ETQ 170F, 170FSE, 178F, 178FE, 178FS Owner's Manual

...

OWNER’S MANUAL

AIR-COOLED DIESEL ENGINE

170F / FE / FS / FSE 178F / FE / FS / FSE 186F / FE / FS / FSE

1

PREFACE

Thank you for purchasing products from Eastern Tool & Equipment, INC. The following

manual is only a guide to assist you and is not a complete or comprehensive manual of all

aspects of maintaining and repairing your engine. The engine you have purchased is a complex

piece of machinery. We recommend that that you consult with a dealer if you have doubts or

concerns as to your experience or ability to properly maintain or repair your engine. You will

save time and the inconvenience of having to go back to the store if you choose to write or call

us concerning missing parts, service questions, operating advice, and/or assembly questions.

Engine Features and Highlights

• Direct fuel injected intake system

• Recoil-type manual starter and or optional electric starter system

• Forced air convection cooling system

• Composite steel fan cover for minimum noise levels

Our four stroke diesel engines are air cooled with a direct fuel injected intake system. They offer

maximum efficiency through the minimal conservation of energy and materials. These diesel

engines are compact and lightweight. They are easily maintained and portable making it

convenient to move. They are widely used as a source of mechanical power for industrial,

agricultural, and machinery equipment. Some applications include irrig ation equipment, diesel

powered pressure sprayers, grass-cutting machines, and soil-sampling machines. Other

applications include vibration rammers, shock rammers, marine engines, lightweight transport

vehicles, portable compressors, and lightweight portable generators.

This operating manual will explain how to operate and maintain your series of engines. Please

read it before running the engine for correct operation.

To ensure long engine life please follow the operating requirements listed in this manual.

If you have any questions or suggestions about this manual, please contact your local dealer or

us. Consumers should notice that this manual might differ slightly from the actual product as

more improvements are made to our products. Some of the pictures in this manual may differ

slightly from the actual product as well. Eastern Tools and Equipment, Inc. reserves the right

to make changes at any time without notice and without incurring any obligation.

2

TABLE OF CONTENTS

Page number

Safety Precautions 4

Chapter 1 Technical Specifications and Data 7

1-1 Technical Specifications 7

1-2 Overall Dimensions and Installation Conditions 9

1-2.1 Belt wheel and engine clearance requirements 10

1-2.2 Crankshaft driving angle conditions 11

1-2.3 Engine electrical system 11

1-3 Diesel engine shaft specifications 12

1-4 Diesel engine part names 13

1-5 Valve timing, initial angle of fuel delivery and valve clearances 14

1-5.2 Initial angle of fuel delivery 14

1-5.3 Valve clearances 14

1-6 Temperature ranges for exhaust and injection pressure specifications 14

1-7 Various engine torque specifications 15

Chapter 2 Diesel Engine Operation Procedures 16

2-1 Engine safety precautions 16

2-2 Fuel choices 16

2-3 Starting the diesel engine 19

2-3.1 Recoil Starting 19

2-3.2 Electric starter 21

2-3.3 Cold starting 21

2-4 Running and stopping the diesel engine 23

2-4.1 Running the diesel engine 23

2-4.2 Routine checks while engine is running 23

2-4.3 Stopping the engine 23

Chapter 3 Technical Maintenance of Diesel Engine 25

3-1 Daily checks and maintenance 25

3-2 Regularly checks and maintenance 25

3-3 Storing the engine for long periods of time 27

Chapter 4 Part Listings 29

4-1 Engine block 30

4-2 Cylinder head assembly 33

4-3 Piston connecting rod and crankshaft balancing mechanism 36

4-4 Fuel system parts 39

4-5 Oil and speed control system 41

4-6 Cooling and recoil starting system 44

4-7 Air cleaner and silencer system 47

Chapter 5 Engine Troubleshooting 50

5-1 Engine is not starting 50

5-2 Diesel engine lacks power 51

5-3 Engine stops automatically 51

5-4 Engine exhaust very black 51

5-5 Engine exhaust very blue 51

5-6 Engine exhaust white 52

5-7 Various methods of checking to see if engine is malfunctioning 52

Limited Warranty 53

Registration Card 55

Comment Card 55

3

SAFETY PRECAUTIONS

Please be sure to follow each instruction carefully

EXHAUST PRECAUTIONS

• Never inhale the exhaust gases, it contains

carbon monoxide, a colorless, odorless and

extremely dangerous gas which can cause

unconsciousness or death

• Never operate the engine indoors or in a

poorly ventilated area, such as a tunnel or

cave, etc.

• Exercise extreme care when operating the

engine near people or animals. Keep the

exhaust pipe free of external objects.

REFUELING PRECAUTIONS

• Be sure to stop the engine before refueling.

• Do not overfill the fuel tank.

• If fuel is spilled, wipe it away carefully and

wait until the fuel has dried before starting

the engine again.

• When changing oil, make sure that the fuel

cap is tightly secured to prevent fuel

leakage.

4

FIRE PREVENTION

• Never operate the engine while

smoking or near an open flame.

• Never use the engine around dry brush,

twigs, cloth-rags, or other flammable

materials.

• Keep the engine at least 3 feet (1 meter)

away from buildings or other

structures.

• Keep the engine away from flammables

and other hazardous materials.

PROTECTIVE COVER

• Always place the protective covers

over the rotating parts. If rotating parts

such as the driving pulley, belts, and

shafts are exposed, serious injuries can

be caused. To prevent injury, please

equip all rotating parts with protective

covers.

