Etel Tool DSB2-P User Manual

Digital servo amplifier |

MOTION TECHNOLOGY |

DSB2-P Hardware manual

|

|

|

|

|

|

|

|

|

|

HEADQUARTERS |

ETEL G.m.b.H |

ETEL Inc. |

ETEL B.V. |

|

|

|

|

|

|

|

|

|

|

ETEL S.A. |

Schillgasse 14 |

333 E. State Parkway, |

Landjuweel 20 |

|

|

|

|

|

|

|

|

|

|

CH-2112 Môtiers |

D-78661 Dietingen |

USA - Schaumburg |

NL-3905 PG Veenendaal |

|

|

|

|

|

|

|

|

|

|

Switzerland |

Germany |

Illinois 60173-5337, |

The Netherlands |

|

|

|

|

|

|

|

|

|

|

Phone : +41 32 862 01 23 |

Phone : +49 741 17453-0 |

Phone : +1 847 519 3380 |

Phone : +31 318 495 200 |

|

|

|

|

|

|

|

|

|

|

Fax : +41 32 862 01 01 |

Fax : +49 741 17453-99 |

Fax : +1 847 490 0151 |

Fax : +31 318 495 210 |

|

DSB2P |

|

904 |

|

ver. |

|

D |

|

|

E-mail : etel@etel.ch |

E-mail : etel@etelgmbh.de |

E-mail : info@etelusa.com |

E-mail : etel@etelbv.nl |

|

|

|

|

|

|

http://www.etel.ch |

|

http://www.etelusa.com |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright ETEL SA. All rights reserved. Reproduction, adaptation or translation of this document is prohibited without prior written permission. ETEL SA. makes no warranty for the use of its products and assume no responsibility for any errors which may appear in this document.

ETEL SA retains the right to make any change to these specifications at any time, without notice.

THIS PAGE IS INTENTIONALLY LEFT BLANK

Hardware manual DSB2-P

Direct Drives & Systems |

3 |

MOTION TECHNOLOGY

Table of contents

1. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

||

|

1.1 |

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

1.2 |

DSB2-P presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.2.1 |

Working principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.2.2 |

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.2.3 |

General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.2.4 |

Interfaces possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

2. |

Models characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

||

|

2.1 |

Modules main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

|

2.2 |

Rack module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

2.2.1 |

Outline and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

2.2.2 |

Block schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

|

2.2.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

|

2.2.4 Mounting systems – Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

||

|

2.3 |

Rack module with heat sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

|

2.3.1 |

Outline and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

|

2.3.2 |

Block schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

|

2.3.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

|

2.3.4 Mounting systems – Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

||

|

2.4 |

Housed module without power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

2.4.1 |

Outline and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

2.4.2 |

Block schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

|

2.4.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

|

2.4.4 |

Mounting systems - installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

|

2.5 |

Housed module with power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

|

2.5.1 |

Outline and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

|

2.5.2 |

Block schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

|

2.5.3 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

2.5.4 |

Mounting systems - installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

3. |

Electrical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

||

|

3.1 |

Encoders connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

3.1.1 Connector J10: TTL position encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

||

|

3.1.2 Connector J1: Analog position encoder (1Vptp, 11µAptp) . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

||

|

3.1.3 Connector J9: Digital Hall encoder & over temperature protection . . . . . . . . . . . . . . . . |

32 |

||

|

3.2 |

Inputs / outputs connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

|

3.2.1 Connector J2: Customers inputs / outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

||

|

3.3 |

Communication connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

ETEL Doc. - Hardware manual # DSB2P 904 / Ver D / 4/11/02

4 |

|

Hardware manual DSB2-P |

|

|

|

|

|

|

|

|

|

|

Direct Drives & Systems |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTION TECHNOLOGY |

||||||||

3.3.1 Connector J3: ETEL-Bus output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

||||||||||

3.3.2 Connector J4: ETEL-Bus input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

||||||||||

3.3.3 Connector J5: ETEL-Bus-Lite serial communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

||||||||||

3.3.4 Connector J6: Download key and EB-RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

||||||||||

3.4 |

Motor connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|||||||||

3.4.1 ETEL motor cables numbering system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

||||||||||

3.4.2 Connector J7: Standard motor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

||||||||||

3.4.3 Connector J7B: Motor connection with short circuit relay option . . . . . . . . . . . . . . . . . |

40 |

||||||||||

3.4.4 Connector J16: Short circuit relay control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

||||||||||

3.5 |

Power connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|||||||||

3.5.1 Connector J11: Rack modules power supply input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

||||||||||

3.5.2 Connector J15: Housed module auxiliary and power supply input . . . . . . . . . . . . . . . . |

43 |

||||||||||

3.5.3 Connector J14: Housed module power supply input . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

||||||||||

3.5.4 Connector J13: Housed module auxiliary supply input . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

||||||||||

3.5.5 Connector J12: External regeneration resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

||||||||||

3.6 |

Optional board connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|||||||||

