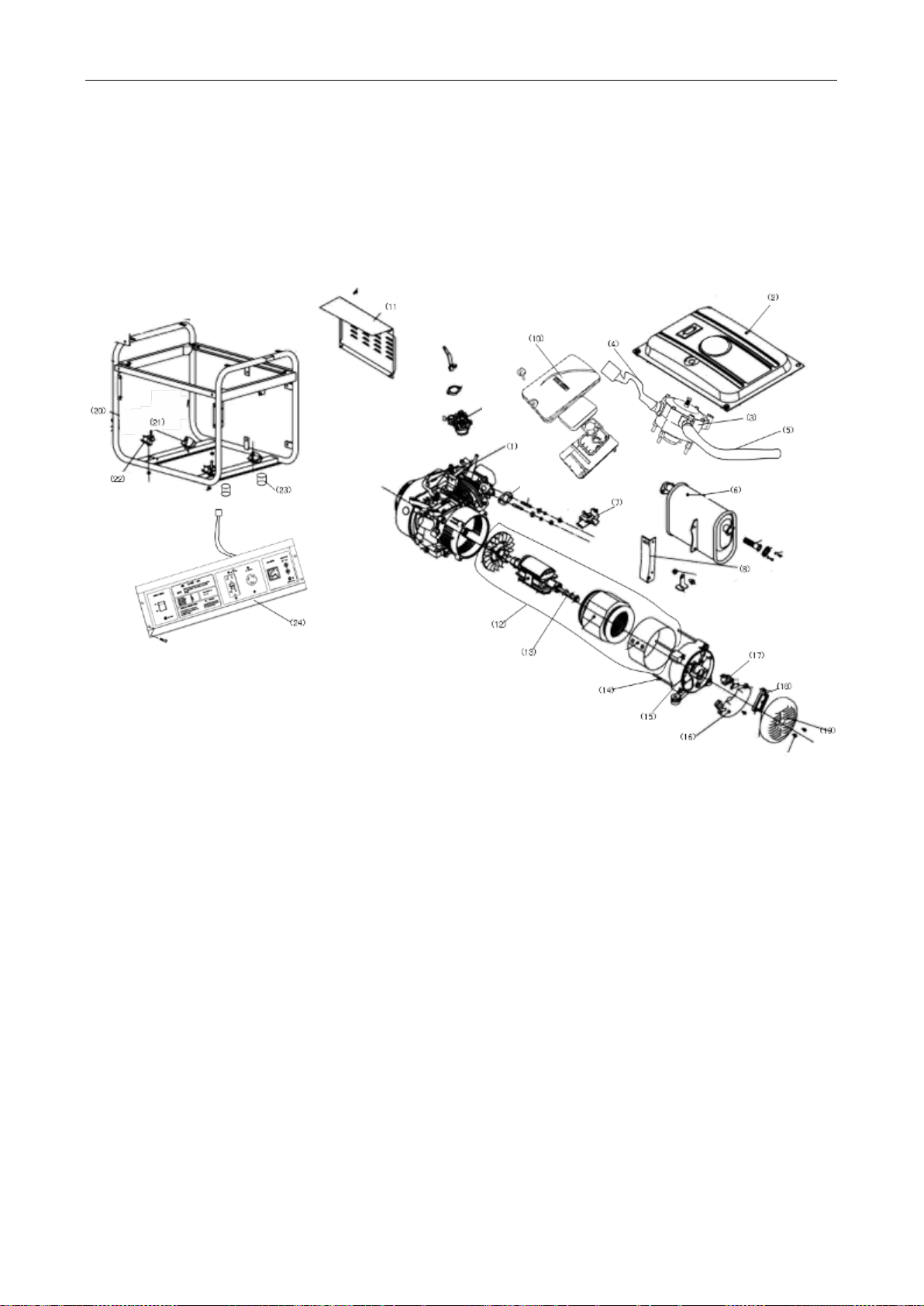

Parts Diagram............... ....... ............................16

Parts List ....................... ....... .......................... 17

Wiring Diagram...................... ....... ...................19

Troubleshooting ................... ....... ....... ............20

Warranty ............................ ....... ....... ............. 21

Warranty Qualifications ........... ....... ................ 21

Repair/Replacement Warranty .......... ....... ...... 21

Do not return the unit to the place of

Purchase...........................................................21

Warranty Exclusions............... .... .................... 21

Normal Wear......................... .... .... ................ 21

Installation, Use and Maintenance..... .... .... .... 21

Other Exclusions ............................ .... .... ....... 21

Limits of Implied Warranty and

Consequential Damage ............... ................... 21

Contact Information .................. .... ................. 21

Address.................................. .... .... ............... 21

Customer Service .................. .... .... ............... 21

Technical Service....................... .... .... ............ 21

Notes ................................ .... .... .... .................22

TABLE OF CONTENTS

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Introduction

Congratulations on your purchase of a

Easterntools & Equipment generator. ETQ

Designs and builds generators to strict

guidelines. With proper use and

Maintenance, this generator will bring years of

satisfying service.

Portable Power Generator

This unit is a LPG engine driven,

alternating current (AC) generator. It is

designed to supply electrical power for

lighting, appliances, tools and similar

equipments.

Accessories

EASTERNTOOLS & EQUIPMENT, INC.

manufactures and sells accessories designed to

help you get the most from your purchase. To find

out more about our covers, power cables and storm

kits, please visit our web site at

www.easterntools.com

This Booklet

Every effort has been made to ensure the accuracy

and completeness of the information in this manual.

We reserve the right to change, alter and/or improve

the product and this document at any time without

prior notice.

Record the model and serial numbers as well as the date and place of purchase for future reference.

Have this information available when ordering parts and when making technical or warranty inquiries.

Eastern Tools & Equipment, Inc. Support

1-888-696-2345

Model Number

CETL ******

Serial Number

Date of Purchase

Purchase Location

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

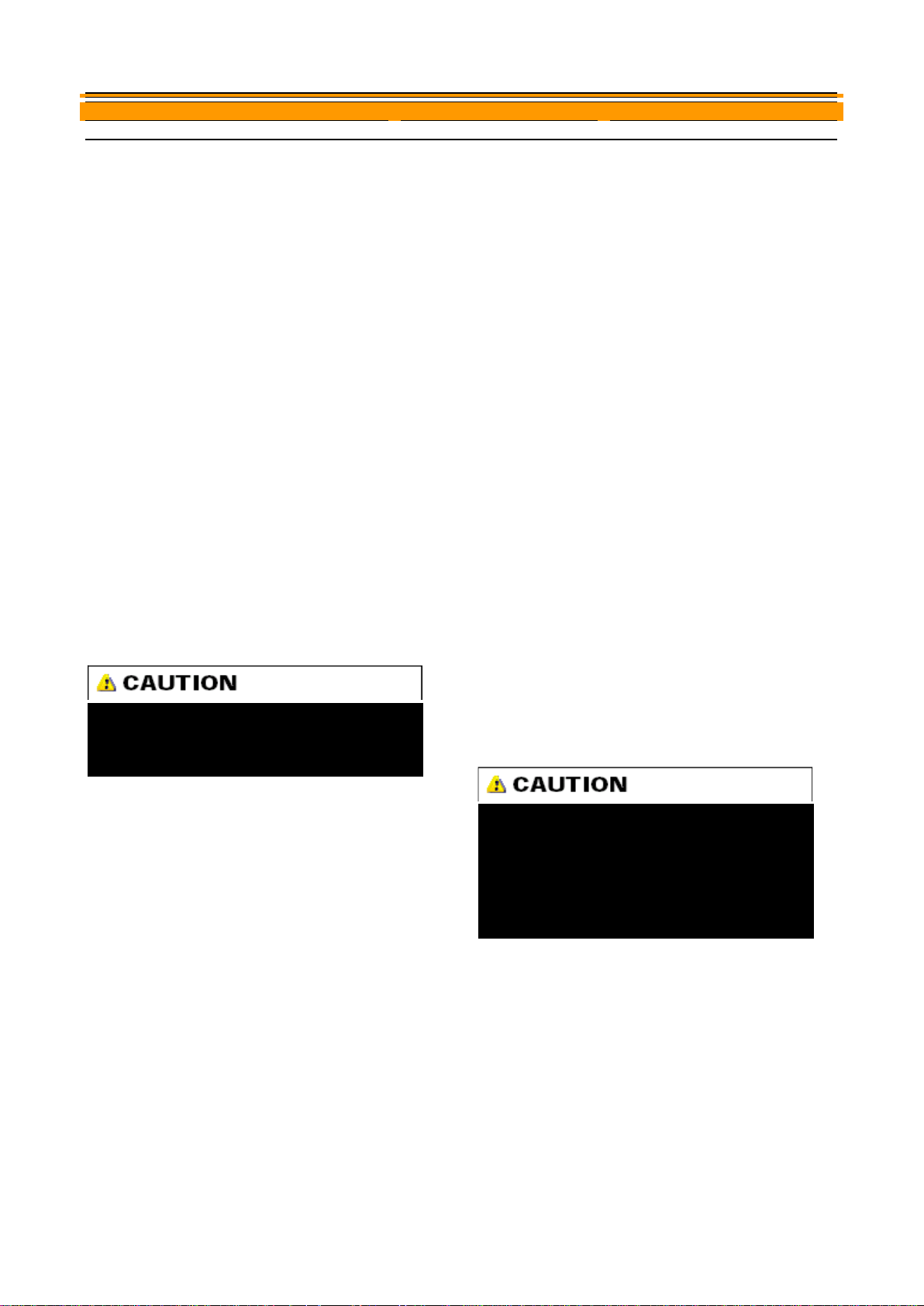

Manual Conventions

This manual uses the following symbols to

help differentiate between different kinds of

information.The safety symbol is used with

a key word to alert you to potential hazards

in operating and owning power equipment.

