Page 1

CE Sensor Rack (ESR Series)

®

ECEM to CEM3 Retrofit Manual

Revision A

Copyright © 2011 Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

Released: September 2011

7144M2310

Rev A

Page 2

ETC permits the reproduction of materials in this manual only for non-commercial purposes. All

other rights are reserved by ETC.

®

ETC

, and Sensor® are registered trademarks of Electronic Theatre Controls, Inc. in the United

States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be provided in its entirety.

Page 3

Introduction

This manual is intended to guide ETC Service Technicians through the process of

upgrading existing CE Sensor rack installations to Sensor3 racks with a CEM3 control

module. This manual covers ESR12, ESR24, ESR36 and ESR48 permanent installation

dimming racks.

Contacting ETC Technical Services

If you have questions about the retrofit process that are not answered in this manual, please

contact ETC Technical Services.

United Kingdom Germany Asia

Electronic Theatre Controls Ltd. Electronic Theatre Controls, GmbH Electronic Theatre Controls Asia, Ltd.

Technical Services Department Technical Services Department Technical Services Department

26-28 Victoria Industrial Estate Ohmstrasse 3 Room 1801, 18/F

Victoria Road, 83607 Holzkirchen, Germany Tower 1, Phase 1 Enterprise Square

London W3 6UU England +49 (80 24) 47 00-0 9 Sheung Yuet Road

+44 (0)20 8896 1000 techserv-hoki@etcconnect.com

service@etceurope.com

Kowloon Bay, Kowloon, Hong Kong

+852 2799 1220

service@etcasia.com

Please email comments about this manual to: TechComm@etcconnect.com

Warnings and Notice Conventions

These symbols are used in Sensor documentation to alert you to danger or important

information:

Note:

CAUTION:

WARNING:

WARNING:

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of electric shock.

Introduction 1

Page 4

Safety

Please note the following safety warnings before use:

• Disconnect power from the racks before all maintenance.

WARNING:

Dimmer racks without an accessible power disconnect device cannot be

serviced safely. Before removing dimmer or control modules for service, deenergise main feed to dimmer rack and follow the appropriate safety

procedures for your region.

Overview of this Manual

Reference this manual throughout the retrofit procedure. The major sections of the

procedure are:

• Preparation, page 5 - before you open the rack.

• Remove the Old, page 5 - labeling and remove the existing equipment.

• Data Terminations, page 7 - adapting and connecting the data terminations.

• Attach new power harness, page 8 - adapting and connecting the power harness for

the new backplane.

• Install the New Backplane, page 10 - transfer the wiring and install new components.

• Change out the AF Cards (if present), page 11 - remove the existing Advanced Feature

cards and install the new ones.

• Change out the Beacon PCB, page 12 - replace the beacon pcb with the new one.

• Verify the Retrofit, page 13 - put the dimmers back in the rack and power up the rack.

• Configure the CEM3, page 13 - program a configuration for the CEM3.

When viewing this document in electronic form (.pdf file) with Adobe Acrobat Reader, blue

italicised text followed by a page number such as “Overview of this Manual, page 2” is a

link within the document. If you click on the link, it will jump to that section or topic.

