Page 1

Assembly Guide

Production Dates: September 2004 - Present

ATTENTION: The part numbers listed in this guide may differ from the parts

required for your particular Source Four fixture. Part numbers for

fixtures change occasionally as parts are replaced or upgraded.

To ensure that you are ordering the proper part for your specific

fixture, please contact your ETC dealer, or ETC Customer Service

for assistance.

Copyright © 2007 Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7061M2500-06.01

Released: August 2007

Rev A

Page 2

Table of Contents

Basic Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Lamp Socket Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Assemble lamp socket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Assemble housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cleaning the reflector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Cleaning the lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Lens identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

ETC®, Emphasis®, Expression®, Insight™, Imagine™, Focus™, Express™, Unison®, Obsession® II, ETCNet2™,

EDMX™, Source Four

of Electronic Theatre Controls, Inc. in the United States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

i Table of Contents

®

, Revolution®, Sensor®, and WYSILink™ are either registered trademarks or trademarks

Page 3

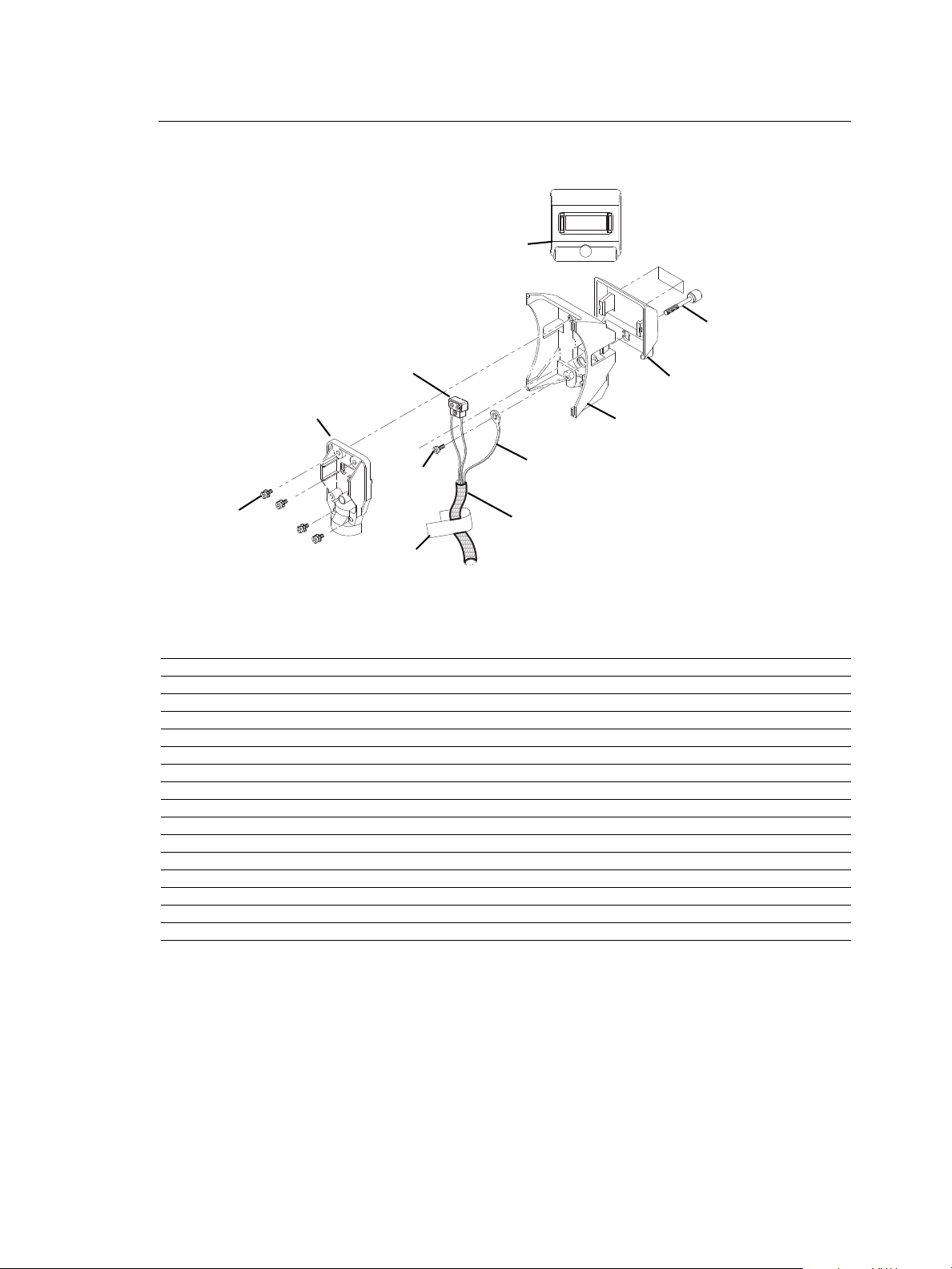

Basic Assembly

DI

RECTI

ON

L

AB

EL

Figure 1

9

10

11

12

1

2

3

4

7

6

5

4

3

8

13

LABEL

DIRECTION

Reference

Number

Part

Number

Description Quantity

Required

1 7061A2001 Lamp socket assembly, black 1

7061A2001-1 Lamp socket assembly, white 1

2 7061A3006 Bracket, yoke, black 1

7061A3006-1 Bracket, yoke, white 1

3 HW5172 Bolt, hex, 1/4-20 x 1”, black zinc 2

4 HW522 Washer, flat, 1/4, black zinc 2

5 HW5125 Bolt, carriage, 5/16-18, black zinc 1

6 HW5126 Washer, flat, 5/16, black zinc 1

7 HW8144 Handle, yoke knob, 5/16-18 1

8 7061A2015 Housing Assembly, EA, black 1

7061A2015-1 Housing Assembly, EA, white 1

9 7061A4002 Lens, clear, VNSP 1

10 7061A4003 Lens, stipple, NSP 2

11 7061A4005 Lens, medium flood, MFL 1

12 7061A4006 Lens, wide flood, WFL 1

13 7061A4029 Lens stop 1

Basic Assembly 1

Page 4

Lamp Socket Assembly

WARNING!

Figure 2

1

2

3

4

5

6

7

8

9

10

11

750

WARNING!

Reference

Number

1 7060A3025 Screw, 1/4-20 x 1.55, knurled 1

2 7060A4019 Label, Fixture Warning 1

3 7061A3023 Burner, casting, black 1

4 7061A3024 Strain relief, black 1

5 7061A4011 Focus handle, black 1

6 7061B7002 Ground Wire, 48” 1

7 HW2182 Screw, 6-32 x 1/4, PhPh, Taptite, zinc 1

8 HW3105 Screw, 8-32 x 1/2, PhPh, Taptite, SEMS 4

9 M706 Complete TP 22 CLCM assembly 1

10 W6195 Sleeve, fiberglass, 39”, black 1

11 7060A4094 Label, 750W, handle, black 1

Part

Description Quantity

Number

7061A3023-1 Burner, casting, white 1