3.6.1 Connector J8: Depends on the type of board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

||||||||||

3.7 |

EMC cables connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|||||||||

3.7.1 |

Cables manufacturing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|||||||||

3.7.2 Connecting the short-circuit relay power cable's shield (J16) . . . . . . . . . . . . . . . . . . . . |

47 |

||||||||||

3.7.3 Connecting the external regeneration resistor cable's shield (J12) . . . . . . . . . . . . . . . . |

47 |

||||||||||

3.7.4 |

Cables installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|||||||||

ETEL Doc. - Hardware manual # DSB2P 904 / Ver D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

5 |

MOTION TECHNOLOGY

Record of revisions, document # DSB2P 904 x

|

|

|

|

Document revisions |

Issue (x) |

|

Date |

|

Modified |

|

|

|||

|

|

|

|

|

1.0 |

|

- |

|

First edition (French) |

|

|

|

|

|

1.1 |

|

23/06/98 |

|

Document updated and translated in English |

|

|

|

|

|

A |

|

14/10/98 |

|

Document completed and updated, doc. numbering system modified |

|

|

|

|

|

B |

|

01/02/99 |

|

Document updated (minor changes and some errors corrected) |

|

|

|

|

|

C |

|

03/03/00 |

|

Document updated (minor changes and guideline for EMC & shielding added) |

|

|

|

|

|

D |

|

04/11/02 |

|

Document updated (housed module updated and some errors corrected) |

|

|

|

|

|

Documentation concerning the DSB2-P

• |

Hardware manual DSB2-P |

(Specifications & electrical interfaces) |

# DSB2P 904 D |

• Operation & software manual |

(DSB2-P programming & regulation description) |

# DSB2P 906 x |

|

• |

EBL Communication manual |

(Communication interface protocol) |

# DSB2P 908 x |

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

6 |

Hardware manual DSB2-P |

Direct Drives & Systems |

MOTION TECHNOLOGY

1.Introduction

This document concerns the following ETEL digital servo amplifier: the DSB2 position controller or DSB2-P, also called 'drive’ in this document.

The purpose of this manual is to give details regarding specifications, installation, interfacing and hardware items. All details for proper connections (power supply, motor, encoder connection, etc...) are provided herein. Detailed information concerning the programming of the drive is provided in the «Operation & software manual».

1.1Safety

Please, read all safety precautions listed below before handling the DSB2-P:

•Never use the DSB2-P for purposes other than those described in this manual.

•A competent and trained technician must install and operate the DSB2-P, respecting all specific regulations of the respective country concerning both safety and EMC aspects.

•Troubleshooting and servicing are permitted only for ETEL technicians and agreed distributors.

•Operating the DSB2-P will make the motor move. Keep away from all moving parts to avoid injuries!

•The safety symbols placed on the DSB2-P or written in this manual must be respected.

Danger: Signals a danger of electrical shock to the operator.

Can be fatal for a person.

Caution: Signals a danger for the DSB2-P. Can be destructive for the material.

A danger for the operator can result from this.

Caution: Indicates electrostatic discharges (ESD), dangerous for the DSB2-P.

The components must be handled in an ESD protected environment, only.

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

7 |

MOTION TECHNOLOGY

1.2DSB2-P presentation

1.2.1Working principle

The DSB2-P is a position, pseudo-speed1 and torque/force digital controller. It has been designed for direct drive applications. Its power bridge PWM switching is determined by the motor position encoder.

The rack module includes on a single board the control circuits, the power bridge and all necessary interfaces for the communication, the encoder and the inputs/outputs.

The housed model includes also the power supplies on a second board inside the same housing.

1.2.2Applications

The DSB2-P can drive mono-phase, two-phase and three-phase motors.

You may obtain brushless torque and linear motors from ETEL, as well as moving coils and moving magnets.

The DSB2-P can drive these motors and also the brushless motors, DC motors, steppers (if they are implemented with incremental encoders available on the market).

