Page 1

Operator Manual

Ethernet

PowerModule

distributed dimmers

1.5 Ethernet connectivity............................... 2

2 Unpacking and installation............................... 2

2.1 Unpacking & checking ............................ 2

2.2 Positioning .............................................. 2

2.3 Connections............................................ 2

2.4 Safety...................................................... 3

3 Control panel layout......................................... 3

4 Function overview............................................ 4

4.1 Maximum and minimum levels................ 4

4.2 Response speed..................................... 4

4.3 Non-dim operation .................................. 4

4.4 Local control ........................................... 4

4.5 Dimmer curves........................................ 4

4.6 Status reporting ...................................... 4

4.7 Backup settings ...................................... 4

5. Information displays and manual control ........ 4

5.1 To check the power supply .................... 4

5.2 To check dimmer performance .............. 4

5.3 To check dimmer software versions ....... 5

5.4 To manually control a dimmer level ....... 5

5.5 To operate the chaser ............................ 5

6 Programming................................................... 5

6.1 Flow chart ............................................... 5

6.2 General Programming Advice................. 6

6.3 Front Panel Controls ............................... 6

6.4 General controls ..................................... 6

6.5 DMX programming.................................. 6

6.6 Serial address......................................... 8

6.7 Maximum & Minimum levels ................... 8

6.8 Response time........................................ 9

6.9 Dimmer curves........................................ 9

6.10 Non-Dim operation...............................10

6.11 Maximum current .................................10

6.12 Voltage regulation ................................11

6.14 Start Mode ...........................................11

6.15 Passwords ..........................................12

6.16 Sleep mode..........................................12

6.17 Fault reporting......................................12

6.18 Return to factory settings .....................13

7. DimSTAT.......................................................13

8. Fault finding...................................................14

8.1 Reported faults ......................................14

8.2 First line maintenance............................14

9. Ethernet module ............................................15

9.1 Introduction ...........................................15

9.2 To set up the Ethernet options ..............15

10. Declaration of conformity.............................17

11. Index............................................................18

Flow chart............................................Appendix 1

Contents

1 Introduction...................................................... 2

1.1 Product range ......................................... 2

1.2 New dimmer design ................................ 2

1.3 Distributed dimming ................................ 2

1.4 Key features of Isine system ................... 2

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 1

Page 2

1 Introduction

1.1 Product range

This handbook describes the operation and

programming of the IES PowerModule range of

Isine dimmers incorporating sinewave dimming

technology. Sinewave dimming produces a pure

sinewave output for a lighting load. The intensity

of the light is controlled by the amplitude of the

sinewave. Other dimmer technologies (traditional

phase control and IGBT reverse-phase) control

the lights intensity by chopping the mains

waveform, which can cause acoustic noise and

electrical interference problems. The dimmers

covered by this handbook are:

2234 PowerModule PM80S

1 x 1.2 kW, 1 x 80 V

2102 PowerModule PM2-2S

2 x 2.5 kW, 22 A single phase

2235 PowerModule PM1-5S

1 x 5 kW, 22 A single phase

2103 PowerModule PM4-2S

4 x 2.5 kW, 44 A single phase

2104 PowerModule PM2-5S

2 x 5 kW, 44 A single phase

2236 PowerModule PM6-2S

6 x 2.5 kW 22 A three phase

2237 PowerModule PM3-5S

3 x 5 kW 22 A three phase

2105 PowerModule PM12S

1 x 12 kW 52 A single phase

2237 PowerModule PM24S

1 x 24 kW 104 A single phase

1.2 New dimmer technology

The PowerModule range of dimmers represents

the most advanced dimming system available

today. The advantages of Isine dimming

technology, as developed by IES in its Isine

design, deliver low-noise, high power dimming

capability with advanced electronic measurement

and control to accommodate variations in the

power supply and load conditions. The dimmers

will automatically compensate for poor mains

regulation, and will respond to a short-circuit faster

than any mechanical protection device.

control options for the broadest range of

applications. Each dimmer channel can be

individually programmed either at the dimmer

itself, or remotely from a PC, and once

programmed, the dimmer can operate simply and

transparently whilst being protected against

inadvertent adjustments. The PowerModule range

is compatible with all other IES dimmers including

the Executive Isine dimmer pack.

1.5 Ethernet connectivity

The Ethernet module supports DMX over Ethernet

and provides extensive configuration facilities

which are described in Chapter 9 ‘Ethernet

module’.

2 Unpacking and installation

2.1 Unpacking & checking

The PowerModule is self-contained and only

requires mounting components (two hook clamps

or ‘C’ clamps and a safety bond), and a suitable

mains input connector. The PowerModule is

packed to withstand normal transportation, but

before operating the unit, check there is no sign of

transit damage which could affect the operation

and safety of the dimmer.

2.2 Positioning

The PowerModule is an extremely versatile

dimmer, and can be located in a variety of

positions. It is designed for natural convection

cooling, hanging by two suspension clamps and

care must be taken to ensure adequate ventilation

around the case. Note that full-power operation is

only possible if the PowerModule is suspended in

free air. If it is used on the ground there may be

insufficient ventilation for continuous service at full

power. Should the PowerModule overheat in this

condition, an internal detection circuit will report an

overheat condition and will progressively reduce

power until a normal operating temperature has

been reached.

2.3 Connections

1.3 Distributed dimming

The high efficiency (low heat dissipation) of the

dimmer circuit, combined with its compact design,

electronic protection and sophisticated status

reporting system, makes the PowerModule ideally

suited to distributed dimming schemes where a

central dimmer room is unavailable or undesirable.

1.4 Key features of Isine system

The Isine system offers low noise dimming (both

acoustic noise from lamp and dimmer as well as

electrical interference are reduced), control of a

wide range of load types, and sophisticated

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 2

2.3.1 Mains connection

If the PowerModule is fitted with a cable then

attach a suitable connector to the cable. If the

PowerModule is fitted with a connector then

provide a suitable power cable with mating

connector. All connections should be made by

qualified personnel.

2.3.2 DMX data signals

All PowerModules are controlled by DMX 512

connected by a shielded two-pair high-speed data

cable with XLR 5-pin connectors (male = input;

female = output).

Page 3

Pin connections:

1 0V shield

2 DMX -

3 DMX +

4 DimSTAT -

5 DimSTAT +

The DMX network supports up to 32

PowerModules connected to one line. For larger

installations, where more DMX lines are required,

the use of a DMX booster/isolator is

recommended. Any booster/isolator used should

support bi-directional data on pins 4 and 5 for

DimSTAT to operate. Suitable boosters are IES

code 9601 (5 channels) or 9815 (10 channels).

Termination is required for both DMX and

DimSTAT data on all networks. The last output

socket in the line should be terminated with two

120Ω 1/4 Watt resistors connected between pins 2

and 3 (DMX) and between 4 and 5 (DimSTAT). A

‘dummy plug’ XLR male connector with

termination resistors is recommended.

2.4 Safety

Even though the PowerModule is equipped with

the latest electronic safety features and in some

cases an RCBO (circuit breaker with residual

current/earth leakage trip), all normal electrical

safety procedures must be followed. Do not use

the dimmer if the mains input cable has been

damaged, or the enclosure is damaged.

