Page 1

Sensor3 CE Rack (ESR3 Series)

®

Installation Manual

Revision F

Copyright © Electronic Theatre Controls, Inc.

All rights reserved.

Product information and specifications subject to change.

Part Number: 7144M2100 Rev F

Released: May 2013

Page 2

ETC permits the reproduction of materials in this manual only for non-commercial purposes.

All other rights are reserved by ETC.

®

ETC

and Sensor® are either registered trademarks or trademarks of Electronic Theatre

Controls, Inc. in the United States and other countries.

ETC intends this document, whether printed or electronic, to be provided in its entirety.

Page 3

Table of Contents

Warnings. . . . . . . . . . . . . . . . . . . . . . . iii

Introduction . . . . . . . . . . . . . . . . . . . . . .1

How to use this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . .1

Warning and Notice Conventions . . . . . . . . . . . . . . . . . .1

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Prepare for Installation . . . . . . . . . . . . .3

Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . . .3

Energising the System . . . . . . . . . . . . . . . . . . . . . . . . . .3

Use 90°C Copper Wire . . . . . . . . . . . . . . . . . . . . . . . . . .3

Where to Mount the Rack . . . . . . . . . . . . . . . . . . . . . . . .4

Dimmer Room Requirements . . . . . . . . . . . . . . . . . . . . .4

Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation of Racks . . . . . . . . . . . . . . .5

Mounting the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mounting Racks on a Wall (ESR3-12 and ESR3-24) . . .5

Installing ESR3-36 and ESR3-48 Racks on the Floor . .6

Pedestal Mounting an ESR3-24 Rack . . . . . . . . . . . . . .6

Securing Sensor3 Racks to a Wall . . . . . . . . . . . . . . . . .7

Wall Mounting Racks Using Vibration Pads . . . . . . . . . .8

Floor Mounting Racks Using Vibration Pads . . . . . . . . .8

Securing Multiple Racks (Optional) . . . . . . . . . . . . . . .10

Rack Cabling Access . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing Line Feed Cable. . . . . . . . . . . . . . . . . . . . . .12

Land Load Wires. . . . . . . . . . . . . . . . .13

Land Load Wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Cut Key Slots for Modules . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cutting Key Slots for 25A and 50A Modules. . . . . . . . .15

Converting Neutral Disconnect Slots . . . . . . . . . . . . . .16

Installing Three-Slot Dimmer Lug Strips . . . . . . . . . . . .17

Control and Data Connections . . . . . .19

Dual and Single Backplane Differences . . . . . . . . . . . .19

Running DMX Cable to Racks. . . . . . . . . . . . . . . . . . . . . . .20

DMX Termination - Screw Terminals . . . . . . . . . . . . . .20

DMX Termination - IDC Connection . . . . . . . . . . . . . . .20

Setting DMX Termination . . . . . . . . . . . . . . . . . . . . . . .21

Running Ethernet to Racks . . . . . . . . . . . . . . . . . . . . . . . . .22

Ethernet with a NEFM. . . . . . . . . . . . . . . . . . . . . . . . . .22

Ethernet with an External Network . . . . . . . . . . . . . . . .22

i

Page 4

Ethernet Network Termination - RJ45 Connector. . . . . 23

Panic Circuit Connections (Optional) . . . . . . . . . . . . . . . . . 23

Panic Circuit backplane connection . . . . . . . . . . . . . . . 23

Dual Tracking Remote Select Switch connection (Optional)24

Station Connection (Optional) . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting Station Wiring . . . . . . . . . . . . . . . . . . . . . . 25

Connect ESD Ground. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Finishing Installation . . . . . . . . . . . . . . 27

Check Backplane DIP Switches . . . . . . . . . . . . . . . . . . 27

Energising the System . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sensor3 Installation Checklist . . . . . . . . . . . . . . . . . . . 28

Sealing Rack Air Leaks . . . . . . . . . . . . . . . . . . . . . . . . 28

Attaching the door . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Checking Rack Installation before Installing Modules . . . . . 31

Before Applying Power to the Rack . . . . . . . . . . . . . . .31

Installing Advanced Features (AF) Cards (Optional) . . 31

Installing the Control Electronics Module (CEM3) . . . . 31

Installing Dimmer Modules . . . . . . . . . . . . . . . . . . . . . . 32

Installing Module Locking Bars. . . . . . . . . . . . . . . . . . . 32

Completing Installation . . . . . . . . . . . . . . . . . . . . . . . . . 32

Appendix A

Appendix B

Appendix C

Testing an Installed Sensor3 Rack . . . . . . . . . . . . . . . . . . . 33

Checking individual dimmer operation . . . . . . . . . . . . . 33

Sensor3 CE Rack Specifications . . . .34

Sensor3 Installation Checklist. . . . . . . 35

Beforehand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DMX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rack - Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

End User Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Emergency Modules . . . . . . . . . . . . . .36

About Emergency Modules . . . . . . . . . . . . . . . . . . . . . 36

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ii Sensor3 CE Rack (ESR3) Installation Manual

Page 5

Warnings

WARNING:

(GB)

WARNUNG:

(DE)

• INCORRECT CONNECTION MAY CAUSE DAMAGE OR INJURY.

• FOR PROFESSIONAL USE ONLY.

• THIS EQUIPMENT MUST ONLY BE CONNECTED AND OPERATED BY

AUTHORISED PERSONNEL.

• READ NOTICES AND WARNINGS IN PRODUCT DOCUMENTATION

BEFORE USE.

• WARNING: HIGH LEAKAGE CURRENT; THIS EQUIPMENT MUST BE

GROUNDED.

• ISOLATE POWER BEFORE REMOVING COVERS.

• FALSCHER ANSCHLUSS KANN ZU BESCHÄDIGUNGEN ODER

VERLETZUNGEN FÜHREN.

• NUR FÜR PROFESSIONELLEN EINSATZ.

• DIESES GERÄT DARF NUR VON AUTORISIERTEM FACHPERSONAL

ANGESCHLOSSEN UND BETRIEBENWERDEN.

• LESEN SIE VOR INBETRIEBNAHME DIE HINWEISE UND WARNUNGEN IN

DER PRODUKTBESCHREIBUNG.

• WARNUNG: DIESES GERÄT MUSS WEGEN MÖGLICHER HOHER

LECKSTRÖME UNBEDINGT GEERDET WERDEN.

• VOR ABNEHMEN DER ABDECKUNGEN UNBEDINGTSPANNUNGSFREI

SCHALTEN.

ADVARSEL:

(DK)

PRECAUCIÓN:

(ES)

• FORKERT TILSLUTNING KAN FORÅRSAGE FEJL OG PERSONSKADE.

• KUN TIL PROFESSIONELT BRUG.

• DETTE UDSTYR MÅ KUN TILSLUTTES OG BETJENES AF AUTORISERET

PERSONALE.

• LÆS NOTES OG ADVARSLER I PRODUKTETS DOKUMENTATION FØR

BRUG.

• ADVARSEL: STÆRKSTRØM, UDSTYRET SKAL JORDFORBINDES.

• AFBRYD STRØMMEN FØR UDSTYRET ADSKILLES.

• UNA CONEXIÓN INCORRECTA PUEDE RESULTAR PELIGROSA ADEMÁS

DE DAÑAR EL EQUIPO.

• SOLO PARA USO PROFESIONAL.

• ESTE EQUIPO DEBE DE SER CONECTADO Y OPERADO ÚNICAMENTE

POR PERSONAS AUTORIZADAS.

• LEER ATENTAMENTE LA DOCUMENTACIÓN ANTES ESTE EQUIPO.

• !PRECAUCIÓN!, ALTAS CORRIENTES DE FUGA, ESTE DEBE DE SER

PUESTO A TIERRA.

• DESCONECTAR LA POTENCIA ANTES DE ABRIR.

Warnings iii

Page 6

VAROITUS:

(FI)

• KYTKENTÄVIRHE VOI AIHEUTTAA LAITTEEN RIKKOUTUMISEN TAI

HENGENVAARAN.

• VAIN AMMATTIKÄYTTÖÖN.

• LAITTEEN SAA KYTKEÄ AINOASTAAN KOULUTETTU, ASIANSA

OSAAVA HENKILÖ.

• LUE VARIOTUKSET LAITTEEN KÄYTTÖOHJEISTA ENNEN KÄYTTÖÄ.

• VAROITUS: SUURI VUOTOVIRTA, LAITE ON EHDOTTOMASTI

MAADOITETTAVA.

• KYTKE VIRRANSYÖTTÖ POIS AINA ENNENKUIN POISTAT LAITTEEN

SUOJUKSET.

ATTENTION:

(FR)

PROEIDOPOIHSH:

(GR)

• DES ERREURS DE CONNEXION ELECTRIQUE POURRAIT PROVOQUER

DES DOMMAGES OU BLESSURES.

• UTILISATION PROFESSIONELLE SEULEMENT.

• CET APPAREIL DOIT ETRE BRANCHÉ ET MANIPULÉ UNIQUEMENT PAR

DES PERSONNES AUTORISÉES.

• LIZEZ ATTENTIVEMENT LES NOTICES ET LES AVERTISSEMENTS DE LA

DOCUMENTATION AVANT L'UTILISATION.

• ATTENTION: COURANT DE FUITE ELEVÉ, CET APPAREIL DOIT ETRE

CONNECTÉ À LA TERRE.

• ISOLER AVANT D'ENLEVER LES COUVERCLES.

•

DAQOS SUNDESMOLOGIA MPOREI NA PROKALESEI

BLABH H TRAUMATISMO.

