ETQ Liquid Propane Operation Manual

1

Eastern Tools & Equipment, Inc

Liquid Propane Portable Generator

Operation Manual

7000 Surge Watts

6000 Continuous Watts

Customer Service (888)-696-2345

www.easterntools.com

Eastern Tools & Equipment. Inc

Ontario, CA U.S.A

2

Thank you for purchasing products from EASTERNTOOLS & EQUIPMENT, INC. We appreciate your

business. The following manual is only a guide to assist you and is not a complete or

comprehensive manual of all aspects of maintaining and repairing your generator. The equipment

you have purchased is a complex piece of machinery. We recommend that that you consult with a

dealer if you have doubts or concerns as to your experience or ability to properly maintain or repair

your equipment. You will save time and the inconvenience of having to go back to the store if you

choose to write or call us concerning missing parts, service questions, operating advice, and/or

assembly questions.

This manual will explain how to operate and service your generator set.

Please fill out the inform ation below. This will help you save time if you ever need to provide the

following information for a warranty repair.

GENERATOR

Model Number: _________________________________________

Serial Number: ____________ ______________________________

E N G I N E

Model Number: _________________________________________

DATE PURCHASED: ____________ ____Day _______________Month ________________YEAR

TABLE OF CONTENTS

Safety warning 3

Sp ecification s/O il 4

Control and Features 5

Reductor assembly 6

Handle and Wheel Kit 7

Starting the unit 8

Connecting loads 8

Stopping the unit 8

Maintenance 9

Trouble shooting 10

Wi re Dia gram 11

Parts Diagram 12

Warranty 13

3

Safety Warning

Please read this manual to understand how to

use your unit as well as understanding the risk

the come with the u nit.

NOTICE exceeding your generator wattage/

amperage coverage capacity can damage your

unit as well as any devices attached to your unit.

