OWNER’S MANUAL

AIR-COOLED DIESEL ENGINE

170F / FE / FS / FSE 178F / FE / FS / FSE 186F / FE / FS / FSE

1

PREFACE

Thank you for purchasing products from Eastern Tool & Equipment, INC. The following

manual is only a guide to assist you and is not a complete or comprehensive manual of all

aspects of maintaining and repairing your engine. The engine you have purchased is a complex

piece of machinery. We recommend that that you consult with a dealer if you have doubts or

concerns as to your experience or ability to properly maintain or repair your engine. You will

save time and the inconvenience of having to go back to the store if you choose to write or call

us concerning missing parts, service questions, operating advice, and/or assembly questions.

Engine Features and Highlights

• Direct fuel injected intake system

• Recoil-type manual starter and or optional electric starter system

• Forced air convection cooling system

• Composite steel fan cover for minimum noise levels

Our four stroke diesel engines are air cooled with a direct fuel injected intake system. They offer

maximum efficiency through the minimal conservation of energy and materials. These diesel

engines are compact and lightweight. They are easily maintained and portable making it

convenient to move. They are widely used as a source of mechanical power for industrial,

agricultural, and machinery equipment. Some applications include irrig ation equipment, diesel

powered pressure sprayers, grass-cutting machines, and soil-sampling machines. Other

applications include vibration rammers, shock rammers, marine engines, lightweight transport

vehicles, portable compressors, and lightweight portable generators.

This operating manual will explain how to operate and maintain your series of engines. Please

read it before running the engine for correct operation.

To ensure long engine life please follow the operating requirements listed in this manual.

If you have any questions or suggestions about this manual, please contact your local dealer or

us. Consumers should notice that this manual might differ slightly from the actual product as

more improvements are made to our products. Some of the pictures in this manual may differ

slightly from the actual product as well. Eastern Tools and Equipment, Inc. reserves the right

to make changes at any time without notice and without incurring any obligation.

2

TABLE OF CONTENTS

Page number

Safety Precautions 4

Chapter 1 Technical Specifications and Data 7

1-1 Technical Specifications 7

1-2 Overall Dimensions and Installation Conditions 9

1-2.1 Belt wheel and engine clearance requirements 10

1-2.2 Crankshaft driving angle conditions 11

1-2.3 Engine electrical system 11

1-3 Diesel engine shaft specifications 12

1-4 Diesel engine part names 13

1-5 Valve timing, initial angle of fuel delivery and valve clearances 14

1-5.2 Initial angle of fuel delivery 14

1-5.3 Valve clearances 14

1-6 Temperature ranges for exhaust and injection pressure specifications 14

1-7 Various engine torque specifications 15

Chapter 2 Diesel Engine Operation Procedures 16

2-1 Engine safety precautions 16

2-2 Fuel choices 16

2-3 Starting the diesel engine 19

2-3.1 Recoil Starting 19

2-3.2 Electric starter 21

2-3.3 Cold starting 21

2-4 Running and stopping the diesel engine 23

2-4.1 Running the diesel engine 23

2-4.2 Routine checks while engine is running 23

2-4.3 Stopping the engine 23

Chapter 3 Technical Maintenance of Diesel Engine 25

3-1 Daily checks and maintenance 25

3-2 Regularly checks and maintenance 25

3-3 Storing the engine for long periods of time 27

Chapter 4 Part Listings 29

4-1 Engine block 30

4-2 Cylinder head assembly 33

4-3 Piston connecting rod and crankshaft balancing mechanism 36

4-4 Fuel system parts 39

4-5 Oil and speed control system 41

4-6 Cooling and recoil starting system 44

4-7 Air cleaner and silencer system 47

Chapter 5 Engine Troubleshooting 50

5-1 Engine is not starting 50

5-2 Diesel engine lacks power 51

5-3 Engine stops automatically 51

5-4 Engine exhaust very black 51

5-5 Engine exhaust very blue 51

5-6 Engine exhaust white 52

5-7 Various methods of checking to see if engine is malfunctioning 52

Limited Warranty 53

Registration Card 55

Comment Card 55

3

SAFETY PRECAUTIONS

Please be sure to follow each instruction carefully

EXHAUST PRECAUTIONS

• Never inhale the exhaust gases, it contains

carbon monoxide, a colorless, odorless and

extremely dangerous gas which can cause

unconsciousness or death

• Never operate the engine indoors or in a

poorly ventilated area, such as a tunnel or

cave, etc.

• Exercise extreme care when operating the

engine near people or animals. Keep the

exhaust pipe free of external objects.

REFUELING PRECAUTIONS

• Be sure to stop the engine before refueling.

• Do not overfill the fuel tank.

• If fuel is spilled, wipe it away carefully and

wait until the fuel has dried before starting

the engine again.

• When changing oil, make sure that the fuel

cap is tightly secured to prevent fuel

leakage.

4

FIRE PREVENTION

• Never operate the engine while

smoking or near an open flame.

• Never use the engine around dry brush,

twigs, cloth-rags, or other flammable

materials.

• Keep the engine at least 3 feet (1 meter)

away from buildings or other

structures.

• Keep the engine away from flammables

and other hazardous materials.

PROTECTIVE COVER

• Always place the protective covers

over the rotating parts. If rotating parts

such as the driving pulley, belts, and

shafts are exposed, serious injuries can

be caused. To prevent injury, please

equip all rotating parts with protective

covers.

• Be careful of hot parts. The muffler

and other engine parts can become very

hot while the engine is running or after

the engine has been run. Always

operate the engine in a safe area and

keep children away from running

engines.

5

SURROUNDINGS

• Operate the engine on a table or level

surface free of small rocks and loose

gravel.

• Operate the engine on a level surface. If

the engine is tilted, fuel may spill from the

gas tank.

NOTE: Operating the engine at a steep incline

may cause the engine to seize up due to

improper lubrication even when the oil level is

a maximum.

• Be careful of fuel spillage when

transporting the engine. Always tighten

the fuel cap and close the fuel strainer cock

before moving the engine around.

• Never move the engine while it is in

operation.

• If the engine will be transported over a

long distance, drain all the fuel from the

fuel tank to prevent fuel leakage.

PRE-OPERATION CHECKS

• Carefully check fuel pipes and fuel joints

for fuel leakage. Leaked fuel creates a

dangerous situation.

• Verify that all the nuts and bolts of the

engine are tights. A loose nut or bolts may

cause serious engine failure and could lead

to serious injuries.

• Always check the engine oil and refill it if

necessary.

• Always check the fuel level and refill it if

necessary. Never overfill the fuel tank

• Avoid wearing dangling or long clothes

such as loose aprons, towels, and waist

belts, as these items may be caught in a

rotating part of the engine.

6

Chapter 1 Technical Specifications and Data

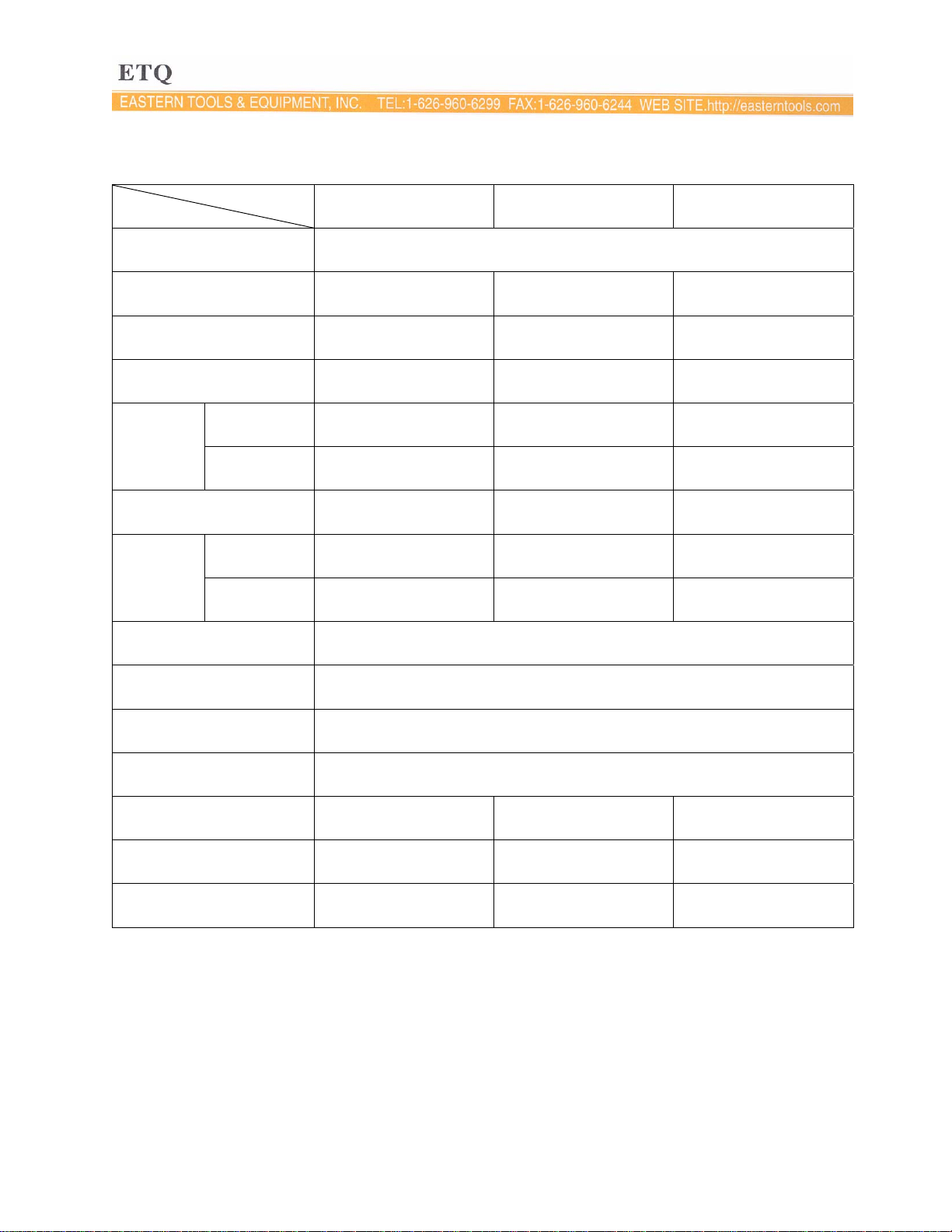

1-1 Technical specifications in English Units

Model

Item

Type Single vertical cylinder, 4-stroke, air-cooled, direct injection

Bore x Stroke (in.) 2.76 x 2.17 3.01 x 2.44 3.39 x 2.76

Displacement (cu. in.) 13.36 18.67 25.51

Speed (rpm) 3600 3600 3600

Continuous 4.0 5.9 8.85 Output

(HP)

