Eton ATV RXL 70, ATV RXL 90R, ATV RXL 50, ATV RXL 90 SERVICE MANUAL

CONTENTS

1. INFORMATION…………………………………………………...2

2. MAINTENANCE………………………………………………….6

3. ENGINE REMOVAL AND INSTALLATION………………….12

4. ENGINE FUEL SYSTEM………………………………………14

5. ENGINE LUBRICATION AND COOLING SYSTEM….…….18

6. ENGINE COMBUSTION SYSTEM…………………………...20

7. TRANSMISSION SYSTEM……………………………………25

8. STEERING SYSTEM…………………………………………..31

9. FRONT WHEEL SYSTEM…………………………………….38

10. REAR WHEEL SYSTEM……..………………………………42

11. FENDERS AND EXHAUST PIPE..………………………….51

12. ELECTRICAL SYSTEM….…………………………….…….55

13. TROUBLE SHOOTING…..……………………………….….62

1

1. INFORMATION

1.1 SAFTY

1.2 NOTES

1.3 SPECIFICATION

1.4 SERIAL NUMBER

1.5 TORQUE VALVE

1.1 SAFETY

● Gasoline is extremely flammable and is explosive under certain condition.

Do not smoke or allow sparks or flames in your work area.

● Never run the engine in a closed area. The exhaust contains poisonous carbon

monoxide gas that may cause loss of consciousness and lead to death.

● The battery electrolyte contains sulfuric acid. Protect your eyes, skin and

clothing. If you contact it, flush thoroughly with water and call a doctor if electrolyte

gets in your eyes.

1.2 NOTES

All information, illustrations, directions and specifications included in this publication are base on the latest

product information available at the time of approval for printing.

JI-EE Dynamic Technology Industry Co., Ltd. reserves the right to make changes at any time without notice and

without incurring any obligation whatever.

No part of this publication may be reproduced without written permission.

2

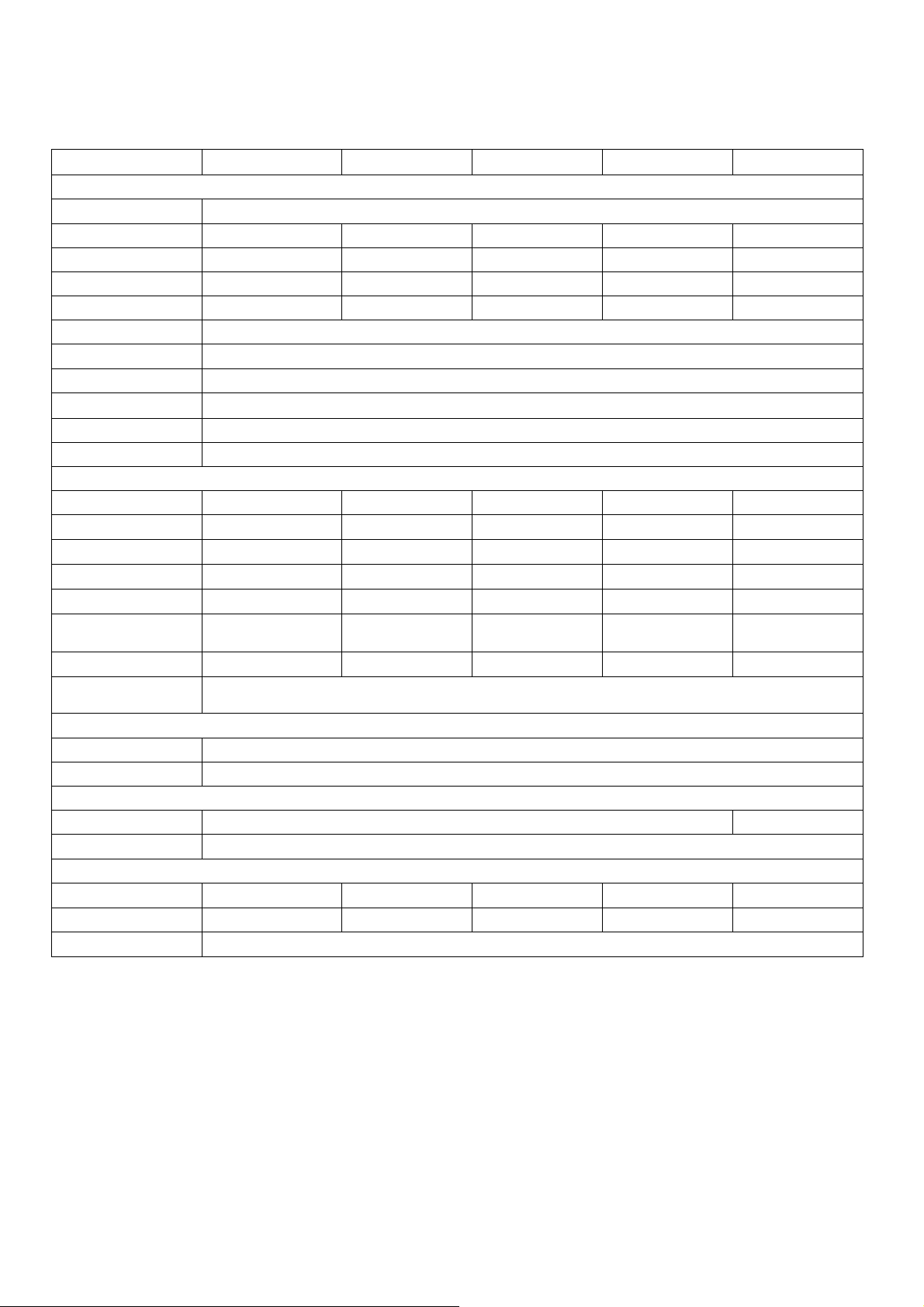

1.3 SPECIFICATION

RXL50 RXL70 RXL90 RXL90R RXL50M

ENGINE

TYPE AIR-COOLING TWO STROKE

DISPLACEMENT

BORE & STROKE 40.0*39.2 mm 47.0*39.2 mm 50.0*42.0 mm 50.0*42.0 mm 40.0*39.2 mm

COMPRESSION

MAXIMUN TORQUE

CARBURETOR MIKUNI VM16 (for other country) / SW 18 mm-Manual Choke (for America)