• Be careful of hot parts. The muffler

and other engine parts can become very

hot while the engine is running or after

the engine has been run. Always

operate the engine in a safe area and

keep children away from running

engines.

5

SURROUNDINGS

• Operate the engine on a table or level

surface free of small rocks and loose

gravel.

• Operate the engine on a level surface. If

the engine is tilted, fuel may spill from the

gas tank.

NOTE: Operating the engine at a steep incline

may cause the engine to seize up due to

improper lubrication even when the oil level is

a maximum.

• Be careful of fuel spillage when

transporting the engine. Always tighten

the fuel cap and close the fuel strainer cock

before moving the engine around.

• Never move the engine while it is in

operation.

• If the engine will be transported over a

long distance, drain all the fuel from the

fuel tank to prevent fuel leakage.

PRE-OPERATION CHECKS

• Carefully check fuel pipes and fuel joints

for fuel leakage. Leaked fuel creates a

dangerous situation.

• Verify that all the nuts and bolts of the

engine are tights. A loose nut or bolts may

cause serious engine failure and could lead

to serious injuries.

• Always check the engine oil and refill it if

necessary.

• Always check the fuel level and refill it if

necessary. Never overfill the fuel tank

• Avoid wearing dangling or long clothes

such as loose aprons, towels, and waist

belts, as these items may be caught in a

rotating part of the engine.

6

Chapter 1 Technical Specifications and Data

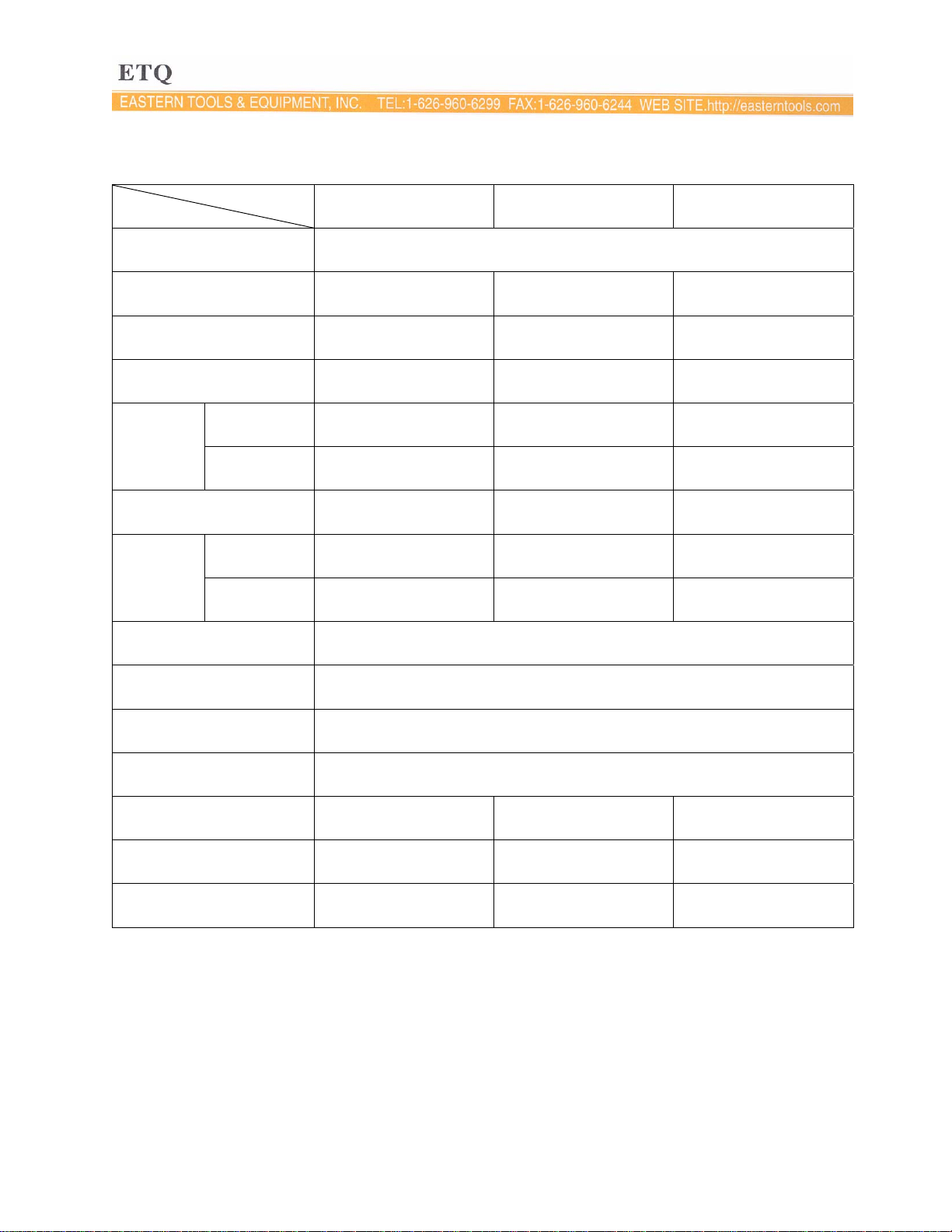

1-1 Technical specifications in English Units

Model

Item

Type Single vertical cylinder, 4-stroke, air-cooled, direct injection

Bore x Stroke (in.) 2.76 x 2.17 3.01 x 2.44 3.39 x 2.76

Displacement (cu. in.) 13.36 18.67 25.51

Speed (rpm) 3600 3600 3600

Continuous 4.0 5.9 8.85 Output

(HP)