Maximum 4.5 6.6 9.85

170F 178F 186F

Fuel tank capacity

(US gallons)

Full 27.1 37.17 55.75 Lube-oil

Capacity

(oz)

Crankshaft direction Clockwise from flywheel end

Cooling type Forced air cooled by flywheel fan

Lubrication type Pressure splash

Starting system Recoil manual start and or optional electric start

Dry weight (recoil) (lbs) 60 73 106

Dry weight (elec.) (lbs)

Dimensions (LxWxH)

(inch)

Effective 8.45 13.51 20.27

13.1 x 14.8 x 16.3 15.1 x 16.6 x 17.7 16.4 x 17.4 x 19.5

.66 .9 1.45

68 84 117

7

Technical specifications in SI units

Model

Item

Type Single vertical cylinder, 4-stroke, air-cooled, direct injection

Bore x Stroke (mm) 70 x 55 78 x 62 86 x 70

Displacement (cc) 211 296 406

Speed (rpm) 3600 3600 3600

Continuous 2.98 4.4 6.6 Output

(kw)

Maximum 3.36 4.92 7.3

170F 178F 186F

Fuel tank capacity

(Liters)

Full .8 1.10 1.65 Lube-oil

Capacity

(L)

Crankshaft direction Clockwise from flywheel end

Cooling type Forced air cooled by flywheel fan

Lubrication type Pressure splash

Starting system Recoil manual start and or optional electric start

Dry weight (recoil) (kg) 27 33 48

Dry weight (elec.) (kg)

Dimensions (LxWxH)

(mm)

Effective .25 .40 .60

332 x 376 x 415 383 x 421 x 450 417 x 441 x 494

2.5 3.4 5.5

31 38 53

8

1-2 Overall engine dimensions

Installation Conditions

(1) There must be a tight stationary foundation for the diesel engine to avoid vibrations or

movement when the engine is running. For prolonged engine life, consider using some

type of motor mount.

(2) Make sure that the centering position of the output shaft is properly aligned.

9

(3) Verify that the dimensions of the hole on the belt wheel and keyway shaft match or

correspond with each other. Also make sure that the bolt of the engine shaft is

tightened to the proper torque specifications.

(4) When the engine is matched with other belt driven machines, the total desired belt

distance traveled by the driven wheel must equal the total distance travele d by the

driver wheel. If this is not properly calculated and matched, the desired speed on the

driven wheel will be incorrect. A formula used to calculate the necessary diameters of

the various wheels is provided below.

The diameter of driving wheel (belt wheel) can be calculates as follows:

Diameter of engine driving wheel (engine pulley) =

Diameter of driven machine x speed of driven machine

Diesel speed (engine speed)

(5) Make sure that the belt has a correct tension to it.

Note: If the belt is to tight, the engine bearings will wear at a high rate leading to engine failure.

If the belt is to loose, the belt will slip at high speeds and high loads causing high pitch whistling

noises.

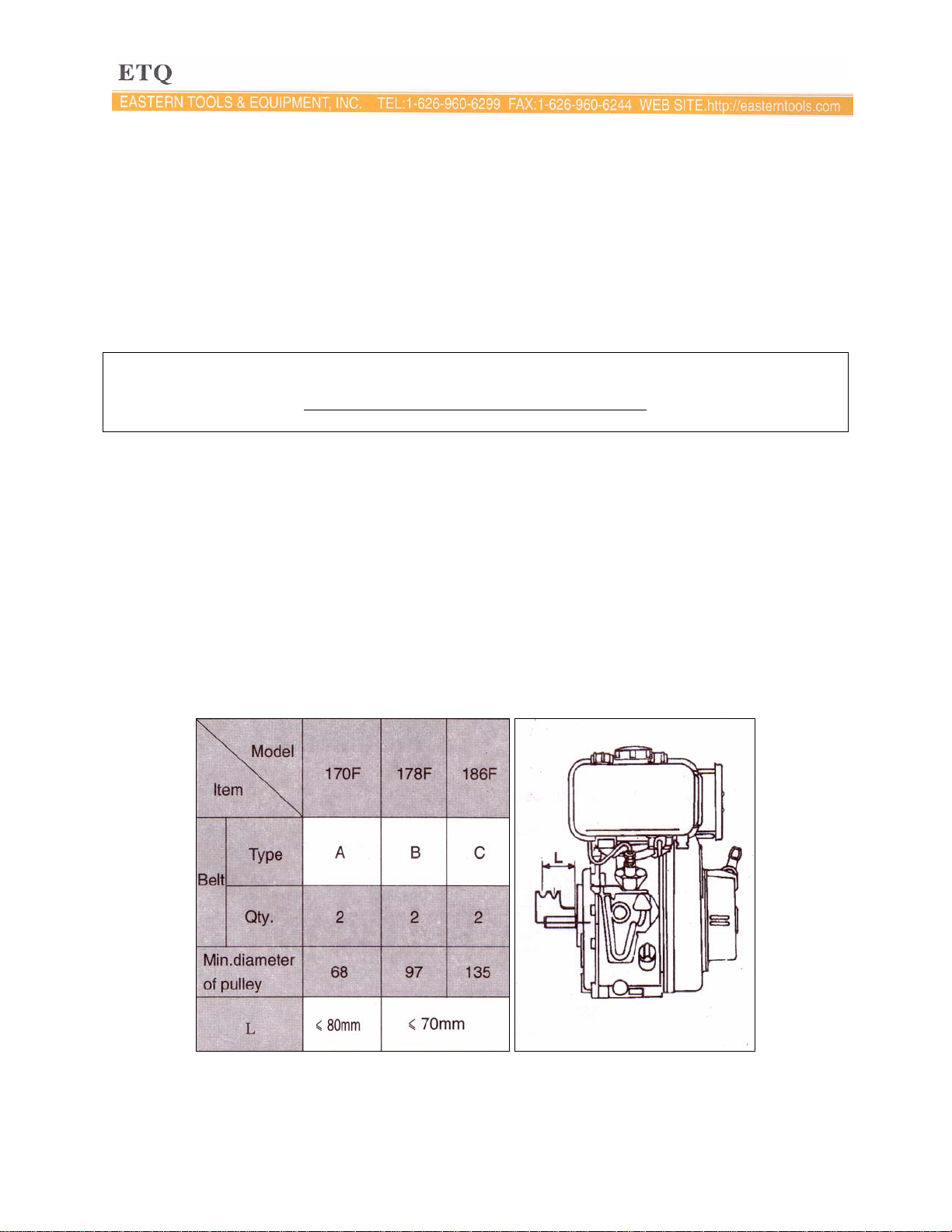

1-2.1 Allowed clearance between belt wheel and engine

The belt pulley wheel should be as close to the engine as possible. The values of L are tabulated

in table 1-1.

Table 1-1. Allowed belt pulley wheel to engine distances.