IGNITION CAPACITOR DISCHARGE

STARTING ELECTRIC/KICK START

LUBRICATION AUTO OIL INJECTION

OIL CAPACITY 1.0 LITER

TRANSMISSION AUTOMATIC (C.V.T. V-Belt)

CHASSIS

OVERALL LENGTH 1470mm (57.9") 1470mm (57.9") 1500mm (59.0") 1500mm (59.0") 1430mm (56.3")

OVERALL WIDTH 850mm (33.5") 850mm (33.5") 850mm (33.5") 850mm (33.5") 820mm (32.3")

OVERALL HEIGHT 830mm (32.7") 830mm (32.7") 900mm (35.4") 900mm (35.4") 800mm (31.5")

SEAT HEIGHT 650mm (25.5") 650mm (25.5") 670mm (26.3") 670mm (26.3") 650mm (25.5")

WHEEL BASE 930mm (36.1") 930mm (36.1") 930mm (36.1") 930mm (36.1") 930mm (36.1")

GROUND

CLEARANCE 110mm (4.3") 95mm (3.7") 120mm (4.7") 130mm (5.1") 110mm (4.3")

DRY WEIGHT 108kg 108 kg 113 kg 113 kg 108kg

FUEL

TANK CAPACITY

SUSPENSION

FRONT DUAL A-ARM

REAR SWING ARM

BRAKES

FRONT DUAL MECHANICAL DRUM N/A

REAR HYDRAULIC DISC

TIRES

FRONT 16" *8"-7 16" *8"-7 18" *7"-8 18" *7"-8 145/70-6

REAR 16" *8"-7 16" *8"-7 18" *9"-8 18" *9"-8 145/70-6

COLORING Red /Blue /Yellow /Black

Specifications subject to change without notice.

49.3 ㏄ 68.0 ㏄ 82.5 ㏄ 82.5 ㏄

9.2:1 8.3:1 7.9:1 7.9:1 9.2:1

5.2 N-m @ 7000rpm 6.3 N-m @ 6000rpm 7.0 N-m @ 7500rpm

7.0 N-m @ 7500rpm 5.2 N-m @ 7000rpm

4.5 LITERS

49.3

3

1.4 SERIAL NUMBER

For this ATV serial; the number of frame and engine are the same position, just like the picture below;

The frame serial number is stamped on the front of the frame.

The engine serial number is stamped on the left side of the crankcase.

Frame serial number

Engine serial number Engine serial number

For RXL 50/70/90/RXL50M For RXL 90R

4

1.5 TORQUE VALUES

For this ATV serial; the torque values of frame and engine are the same, just like the picture below;

ENGINE

● Cylinder head nut

28-30 N.m (20.7-22.1 lbf.ft)

● Spark plug

● Cylinder head bolt

● Alternator bolt

FRAME

● Handlebar upper holder bolt

● Steering shaft nut

● Steering shaft bushing holder nut

● Wheel rim bolt

● Tie rod lock nut

● King pin nut

● Handlebar lower holder nut

● Front wheel bolt

● Front axle nut

● Front brake arm nut

12-19 N.m (8.9-14.0 lbf.ft)

20-30 N.m (14.8-22.1 lbf.ft)

8-12 N.m (5.9- 8.9 lbf.ft)

24-30 N.m (17.7-22.1 lbf.ft)

50-60 N.m (36.9-44.3 lbf.ft)

24-30 N.m (17.7-22.1 lbf.ft)

18-25 N.m (13.3-18.4 lbf.ft)

35-43 N.m (25.8-31.7 lbf.ft)

30-40 N.m (22.1-29.5 lbf.ft)

40-48 N.m (29.5-35.4 lbf.ft)

24-30 N.m (17.7-22.1 lbf.ft)

55-65 N.m (40.6-47.9 lbf.ft)

4-7 N.m (3.0- 5.2 lbf.ft)

● Rear brake arm nut

● Rear axle nut

● Rear wheel bolt

● Exhaust muffler mounting bolt

● Engine hanger bolt

7-12 N.m (5.2- 8.9 lbf.ft)

40-60 N.m (30-45 lbf.ft)

24-30 N.m (17.7-22.1 lbf.ft)

30-35 N.m (22.1-25.8 lbf.ft)

24-30 N.m (17.7-22.1 lbf.ft)

5

2. MAINTENANCE

2.1 MAINTENANCE DATA 2.8 IDLE SPEED

2.2 MAINTENANCE SCHEDULE 2.9 DRIVE CHAIN

2.3 FUEL TUBE 2.10 BRAKE SYSTEM

2.4 THROTTLE OPERATION 2.11 WHEELS AND TIRES

2.5 THROTTLE CABLE ADJUSTMENT 2.12 STEERING SYSTEM

2.6 AIR CLEANER 2.13 TOE-IN

2.7 SPARK PLUG 2.14 GEAR OIL

2.1 MAINTENANCE DATA

SPECIFICATION

SPARK PLUG:

SPARK PLUG GAP: 0.6-0.7 mm

RECOMMENDED SPARK PLUGS: NGK BPR7HS

THROTTLE LEVER FREE PLAY: 5-10 mm

IDLE SPEED: 1800±100 rpm

BRAKE LEVER FREE PLAY: 15-25 mm

DRIVE CHAIN SLACK 10-25 mm

FRONT/REAR TIRE PRESSURE MIN 3.2 psi (0.23 kg/cm

MAX 4.0 psi (0.28 kg/cm2)

TOE-IN 5±10 mm

TORQUE VALUES

SPARK PLUG 12-19 N.m

TIE-ROD LOCK NUT 35-43 N.m

ENGINE OIL JASO FC Grade or same degree oil

GEAR LUBRICATION OIL SAE 90

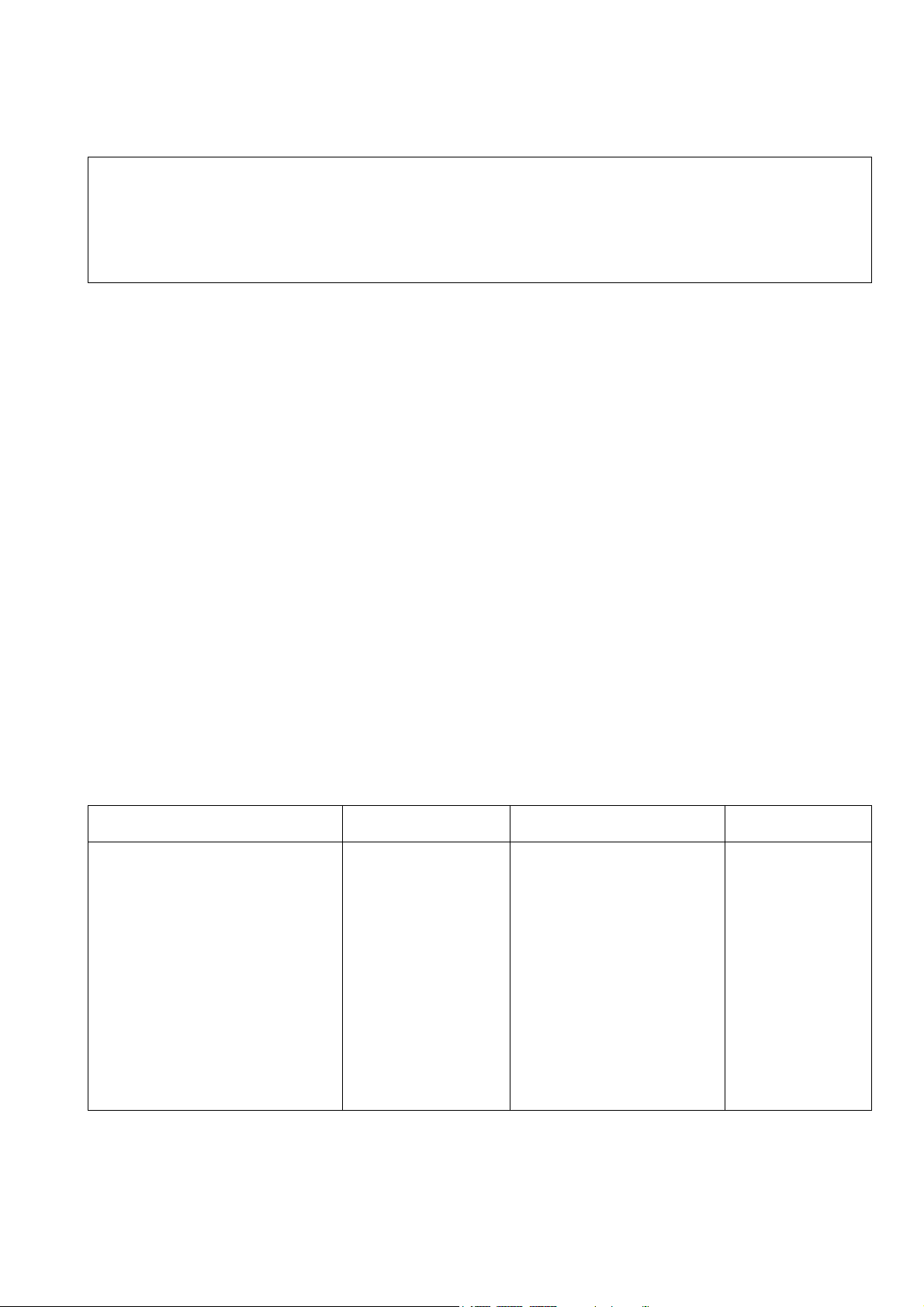

2.2 MAINTENANCE SCHEDULE

The maintenance internals in the follow table is based upon average riding, conditions. Riding in

unusually

dusty areas, require more frequent servicing. (For ATV all serial in this service manual)

INITIAL SERVICE

(First week)

FUEL LINE I

THROTTLE OPERATION I I

AIR CLEANER C

SPARK PLUG I

CARBURETOR IDLE SPEED I I

DRIVE CHAIN I, L I, L

BRAKE SHOE WEAR I

BRAKE SYSTEM I I

NUT, BOLT, FASTENER I I

WHEEL I I

STEERING SYSTEM I

SUSPENSION SYSTEM I

C.V.T. AIR FILTER C

GEAR OIL R

REVERSE GEAR OIL-RXL90R R

Note – I: Inspect and Clean, Adjust, Lubricate or Replace, if necessary

C: Clean L: Lubricate R: Replace

REGULAR SERVICE

(Every 30 operating days)

2

)

EVERY YEAR

6

2.3 FUEL TUBE

Inspect the fuel lines for deterioration, damage or

leakage and replace if necessary. (For RXL50 / 90)

(For RXL70 / RXL90R / RXL50M)

2.4 THROTTLE OPERATION

Inspect for smooth throttle lever full opening and

automatic full closing in all steering positions.