Maximum 4.5 6.6 9.85

170F 178F 186F

Fuel tank capacity

(US gallons)

Full 27.1 37.17 55.75 Lube-oil

Capacity

(oz)

Crankshaft direction Clockwise from flywheel end

Cooling type Forced air cooled by flywheel fan

Lubrication type Pressure splash

Starting system Recoil manual start and or optional electric start

Dry weight (recoil) (lbs) 60 73 106

Dry weight (elec.) (lbs)

Dimensions (LxWxH)

(inch)

Effective 8.45 13.51 20.27

13.1 x 14.8 x 16.3 15.1 x 16.6 x 17.7 16.4 x 17.4 x 19.5

.66 .9 1.45

68 84 117

7

Technical specifications in SI units

Model

Item

Type Single vertical cylinder, 4-stroke, air-cooled, direct injection

Bore x Stroke (mm) 70 x 55 78 x 62 86 x 70

Displacement (cc) 211 296 406

Speed (rpm) 3600 3600 3600

Continuous 2.98 4.4 6.6 Output

(kw)

Maximum 3.36 4.92 7.3

170F 178F 186F

Fuel tank capacity

(Liters)

Full .8 1.10 1.65 Lube-oil

Capacity

(L)

Crankshaft direction Clockwise from flywheel end

Cooling type Forced air cooled by flywheel fan

Lubrication type Pressure splash

Starting system Recoil manual start and or optional electric start

Dry weight (recoil) (kg) 27 33 48

Dry weight (elec.) (kg)

Dimensions (LxWxH)

(mm)

Effective .25 .40 .60

332 x 376 x 415 383 x 421 x 450 417 x 441 x 494

2.5 3.4 5.5

31 38 53

8

1-2 Overall engine dimensions

Installation Conditions

(1) There must be a tight stationary foundation for the diesel engine to avoid vibrations or

movement when the engine is running. For prolonged engine life, consider using some

type of motor mount.

(2) Make sure that the centering position of the output shaft is properly aligned.

9

(3) Verify that the dimensions of the hole on the belt wheel and keyway shaft match or

correspond with each other. Also make sure that the bolt of the engine shaft is

tightened to the proper torque specifications.

(4) When the engine is matched with other belt driven machines, the total desired belt

distance traveled by the driven wheel must equal the total distance travele d by the

driver wheel. If this is not properly calculated and matched, the desired speed on the

driven wheel will be incorrect. A formula used to calculate the necessary diameters of

the various wheels is provided below.

The diameter of driving wheel (belt wheel) can be calculates as follows:

Diameter of engine driving wheel (engine pulley) =

Diameter of driven machine x speed of driven machine

Diesel speed (engine speed)

(5) Make sure that the belt has a correct tension to it.

Note: If the belt is to tight, the engine bearings will wear at a high rate leading to engine failure.

If the belt is to loose, the belt will slip at high speeds and high loads causing high pitch whistling

noises.