•

MONO GIA EPAGGELMPTIKH CRHSH.

•

H SUNDESH KAI O CEIRISMOS TOU

MHCANHMATOS NA GINEI MONO APO

EXOUSEIODOTHMENO PROSWPIKO.

•

PRIN APO THCRHSH DIABASTE TIE

PROEIDOPOIHSEIS STO EGCEIRIDIO.

•

PROEIDOPOIHSH: MEGALH DIARROH REUMATOS,

AUTOS O EXOPLISMOS PREPRI NA GEIWNETAI.

•

APOMOMWSTE THN TROFODOSIA PRIN THN

AFPIRESH TWN KAPAKIWN.

ATTENZIONE:

(IT)

iv Sensor3 CE Rack (ESR3) Installation Manual

• L’ERRATA CONNESSIONE PUO CAUSARE DANNI A COSE E A

PERSONE.

• SOLO PER USO PROFESSIONALE.

• QUESTO EQUIPAGGIAMENTO DEVE ESSERE COLLEGATO O AXIONATO

SOLAMENTE DA PERSONALE AUTORIZZATO.

• LEGGERE GLI AVVISI E LE SEGNALAZIONI CONTENUTI NELLA

DOCUMENTAZIONE DEL PRODOTTO PRIMA DELL’USO.

• ATTENZIONE: ALTE CORRENTI DI PERDITA, QUESTO

EQUIPAGGIAMENTO DEVE ESSERE COLLEGATO A TERRA.

• TOGLIERE TENSIONE PRIMA DI RIMUOVERE I COPERCHI.

Page 7

WAARSCHUWING:

(NL)

• VERKEERD AANSLUITEN KAN RESULTEREN IN SCHADE OF

LETSEL.

• ALLEEN VOOR PROFESIONEEL GEBRUIK.

• DEZE APPARATUUR MAG ALLEEN DOOR GESPECIALISEERD

PERSONEEL AANGESLOTEN WORDEN.

• LEES EERST DE GEBRUIKSAANWIJZING VOOR HET APPARAAT TE

GEBRUIKEN.

• WAARSCHUWING: DIT APPARAAT MOET GEAARD ZIJN!

• SCHAKEL DE VOEDINGSSPANNING UIT VOOR OPENEN VAN DE

KAST.

ADVARSEL:

(NO)

AVISO:

(PT)

• FEIL KOBLING KAN FORÅRSAKE STOR SKADE.

• KUN FOR PROFESJONELT BRUK.

• DETTE UTSTYRET MÅ KUN KOBLES OG OPERERES AV AUTORISERT

PERSONEL.

• LES BRUKSANVISNING OG SPESIELT ADVARSLER FØR BRUK.

• ADVARSEL: DETTE UTSTRYRET HAR HØYE LEKKASJE STRØMMER.

UTSTYRET MÅ VÆRE JORDET.

• SKRU AV STRØMMEN FØR DU TAR AV DEKSLER.

• LIGAÇÃO INCORRETA PODE CAUSAR DANOS PESSOAIS OU/E

MATERIAIS.

• SOMENTE PARA USO PROFISSIONAL.

• ESTE EQUIPAMENTO DEVE SER LIGADO E OPERADO UNICAMENTE

POR PESSOAL AUTORIZADO.

• LEIA AS INSTRUÇÕES E AVISOS NA DOCUMENTAÇÃO DO

EQUIPAMENTO ANTES DE USAR.

• AVISO: ELEVADA CORRENTE DIFFERENCIAL, ESTE EQUIPAMENTO

DEVE SER LIGADO À TERRA.

• ISOLAR O CIRCUITO ANTES DE REMOVAR AS TAMPAS.

VARNING:

(SE)

• FELAKTIG ANSLUTNING KAN ORSAKA OLYCKOR ELLER SKADOR.

• FÖR PROFFESSIONELT BRUK.

• UTRUSTNINGEN FÄR ENDAST ANVÄNDAS OCH ANSLUTAS AV

SÄRSKILT INSTRUERAD PERSONAL.

• LÄS INSTRUKTIONER I DOKUMENTATIONEN FÖRE ANVÄNDING.

• VARNING: LIVSFARLIG SPÄNNING. UTRUSTNINGEN MÄSTE VARA

SKYDDSJORDAD.

• BRYT STRÖMMEN INNAN HÖLJET BORTTAGES.

Warnings v

Page 8

DIKKAT:

(TR)

• YANLIŞ BAĞLANTI, HASAR VEYA YARALANMALARA SEBEP OLABİLİR.

• YALNIZCA PROFESYONEL KULLANIM İÇİNDİR.

• BU CİHAZ, YALNIZCA YETKİLİ BİR KİŞİ TARAFINDAN BAĞLANMALI VE

KULLANILMALIDIR.

•CİHAZI KULLANMADAN ÖNCE KULLANMA KILAVUZUNDAKİ UYARILAR

BÖLÜMÜNÜ DİKKATLİCE OKUUN

•DİKKAT: YÜKSEK KAÇAK AKIM. CİHAZ MUTLAKA

TOPRAKLANMALIDIR.

• KAPAKLARI AÇMADAN ÖNCE ENERJİ BAĞLANTISINI MUHAKKAK

KESİN.

VAROVÁNÍ:

(CZ)

• Nesprávné připojení může způsobit škodu nebo zranění.

• POUZE PRO PROFESIONÁLNÍ POUŽITÍ!

•Toto zařízení musí být zapojeno a provozováno pouze

oprávněnou osobou!

•Před použitím si pečlivě přečtěte oznámení a varování v dokumentaci k

produktu.

• VAROVÁNÍ: Vysoký svodový proud; Toto zařízení musí být

UZEMNĚNO!

•Před odstraněním krytů odpojte zařízení od sítě!

Меры предосторожности:

(RU)

• Неправильное подключение может привести к

повреждению оборудования или травме

• Только для профессионального применения

• Подключение и обслуживание должно производиться

обученным персоналом

• Перед использованием внимательно изучите

сопроводительную документацию

• Осторожно: Высокие токи утечки; оборудование

должно быть надежно заземлено

• Перед снятием кожуха отключите питание установки

vi Sensor3 CE Rack (ESR3) Installation Manual

Page 9

Introduction

Welcome to the installation manual for Sensor®3 CE racks. This manual contains the

procedures for safe and efficient installation of Sensor3 rack dimming systems. There are

four sizes of installation racks:

• ESR3-12 – Twelve dimmer slots (up to 24 circuits)

• ESR3-24 – Twenty-four dimmer slots (up to 48 circuits)

• ESR3-36 – Thirty-six dimmer slots (up to 72 circuits)

• ESR3-48 – Forty-eight dimmer slots (up to 96 circuits)

How to use this Guide

Use this guide during system installation. It contains complete installation instructions.

• Prepare for Installation, page 3 tells you about things you should check before

commencing installation, like space, power and cooling requirements for your Sensor3

installation.

• Installation of Racks, page 5 tells you how to mechanically install the racks and connect

the feeder cables.

• Land Load Wires, page 13 tells you how to connect the outgoing wiring to your loads.

• Control and Data Connections, page 19 tells you how to connect DMX, Ethernet and

other data wiring to your rack.

• Finishing Installation, page 27 tells you how to finish the installation of your rack. Note

that the operations in this chapter should be performed by ETC trained technicians.

When viewing this document in electronic form (.pdf file) with Adobe Acrobat Reader, blue

italicised text followed by a page number such as How to use this Guide, page 1 is a link

within the document. If you click on the link, it will jump to that section or topic.

Warning and Notice Conventions

These symbols are used in the Sensor3 documentation to alert you to danger or important

information.

Note:

CAUTION:

WARNING:

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

WARNING:

Introduction 1

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of electric shock.

Page 10

Contacting ETC

If you are having difficulties, your most convenient resources are provided in this installation

manual. To search more widely, try the ETC website at www.etcconnect.com

these resources is sufficient, contact ETC Technical Services directly at one of the offices

identified below.

Americas United Kingdom

Electronic Theatre Controls Inc. Electronic Theatre Controls Ltd.

Technical Services Department Technical Services Department

3031 Pleasant View Road 26-28 Victoria Industrial Estate

Middleton, WI 53562 Victoria Road,

800-775-4382 (USA, toll-free) London W3 6UU England

+1-608 831-4116 +44 (0)20 8896 1000

service@etcconnect.com service@etceurope.com

Asia Germany

Electronic Theatre Controls Asia, Ltd. Electronic Theatre Controls GmbH

Technical Services Department Technical Services Department

Room 605-606 Ohmstrasse 3

Tower III, Enterprise Square 83607 Holzkirchen, Germany

9 Sheung Yuet Road +49 (80 24) 47 00-0

Kowloon Bay, Kowloon, Hong Kong techserv-hoki@etcconnect.com

+852 2799 1220

service@etcasia.com

. If none of

Please email comments about this manual to: TechComm@etcconnect.com

2 Sensor3 CE Rack (ESR3) Installation Manual

Page 11

Chapter 1

Prepare for Installation

Unpack and Inspect

Before you begin installation, check your shipment and confirm it arrived complete and

undamaged.

Step 1: Check the shipping container for physical damage.

Step 2: If you find damage, document it to help with a claim against your shipper.

Step 3: Unpack your order and check the contents against the packing list to be sure

your order is complete.

Step 4: If you discover a problem, contact your dealer or nearest ETC office.

Main Circuit Breaker Protection

Before beginning installation of your Sensor3 dimmer rack(s), make sure you have installed

a main circuit breaker cabinet or other readily accessible input power disconnect device.