Inspect if there is no deterioration, damage or kinking

in the throttle cable, replace it if necessary.

Check the throttle lever,

of the throttle lever.

Disconnect the throttle cable at the upper end.

Lubricate the cable with commercially lubricant to

prevent premature wear.

free play is 5-10 mm at the tip

2.5 THROTTLE CABLE ADJUSTMENT

Slide the rubber cap of the adjuster off the throttle

Housing, loosen the lock nut and adjust the free play

of the throttle lever by turning the adjuster on the throttle

housing. Inspect the free play of the throttle lever.

7

2.6 AIR CLEANER

Unscrew the air cleaner cover screws.

Pull out the air filter element from the air cleaner case.

Wash the element in non-flammable solvent, squeeze

out the solvent thoroughly.

Let it dry.

Soak the filter element in gear oil and then squeeze

out the excess oil.

Install the element into air cleaner carefully.

2.7 SPARK PLUG

This spark plug located at the front of the engine.

Disconnect the spark plug cap and unscrew the spark plug.

Check the spark plug electrodes for wearness.

Change a new spark plug if the electrodes and insulator tip

appear unusually fouled or burned.

Discard the spark plug if there is apparent wear or if the

insulator is cracked or chipped.

The spark plug gap shall keep in 0.6-0.7mm.

With the sealing washer attached, thread the spark plug in

by hand to prevent cross threading.

Tighten the spark plug with 12-19 N.m

2.8 IDLE SPEED

Connect an engine speed meter.

Warm up the engine, 10 minutes are enough.

Turn the idle-speed adjust screw on the carburetor

to obtain the idle speed. “Turn in” (clockwise) will get higher

speed. “Turn out” (counter clockwise) will get lower speed.

IDLE SPEED: 1800±100 rpm

2.9 DRIVE CHAIN

Inspect the chain slack. The standard is 10-25mm.

8

Adjust the chain slack.

Loose the lock bolts (4 pcs) then adjust the drive chain

slack by turn the adjusting nut.

Tighten the four lock bolts.

When the drive chain becomes very dirty, it should be

removed, cleaned and lubricated by specify lubricator.

Using commercial chain lubricant to lubricate the drive

chain.

Clean the drive chain with kerosene and wipe it dry.

Inspect the drive chain for possible wear or damage.

R eplace the chain, if it is worn excessively or damaged.

Inspect the sprocket teeth, if it is excessive wear

r damage, replace it. o

Inspect the chain-tensioned roller.

R eplace it, if necessary.

2.10 BRAKE SYSTEM

Inspect the front brake lever and cable for excessive

play or other damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end of the

rake lever. The standard of free play is 15-25 mm. b

(For RXL50 / 90 / RXL90R, the ATV RXL50M doesn’t have

t he front brake lever. )

9

For RXL50M, because it have parking brake in rear tire.

So, its controller is at the handler bar right side.

Inspect the rear brake lever and cable for excessive

play or other damage.

Replace or repair if necessary.

Measure the free play of the rear brake lever at the end of

the lever. The standard is 15-25 mm.

( For all type)