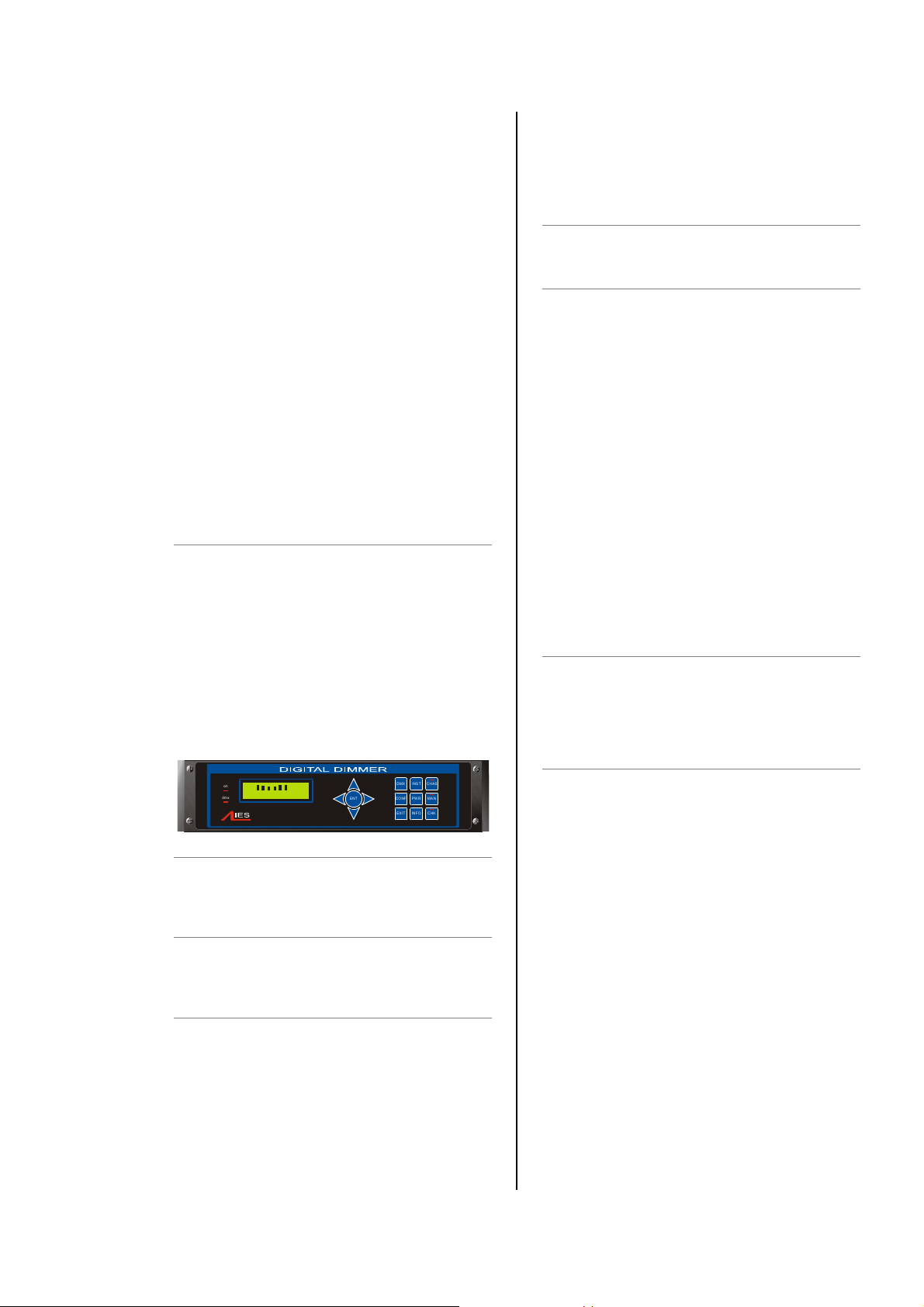

3 Control panel layout

Í Left cursor. Move cursor left in

display screen.

Î Right cursor. Move cursor right in

display screen.

DMX

Selects the DMX address of each channel.

INST

INSTall function. To set up dimmer options:

• Line voltage, frequency and maximum

current

• DimSTAT communication address

• DMX failure options

• DMX backup levels

• DMX configuration (individual or combined)

• Channel configuration (individual or

combined)

• Sleep mode

• Voltage regulation

• Current limit

• Minimum level reset (preheat off when DMX

is not present)

• Voltage calibration

• Factory reset

• Channel information

• Password set-up

• Dimmer hardware configuration

CHAS (with LED)

CHASe. Provides access to the dimmer’s internal

20-pattern chase effects system for stand-alone

display effects. The LED illuminates when the

dimmer is in the ‘chase’ mode.

on

dmx

L D:001*

CH 1 2 3 4 5 6 A:016*

ENT

DMX INST CHAS

PWR MANCONF

INFO CH KEXIT

ON LED

Illuminates red when power is applied, and the

RCBO or MCB is switched on.

DMX LED

Illuminates red continuously when valid DMX is

present and flashes when there is no DMX signal.

ENT & arrows

ENT (ENTer) completes a programming step and

records the information in the memory. The four

arrows provide navigation through the set-up

menu, and the means to enter data.

Ï Up. Higher level menu feature or

move cursor up in display screen or

number increment.

Ð Down. Lower level menu feature or

move cursor down in display screen

or number decrement.

CONF

CONFigure. Access to a sub-menu to set the

detailed configuration of individual or combined

dimmer channels. Options:

MAX MAXimum. Sets the

maximum output level from

30% to 100%, individually

or combined.

MIN MINimum. Sets the

minimum output level from

0% to 29.9%, individually or

combined.

T-IN Response time to fade in

from 0.00 secs to 99.9

secs.

T-OUT Response time to fade out

from 0.00 secs to 99.9

secs.

CURVE Dimmer law selection

NONDIM I/O. On/off operation

PRIORITY Priority channel (the last to

be reduced if the maximum

preset current is exceeded

by the module)

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 3

Page 4

MODE Start mode (normal, soft

start, burst, proportional,

blink)

the different visual responses of a live audience or

a TV camera, and to provide improved dimming of

non-resistive loads such as fluorescent tubes.

MAN

MANual. Provides manual control of each channel

for circuit testing and focussing.

EXIT

Returns to the opening screen menu option

without recording changes.

INFO

INFOrmation. Provides a display of the nominal

supply voltage, current, frequency and Ethernet

settings. After 3 secs. also gives details of the

installed software versions.

CHK (with LED)

ChecK. Displays a log of any circuit or dimmer

faults. LED illuminates if an error occurs.

4 Function overview

4.1 Maximum and minimum levels

The maximum output of the dimmer may be

adjusted to improve lamp life or to limit the power

used. A minimum level (preheat) may be

necessary with some filaments to improve the

speed of fast flashes or chases. An option exists

to switch off the preheat when the DMX signal is

not present (i.e. when the control desk is switched

off).

4.2 Response speed

The time taken for a dimmer to fade to the applied

control signal level is used to control the rate of

change of the current to the filament to improve

the life of higher wattage lamps.

4.6 Status reporting

All IES dimmers incorporate a bi-directional

communications system called DimSTAT which

provides feedback of the dimmer status and fault

reporting to a PC. DimSTAT also enables a

remote PC to control any dimmer in the network,

and to update the dimmer’s internal operating

software and preset options.

4.7 Backup settings

Should the DMX signal fail, the PowerModule can

be programmed to hold the present level, fade to

zero or fade to a pre-programmed backup level.

5. Information displays and

manual control

This group of buttons provides direct access to

detailed set-up and status information and manual

override controls, and do not require passwords

for access.

5.1 To check the power supply

1. Press PWR.

2. The screen shows:

U:242 V

I: 00 A

Where: U is the mains input voltage in

Volts, I is the instantaneous

load current in Amps (three

phases shown for PM3 and 6;

one for PM1, 2 and 4).