10

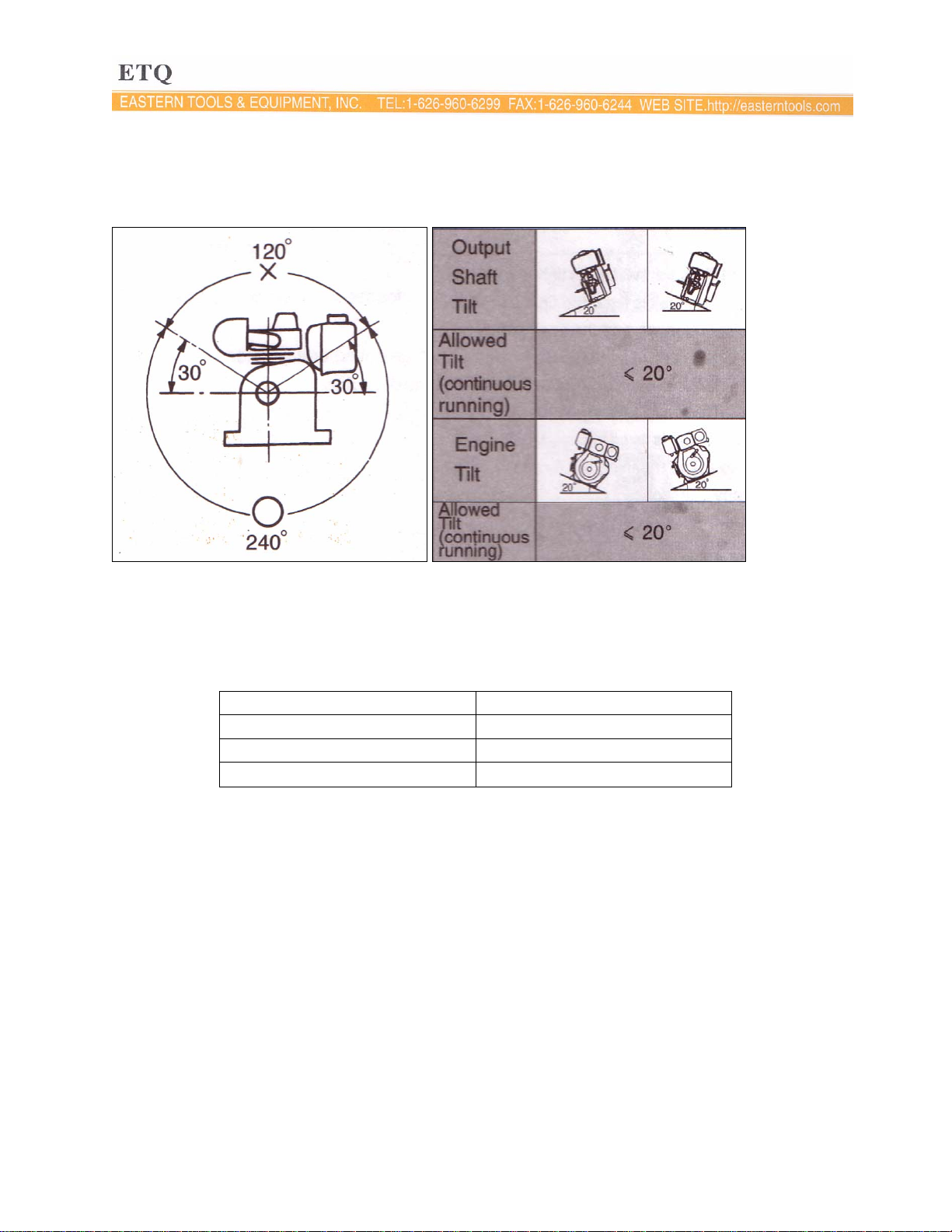

1-2.2 Crankshaft driving angles must be less than 120o, see Fig 1-1

The tilt must be kept within the allowed values shown in Fig 1-2

Fig 1-1. Allowed driving angles. Fig 1-2. Allowed tilt angles.

1-2.3 Please contact our dealers about the electric circuits involved with this engine.

We recommend the use of accumulators rated at 20 hours shown in table 1-2.

Table 1-2.

Model Units: (amp-hours)