1.2.3General operating conditions

The DSB2-P is designed to operate in a non-aggressive environment, with normal conditions of temperature, humidity, pressure and cleanliness. More specific information is given for each model in §2.

The DSB2-P is not designed or intended for use in the on-line control of air traffic, aircraft navigation and communications or in the design, construction, operation and maintenance of any nuclear facility.

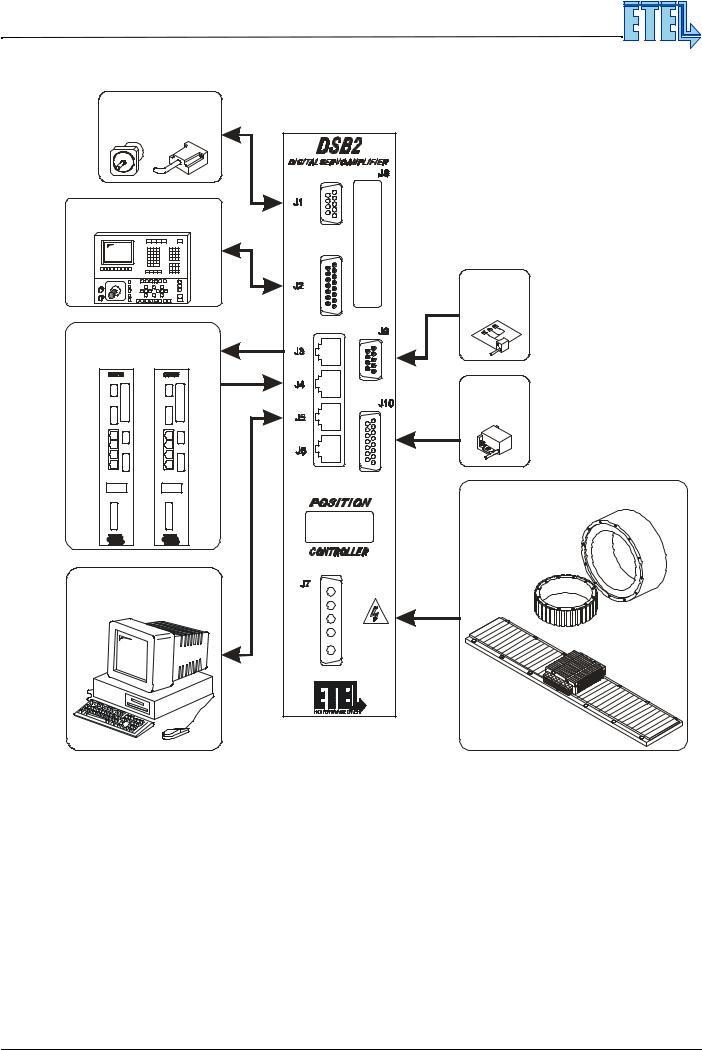

1.2.4Interfaces possibilities

Motor and its position encoder:

To control the position of a rotary or linear motor, the DSB2-P needs the signal coming from an analog or TTL encoder linked to this motor.

Communication:

The user can set the DSB2-P with a PC (Win9x/2000/NT/XP) using ETEL Tools (ETT) software through the ETEL-Bus-Lite (RS232 / RS422) communication port. See the «ETT Setup software manual» and the «EBL Communication manual» for more information.

After the drive setting, an 'host' (a PC, a CNC2machine-tool, or a PLC3, f.e.) may be linked to the same interface to send 'on-line' commands to the DSB2-P or / and to continuously check its status. See the «DSB2-P Operation & software manual» for more details.

The user can daisy chain up to 32 DSB2-Ps (up to 31 slaves per master) on the ETEL-Bus (EB) communication bus.

Inputs / Outputs:

The customer's inputs / outputs can be digital and analog signals coming from a CNC machine-tool, a PLC or a joystick for example (see the diagram on next page).

The electrical interface details are given in §3.

1.If you specifically need a speed control, use a 2.Computer Numerical Control 3.Programmable Logic Controller

DSB2-S drive (refer to the DSB2-S specific documentation).

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

8 |

Hardware manual DSB2-P |

Direct Drives & Systems |

MOTION TECHNOLOGY

The solutions used in most applications are outlined below:

Rotary / linear analog encoder or ETEL magnetic encoder

Customers inputs / outputs (CNC, PLC or joystick, f.e.)