3. Press EXIT to leave the screen.

4.3 Non-dim operation

Each dimmer may be selected to operate as a

dimmer or as a non-dim switch.

4.4 Local control

PowerModules have a range of integrated control

facilities for basic operation without a control desk.

These include live manual control of each dimmer

level, preset recorded levels for fixed display

lighting, and access to an in-built chaser which

provides 20 chase patterns.

4.5 Dimmer curves

A selection of dimmer curve transfer functions (the

relationship between control signal level and

dimmer output) are available to compensate for

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 4

5.2 To check dimmer performance

1. Press INST.

2. Press Ð or Ï to choose CHANNEL

INFO menu. Press ENT.

3. The screen shows:

INFO CH:[1]

CURRENT 04.7A

4. Press Í or Î to select other

information as follows:

CURRENT: current in Amps measured at

the output

VOLTAGE: voltage at the input of the

dimmer

Page 5

TEMPERATURE: Isine dimmer module

temperature

DMX: DMX level received

ACTUAL: the level the dimmer is

responding to (may differ from DMX

value due to MIN, MAX or MAN

influence).

STATUS: error message(s) with details.

4. Press Ï or Ð to select another dimmer

channel (shown in square brackets), or,

5. Press EXIT to leave the screen.

5.3 To check dimmer software versions

1. Press INFO, and wait for 3 seconds.

2. After displaying the nominal voltage,

current and frequency settings, the

screen shows:

P1:1.44 P2:1.44

P3:1.44 SYS:3.10

Where: P1, P2 and P3 are the dimmer

processor software versions (P1 is only

shown on 1, 2 and 4 channel

PowerModules), and SYS is the front

panel processor software.

Note: All dimmer processor software will hav e

the same version number, but it will not

be necessarily the same version as for

the front panel. All software versions in

the same installation should be identical.

If they are not, contact your local

distributor or IES directly.

3. After 3 seconds, the screen

automatically resets to show the normal

output details.

4. Press Ï or Ð to adjust the level. The

dimmer output is live while the level is

being adjusted.

5. Press ENT to leave the menu and

record the changes or EXIT to leave the

previous settings unchanged.

5.5 To operate the chaser

The PowerModule has a sequence chaser to

provide basic effects without a control desk. This

is primarily used for exhibition and display lighting

purposes. Twenty different effect sequences are

pre-programmed into the PowerModule, and

controls are provided to adjust master level, chase

speed and to choose between fading and

switching between steps.

1. Press CHAS.

2. The screen displays shows:

CH ST SP L FADE

01 00 1.0 OFF

where:

CH is chase number

ST is step number

SP is speed (in seconds) from one step to

another

L is a bar graph showing the master

intensity

FADE selects either a fading chase (ON) or

a switching chase (OFF)

3. Press Í or Î to put the underline

beneath the CH number, and use Ï and

Ð to select the chase number required.

4. Press ENT to start the chase, and the

screen shows e.g.:

5.4 To manually control a dimmer level

It is possible to control any dimmer directly from

the front panel using the cursor controls to set the

desired level. This can be used for testing circuits,

overriding control signals or setting an

independent fixed level. The level is mixed with

any other incoming signal on a highest level takes

precedence basis.

1. Press MAN.

2. The screen shows:

L: 242V

CH:T123456 08 A

3. Use Í or Î to select a channel number

(active channel number is underlined),

or ‘T’ which controls all channels

together.

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 5

6 Programming

6.1 Flow chart

The flow chart showing the menu structure and

options is included as an appendix at the end of

CH __ AUTO

05 01 1,0 OFF

5. The step number will increment as the

chase progresses, restarting at 1 at the

end of each cycle.

With the chase number underlined, press Ï

or Ð to switch to another chase pattern.

Use Í and Î to underline (select) the level

or FADE and press Ï or Ð to adjust the

master level for each step (shown on

the bar graph) and to choose between

FADE ON (fades between steps) and

FADE OFF (switches between steps).

Page 6

this manual. As the Ethernet programming options

are relatively complex and only have to be

changed infrequently, they are discussed in

Chapter 9 “Ethernet module”.

6.2 General Programming Advice

6.2.1 Passwords

For clarity, the following sections which describe

programming activities do not refer to the entry of

passwords. Passwords are included to prevent

unauthorised access to the DMX, CONFigure and

INSTall menu trees. The passwords are 4-digit

numbers with a factory default of 0000 (no

password necessary). It is possible to have the

same password for all, or separate passwords for

each menu tree. If any of the protected menus is

selected, the next screen requests a password.

This is achieved by pressing the relevant Í and

Î cursor buttons to select the digit, and the Ï

and Ð cursor buttons to enter the number.

6.2.2 Navigation through the menus

The cursor buttons are used to move around the

menu screens, and to activate a set-up option or

parameter prior to adjustment. When a parameter

or option is activated, it is shown in square

brackets, e.g. [240] and it is this item which you

are changing on the screen. When you press ENT

to confirm the change, the screen will show:

DATA IS STORED

IN MEMORY

As this happens for each menu option, it is not

included in each following instruction.

6.2.3 Channel characteristics

All dimmer-specific functional parameters may be

set separately for each dimmer. Thus each

dimmer may have a different response time,

curve, maximum level etc. if required.

Alternatively, all dimmers in one PowerModule can

be programmed together, depending on whether

the dimmer set-up has been set to ‘SINGLE or

‘JOINED’ (see paragraph 6.4.1). If the

configuration is set to single, a number is shown in

each relevant channel reference [4], and if all

dimmers are programmed together, a T is shown

in square brackets [T]. Note that if T is activated,

an underscore bar is added, making it appear as

an ‘I’.

L: _ D:001?

CH:123456 A:032v

This display shows the channel levels (bar graphs

at the top left), the DMX address of the first

channel in the PowerModule (D:xxx) and the

DimSTAT address of the unit (A:xxx). The number

of bar graphs shown relates to the number of

dimmers in the PowerModule – either 1, 2, 4 or 6.

Note: A question mark (?) adjacent to the DMX

address shows the DMX signal is not

valid, and the ‘v’ adjacent to the

DimSTAT address number indicates

communication is active.

6.4 General controls

PowerModule dimmers can store performance

characteristics individually for each dimmer or

combined for all dimmers in the module. This

feature is independent of the choice of DMX

numbering scheme, thus the dimmers may have

individual characteristics, but with consecutive

DMX addresses.

6.4.1 To change the dimmer characteristic setup scheme

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu.

Press ENT.

3. Press Ð or Ï to choose CONFIG

CHANNEL menu.

Press ENT.

4. The screen shows:

GENERAL

CH_CONF. [SINGLE]

5. Use Ï or Ð to select either SINGLE (for

different individual channel parameters)

or JOINED (if all dimmers have the

same characteristics).

6. Press ENT (to record the changes) or

EXIT (to leave the previous settings

unchanged, and return to the home

page).

6.5 DMX programming

6.3 Front Panel Controls

All of the performance and control characteristics,

measurements and status reports, are available

from the front panel controls and LCD screen.

When power is applied and the MCB or RCBO is

switched on, the power LED will illuminate. The

DMX LED will illuminate if a valid DMX signal is

present. During the power-up reset process, the

LCD display shows identification details and the

software version before displaying the output

screen:

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 6

Each dimmer in the PowerModule is assigned a

DMX channel number. A feature is provided to set

sequential number groups (‘Start’ addressing)

instead of individual settings. When programming

a PowerModule, IT IS IMPORTANT TO SET THE

DMX ADDRESSING SCHEME before the

individual characteristics are set, as a later change

can reset previously recorded individual channel

characteristic settings.