170F 18~24

178F 24~26

186F 36~45

11

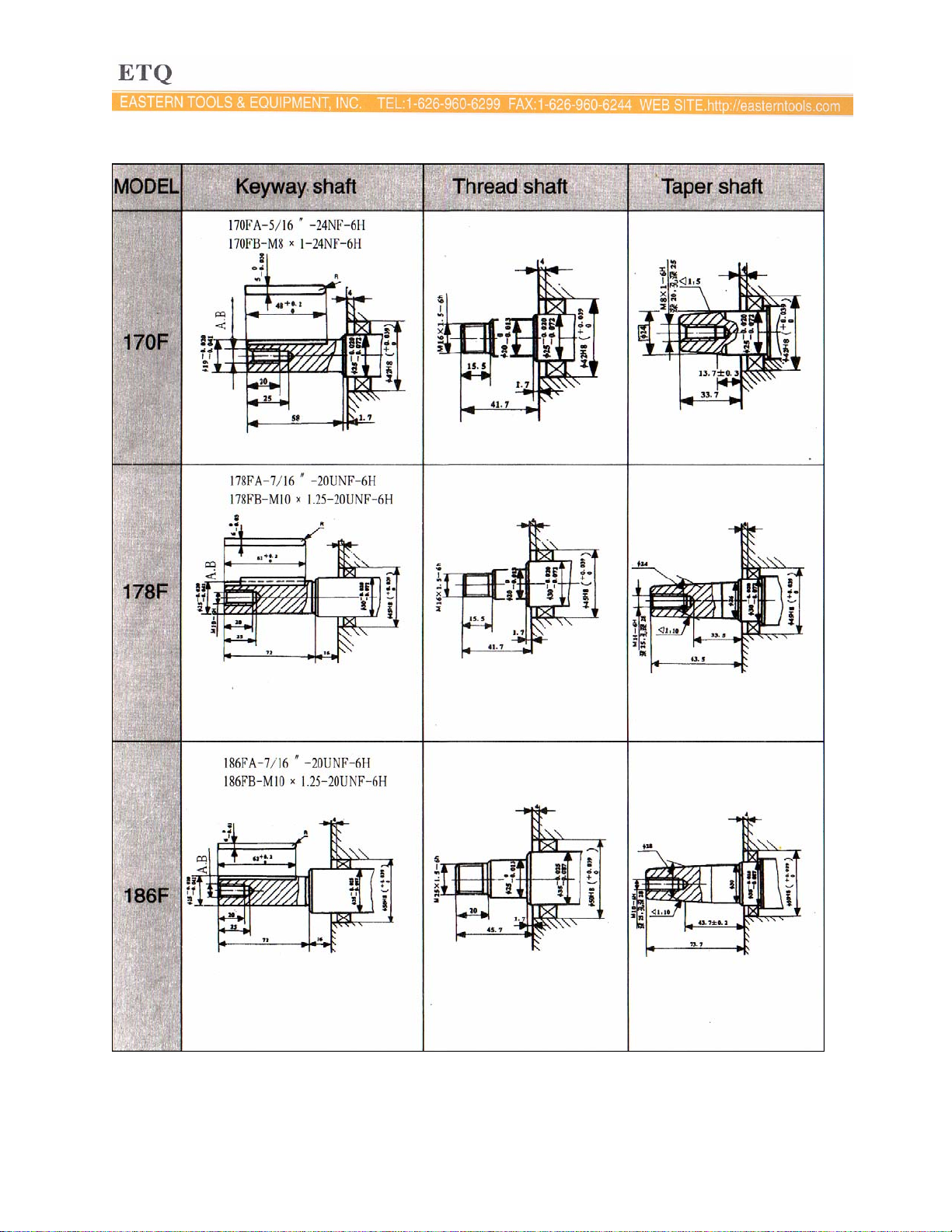

1-2 Diesel Engine shaft specifications units: mm

12

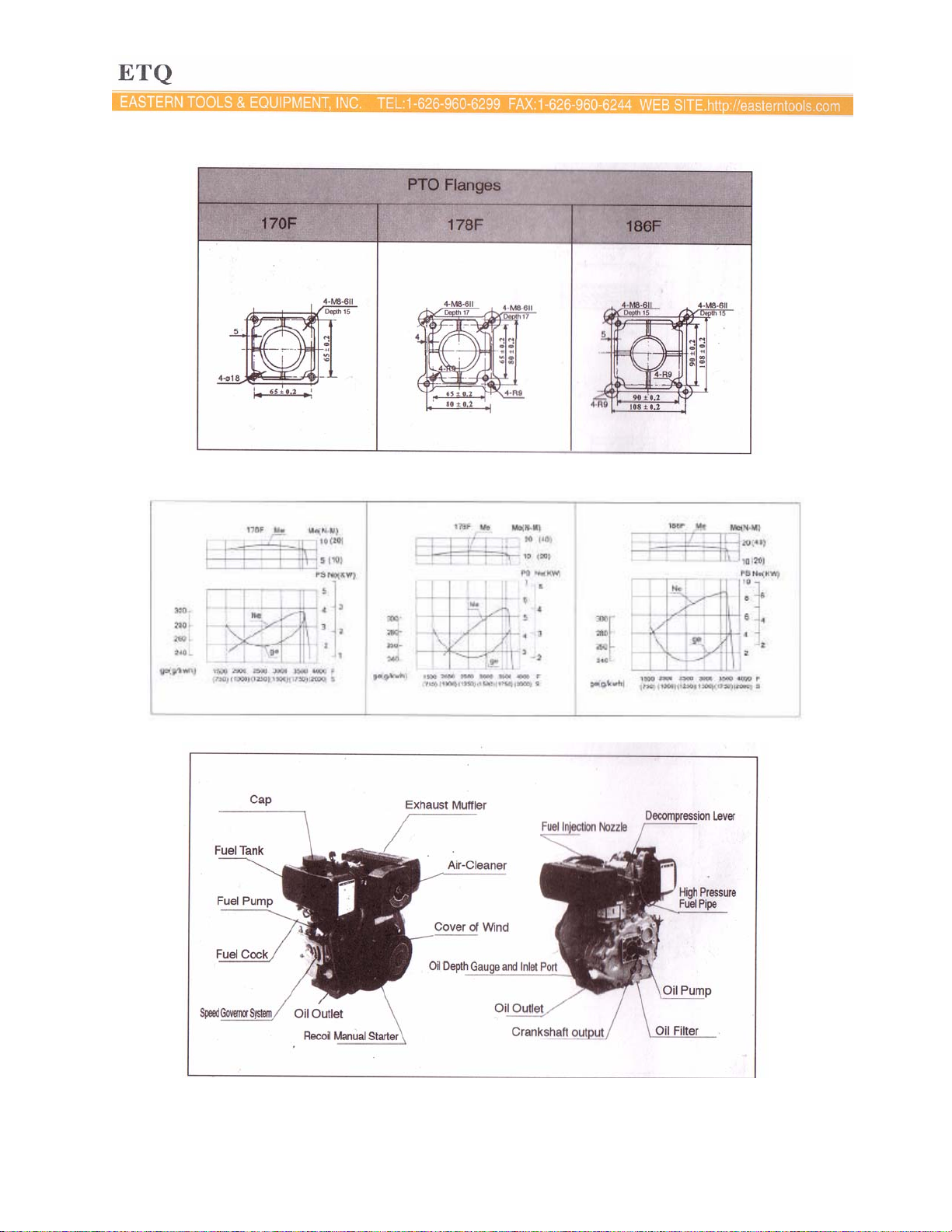

Sizes of PTO flanges

Diesel Engine Power Curves

1-4 Names of Diesel Engine Parts

13

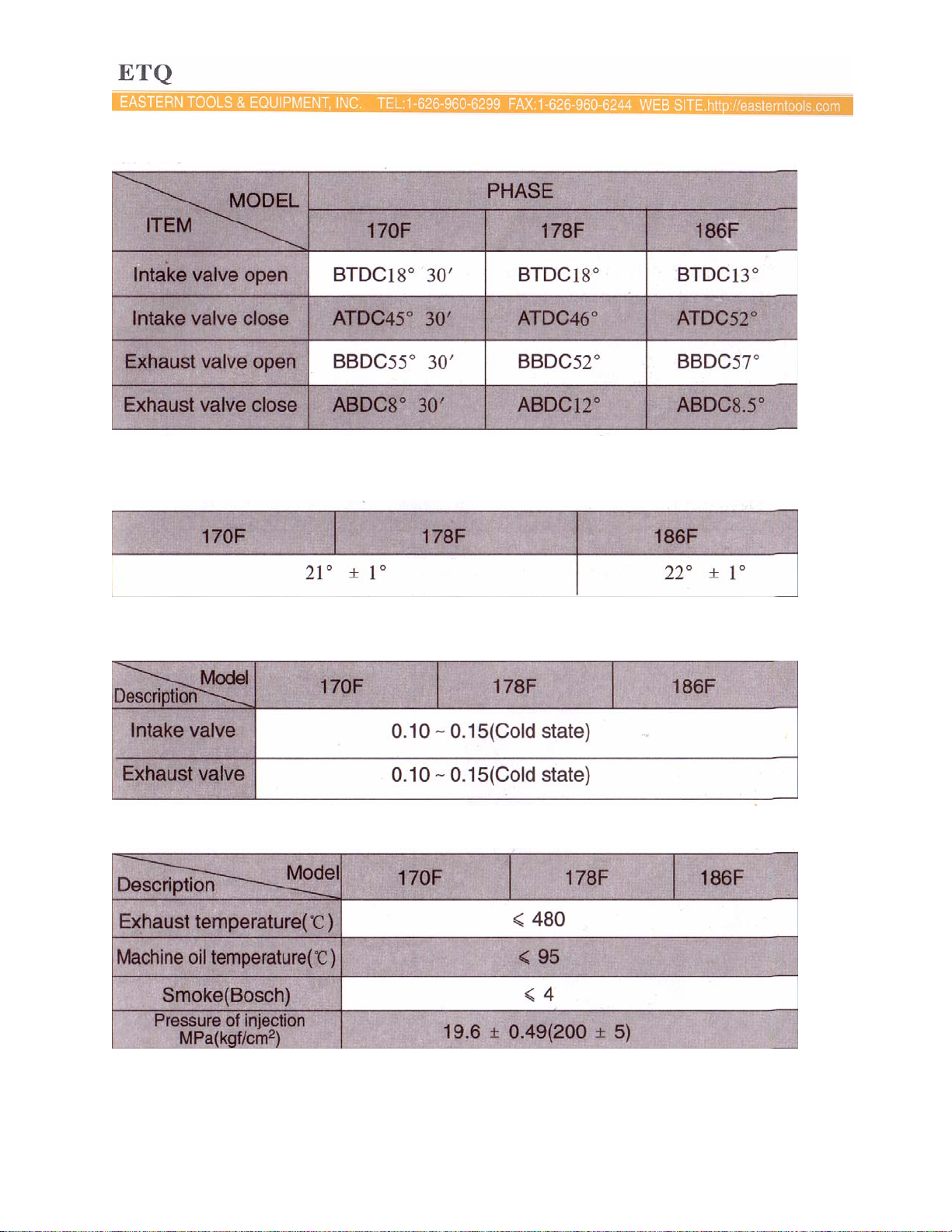

1-5 Valve timing, initial angle of fuel delivery and valve clearances. Units: Degrees

Table 1-3.

1-5.2 Initial angle of fuel delivery Units: Degrees

Table 1-4

1-5.3 Valve Clearances

Table 1-5

1-6 Temperature ranges for exhaust and injection pressure specifications

14

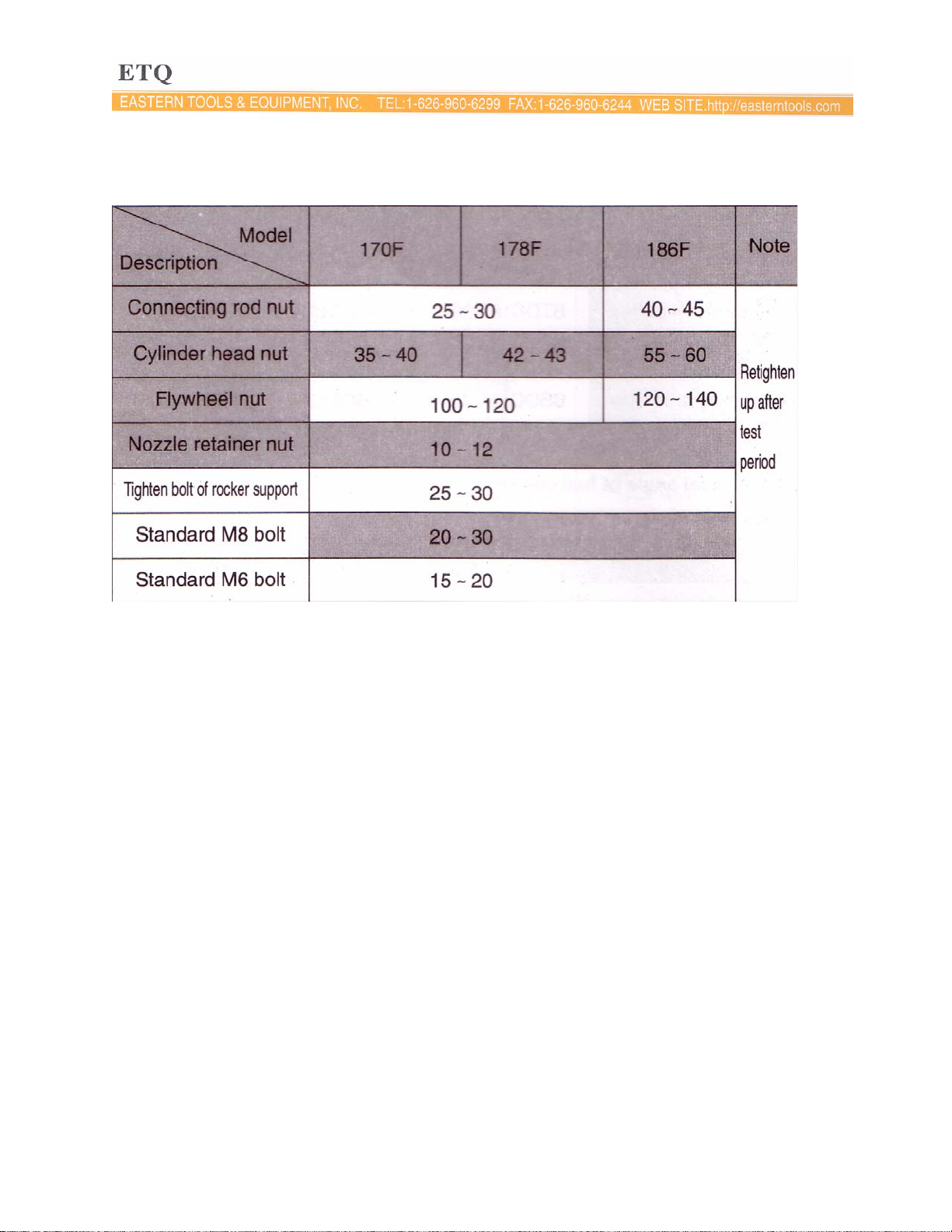

1-7 Torque specifications for various engine nuts and bolts

Table 1-7. Torque specifications in SI units Units: N m

15

CHAPTER 2 DIESEL ENGINE OPERATION

2-1 Please pay close attention for safe operation of the diesel engine.

1. The fuel used must be filtered by silk fabric or settled for 24 hours before it is used in the

engine. Never add oil to the crankcase when the engine is running.

2. Keep flammable and combustible goods away from engine while engine is running. The

engine should be placed in a simple ventilated place.

3. Do not touch the muffler when the engine is running or just after it has stopped.

4. The diesel engine should be operated at its rated power and rated speed. If abnormal

operating conditions are detected, stop the engine immediately to check and fix the

problem.

5. A new engine must be properly broken in. For the first 20 hours, run the engine at low

speed and low loads. Do not allow engine to run at high speeds and high loads during the

break in period.