Digital Hall

sensor and

temperature protection

ETEL DSB2-P (up to 31 slaves)

Linear / rotary TTL encoder

Rotary or linear motor

Communication with PC / CNC / PLC (setup with ETT software or 'host' commands)

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

9 |

MOTION TECHNOLOGY

2.Models characteristics

Four models of the DSB2-P are available, according to the needs:

1.Rack module (see §2.2)

2.Rack module with heat sink (see §2.3)

These 2 modules are dedicated to be mounted inside a standard 6U rack (19 in). They do not include any power supply board and need to be powered through their DC power connector (J11) by an external power supply (the ETEL DSO-PWR, f.e.), ideally installed inside of the rack.

3.Housed module without power supply (see §2.4)

4.Housed module with power supply (see §2.5)

These two modules are a 'stand alone' drive. They includes a complete drive with either its power supply or an external power connector inside the same housing. The main difference between the rack modules and the housed module outlines concerns the power supply connectors.

2.1Modules main features

|

|

Rack module |

Standard (10F wide / 6U high) rack module. |

|||

|

|

|

|

|

|

Up to 21 A output current (2 secs.) depending on the model. |

|

|

|

|

|

|

Needs a regulated 24 - 340 Volts DC supply input. An ETEL power supply is available: DSO-PWR. |

|

|

|

|

|

|

Position, pseudo-speed, or force reference. Pulse/direction mode available. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Two 16 bits microprocessors. |

|

|

|

|

|

|

Communication with PC / CNC / PLC through RS232 / RS422, up to 115'200 bauds (EBL open protoc). |

|

|

|

|

|

|

Multi-axis communication, up to 32 drives daisy-chained (ETEL-BUS, closed protocol). |

|

|

|

|

|

|

Analog or TTL position encoder interface. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional interfaces: DSO-SIO, DSO-PRO, DSO-CAN and DSO-MAC. |

|

|

|

|

|

|

User programmable sequences. |

|

|

|

|

|

|

Specific ETEL graphical interface for setup, tuning and monitoring called ETEL Tools (ETT). |

|

|

|

|

|

|

|

|

Rack module with heat sink |

Standard (14F wide / 6U high) rack module. |

||||

|

|

|

|

|

|

Up to 42 A (2 secs.) / 56 A (1 sec) output current, depending on the model. |

|

|

|

|

|

|

Needs a regulated 24 - 340 Volts DC supply input. An ETEL power supply is available: DSO-PWR. |

|

|

|

|

|

|

Position, pseudo-speed, or force reference. Pulse/direction mode available. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Two 16 bits microprocessors. |

|

|

|

|

|

|

Communication with PC / CNC / PLC through RS232 / RS422, up to 115'200 bauds (EBL open protoc). |

|

|

|

|

|

|

Multi-axis communication, up to 32 drives daisy-chained (ETEL-BUS, closed protocol). |

|

|

|

|

|

|

Analog or TTL position encoder interface. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional interfaces: DSO-SIO, DSO-PRO, DSO-CAN and DSO-MAC. |

|

|

|

|

|

|

User programmable sequences. |

|

|

|

|

|

|

Specific ETEL graphical interface for setup, tuning and monitoring called ETEL Tools (ETT). |

|

|

|

|

|

|

|

|

Housed module |

'Stand alone' housed model (65.2 x 168.7 x 318 [mm]). |

||||

|

without power supply |

|||||

|

Up to 21 A output current (2 secs.) depending on the model. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Needs a regulated 24 - 340 Volts DC supply input. |

|

|

|

|

|

|

Position, pseudo-speed, or force reference. Pulse/direction mode available. |

|

|

|

|

|

|

Two 16 bits microprocessors. |

|

|

|

|

|

|

Communication with PC / CNC / PLC through RS232 / RS422, up to 115'200 bauds (EBL open protoc). |

|

|

|

|

|

|

Multi-axis communication, up to 32 drives daisy-chained (ETEL-BUS, closed protocol). |

|

|

|

|

|

|

Analog or TTL position encoder interface. |

|

|

|

|

|

|

Optional interfaces: DSO-SIO, DSO-PRO, DSO-CAN and DSO-MAC. |

|

|

|

|

|

|

User programmable sequences. |

|

|

|

|

|

|

Specific ETEL graphical interface for setup, tuning and monitoring called ETEL Tools (ETT). |

|

|

|

|

|

|

|

|

Housed module |

'Stand alone' housed model (96 x 222 x 306 [mm]). |

||||

|

with power supply |

Up to 42 A (2 secs.) / 56 A (1 sec) output current, depending on the model. |

||||

|

|

|

|

|

|

Supplied from mains: 84 - 240 Vac (50-60 Hz). |

|

|

|

|

|

|

Power supply and fan integrated. |

|

|

|

|

|

|

Position, pseudo-speed, or force reference. Pulse/direction mode available. |

|

|

|

|

|

|

Two 16 bits microprocessors. |

|

|

|

|

|

|

Communication with PC / CNC / PLC through RS232 / RS422, up to 115'200 bauds (EBL open protoc). |