7061A3024-1 Strain relief, white 1

7061A4011-1 Focus handle, white 1

W689-1 Sleeve, fiberglass, 39”, white 1

7060A4095 Label, 750W, handle, white 1

Required

2 Source Four PAR Assembly Guide

Page 5

Assemble lamp socket

Figure 3

TP22

assembly (9)

Knurled head

screw hole

Sleeving (10)

Ground wire (6)

and 6-32 x 1/4

screw (7)

Strain relief

casting (4,)

Burner casting

(3)

Tighten 2

Tighten 1

Tighten 3

Tighten 4

Tools Required:

• #2 Phillips screwdriver

Step 1: Install the ground wire (6) and the TP22 assembly (9) in the sleeving (10). See

Figure 3.

Step 2: Snap the focus handle (5) onto the burner (3). See Figure 2.

Step 3: Secure the ground wire lug (6) onto the burner casting (3) using screw (7).

Note:

Step 4: Place the TP22 assembly (9) into the burner casting (3). See Figure 3.

Position the wires with the green ground wire on top of the two TP22 white leads.

Make sure the green ground wire is not touching any part of the burner casting.

Step 5: Insert the screws (8) into the four positions in the strain relief casting (4). See

Figure 3.

Step 6: Position the sleeving assembly (10) as shown in Figure 3. Fold the sleeving so it

fits cleanly in the slot between the burner and the strain relief.

Step 7: Place the strain relief (4) on the burner casting (3). Loosely attach the screws (8).

The TP22 assembly (9) must be centered in the strain relief opening (4). See

Figure 3.

Step 8: To guard against stripping the screws, tighten them in the order shown in

Figure 3.

Step 9: Make sure the focus handle is secure, then insert the knurled head screw (1)

through the handle (5) into the burner casting (3). Tighten securely.

Lamp Socket Assembly 3

Page 6

Housing Assembly

Figure 4

1

3

2

4

5

5

6

7

(2 placesboth sides)

8

9

10

11

12

13

14

Reference

Number

1 7060A3100 Clip, gel retainer 1

2 7061A3013 Spring clip, rotator 1

3 7061A3014 Reflector, molded glass, coated, black 1

4 7061A3025 Barrel, right, black 1

7061A3025-1 Barrel, right, white 1

5 7061A2019 Barrel, left, black 1

7061A2019-1 Barrel, left, white 1

6 7061A3029 Clip, rotator, pressure 1

7 7061A4001 Pad, silicon, reflector mount 4

8 7061A4012 Lens rotator, black 1

9 7061A4029 Lens stop 1

10 7061A4030 Label, ETC S4 PAR, black 1

11 HW492 Screw, 10-32 x 5/8, PhPH, Taptite 3

12 HW4145 Screw, 10-32 x 3/8, PhPH, Taptite, BO 1

13 HW6128 Plug, focus knob, black 1

14 HW750 Spring, retainer 1

Part

Description Quantity

Number

7061A3014-1 Reflector, molded glass, coated, white 1

7061A4012-1 Lens rotator, white 1

7061A4030-1 Label, ETC S4 PAR, white 1

HW6128-1 Plug, focus knob, white 1

Required

4 Source Four PAR Assembly Guide

Page 7

Assemble housing

ALIGN ROTATOR CLIP

ALIGN ZOOM LENS

C

T

E

Source Four PAR

Figure 5

Left barrel alignment arrow

Label (10) alignment

Align rotator spring clip (2) on rotator

with rotator tab on left barrel (6)