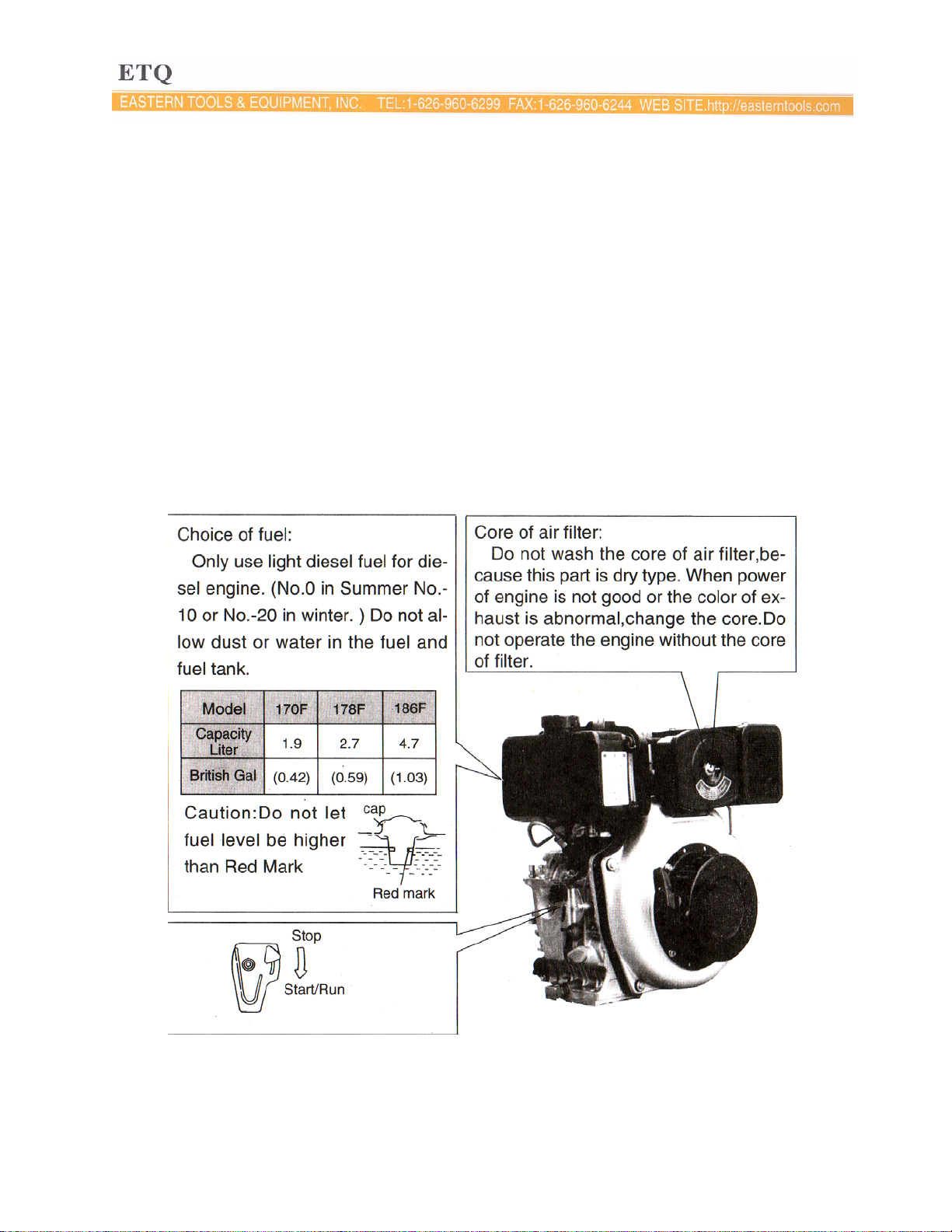

2-2 Fuel Choices

16

Oiling plug:

In winter, if it is difficult to start the

engine, pull the plug out and fill 2cc of lube oil

into the hole and then put the plug back in

place. Make sure the plug is tight, if not, the

engine can absorb dust into the combustion

chamber and damage itself.

Muffler

The factory has replaced the

engine fuel and engine oil

once already. To check the

fuel pipeline, make sure the

fuel line is completely

drained. IF there is air in the

pipeline, drain it out. To do

this, loosen the nut between

the injection pump and fuel

pipe, then drain out the air

until there are no bubbles

left in fuel line.

Compression release lever:

Push the lever down

to start the engine

Oil Lubricant Inlet:

Place the engine on level ground and fill the lubricant into the inlet. When checking the

oil level, gently place the dipstick into the oil. Do not turn the oil scale.

17

If your engine is still relatively new, follow the break in procedure. The life of the engine

will shorten if it is overloaded during its break in period. For the first 20 hours, the engine

must be started and stopped according to the test run method.

Avoid overloading the engine

Change the engine oil regularly. Below a table for the interval of oil changes will be

provided.

18

2-3 Starting the Diesel Engine

2-3.1 Recoil Starting

Note: When the engine is running, do not pull the recoil handle, otherwise the engine may be

damaged.

19

20

2-3.2 Diesel engine with electric starter system

(1) Starting

The preparation of the diesel engine for the electric starting system is the same as the

manual recoil type.

a. Open the fuel cock.

b. Set the speed governor lever to the start position.

c. Turn the start switch clockwise to the “Start” position.

d. If the engine is started, immediately remove your hand away from the key

switch.

e. If the engine does not start after 10 seconds, wait awhile (about 15 seconds)

before trying to start the engine again.

(2) Battery

2-3.3 Cold starting

If the engine is difficult to start in winter, take off the rubber seal plug and put 2cc of

machine oil into the hole.

Notice: Engines supplied to the Torrid Zone will not contain the rubber plug. A solid

plug is provided instead.

If you run the starter motor to long, the voltage of

the accumulator will drop and the motor may be

damaged. Keep the key switch in the “ON” position

a. Always check the liquid level of the battery every month, if the level is lower

than the low limit mark, refill the battery with distilled water till you reach the

upper limit mark.

If the liquid level in the battery is to low, the electric

starter will not function to its best potential. Always keep

the level of the liquid in the battery between the upper and

lower limits. If there is too much liquid, the liquid will

splash onto other nearby parts thereby ruining the battery.

21

Warning:

Never use flammable liquids as fuel, such as gasoline etc. Also, never

take away the air cleaner for easy starting of the engine, doing so may

cause explosions from the intake gases.

Never take the oil plug unless you’re planning on filling the oil. If the

plug is not in place, rain, dust, and other impurities may be sucked into

the engine causing serious damage to the engine parts.

22

2-4 Running and stopping of the Diesel Engine

2-4.1 Running the Diesel engine

(1) Preheat the engine for three minutes at no load.

(2) Set the speed governor lever to the desired speed.

2-4.2 Checks on the engine while the engine is running.

2-4.3 Stopping the engine

Use the speed governor lever to control the

speed of the engine. Never loosen or

(1) Check to see whether there are abnormal noises such as vibration.

(2) Check to make sure there is good combustion. (Extremely high speeds

are not recommended for the engine, as that will decrease engine life.)

(3) Check to see the color of the exhaust gases to see if it is to white or to

black.

(4) If any of these conditions are detected, stop the engine immediately

and contact your nearest dealer for repair information.

(1) First, bring down the speed of the engine by using the speed governor.

Let it run for 3 minutes at no load before stopping it.

(2) Then stop the engine.

Sudden stops to the engine will cause abnormal

temperature increases in the block of the engine.

Decrease the load gradually when stopping the engine.

Also, never stop the engine with the decompression

(3) Set the fuel cock at “S” (stop position)

lever.

23

(4) If the engine comes with an electric starter, turn the starting switch to

the “Off” position.

(5) Pull the recoil handle slowly until pressure is felt by your hand, this

means the piston is on the compression stroke; where the intake and

exhaust valves are closed and then let the handle recoil back into the

engine. This natural position will prevent rust from occurring when

the engine is being stored for long periods of time.

Note: Only perform step 5 when the engine is off. Doing so otherwise

will damage the engine.

24

CHAPTER 3. TECHNICAL MAINTENANCE OF DIESEL ENGINE

3-1 Daily checks and maintenance

Check the oil level of the engine to see whether it is between the upper and lower limits.

Check to see whether there any oil leaks within the engine.

Keep the engine clean by cleaning up the dirt and other greasy deposits on the engine.

3-2 Regularly checks and maintenance

Regular checks and maintaining are very important for normal operation and engine life. The

following table indicates what is necessary to be performed at specific time intervals. The

marks signify that a special tool or technique is needed for maintenance. Please contact your

local dealer for special maintenance.

25

26

The core of the air filter may become dirty from various impurities. If this occurs, the

performance of the engine will decrease because the amount of air entering the combustion

chamber is incorrect. Also, because the amount of air is incorrect, the amount of fuel entering

also becomes incorrect leading to an overall incorrect air/fuel mixture. This will lead to poor

performance of the diesel engine. Always keep the air filter and air filter core clean.

3-3 Storing the engine for long periods of time.

Please follow the instructions below if you plan on storing the engine for long periods of time.

(1) Run the engine for three minutes to burn out the excess fuel in the chamber.

(2) Quickly drain way the engine oil lubricant before the engine becomes cool and refill it

with new oil. The figure below shows where the oil plugs are.

27

(3) Take the rubber plug off the cover of the rocker shaft and put about 2cc of lubricant into

it and put the plug back in place. The figure below shows where to access the plug.

(4) For recoil starting engines, push the decompression lever down and pull the recoil

starter two or three times. This pushes all the excess intake mixture out of the

combustion chamber.

(5) For engines that come with an electric starter, hold down the decompression lever and

turn the start key switch to the start position. Let the engine rotate for about two to three

seconds. Once again, this pushes all the excess intake mixture out of the combustion

chamber.

(6) Now pull the decompression lever up and pull on the recoil starter slowly until you feel

resistance. The resistance point occurs on the compression stroke where the intake and

exhaust valves are closed. It is also the point that will prevent moisture from entering the

chamber to cause rust.

(7) Finally, clean excess oils from the engine and put the engine in a nice dry place.