6.5.1 To set up DMX addressing scheme

1. Press INST.

Page 7

2. Press Ð or Ï to choose GENERAL

SETTINGS menu.

Press ENT.

3. Press Ð or Ï to choose DMX

ADDRESS menu.

Press ENT.

4. The screen shows:

GENERAL

DMX MODE [SINGLE]

5. Use Ï or Ð to select either SINGLE (for

different individual DMX addresses) or

JOINED (if the dimmers are numbered

sequentially from the start address).

6. Press ENT (to record the changes) or

EXIT (to leave the previous settings

unchanged, and return to the home

page).

6.5.2 To set up DMX addresses

1. First set the DMX scheme as described

above (either individual or start

address).

2. Press DMX, and the screen displays:

DMX ADDRESS

ENTER

3. Press ENT, and the screen displays:

DMX: [001] 002

CHAN.: 1 2

4. If SINGLE has been selected, two

channels are displayed at a time, with

their relevant DMX address. Use Ï and

Ð to select the address needed for the

first dimmer channel and move to other

channels by pressing Í and Î and

continue adjusting each DMX address

by pressing Ï and Ð as before.

5. If JOINED has been selected, only one

DMX number line is entered which is the

number for dimmer 1. The remaining

dimmers are automatically addressed in

sequential order.

6. Press ENT to store the settings and to

return to the previous menu.

Note: DMX address 000 deselects the channel

from operation. Valid DMX numbers are

between 001 - 512. If higher dimmer

numbers are used by the control desk,

the number has to be rationalised to a

base of 512 for the dimmer address.

DMX ADDRESS

ENTER

2. Press Ð, and the screen displays:

UNIVERSE ADDRESS

ENTER

3. Press ENT, and the screen displays:

UNI: [001] 002

CHAN.: 1 2

You can now set each channel to a

different DMX universe. For most

applications it is advisable to use only

one universe for each dimmer pack.

Alternatively, you could use one

universe for DMX-A (internal dimmers

and DMX-A output) and one for DMX-B

(DMX-B output).

4. Press ENT to store the settings and to

return to the previous menu.

6.5.4 To set up a DMX backup condition

The PowerModule is equipped with a choice of

responses to the failure of the DMX signal. The

dimmers can be set to hold their last DMX level,

fade to zero over 5 seconds, or fade to a preset

memory setting. This choice is available per

PowerModule.

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu. Press ENT.

3. Press Ð or Ï to choose DMX FAIL

menu. Press ENT.

4. The screen shows:

GENERAL

DMX FAIL [HOLD]

5. Use Í or Î to select one of the 3

options available:

RESET: sets all dimmers to zero after 5

seconds

HOLD: maintains the last valid DMX

levels until DMX is restored

BACKUP: selects dimmer levels

programmed with the

PRESETS memory function

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.5.3 To set up DMX universes

1. Press DMX, and the screen displays:

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 7

Note: If BACKUP has been set, do not forget

to set the relevant DMX backup state.

Page 8

6.5.5 To set up DMX Backup preset

1. Press INST.

2. Press Ð or Ï to choose DMX BACKUP

menu. Press ENT.

3. The screen shows:

L: 242V

CH:T123456 00 A

4. Use Í or Î to select a channel number

(active channel number is underlined) or

T if all channels are to be set together.

5. Press Ï or Ð to adjust the backup level.

The dimmer output is live while the

backup levels are adjusted.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.5.6 To set up a DMX Minimum reset

In order to reduce dynamic filament noise in some

types of 120V PAR lamps, it is sometimes

necessary to use a low preheat level. DMX

minimum reset is the automatic means to switch

any preheat levels off when DMX is not present

(i.e. when the control desk is switched off, but the

dimmers remain on).

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu.

Press ENT.

3. Press Ð or Ï to choose MIN RESET

menu. Press ENT.

4. The screen shows:

GENERAL

MIN RESET: [OFF]

5. Use Ï or Ð to select either AUTO

(preheat switches off when DMX is off)

or OFF (preheat runs continuously).

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.6 Serial address (PC address)

The DimSTAT PC address shown on the output

screen as A:XXX is the unique number which is

used by network to identify each dimmer unit for

the purpose of reporting status information and for

transferring data between the dimmer unit and PC.

If a dimmer unit is removed from the network and

replaced by another, DimSTAT will automatically

prompt for an update of configuration information

when the PC address is entered. DimSTAT

identifies the new unit on the network, and

prompts the operator to download the previous

characteristics file from the PC to the new dimmer.

The PC address is associated with a unique

factory serial number which is permanently stored

in the dimmer. An Autoreload function is also

provided to reinstate the PC address after a

factory reset.

6.6.1 To set up a serial address

1. Press INST.

2. Press Ð or Ï to choose DIMSTAT

ADDRESS menu. Press ENT.

3. The screen shows:

ADDRESS: [001]

AUTO-RELOAD NO

4. Press Ï or Ð to set the address number

between 001 and 255.

5. Press Î to select auto-reload options of

YES or NO.

Press ENT to leave the menu and record

the changes or EXIT (to leave the

previous settings unchanged).

6.7 Maximum & Minimum levels

It is possible to affect the output range of a

dimmer by setting a minimum level and/or a

maximum level. A minimum level is used to

provide a pre-heat to preheat lamp filaments,

whereas the maximum level is used to limit power

and extend lamp life. Minimum levels may be set

between 0% to 29.9%, and maximum levels from

30% to 100%. Factory default levels are 0% for

minimum and 100% for maximum. One common

use for a reduced maximum level is to control

110 V lamps but the 110 V dimmer curve is

recommended as it produces a smoother control

over the whole range of intensity. However the

operation of this channel should be compared with

other lamps in the rig to ensure uniformity of

response.

Note: In the case of high inrush loads (e.g. PAR

cans) where flashing on from a cold

state is required in a silent auditorium, or

for 5kW lamps where the high inrush

current could cause the shortcircuit

protection to report and error, it is

recommended to set a ‘minimum’

preheat level to 5%. See also the

section on DMX Minimum Reset.

6.7.1 To set-up max and min levels

1. Press CONF.

The screen shows the individual channel

number (or T if the dimmer set-up

scheme copies characteristics to all

dimmers in the rack) and gives access

to all configuration options.

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 8

Page 9

CONFIG: CH:[1]

MAX: 100%

2. Press Ï or Ð to select the required

dimmer number.

3. Press Î to select the maximum or

minimum option, and to highlight the

recorded value (in square brackets):

CONFIG: CH:1

MIN: [00.0%]

4. Setting options:

MIN: minimum level, 00% to 29.9%.

MAX: maximum level, 30% to 100%.

5. Press Ï or Ð to select the level (shown

in square brackets).

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.8 Response time

Each dimmer has two times associated with it

which control the minimum time to fade in and out,

and are called T-IN and T-OUT. These times are

referred to as ‘response times’ and are used to

protect the lamp filaments from thermal damage,

and for reducing surges in the system. The default

times are currently zero seconds (for the fastest

response). Values recommended are 0.01 s for a

1 kW load, 0.1 s for a 2 kW load, and 0.5 s for a 5

kW load.

6.8.1 To set-up response times

1. Press CONF.

2. The screen shows the individual

channel number (or T if the dimmer setup scheme copies characteristics to all

dimmers in the rack) and gives access

to all configuration options.

3. Press Ï and Ð to select the dimmer

number.

the minimum recommended is 0.05 s.