2 CEM3 Sensor ESR Rack Retrofit Manual

Page 5

Section 1

Unpack and Organise

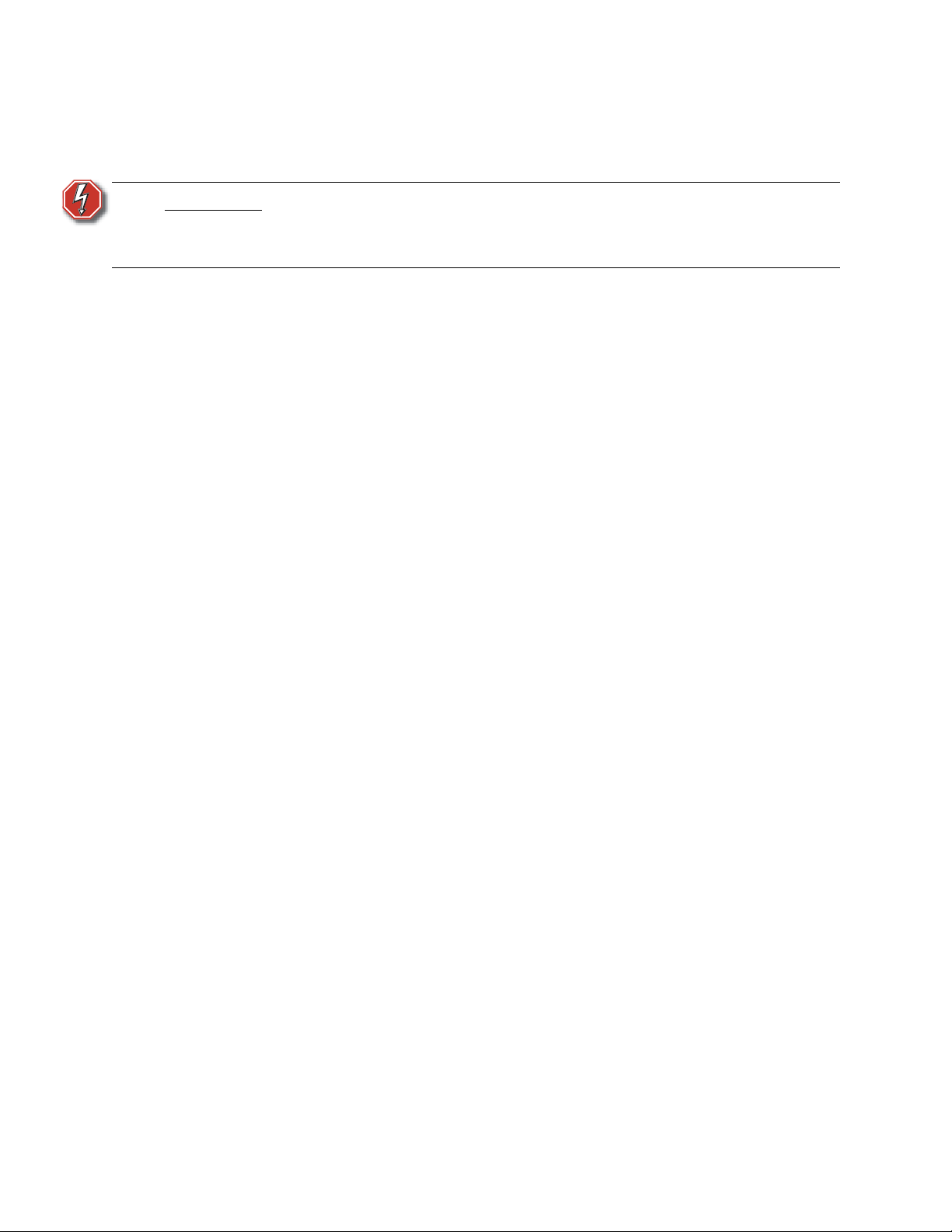

The table below lists the parts and components needed to retrofit a CE Sensor rack

(ESR12, 24, 36 or 48) to become a Sensor3 rack with a CEM3. Each part is listed to reflect

the different quantities for the different kits and types of racks.

Parts/Components

ETC Part Number

Beacon Door Acrylic

7051A4116

CAT5 Termination Kit

4101A2003

Sensor3 Beacon Blue Assembly

7141B5109

Sensor3 Install Rack Door Label

7141A4001

8-pin Screw Terminal Data Connector

J3407-F

ECEM Classic to CEM3 Power Adapter Harness, ESR12

7144B7002

ECEM Classic to CEM3 Power Adapter Harness, ESR24-48

7144B7003

CE Sensor3 Install Rack Backplane Assembly, Sgl Height

7144A2000-CFG

CE Sensor3 Install Rack Backplane Assembly, Dbl Height

7144A2001-CFG

Sensor+/3 Filler Module

7150A3010

Sensor Rack CEM Classic to CEM3 Retrofit Manual

7144M2310

CAT5e Cable RJ45/RJ45 UTP 2ft

Parts Included in the Kits

N4035

Screw 6-32 X 3/8 Ph PH MS CP W/Patch

HW222

Screw M4 X 10mm Ph PH MS W/Patch

HWM1346

Cable tie 4" Hi-temp Black

HW7121

CEM3 Backplane 1/8” #8 screw spacer

HW9343

Tie-mount (sticky-back)