28

CHAPTER 4 PART LISTINGS

Diesel Engine Exploded View

29

4-1 Engine Block

Table 4-1. Please refer to Fig 4-1 for illustration

Number Part Number Name of Part Qty each set

1 ETQ1710626 Bolt M10 x 20 (GB5787-86) 2

2 ETQ 17138 Starter motor hole cover 2

ETQ 70-1704901 2

3 ETQ 78-1704902 Cylinder head nuts (long) 2

ETQ 86-1704903 2

ETQ 70-1705001 2

4 ETQ 78-1705002 Cylinder head nuts (short) 2

ETQ 86-1705003 2

ETQ 70-1704801 2

5 ETQ 78-1704802 Cylinder head nut gasket 2

ETQ 86-1704803 2

ETQ 70-1719504 1

6 ETQ 78-1719704 Cylinder head gasket (0.4) 1

ETQ 86-1706314 1

7 ETQ 70/78-17182 Oval ring gasket 5.1 x2.5 1

ETQ 86-1720106 Oval ring gasket 5.1 x2.6 1

ETQ 70-1700201 2

8 ETQ 78-1700202 Cylinder head bolts (long) 2

ETQ 86-1700203 2

ETQ 70-1700301 2

9 ETQ 78-1700302 Cylinder head bolts (short) 2

ETQ 86-1700303 2

ETQ 70-1700107 2

10 ETQ 78-1700103 Engine block 1

ETQ 86-1700110 1

ETQ 70-1711702 1

11 ETQ 78-1711702 Rear oil seal 30 x 45 x 8 1

ETQ 86-1711704 Rear oil seal 35 x 50 x 8 1

12 ETQ 17121 Oil drain plug 1

13 ETQ 17120 Oil drain plug gasket 1

14 ETQ 1711324 O ring for oil dipstick 2

15 ETQ 17123 Fuel pump fastening bolt (short) 1

16 ETQ 17122 Fuel pump fastening bolt (long) 2

17 ETQ 1719605 Fuel injector gasket (0.5) 1

18 ETQ 70-1702001 Oil dipstick 2

ETQ 78/86-1702002 2

19 ETQ 1710103 M6 nut 3

20 ETQ 17159 Sealing plate gasket 1

21 ETQ 17158 Sealing plate 1

22 ETQ 17195 Thrust piece 1

23 ETQ 1710636 Flange face with bolts (GB5789-86) 1

30

24 ETQ 1710010 Needle bearing 7941/15 1

ETQ 70-1710006 Ball bearing 306 (GB/T276-94) 1

25 ETQ 78-1710007 Ball bearing 307 (GB/T276-94) 1

ETQ 86-1710008 Ball bearing 308 (GB/T276-94) 1

ETQ 70-1704601 1

26 ETQ 78-1704602 Crankcase cover gasket 1

ETQ 86-1704603 1

ETQ 70-1710002 Bearing 205 (GB/T276-94) 1

27 ETQ 78-1710003 Bearing 206 (GB/T276-94) 1

ETQ 86-1710004 Bearing 207 (GB/T276-94) 1

28 ETQ 1711111 Retaining pin 8x12 (GB119-86) 2

29 ETQ 78/86-17080 Fuel Pipe 1

ETQ 70-1701901 1

30 ETQ 78-1701902 Crankcase cover 1

ETQ 86-1701904 1

31 ETQ 17133 Inner Hexagon Plug G1/8 1

ETQ 70-1710083 M8 x 33.5 Bolt 1

ETQ 70-1711062 M6 x 25 14

32 ETQ 78-1710083 M8 x 33.5 Bolt 15

ETQ 86-1710083 M8 x 33.5 Bolt 16

ETQ 70-1711701 Front oil seal 25 x 42 x 10 1

33 ETQ 78-1711703 Front oil seal 30x 45 x 10 1

ETQ 86-1711705 Front oil seal 35 x 50 x 10 1

ETQ 70-1701801 1

35 ETQ 78-1701802 Main Bushing 1

ETQ 86-1701803 1

36 ETQ 78-1701903 Front side crankcase cover 1

37 ETQ 78-1711703 Front side oil seal 1

38 ETQ 70-1711602 Aluminum Plug Diameter 8 x 8 2

ETQ 78/86-1711602 3

Note: If purchasing the engine cylinder block, the included parts are numbers 1, 2, 8, 9, 10, 12,

13, 14, 15, 16, 18 and 24. The parts of the crankcase cover include numbers 14, 18, 27, 28, 29,

30, 31, 35 and 38.

31

Fig 4-1. Exploded view of engine block assembly

32

4.2 Cylinder head Assembly

Table 4-2. Part listing for cylinder head assembly. Please refer to Fig 4-2

No. Code Names of Parts Qty each set

1 ETQ 70/78-1710755 M6 x 55 Flanged Bolt (GB5789-86) 2

ETQ 86-1710730 M6 x 70 Flanged Bolt (GB5789-86) 2

2 ETQ 17142 Oiling hole plug 1

3 ETQ 17139 Decompression shaft 1

4 ETQ 1711310 O ring 10 x 1.9 (GB1235-76) 1

5 ETQ 17140 Decompression shaft spring 1

6 ETQ 1711103 Retaining pin 3 x 16 (GB119-86) 1

7 ETQ 70/78-17066 Cylinder head cover 1

ETQ 86-1706603 1

8 ETQ 70/78-17170 Cylinder head cover gasket 1

ETQ 86-1717001 1

9 ETQ 70/78-17168 Rocker arm 1

ETQ 86-1716801 1

9A ETQ 17165 Valve clearance adjusting screw 2

10 ETQ 70/78-1710745 Rocker arm shaft fastening bolt 1

ETQ 86-1716901 1

ETQ 70-1705201 2

11 ETQ 78-1705202 Adjusting valve spacer 2

ETQ 86-1705203 2

ETQ 70-1702701 4

12 ETQ 78-1702702 Valve clip 4

ETQ 86-1702703 4

ETQ 70-1702801 2

13 ETQ 78-1702802 Valve spring seat 2

ETQ 86-1702803 2

ETQ 70-1702901 2

14 ETQ 78-1702902 Valve spring 2

ETQ 86-1702903 2

ETQ 70-1702003 2

15 ETQ 78-1702004 Valve guide oil seal 2

ETQ 86-1702100 2

16 ETQ 70/78-17136 Valve spring washer 2

ETQ 86-1713601 2

17 ETQ 1711104 Pin 4 x 8 (GB119-86) 1

18 ETQ 1710920 Double ended stud AM8 x 20 (GB899-88) 2

ETQ 70-1702403 1

19 ETQ 78-1702402 Cylinder Head 1

ETQ 86-1702404 1

20 ETQ 70/78-1710955 Double ended bolt AM6 x 55 (GB900-88) 2

ETQ 86-1710956 Double ended bolt AM6 x 75 (GB900-88) 2

ETQ 70-1702501 1

21 ETQ 78-1702601 Intake valve 1

33

ETQ 86-1702503 1

ETQ 70-1702502 1

22 ETQ 78-1702602 Exhaust valve 1

ETQ 86-1702605 1

23 ETQ 1710103 M6 (GB6177-86) Nut 2

24 ETQ 1717302 Fuel injector pressure plate 1

25 ETQ 1724502 Fuel injector gasket 1

ETQ 70-1712201 AM 6 x 42 Fuel injector bolt 2

26 ETQ 78-1712201 AM 6 x 42 Fuel injector bolt 2

ETQ 86-17122 Fuel injector bolt (long) 2

27 ETQ 17141 Breather assembly 1

28 ETQ 1711312 O ring 12 x 1.9 1

Note: The parts of the cylinder head cover included are numbers 2, 3, 4, 5, 6, 7, 27, 28 and 29.

The parts of the rocker arm include 9 and 9a.

The parts of the cylinder head include 12, 13, 14, 15, 16, 17, 18, 19, 20, 22 and 26.

34

Fig 4-2. Exploded view of cylinder head

35

4-3 Piston connecting rod and crankshaft balancing mechanism

Table 4-3. Please refer to Fig 4-3 for a complete illustration of the parts.

No. Code Name of Part Qty each set

ETQ70-1701403 1

1 ETQ 78-1701402 Piston Rings 1

ETQ 86-1701404 1

ETQ 70-1701601 Retainer clip of Piston pin Dia. 19mm 2

2 ETQ 78-1701602 Retainer clip of Piston pin Dia. 21mm 2

ETQ 86-1701603 Retainer clip of Piston pin Dia. 23mm 2

ETQ 70-1701200 1

3 ETQ 78-1701202 Piston 1

ETQ 86-1701204 1

ETQ 78FS-1701203 1

ETQ 70-1701701 1

4 ETQ 78-1701702 Piston pin 1

ETQ 86-1701703 1

ETQ 70-1701301 1

5 ETQ 78-1701302 Connecting rod 1

ETQ 86-1701303 1

ETQ 70-1701501 1

6 ETQ 78-1701502 Connecting rod journal bearing 1

ETQ 86-1701503 1

ETQ 70-1710001 Bearing 202 (GB/T276-94) 2

7 ETQ 78-1710001 2

ETQ 86-1710000 Bearing 203 (GB/T276-94) 2

ETQ 70-1706501 1

8 ETQ 78-1706502 Balancing Shaft 1

ETQ 86-1706503 1

9 ETQ 1710507 Key 5 x 7 (GB1096-79) 2

ETQ 70-1707701 1

10 ETQ 78-1707702 Balancing Shaft Timing Gear 1

ETQ 86-1707703 1

11 Bolt (included with diesel engine) 1

ETQ 70-1700801 1

12 ETQ 78-1700802 Crankshaft timing gear 1

ETQ 86-1700803 1

13 ETQ 70/78-1710512 Key 5 x 12 (GB1096-79) 2

ETQ 86-1710512 Key 5 x 12 (GB1096-79) 1

13A ETQ 86-1710514 Key 5 x 14 (GB1096-79) 1

14 ETQ 70-1710530 Key 5 x 30 (GB1096-79) 1

ETQ 78/86-1710563 Key 6 x 63 (GB1096-79) 1

ETQ 70-1700601 1

15 ETQ 78-1700701 Crankshaft 1

ETQ 86-1700708 1

16 ETQ 1711601 6 x 8 Plug 1

36

ETQ 70-1707801 1

17 ETQ 78-1707802 Balancing Shaft Driving Gear 1

ETQ 86-1707803 1

ETQ 70-1704400 1

18 ETQ 78-1704404 Flywheel 1

ETQ 86-1704409 1

19 ETQ 70/78-17156 Flywheel nut gasket 1

ETQ 86-1715601 1

20 ETQ 70/78-17155 Flywheel nut 1

ETQ 86-1715501 1

ETQ 70-1704501 1

21 ETQ 78-1704502 Flywheel ring gear (for electric starter) 1

ETQ 86-1705504 1

22 ETQ 1704705 Sleeve of fuel pump rod 1

ETQ 70-1705101 2

23 ETQ 78-1705102 Push rod 2

ETQ 86-1705103 2

ETQ 70-17157 2

24 ETQ 78-17157 Tappet 2

ETQ 86-1715701 2

25 ETQ 70/86-1710514 Key 5 x 14 (GB1096-79) 1

ETQ 78-1710504 Key 4 x 12 (GB1096-79) 1

ETQ 70-1701001 1

26 ETQ 78-1701002 Camshaft 1

ETQ 86-1701000 1

26S ETQ 78-1701003 Front Side Camshaft 1

ETQ 70-1701101 1

27 ETQ 78-1701102 Camshaft timing gear 1

ETQ 86-1701103 1

28 ETQ 78-1700702 FS crankshaft 1

30 ETQ 78-1710545 Key 8 x 45 (GB1096-79) camshaft key 1

31 ETQ 78-1704403 FS Flywheel 1

32 ETQ 78-1704503 FS flywheel ring gear 1

Note: The included parts with the piston connecting rod are numbers 1,2,3,4,5 and 6

The included parts with the balancing shaft are numbers 8, 9 and 10.