|

|

|

|

|

|

Multi-axis communication, up to 32 drives daisy-chained (ETEL-BUS, closed protocol). |

|

|

|

|

|

|

Analog or TTL position encoder interface. |

|

|

|

|

|

|

Optional interfaces: DSO-SIO, DSO-PRO, DSO-CAN and DSO-MAC. |

|

|

|

|

|

|

Options: Phases short-circuit relay - Output for external regeneration resistor. |

|

|

|

|

|

|

User programmable sequences. |

|

|

|

|

|

|

Specific ETEL graphical interface for setup, tuning and monitoring called ETEL Tools (ETT). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

10 |

Hardware manual DSB2-P |

Direct Drives & Systems |

MOTION TECHNOLOGY

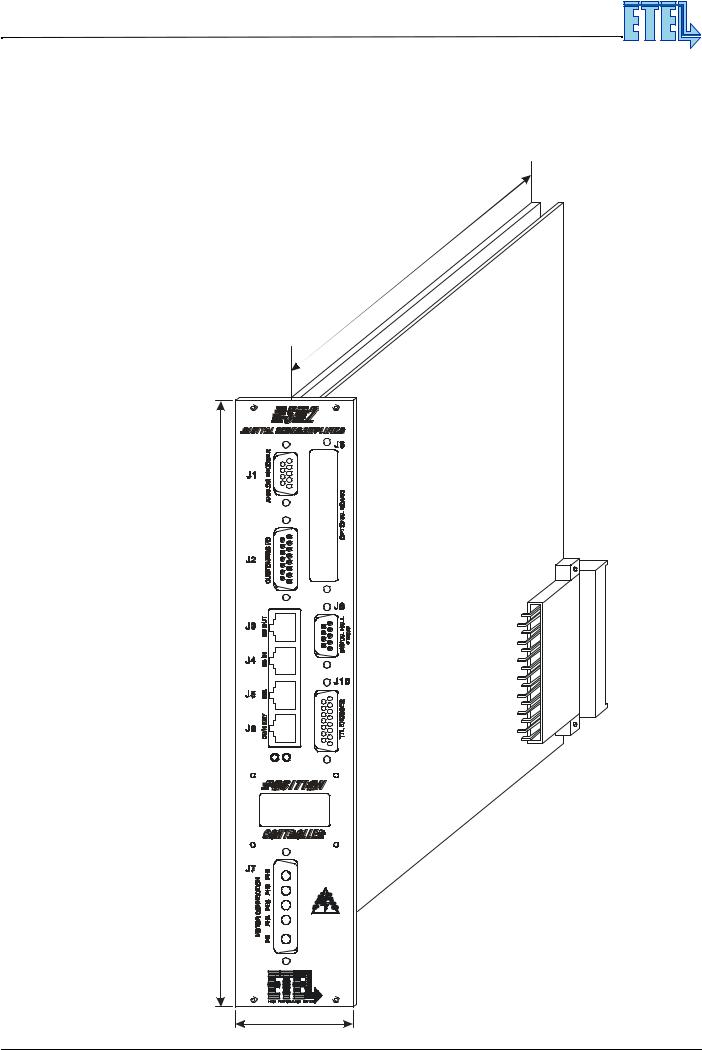

2.2Rack module

Type # : D S B 2 P x x 1 – x x x E

2.2.1Outline and dimensions

Refer to the following chapters for details about the connectors:

J1 see §3.1.2

J2 see §3.2.1

J3 see §3.3.1

J4 see §3.3.2

J5 see §3.3.3

J6 see §3.3.4

J7 see §3.4.1 |

|

|

J8 see §3.6.1 |

|

|

J9 see §3.1.3 |

|

|

J10 see §3.1.1 |

164.00 |

|

J11 see §3.5.1 |

||

|

|

J11 |

261.80 |

|

|

SERVO |

SERVO |

|

ERROR |

ON |

|

|

|

Standard 6U 10F |

|

DANGER |

Unit: [mm] |

|

|

Weight: 1.1 Kg |

|

HIGT |

|

|

VOLTAGE |

|

50.60 |

|

|

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

11 |

MOTION TECHNOLOGY

2.2.2Block schematics

In the DSB2-P rack module, all parts are on a single board called the servo board.