HW741

Heat Shrink 1-1/2” x 4-1/2” Black

W682

ESR12 Rack

7144K1000

11

11

11

11

22

1

1

11

11

33

33

28 28

33

14 14

22

ER24-48 Rack

7144K1001

1

1

1

Additional Items

Sensor3 AF Card (for all AF racks)

7150B5623

CEM3

7140A1001

Additional

Line Items

up to 4*

1

* Need/quantity based on specific rack type. For details contact ETC Technical Services (see Contacting ETC

Technical Services, page 1).

1 Unpack and Organise 3

Page 6

Required Tools

#1 Phillips screwdriver

#2 Phillips screwdriver

6mm flat head screwdriver

PVC Electrical tape

Heat gun

Diagonal wire cutter

Permanent marker

Wire strippers

4 CEM3 Sensor ESR Rack Retrofit Manual

Page 7

Section 2

The Retrofit

Preparation

Step 1: Use Sensor Configuration Editor and a SLTA if you wish to download and save

the current Sensor configuration out of the racks for later reference. For

information on this process contact ETC Technical Services (see page 1).

Step 2: Turn off main power to the rack(s).

Step 3: Remove the eight dimmer modules above the ECEM (if retrofitting an ESR36 or

48 rack, remove the eight modules below the ECEM as well). Note and document

the modules’ order/positioning in the rack for proper insertion and configuration

later.

Step 4: Use a digital voltmeter to VERIFY that power is off by checking voltages for all

combinations between the phase bars, neutral and earth.

Step 5: Remove the ECEM(s) from the rack.

Remove the Old

Note:

Many of the components you will be removing are valuable dimming components

and can be used by ETC to support other systems.

Please return old ECEM processors, ECEM backplanes, and fan relays to the

local ETC office (see page 1 for address).

Step 1: Unscrew the power backplane connector(s) from the old backplane metal

Step 2: Feed the power connectors through the backplane metal so they are loose next

to the phase bars.

Step 3: Unscrew the backplane PCB from the backplane metal by undoing the remainder

of the screws

Step 4: Unscrew the backplane metal from the rack by undoing the two screws that go

2 The Retrofit 5

Page 8

through the standoffs on the side of the backplane into the rack metal

Step 5: Pull backplane towards the front of the rack to free the backplane side tabs

Step 6: Bend the right side of the backplane metal toward the centre (away from the side

of the rack)

Step 7: Slide backplane metal forward to remove it from the rack, cut the earth lead to

the chassis and discard the wire.

Step 8: Mark the connectors on the grey dimmer output ribbon cables (using permanent

marker).

• The connectors are designated 1-24, 25-48, 49-72 and 73-96 (depending on

the size of the rack, you may have fewer ribbon cables).

• The connector can be identified by referring to the white printing on the old

backplane PCB

Step 9: Once all the ribbon cables are marked, disconnect them.

Step 10: If fitted, remove the ferrite toroids from the cables and discard.

Step 11: Document and remove the input data wires (ETCLink, DMXA, DMXB and Panic).

Note:

Be sure to note and label the wires before disconnecting them from the terminal

strips. You will need to connect these wires to the new backplane in the correct

order later.

Step 12: Disconnect the 5 pin beacon & fan relay control connector from the backplane

PCB

Step 13: If in a dual tracking system, disconnect the 3 pin local switch connector from the

backplane

Step 14: Remove the backplane PCB and return the backplane to ETC Technical

Services (see page 1).

Step 15: Cut the 5 pin header from the beacon cable, as close as possible to the connector

that was connected to the backplane PCB.

Step 16: Locate the fan filter relay board for your rack. The fan filter relay board is located

behind the ECEM attached to the back of the rack for ESR24,36 and 48 racks.