The included parts with the crankshaft are numbers 9, 12, 13, 15 and 17.

37

Fig 4-3. Exploded view of Piston / Crank Assembly

38

4-4 Fuel System Parts

Table 4-4. Fuel system parts; please refer to Fig 4-4 for a complete illustration.

No. Code Name of part Qty each set

1 ETQ 1710745 M8 x 45 (GB5787-86) Bolt 1

2 ETQ 17185 Upper fuel tank bracket fastener 1

3 ETQ 1710208 Flat washer 8 (GB97.1-85) 1

ETQ 70-1705801 1

4 ETQ 78-1705802 Upper fuel tank bracket 1

ETQ 86-1705803 1

5 ETQ 1705301 Injector 1

6 ETQ 17212 Hose Clamp 2

7 ETQ 17192 Fuel Pipe 1

8 ETQ 17184 Rubber fuel tank mount 4

ETQ 70-1704201 1

9 ETQ 78-1704202 Fuel Tank 1

ETQ 86-1704203 1

10 ETQ 17212 Fuel Pipe connectors 2

11 ETQ 17147 Fuel Pipe 1

12 ETQ 17151 M6 (GB6177-86) Fuel drain gasket 1

13 ETQ 17152 Fuel drain plug 1

14 ETQ 17183 Lower fuel tank bracket 1

15 ETQ 1710714 M6 x 14 (GB5787-86) Bolt 2

16 ETQ 1710106 M6 (GB6177-86) Nut 2

17 ETQ 1710206 M6 (GB97.1-85) Flat washer 1

18 ETQ 17150 Fuel tank cock assembly 1

19 ETQ 17154 Flat washer 1

20 ETQ 1719403 Fuel pipe clamp 2

21 ETQ 17189 Fuel pipe 1

22 ETQ 17148 Fuel filter gasket 1

ETQ 70-1704301 1

23 ETQ 78-1044302 Fuel filter assembly 1

ETQ 86-1704303 1

ETQ 70-1704702 1

24 ETQ 78-1704702 Fuel injector pump 1

ETQ 86-1704700 1

ETQ 70-1705601 1

25 ETQ 78-1705602 High pressure fuel pipe 1

ETQ 86-1705603 1

26 ETQ 17146 Fuel cup filter 1

27 ETQ 17153 Fuel cap assembly 1

28 ETQ 1705302 Fuel injector cap 1

Note: The fuel tank assembly comes with numbers 9, 10, 11, 12, 13, 16, 17, 18, 19, 22, 23, 26

and 27.

39

Fig 4-4. Exploded view of fuel tank parts

40

4-5 Oil and speed control system

Table 4-5. Please refer to Fig 4-5 for a complete illustration.

No. Code Name of part Qty each set

1 ETQ 70-1710712 M6 x 12 (GB5787-86) Bolt 2

2 ETQ 70-17187 Oil filter cover 1

3 ETQ 70-17188 Oil filter cover gasket 1

4 ETQ 70-1711314 Sealing Ring 20 x 2.5 1

ETQ 78/86-1711316 Sealing Ring 20X2.65 1

5 ETQ 70-1702101 Oil filter assembly 1

6 ETQ 1710712 M6 x 12 (GB5787-86) Bolt 3

7 ETQ 17022 Oil pump cover 1

8 ETQ 1711334 O ring 34.5 x 1.8 (GB3452.1-82) 1

ETQ 70-17135 1

9 ETQ 78-17135 Oil Pump 1

ETQ 86-1713501 1

10 ETQ 1711103 3 x 16 (GB119-82) pin 1

11 ETQ 78/86-1710714 M6 x 14 (GB5789-86) 1

12 ETQ 78/86-1702103 Oil filter cleaning element 1

13 ETQ 70-1711314 Sealing ring 20 x 2.5 1

ETQ 78/86-1711316 Sealing ring 20 x 2.65 1

14 ETQ 78/86-17080 Oil Guide 1

ETQ 70-1702301 1

15 ETQ 78-1702302 Oil pump driving gear 1

ETQ 86-1702302 1

16 ETQ 17132 Fly block pin 1

17 ETQ 17131 Fly block 2

18 ETQ 17234 Governor fork tappet 2

19 ETQ 17125 Lever shaft gasket 1

20 ETQ 1710009 Bearing 7941/8 (GB290-64) 1

ETQ 70-1700501 2

21 ETQ 78-1700502 Fork lever assembly 1

ETQ 86-1700503 1

22 ETQ 17124 Washer 1

ETQ 70-17126 1

23 ETQ 78-17126 Fuel controller parts 1

ETQ 86-1712601 1

24 ETQ 17164 Handle bracket 1

25 ETQ 17167 Speed-control lever 1

26 ETQ 1710714 M6 x 14 (GB5787-86) 1

27 ETQ 1710714 M6 x 18 (GB5787-86) 1

28 Lead seal 1

29 ETQ 17162 Return spring 2 1

30 ETQ 17161 Return spring 1 1

ETQ 70-17160 1

41

31 ETQ 78-17160 Speed-control spring 1

ETQ 86-1716001 1

32 ETQ 1710645 M6 x 45 (GB6172-86) Bolt 1

33 ETQ 1710111 M10 x 1.25 Nut 1

34 ETQ 1706701 FG Lever 1

35 ETQ 1706901 FG governor spring 1

36 ETQ 1710714 M6 x 14 (GB5789-86) Bolt 1

37 ETQ 1710106 M6 (GB39-88) Nut 1

38 ETQ 1716801 Washer 2

39 ETQ 1730720 Shaft Handle 1

42

Fig 4-5. Lubrication and speed control system

43

4-6 Cooling and recoil starting system

Table 4-6. Please refer to Fig 4-6 for illustration.

No. Code Name of part Qty each set

ETQ 70-1703401 1

1 ETQ 78-1703402 Recoil case assembly 1

ETQ 86-1703404 1

1S ETQ 78-1703404 178FS case assembly 1

2 ETQ 1710708 M6 x 8 (GB5787-86) 4

ETQ 70-1703501 1

3 ETQ 78-1703502 Recoil starter rope 1

ETQ 86-1703503 1

ETQ 70-1703801 1

4 ETQ 78-1703802 Recoil starter handle 1

ETQ 86-1703802 1

5 ETQ 70/78-1703301 Flat Torsional spring 1

ETQ 86-1703303 1

ETQ 70-1703201 1

6 ETQ 78-1703202 Recoil reel 1

ETQ 86-1703203 1

7 ETQ 70-1704003 Starting claw 2

ETQ 78/86-1704005 2

8 ETQ 70-17218 Helical spring 1

ETQ 78/86-1721801 1

9 ETQ 70-17219 Torsional spring 1

ETQ 78/86-1721901 1

10 ETQ 70-1704004 Starting claw plate 1

ETQ 78/86-1704006 1

11 ETQ 70-17039 Friction plate 1

ETQ 78/86-1703902 1

12 ETQ 70-1703903 Friction plate gasket 1

ETQ 78/86-1703803 1

13 ETQ 1710306 Spring washer 1

14 ETQ 1710106 M6 (GB6170-86) Nut 1

15 ETQ 1710712 M6 x 12 (GB6170-86) 3 or 4

ETQ 70-1705701 1

16 ETQ 78-1705702 Starter 1

ETQ 86-1705703 1

ETQ 70-1704101 1

17 ETQ 78-1704102 Recoil starter cover 1

ETQ 86-1704105 1

17S ETQ 78-1704106 Recoil starter cover assembly 1

18 ETQ 78-1710622 M6 x 22 (GB5787-86) Bolt 5

ETQ 70/86-1710622 4

19 ETQ 78-1710207 M6 washer (GB90-85) 5

ETQ 70/86-1710207 4

44

20 ETQ 78-17145 Collar 5

ETQ 70/86-17145 4

21 ETQ 78-17143 Shock absorber 5

ETQ 70/86-17143 4

22 ETQ 17144 Shock pads 1

23 ETQ 78/86-17127 Shock isolator 1

24 ETQ 78/86-17129 Collar 1

25 ETQ 78/86-17128 Pad 1

ETQ 70-1700401 1

26 ETQ 78-1700402 Wind leading plate 1

ETQ 86-1700403 1

ETQ 70-1710712 M6 x 12 (shaped piece) Bolt 1

27 ETQ 78-1710718 M6 x 18 (shaped piece) Bolt 1

ETQ 86-1710614 M6 x 22 (shaped piece) Bolt 1

45

Fig 4-6. Exploded view of cooling and recoil starting system.

46

4-7 Air cleaner and silencer system

Table 4-7. Please refer to Fig 4-7 for a complete illustration.