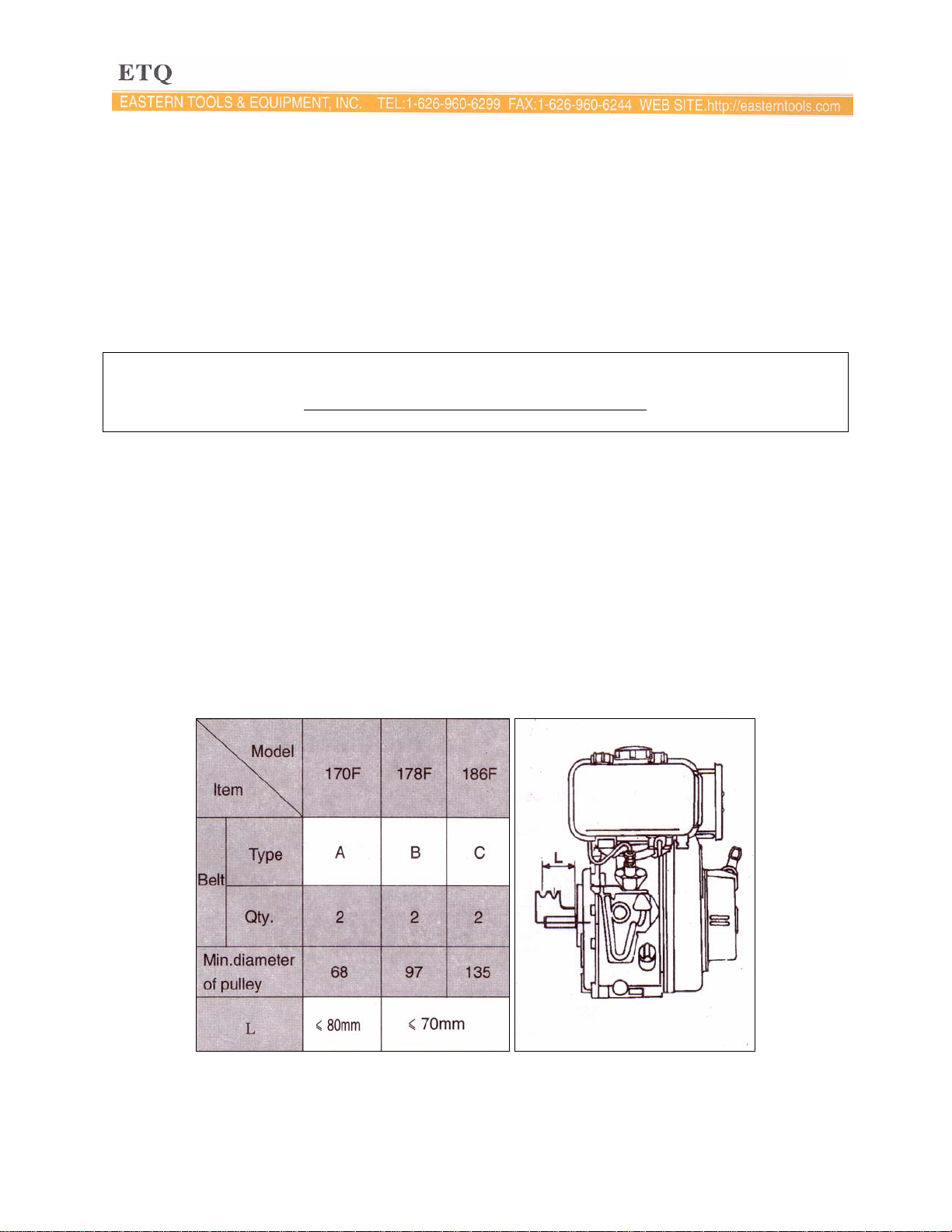

1-2.1 Allowed clearance between belt wheel and engine

The belt pulley wheel should be as close to the engine as possible. The values of L are tabulated

in table 1-1.

Table 1-1. Allowed belt pulley wheel to engine distances.

10

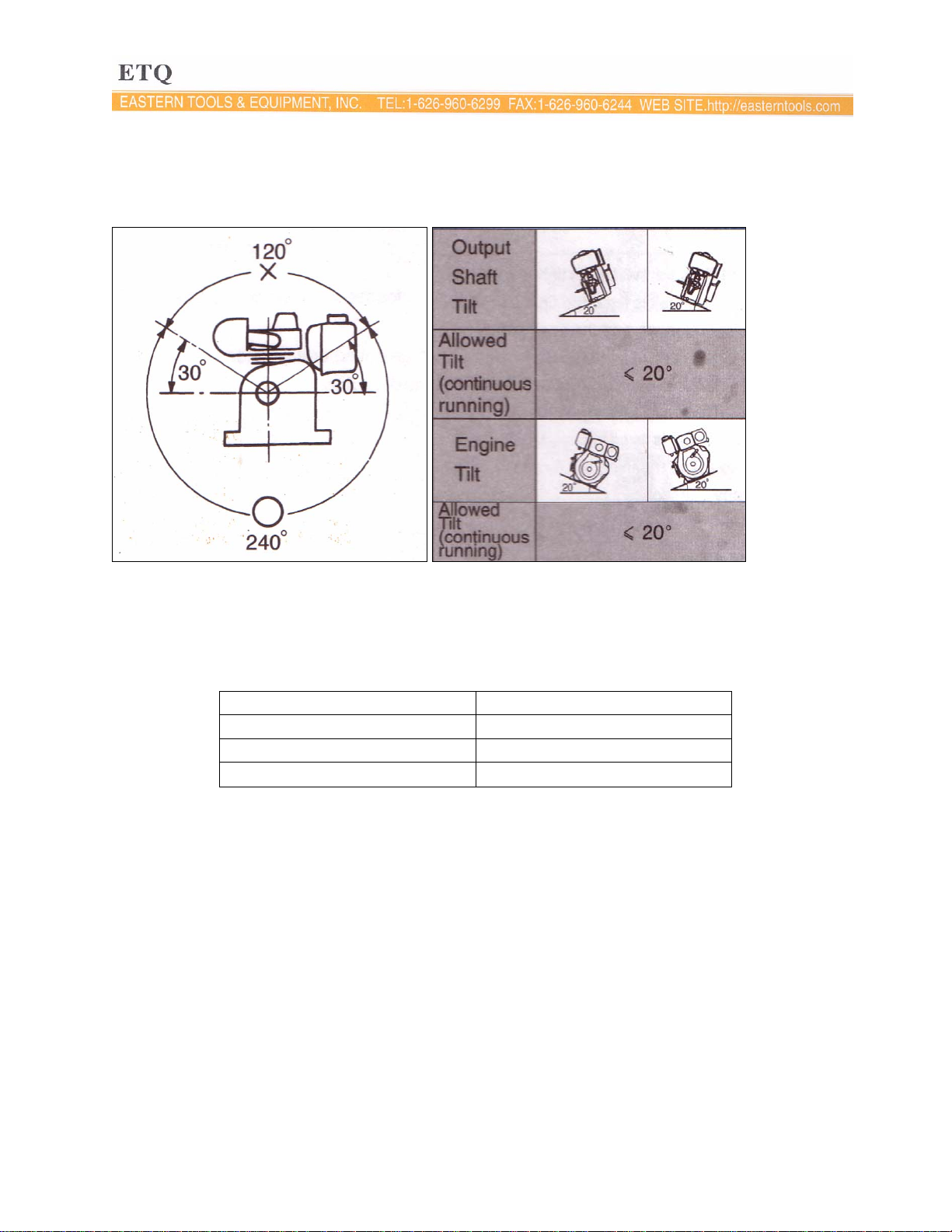

1-2.2 Crankshaft driving angles must be less than 120o, see Fig 1-1

The tilt must be kept within the allowed values shown in Fig 1-2

Fig 1-1. Allowed driving angles. Fig 1-2. Allowed tilt angles.