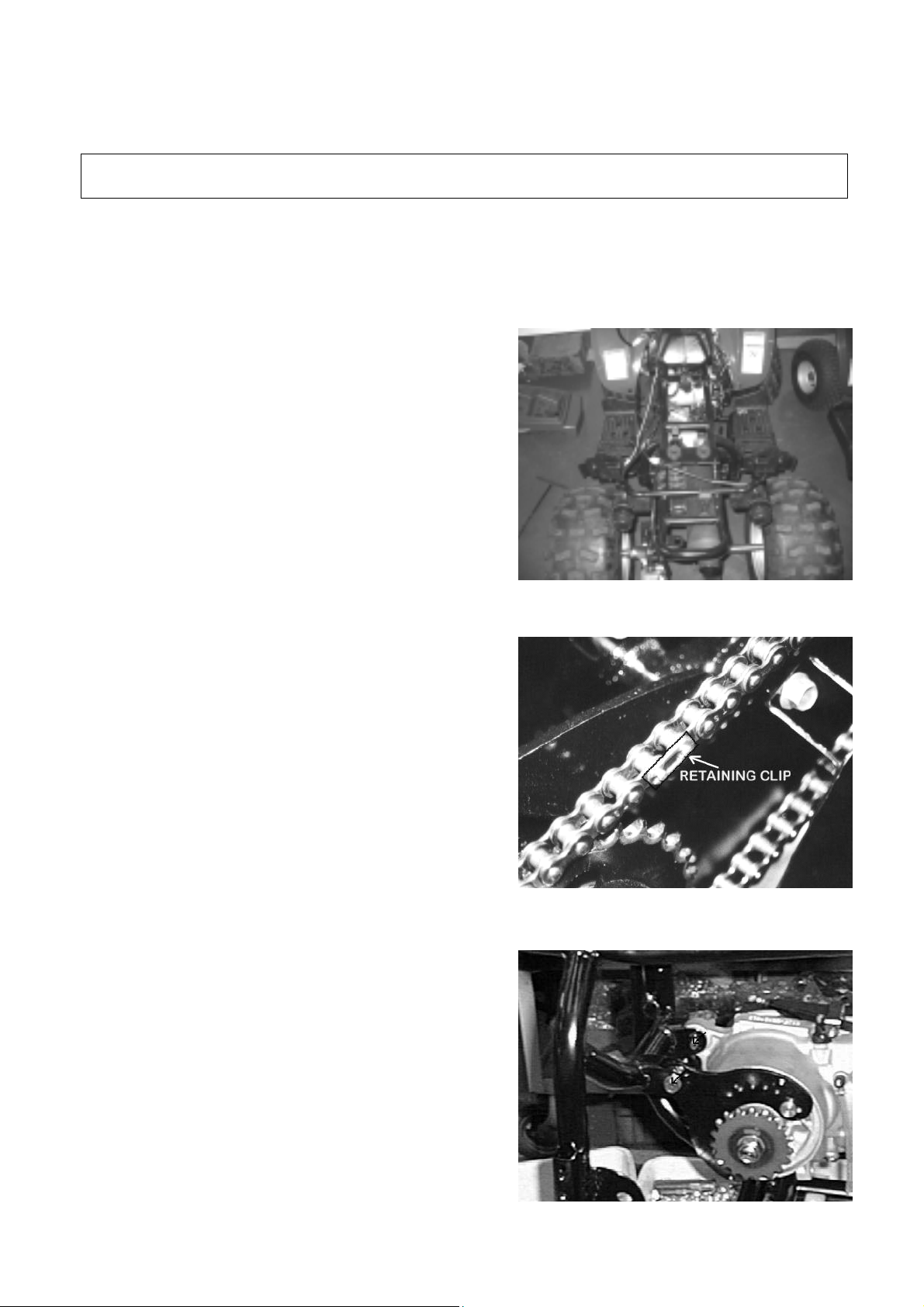

2.11 WHEELS AND TIRES

Inspect the tire surfaces for cuts, nails or other

sharp objects.

Check the tire surfaces at cold tire condition.

The standard of tire pressure is

MIN 3.2 psi. (0.23 kgf/cm

MAX 4.0 psi. (0.28 kgf/cm

2.12 STEERING SYSTEM

Check the free play of the steering shaft with the front

wheels, turned straight ahead.

When there is excessive play, inspect the tie-rod,

kingpin bushing and ball joint.

2

)

2

)

10

2.13 TOE-IN

Let the vehicle on level ground and the front wheels

facing straight ahead.

Mark the centers of the tires to indicate the axle

center height.

Measure the distance between the marks.

Carefully move the vehicle back, let the wheels have

turned 180 °, so the marks on the tires are aligned

with the axle center height.

Measure the distance between the marks.

Calculate the difference in the front and rear

measurements.

Toe-in: 5±10mm

If the toe-in is out of standard, adjust it by changing

the length of the tie-rods equally by turning the tie-rod

while holding the ball joint.

Tighten the lock nuts.

Torque: 35-43 N.m

2.14 GEAR OIL

Gear oil needs to be changed every year.

There is a gear oil release bolt at the rear of engine.

Unscrew this release bolt and can let the dirty oil flow out.

The re-add oil hole is on the engine case beside gearbox.

(CAUTION: Only the ATV RXL 90R must add the reverse oil)

11

3. ENGINE REMOVAL AND INSTALLATION

3.1 SERVICE INFORMATION 3.3 ENGINE INSTALLATION

3.2 ENGINE REMOVAL

3.1 ENGINE SHALL BE REMOVED IN THE CONDITIONS OF NECESSARY REPAIRMENT OR

ADJUSTMENT TO THE TRANSMISSION AND COMBUSTION SYSTEM ONLY

3.2 ENGINE REMOVAL

Remove the seat and rear fender. (Chapter 11)

Remove the spark plug cap from the spark plug.

Remove the exhaust pipe.

Disconnect the carburetor cable by unscrew two screws

on top of the carburetor.

Take off oil pump cable from the oil pump control plate.

Oil pump is under the right side of engine.

Disconnect the wire connectors. There are three

connectors for carburetor auto-choke, starter motor

and generator respectively.

Remove the drive chain cover. This is under the chain.

Remove the drive chain retaining clip and master link,

and remove the drive chain.

Remove the three engine hanger nuts and bolts.

Remove the engine from the right side of frame.

(The pictures of right side are for ATV RXL 50 / 70 / 90

and RXL 50M)

12

(The right side picture is for ATV RXL 90R)

3.3 ENGINE INSTALLATION

Engine installation is essentially the reverse order of removal.

The torque of engine hanger bolt is 24-30 Nm

Route the wires and cable in reverse order properly.