Consumers should notice that this manual might

differ slightly from the actual product as more

improvements are made to our products. Some

of the pictures in this manual may differ slightly

from the actual product as well. Eastern Tools

and Equipment, Inc. reserves the right to make

changes at any time without notice and with out

incurring any oblig ation

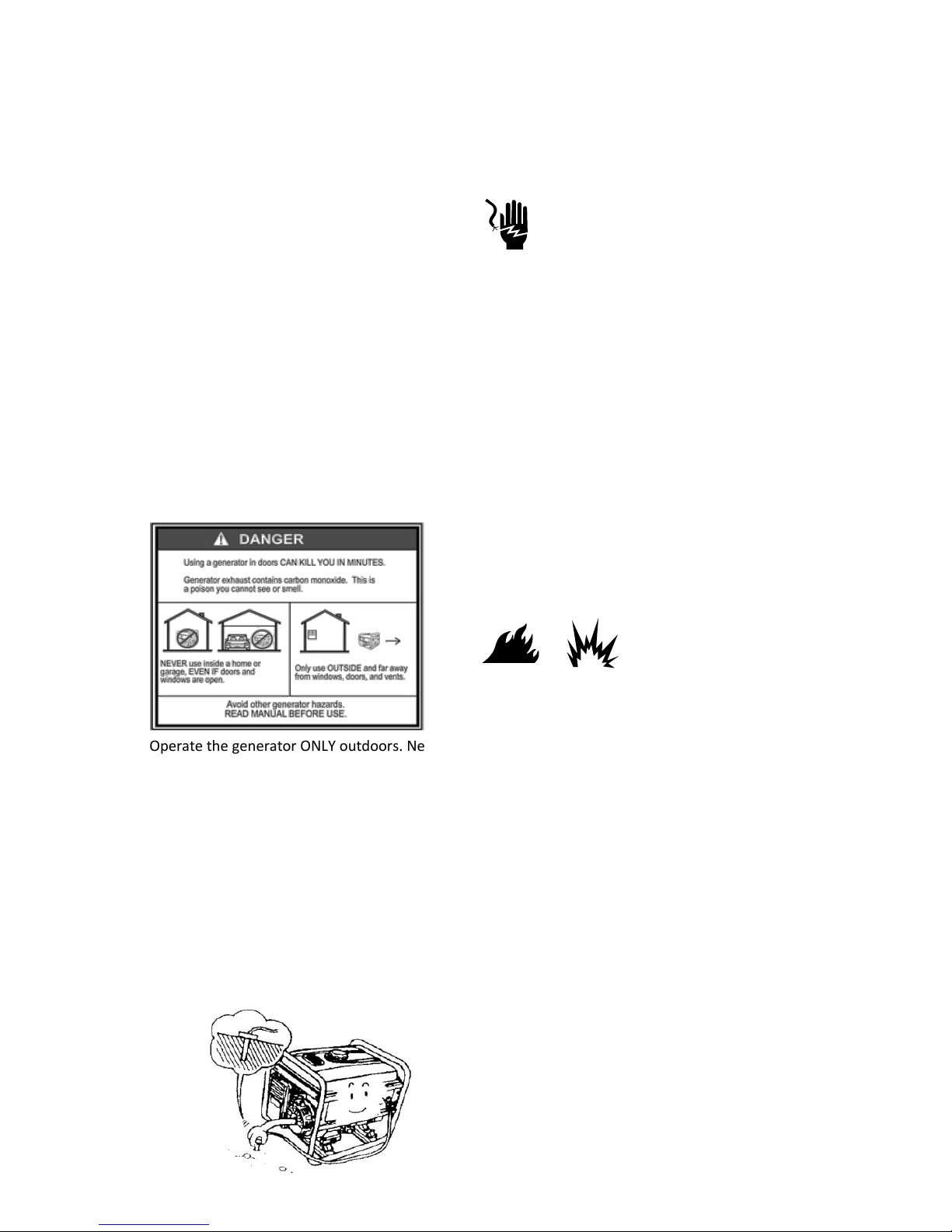

CARBON MONOXIDE WARNING

Operate the generator ONLY outdoors. Never

run the generator indoors as the engine gives

off poisonous carbon monoxide, an odorless and

colorless gas. Inhaling carbon monoxide will

cause nausea, fainting or death. Also, keep the

generator at least 3 feet away from flammable

ma tter fo r ade qua te ventila tion

GROUNDING THE UNIT

Always properly ground the generator. Failing to

do so can result in electrocution, particularly if

the generator is equipped with a wheel kit.

ELECTRIC SHOCK AND SHORT CIRCUIT

Be sure to notify the utility company

when using the generator for backup

power. Use approved transfer

equipment to isolate the generator from electric

utility. In highly con ductive area such as metal

decking or steel work, use a ground circuit fault

interrupter. Never touch the generator if the

generator is wet. Also, never touch the

generator if your hand is wet. Never operate

your generator if the weather conditions call for

any type of precipitation such as rain, snow, or

fog.

Do not use electrical cords that have been

damaged (worn, bare, frayed)

Do not touch bare receptacles or wires

Do not allow children to operate the generator.

FUEL SAFETY

When using the LPG generator, please be sure

that ther e is som e dis tance between LGP tank

and the LPG generator, to prevent unnecessary

danger because of the high temperature surface

area of the LPG tank. When using the unit,

please check the surface temperature of the

LP G t ank.

Place the generator in a well-ventilated area. DO

NOT place the generator near vents or intakes

where exhaust fumes could be drawn into

occupied or confined spaces. Carefully consider

wind and air currents when positioning

generator. Please do not light a cigarette near

the LPG generator.

GENERATOR SAFETY

Do not start g enerator with electr ica l d evices

conn ected to it. Start the gen erator first an d

after the speed of the generator stabilizes,

electrical loads can be applied to it.

When connecting electrical loads, make sure the

devices are "OFF" first before connecting them.

4

Keep the same concept when disconnecting

electrical devices; make sure all devices are in

the "OFF" position before disconnecting.

Operate the generator on level surfaces only.

Inclined surfaces reduce the effective lubrication

of the engine.

Do not expose the generator to excessive

moisture, dust, dirt, or corrosive vapors.

NOTICE poor treatment of your equipment

can greatly reduce the life of the LPG generator.

Use the generator for its intended usage. If you

have any concerns about maintain your unit

contact a local service center or called customer

service (888)-696-2345. Operate the LPG

generator on a level surface and do not place

objects in the units recoil slots.