Align rib on reflector (8) with left barrel (6) pocket

Tools Required:

• Minimally padded work surface (cardboard, carpet, or rubber mat recommended)

• Phillips screwdriver

WARNING:

Step 1: Install the reflector mount silicon pads (7) in the left barrel assembly (6). Install

Step 2: Install the lens stop (9) and rotator spring clip (2) into the lens rotator (8). Install

Step 3: Install the rotator pressure clip (6) into the left barrel (5) and attach using screw

Step 4: Install the gel retainer clip (1) and the spring retainer (14) into the right barrel (4).

Step 5: Install the reflector (3) into the left barrel (5). Align the rib on the reflector with the

Step 6: Attach the right barrel (4) to the left barrel (5) using three screws (11). Hand

Step 7: Clean reflector. See “Cleaning the reflector” on page 6.

Step 8: Check for ease of movement of the gel clip retainer (1). The clip should latch into

Step 9: Check for smooth rotation of the lens rotator (8).

Step 10: Snap the focus knob plug (13) into the bottom of the fixture.

Step 11: Attach label (10) onto the left barrel as shown in Figure 5.

This procedure may crack or break the reflector. Always wear gloves, safety

glasses, and a dust mask when performing this procedure.

the pads in two places on both sides. See Figure 4.

the lens rotator into the left barrel (5).

(12).

left barrel pocket as shown in Figure 5.

tighten only (25 in. lbs.).

the left barrel in the down position and be free of binding.

Housing Assembly 5

Page 8

Step 12: Hold the lens by the edge and position it so the wave side faces the rear of the

Spring clip

Retaining clip

Lens Catcher

Spring clip

Retaining clip

Tab

Figure 6

fixture. See Figure 6.

Step 13: From the top of the fixture, slide the lens behind the lens catchers and position it

behind the tabs on the bottom of the lens rotator ring.

Step 14: Gently push the top of the lens inward until it snaps behind the spring clip.

Step 15: Install the lamp socket assembly (See “Assemble lamp socket” on page 3.) to the

barrel housing assembly and secure with brass knurled screw on rear of lamp

socket assembly.

Cleaning the reflector

WARNING:

Step 1: Remove the lens to expose the reflector so you can access it from the front of the

Step 2: Remove dust with a blast of oil-free air or wipe with a clean, lint-free cloth.

Step 3: Reinstall a lens before using the luminaire.

Do not use ammonia-based or other harsh commercial cleaners. Clean

reflector only as directed.

Commercially available glass cleaning agents should be avoided as they

may contain ammonia, other harsh chemical detergents or abrasive agents.

These cleaners may damage the glass surface and the Anti-Reflective

coatings. Do not immerse or soak the glass in any cleaning solution.

luminaire.

Isopropyl alcohol, distilled water or a 50%-50% mixture of each can be used to

clean the glass surface.

Cleaning the lens

WARNING:

Remove dust with a blast of oil-free air or wipe with a clean, lint-free cloth. Isopropyl alcohol,

distilled water or a 50%-50% mixture of each can be used to clean the glass surface.

Do not use ammonia-based or other harsh commercial cleaners. Clean lens

only as directed.

Commercially available glass cleaning agents should be avoided as they

may contain ammonia, other harsh chemical detergents or abrasive agents.

These cleaners may damage the glass surface and the Anti-Reflective

coatings. Do not immerse or soak the glass in any cleaning solution.

6 Source Four PAR Assembly Guide

Page 9

Lens identification

Figure 7

Lenses for the Source FourPAR come in four varieties. The type or beam spread can be

identified by the texture of the lens.

VNSP

NSP

XWFL

(Optional)

Very narrow spot

Clear glass

15° Round beam shape

MFL

Medium flood

Fewer facets, sized 6 x 22mm

21° x 34° Oblong beam shape

Narrow spot

Stipple glass (slight diffuse texture)

19° Round beam shape

WFL

Wide flood

Many facets, sized 6 x 12mm

30° x 51° Oblong beam shape

Extra-wide, or buxom, lens

Molded, borosilicate lens, multi-faceted

60° Round beam shape

Housing Assembly 7

Page 10

8 Source Four PAR Assembly Guide

Page 11

Housing Assembly 9

Page 12

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Ennio Quirino Visconti, 11, 00193 Rome, Italy Tel +39 (06) 32 111 683 Fax +39 (06) 32 656 990

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7061M2500-06.01

Rev A Released 08/2007

Copyright © 2007 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...