Follow all safety messages to avoid or reduce

the risk of serious injury or death.

If you have questions regarding your generator,

we can help. Please call our help line at 1-888696-2345

?

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous

situation, which if not avoided, may result in

minor or moderate injury.

CAUTION when used without the safety alert

symbol indicates a potentially hazardous situation

which, if not avoided, may result in property

damage.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Safety Rules

Read this manual thoroughly before operating

your generator. Failure to follow instructions

could result in serious injury or death.

The engine exhaust from this product contains

chemicals known to the state of California to

cause cancer, birth defects, or other

reproductive harm.

Generator exhaust contains carbon monoxide,

an odorless poison gas. Breathing carbon

monoxide will cause nausea, dizziness, fainting

or death.

Operate generator outdoors only in a well

ventilated area

DO NOT operate the generator inside any building,

enclosure or compartment, including the generator

compartment of a recreational vehicle.

DO NOT allow exhaust fumes to enter a confined

area through windows, doors, vents or other

openings.

Rotating parts can entangle hands, feet, hair,

clothing and/or accessories.

Traumatic amputation or severe laceration can

result.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

Operate equipment with guards in place.

DO NOT wear loose-fitting clothing, dangling

drawstrings or items that could become caught.

Generator produces powerful voltage.

DO NOT touch bare wires or receptacles.

DO NOT use electrical cords that are worn, damaged

or frayed.

DO NOT operate generator in wet weather.

DO NOT allow children or unqualified persons to

operate or service the generator

Use a ground fault circuit interrupter (GFCI) in damp

areas and areas containing conductive

material such as metal decking.

Use approved transfer equipment to isolate generator

from your electric utility and Notify your utility company

before connecting your generator to your power

system.

Sparks can result in fire or electrical shock.

When servicing the generator:

Disconnect the spark plug wire and place it where it

cannot contact the plug.

DO NOT check for spark with the plug is removed.

Use only approved spark plug testers.

Running the engine produces heat.

Severe burns can occur on contact.

Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least three feet of clearance on all ides to

ensure adequate cooling.

Maintain at least five feet of clearance from

combustible materials.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

When adding or removing fuel

Always keep fuel away from sparks, open flames, pilot

lights, heat and other sources of ignition.

DO NOT light or smoke cigarettes.

When starting the generator

DO NOT attempt to start a damaged generator.

Make certain that the generator is resting firmly on

level ground.

When operating the generator:

DO NOT move or tip the generator during operation.

When transporting or servicing the

generator:

Make certain that the fuel shutoff valve is in the off.

Disconnect the spark plug wire.

When storing the generator:

Store away from sparks, open flames, pilot lights, heat

and other sources of ignition.

Rapid retraction of the starter cord may cause

unintentional startup, which can result in

entanglement, traumatic amputation or laceration.

Broken bones, fractures, bruises or sprains could

result.

When starting engine, pull the starter cord slowly until

r e s i s t a n c e i s f e l t a n d t h e n p u l l r a p i d l y t o avoid kickback.

DO NOT start or stop the engine with electrical devices

plugged in.

DO NOT overload the generator.

Start the generator and allow the engine to stabilize

before connecting electrical loads.

Connect electrical equipment in the off position, and

then turn them on for operation.

Turn electrical equipment off and disconnect before

stopping the generator.

DO NOT tamper with the governed speed.

DO NOT modify the generator in any way.

Exceeding the generator’s running capacity can

damage the generator and/or electrical devices

connected to it

Improper treatment or use of the generator can

damage it, shorten its life and void your warranty.

Use the generator only for intended uses.

Operate only on level surfaces.

DO NOT expose generator to excessive moisture, dust,

or dirt.

DO NOT allow any material to block the cooling slots.

If connected devices overheat, turn them off and

disconnect them from the generator.

DO NOT use the generator if:

Electrical output is lost

Equipment sparks, smokes or emits flames

Equipment vibrates excessively

When use the LPG generator, if find any

abnormality (LPG leakage or strange smells),

please turn off the unit & LPG tank immediately

and then check the connection tube to insure to

use the unit safely.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

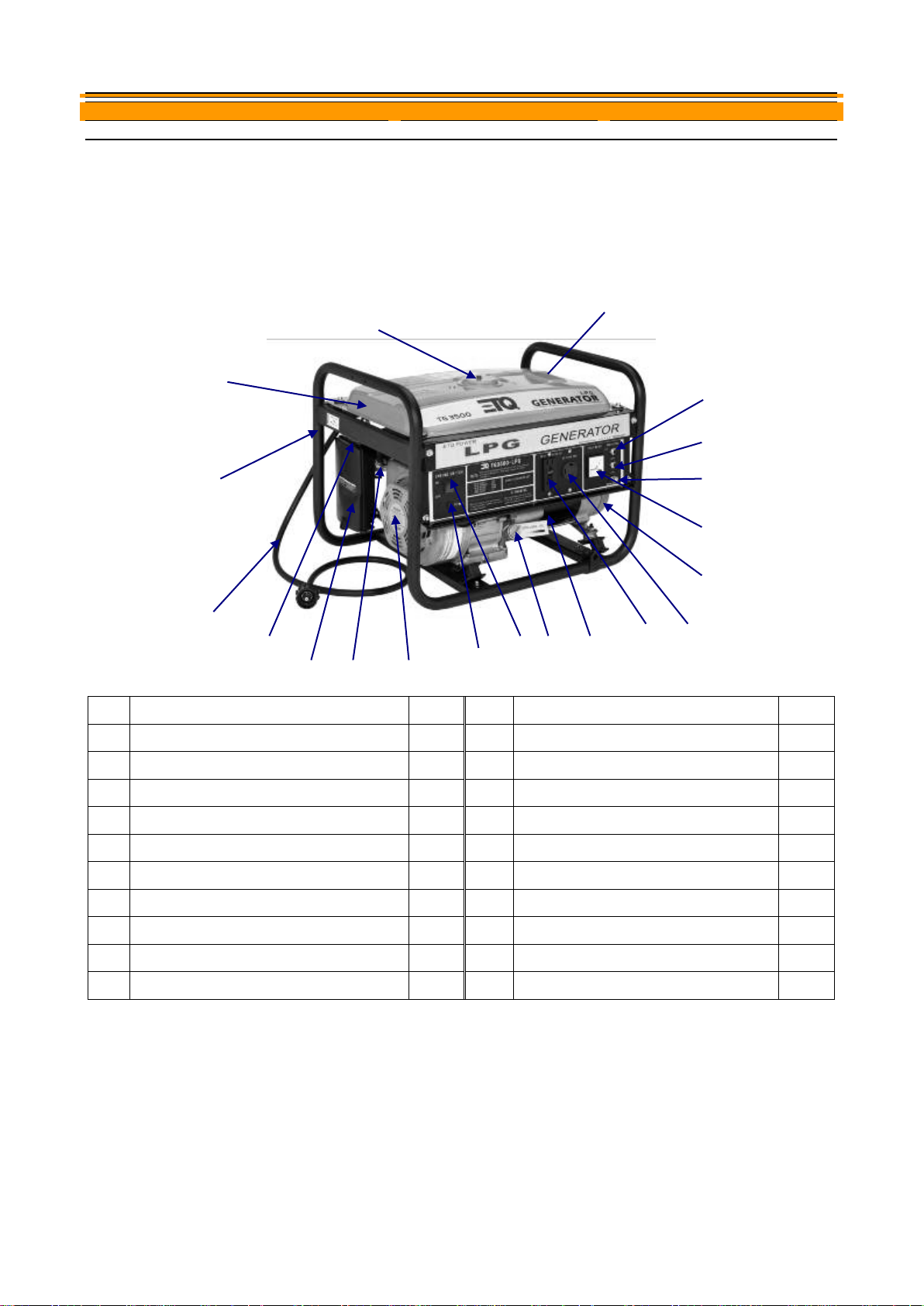

Controls and Features

Read this owner’s manual before operating your generator. Familiarize yourself with the location and function

of the controls and features. Save this manual for future reference.