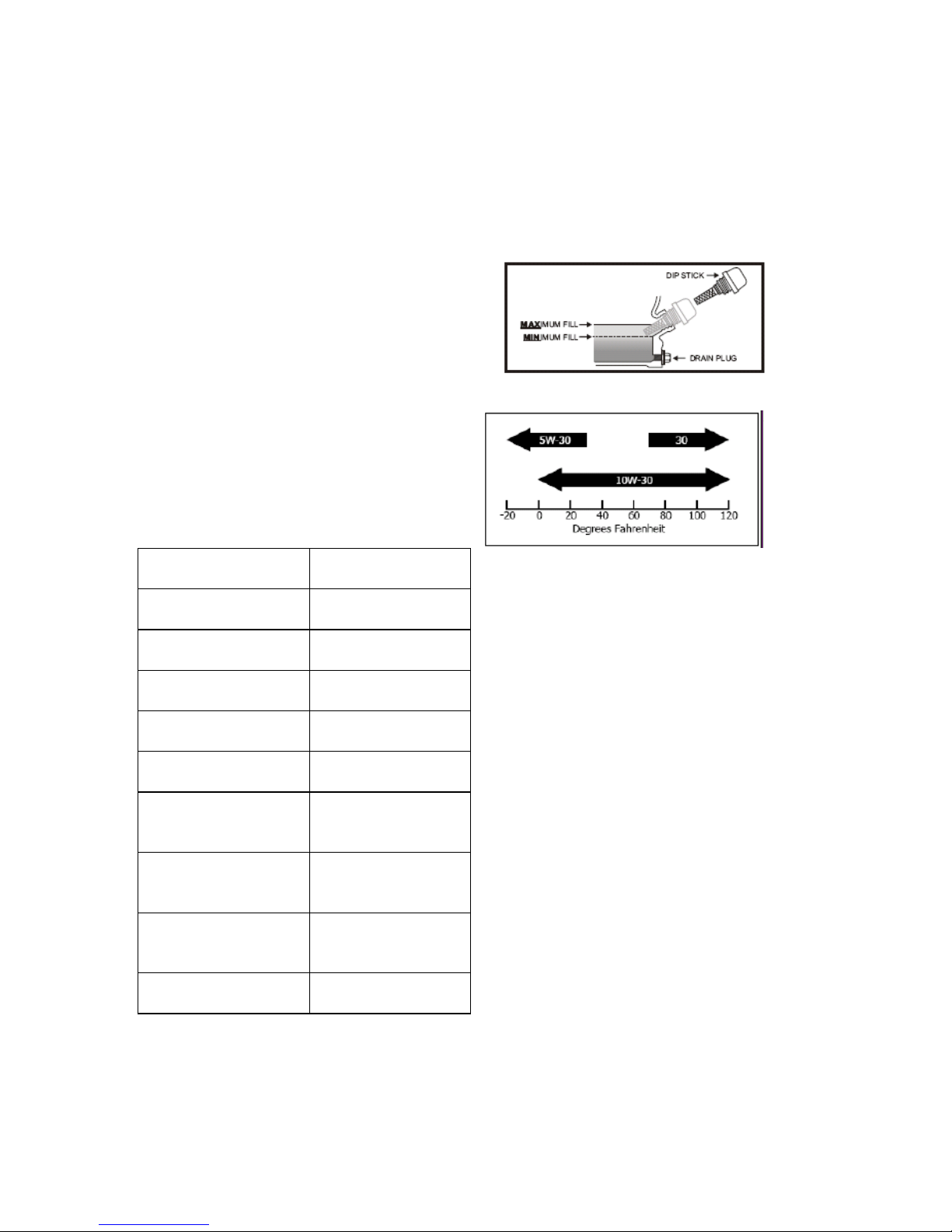

Generator Specifications

Running Wattage

6000 Watts

Starting Wattage

7000 Watts

AC Load

120V/240V

Phase

Single

T.H.D.

<5%

Weight

193.8 lbs. (87.9 kg)

Height

23.31 inches (59.2

cm)

Wi dth

16.93 inches (42.0

cm)

Length

17.13 inches (43.5

cm)

Frequency

60Hz

OIL

Change oil when the engine is warm. Refer to

the oil specification to select the proper grade of

oil for your operating environment.

1. Remove the oil drain plug with a 15 mm

socket and extension.