It needs to be powered by an external power supply. The power supply developed by ETEL (refer to the DSO-PWR User's manual) is designed to fit most applications. If you use another power supply, it must meet all the specifications given on the next page.

On the servo board, the power part and the control part are galvanically separated. Also, some inputs and outputs are insulated from the control part by optocouplers.

EXTERNAL POWER SUPPLY

|

|

|

dI / dt |

|

SERVO |

|

|

|

|

BOARD |

|

||

|

|

|

limitor |

|

||

|

|

|

|

|

|

|

|

Fly- |

|

|

|

GNDpwr |

IGBT power bridge |

|

|

|

|

+Vpwr |

|

|

|

back |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Over / |

IGBT |

(POWER) |

|

|

|

+15V* |

galvanic |

|

||

|

|

under |

drive |

|

||

|

|

+15V |

insulation |

|

||

|

|

voltage |

unit |

|

||

|

|

|

(CONTROL) |

|

||

|

|

|

|

|

|

|

|

DC / DC |

0V |

|

|

|

|

|

(POWER) |

-15V |

Overcurrent |

|

|

|

|

galvanic |

+5V |

detection |

|

|

|

|

insulation |

0V |

|

|

|

|

insu- |

(CONTROL) |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

lated |

Digital |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

inputs |

|

|

|

|

|

|

Digital |

Digital |

|

Digital |

Current meas. |

PH1 PH2 |

PH3 |

||

|

current |

|

|

||||||

3 |

outputs |

control |

|

|

|||||

|

|

loop |

ph 1 & 3 |

|

|

|

|||

|

|

|

|

|

|

|

|

||

|

Digital hall |

|

|

|

|

# |

|

|

|

|

encoder input |

|

|

|

|

~ |

|

|

|

|

Temp |

|

|

|

|

A / D |

|

|

|

|

|

|

|

|

conversion |

|

|

|

|

|

protection |

|

|

|

|

|

|

|

|

insu- |

input |

|

|

|

|

|

|

|

|

A / D |

# |

|

|

|

|

|

|

|

|

lated |

|

|

|

|

|

|

|

||

|

conversion |

~ |

Analog |

|

|

Digital |

ETEL- |

(CONTROL) galvanic insulation POWER( ) |

|

|

|

+ - |

|

|

|||||

|

Analog |

ETEL- |

|

Optional |

|

||||

|

bus-lite |

encoder |

encoder |

|

bus |

|

|||

|

input |

board |

|

|

|||||

|

IN / OUT |

input |

|

input |

IN / OUT |

|

|||

|

|

|

|

|

|||||

PH1 |

PH2 |

PH3 PH4 |

TO MOTOR

Caution: Auxiliary GND (marked 0V in the control part) is internally connected to the front panel of the drive.

Power GND (marked GNDpwr in the power part) is connected to the front panel of the drive through a 22nF capacitor.

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

12 |

Hardware manual DSB2-P |

|

|

|

|

|

|

|

|

|

Direct Drives & Systems |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTION TECHNOLOGY |

|||||||||

2.2.3 |

Specifications |

|||||||||

To meet the specifications listed below, it is recommended to use an ETEL power supply with these 10F rack modules.

There are two types of 10F wide rack modules, according to your power needs. The DSB2-PX21 and the DSB2-PX31. Their auxiliary circuits can be supplied with 96-340Vdc (option -X1) or with 24-55Vdc (option -X2). All specifications are given at 25°C ambient temperature:

|

DSB2-PXX1 POWER FEATURES |

|

|

||

|

Characteristics |

|

-PX21- |

|

-PX31- |

|

|

|

|||

|

|

|

|

|

|

|

Voltage (up to) |

|

|

340 Vdc |

|

|

|

|

|

|

|

|

3-phase motor |

|

4.9 A |

|

4.9 A |

|

|

|

|

|

|

|

Continuous current |

|

3.5(1) Arms |

|

3.5(1) Arms |

|

3-phase motor |

|

11 A |

|

21 A |

|

|

|

|

|

|

|

Max. current during 2 seconds |

|

7.5 Arms |

|

15 Arms |

|

|

|

|

||

|

|

|

|

|

|

Output to the motor |

2-phase motor |

|

4 A |

|

4 A |

|

Continuous current |

|

2.8(1) Arms |

|

2.8(1) Arms |

|

2-phase motor |

|

11 A |

|

21 A |

|

|

|

|

|

|

|

Max. current during 1 second |

|

7.5 Arms |

|

15 Arms |

|

|

|

|

||

|

|

|

|

|

|

|

PWM switching frequency |

|

|

12 / 24 kHz(2) |

|

|

Current ripple frequency |

|

|

24 / 48 kHz(2) |

|

Power supply input |

DC voltage |

|

|

24 - 340Vdc |

|

|

|

|

|

|

|

Max. DC current at 24 - 340 Vdc |

|

8 A / 16 A peak |

|

15 A / 30 A peak |

|

|

|

|

|||

|

|

|

|

|

|

|

DC voltage |

|

|

96-340 Vdc |

|

Auxiliary supply input |

|

|

|

|

|

Max. DC current at 96 Vdc |

|

|

0.5(3) A |

||

for DSB2-PXX1-X1 |

|

|

|

|

|

|

Max. DC current at 340 Vdc |

|

|

0.15(3) A |

|

|

DC voltage |

|

|

24-55 Vdc |

|

Auxiliary supply input |

|

|

|

|

|

Max. DC current at 24 Vdc |

|

|

0.6(3) A |

||

for DSB2-PXX1-X2 |

|

|

|

|

|

|

Max. DC current at 55 Vdc |

|

|

0.25(3) A |

|

(1): Continuous current can be reached only with forced cooling (external fan necessary).

(2): If the firmware is 3.xx, PWM at 24kHz only.

(3): No optional board mounted within the drive, no external device connected to the I/O.

DSB2-PXX1 CONTROL FEATURES

|

Characteristics |

All models |

|

|

|

|

|

|

Digital current loop sampling time |

41.6 s |

|

|

|

|

|

General |

Phases commutation |

with encoder position or digital hall effect |

|

|

|

||

Motion profiles |

Trapezoidal / S-curve / Step / look-up table |

||

|

|||

|

|

|

|

|

Two 16 bits microprocessors |

Dual 80296 |

|

|

|

|

|

Position references |

Position loop sampling time |

166.67 s |

|

|

|

||

Position, pseudo-speed or force reference |

± 10 V |

||

|

|||

|

|

|

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

13 |

MOTION TECHNOLOGY

|

DSB2-PXX1 CONTROL FEATURES |

||

|

Characteristics |

|

All models |

|

|

||

|

|

|

|

|

ETEL-BUS-LITE host (PC) communication |

|

RS232 or RS422 / 9'600 to 115'200 bauds |

|

|

|

|

|

ETEL-BUS multi-axis communication |

|

RS422 / 460'000 bauds or RS232 / 115‘200 (up to 32 axis) |

|

|

|

|

Standard interfaces |

Pulse/direction mode available |

|

Max. 3 MHz |

|

|

|

|

CAN bus interface option |

|

with DSO-CAN board |

|

|

|

||

|

|

|

|

|

PROFIBUS interface option |

|

with DSO-PRO board |

|

|

|

|

|

MACRO bus interface option |

|

with DSO-MAC board |

|

|

|

|

Position |

Analog 1Vptp or 11uAptp |

|

Max. 320kHz in. / Up to 2'048 (x4) interpolation factor |

|

|

|

|

encoders interfaces |

Digital TTL (RS422) |

|

Max. 10 MHz input frequency |

|

|

|

|

|

Digital inputs, insulated |

|

6 (+ 8 with DSO-SIO option) |

|

|

|

|

User's |

Digital outputs, insulated |

|

3 (+ 8 with DSO-SIO option) |

|

|

|

|

inputs / outputs |

Analog outputs |

|

1 (+ 2 with DSO-SIO option) |

|

|

|

|

|

Analog outputs |

|

0 (+ 2 with DSO-SIO option) |

|

|

|

|

|

Setup software 'ETEL Tools' |

|

Windows 9x / 2000 / NT / XP |

|

|

|

|

|

DLL files |

|

Windows 9x / 2000 / NT / XP / QNX4 |

Software / |

|

|

|

User's programmable sequence (# of lines) |

|

5'420 |

|

Programmability |

|

||

|

|

|

|

|

Liquid Crystal Display (# of characters) |

|

16 |

|

|

|

|

|

Firmware update through serial link |

|

RS232 |

|

|

|

|

2.2.4Mounting systems – Installation requirements

The rack modules are mounted vertically inside a sub-rack:

|

|

483.00 (19'') |

|

|

426.72 (84F) |

265.90 |

261.80 (6U) |

190.50 |

|

|

465.10 |

Sub-rack depth: 239.24 |

Unit: [mm] |

In the solution outlined above, seven DSB2-PXX1 are powered by a DSO-PWR (ETEL's power supply).