13

4. ENGINE FUEL SYSTEM

4.1 TROUBLESHOOTING 4.3 CARBURETOR

4.2 FUEL TANK

4.1 TROUBLESHOOTING

ENGINE CAN NOT START

★

NO FUEL IN TANK

ENGINE IDLES UNSTEADY, STALLS OR RUNS

POORLY

LEAN MIXTURE

★

N

★

OO MUCH FUEL GO INTO CYLINDER

T

★

N

★

A

★

U

IDLE SPEED SCREW

★

I

GNITION MALFUNCTION

★

UEL/AIR MIXTURE RATIO NO GOOD

F

★

A

★

NSULATOR LEAKS

I

★

UEL TANK CAP BREATHING HOLE

F

CLOGGED

★

FUEL JET OF CARBURETOR CLOGGED

★

F

UEL TANK CAP BREATHING HOLE

CLOGGED

★

UEL FILTER CLOGGED

F

O FUEL TO CYLINDER

O SPARK AT PLUG

IR CLEANER CLOGGED

NPROPER ADJUSTMENT TO THE

IR CLEANER DIRTY

RICH MIXTURE

★

F

UNSMOOTHLY

★

F

LOW

★

F

CARBURETOR

★

F

★

A

CLOGGED

★

A

14

UEL FLOWS IN THE TUBE

LOAT LEVEL IN CARBURETOR TOO

LOAT NEEDLE VALVE IN

FAULTY

LOAT LEVEL TOO HIGH

IR DUCT IN CARBURETOR IS

IR CLEANER DIRTY

4.2 FUEL TANK

REMOVAL

Remove the seat and rear fender.

Disconnect the fuel line from the carburetor.

Remove the fuel tank cap and front fender.

Unscrew the fuel tank fixed bolts.

Note: Keep gasoline away from flames or sparks.

Wipe up spilled gasoline at once.

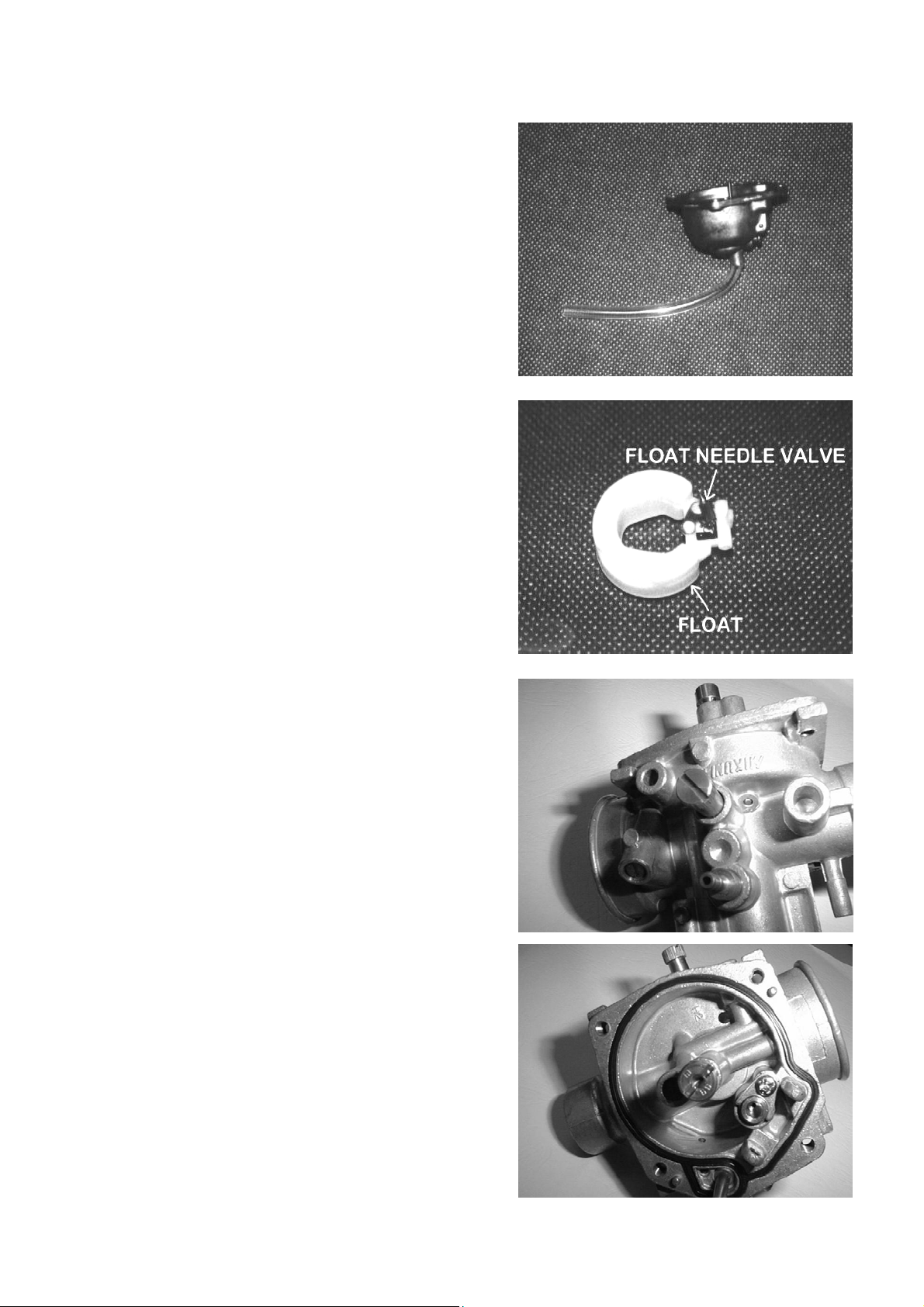

4.3 CARBURETOR

REMOVAL

Remove the air cleaner.

Disconnect the fuel line and auto-choke electric wire.

Unscrew the intake pipe mounting bolts at the

carburetor then removes the carburetor.