See Appendix A: Sensor3 CE Rack Specifications, page 34, for individual rack power

requirements.

WARNING:

Dimmer racks installed without an accessible power disconnect device

cannot be serviced or operated safely.

Energising the System

Sensor3 racks should only be energised by an authorised ETC representative. Wiring

errors in unauthorised installations may endanger personnel or cause system damage and

failure.

WARNING:

CAUTION:

Do not attempt to energise the system without proper approval. Energising

the system without correct inspection may result in serious injuries.

Energising your system without proper inspection may result in equipment

damage that may not be covered under your warranty!

Use 90°C Copper Wire

Use only 90°C-rated copper wiring installed in accordance with all applicable electrical

codes.

1 Prepare for Installation 3

Page 12

.

S

e

n

s

o

r

S

e

n

s

o

r

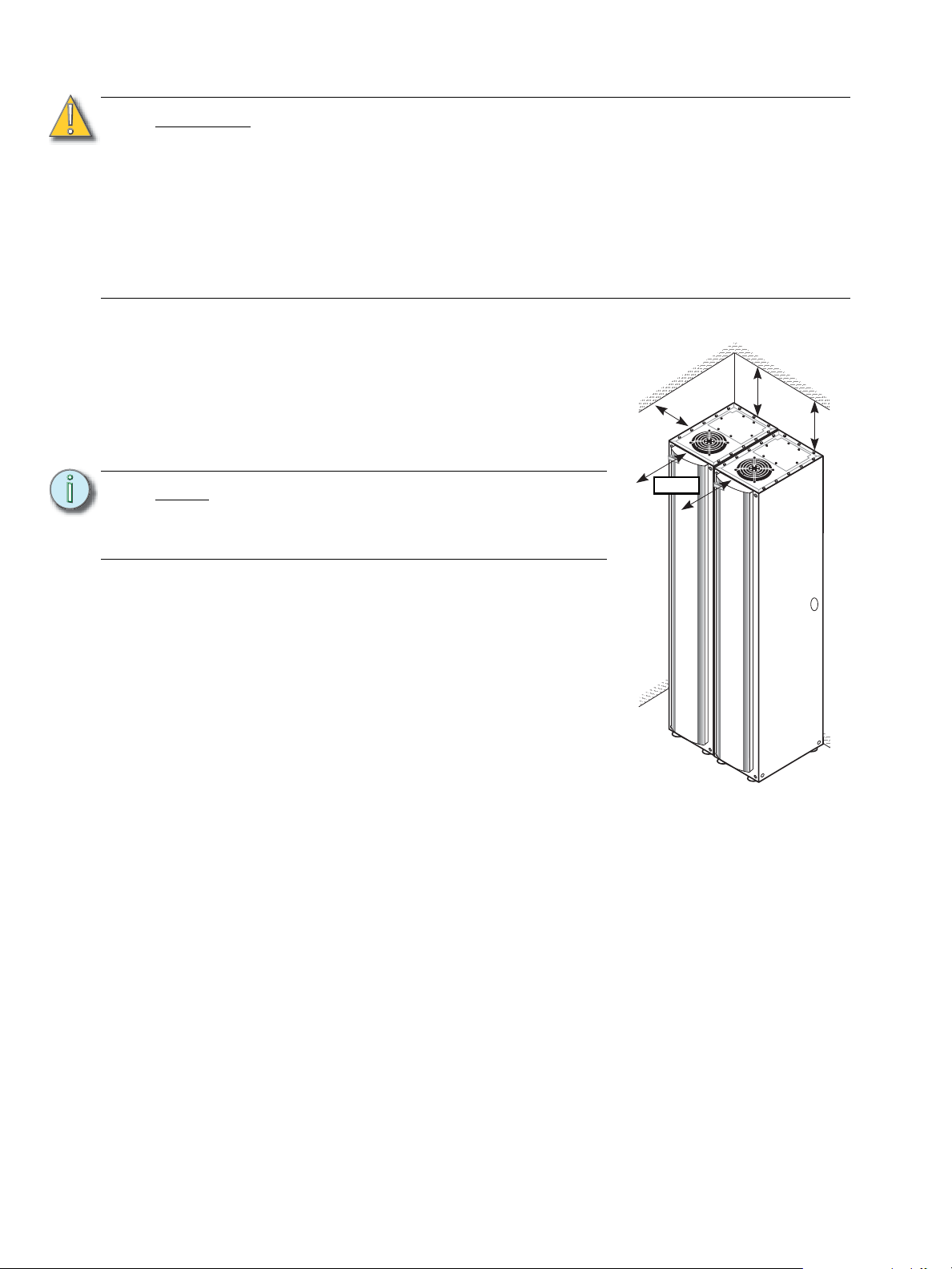

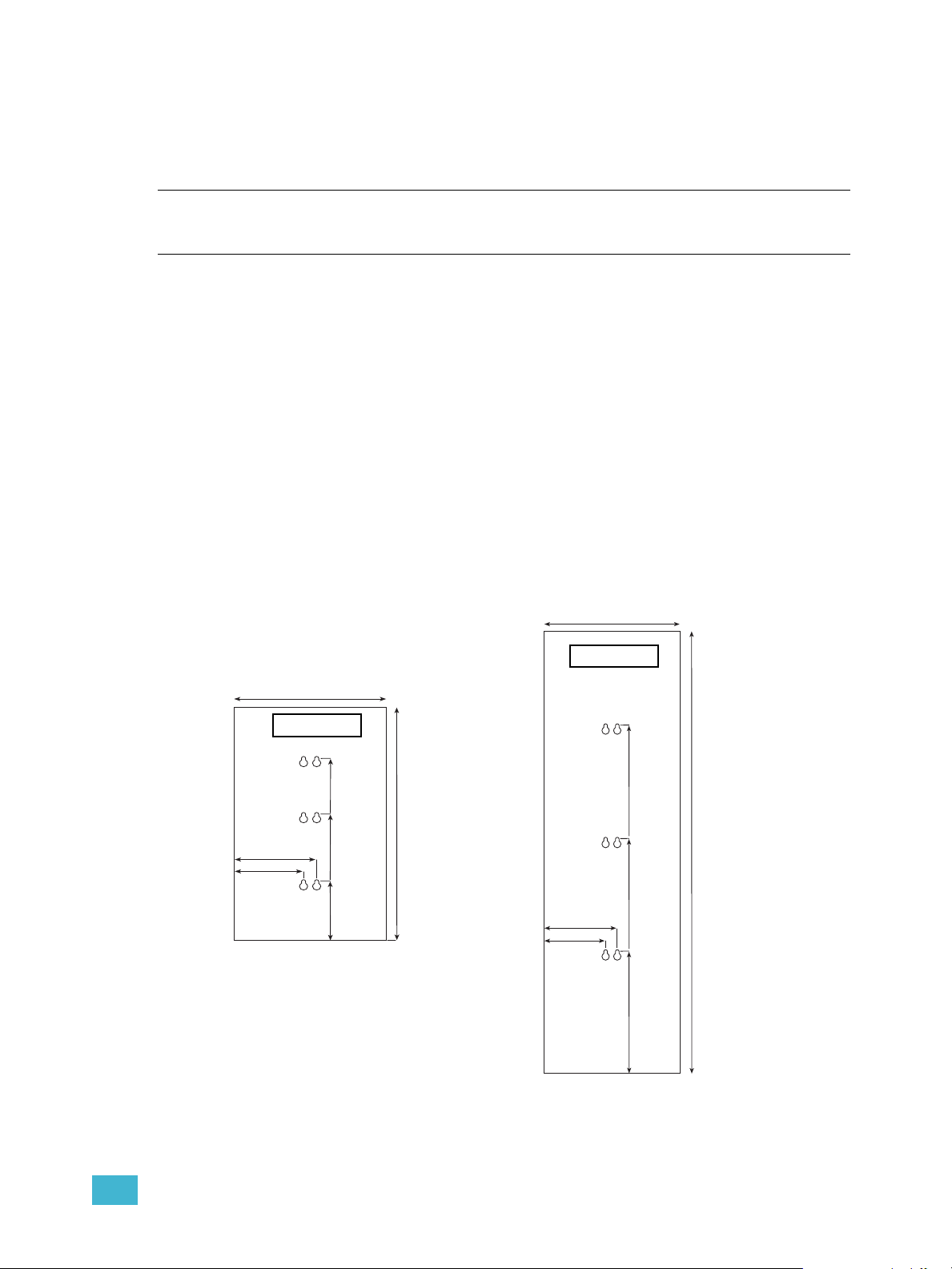

Figure 1: Sensor3 rack clearances

150mm

250mm

410mm

CAUTION:

A two-wire circuit with separate phase and neutral conductors is required for

every branch circuit that will be connected to the dimmer rack. Shared neutral

circuit arrangements are not recommended for phase-control dimming systems

due to harmonics and potentially elevated neutral currents in a shared neutral

arrangement.

For retrofit installations where shared neutral circuits are already installed, or track

lighting installations where the track has a shared neutral, consult ETC Technical

Services for rack installation guidelines.

The Neutral of the supply to the dimming system should have at least the same

cross-sectional area as the phase conductors

Where to Mount the Rack

Sensor3 dimmer racks require 25cm of top clearance

for proper airflow through the cabinet. To allow the door

to open sufficiently to install and remove modules,

install the rack with 41cm of front clearance and 15cm

clearance to the left of the door hinge from walls or

other equipment.

Note:

Additional Sensor3 racks of the same size are

the single exception to the 15cm left clearance

rule. They can be installed side by side without

problems.