• The fan filter relay board is located at the top of the rack in ESR12 racks

6 CEM3 Sensor ESR Rack Retrofit Manual

Page 9

Step 17: Disconnect the three Molex power connectors and the small relay control

Power In

Power Out

Control Input

Beacon

Pin-out

Black

Blue

Red

connector from the fan filter relay board.

Note:

Step 18: By pulling the relay control wires through, you should be able to remove them

Step 19: Remove the harness that ran from the fan filter relay board to the ECEM power

The fan filter relay board is not used after upgrade. It can be removed from the

rack if desired, or left in place.

from the rack. You will be left with three beacon wires at the backplane location.

connector, carefully clipping cable ties as required.

Data Terminations

Connect beacon wires

Step 1: Strip 6mm (1/4 inch) of insulation from the end of the remaining red,

Step 2: Connect the three wires to the 3 pin phoenix connector supplied in

blue and black wires (the beacon wires)

the new backplane, in the order shown at right.

123

J16

2 The Retrofit 7

Page 10

Transfer DMX Wires

When transferring wire groups be sure to transfer all wire groups (except those designated

as ETCLink) to the new connectors separately to avoid confusion.

a: In most cases stranded wire has been used for the data terminations. If so,

terminate the DMX wiring to the new connectors (found in the kit) in the same

manner as they were to the old backplane. Double-up the DMXA pass-thru

wiring to the same terminals as the DMXA wires. The DMX pass-thru

connector on the CEM3 backplane will not be used.

b: If Category 5 type cabling (or better) has been used for the DMX wire runs, IDC

connectors must be used (ordered separately) for the new terminations.

Connect the pass-thru wires to an IDC connector and land the rack-to-rack

jumper connections on the separate “DMX PASS-THRU” connector (J12) on

the new backplane. DMXA PASS-THRU = Common - 1, Negative - 2, Positive

- 3. DMXB PASS-THRU = Common - 4, Negative - 5, Positive - 6.

CAUTION:

Step 3: Connect the DMXA wires to an 8-pin connector. DMXA wires connect to the

Step 4: Connect the DMXB wires to another 8-pin connector. DMXB wires connect to the

If using the IDC connector for CAT5 solid-core wiring, you must start with clean

wire ends (clip the old punched end). Re-punching the old ends could result in an

intermittent or failed connection.

following terminals: Gray wire (Common)- 1, Black (DMX Negative) - 2, Red

(DMX Positive)- 3.

following terminals: Clear wire (Common) - 1, Black (DMX negative) - 2, White

(DMX Positive) - 3.

Cap ETCLink Wires (if present)

Step 5: Locate the ETCLink wires you removed from the backplane

Step 6: Secure wires as follows:

a: Cut all bare ends from the link wires.

b: Safely cap the wire ends.

c: Coil the wires into a neat bundle and secure with a wire tie.

d: Secure the cabling to the side or back of the rack with tie mounts and wire ties

so they do not interfere with normal rack function

Note:

Wire runs for ETCLink are abandoned in the rack and can be used in the future as

DMX wire runs in the event that a DMX line must be replaced for any reason.

.

Attach new power harness

Step 1: Connect the transition power harness to the two molex connectors that were

disconnected from the fan filter relay board

Step 2: Run the transition harness into position at the left hand side of the rack for

connection to the new backplane.

• For ESR36 and 48 racks, it runs behind the L2 Phase bar

• For ESR24 and 12 racks it runs into the open space behind the backplane

Step 3: Run the earth wire to the earth bar of the rack and secure it using the small screw

on the bar.

• Due to different rack sizes, there may be extra earth cable left. If so, bunch

it neatly and cable tie it into the back of the rack.

Step 4: Secure the transition harness using the provided 4” cable ties and sticky bases.