Faster response times should be used

with care, and with lower wattage loads.

6.9 Dimmer curves

Dimmer curves (dimmer laws) are used to adjust

the relationship between control level and light

output. This enables the dimmer to be fine-tuned

to accommodate the preferences of a live

audience or a television camera. There are 8

factory standard dimmer laws, and a provision for

further custom selectable curves in later software

releases.

The factory default law (0) is Linear Law. The

following dimmer curves are available:

LINEAR linear relationship (standard)

LINEAR5 LIN5 (as linear but with a small

offset at 50%)

INV.LIN inverted (when control = zero,

dimmer = full etc.)

110V LIN 110V lamp load, linear law

S-LAW S-Law

BBC BBC specification (modified

square law for TV applications)

FLU-50 fluorescent (minimum 50%)

FLU-30 fluorescent (minimum 30%)

FLASH flash effect (light switches on

and off as the control fades up

and down)

NONDIM non-dim operation (see note

below)

9-14 for future use

Note: There are two options for setting Non-

Dim (switch) operation – via the CURVE

menu and the NON-DIM menu, both

found in CONF. For Non-Dim operation,

either or both options may be set, but for

normal dimmer operation BOTH must be

set to ‘NO’.

CONFIG: CH:[1]

MAX: 100%

4. Press Î to select the response times T-

IN or T-OUT, and to select the recorded

value (in square brackets):

CONFIG: CH:[1]

T_OUT: [00.00]SEC

5. Adjust the time by pressing Ï and Ð.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

Note: Zero (0) seconds should not be used

with TV-type high wattage lamps, where

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 9

6.9.1 To select a dimmer curve

1. Press CONF.

2. The screen shows the individual

channel number (or T if the dimmer setup scheme copies characteristics to all

dimmers in the rack) and gives access

to all configuration options.

3. Press Ï or Ð to select the channel

number.

CONFIG: CH:[1]

CURVE: LINEAR

4. Press Î to select the CURVE option

(shown in square brackets) and set the

curve option by pressing Ï and Ð.

Page 10

5. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.10 Non-dim operation

PowerModules may be set to switch on and off

rather than dim, and in this way are used for many

other functions such as switching power to

working lights, non-dim and auxiliary circuits.

There are two methods of selecting non-dim

operation – as described here, and also as one of

the ‘Dimmer Curves’ as described in the previous

section. In this mode the channel switches on at

6% and switches off at 5%.

6.10.1 To select a dimmer to operate as a nondim switch

1. Press CONF.

2. The screen shows the individual

channel number (or T if the dimmer setup scheme copies characteristics to all

dimmers in the rack) and gives access

to all configuration options.

3. Press Ï or Ð to select the channel, and

then press Î to select the NON-DIM

option shown as follows:

CONFIG: CH:1

I/O: [NO]

4. Press Ï or Ð to select I/O operation

(either YES for Non-Dim or NO for

normal dimming operation).

5. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

Note: A special feature is included to

prevent damaging accidental ‘flashing’ to

discharge loads. If T-IN is set to, say, 10

secs. and T-OUT to 99secs, then the on

period is fixed for 10 seconds, and 99

seconds has to elapse before switching on

is possible again.

6.11 Maximum current

Each PowerModule has a facility to measure the

current and to restrict the operation of all dimmers

(or in the case of PM3 or 6, the dimmers on each

phase) to ensure the maximum current is not

exceeded. This operates as a ‘maximum demand’

protection system, and reduces the levels of all

dimmers on the phase which is exceeding the

preset current.

However, to eliminate the risk of an important light

automatically dimming during a performance, it is

possible to prioritise the channels which will

reduce in intensity to ensure the maximum

demand is not exceeded. This is achieved by

setting the dimmer channel to “priority”, and it will

then ignore any instruction to reduce level if the

maximum demand is exceeded. Similarly, non-dim

channels are also unaffected by the current

limiting function.

This function is activated in three steps: setting a

current limit, choosing any priority channels, and

activating current limiting as described below.

6.11.1 To set up maximum current levels

1. Press INST.

2. Press Ð or Ï to choose LINE

PARAMETERS menu. Press ENT.

3. The screen shows:

LINE V[240]

I:40 FREQ:50

4. Press Ï or Ð to set the typical voltage

of the mains supply (shown in square

brackets).

5. Press Î to select maximum current for

the module (or per phase for the PM6),

and adjust the level using Ï and Ð.

6. Press Î to select frequency and press

Ï or Ð to switch between 50Hz or

60Hz.

7. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.11.2 To set up priority channels

1. Press CONF.

2. The screen shows the individual

channel number (or T if the dimmer setup scheme copies characteristics to all

dimmers in the rack) and gives access

to all configuration options.

3. Press Ï or Ð to set the channel number

required, followed by Î repeatedly to

select PRIORITY option shown as

follows:

CONFIG: CH: T

PRIORITY: [NO.]

4. Press Ï or Ð to select this channel for

priority operation (either YES for priority

or NO for normal operation).

Note: If set to No, the dimmer will take part in a

general reduction of the intensity if the

preset maximum current (maximum

demand) for the phase in this dimmer

rack is exceeded. If set to Yes, the

dimmer will remain at its level, and

others will reduce in level to maintain the

maximum phase current.

5. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 10

Page 11

6.11.3 To activate current limitation

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu. Press ENT.

3. Press Ð or Ï to choose CURRENT

LIMIT menu. Press ENT.

4. The screen shows:

GENERAL

CUR.LIMIT: [ON]

5. Press Ï or Ð to set the current limiting

function either ON or OFF (shown in

square brackets).

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.12 Voltage regulation

Voltage regulation is a software feature which

maintains the dimmed level of channels in the

event of the mains supply fluctuating (e.g. when

power is supplied from a generator source or a

high-impedance main). The dimmer’s incoming

voltage is measured, and if it diverts from the

anticipated incoming voltage, the dimmer will

adjust the output accordingly to maintain a

constant voltage at the output. The dimmer will

maintain output to about 1V for every 10V input

voltage swing. This feature does not maintain the

voltage of full-on dimmer channels, as the

regulation circuit can only work with sufficient

voltage headroom. Programming involves two

stages, firstly setting the nominal voltage, and

secondly activating the voltage regulation

software.

6.12.1 To set nominal voltage

1. Press INST.

2. Press Ð or Ï to choose LINE

PARAMETERS menu. Press ENT.

3. The screen shows:

LINE V[230]

I:44 FREQ:50

4. Press Ï or Ð to set the voltage

expected (shown in square brackets).

5. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.12.2 To activate voltage regulation

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu. Press ENT.

3. Press Ð or Ï to choose VOL.

REGULATION menu. Press ENT.

4. The screen shows:

GENERAL

VOL.REG. [ON]

5. Press Ï or Ð to set the voltage

regulation function either ON or OFF

(shown in square brackets).

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.14 Start Mode

PowerModules are equipped with a software

feature to alter the criteria for dimming cold

filaments. The response of a dimmer depends on

the resistance of the filament, which varies

according to temperature. A cold filament has a

slower response than a warm filament. Although

the Isine modules restrict maximum current to 10

times the nominal current, if the complete rig is

subject to a sudden loss and resumption of power,

it is possible for the combined cold switch-on load

to exceed the diversified power supply can

withstand, resulting in nuisance tripping of circuit

breakers. For this reason, the dimmers are

installed with a range of start modes to give the

users flexibility in the set-up characteristics of the

dimmer.