Dimmer Room Requirements

• A main circuit breaker cabinet or other readily

accessible input power disconnect device.

• A clean (not dusty) temperature-controlled

environment

• Restricted public access to prevent tampering

• Soundproofing or performance area separation to

muffle ventilation fan noise

Please see Appendix A: Sensor3 CE Rack

Specifications, page 34, for environmental details.

Wire Routing

ESR3-12 racks are normally wall-mounted. ESR3-24

racks can be wall or pedestal mounted. ESR3-36 and

ESR3-48 racks are designed to be free standing.

Install racks with the CEM3 about 100cm from the floor. In ESR3-12 and ESR3-24 racks,

the CEM3 is in the bottom slot. In ESR3-36 and ESR3-48 racks, the CEM3 slot is in the

middle.

Sensor3 racks have access panels at the top and bottom, and conduit knockouts at the

side. Line and load wiring can enter from the top or bottom. Control cables can enter from

the top, bottom or side. Signal and power wiring must be run in separate conduits.

4 Sensor3 CE Rack (ESR3) Installation Manual

Page 13

Chapter 2

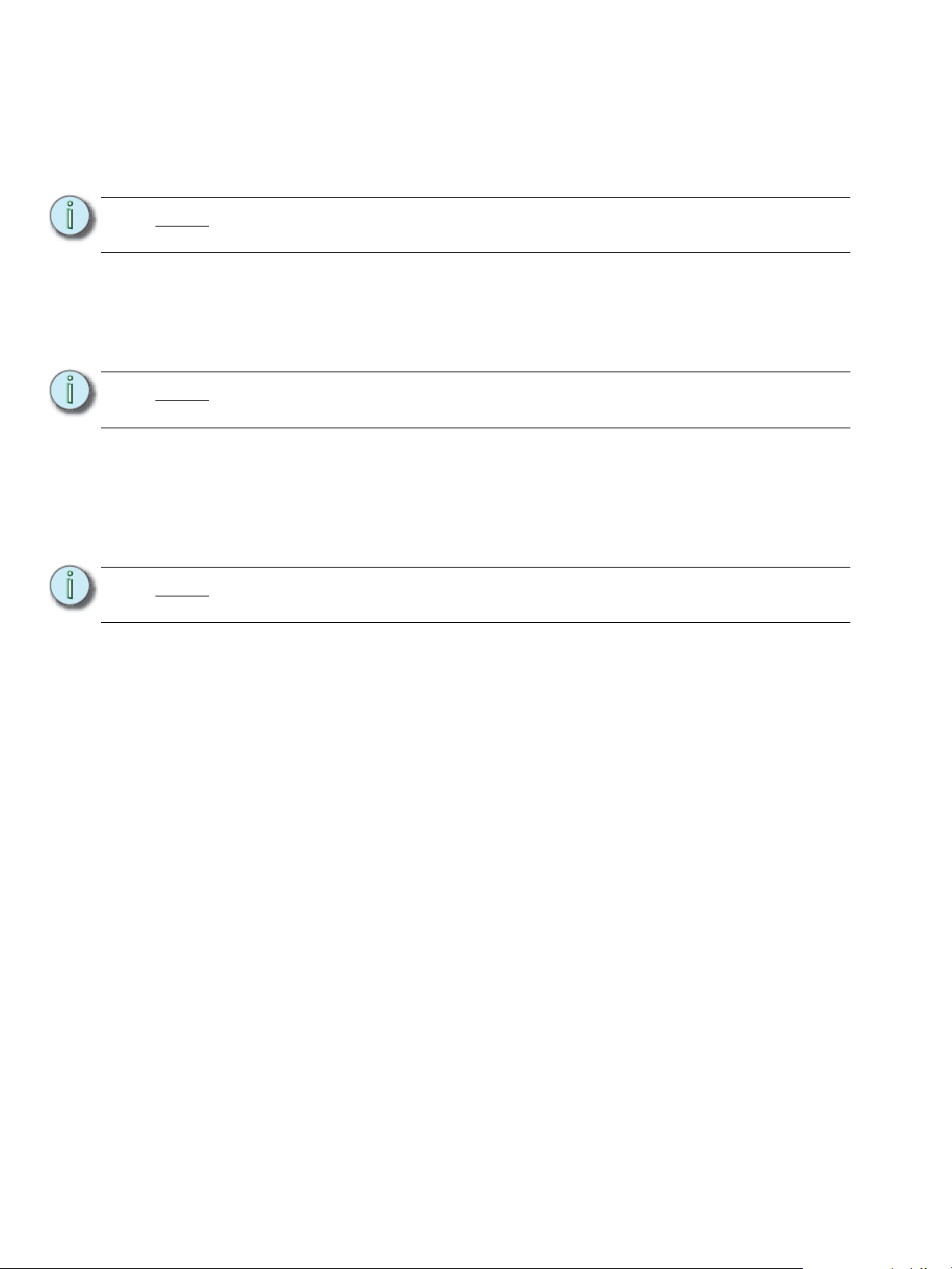

481mm

375mm

326mm

137mm

650mm

203mm

171mm

ESR3-12 rack

375mm

203mm

171mm

1213mm

925mm

616mm

306mm

ESR3-24 rack

Installation of Racks

Mounting the Rack

• ESR3-12 racks are normally wall-mounted.

• ESR3-24 racks can be mounted to a wall or floor-mounted on an optional pedestal.

• ESR3-36 and ESR3-48 racks are floor standing.

Mounting Racks on a Wall (ESR3-12 and ESR3-24)

The wall must be strong enough to hold the racks. Please see Appendix A: Sensor3 CE

Rack Specifications, page 34 for rack and module weights.

Step 1: Determine where your rack will be installed using Figure 1: Sensor3 rack

clearances on page 4 and use the appropriate diagram from Figure 2 to mark

your mounting holes.

Step 2: Use the mounting slot dimensions to mark the hole locations. You must supply

your own M10 mounting hardware.

Step 3: Drill the holes and install the hardware.

Step 4: Attach the rack to the wall.

Figure 2: ESR3-12 and ESR3-24 wall mount hole diagrams

2 Installation of Racks 5

Page 14

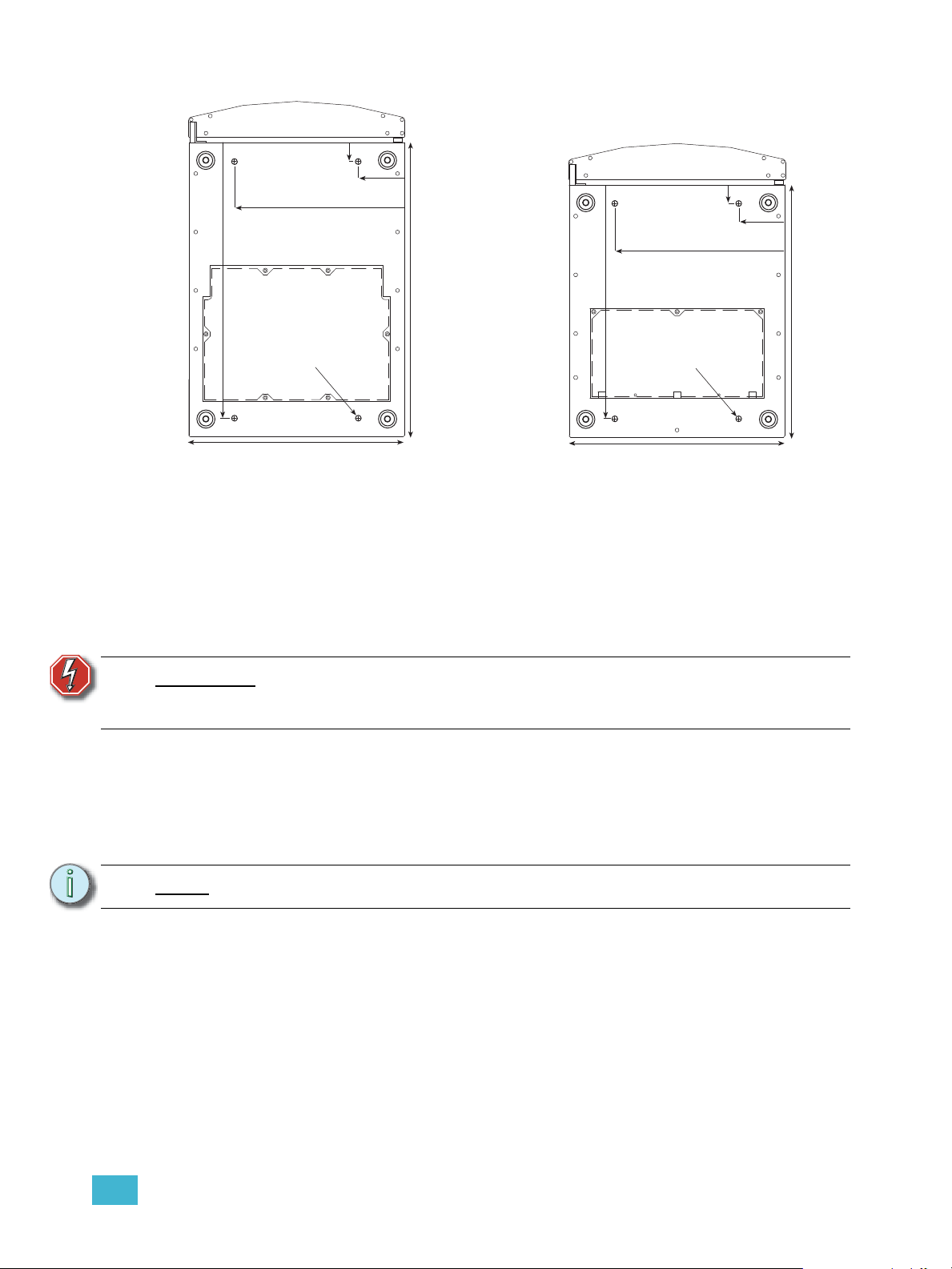

Installing ESR3-36 and ESR3-48 Racks on the Floor

Step 1: Determine where your rack will be installed using Figure 1: Sensor3 rack

clearances on page 4 and use the appropriate diagram from Figure 3 to mark

your mounting holes.