Note: Turn fuel cup on (off) position

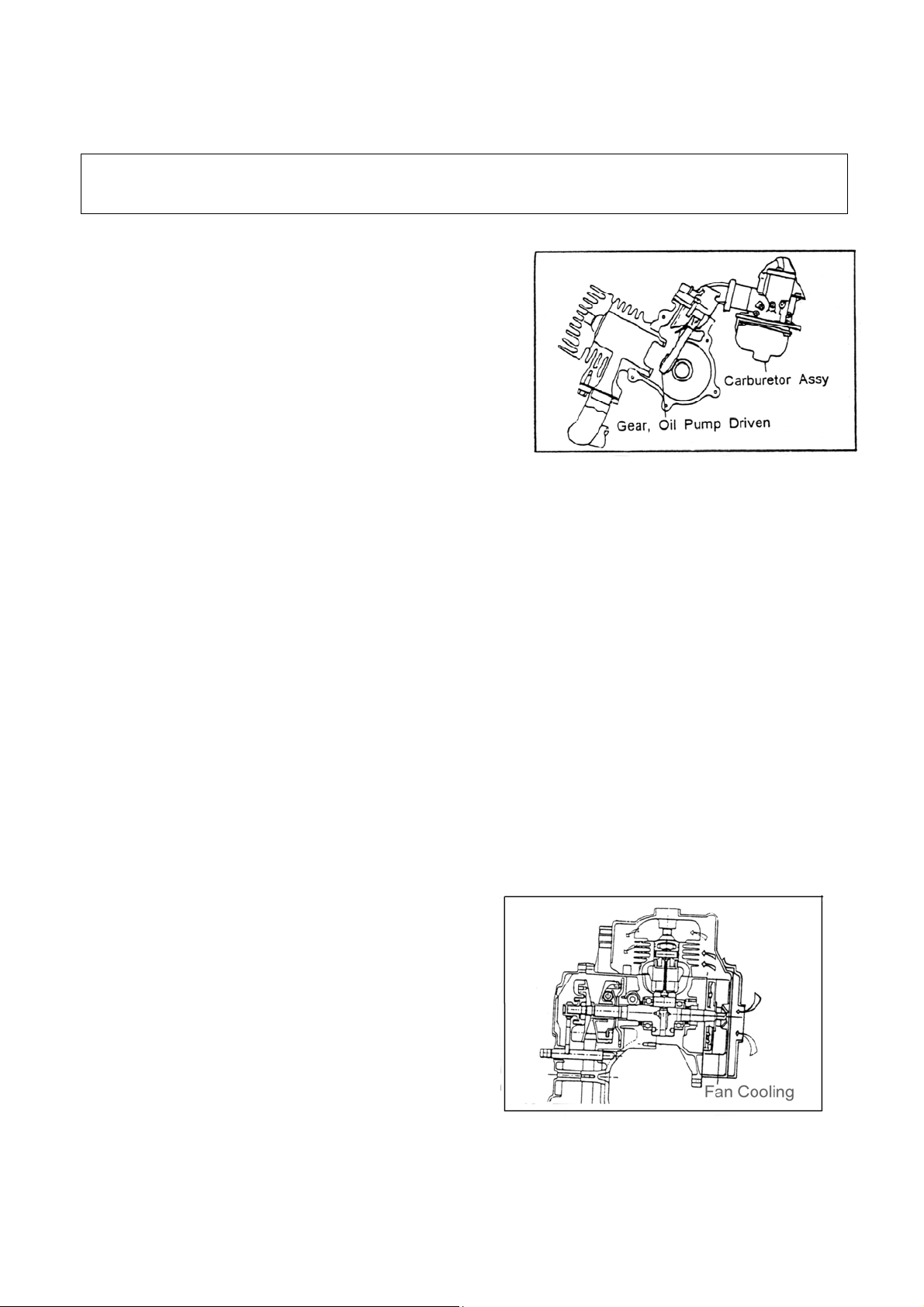

Remove the carburetor cap.

Remove the throttle cable from the throttle valve while

depressing the throttle valve spring.

Remove the needle clip retainer, the jet needle and

needle clip. Inspect the throttle valve and

jet needle surface for wearness, scratches or dirt.