Generator

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1

AC CIRCUIT BREAKER 20A

1

11

OIL INDICATOR LIGHT ASSY

1

2

AC CIRCUIT BREAKER 25A

1

12

RECOIL STARTER

1

3

LUG GROUND

1

13

COCK ASSY.FUEL

1

4

VOLTMETER

1

14

AIR CLEANER

1

5

BRACKET,RR.,MOTOR

1

15

CHOKE ROD

1

6

3-POLE RECEPTACLE L5-30R

1

16

TUBE,LPG

1

7

120V RECEPTACLE 5-20R

1

17

FRAME COMP

1

8

MOTOR ASSY.,STARTING

1

18

TANK TOP COMP,FUEL

1

9

CAP ASSY,OIL FILLER

1

19

REDUCTOR ASSY

1

10

ENGINE SWITCH

1

20

MUFFLER COMP

1

WARNING: DO NOT exceed the generator’s wattage/amperage capacity. Our products are

continuously being changed and improved. Every effort has been made to ensure that information in the

manual is accurate and up to date. However, we reserve the right to change, alter or otherwise improve

the product and this manual at any time without prior notice.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Operation instruction of REDUCTOR ASSY

NO.

DESCRIPTION

Qty

NO.

DESCRIPTION

Qty

1

High-pressure intake tube(1000mm)

1 5 Mix device( the same as carburetor)

1

2

REDUCTOR ASSY

1

6

LPG denser device (bottom)→mounted

onto REDUCTOR valve

1

3

TANK TOP COMP,FUEL

1

7

LPG air-pressure adjusting bottom →

mounted onto REDUCTOR valve

1

4

Low-pressure outlet tube

1

Instruction on LPG denser device (bottom)

T o develop cold start performance of LPG generator unit, the air REDUCTOR ASSY includes one LPG denser device

(bottom), the detailed operation of the bottom is shown below.

When starting the cold LPG generator unit, open the valve of the LPG tank, close the resistance air valve handle, press

the LPG denser device (bottom) lightly, and hold for 1-2 seconds, then stop. Start the engine normally, and after

finishing the start up, please open resistance air valve handle.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

IN

OUT

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

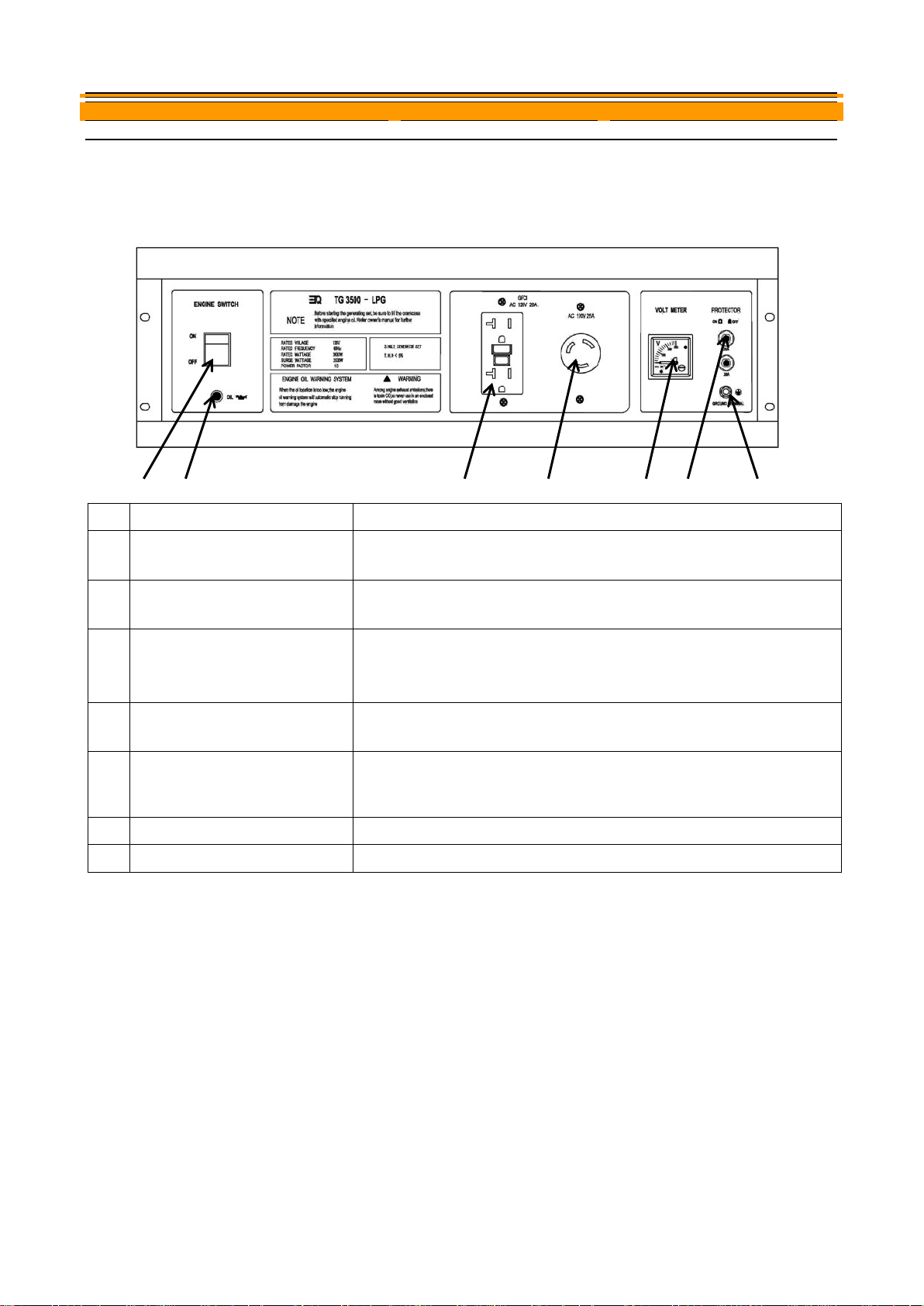

Power Panel

NO.

ITEM

EXPLAIN

(1)

Engine Switch

Flip the switch to the “On” position and pull the recoil starter to start the

generator. Turn to the “Off” position to turn off the generator.

(2)

Low Oil Sensor

Senses low oil condition and flashes; prevents engine from starting and/or

running if oil falls below the safety threshold.

(3)

120V 20A Duplex(GFCI→5-20R)

Protected by a 20 A circuit breaker. Use this duplex to operate 120 Volt AC,

single phase, 60 Hz loads requiring up to 20 Amps 0r 2400 Watts of power.

It has the protection function of electricity leakage (GFCI)

(4)

120V 20A Duplex(L5-30R)

Protected by a 25 A circuit breaker. This receptacle powers 120 Volt AC, 60

Hz, single phase loads requiring up to 25 Amps or 3000 watts of power.

(5)

VOLTMETER

Index style voltage meter, when running the generator unit, it shows

the current voltage; when turn off the generator unit, the reading

returns to”0”.

(6)

AC CIRCUIT BREAKER

Protects the generator against electrical overload.

(7)

LUG GROUND

Consult an electrician for local grounding regulations.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