Note:

Step 2: Drill the holes and install your own M10 mounting hardware.

Step 3: Position the rack in the desired location.

Step 4: Adjust the leveling feet with an open ended 12mm spanner until the rack is level

Note:

Step 5: Secure the rack to the floor using your mounting hardware.

Sensor3 racks of the same size are the single exception to the 15cm left clearance

requirement. They can be installed side by side without problems.

and vertical.

Sensor3 installation racks are tall, narrow, and heavy. Use caution to keep racks

stable until the rack is secured to the floor or wall.

Pedestal Mounting an ESR3-24 Rack

Step 1: Use Figure 3 to mark the location of the ESR3-24 mounting holes. The ESR3-24

pedestal has the same floor mounting dimensions as the ESR3-24 rack.

.

Note:

Step 2: Drill holes or mount floor hardware and position the pedestal on them.

Step 3: Secure the pedestal base to the floor.

Step 4: Position the rack on the pedestal and align the mounting holes.

Step 5: Bolt the rack into place.

You must supply M10 mounting hardware. The pedestal has four mounting holes

into the floor and four securing the rack.

6 Sensor3 CE Rack (ESR3) Installation Manual

Page 15

Securing Sensor3 Racks to a Wall

ESR3-48 Floor mount hole diagram ESR3-36 / ESR3-24 Floor mount hole

Dia. 10mm

480mm

294mm

79mm

32mm

373mm

511mm

Figure 3: Hole diagrams for mounting racks to the floor

Dia. 10mm

404mm

294mm

79mm

32mm

373mm

436mm

Racks installed on the floor or a pedestal can also be secured to a wall for greater stability.

Step 1: Prepare the rack for floor or pedestal mounting (Installing ESR3-36 and ESR3-

48 Racks on the Floor, page 6 or Pedestal Mounting an ESR3-24 Rack, page 6).

WARNING:

Note:

Make sure the holes for the mounting hardware are located where the

hardware cannot come into contact with electrical wiring. Make all

modifications in accordance with your country’s electrical codes.

Step 2: Mark the locations for your securing hardware on the wall.

• For ESR3-12 or ESR3-24 racks, use the diagram in Figure 2 to determine

where you need to install your hardware.

• For ESR3-36 and ESR3-48 racks, put the rack in position and mark the holes

directly.

Step 3: Drill holes or install mounting hardware in the marked locations.

Step 4: Finish mounting the rack to the floor or pedestal.

Step 5: Attach the rack to the wall with your securing hardware.

Be sure to level your racks before marking the hole positions.

2 Installation of Racks 7

Page 16

Wall Mounting Racks Using Vibration Pads

Figure 4: Positioning a vibration pad

on a wall

Align the center of the fitting over the diagram

hole location and mark the position of the fitting

bolts

50cm

50cm

25cm 25cm

ETC Part# HW6111

Figure 5: Floor vibration pad

Center the fitting over the mount hole location

from the diagram and mark the positions for the

fitting hardware

ETC Part#

HW6109

38mm

38mm

Vibration damping fittings are available as an option

for wall mounted racks. The wall must be strong

enough to hold the racks. Please see Appendix A:

Sensor3 CE Rack Specifications, page 34 for rack

and module weights.

Note:

Note:

Be sure this mounting method complies

with your countries building and electrical

codes.

Step 1: Mark the hole locations on the wall from

Figure 2: ESR3-12 and ESR3-24 wall

mount hole diagrams on page 5.

ETC’s wall mount vibration pads (ETC

Part# HW6111) attach to racks with the

provided bolts that are slightly larger than

the top of the keyhole slots. The bolt works

fine installed in the lower portion of the slot,

but the rack will mount slightly higher

(approx. 10mm) than the diagram indicates.

Step 2: Align the center of the fitting over the hole locations from the diagram. Mark the

position for two fitting bolts for each vibration pad (the middle holes are

recommended).

Step 3: Drill the holes and secure the fittings to the wall. You must supply your own M10

mounting hardware.

Step 4: Remove the included bolt and washer from each vibration fitting.

Step 5: Position the rack on the wall so the centers of the vibration fittings align with the

wall mounting slots.

Step 6: Secure the rack to its vibration pad with the included bolts and washer.

CAUTION:

Floor Mounting Racks Using Vibration Pads

ESR3-36 and ESR3-48 racks can be floor mounted on

Note:

8 Sensor3 CE Rack (ESR3) Installation Manual

optional vibration damping fittings (ETC

Part# HW6109).

Step 1: Determine where your rack will be installed

Step 2: Use the appropriate diagram from

Unless the all mounting and connections are done in a flexible manner, the

effectiveness of the vibration pads will be reduced or completely negated. This

includes the use of at least 30cm of flexible conduit or flexible cable for all of the

electrical connections to the rack(s).

using Figure 1: Sensor3 rack clearances on

page 4.

Be sure this mounting method complies with

local building and electrical codes.

Level racks before marking the hole positions.

Figure 3: Hole diagrams for mounting racks

Page 17

to the floor on page 7 to mark your hole locations.

Step 3: Align the center of the vibration fitting over the hole locations from the diagram.

Mark the positions for two bolts for each vibration pad.

Step 4: Drill the holes and secure the pads to the floor. You must supply your own M8

mounting hardware.

Step 5: Remove the included bolt and washer from each vibration pad.

Step 6: Position the rack on the pads so the center holes of the pads align with the

mounting holes in the base of the rack.

Step 7: [Optional] If required, secure the rack to a wall using wall mount vibration pads

(ETC Part# HW6111). If the vibration pads have been requested for the

installation, they are included with the rack.

• Follow instructions from Securing Sensor3 Racks to a Wall, page 7 to drill

holes in the back of the rack for wall mounting.

• Mount the rack to the wall using the procedure from Wall Mounting Racks

Using Vibration Pads, page 8, above.

Step 8: Secure the rack to the pads with the included bolts.

CAUTION:

Unless the all mounting and connections are done in a flexible manner, the

effectiveness of the vibration pads will be reduced or completely negated. This

includes the use of wall vibration pads when mounting to the floor and at least

30cm of flexible conduit or flexible cable for all of the electrical connections to the

rack(s).

2 Installation of Racks 9

Page 18

Securing Multiple Racks (Optional)

Hole for bolting

racks together

(recessed)

Hole for bolting

racks together

Figure 6: Placement of rack connecting holes

Temporarily remove

six screws from this

area

Install the rack splice and

replace the screws to

secure it

Figure 7: Screws to remove to connect two racks

Multiple racks can be connected to each other for greater stability.

Note:

If you want to install the control cable through the side of the racks, you should

remove the side cable knockouts before connecting the rack.

Step 1: Use M8 spin lock bolts and lock nuts in the front and at the back to bolt the racks

together at the bottom.

Note:

The front bolt is difficult to reach – you may need a magnetic bolt-driver or socket

extension.

Step 2: (ESR3-36 and ESR3-48 only) Remove six screws from the tops of adjacent

racks, as shown below.

Step 3: (ESR3-36 and ESR3-48 only) Place a rack splice plate over the empty screw

holes and replace the screws you removed in Step 2 as shown above.

Repeat Steps 1, 2 and 3 until you have secured all the racks.

10 Sensor3 CE Rack (ESR3) Installation Manual

Page 19

Rack Cabling Access

Figure 8: ESR3 access panels

Bottom access panel

Top access panel

ESR3 racks have removable top and bottom access panels.

Conduit Connections

Step 1: Remove the desired access panel from the rack.

Step 2: Cut access holes in the top and bottom access panels.

Step 3: Install your cabling into the holes.

Step 4: Re-install the access panel so that there are minimal air gaps. See “Sealing Rack

Air Leaks” on page 28. for more information

.

WARNING:

Note:

Cutting holes in the rack plates in situ may introduce metal debris into the

dimmer cabinet.

Trunking or Wire Trough Connections

Step 1: Remove the desired access panels.

Step 2: Cut suitable openings to mate with the trunking or trough using a jigsaw or

hacksaw.

Step 3: Reinstall panel on to rack

Step 4: Install a fiche paper lining or grommeting material in the access panel opening.

Wire openings must have fittings or linings to protect cable insulation from

damage by sharp metal edges.

Step 5: Position the trunking or wire trough above the prepared opening.

2 Installation of Racks 11

Page 20

Connect Line Power Wiring

Figure 9: Line and Load Connections

L1

connections

Line Neutral

connections

L2

connections

Load Neutral

lug

L3

connections

Load Earth

lug (behind

phase lug)

IEC Connector

for NEFM

(optional)

ETC recommends routing line (feeder) cables first,

load neutral and load earth wires next, and load

phase wires last.

CAUTION:

Line and load wires used with Sensor3

dimming systems must be copper. Do not

use wire containing aluminium or other

metals.

CAUTION:

Dress wires neatly and avoid leaving extra

wire inside the rack. Too much clutter

(especially along the right side of the rack)

can restrict air circulation and reduce

cooling efficiency. If cabling interferes with

airflow during operation, the rack may shut

down due to overheating.