15

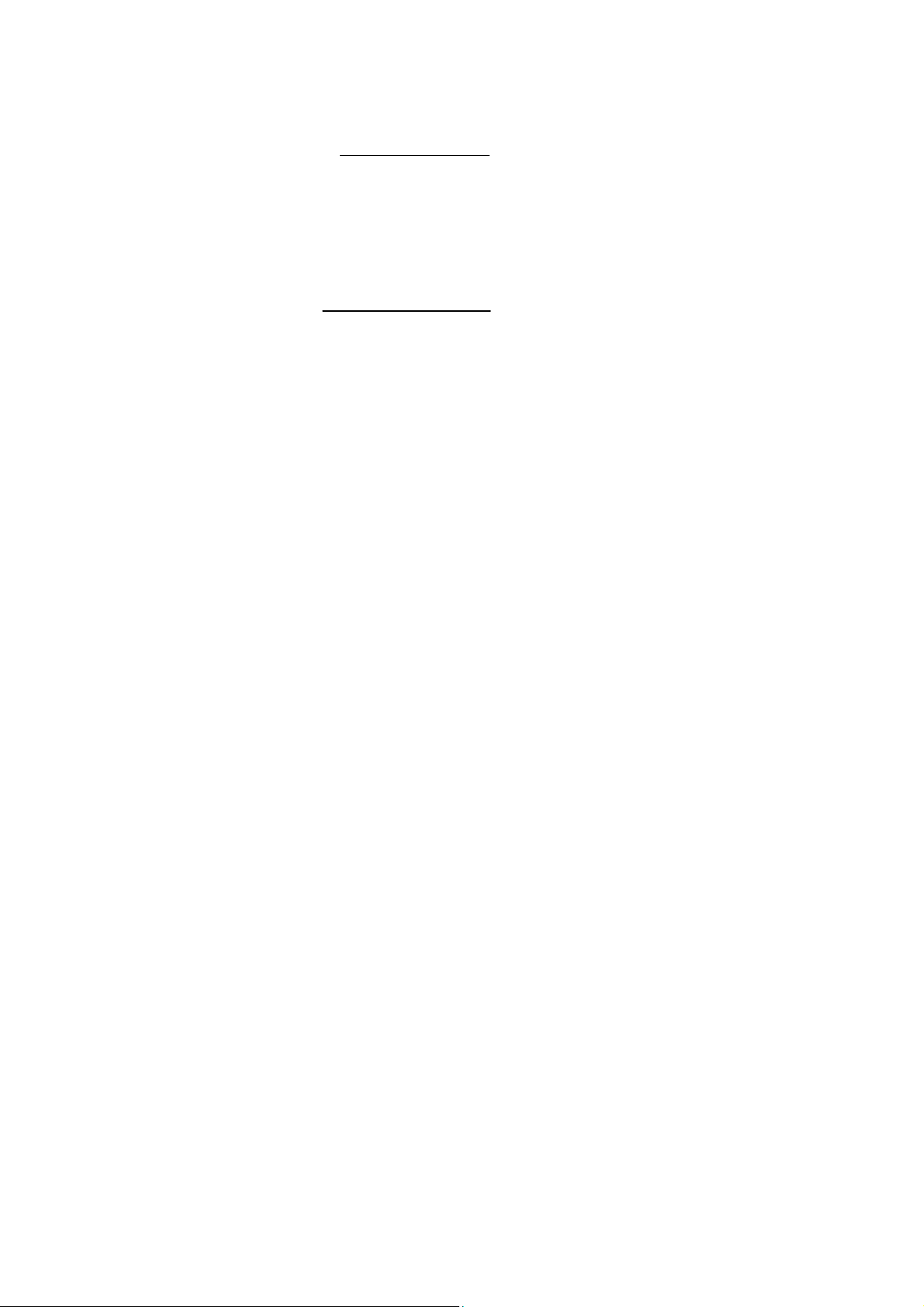

DISASSEMBLY

Unscrew the float chamber screws and remove

the float chamber.

Disassembly the float arm pin, float and

float needle valve.

Inspect the seat of the float needle valve for

wear or damage.

Disassembly the idle jet, main jet, idle speed adjust

screw and idle mixture adjusts screw.

Inspect all the jets and screws for wear or damage.

Clean the passages and jets with compressed air.

16

ASSEMBLY

Clean all parts in solvent and blow it dry with compressed air.

Assembly is essentially the reverse order of disassembly.

THROTTLE VALVE ASSEMBLY

Install the needle clip on the jet needle.

Install the jet needle into the throttle valve.

Assembly the throttle cable, spring and the throttle valve.

Align the throttle valve groove with the idle speed adjust

screw and install the carburetor cap to the carburetor.

17

5. ENGINE LUBRICATION AND COOLING SYSTEM

5.1 ENGINE LUBRICATION SYSTEM 5.4 COOLING SYSTEM

5.2 CAUTION

5.3 OIL PUMP

5.1 ENGINE LUBRICATION SYSTEM

The engine drives the pump gears of oil pump

crankshaft. Pump gears rotate the plunger shaft in oil

pump. This shaft sent the lubricating oil into the crankcase

to mix with the mixture of air-fuel flow evenly.

The oil drops and foam cover the cylinder inner wall,

piston surface and piston rings.

5.2 CAUTION

Having enough oil supply to engine is very important.

If the oil quantity is not enough, this engine will be serious scratched, and then this engine will stop, even

cannot work again.

When this engine is serious scratched, you need to change the piston, piston rings and cylinder together.

Also you need to check the combustion system and lubrication system carefully.

5.3 OIL PUMP

The quantity of oil that deliver out from oil pump increased by the engine speed and the carburetor throttle

open width. Oil pump is under the right side of the engine and connected by a control cable of throttle.

5.4 COOLING SYSTEM

The engine-cooling fan sucks the air.

The cooling fan is on the right side of engine.

The air is forced to flow through cylinder fin and

cylinder head. So, the cylinder and piston will not

over heat.

5.5 TROUBLESHOOTING

18

5.5 TROUBLESHOOTING

NO ENOUGH OIL SUPPLY TO ENGINE

ALWAYS INSUFFICIENT OIL LEVEL

IN LUBRICATE OIL TANK

THE OIL LEVEL IN OIL TANK IS TOO LOW.

★

OIL TUBES WERE NOT FIXED WELL.

★

OIL HAS LEAKAGED FROM TUBE ENDS.

★

OIL TUBES WERE BROKEN.

★

OIL TUBES WERE CLOGGED.

★

OIL PUMP CANNOT WORK.

★

EXTERNAL OIL LEAKS

★

WORN CYLINDE HEAD GASKET

★

WORN PISTON RINGS

★

19

Loading...

Loading...