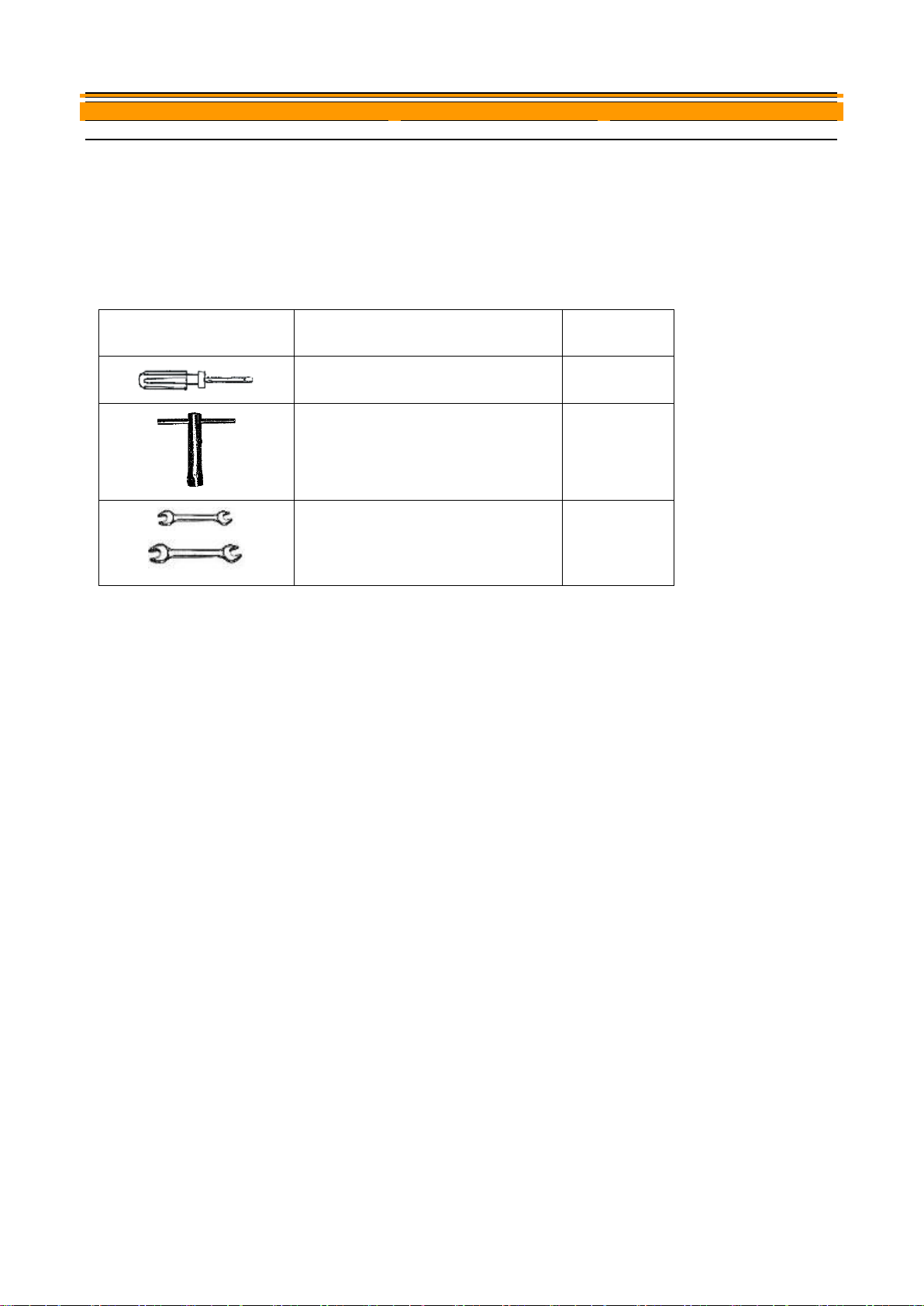

Parts Included

Your CETL***** LPG Powered Generator ships with the following parts:

DESCRIPTION

QTY

Flat Head Screwdriver

1

Spark Plug Wrench

1

Wrench, 8×10 17×19

1

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Assembly

Your generator requires some assembly.

This unit ships from our factory without oil.

It must be properly serviced with fuel and oil before

operation.

If you have any questions regarding the assembly

of your generator, call our help line at

1-888-696-2345.Please have your serial number

and model number available.

Remove the Generator from the

Shipping Carton

1. Set the shipping carton on a solid, flat surface.

2. Remove everything from the carton except the

generator.

3. Carefully cut each corner of the box from top to

bottom. Fold each side flat on the ground to provide

a surface area to install the wheel kit and support

leg.

Install the Wheel Kit

You will need the following tools to install the

wheels:

12 mm wrench

Socket wrench with a 12 mm socket Pliers

1. Before adding oil to the engine, tip the generator

slowly so that the engine side is up.

2. Attach the axle to the bottom of the frame with

four mounting bolts and nuts.

3. Slide a wheel onto the axle.

4. Place a washer on the end.

5. Install the cotter pin through the hole on the end

of the axle.

6. Carefully bend the legs of the cotter pin back

around the axle.

7. Repeat steps 3-6 to attach the second wheel.

Install the Support Leg

1. Attach the rubber vibration mount to the support

leg with a cap screw (M8x20) and lock nut (M8).

2. Attach the support leg to the generator frame with

cap screws (M8x30) and lock nuts (M8).

3. Tip the generator slowly so that it rests on the

wheels and support leg.

Install the Handle

1. Place the handle over the mounting channel on

the frame.

2. Secure the handle to the frame using the two

handle bolts.

3. Place a lock nut (M8) on the end of each bolt and

fasten securely. DO NOT over tighten the lock nuts.

Install the Spark Arrester (optional)

Insert the spark arrester screen into the muffler

outlet. Secure the spark arrester by placing the

cover plate over the end of the screen, with the

lettering facing outward.

Secure the cover plate with the two screws and lock

washers provided with the spark arrester kit.

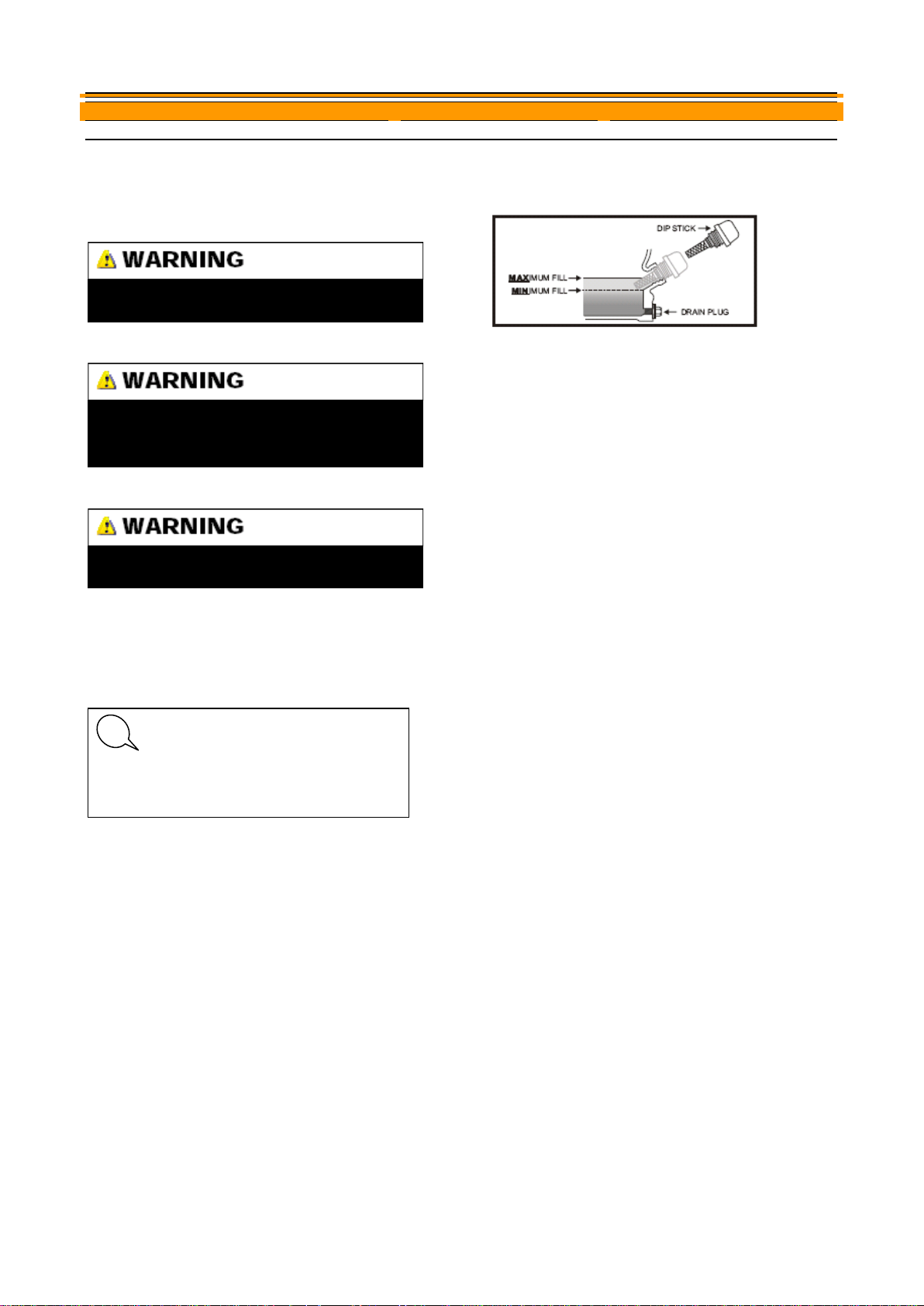

Add Engine Oil

1. Place the generator on a flat, level surface.

2. Remove oil fill cap/dipstick to add oil.

3. Add 0.63 qt (0.6 L) of oil and replace oil fill

cap/dipstick.

4. Check engine oil level daily and add as needed.

The wheel kit is not intended for over-the-road

use.

DO NOT attempt to crank or start the engine before

it has been properly filled with the recommended

amount of oil. Damage to the generator as a result

of failure to follow these instructions will void your

warranty.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

1. LPG gas pressure area:0.2~0.7MPa.

2. DO NOT use gasoline as fuel.

3. Connect LPG tube on LPG tank and fasten it.

4. Turn the LGP tank valve to "ON” position - full

open.

5. Screw on the trachea tie-in

6. Check all connections for propane leaks with

soapy water and tighten connections.

7. If air pressure is low change the tank. When

propane pressure is low, replace with a full

tank.

Grounding

Your generator must be properly connected to an

appropriate ground to help prevent electric shock.

A ground terminal connected to the frame of the

generator has been provided on the power panel.