2. Allow the oil to drain completely.

3. Replace the drain plug.

4. Remove oil fill cap/dipstick to add oil.

5. Add 0.63 qt (0.6 L) of oil and replace oil fill

cap/dipstick.

6. Dispose of used oil at an approved waste

management facility.

Oil capacity is 1.16 qt (1.1 L).

SPARK PLUGS

1. Remove the spark plug cable from the spark

plug.

2. Use the spark plug tool that shipped with

your generator to remove the plug.

3. Inspect the electrode on the plug. It must be

clean and not worn to produce the spark

required for ignition.

4. Make certain the spark plug gap is 0.7 -

0.8mm (0.028 - 0.031 in.).

5. Refer to the spark plug recommendation

chart when replacing the plug.

6. Carefully thread the plug into the engine.

7. Use the spark plug tool to firmly install the

plug.

8. Attach the spark plug wire to the plug.

Your generator comes equipped with a ¾” long

reach plug (18 mm)

Intermittent use (less than 1 hour/month) or

colder temperatures (below 60°F)

N G K B 4 E S o r S T A R F 6 T C

Moderate use (less than 3 hours/month) or

Seasonal temperatures (50-80°F)

N G K B 4 ES or STAR F6TC

Extreme use (continuous) or hot climates(80100°F)N G K B 4 E S o r S T A R F 6 T C