Preparing Line Feed Cable

Line cable and power wire should enter the rack

through the designated top and bottom access

points.

Line feed wires connect on the rack’s line phase,

neutral and earth bus bars. Each bus bar has one or

two 12mm studs to secure a lug connection for the

line feed wires. The installer must provide the line

feed connecting lugs.

Pull the line phase, neutral and earth cables to the

rack through the openings you prepared previously.

See “Rack Cabling Access” on page 11.

Line Earth

connections

Load Phase

lug

Step 1: Pull the line phase, Neutral and Earth

cables to the rack through the openings

you prepared previously.

Step 2: Cut the wires to length such that they

reach the correct stud

Step 3: Prepare the end of the wire and fit the

desired termination.

Step 4: Attach the lug to the correct phase,

neutral or earth stud as shown in

12 Sensor3 CE Rack (ESR3) Installation Manual

Step 5: Tighten the lugs to 59.5Nm.

Figure 9: Line and Load Connections on

page 12.

Page 21

Chapter 3

Figure 10: Line and

load wiring example

Dress and connect load

wires neatly without leaving

extra wire in the rack.

Double-height 50 amp lug

6/10/15/25 amp lug

Dual 15/25 amp lugs (fluorescent)

Switched

Control or

Dimmed

Figure 11: Load lug types

Land Load Wires

Land Load Wires

Each dimmer has three sets of lugs connected to phase,

neutral and earth. Phase and earth lugs are on the right side

of the rack, neutral lugs are on the left. Lugs can be single 6/

10/15/25 amp, paired 15/25 amp fluorescent, or doubleheight 50 amp.

Note:

CAUTION:

Step 1: Route the load wires to the rack(s).

Step 2: If using Multicore cable, strip back the sheath so

When using ED15AFRF modules connected to

dimmable fluorescent 3-wire ballasts, wire the top

lug in each slot to the ballast’s non-dimmed power

lead and the bottom lug to the dimmed ballast

control lead.

Dress and terminate wires neatly and avoid leaving

extra wire inside the rack. Too much clutter

(especially along the right side of the rack) can

restrict air circulation and reduce cooling efficiency.

If cabling interferes with airflow during operation,

the rack may shut down due to overheating.

Load wires should not cross between racks. They

should enter the rack in which they will be

terminated.

Phase and neutral load wiring must follow the same

conduit/path for each circuit.

3 Land Load Wires 13

Page 22

that phase, neutral and earth can be corrected to the relevant lugs as shown.

Figure 12: Load cable connection to lugs

Load Neutral (blue

wires) are landed on

load neutral lugs

attached to the main

neutral bus plate

Each dimmer’s load

lug set is at the same

height.

Load Phase

(brown wire)

Load Earth

(green wire with

yellow stripe)

The Right way

Insert the wire between the pressure plate and

the back of the lug and clamp the plate on top of

the wire.

The Wrong way

Don’t clamp the wire on top of the

pressure plate with the lug screw.

Pressure Plate

Lug Screw

Step 3: Fit load earth wires into the earth lugs as shown below and torque to the

recommended value from Table 1.

• Insert the wire under the pressure plate and tighten it onto the wire with the

screw. Do not clamp the wire directly under the screw.

Step 4: Fit load neutral wires into the neutral lugs in the same manner and torque to the

Step 5: Fit load phase wires into the phase lugs in the same manner and torque to the

WARNING:

CAUTION:

Step 6: Tighten all load connections to the torque specified in the table below.

14 Sensor3 CE Rack (ESR3) Installation Manual

Figure 13: Connecting lug wires

recommended value.

recommended value.

If any wire splices are required (none are recommended), they must be

made with a crimp-style butt-splice. Terminal block is NOT acceptable.

To prevent interference with cooling airflow, do not run load wires from one rack

through a different rack. See Sealing Rack Air Leaks, page 28 for more

information.

Table 1: Lug torque values

Cable size Torque (Nm)

2

1.5mm

2

2.5mm

2

4.0mm

2

6.0mm

2

10mm

2

16mm

4.0 Nm

4.0 Nm

4.0 Nm

4.5 Nm

4.5 Nm

5.0 Nm

Page 23

Cut Key Slots for Modules

Figure 14: Cutting Key Slots

Cut/remove for 25A module

Cut/remove for 50A module

Sensor3 dimming and control modules are easily slid into place by hand. Each module slot

is keyed to accept only a module with the correct current rating for the slot.

Cutting Key Slots for 25A and 50A Modules

Modules with current capacities higher than 15A are prevented from fitting into incorrect

slots by the module cutout bar to the left of the rack. If you have supplied a configuration

chart to ETC these should be cut out correctly for you; otherwise you will have to cut the

bar on site.

Step 1: Ensure power to the rack is turned off and the modules are removed

Step 2: Locate which slots will be fitted with 25A and 50A modules

Step 3: Using a pair of large wire cutters, open the required notch in the bar

• For 25A modules, open the top notch

• For 50A modules, open the bottom notch

CAUTION:

Ensure that the metal swarf created by cutting the key slots does not cause any

shorting within the rack. Clean the rack after cutting key slots.

3 Land Load Wires 15

Page 24

Converting Neutral Disconnect Slots

Figure 15: Removing a lug

Use a small flat screwdriver

to lift the lug tab enough to

release the lug from the strip

and pull it out.

Figure 16: Converting Neutral Disconnect lugs to use single pole dimmers

There are two classes of modules available for Sensor3 CE racks - modules which break

the neutral, such as RCD or ND modules, and single pole modules that do not. Normally

your rack will be configured by ETC at the factory for the correct module types, however if

you have a mixture of modules or you have not been able to supply details of slot

allocations you may need to configure some slots on site.

Step 1: Determine which dimmer slots you will be converting. You can convert either

individual slots or a three-slot strip at a time.

Step 2: Gently bend the neutral lug retraining tab out with a

small flat blade screwdriver until the lug releases and

you are able to pull it out. See Figure 15.

CAUTION:

Step 3: Use a flat blade screwdriver to loosen the threaded

Step 4: Repeat Step 2 and Step 3 for the other dimmer slot

Step 5: Install a Neutral lug jumper into the lugs and tighten

Step 6: Slide the jumpers into the plastic lug strip until the lug tab clicks into place.

Step 7: Secure the jumper to the thread on the Neutral bus bar using the provided

Repeat Steps 1 through 6 for any other lugs you want to convert

Lug catches will break if bent too far. Only bend the

catch until the lug releases.

inserts until the contact plates can slide out of both

lugs.

lug.

the threaded inserts.

M3x8mm screw.

16 Sensor3 CE Rack (ESR3) Installation Manual

Page 25

Installing Three-Slot Dimmer Lug Strips

Figure 17: Removing or installing a

Neutral lug strip

Step 1: Use a Phillips screwdriver to remove the two

screws securing the lug strip to the left side

of the rack.

Step 2: Remove the lug strip and replace it with one

containing a three-slot Neutral jumper.

Step 3: Secure the strip to the rack with the screws

you removed in Step 1.

Secure the jumper to the main Neutral bus PEM inserts

using the two screws provided with the jumper.

3 Land Load Wires 17

Page 26

18 Sensor3 CE Rack (ESR3) Installation Manual

Page 27

Chapter 4

Figure 18: Single Backplane

Figure 19: Dual Backplane

Control and Data Connections

Sensor3 racks support a variety of control and data connections on the CEM3 backplane.

CEM3 backplanes have connectors for:

• Two DMX512 Cables (Universes)

• External Panic Circuit Activation and Indication

• Remote Redundant Tracking selection switch (Dual Backplane Only)

• Ethernet Network

• Station Wiring

Dual and Single Backplane Differences

To use dual control modules your rack must be fitted with a dual tracking backplane. Racks

without dual tracking may have an empty second slot, or use the second slot to hold a

network switch. The exception is ESR3-12 racks, which only have space for a single control

module.

Racks with a dual backplane also have a three position switch which allows manual

switching of control of the rack to the top CEM3, the bottom CEM3, or for automatic

switching between the two.

4 Control and Data Connections 19

Page 28

Running DMX Cable to Racks

Figure 20: Side

data knockouts

1234567812345678

COM

n/c

n/c

n/c

n/c

n/c

n/c

n/c

n/c

n/c

n/c

Data + (Red)

Data - (Black)

From source

DMX A

If daisy-chaining to

another rack or

DMX device...

COM

Data + (Red)

Data - (Black)

From source

DMX B

If daisy-chaining to

another rack or

DMX device...

Figure 21: Stranded DMX Connection

Note:

Note:

Note:

If the system includes a Panic circuit, stations or Remote Tracking Selection, pull

the necessary wires with the data cables to all required racks.

Step 1: Remove the desired top, bottom or side conduit knockout

from the first rack on the left or right of the group of racks. See

Figure 20:Side data knockouts for knockout locations.

Step 2: Remove the 25mm side data conduit knockouts between the

first rack and the other racks in the group.

Using side knockouts for data cable conduit between racks is

recommended because it provides the most direct route

between CEM3 backplanes. You can use the top and bottom

openings if desired.

Step 3: Attach control cable conduit in the first knockout hole and the

knockouts between the remaining racks.

If you are installing control cable in racks that are joined

together, install IP20 rated conduit bushing into the knockout

holes between the racks

Step 4: Pull DMX512 cables through the conduit connection on the first rack and through

the connections between racks until the cable reaches the last rack in the group.

Leave 250-300mm of slack at each rack’s backplane.