For remote grounding, connect a length of heavy

gauge (14 AWG minimum) copper wire between the

generator ground terminal and a copper rod driven

into the ground. We strongly recommend that you

consult with a qualified electrician to ensure

compliance with local electrical codes.

The engine is equipped with a low-oil-shutoff and

this will stop when the oil leve l i n the crankc ase falls

below the threshold level.

Check oil often during the break-in period. Refer to

the Maintenance section for recommended service

intervals.

?

The generator rotor has a sealed, pre-lubricated

ball bearing that requires no additional lubrication

for the life of the bearing.

?

Use clean, fresh, regular LPG with LPG gas

pressure area:0.2~0.7MPa.

DO NOT mix oil with fuel.

DO NOT use gasoline as fuel.

Connect LPG tube on LPG tank and fasten it.

Turn the LGP tank valve to "ON” position - full open.

Screw on the trachea tie-in

Check the LPG to see if it is leaking and then

guarantee it.

When the air-pressure is lower than standard range,

please change LPG tank.

Failure to properly ground the generator can result

in electric shock.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Generator Location

Please consult your local authority. In some areas,

generators must be registered with the local utility.

Generators used at construction sites may be

subject to additional rules and regulations.

This generator must have at least five feet of

clearance from combustible material. Leave at least

three feet of clearance on all sides of the generator

to allow for adequate cooling,maintenance and

servicing.

Place the generator in a well-ventilated area.

DO NOT place the generator near vents or intakes

where exhaust fumes could be drawn into occupied

or confined spaces. Carefully consider wind and air

currents when positioning generator.

Grounding

The generator system ground connects the frame to

the ground terminals on the power panel.

The system ground is connected to the AC neutral

wire.

Surge Protection

Electronic devices, including computers and m any

programmable appliances use components that are

designed to operate within a narrow voltage range

and may be affected by momentary voltage

fluctuations.

While there is no way to prevent voltage fluctuations,

you can take steps to protect sensitive electronic

equipment.

1.Install UL1449, CSA-listed, plug-in surge

suppressors on the outlets feeding your sensitive

equipment.

Surge suppressors come in single- or multi-outlet

styles. They’re designed to protect against virtually

all shortduration voltage fluctuations.

2. Obtain an Uninterruptible Power Supply (UPS)

device.

Most UPS devices come with a rechargeable

battery between the electronic equipment and

power supply source. The device buffers the voltage

and protects against virtually all shortduration

voltage fluctuations.

Starting the Engine

1. Make certain the generator is on a flat, level

surface.

2. Disconnect all electrical loads from the generator.

Never start or stop the generator with electrical

devices plugged in or turned on.

3. Connect LPG tube to the LPG tank, and then

open the LPG valve slowly, till it totally open (to

insure no LPG leakage).

4. Move the choke lever to the “Choke” position.

5. Press the denser bottom of the REDUCTOR

ASSY and hold 1~2 seconds;

6. Pull the starter cord slowly until resistance is felt

and then pull rapidly

7. As engine warms up, move the choke lever to

“Run”.

Connecting Electrical Loads

1.Let the engine stabilize and warm up for a few

minutes after starting

2. Plug in and turn on the desired 120 Volt AC single

phase, 60 Hz electrical loads.

Prohibit using CNG, NG or gasoline as fuel.

DO NOT connect 3-phase loads to the generator.

DO NOT connect 50 Hz loads to the generator.

DO NOT overload the generator.

Voltage fluctuation may impair the proper

functioning of sensitive electronic equipment.

If the engine starts but does not run, make certain

that the generator is on a flat, level surface. The

engine is equipped with a low oil sensor that will

prevent the engine from running

when the oil level falls below a critical threshold.

?

1. When using the LPG generator, please be

sure that there is some distance between LGP

tank and LPG generator, to prevent

unnecessary danger because of high

temperature surface of LGP tank;

2. When using the unit, please check the

surface temperature of LPG tank.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Stopping the Engine

1.Turn off and unplug all electrical loads.Never start

or stop the generator with electrical devices plugged

in or turned on.

2.Let the generator run at no-load for several

minutes to stabilize internal temperatures of the

engine and generator.

3. Turn the ignition switch to the “Off” position.

4.Turn the fuel valve to the “Off” position.

Do Not Overload Generator

Capacity

Follow these simple steps to calculate the running

and starting watts necessary for your purposes.

1. Select the electrical devices you plan on running

at the same time.

2. Total the running watts of these items.

This is the amount of power you need to keep your

items running.

3. Identify the highest starting wattage of all devices

identified in step 1. Add this number to the number

calculated in step 2.

2. Surge wattage is the extra burst of power needed

to start some electric driven equipment. Following

the steps listed under “Power Management” will

guarantee that only one device will be starting at a

time.

Power Management

Use the following formula to convert voltage and

amperage to watts:

Volts x Amps = Watts

To prolong the life of your generator and attached

devices, follow these steps to add electrical load:

1. Start the generator with no electrical load

attached.

2. Allow the engine to run for several minutes to

stabilize.

3.Plug in and turn on the first item. It is best to attach

the item with the largest load first.

4.Allow the engine to stabilize.

5.Plug in and turn on the next item.

6. Allow the engine to stabilize.

7. Repeat steps 5-6 for each additional item.

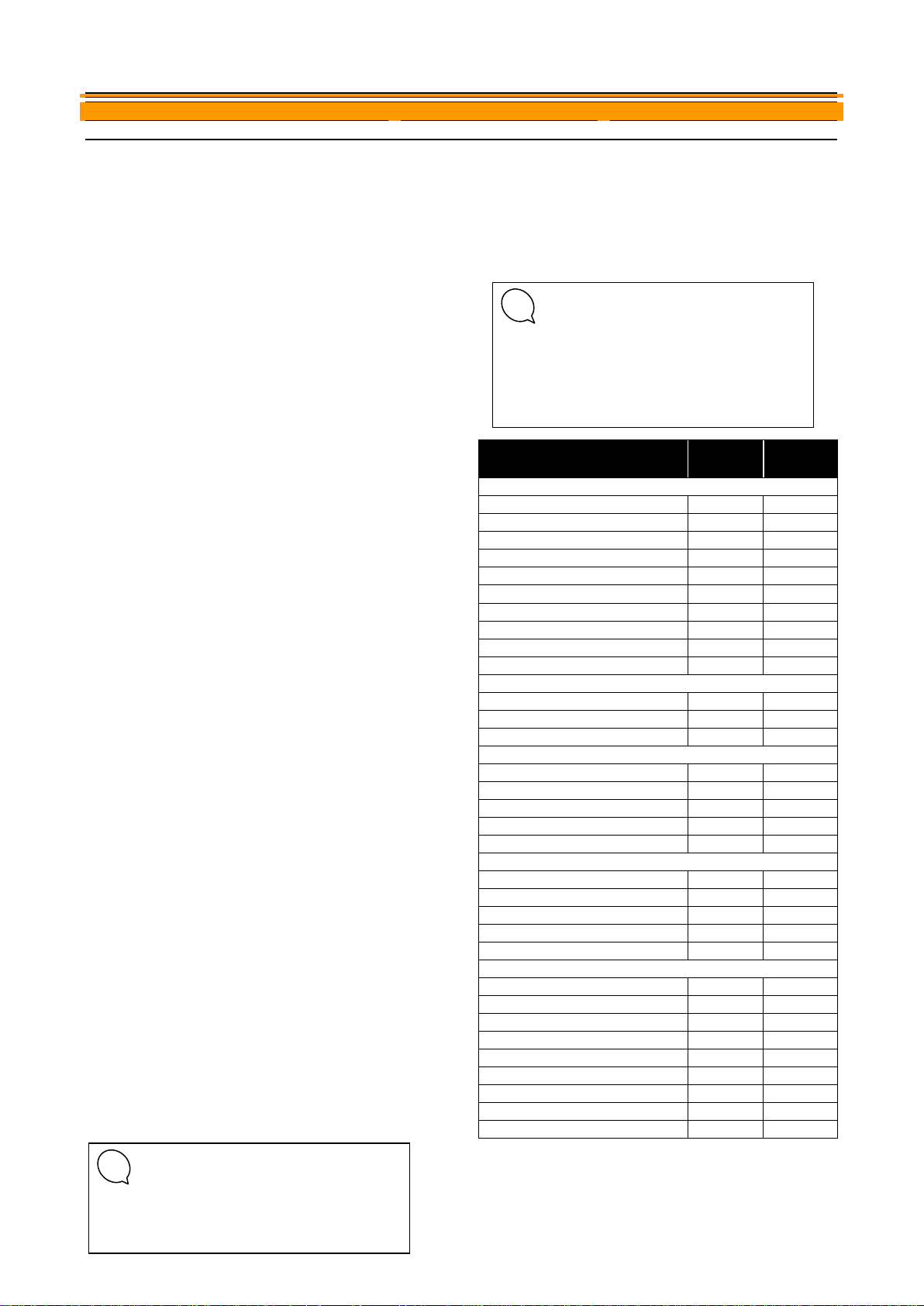

Wattage Reference Chart

Use the chart to determine approximate wattage

requirements for your equipment.