5

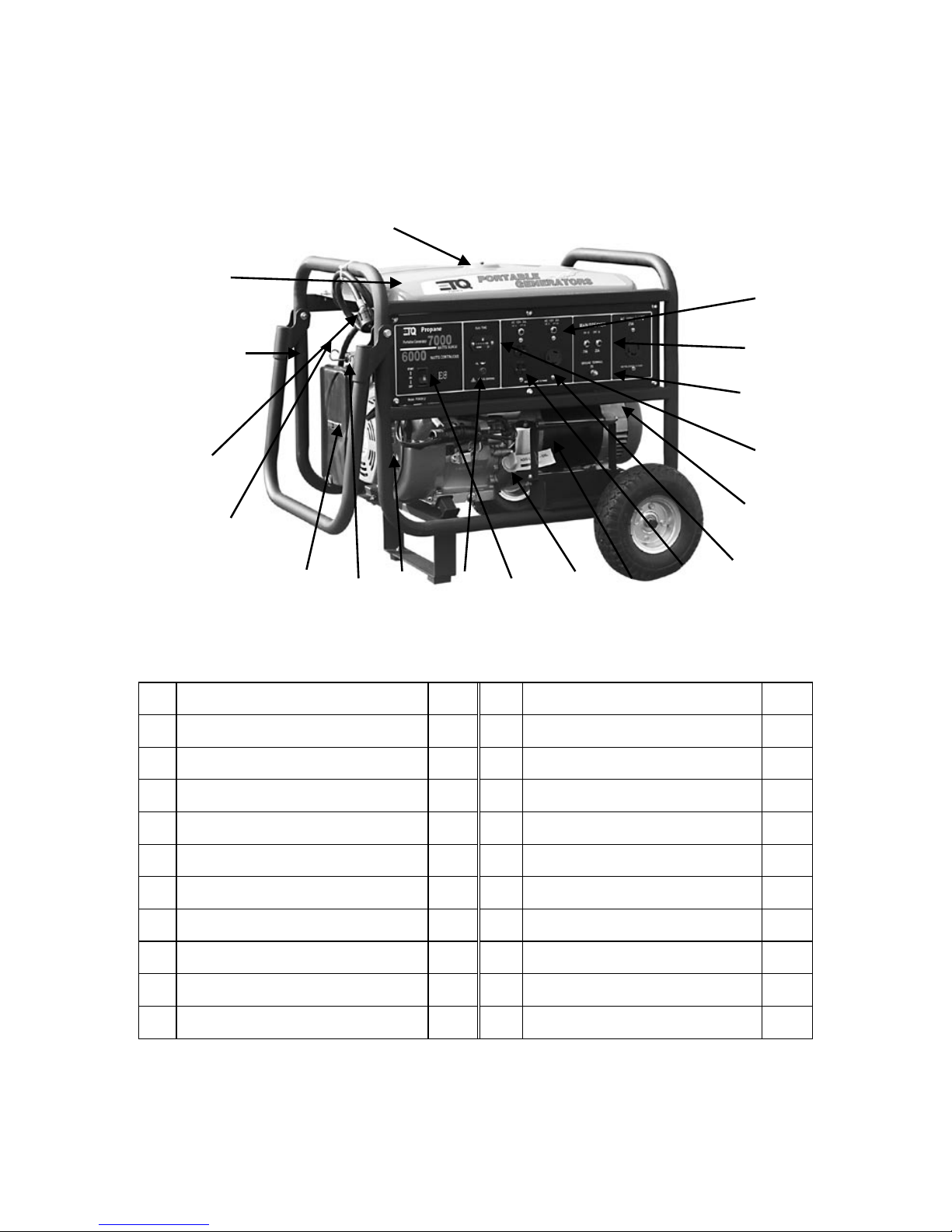

Controls and Features

Read this owner’s manual before operating your generator. Familiarize yourself with the location

and function of the controls and features. Save this manual for future reference.

NO.

D E S C R I P TI O N

Qty

NO.

D E S C R I P TI O N

Qty

1

AC CIRCUIT BREAKER 20A

1

11

OIL INDICATOR LIGHT ASSY

1

2

AC CIRCUIT BREAKER 30A

1

12

RECOIL STARTER

1

3

LUG GROUND

1

13

COCK ASSY.FUEL

1

4

HOUR METER

1

14

AIR CLEANER

1

5

BRACKET,RR.,MOTOR

1

15

CHOKE ROD

1

6

3-POLE RECEPTACLE L5-30R

1

16

T U B E , L P G

1

7

120V RECEPTACLE 5-20R

1

17

F R A M E C O M P

1

8

MOTOR ASSY.,STARTING

1

18

TANK TOP COMP,FUEL

1

9

CAP ASSY,OIL FILLER

1

19

REDUCTOR A S SY

1

10

ENGINE SWITCH

1

20

MUFFLER COMP

1

WARNING: DO NOT exceed the generator’s wattage/amperage capacity. Our products are

continuously being changed and improved. Every effort has been made to ensure that information

in the manual is accurate and up to date. However, we reserve the right to change, alter or

otherwise improve the product and this manual at any time without prior notice.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(5)

(6)

(7)

(4)

(1)

(2)

(3)

6

Operation instruction of REDUCTOR ASSEMBLY

Instruction on LPG denser device (bottom)

To develop cold start performance of LPG generator unit, the air REDUCTOR ASSY includes one LPG

denser device (bottom), the detailed operation of the bottom is shown below.

When starting the cold LPG generator unit, open the valve of the LPG tank, close the resistance air

valve handle, press the LPG denser device (bottom) lightly, and hold for 1-2 seconds, then stop.

Start the engine normally, and after finishing the start up, please open resistance air valve handle.

Parts

Included in with your unit are: (1) Flat head screwdriver, (1) Spark Plug Wrench, (1) 8 x 10 Wrench,

(1) 17x 19 wrench, (2) wheels, (1) axle, (1) handle bar, (1) leg stands

NO.

D E S C R I P TI O N

Qty

NO.

DESCR I P T I O N

Qty

1

High-pressure intake

tube(1000mm)

1 5 Mix device( the same as carburetor)

1

2

REDUCTOR ASSY

1

6

LPG denser device (bottom)→m ounted onto

REDUCTOR valve

1

3

TANK TOP COMP,FUEL

1

7

LPG air-pressure adjusting bottom→mounted

onto REDUCTOR valve

1

4

Low-pressure outlet tube

1

(1)

(2)

(3)

(4)

(5)

(6)

(7)