No. Code Name of part Qty each set

ETQ 70-1703101 2

1 ETQ 78-1703102 Intake pipe gasket 1

ETQ 86-1703103 1

ETQ 70-1703001 1

2 ETQ 78-1703002 Intake pipe 1

ETQ 86-1703003 1

3 ETQ 70/78-17175 Air cleaner gasket 3

ETQ 86-1717501 1

4 ETQ 17137 Bolt 1

1

5 ETQ 1710722 M6 x 22 (GB5789-86) Shaped bolt 1

1

6 ETQ 70/78-17174 1

ETQ 86-1717401 Air filter assembly 1

7 ETQ 1710103 M6 (GB6177-86) Nut 1

8 ETQ 70/78-1717602 Air filter element 1

ETQ 86-1717601 1

9 ETQ 70/78-17186 Muffler gasket 1

ETQ 86-1718601 1

ETQ 70-1705401 1

10 ETQ 78-1705402 Muffler assembly 1

ETQ 86-1705403 1

11 ETQ 1710208 Flat washer Dia. 8 2

12 ETQ 1710308 Spring washer Dia. 8 2

13 ETQ 1710108 M8 (GB6170-86) Nut 1

14 ETQ 70-1710714 M6 x 14 (GB5789-86) Bolt 2

ETQ 78/86-1710757 M8 x 14 (GB5789-86) Bolt 2

ETQ 70-1705501 1

15 ETQ 78-1705502 Muffler screen cover 1

ETQ 86-1705503 1

16 ETQ 1710708 M6 x 14 (GB5789-86) Bolt 1

17 ETQ 70/78-1705404 Muffler tail pipe 1

ETQ 86-1705406 1

18 ETQ 70/78-17179 Inner shock proof sealing ring 1

ETQ 86-1718002 1

19 ETQ 70/78-17180 Bottom case assembly of Air Clea ner 1

ETQ 86-1718003 1

20 ETQ 70/78-17178 Outer shock proof sealing ring 1

ETQ 86-1718001 1

21 ETQ 70/78-17181 Air filter shock absorber 1

ETQ 86-1718101 1

22 ETQ 70/78-1710103 Collar (GB6177-86) 1

ETQ 86-1720106 Collar (GB6177-86) 1

47

23 ETQ 70/78-17182 Air filter shock absorber 1

ETQ 86-1720106 1

24 ETQ 17177 1

25 ETQ 70/78-1710107 M6 butterfly nut 1

ETQ 85-1710109 M8 butterfly nut 1

Fig 4-7. Exploded view of muffler assembly

48

49

CHAPTER 5 ENGINE TROUBLESHOOTING

5-1 Engine is not starting

Possible Cause Remedy

Weather is cold. Engine oil may have become

overly adhesive.

Fuel system may be contaminated with water. Clean the fuel filter and fuel pipe, and then replace

The fuel has thickened and does not permit easy

flow.

There is air in the fuel system. Drain out the air and fuel and tighten the

Very little fuel injected into cylinder or the injected

spray is bad.

Incomplete combustion The spray nozzle may be bad, or the delivery angle

Fuel delivery is not constant Fuel level in fuel tank may be to low. Fill the fuel

Low compression Replace head gasket or tighten the cylinder head

Piston rings worn leading to low compression Change the piston rings.

Piston ring gaps may all be set up in a line Make sure each piston ring gap is off by an angle

Piston rings are stuck or broken Clean the rings and cylinder with diesel fuel and or

Gas valves are leaking Grind the gas valves, if the vestige is too deep,

Incorrect valve clearance Adjust the clearance as specified in the technical

The valve stem is clipped on the guide pipe Disassemble the gas valve and clean the stem and

5-2 Diesel engine lacks power

Put engine oil into crankcase after preheated. Put

engine oil into the inlet manifold. Disconnect the

belts to the engine and run engine under no load

conditions until the engine becomes hot. Then

connect the belts back and start the engine again.

the fuel with new fuel.

Use the correct specific fuel.

connectors of the fuel pipe.

Check the position of the speed governor handle

and clean the fuel injector spray nozzle. Check the

fuel pump and change the pump or fuel nozzle if

necessary.

may be incorrect. The gasket of the cylinder head

may be leaking and the pressure of compression is

not held. Fix each component that is necessary to

achieve correct compression and a correct angle of

spray.

tank until it is full. Or the fuel pipe or fuel filter

may be clogged, fix this by replacing them.

bolts in a diagonal line pattern. If changing the

head gasket, tighten the cylinder head bolts once

again after running the engine.

of 120 degrees from each other.

replace the rings if necessary.

please send it to the factory for replacement

specifications chart.

guide pipe.

50

Possible Cause Remedy

Fuel system clogged. Clogged fuel line or clogged

fuel filter.

Fuel pump is bad. Service or change the damaged parts of the fuel

Nozzle not operating correctly or incorrect

injection pressure.

Carbon deposits in the spray hole. Clean out the spray hole.

Adhered needle valve. Clean or change needle valve.

Fitting between the needle valve and needle valve

body is too loose.

Air filter is dirty. Disassemble the air filter assembly and clean the

Engine may be to slow. Check the speed of the tachometer. Adjust the

5-3 Engine stops automatically

Possible cause Remedy

No fuel in system. Add fuel to the fuel tank.

Fuel line is clogged. Clean out fuel line.

There is air in fuel system. Clean out the system and put new fuel in.

Needle valve of nozzle adhered. Clean or grind the nozzle if necessary replace the

Air filter is clogged. Clean the air filter.

The load suddenly increases. Decrease the load.

5-4 Engine exhaust very black

Possible cause Remedy

Overloaded engine Decrease the load. If driven machine is not

Bad fuel injection. Check the fuel injection pressure and spraying

Not enough intake air or problems with leaking air. Clean the air filter and check to see what the cause

5-5 Engine exhaust very blue

Possible cause Remedy

Engine oil in the cylinder. Check the oil level and drain out unnecessary engine

Piston ring worn or piston ring gaps are all

aligned to permit oil to travel up into

combustion chamber.

Worn piston or worn cylinder. Replace as necessary.

Valve and or valve guide worn. Change the valve or valve guide as necessary.

Clean fuel filter and fuel pipe. Check the fuel

switch, it should be opened fully.

pump.

Adjust the injection pressure.

Change the needle valve or needle valve body.

core and air filter.

high speed limiting screw.

nozzle.

properly fitted with proper engine, change the

engine.

conditions. Correct or replace the nozzle.

of the leak is and fix as necessary.

oil.

Check or change the piston rings and make sure the

gaps are not all aligned.

51

5-6 Engine exhaust white

Possible cause Remedy

There is water in the diesel fuel Clean the fuel tank and diesel filter, replace the

diesel fuel.

5-7 Various methods of checking to see if the engine is malfunctioning

Possible cause Remedy

High and low speed fluctuation. Check the speed governor system to see if it is

loose. Also, check to make sure there is no air

in the fuel system.

Abnormal sounds suddenly appear. Check each rotating part carefully.

Sudden appearance of black smoke from

exhaust.

There are metal knocking sounds in the

cylinder.

Check the fuel system, especially the injection

nozzle.

The fuel delivery angle is too large. Adjust it

to the correct specifications.

52

Limited Warranty

Eastern Tools & Equipment, Inc. will repair or replace, free of charge, any part or parts of the generator that are defective in

material or workmanship or both. Transportation charges on parts submitted for repair or replacement under this Warranty must

be borne by purchaser. This warranty is effective for the time period and subject to the conditions provided for in this policy.

For warranty service, find the nearest Authorized Service Dealer by contacting the place of purchase or Eastern Tools &

Equipment, Inc. THERE IS NO OTHER EXPRESSED WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM

PURCHASE, OR TO THE EXTENT PERMITED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED.

LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES ARE EXCLUDED TO THE

EXTENT EXCLUSION IS PERMITTED BY LAW. Some states do not allow limitations on how long an implied warranty

lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation and

exclusion may not ap ply to you. This warranty giv es you specific legal rights and you may also have other rights, which vary

from state to state.

Eastern Tools & Equipment, Inc.

WARRANTY PERIOD***

WITHIN U.S.A AND CANADA OUTSIDE U.S.A. AND CANADA

ENGINES

DIESEL ENGINE 1 year

CONSUMER

USE

or 1000 hours

COMMERCIAL

USA

1 year

or 1000 hours

CONSUMER

USE

1 year

or 1000 hours

COMMERCIAL

USE

1 year

or 1000 hours

About Your Product Warranty

Eastern Tools & Equipment, Inc. welcomes warranty repair and apologizes to you for being inconvenienced. Any Authorized

Service Dealer may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes warranty service may

be inappropriate. For example, warranty would not apply if an engine is damaged because of misuse, lack of routine

maintenance, shipping, handling, warehousing and improper installation. Similarly, warranty is void if the serial number on the

engine has been removed or if the engine has been altered or modified. If a customer differs with the decision of the Service

Dealer, an investigation will be made to determine whether the warranty applies. Ask the Service Dealer to submit all supporting

facts to his Distributor or the factory for review. If the distributor or the factory decides that the claim is justified, the customer

will be fully reimbursed for those items that are defective. To avoid misunderstanding, which might occur between the customer

and the dealer, listed below are some of the causes of engine failure that the warranty does not cover.

Normal wear:

Engines and generators, like all mechanical devices, need periodic parts service and replacement to perform well. Warranty will

not cover repair when normal use has exhausted the life of a part of an engine.

53

Improper maintenance:

The life of an engine or your equipment depends upon the conditions under which it operates, and the care it receives. Some

applications, such as tillers, pumps, and rotary movers, are very often used in dusty or dirty conditions, which can cause what

appears to be premature, wear. Such wear, when caused by dirt, dust, spark pug cleaning grit, or other abrasive material that has

entered the engine because of improper maintenance is not covered by warranty.

54

Note: Please mail the above card to: Eastern Tools & Equipment, Inc.

4951 Commerce Dr.

Baldwin Park, CA 91706

55

EASTERN TOOLS & EQUIPMENT, INC.

TELEPHONE: 1-626-960-6299

TELEPHONE: 1-626-960-6244

WEB SITE.http://easterntools.com

56

Loading...

Loading...