Item

Running

Watts

Starting

Watts

Essentials

Light Bulb 100W

100

Refrigerator/Freezer

1200

2400

Freezer

500

500

Sump Pump

600

1800

Well Pump 1 HP

2000

4000

Water Heater

4000

Security System

180

AM/FM Radi o

300

Garage Door Opener 1/2 HP

500

600

Battery Charger 12V DC

110

Heating/Cooling

Air Conditioner 12000 BTU

1700

2500

Fan

300

600

Furnace Fan 1/3 HP

1200

2000

Home Appliances

Microwave 1000W

1000

Electric Range - One Element

1500

Electric Skillet

1250

Coffee Maker

1500

Clothes Washer

1200

Entertainment

CD/DVD Player

100

VCR

100

Stereo Receiver

450

Television 27"

500

PC with 15" Monitor

800

Job Site

Belt Sander 3"

1000

1500

Bench Grinder 6"

700

1500

Circular Saw

1500

1500

Compressor 1 1/2 HP

2500

2500

Edge Trimmer

500

500

Hand Drill 1/2"

1000

1000

Lawn Mower

1200

1800

Paint Sprayer

600

1200

Table Saw

2000

2000

Never exceed the generator capacity when

adding loads.

?

Starting watts can exceed three times the

running watts. The values in the following table

are approximate. Refer to your tool or appliance

for actual wattage consumption.

?

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Maintenance

The owner/operator is responsible for all periodic

maintenance.

Complete all scheduled maintenance in a t imely

manner. Correct any issue before operating the

generator.

Engine Maintenance

To prevent accidental starting, remove and ground

spark plug wire before performing any service.

Oil

Change oil when the engine is warm. Refer to the oil

specification to select the proper grade of oil for your

operating environment.

1. Remove the oil drain plug with a 15 mm socket

and extension.

2. Allow the oil to drain completely.

3. Replace the drain plug.

4. Remove oil fill cap/dipstick to add oil.

5. Add 0.63 qt (0.6 L) of oil and replace oil fill

cap/dipstick.

6. Dispose of used oil at an approved waste

management facility.

Spark Plugs

1. Remove the spark plug cable from the spark plug.

2.Use the spark plug tool that shipped with your

generator to remove the plug.

3. Inspect the electrode on the plug. It must be clean

and not worn to produce the spark required for

ignition.

4. Make certain the spark plug gap is 0.7 - 0.8mm

(0.028 - 0.031 in.).

5. Refer to the spark plug recommendation chart

when replacing the plug.

6. Carefully thread the plug into the engine.

7. Use the spark plug tool to firmly install the plug.

8. Attach the spark plug wire to the plug.

Air Filter

1. Remove the snap-on cover holding the air filter to

the assembly.

2. Remove the foam element.

3. Wash in liquid detergent and water.

Squeeze thoroughly dry in a clean cloth.

4. Saturate in clean engine oil.

5. Squeeze in a clean, absorbent cloth to remove all

excess oil.

6. Place the filter in the assembly.

7. Reattach the air filter cover and snap in place.

Never operate a damaged or defective generator.

Tampering with the factory set governor will void

your warranty.

Improper maintenance will void your warranty.

For service or parts assistance, contact our

help line at 1-888-696-2345.

?

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Spark Arrester (if installed)

1. Allow the engine to cool completely before

servicing the spark arrester.

2. Remove the two screws holding the cover plate

which retains the end of the spark arrester to the

muffler.

3. Remove the spark arrester screen.

4. Carefully remove the carbon deposits from the

spark arrester screen with a wire brush.

5. Replace the spark arrester if it is damaged.

6. Position the spark arrester in the muffler and

attach with the two screws.

Cleaning

Use a damp cloth to clean exterior surfaces of the

engine.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and

debris from the engine.

Adjustments

The air-fuel mixture is not adjustable.

Tampering with the governor can damage your

generator and your electrical devices and will void

your warranty.

recommends that you contact our service line at

1-888-696-2345 for all other service and/or

adjustment needs.

Maintenance Schedule

Follow the service intervals indicated in the

schedule below.

Service your generator more frequently when

operating in adverse conditions.

Contact our help line at 1-888-696-2345 to locate

the nearest Eastern Tools & Equipment

certified service dealer for your generator or engine

maintenance needs.

Every 8 hours or daily

Check oil level

Clean around air intake and muffler

First 5 Hours

Change oil

First 10 hours

Check/Adjust Valve Clearance *

Every 50 hours or every season

Clean air filter

Change oil if operating under heavy load or in hot

environments

Every 100 hours or every season

Change oil

Clean/Adjust spark plug

Check/Adjust valve clearance *

Clean spark arrester

Clean fuel tank and filter *

Every 3 years

Replace fuel line

* To be performed by knowledgeable,

experienced owners or Eastern Tools & Equipment

certified service dealers

Generator Maintenance

Make certain that the generator is kept clean and

stored properly. Only operate the unit on a flat, level

surface in a clean, dry operating environment. DO

NOT expose the unit to extreme conditions,

excessive dust, dirty, moisture or corrosive vapors.

Use a damp cloth to clean exterior surfaces of the

generator.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and

debris from the generator.

Inspect all air vents and cooling slots to ensure that

they are clean and unobstructed.

DO NOT spray engine with water.

Water can contaminate the fuel system.

DO NOT use a garden hose to clean the

generator.

Water can enter the generator through the

cooling slots and damage the generator

windings.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Storage

The generator should be started at least once every

14 days and allowed to run for at least 20 minutes.

For longer term storage, please follow these

guidelines.

Engine Storage

1. Allow the engine to cool completely before

storage.

2. Clean the engine according to the instructions in

the Maintenance section.

3. Change the oil.

4. Remove the spark plug and pour about ½ ounce

of oil into the cylinder. Crank the engine slowly to

distribute the oil and lubricate the cylinder.

5. Reattach the spark plug.

Generator Storage

1. Allow the generator to cool completely before

storage.

2. Turn off the fuel supply at the fuel valve.

3. Clean the generator according to the instructions

in the Maintenance section.

4. Store the unit in a clean, dry area.

5. Store in a clean, dry place out of direct sunlight.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Specifications

Engine Specifications

Engine 208 cc OHV

EPA certified

Generator Specifications

Running Wattage 3000 Watts

Starting Wattage 3500 Watts

AC Load 120V

Phase Single

Frequency 60 Hz

T.H.D <5%

Weight 102.42 lbs. (46.5 kg)

Height 23.31 inches (59.2 cm)

Width 16.93 inches (43.0 cm)

Length 17.13 inches (43.5 cm)

Fuel

LPG gas pressure area:0.2~0.7MPa.

Oil

Oil capacity is 0.63 qt (0.6 L).

Spark Plugs

Your generator comes equipped with a ¾” long

reach plug (18 mm)

Intermittent use (less than 1 hour/month) or colder

temperatures (below 60°F)

NGK B4ES or STAR F6TC

Moderate use (less than 3 hours/month) or

Seasonal temperatures (50-80°F)

NGK B4ES or STAR F6TC

Extreme use (continuous) or hot climates

(80-100°F)

NGK B4ES or STAR F6TC

Make certain the spark plug gap is 0.7 -

0.8mm (0.028 - 0.031 in.).

Valve Clearance

Intake 0.10-0.12mm (0.004 – 0.005 in.)

Exhaust 0.15-0.17mm (0.006 – 0.007 in.)

Parts Diagram

(25)

(9 )

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Parts List

NUMBER

PART NUMBER

DESCRIPTION

QTY

1

E0001-170-00

ENGINE ASSY

1

2

16520-T40-00

TANK TOP COMP , F U E L

1

3

33710-L68-00

CONNECT V ALVE ASSY

1

4

15761-L68-00

MINUS PRESS DUCT

1

5

15762-L68-00

L O W -PRESSURE OUTTAKE TUBE

1

6

18310-170-00

MUFFLER COMP

1

7

18383-168-00

SUPPORTING PLSTE

1

8

18382-168-00

MUFFLER STAY

1

9

16100-170-00-LPG

CARBURETOR ASSY

1

10

17250-168-00

AIR/C

1

1 1

18320-168-00

PROTR,OUT MUFFLER

1

12

31200-S30-00

MOTOR ASSY.,STARTING(3.0KW)

1

13

95701-08220-00

BOLT (ROTOR)8×220

1

14

95701-06165-00

BOLT FLANGE(STATOR) 6×165

4

15

31170-168-00

GENERATOR STA Y

1

16

30300-168-00

VOLTAGE REGULATOR(3KW)

1

17

31160-168-00

BRUSH ASSY

1

18

19620-168-00

CONNECTION FLAT

1

19

31203-168-00

BRACKET ,RR.,MOTOR

1

20

50310-T40-00

FRAME COMP

1

21

77320-168-00

BOTTOM RUBBER A

2

22

77330-168-00

BOTTOM RUBBER B

2

23

60407-168-00

RUBBER,BOTTOM (NUT)