IN

OUT

7

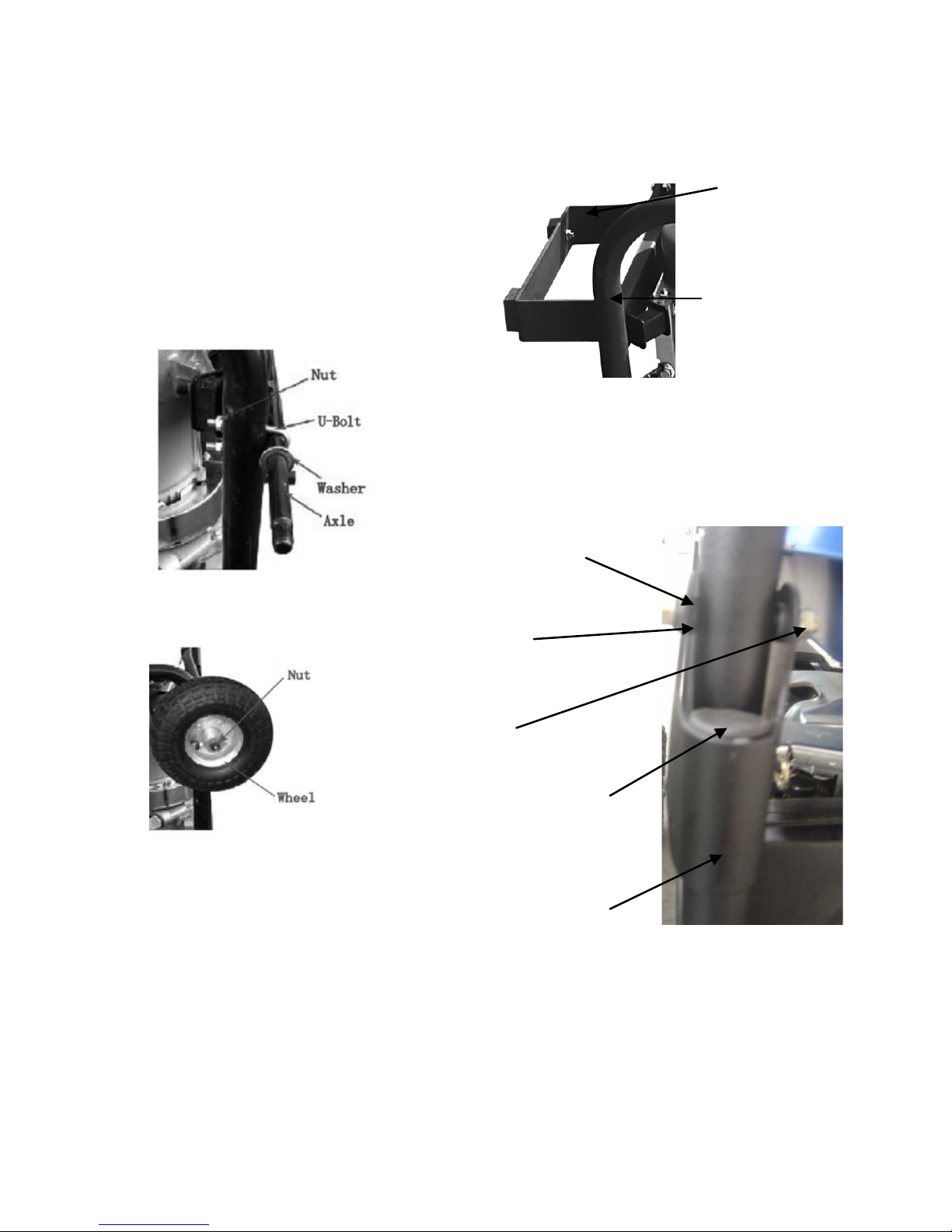

HANDLE AND WHEEL KIT ASSEMBLY

The wheel kit mist be assembled when there are

no liquids in the generator.

1. Place the generator on its side. (engine side

down).

2. Secure the axle with two u bolts.

3. Screw on the nuts onto the u-bolts to secure

the axle.

4. Place the washer onto the axle.

Place the wheel onto the axle.

Tighten down the wheel securely with a bolt.

1. Use the bolt and nut provided to secure the

foot tightly onto the frame of the generator.

2. Flip the generator back to its normal upright

position.

3. Now you are ready to install the handle bars.

1. Put the grips onto the handle bars.

2. Secure the bracket bolt and nut.

3.Make sure that the bracket is nicely tightened

down.