DMX Termination - Screw Terminals

Step 1: Terminate the cable(s) as shown below

using the termination kit included with

the rack (in the rack door). Refer to the

guide included with the kit for detailed

termination instructions.

Step 2: Connect the DMX header to the

relevant socket on the rear of the

backplane.

Note:

DMX Termination - IDC Connection

Only one screw header is supplied with

the rack. You may use the header to

terminate DMX A and DMX B to “PASSTHRU” if needed.

Step 1: Terminate the cable as shown below

using an IDC termination kit. Note that

an IDC termination kit is not included

20 Sensor3 CE Rack (ESR3) Installation Manual

Page 29

with the rack and should be ordered separately.

12345678 1234567812345678

n/c

n/c

COM

Data +

Data +

Data -

Data - ORG

W/ORG

BRN

GRN

W/GRN

BLU

W/BLU

W/BRN

COM

Data +

Data - ORG

W/ORG

W/BRN

COM

Data +

Data - ORG

W/ORG

W/BRN

ORG

W/ORG

BRN

GRN

W/GRN

BLU

W/BLU

W/BRN

COM

If daisy-chaining to

another rack or

DMX device...

DMX A

Thru

DMX B

Thru

From source

DMX A

From source

DMX B

Figure 22: IDC DMX Connection

Step 2: If needed, terminate both the outgoing cables into the third header, “PASS-

THRU”. This header is located below the primary DMX headers and has both the

DMX A and DMX B connections available as shown above.

Setting DMX Termination

After completing data connections you must properly terminate each DMX line using the

termination DIP switches on the CEM3 backplane. Data termination eliminates signal

“reflections” at the end of the network that interfere with network functions. Each DMX line

should have termination turned On at the last network connection.

Step 1: Locate the termination DIP switches on the CEM3 backplane.

Step 2: Using the label on the backplane to match data connections to the associated

termination DIP switches.

Step 3: Set the termination switches to On (Up) or Off (Down) depending on the

connection status:

• If the connection is jumpered to another rack or device, turn termination Off.

• If the connection ends at the rack, turn termination On.

Note:

• If a data connector is not used, either setting is acceptable.

The termination switches should not be set to the “RDM” position unless

recommended by ETC.

4 Control and Data Connections 21

Page 30

Running Ethernet to Racks

Figure 23: Ethernet connections with a NEFM

Ethernet

Ethernet

Sensor3 racks

Congo

CEM3

NEFM

CEM3

Figure 24: Ethernet connections with an external network

Congo

Sensor3 racks

Ethernet Ethernet

CEM3 CEM3 CEM3 CEM3

Sensor3 racks use Ethernet for communication with each other and sometimes for

communication with the lighting console. It is therefore important that all racks are linked

via Ethernet. This may either be done using an NEFM (Network Electronics Filler Module A network switch built into the lower slot of one of the racks) or using an external network

hub or switch.

Ethernet with a NEFM

If one of your racks is supplied with a NEFM, run a CAT5 cable from each rack to the rack

with the NEFM. You may make the connection either using prefabricated CAT5 network

cables, or using CAT5 cable and the termination kits provided.

Ethernet with an External Network

If the system has an external network, connect each rack to the external hub or switch using

CAT5 cable. A network termination kit is provided with each rack (in the door) for the

Sensor3 rack. You may need to provide termination at the network switch, e.g. a patch

panel.

22 Sensor3 CE Rack (ESR3) Installation Manual

Page 31

Ethernet Network Termination - RJ45 Connector

Maintained

Closure

To trigger Panic,

use a

To external

indicators

(such as a

lamp or relay)

+24Vdc

(max 25mA

each)

To external

indicators

(such as a

lamp or relay)

+24Vdc

(max 25mA

each)

For Panic SEND/RTN:

NO - Normally Open closure

Disabled - Panic Disabled

NC - Normally Closed closure

To Sensor3

compatible

stations

SEND

Figure 25: Backplane Panic Connections

Step 1: Follow the directions provided in the Ethernet Termination Kit to terminate the

incoming CAT5 cable in the RJ45 UTP connector in the surface mounting box.

The kit is included with the dimmer rack door. Use the instructions provided with the kit for

proper Category 5 cable termination.

Step 2: The surface mount box should be installed with the double-sided tape inside the

rack.

• ESR3-36, ESR3-48: To the underside of the CEM3 backplane bracket.

• ESR3-12, ESR3-24: To the bottom of the rack behind the backplane.

Step 3: Use the provided male-to-male Ethernet patch cable to connect the surface

mounting box female RJ45 connector to the female RJ45 connector on the

CEM3 backplane.

Panic Circuit Connections (Optional)

Sensor3 racks can connect to an external Panic circuit if desired. Panic can be triggered by

a normally open or normally closed contact. The racks can also provide a feed to a lamp or

LED to indicate whether panic is active.

Panic Circuit backplane connection

Step 1: Pull two 1.5mm2 wires from your Panic contact location to the CEM3 backplane

through the data cable conduit or trunking. See Running DMX Cable to Racks,

page 20 for data conduit installation details.

Step 2: Connect the wires to the connector on the CEM3 backplane. Connect the Panic

contact input between “PANIC RTN” and “PANIC IN”.

Step 3: Optionally, connect an external panic indication lamp between “PANIC OUT” and

“COM”. When panic is active, there will be a supply of +24VDC between “PANIC

OUT” and “COM”, with a maximum current draw of 25mA.

Step 4: Set the switch on the backplane to indicate the contact type: Normally Open (NO)

or Normally Closed (NC).

4 Control and Data Connections 23

Page 32

Dual Tracking Remote Select Switch connection (Optional)

1 2 3 4+24Vdc COM

J12

Figure 26: J12 Dual Tracking remote connector wiring

Header at the top of the

backplane PCB

Orange remote tracking header.

Pin 1 is the pin closest to the phase

bars (left side of the rack as you look

in)

Position A - Primary

Position B - Secondary

An indicator lamp

50mA 24Vdc max for

internal power supply

If desired, a remote switch can be wired to the CEM3 backplane to control CEM3 selection

in racks equipped with ETC’s Redundant Tracking CEM3 option.

Note:

Note:

You must supply your own enclosed single-pole double-throw center-off switch to

install a remote select switch. You may optionally use an external 24V DC power

supply, or use the power supply from the rack backplane.

2

Step 1: Pull 1.5mm

wires between your remote switch and the CEM3 backplane

through the data cable conduit. See Running DMX Cable to Racks, page 20 for

data conduit installation details. For systems with no requirement for remote

tracking status indication three wires are required, otherwise four wires will be

required.

Step 2: Connect the remote switch wires to the J12 connector on the rear of the

backplane.

The J12 connector is a removable plug header and is easier to wire when it is

disconnected from the backplane in an installed rack.

Step 3: Wire the remote switch and indicator to the J12 connector according to

Figure 26.

24 Sensor3 CE Rack (ESR3) Installation Manual

Page 33

Station Connection (Optional)

to stations

Figure 27: Connection of station wiring

Sensor3 racks support ETC’s range of stations. The station network should be wired in

Belden 8471 or an equivalent cable. Stations are topology-free. Wiring may be bus, star,

loop, home run or any combination of these.

B

e

l

d

Connecting Station Wiring

Step 1: Cut the Belden 8471 cable so that a 20cm tail extends from the edge of the

backplane.

Step 2: Strip 18cm of the outer jacket off.

Step 3: Strip 6mm of insulation from the ends of the Belden 8471 wires.

Step 4: Insert the white wire into “STATION +” terminal on the backplane board. Tighten

the screw firmly.

Step 5: Insert the black wire into “STATION -” terminal on the backplane board. Tighten

the screw firmly.

e

n

8

4

7

1

SEND

Connect ESD Ground

For installations with data runs of Belden 8471 installed in earthed metal conduit there is no

need to run and terminate an additional ESD drain wire. For installations not installed in

earthed metal conduit, run a 2.5mm

the instructions below for termination.

Step 1: Locate the earth terminal bar to the right of the rear of the dimmer rack.

Step 2: Strip 6mm of insulation from the ends of the 2.5mm

Step 3: Insert the earth wire into an available earth lug and secure with the set screw.

2

ESD drain wire with the Belden 8471 cable. Follow

2

ESD drain wire.

4 Control and Data Connections 25

Page 34

26 Sensor3 CE Rack (ESR3) Installation Manual

Page 35

Chapter 5

Finishing Installation

The steps in this chapter should only be performed by, or after receiving approval from, an

authorised ETC representative.

Check Backplane DIP Switches

The backplane of your rack features a set of eight DIP switches allowing configuration of

the rack type. The CEM3 reads these DIP switches to determine the rack type, phasing and

available modules. Compare the position of these DIP switches to the table below and, if

necessary, set them to the correct position using a jewellers screwdriver.

Use the following chart to determine your required DIP switch settings:

DIP Switch Number

Rack Model

ESR3-12 On On

ESR3-12N On On On

ESR3-12AF On On On

ESR3-12AFN On On On On

ESR3-24 On On

ESR3-24N On On On

ESR3-24AF On On On

ESR3-24AFN On On On On

ESR3-36 On On

ESR3-36N On On On

ESR3-36AF OnOnOn

ESR3-36AFN On On On On

ESR3-48 On

ESR3-48N On On

ESR3-48AF On On

ESR3-48AFN On On On

12345678

Energising the System

You need ETC approval to apply power to your dimming system. Wiring errors in

unauthorised installations may endanger operators or cause system damage and failure.

WARNING:

CAUTION:

Do not attempt to energise the system without proper approval. Energising

the system without ETC approval may result in serious injuries.