8 CEM3 Sensor ESR Rack Retrofit Manual

Page 11

Backplane Settings

Set termination to “Off”

(middle position)

Set DIP switches

Emergency Contact

(Panic) switch

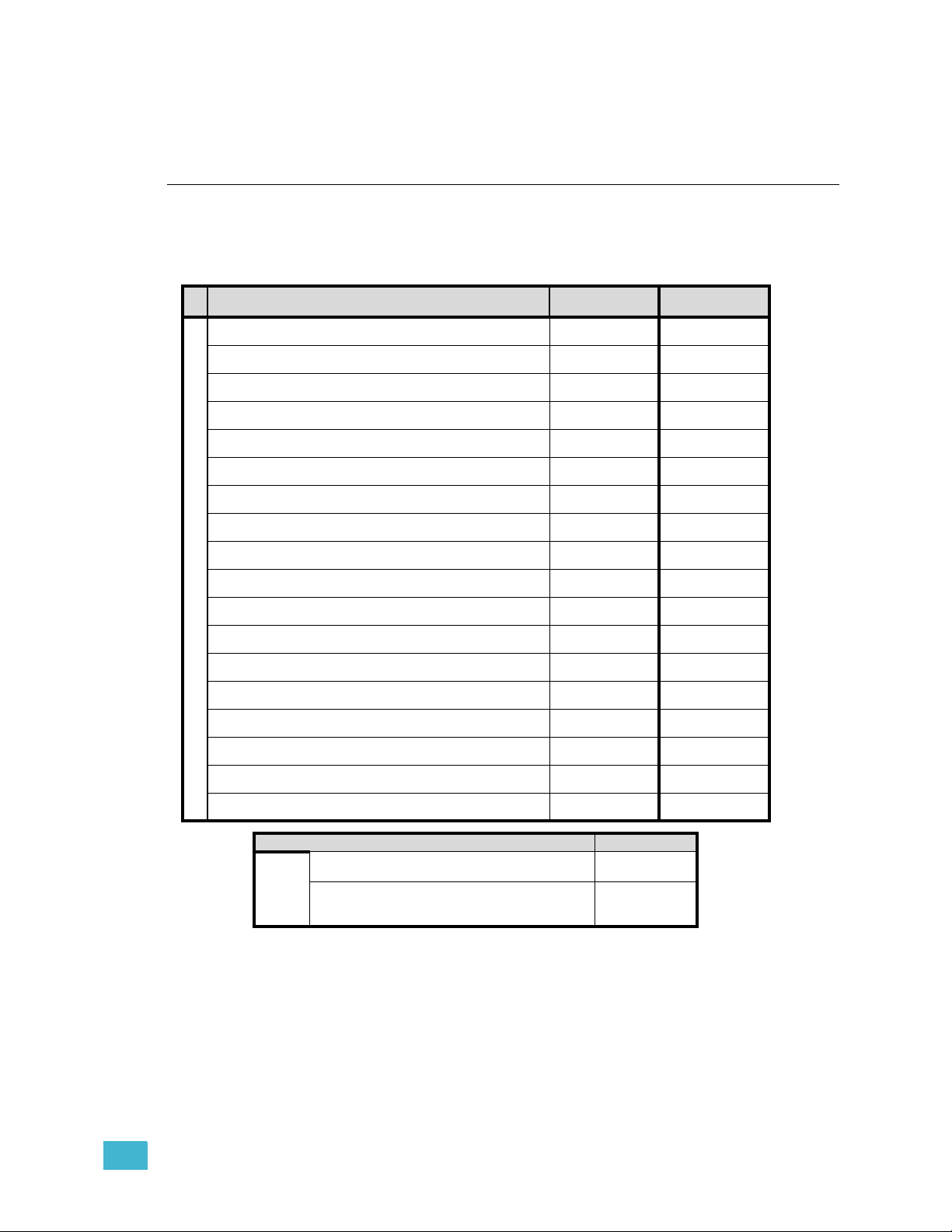

Upgrade kit backplanes ship from the factory with all DIP switches in the off (down) position.