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

14 |

Hardware manual DSB2-P |

Direct Drives & Systems |

MOTION TECHNOLOGY

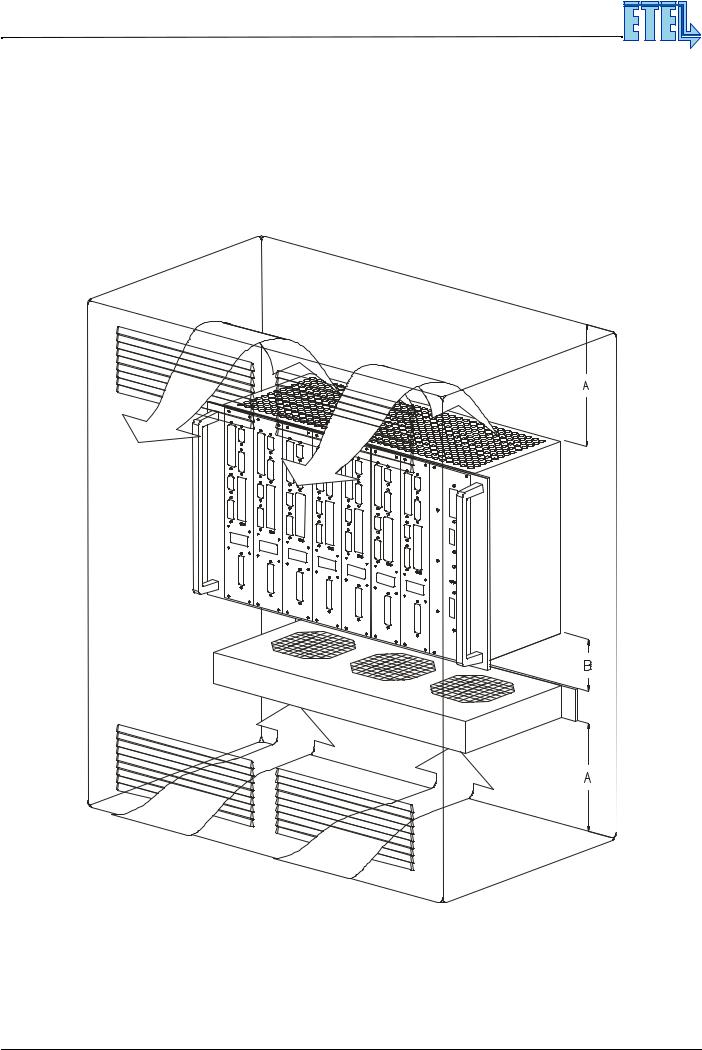

The sub-rack systems shall be protected against any splashes of liquid and any contacts with smoke and dust. It is strongly recommended to install them inside a closed cabinet and to screw them on a metallic plate, where no vibrations will occur.

Fresh air is necessary to cool them (the flow depends of the user application). It is recommended to install fans on the sub-rack or in the cabinet to guarantee an air flow (fan power depends on the user application).

This drawing shows a sub-rack with rack modules, inside a cabinet:

The following distances are recommended: A = 100 [mm], B = 0 [mm] (drawing out of scale).

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Hardware manual DSB2-P

Direct Drives & Systems |

15 |

MOTION TECHNOLOGY

2.3Rack module with heat sink

Type # : D S B 2 P x x 2 – x x x E

2.3.1Outline and dimensions

Refer to the following chapters for details about the connectors:

J1 see §3.1.2

J2 see §3.2.1

J3 see §3.3.1

J4 see §3.3.2

J5 see §3.3.3

J6 see §3.3.4

J7 see §3.4.1 |

|

|

|

J8 see §3.6.1 |

|

|

|

J9 see §3.1.3 |

|

|

|

J10 see §3.1.1 |

|

|

|

J11 see §3.5.1 |

|

164.00 |

|

261.80 |

|

|

J11 |

|

|

|

|

SERVO |

SERVO |

|

|

ERROR |

ON |

|

|

|

|

|

Standard 6U 14F |

|

|

DANGER |

Unit: [mm] |

|

|

|

|

|

|

|

Weight: 2 Kg |

|

|

HIGT |

|

|

|

VOLTAGE |

|

50.60 |

|

|

|

ETEL Doc. - Hardware manual # DSB2P 904 / Ver. D / 4/11/02

Loading...

Loading...