1-2.3 Please contact our dealers about the electric circuits involved with this engine.

We recommend the use of accumulators rated at 20 hours shown in table 1-2.

Table 1-2.

Model Units: (amp-hours)

170F 18~24

178F 24~26

186F 36~45

11

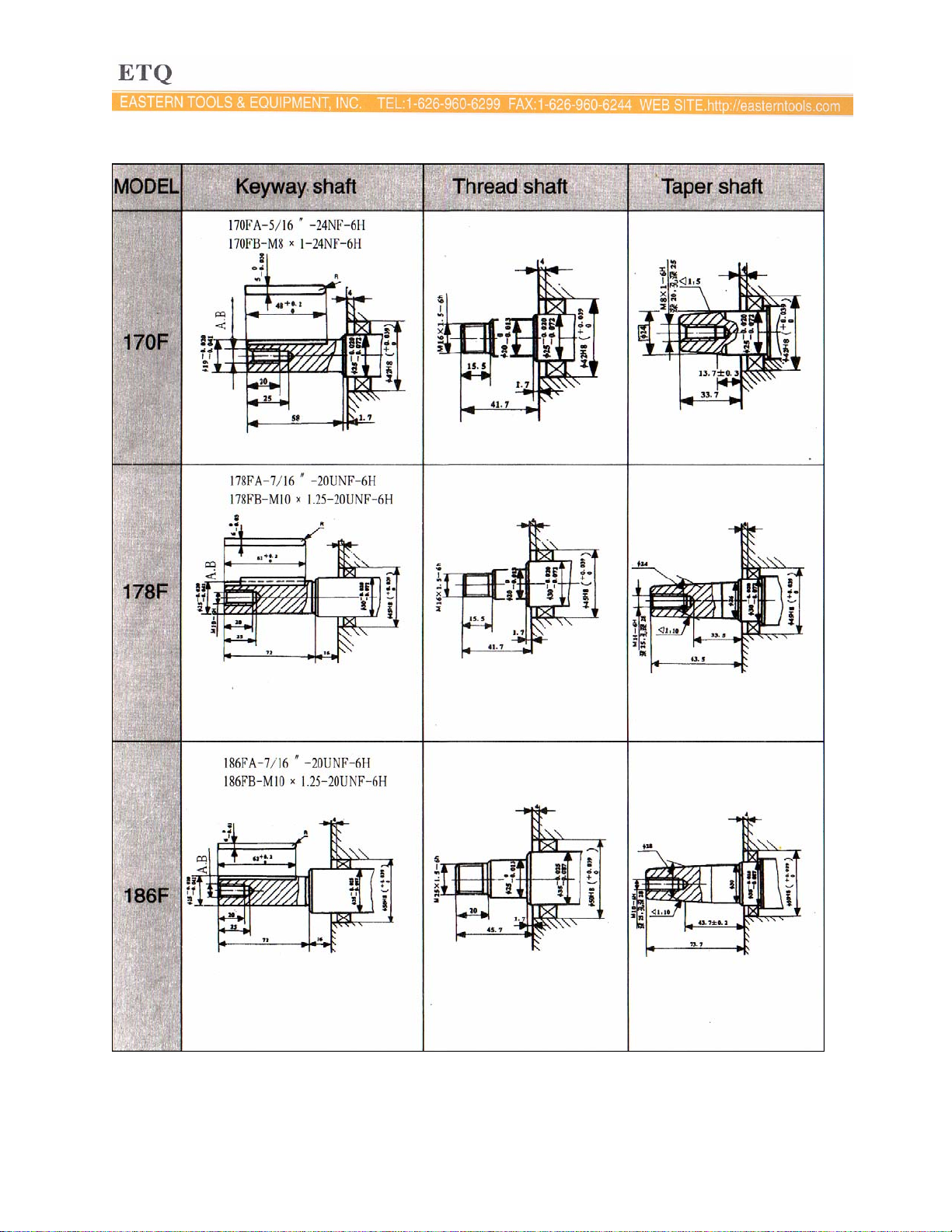

1-2 Diesel Engine shaft specifications units: mm

12