An additional feature is Blink mode which flashes

the dimmer channel with a controllable markspace and flash rate for warning signs in the

studio or backstage. The options are:

BASIC: Normal mode

SOFT START: If the circuit has not been

used for 5 minutes, the initial

response time is automatically

set to 500 ms

BURST: If the circuit has not been used

for 5 minutes, the dimmer

burst-fires 20 cycles at full

power to heat the filament

rapidly and to improve

response.

PROP: Proportional burst start mode.

The number of full power

cycles is in relation to the

speed of rise of DMX signal

between 0% and 9%.

BLINK: Flashes the output to full. T-IN

sets the fade in time, T-OUT

sets the fade out time, and the

DMX level sets the flash

period.

6.14.1 To set start mode

1. Press CONF.

2. The screen shows the individual

channel number (or T if the dimmer setup scheme copies characteristics to all

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 11

Page 12

dimmers in the rack) and gives access

to all configuration options.

3. Press Ï or Ð to select the relevant

channel number and then repeatedly

press Î to select the START option

shown as follows:

CONFIG: CH:2

MODE: [BASIC]

4. Press Ï or Ð to select the start mode

required.

Note: If BLINK has been selected t hen set the

T-IN and T-OUT times to create the

required flash characteristic. The DMX

level then controls these times

proportionally. (E.g. at 100% DMX the

full in and out times are used, and at

50% the times are halved.)

Press ENT to leave the menu and record

the changes or EXIT (to leave the

previous settings unchanged).

6.15 Passwords

Note: Make a copy of passwords in the back

of this handbook, as the passwords can

be interrogated only via a DimSTAT link

to a remote PC. Resetting the password

to 0000 disables the previous setting.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.16 Sleep mode

The SLEEP function has been included to switch

off the backlit LCD screen during a performance

when the control panels are in view of an

audience or camera. When enabled, the sleep

function switches off the backlight a short time

after the last touch of a panel button, and switches

back on when a front panel button is pressed.

6.16.1 To set the dimmer rack to ‘Sleep’ mode

1. Press INST.

2. Press Ð or Ï to choose GENERAL

SETTINGS menu. Press ENT.

Press Ð or Ï to choose SLEEP MODE

menu. Press ENT.

4. The screen shows:

Passwords are used at 3 levels of the

PowerModule dimmer set-up procedure: DMX,

CONF and INST. One password or 3 separate

passwords may be used to give a range of access

options. Passwords are in the form of 4 digit codes

and may be set and used from the front panel of

the dimmer and DimSTAT, but passwords may

only be read using DimSTAT. Passwords set to

0000 give unrestricted access.

Note: If the password is set to 0000 (factory

default) the menus are open, and no

prompts to enter a password are seen

on the display.

6.15.1 To set-up passwords for the first time,

and to alter a previous password

Note: The procedures for programming

passwords for DMX programming,

Channel configuration and Installation

are identical. The procedure for

programming the DMX password is

described below.

1. Press INST.

2. Press Ð or Ï to choose PASSWORD

DMX menu. Press ENT.

3. The screen shows:

NEW PASSWORD

[*]:*:*:*

4. Press Í or Î to select a digit to enter

(shown in square brackets).

5. Press Ð or Ï to adjust the digit.

GENERAL

SLEEP MODE [ON]

5. Use Ï or Ð to select either ON or OFF.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

6.17 Fault reporting

If a discrepancy in the normal operating

parameters is registered, the PowerModule will

report the potential fault and will take action to

minimise the effect of the fault. The CHK LED

illuminates if a fault is recorded, and any circuit

errors are reported on the screen above the

channel number affected as shown below for

channel 5 which is displaying a short-circuit

condition:

L: s D:025

CH:123456 A:001v

code ‘l’ = no load (control present but no

output)

code ‘s’ = short circuit

code ‘t ‘= over-temperature

code ‘o’ = overload (e.g. 4kW plugged

into a 2kW dimmer)

code ‘c’ = internal dimmer control faulty

(e.g. output with no control

signal)

code ‘v’ = voltage out of range (either

over or under voltage)

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 12

Page 13

code ‘d’ = fault has persisted beyond a

default auto-reset time, and the

dimmer has been disabled and

is now awaiting manual

intervention and reset.

The channel display indicators give the last

recorded fault condition. If the fault is a selfresetting fault, or if the dimmer is automatically

disabled, the reason for the problem may not be

obvious from the channel display. However, a log

of the errors is shown in detail through DimSTAT,

and a summary of the history is shown using the

dimmer’s LCD screen as follows. Faults are

discussed in greater detail in Section 8 ‘Fault

finding’.

6.17.1 To check fault reports and to reset the

log

1. Press CHK.

Note: This screen never requires a password.

2. The screen shows:

ERR.STATUS: CH:01

SHORT 03

where: 03 is the short circuit error code, and

01 is the affected dimmer circuit within

the module.

3. Press Ð or Ï to view any other reports

in the error log.

4. Press ENT to leave the menu and

CLEAR the log or EXIT (to leave the log

unchanged).

6.18 Return to factory settings

The PowerModule is supplied with a set of factory

default settings and recommended software setup parameters. It is advisable to reset the dimmer

software to the original factory settings in the case

of a significant software update.

6.18.1 To reset the dimmer rack to factory

default settings

1. Press INST.

2. Press Ð or Ï to choose FACTORY

RESET menu. Press ENT.

3. The screen shows:

ARE YOU SURE ! !

CLEAR MEM. [NO]

4. Press Ï or Ð to select YES (shown in

square brackets).

5. Press ENT to leave the menu and reset

the PowerModule’s memory or EXIT (to

leave the previous settings unchanged).

The factory defaults are:

AUTORELOAD: NO

CHANNEL CONFIG.: JOINED

CURRENT: 44A

CURRENT LIMITATION: OFF

CURVE: LINEAR

DMX ADDRESS: 001

DMX BACKUP: all 00

DMX FAIL: RESET

DMX MODE: JOINED

DMX MINIMUM RESET: OFF

FREQUENCY: 50Hz

MAXIMUM: 100%

MINIMUM: 0.00%

MODE: BASIC

NON-DIM (I/O): NO

PASSWORDS: all 0000

PC ADDRESS: 000

PRIORITY: NO

SLEEP: OFF

T-IN: 0.00 secs

T-OUT: 0.00 secs.

VOLTAGE: 235V

.

VOLTAGE REGULATION: OFF

7. DimSTAT

DimSTAT provides a system-wide network, and

operates on a host polling protocol where the PC

searches for connected dimmers at initiation, and

then regularly polls dimmers for data to display. If

a fault occurs, the PC’s display instantly shows the

detail, and if the fault is cleared the system resets

accordingly. Information displayed includes: DMX

start address per unit, DMX OK, line voltage,

current per channel, dimmer curve, response time,

maximum and minimum current, type of fault

reported (temperature, overload etc.), date and

time of fault. It is possible to set the dimmer curve,

start address and pre-heat from DimSTAT

software on the PC. The operation and

performance of the PowerModule dimmer is

monitored constantly and comprehensively by the

on-board data processors, and this information is

available on the LCD screen of the dimmer, and

through DimSTAT. The parameters measured and

reported are:

a) DMX OK

b) DMX channel numbers

c) DMX levels

d) line voltage

e) current per dimmer

f) current per phase per module

g) frequency

h) dimmer curve

i) temperature per module

j) Cosine φ (power factor including higher

harmonics)

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 13

Page 14

For further information, please refer to the

DimSTAT software manual.

8. Fault finding

8.1 Reported faults

8.1.1 No load (control present but no output)

This can be reported if either a load fails (lamp

blows without shorting the output first), or the load

is disconnected in error, or a load is not

connected.