4

24

33100-L35-00

CONTROL PANEL ASSY

1

25

18381-170-00

GASKET,MUFFLER

2

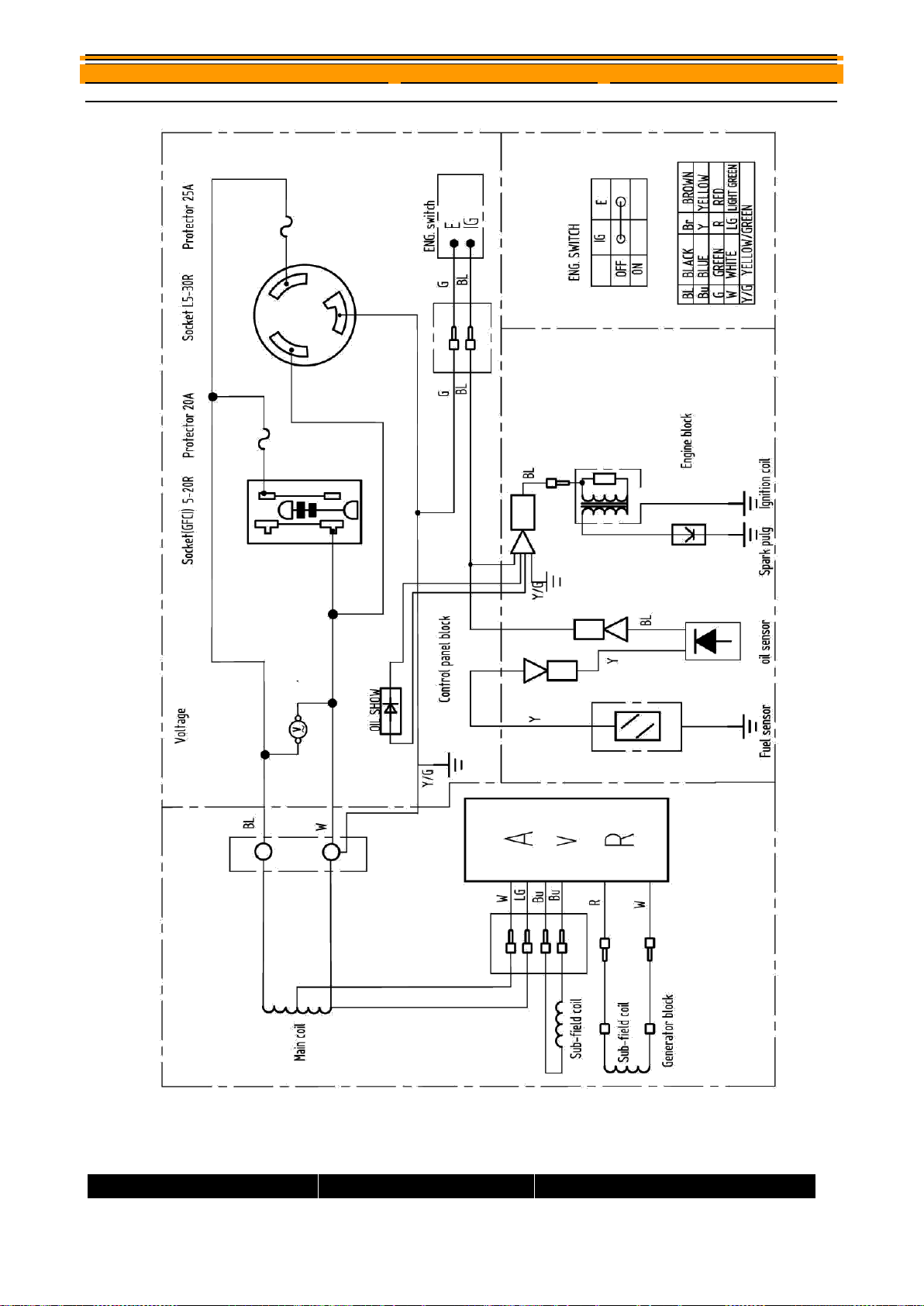

Wiring Diagram

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Troubleshooting

Problem

Cause

Solution

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

Generator will not start

No Propane

New Tank

Faulty spark plug

Replace spark plug

Unit loaded during start up

Remove load from unit

Generator will not start;

Generator starts but runs roughly

Low oil level

Fill crankcase to the proper level

Place generator on a flat, level surface

Choke in the wrong position.

Adjust choke.

Spark plug wire loose

Attach wire to spark plug

Generator shuts down during

operation

Out of Propane

Refill propane

Low oil level

Fill crankcase to the proper level.

Place generator on a flat, level surface

Generator cannot supply enough

power or overheating

Generator is overloaded

Review load and adjust. See “Power

Management”

Insufficient ventilation

Check for air restriction. Move to a well

ventilated area

No AC output

Cable not properly connected

Check all connections

Connected device is defective

Replace defective device

Circuit breaker is open

Reset circuit breaker

Capacitor defective

Replace capacitor (Service Center)

Faulty brush assembly

Replace brush assembly (Service Center)

Faulty AVR

Replace AVR (Service Center)

Loose wiring

Inspect and tighten wiring connections

Other

Contact the help line.

Generator gallops

Engine governor defective

Contact the help line

Repeated circuit breaker tripping

Overload

Review load and adjust. See “Power

Management”

Faulty cords or device

Check for damaged, bare or frayed wires.

Replace defective device

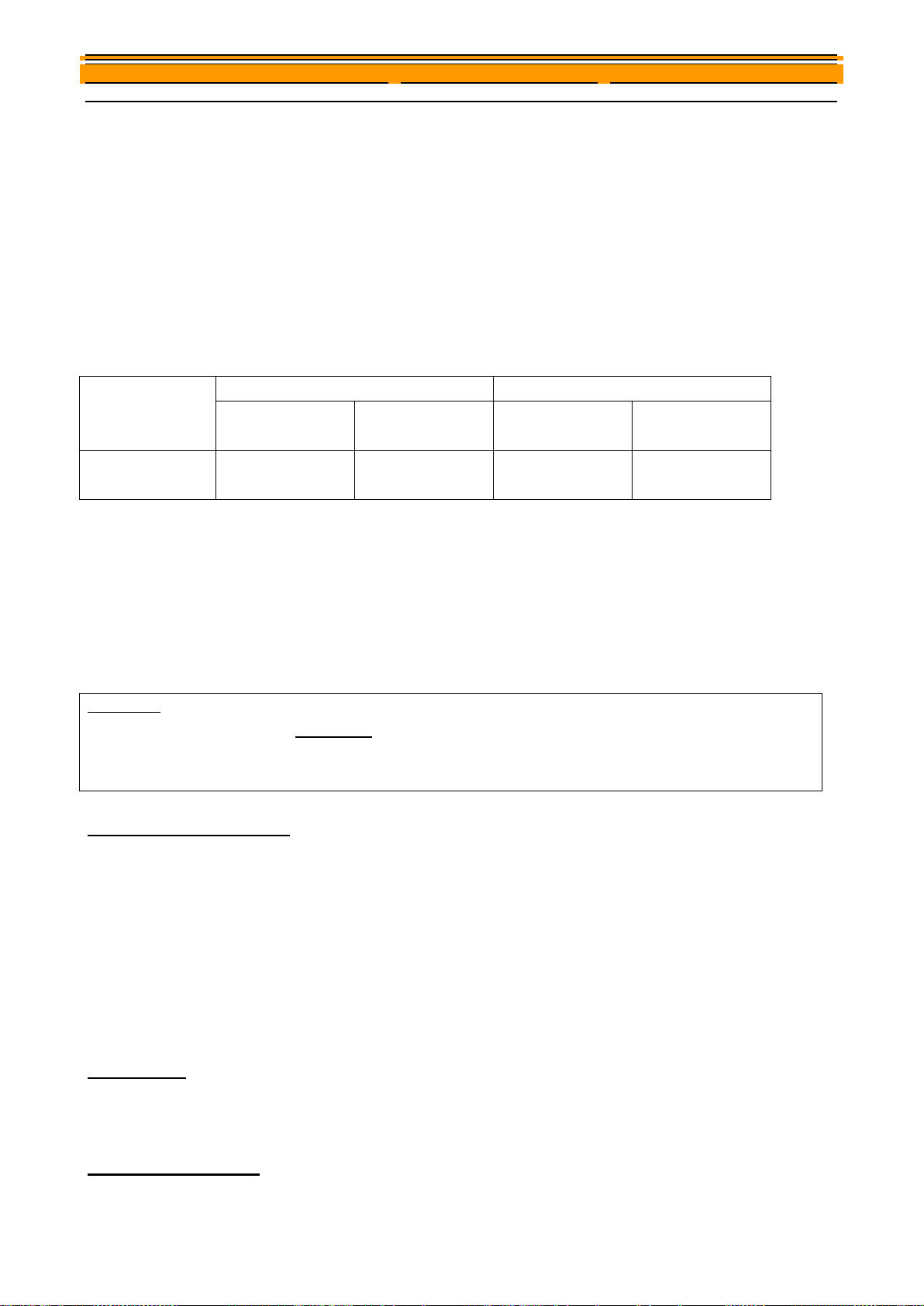

LIMITED WARRANTY

Eastern Tools & Equipment, Inc. will repair or replace, free of charge, any part or parts of the generator that are

defective in material or workmanship or both. Transportation charges on parts submitted for repair or replacement under

this Warranty must be borne by purchaser. This warranty is effective for the time period and subject to the conditions

provided for in this policy. For warranty service, find the nearest Authorized Service Dealer by contacting the place of

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

purchase or Eastern Tools & Equipment, Inc. THERE IS NO OTHER EXPRESSED WARRANTY. IMPLIED

WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITED BY LAW ANY AND ALL IMPLIED

WARRANTIES ARE EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL

WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states do not allow

limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific

legal rights and you may also have other rights, which vary from state to state.