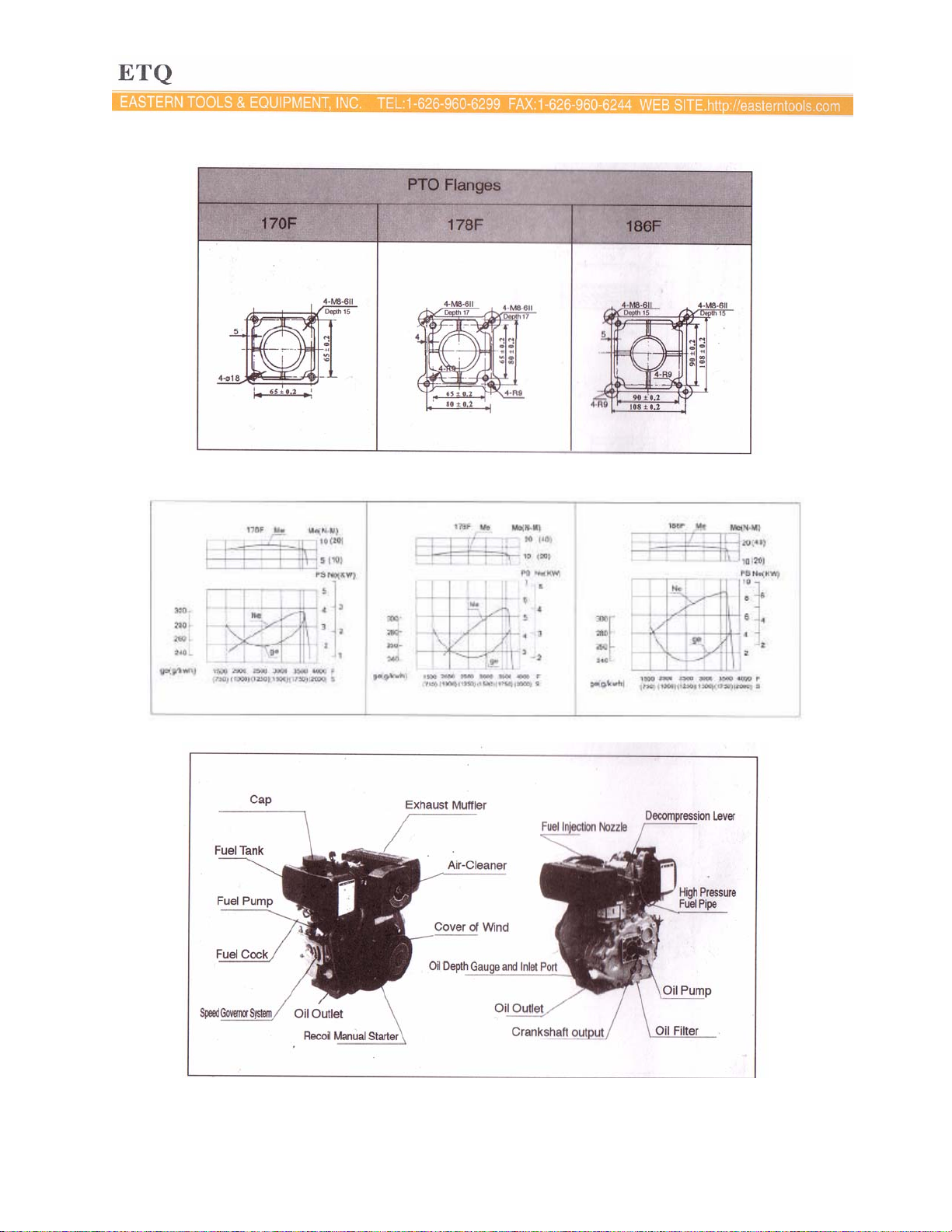

Sizes of PTO flanges

Diesel Engine Power Curves

1-4 Names of Diesel Engine Parts

13

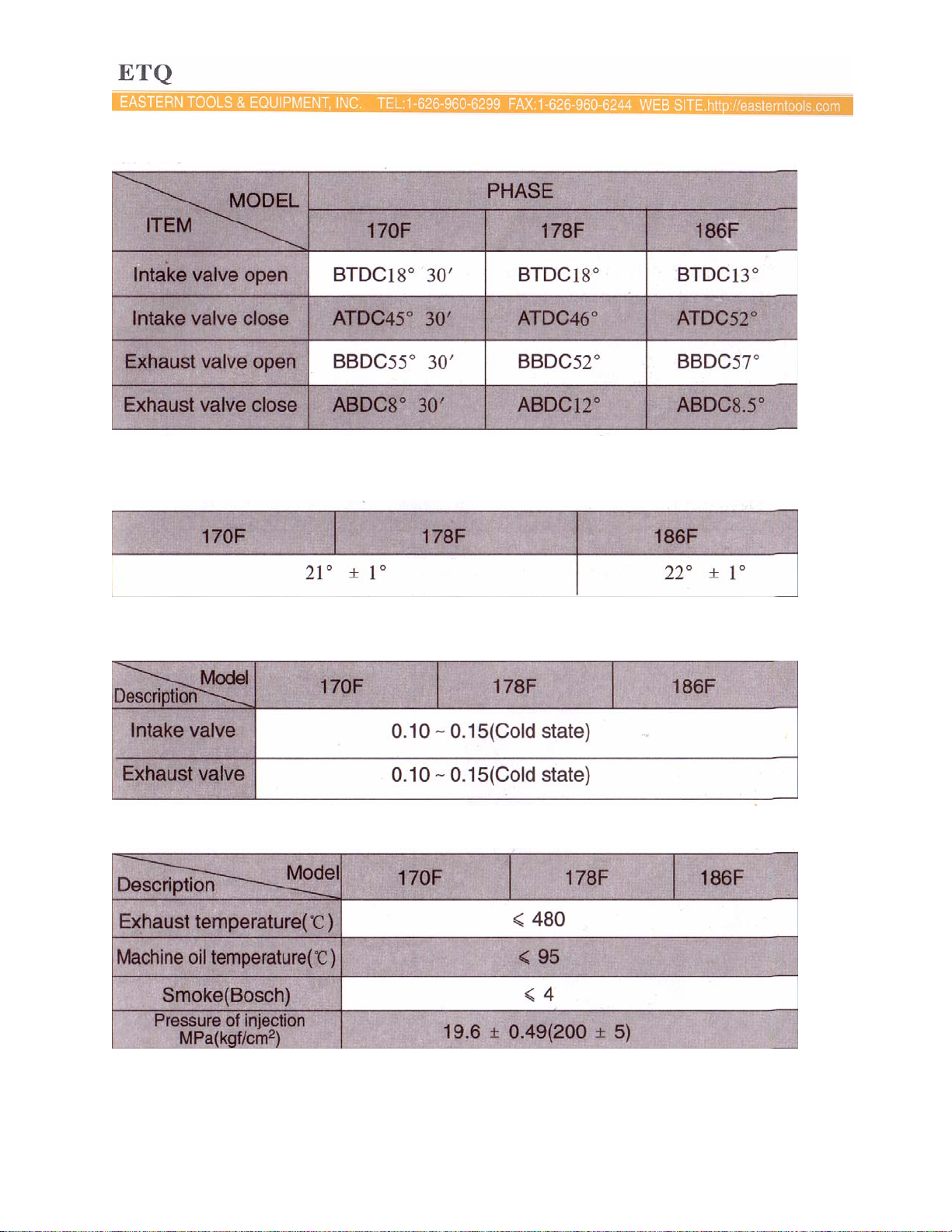

1-5 Valve timing, initial angle of fuel delivery and valve clearances. Units: Degrees

Table 1-3.

1-5.2 Initial angle of fuel delivery Units: Degrees

Table 1-4

1-5.3 Valve Clearances

Table 1-5