8.1.2 Short circuit

This can happen if a lamp filament blows, or if a

faulty cable or luminaire is connected to the circuit.

A temporary short circuit such as a lamp failure

will produce a SHORT report in the log, but the

dimmer will usually reset to normal operation

when the fault has cleared. If the fault continues,

the report will change to DISABLE. Disconnect the

load from the dimmer and check the circuit wiring

and connected loads for the short.

8.1.3 Over-temperature

If one of the Isine modules exceeds an operating

temperature of 78°C, the dimmer will switch off

and report an over-temperature condition. This

can be caused if the ventilation is obstructed (e.g.

the dimmer is resting on the floor and is being

used continuously at full load).

Note: if the dimmer module is not suspended

in free air then it will cooled less

effectively and its power handling

capacity will be limited.

8.1.4 Overload

The dimmer will respond quickly to any error

which demands a higher current than expected,

for example 4 kW plugged into a 2.5 kW dimmer.

The dimmer will automatically switch off and after

3 seconds will attempt to fade up the circuit again.

If this process fails 3 times, the dimmer will report

an overload and will disable until the fault is

cleared and the dimmer reset.

8.1.5 Control

The control fault indicates a problem controlling

the load within the dimmer. This can result in the

dimmer channel giving a full output under any

control condition, and can only be repaired by

exchanging an Isine module. However, if this fault

occurs the dimmer circuit should be carefully

assessed to find a cause before another module

suffers the same problem. Typical system

problems are high voltage spikes caused by an

unbalanced generator supply.

8.1.6 Voltage out of range

If the supply voltage varies above or below the

nominal voltage anticipated (and set as the

benchmark) the dimmer will close down and report

a voltage error. In the case of temporary supply

fluctuations, the fault will auto-reset, but if the

dimmer shuts down, the first point to check is the

voltage calibration setting of the dimmer to make

sure it is set to the local supply voltage.

8.1.7 Disable

If a fault persists beyond the auto-reset time of 10

seconds, the dimmer will close down awaiting

manual intervention and reset. Check the fault log

to see the type of fault which caused the dimmer

to disable.

8.2 First line maintenance

This check list provides initial assistance in the

case of a problem which has not been identified

and reported by the dimmer’s own software.

8.2.1 LCD display blank

Check all power supply connections. Check

module’s RCBO or MCB is on.

8.2.2 LCD display corrupted

Switch off and on again. If the fault persists, open

the module and check all connections, and that

plug-in ICs are secure in their sockets.

8.2.3 No output from one channel

Check the control signal is active. Check the DMX

address is correct. Check there is no ‘l’ showing

on the output screen. Remove the module and

check the internal 15 A fuse.

8.2.4 RCBO trips continuously

Unplug all load plugs. If the fault persists, refer to

service technician. If the RCBO holds in, replace

one plug at a time until the RCBO trips again.

Check the circuit (cables, plugs and sockets,

distribution, lights) for a loose terminals, a phase

to neutral short, a phase to earth short or a neutral

to earth short and correct where necessary.

8.2.5 Dimmer output is full on all the time

Disconnect the DMX cable to isolate control. If the

dimmer is still on, check a) the MANual level has

not been set to 100%; b) the dimmer curve has

not been set to ‘Inverted’; c) the MIN level is at

zero. If the dimmer is still on, and there is no

‘Control’ fault identified, refer to a service

technician.

If the dimmer switches off when the DMX cable is

removed, check that both NON-DIM mode

selections (dimmer curve and Channel

Configuration I/O) are set to OFF. If one or both

these functions are set to ON, the dimmer will be

operating in Non-Dim mode.

8.2.6 Lamp filaments are noisy

Replace the lamp with a new lamp, and in the

case of 110 V PAR lamps, try the circuit with a

different manufacturer’s lamp, as some lamps are

noisy even on smooth mains supplies.

8.2.7 Dimmers work, but DimSTAT doesn’t

recognise all or some dimmers

Check the DMX network to ensure 2-pair cable is

used and correctly connected throughout. If a

DMX booster/isolator unit is used in the network,

check that it supports bi-directional data on pins 4

and 5.

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 14

Page 15

8.2.8 Voltage regulation is not operating

properly

The PowerModule uses a relative measurement of

mains voltage in the general operation of the

dimmer circuit, in the status reporting system, fault

detection and reporting, and output voltage

compensation. For accurate measurement and

operation, the incoming mains supply voltage at

the dimmer is calibrated at the factory. If this

calibration is wrong, the voltage-related

parameters will be affected. The solution is to

recalibrate the PowerModule.

Note: IMPORTANT. This set-up procedure

may only be carried out by a qualified

electrical engineer as it involves an

accurate measurement of the mains

supply.

8.2.9 To calibrate line voltage

This requires a true RMS digital voltmeter, and a

safe means of connecting the voltmeter to the

dimmer’s supply. If the mains supply is known to

have a high impedance, it is advisable to take the

measurement under normal operating loads so

that voltage drop in the supply can be

accommodated in the measurement.

1. Measure the voltage of the

PowerModule power supply.

2. Press INST.

3. Press Ð or Ï to choose

CALL.VOLTAGE menu. Press ENT.

4. The screen shows:

SERV CODE ????

ENTER ↵ ÅÇÈÆ

5.Enter the service password. Press Ï to

set the digit and press Î to enter the

other digits. The screen now shows:

L-1 L-2 L-3

[242] --- ---

Note: The screen shows L-1, L-2 and L-3 for

the three-phase PM6 PowerModule.

5. Press Ð and Ï to adjust the voltage to

match the voltage measured at the

supply. Continue with the other two

phases in the case of the PM6.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

9. Ethernet module

9.1 Introduction

The Ethernet module supports virtual connections

using the Compulite protocol and offers a wide

range of settings. The DMX address structure is

multilayered and based on the Avab protocol:

there are ten logical networks (0-9), each with 32

DMX universes (1-32), and each universe has

512 DMX channels (1-512). It is normally

advisable to use only one logical network per

auditorium, to simplify the system.

DMX universes

Each Ethernet dimmer module supports an A and

a B DMX universe. The A universe is used for the

internal dimmers (and any dimmers connected to

the DMX-A Through output) and the B universe is

used for equipment connected to the DMX-B

output (e.g. scrollers, motorised yokes, etc.).

However, if required A and B could be set to the

same universe.

Non-Ethernet operation

If the module does not receive Ethernet data it will

respond to the data received on the DMX-A input

which is also sent to the DMX-A Through output.

(If both the Ethernet and the DMX-A input receive

data the module will only respond to the Ethernet

data.)

Please note that you will need to be familiar with

your lightboard, the network at your site and basic

networking concepts to make the settings

effectively. Setting the universe for each channel

(where required) is discussed in section 6.5.3 (To

set up DMX universes).

Ethernet settings

The following Ethernet settings are available:

- IP address: this is unique to each module, and

should be selected in consultation with your

network manager. In this example we will use

172.22.4.10.

- Subnet mask: leave at the default value of

255.255.0.0.

- Gateway: leave at the default value of 0.0.0.0.

- Net/Universe A: used to select the logical

network (0-9) and universe (1-32) used for the

DMX-A signal (normally used for the internal

dimmers).

- Net/Universe B: as above, now for the DMX-B

signal (normally used for external equipment).

9.2 To set up the Ethernet options

The network structure and addressing scheme

should be designed in detail before setting the

Ethernet options, to ensure a smoothly working

system. This information should be carefully

archived as it will be needed in future when any

changes are made to the networked dimmer

system.