Eastern Tools & Equipment, Inc.

WARR A N T Y P ER I O D***

ENGINES

WITHIN U.S.A AND CANADA

OUTSIDE U.S.A. AND CANADA

CONSUMER

USE

COMMERCIAL

USE

CONSUMER

USE

COMMERCIAL

USE

GASOLINE

GENERATOR

1 year

90 days

1 year

90 days

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of

time stated in the table above. “Consumer use” means personal residential household use by a retail consumer. “Commercial use”

means all other uses, including the commercial, income producing or rental purpose. Once the engine has experienced commercial

use, it shall thereafter be considered as a commercial use engine for purpose of this warranty. Engines use in competitive racing or

commercial or rental tracks are not warranted.

***A two-year warranty applies to the emission control system on engines certified by EPA and CARB.

I M P O R T A N T

“WARR ANTY RE GISTRATI ONS IS NECESSARY TO OBTAIN LIMITED WARRANTY ON EASTERN TOOLS & EQUIPMENT ,

INC., ENGINES. THE WAR RANTY REGI STRATION CARD MUST BE RETURNED WITHIN 15 DAYS OF PURCHASE FOR

LIMITED WARR ANTY TO BE VALID”

About Your Product Warranty

Eastern Tools & Equipment, Inc. welcomes warranty repair and apologizes to you for being inconvenienced. Any Authorized Service

Dealer may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes warranty service may be

inappropriate. For example, warranty would not apply if an engine is damaged because of misuse, lack of routine maintenance,

shipping, handling, warehousing and improper installation. Similarly, warranty is void if the serial number on the engine has been

removed or if the engine has been altered or modified. If a customer differs with the decision of the Service Dealer, an investigation will

be made to determine whether the warranty applies. Ask the Service Dealer to submit all supporting facts to his Distributor or the

factory for review. If the distributor or the factory decides that the claim is justified, the customer will be fully reimbursed for those items

that are defective. To avoid misunderstanding, which might occur between the customer and the dealer, listed below are some of the

causes of engine failure that the warranty does not cover

Normal wear:

Engines and generators, like all mechanical devices, need periodic parts service and replacement to perform well. Warranty will not

cover repair when normal use has exhausted the life of a part of an engine.

Improper maintenance:

The life of an engine or your equipment depends upon the conditions under which it operates, and the care it receives. Some

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

applications, such as tillers, pumps, and rotary movers, are very often used in dusty or dirty conditions, which can cause what appears

to be premature, wear. Such wear, when caused by dirt, dust, spark pug cleaning grit, or other abrasive material that has entered the

engine because of improper maintenance is not covered by warranty.

This warranty cover engine related defective material and/or workmanship only , and not replacement or refund of the

equipment to which the engine may be mounted. Nor des the warranty extend to repairs required because of:

1. Problems caused by parts that are not original eastern tools & equipment, inc., parts.

2. Equipment controls or installations that prevent starting, cause unsatisfactory engine performance, or shorten engine life.

(Contact equipment manufacturer.)

3. Leaking carburetor, clogged fuel pipes, sticking valves, or other damage, caused by using contaminated or stale fuel. (Use

clean, fresh, lead-free gasoline.)

4. Parts which are scored or broken because an engine was operated with insufficient or contaminated lubricating oil, or and

incorrect grad of lubricating oil (check oil level daily or after every 8 hours of operation. Refill when necessary and change at

recommended intervals.) Engine damage may occur if oil level is not properly maintained. Read Operating & Maintenance

Instructions.

5. Repair or adjustment of associated parts or assemblies such as clutches, transmissions, remote controls, etc., which are not

manufactured by Eastern Tools & Equipment, Inc.

6. Damage or wear to parts caused by dirt, which entered the engine because of improper air filter maintenance, re-assembly,

or use of a non-original air filter element or cartridge. Read Operating & Maintenance Instructions.

7. Parts damaged by over-speeding, or overheating caused by grass, debris, or dirt, which plugs or clogs the cooling fins, or

flywheel are, or damaged caused by operating the engine in a confined area without sufficient ventilation.

8. Engine or equipment parts broken by excessive vibration caused by a loosen cutter blades unbalanced blades or loose

unbalanced impellers, improper attachment of equipment to engine crankshaft, over speeding or other abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid object with the cutter blade of a rotary lawn mower, or excessive

v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion chamber, valves, valve seats, valve guides, or burned starter motor

winding, caused by the alternated fuels such as, liquefied petroleum, natural gas, altered gasoline’s etc.

Warranty is available only through service dealers, which have been authorized by Eastern Tools & Equipment, Inc.,

please contact the place of purchase or Eastern Tools & Equipment, Inc. for a Service Dealer near you.

ETQ

EASTERN TOOLS & EQUIPMENT INC

Tel: (888)696-2345

Web Site: easterntools.com

CALIFORNIA & USEPA EMISSION CONTROL WARRANTY STA TEMENT

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB) and Eastern Tools & Equipment, Inc.

are pleased to explain the Federal and California Emission Control System Warranty on your small nonroad engine. In California, new

small nonroad engines must be designed, built and equipped to meet the State’s stringent and anti-smog standards. Eastern Tools &

Equipment, Inc. must warrant the emission control system on your small nonroad engine for the periods of time listed above listed

above provided there has been no abuse, neglect or improper maintenance of your small nonroad engine.

Your emission control system may include parts such as the carburetor, or fuel-injection system, the ignition system and catalytic

converter. Also included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Eastern Tools & Equipment, Inc. will repair your small nonroad engine at no cost to you including

diagnosis, parts and labor.

OWNER’S WARRANTY RESPONSIBILITIES

As the small nonroad engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s

Manual. Eastern Tools & Equipment, Inc. recommends that you retain all receipts covering maintenance on your small nonroad engine,

but Eastern Tools & Equipment, Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of

all scheduled maintenance.

As the small nonroad engine owner, you should, however, be aware that Eastern Tools & Equipment, Inc. may deny you warranty

coverage if your; small nonroad or part thereof has failed due to abuse, neglect, improper maintenance or unapproved modificati on s.

You are responsible for presenting your small nonroad engine to Eastern Tools & Equipment, Inc. distribution center as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities or request warranty service you should contact either the

place of purchase or Eastern Tools & Equipment, Inc., c/o Service Manager, Engine and Equipment Service Division.

IMPORTANT NOTE:

This warranty statement explains your rights and obligations under Emission Control system Warranty (ECS Warranty), which is

provided to our by Eastern Tools & Equipment, Inc. pursuant to California law, Eastern Tools & Equipment, Inc. also provides to original

purchasers of new Eastern Tools & Equipment, Inc. engines. Eastern Tools & Equipment, Inc. Limited Warranties for New engines &

other Equipment associated with the engine (Eastern Tools & Equipment, Inc. Products Warranty), which is enclosed with all New

Eastern Tools & Equipment, Inc. engines and products on a separate sheet. The ECS Warranty applies only to the emission control

system of your new engine. To the extent that there is any conflict in terms between the ECS Warranty and the Eastern Tools &

Equipment, Inc., Warranty, the ECS Warranty shall apply except in any circumstances in which the Eastern Tools & Equipment, Inc.

Product Warranty may provide a longer warranty period. Both the ECS Warranty and the Eastern Tools & Equipment, Inc. product

Warranty describe important right and obligations with respect to your new engine.

Eastern Tools & Equipment, Inc. at its location in Ontario, California can perform warranty service or any authorized service dealer

near you. At the time of requesting warranty service, evidence must be presented of the date of sale to the original purchaser . T h e

purchaser shall pay any charges for transporting the product to and from the place when the inspection and/or warranty preformed.

The purchaser shall be responsible for any damage or loss incurred in connection with the transportation of any engine or any part(s)

thereof submitted for inspection and/or warranty work.

If you have any questions regarding your warranty rights and responsibilities, you should contact Eastern Tools & Equipment, Inc.

Loading...

Loading...