1-6 Temperature ranges for exhaust and injection pressure specifications

14

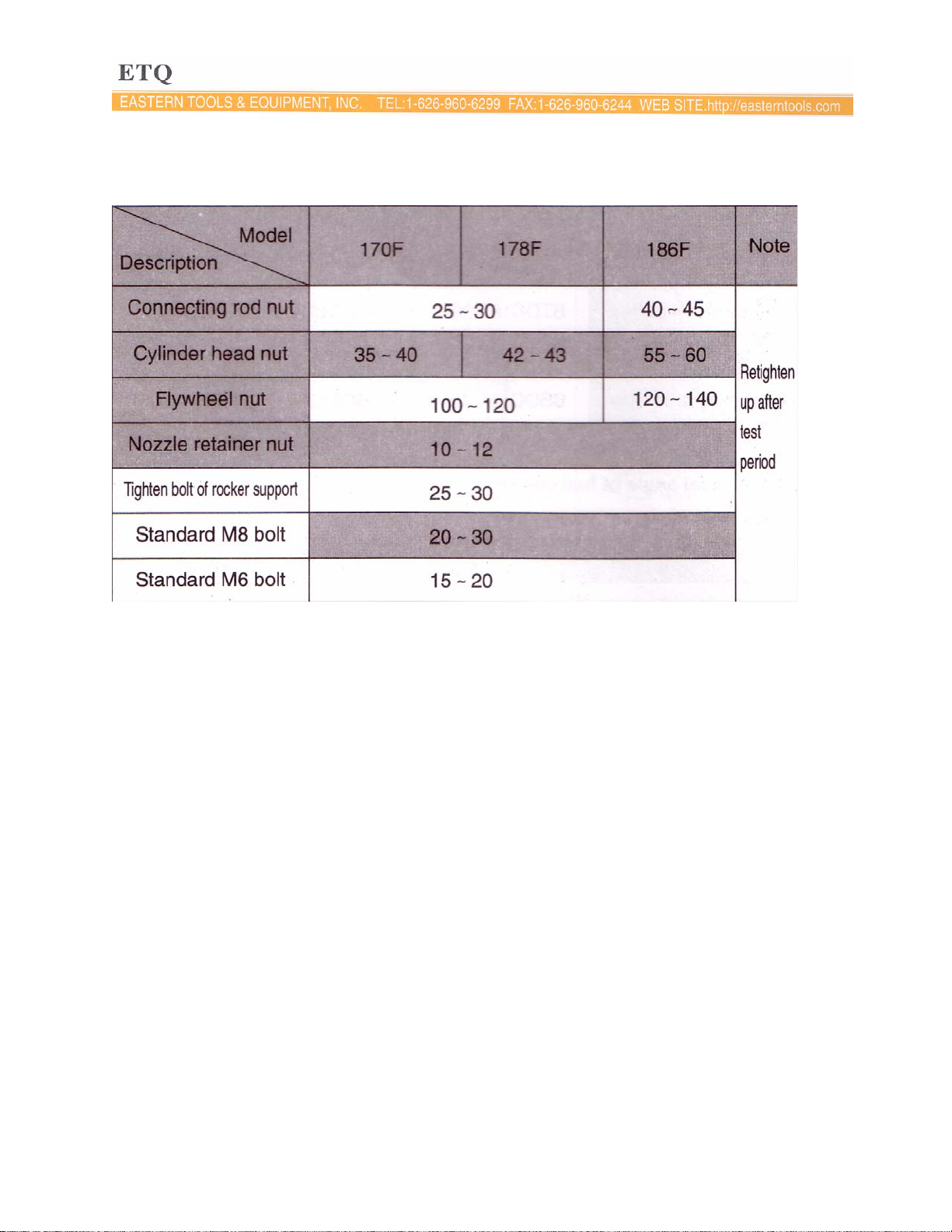

1-7 Torque specifications for various engine nuts and bolts

Table 1-7. Torque specifications in SI units Units: N m

15

CHAPTER 2 DIESEL ENGINE OPERATION

2-1 Please pay close attention for safe operation of the diesel engine.