4. Place the handle bar into the bracket.

5. Secure with a bolt and nut

Foot

Bo lt + Nut

HANDLE PIPE COMP

IMMOBILITY PIECE TOP

NUT

WASHER

BOLT FLANGE

8

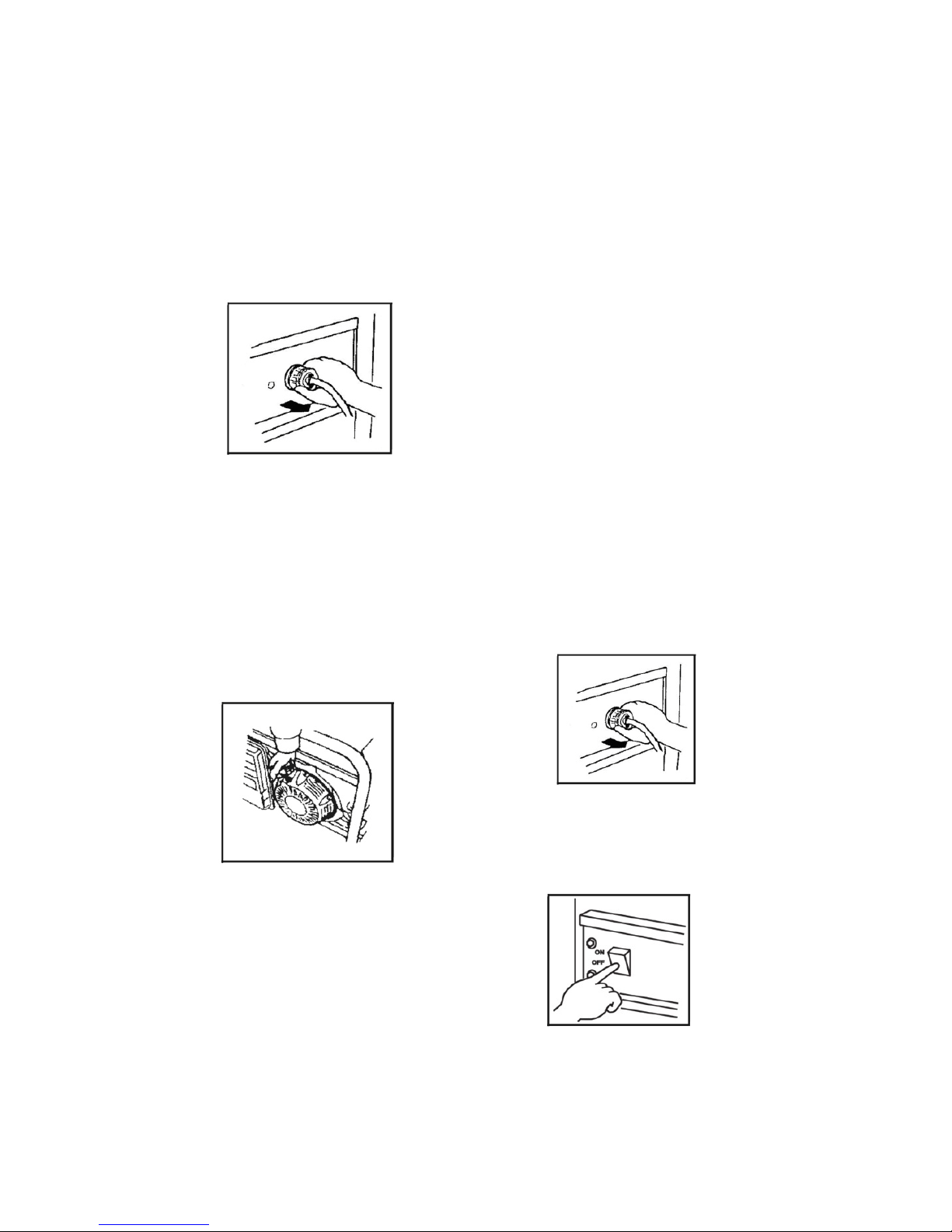

STARTING THE UNIT

Make certain the generator is on a flat, level

su rface.

2. Disconnect all electrical loads from the

generator. Never start or stop the generator

with electrical devices plugged in or turned on.

Disconnect electrical devices

3. Connect LPG tube to the LPG tank, and then

open the LPG valve slowly, till it totally open (to

insure no LPG leakage).

4. Move the choke lever to the “Choke”

position.

5. Press the denser bottom of the REDUCTOR

ASSY and hold 1~2 seconds;

6. Pull the starter cord slowly un til resistance is

felt and then pull rapidly

Recoil starting rope

7. As engine warms up, move the choke lever to

“Run”.

CONNECTING ELECTRICAL LOADS AND

ELECTRICAL CAPACITY

After sta rting th e gen erato r, let the engine

warm up after connecting electrical loads to it.