1. Press INST.

2. Press Ð or Ï to choose the

ETHERNET SETUP menu. Press ENT.

3. Press Ð or Ï to choose the IP

ADDRESS menu. Press ENT.

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 15

Page 16

4. The screen shows:

IP ADDRESS

[172].22.10.100

5. Use the arrow keys to set the address,

which should be different for each

dimmer module.

6. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

7. Once you have returned to the

ETHERNET SETUP menu, press Ð or

Ï to choose the NET/UNIVERSE A

menu (there is no need to change the

subnet mask and gateway settings).

Press ENT.

8. The screen shows:

NET A:[0], 01UA

ENTER

9. Use the arrow keys to set the logical

network and universe for DMX-A (in the

screen above network 0 and universe 1

are selected).

10. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

11. Once you have returned to the

ETHERNET SETUP menu, press Ð or

Ï to choose the NET/UNIVERSE B

menu. Press ENT.

12. The screen shows:

NET B:[0], 02UB

ENTER

13. Use the arrow keys to set the logical

network and universe for DMX-B (in the

screen above network 0 and universe 2

are selected).

14. Press ENT to leave the menu and

record the changes or EXIT (to leave

the previous settings unchanged).

After completing the settings it is advisable to test

the whole system, including any peripherals

connected to the DMX outputs of the networked

dimmers.

IES Ethernet PowerModule Operators’ Manual v1.4 Isine 16

Page 17

10. Declaration of conformity

I.E.S. B.V.

DECLARATION OF CONFORMITY

According to ISO / IEC Guide 22

Manufacturer’s name: I.E.S. B.V.

Manufacturer’s address: Wageningselaan 52-54

3903 LA Veenendaal

Netherlands

Declares that the product:

Product name: PowerModule

Model number: PowerModule no.2234 / 2101 / 2102 / 2235 /

2103 / 2104 / 2236 / 2237 /

2105 / 2106 / 9820.

Conforms to the following product Specifications:

Emission EN 50081-1 / EN 50081-2

EN 55011

EN 55014

Immunity EN 50082-1 / EN 50082-2

EN 55024-2 6 kV Contact discharge

8 kV Air discharge

EN 55024-3 3 V / m

EN 55024-4 1 kV Signal lines

2 kV Power lines

Supplementary information: The product complies with the EMC Directive

89/336/EEC.

Veenendaal

December 2000

J.H.D. de Jonge

Technical Manager

IES Ethernet PowerModule Operators’ Manual v1.4 17

Page 18

11. Index

address structure...................................................15

Avab protocol.........................................................15

Backup settings

defined................................................................4

BASIC

mode defined ....................................................11

BLINK

mode defined ....................................................11

BURST

mode defined ....................................................11

calibrate line voltage

how to ...............................................................15

Channel characteristics ...........................................6

CHAS

front panel control ...............................................3

chaser operation

how to .................................................................5

CHECK

illuminated sign .................................................12

CHK

front panel control ...............................................4

Compulite protocol.................................................15

CONF ......................................................................3

Connections.............................................................2

Control

error message...................................................14

Control panel layout.................................................3

current limitation

enable & disable ...............................................11

data

view channel data ...............................................4

data signals .............................................................2

Declaration of conformity.......................................17

dimmer

data.....................................................................4

dimmer characteristic set-up scheme

to change ............................................................6

dimmer curve

setup ...................................................................9

Dimmer curves.........................................................9

defined................................................................4

dimmer level

chaser control .....................................................5

manual control ....................................................5

DimSTAT ...............................................................13

fault finding .......................................................14

disabled

error message.............................................13, 14

Distributed dimming.................................................2

DMX

front panel control button ....................................3

DMX address

setup ...................................................................7

DMX addressing scheme:........................................6

DMX backup condition

setup ...................................................................7

DMX backup preset

setup ...................................................................8

DMX booster/isolator ...............................................3

DMX data signals.....................................................2

DMX LED ................................................................ 3

DMX Minimum reset

setup................................................................... 8

DMX network........................................................... 3

DMX programming .................................................. 6

DMX universes...................................................... 15

ENT & cursor arrows............................................... 3

errors reported

codes................................................................ 12

Ethernet connectivity............................................... 2

Ethernet module.................................................... 15

Ethernet options

setting up.......................................................... 15

Ethernet settings ................................................... 15

EXIT

front panel control............................................... 4

Factory defaults

defined..............................................................13

factory settings...................................................... 13

Fault finding...........................................................14

Fault reporting....................................................... 12

faults

history report .................................................... 13

filaments are noisy

fault finding....................................................... 14

First line maintenance........................................... 14

Front Panel Controls ............................................... 6

Function overview ................................................... 4

General controls...................................................... 6

IGBT dimming technology....................................... 2

INFO

front panel control............................................... 4

Information displays ................................................ 4

INST

front panel control button.................................... 3

installation ............................................................... 2

Introduction ............................................................. 2

IP address............................................................. 15

Isine technology

IGBT dimming .................................................... 2

Key features of Isine system ................................... 2

LCD display

fault finding....................................................... 14

live data

view channel data............................................... 4

Local control

defined................................................................ 4

location.................................................................... 2

logical networks..................................................... 15

MAN

front panel control............................................... 4

manual control......................................................... 4

manually control a dimmer level

how to................................................................. 5

max. and min levels:

setup................................................................... 8

Maximum

levels - defined ................................................... 4

Maximum & Minimum levels.................................... 8

Maximum current .................................................. 10

IES Ethernet PowerModule Operators’ Manual v1.4 18

Page 19

maximum current levels

setup .................................................................10

MCB

fault finding .......................................................14

minimum

levels - defined....................................................4

Minimum reset

DMX control ........................................................8

Navigation through the menus.................................6

no control

error message.............................................12, 14

no load

error message.............................................12, 14

Non-dim operation

defined................................................................4

Non-Dim operation.................................................10

non-dim switch

setup .................................................................10

Non-Ethernet operation .........................................15

ON LED ...................................................................3

output

fault finding .......................................................14

Over temperature

error message...................................................14

overload.................................................................12

error message...................................................14

passwords

setup .................................................................12

Passwords .............................................................12

PASSWORDS .........................................................6

Pin connections .......................................................3

Positioning...............................................................2

power supply

checking..............................................................4

priority channels

setup .................................................................10

Product range ..........................................................2

Programming ...........................................................5

Programming Advice ...............................................6

PROPortional

mode defined ....................................................11

RCBO

fault finding....................................................... 14

RCD

fault finding....................................................... 14

Reset

factory defaults................................................. 13

Response speed

defined................................................................ 4

Response time ........................................................ 9

response times

setup................................................................... 9

Safety...................................................................... 3

serial address

setup................................................................... 8

Serial address ......................................................... 8

short circuit

error message .................................................. 12

Short circuit

error message .................................................. 14

Sleep mode ........................................................... 12

setup................................................................. 12

SOFT START

mode defined.................................................... 11

software

checking installed versions................................. 5

start mode

setup................................................................. 11

Start Mode............................................................. 11

Status reporting

defined................................................................ 4

temperature

error message .................................................. 12

universes............................................................... 15

Unpacking ............................................................... 2

voltage

error message ............................................ 12, 14

voltage regulation

setup................................................................. 11

Voltage regulation ................................................. 11

XLR

pin connections .................................................. 2

IES Ethernet PowerModule Operators’ Manual v1.4 19

Page 20

Appendix 1: Flowchart

IES Ethernet PowerModule Operators’ Manual v1.4 20

Loading...

Loading...