You will have to set the DIP switches on the new backplane to match your rack. You will

also have to verify the termination switch settings.

a: Set both termination switches to “Off” (middle position) for all racks except the

last rack in your system.

b: Set the termination switches for the last rack in the system to “ON” (top

position).

c: Using a precision screwdriver, set the DIP switches to match your rack type

according to:

• number of modules (12, 24, 36 or 48)

• whether the rack has Advanced Features (AF)

Use the following chart to determine your required DIP switch settings:

Rack Model 12345678

ESR3-12 On On

ESR3-12N On On On

ESR3-12AF On On On

ESR3-12AFN On On On On

ESR3-24 On On

ESR3-24N On On On

ESR3-24AF On On On

ESR3-24AFN On On On On

ESR3-36 On On

ESR3-36N On On On

ESR3-36AF On On On

ESR3-36AFN On On On On

ESR3-48 On

ESR3-48N On On

ESR3-48AF On On

ESR3-48 AFN On On On

DIP switch Number

“On” position = switch pushed to the top

d: Check to see that the “Emergency Contact” switch is set to the appropriate

position.

• If your system has no panic circuit, the switch should be set to the middle

position, “DISABLED”.

• If your panic circuit includes a N

ormally Open contact closure, the switch

should be set to the top position (NO).

• If your panic circuit includes a N

ormally Closed contact closure, the switch

should be set to the bottom position (NC).

2 The Retrofit 9

Page 12

Terminating the ethernet cable inside the rack

DMX ADMX BDMX Thru

Beacon

Power

CEM3 Ribbon Cable Layout

1

2

3

4

(25-48)

(73-96)

(49-72)

(1-24)

Since you will be adding ethernet capability to your ESR rack, ETC has provided the CAT5

Termination Kit (ETC Part#4101A2003). This kit includes a CAT5 connector and a small

surface mount box (called a “Biscuit Box”) as well as an instruction sheet.

Follow the instructions in this kit for terminating the ethernet cable at the CAT5 connector

and enclosing the connector in the biscuit box. The biscuit box will then be mounted inside

of the ESR rack in the next section.

Install the New Backplane

Step 1: Bend one arm of the new backplane metal in

towards the opposite arm (about 30 deg).

Step 2: Insert the backplane metal on an angle. Then

straighten it once it is past the face of the rack.

Push it into the rack far enough that it stays in

place, but leave yourself some room to make

the power and data connections.

Step 3: Make the power and data connections on the

backplane.

a: Install the dimmer output ribbon cables.

Open the black retaining tabs for each

connector until they are at a 45° angle to the

backplane. Press the ribbon cables into their respective locations until the tabs

lock in place at a 90° angle to the backplane.

Note: The order/layout for the cables is not the same as on the old backplane

(see illustration below). Make sure the proper side is facing up on each

connector and that each connector is fully seated.

b: Install the power harness (Look at the pin shapes for proper orientation. It will

only fit one way.)

c: Install the DMX connections. (The wires travel out of the top on both styles of

connectors.)

d: Install the 3-pin beacon connector (The wires travel out of the top of the

connector)

e: Connect the CAT5 biscuit box to the ethernet connector on the backplane using

the 1' CAT5 Ethernet cable. (Not shown in the drawing below for clarity.)

• In an ESR12 or ESR24, use the double-stick tape (on the box) to secure the

biscuit box to the bottom of the rack behind the backplane.

• In an ESR36 or ESR48, use the double-stick tape (on the box) to secure the

biscuit box to the interior rear wall of the rack, behind the backplane.

10 CEM3 Sensor ESR Rack Retrofit Manual

Step 4: Push the backplane completely into place in the rack. Be careful not to disrupt

the power and data connections you just made. Make sure none of the wiring

Page 13

becomes stressed or pinched.

Screw with

sleeve

Single-height backplane shown.

Flip tab down, pull card out

1

2

LEDs found

on newer

cards

AF Card Addressing

Card 1

Card 2

Card 3

Card 4

S

W

1

S

W

2

S

3

S

1

ESR3-12

ESR3-24

ESR3-48

2

3

4

Sensor+

O = Switch in down position

ESR3-36

Step 5: Insert the backplane tabs in the

sides of the rack.