Do not have any electrical loads connected

befo re startin g the generat or.

Make sure all electrical devices are 60 Hz

devices.

Do not connect 50 Hz devices to the generator.

Do not connect 3-phase loads to the generator.

Do not overload the generator.

Before beginning your work, you must verify

that the rated (running) and surge (starting)

watts for the items you will power at the same

time are within the generators operating

capacity. Please refer to the following Table 1

for wattage / amperage ratings. Also, to prolong

the life of your generator, prolong the life of

your generator, sequentially add loads and

permit the generator to stabilize before adding

another load. Never exceed the capacity of the

generator.

Es timate how ma ny su rge ( starting) wat ts you

will need. Surge wattage is the short burst of

power needed to start electric motor-driven

tools or appliances such as a circular saw or

refrigerator.

Stopping the Engine

1.Turn off and unplug all electrical loads. Never

start or stop the generator with el ectri cal

devices plugged in or turned on.

2.Let the generator run at no-load for several

minutes to stabilize internal temperatures of the

engine and generator.

3. Turn the ignition switch to the “Off” position.

4.Turn the fuel valve to the “Off” position.

9

MAINTENANCE

Generator maintenance consists of keeping the

unit clean and dry. Be sure to store the unit in a

clean and dry environment, where it will not be

exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling slots should always be

clean and free from clogs.

Note: Do not use a garden hose to clean the

generator. Water can enter the fuel and intake

system and cause problems. In addition, if water

and dirt buildup on the generators internal

windings, the resistance of these windings will

decrease.

• To clean the generator, use a damp cloth

to wipe the exterior surfaces.

• Use a soft bristle brush to loosen caked on

dirt of oil.

• Use a vacuum cleaner to pick up loose dirt

and debris.

• Compressed air (not to exceed 25 psi) may

be used to blow away dirt.

S PA R K P LU G

• Remove the spark plug

• Remove the carbon deposits

• Check for discoloration. Standard is tan in

color.

• Check spark plug gap

Make certain the spark plug gap is

0.7 -0.8mm (0.028 - 0.031 in.).

AIR FILTER

• Unscrew the bolt from the air cleaner

cover, and re move the air cleaner cover.

• Check the air cleaner element to be sure

they are clean and in good condition.

• If the air filter is dirty, remove and clean

the element.

• Wash in solvent

• Squeeze

• Soak oil

• Squeeze dry

• Reinstall the air cleaner element and

secure the cover by setting the cover

spring.

RECEPTACLES

This generator is equipped with the following

Receptacles

NEM A 5-20R: 12 5 V o l t , 2 0 A m p G F C I D u p l e x

Receptacle

L5-30R: 120Volt, 30Amp Twist Lock Receptacle

10

TROUBLE SHOOTING

P ro b le m

Ca use

So lut ion

Gene rator will no t start

No Propane

New Tank

Faulty spark plug

Replace spark plug

Unit loaded during start up

Remove load from unit

Gene rator will no t start;

Generator starts but runs

roughly

Low oil level

Fill crankcase to the proper level

Place generator on a flat, level

su rface

Choke in the wrong

position.

Adjust choke.

Spark plug wire loose

Attach wire to spark plug

Generator shuts down

during

operation

Out of Propane

Refill propane

Low oil level

Fill crankcase to the proper lev el.

Place generator on a flat, level

su rface

Generator cannot supply

enough

power or overheating

Generator is overloaded

Review load and adjust. See “Power

Management”

Insufficient ventilation

Check for air restriction. Move to a

well ventilated area

No AC output

Cable not properly

connected

Check all connections

Connected device is

defective

Replace defective device

Circuit breaker is open

Reset circuit breaker

Capacitor defective

Replace capacitor (Service Center)

Faulty brush assembly

Replace brush assembly (Service

Center)

Fa ulty AVR

Replace AVR (Service Center)

Loose wiring

Inspect and tighten wiring

connections

Other

Contact the help line.

Generator gallops

Engine governor defective

Contact the help line

Repeated circuit breaker

tripping

Overload

Review load and adjust. See “Power

Management”

Faulty cords or device

Check for damaged, bare or fray ed

wires. Replace defective device

Loading...

Loading...