1. The fuel used must be filtered by silk fabric or settled for 24 hours before it is used in the

engine. Never add oil to the crankcase when the engine is running.

2. Keep flammable and combustible goods away from engine while engine is running. The

engine should be placed in a simple ventilated place.

3. Do not touch the muffler when the engine is running or just after it has stopped.

4. The diesel engine should be operated at its rated power and rated speed. If abnormal

operating conditions are detected, stop the engine immediately to check and fix the

problem.

5. A new engine must be properly broken in. For the first 20 hours, run the engine at low

speed and low loads. Do not allow engine to run at high speeds and high loads during the

break in period.

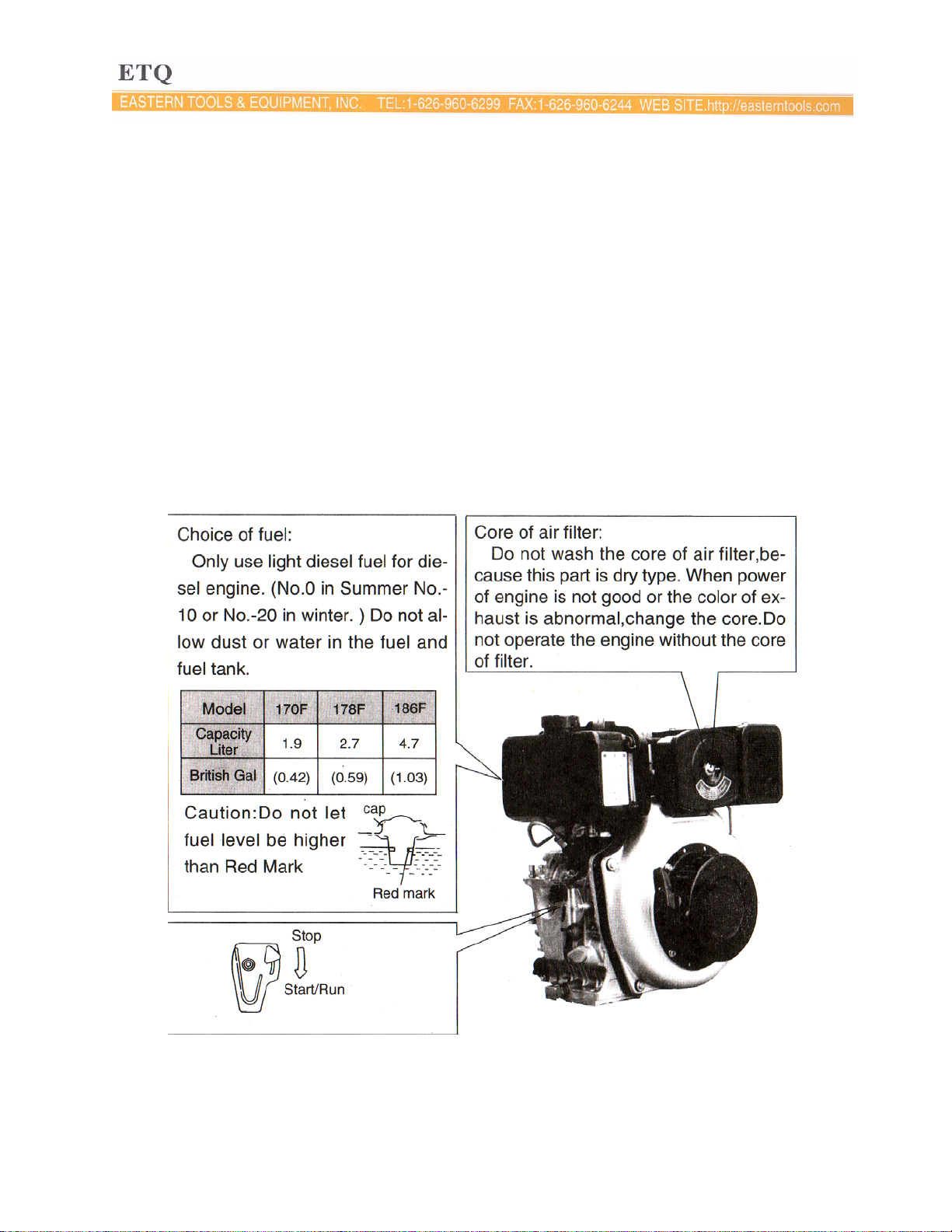

2-2 Fuel Choices

16

Oiling plug:

In winter, if it is difficult to start the

engine, pull the plug out and fill 2cc of lube oil

into the hole and then put the plug back in

place. Make sure the plug is tight, if not, the

engine can absorb dust into the combustion

chamber and damage itself.

Muffler

The factory has replaced the

engine fuel and engine oil

once already. To check the

fuel pipeline, make sure the

fuel line is completely

drained. IF there is air in the

pipeline, drain it out. To do

this, loosen the nut between

the injection pump and fuel

pipe, then drain out the air

until there are no bubbles

left in fuel line.

Compression release lever:

Push the lever down

to start the engine

Oil Lubricant Inlet:

Place the engine on level ground and fill the lubricant into the inlet. When checking the

oil level, gently place the dipstick into the oil. Do not turn the oil scale.

17

Loading...

Loading...