Step 6: With the tabs fully inserted in the

sides of the rack, pull the

backplane towards the front of

the rack to line up the screw

holes in the upper side corners

to line up.

Step 7: Install one screw with a sleeve in the upper-corner (for single-height backplanes)

or the middle of the rear edge (for dual-height backplanes) of each side of the

backplane.

Note:

You cannot use the old screws without the additional shoulder-sleeve as they will

block the CEM3 from being fully inserted.

Change out the AF Cards (if present)

If your rack supports Advanced Features (AF)

you will need to replace the AF cards as well.

CEM3 only supports use of the newer-style AF

cards, which have eight address switches and

two LEDs (shown at right).

AF cards are located on the right side of the

dimmer module slot between the copper neutral

busses and the dimming circuitry cards.

To replace the AF cards:

Step 1: Remove the old AF cards by flipping

the white retainer tab on the cards into

the down position.

Step 2: Pull the old cards out of the slots.

Step 3: Set the DIP switches on the new cards according to the chart below. Only the first

two DIP switches are used.

Step 4: Slide the new AF cards completely into the vacant slots starting with card #1 in

the top. The number of cards depends on rack size.

Step 5: Flip the white tab up to lock the new card in place.

2 The Retrofit 11

W

W

4

Page 14

Change out the Beacon PCB

Step 1: Remove the top four dimmer modules from the rack to allow access to the PCB.

Step 2: Remove the two screws that hold the beacon PCB in the face of the rack.

Note:

Step 3: Pull the PCB down from inside the rack

Step 4: Note the orientation of the connector and

Step 5: Attach the wire harness to the new

Step 6: Install the new beacon PCB (ETC Part #

Be sure to use a properly sized screw driver (#2 Phillips) and a good amount of

force as these screws are kept in place with thread locker. Don’t worry about

damaging the existing screws (replacements are provided) or shearing off the

heads of the screws (the screw shanks are threaded into the PCB’s standoffs).

case. (The wire harness will only allow a

few inches of movement).

unplug the wire harness from the old

beacon PCB.

beacon PCB making sure the connector

is in the same orientation as before.

7141B5109) with two screws (ETC Part #

HW222) (two new screws of the same type are provided in case the old ones

were damaged during the removal process).

Finishing Touches

Step 1: Remove the old Sensor beacon acrylic in the door by loosening the two retaining

screws with a #2 Phillips screwdriver. You may discard the beacon acrylic.

Step 2: Install the Sensor3 beacon acrylic in

the door.

Step 3: Carefully peel the old Sensor label

from the front of the door and discard.

Step 4: Clean the door surface to remove any

dirt or old adhesive and wait until it is

clean and dry

Step 5: Apply the new Sensor3 label to the

front of the door. Line up the label

around the opening for the acrylic in

the door and be sure the label is

straight. Press and wipe with a piece

of cloth or paper towel to make sure

the label is flat & smooth and properly

adhered to the rack door.

12 CEM3 Sensor ESR Rack Retrofit Manual

Page 15

Repeat the above steps for the remainder of connected racks.

Note:

Please return old ECEM processors, ECEM backplanes, and fan relays to the

local ETC office (see page 1 for address).

Verify the Retrofit

Step 1: Put the dimmer modules back in the rack in the correct/original order.

Step 2: Put the CEM3 in the rack.

Step 3: Power up the rack.

Step 4: Check that the CEM3 powers up and the rack fan turns on. (The only rack errors

should be a lack of DMX on the ports if the DMX source is not present.)

Configure the CEM3

Step 1: Configure the rack to reflect the dimmer module types installed. Verify that the

rack type is correct (CEM3 should have determined this from the DIP switch

settings - see Backplane Settings, page 9). Configuration of the CEM3 is done

using the front face panel interface. See the CEM3 Quick Guide that ships with

the CEM3 for more information.

Step 2: Configure the data types that will be used (DMX and sACN) including the rack

patch.

2 The Retrofit 13

Page 16

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Pieve Torina, 48, 00156 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0) 20 8752 8486

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7144M2310

Rev A Released 2011-09

Copyright © 2011 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...