Energising your system without ETC approval may result in equipment damage

that may void your warranty!

Contacting ETC

To obtain ETC approval or for referral to an authorised ETC representative, contact ETC

as shown in Contacting ETC, page 2.

5 Finishing Installation 27

Page 36

Sensor3 Installation Checklist

Table 2: Loose parts shipped with ESR3 rack doors

Quantity ETC Part Number Descriptions

1 4100A1012 DMX Cable Prep Kit w/ 1 screw connector

1 4101A2003 Ethernet Term Kit

1

7051A2009(ESR3-48/36/24)

7051A3006(ESR3-12)

Rack Bottom Hinge

1 7051A3006 Door Top Hinge

2 HW253 Screw 6-32x3/8 truss SS

3 HW757 Pin, Taper 5/32x1.0

6 HW327 Washer, Flat #8 .188x.375x.049 SS

1 HW8202 Door Key

1 7051A4116 Beacon Acrylic

A checklist is provided in Appendix B: Sensor3 Installation Checklist, page 35. Following

this checklist will help ensure that your Sensor3 system operates reliably and without

problems. The checklist is a summary version of the steps in this chapter.

Sealing Rack Air Leaks

After you have installed all conduit, trunking and cables to the rack and connected all wiring,

you must seal any air leaks in the rack cabinet created during the installation process. Use

urethane aerosol foam to fill air gaps.

Step 1: Seal all access holes.

Step 2: Re-install access panels removed during installation, or completely cover their

openings with fiche paper and urethane aerosol foam or duct seal.

Step 3: Seal any air gaps caused by bent access panels.

Step 4: Fill in any gaps inside partially filled wiring conduit or trunking.

Step 5: Fill in other gaps or holes in the cabinet created during installation.

CAUTION:

Air leaks can cause dimmer racks to overheat during operation and shut down.

Attaching the door

All Sensor3 racks are delivered with the doors separated. This improves access to the rack

interior for wiring and other installation work. Some loose door installation parts are bundled

with the doors as detailed below in Table 2.

When interior wiring is completed, attach the rack door. Do not operate your dimmer rack

without a door installed.

CAUTION:

Dimmer rack doors filter and regulate ventilation airflow. Operating without the

door can contaminate the rack interior with dust and cause rack modules to

overheat.

Step 1: Insert the top hinge into the slot on the top of the rack and attach it to the frame

28 Sensor3 CE Rack (ESR3) Installation Manual

Page 37

with two Phillips head screws (included).

Top hinge being inserted Top hinge in place

Bottom hinge

being inserted

Bottom hinge

in place

Bottom hinge

in place

Bottom hinge

being inserted

Figure 28: Attaching the top door hinge

Step 2: The bottom hinge on the ESR3-12 is a different design from the one used on the

ESR3-24, ESR3-26 and ESR3-48.

• ESR3-12 – Insert the bottom hinge into the slot on the bottom of the rack and

attach it to the frame with two Phillips head screws (included).

Figure 29: Attaching the ESR3-12 bottom hinge

• ESR3-24, ESR3-36 and ESR3-48 – Remove the large Phillips head screw,

insert the hinge into the slot and secure it by replacing the screw.

Figure 30: Attaching the ESR3-48 bottom hinge

• Drive the narrow end of one taper pin into the bottom of the door. Put the

5 Finishing Installation 29

Page 38

taper pin through the washers and into the hole on the lower hinge.

ESR3-48 lower hinge ESR3-12 lower hinge

Door

Taper pin

Door

Taper pin

Washers

Washers

Taper pin

Figure 31: Installing the bottom taper pin

Step 3: Hold the door in place and insert the other taper pin, narrow end down, through

the top hinge and washer.

Figure 32: Installing the top taper pin

Step 4: Take the Sensor3 beacon block, insert it through the slot on the upper left corner

of the door and secure it with two Phillips head screws (included).

Figure 33: Installing the beacon block

30 Sensor3 CE Rack (ESR3) Installation Manual

Page 39

Checking Rack Installation before Installing Modules

AF Card Addressing

Card 1

Card 2

Card 3

Card 4

S

W

1

S

W

2

S

3

S

1

ESR3-12

ESR3-24

ESR3-48

2

3

4

Sensor+

O = Switch in down position

ESR3-36

Figure 34: AF3 Card Addressing

It is a good idea to check the installation before applying power to the rack.

Before Applying Power to the Rack

WARNING:

RISK OF ELECTRIC SHOCK! Power must be turned OFF when you perform

this procedure.

Step 1: Clean out dust, metal scraps or other debris from the rack interior.

• ETC recommends vacuuming the rack interior before installing modules.

Step 2: Check for loose connections, bare wires or damaged insulation.

Step 3: Correct air leaks caused by misaligned or removed panels, empty screw holes,

or conduit openings.

Step 4: Remove the cardboard protective cover from the top fan grille. Spin the top

cooling fan to be sure it is not obstructed.

Step 5: Check resistance between phases, Neutral and Earth for short circuits:

a: Phase to Phase; resistance should be 500k ohms or higher

b: Phases to Earth; resistance should be 500k ohms or higher

c: Neutral to Earth; resistance should be very close to 0 ohms

d: Phases to Neutral; resistance should be 500k ohms or higher

Installing Advanced Features (AF) Cards (Optional)

If your rack is an Advanced Features

rack, it should be supplied with AF cards

from the factory. Normally these will be

pre-fitted for you, however if you do need

to fit the cards use the following

procedure:

W

W

4

Step 1: Address your AF cards using

the DIP switches as shown in

Figure 34

Step 2: Locate the AF card slots at the

right hand side of the rack

Step 3: Insert the AF cards into the

slots and push until securely seated, a tangible click occurs when fully inserted.

Installing the Control Electronics Module (CEM3)

Step 1: Inspect the CEM3 for loose components or other shipping damage.

Step 2: Slide the CEM3 into the rack.

Step 3: Push on either side of the CEM3 until it is flush with the front of the rack. Do not

push in the centre as you may cause damage to the display.

5 Finishing Installation 31

Page 40

Installing Dimmer Modules

Step 1: Inspect each dimmer module for loosened components or shipping damage.

Step 2: Slide dimmer modules into the rack. If you are installing a mix of module types,

consult the included project drawings for the correct module order.

Step 3: Push each module into its slot until it is flush with the front of the rack.

Installing Module Locking Bars

CAUTION:

The module locking bars to the left of the rack are provided to prevent module removal

without use of a tool. It is an important requirement that they are fitted once installation is

complete.

Step 1: Slacken off the three Phillips screws that secure each module locking bar in

Step 2: Slide the module locking bars to the right fully, so that they overlap the edge of

Step 3: Tighten the Phillips screws fully and check that modules cannot be removed.

The module locking bars should always be installed once installation is complete.

Failure to do so leaves the end user open to risk of electric shock.

place.

the dimmer modules.

Completing Installation

Once you have completed installation, please fill in Appendix B: Sensor3 Installation

Checklist, page 35 for the system and return it to ETC. The system will then be covered

under the ETC warranty programme.

32 Sensor3 CE Rack (ESR3) Installation Manual

Page 41

Testing an Installed Sensor3 Rack

After finishing installation, use this procedure to perform a functional check.

Note:

Step 1: Make sure power is disconnected at the main circuit breaker.

Step 2: Open the door and set all the dimmer module circuit breakers to Off.

Step 3: Remove the CEM3 and set the test switch to TEST.

CAUTION:

Step 4: Replace the CEM3 and close the door.

Step 5: Apply power at the main circuit breaker

WARNING:

Step 6: Observe the rack for obvious faults:

Go over the Sensor3 installation checklist in Appendix B: Sensor3 Installation

Checklist, page 35 before energising the rack.

Caution: With the test switch on TEST, all dimmers drive to full output. Your power

supply may not have enough capacity to operate the rack at full output. To avoid

tripping your main circuit breakers, make sure you have set all dimmer module

circuit breakers to Off before applying power.

.

3-Phase Mains voltage is present inside the rack during this procedure. Do

not remove rack modules when power is applied.

• Flashing Sensor beacon

• Any indication of shorting or burning from rack components

Checking individual dimmer operation

Step 1: Open the dimmer rack door.

Step 2: Set one dimmer module circuit breaker to On and check these functional

indications:

• Signal LEDs on the dimmer modules lit

• The dimmer’s lighting loads are on (if visible)

• The rack cooling fan is running

• Dimmer hum increases slightly

Step 3: Set the circuit breaker to Off, and repeat Step 2 with each dimmer module in the

rack.

If all indications are normal after testing the dimmer modules, the rack is functional.

Step 4: Remove power at the main circuit breaker.

Step 5: Open the rack door, remove the CEM3 and set the Test switch to NORM.

Step 6: Replace the CEM3 and close the rack door.

Step 7: An Authorized Service Center (ASC) may now configure the CEM3 processor(s)

and test the dimming system using the facility control system.

Step 8: Deliver all ETC documentation to the system operator.

5 Finishing Installation 33

Page 42

Appendix A

Sensor3 CE Rack Specifications

All of the rack specifications apply to all of the ESR3 series

of racks unless otherwise noted.

General

Racks available in four sizes

ESR3-12 12 modules, 24 dimmers maximum

ESR3-24 24 modules, 48 dimmers maximum

ESR3-36 36 modules, 72 dimmers maximum

ESR3-48 48 modules, 96 dimmers maximum

Dual density (two dimmers per module) and single density

dimmer modules available

Environmental

Operating temperature: 0-40C / 32-104F

Dimmer room HVAC systems must at all times maintain the

specified ambient temperature at the dimmer rack.

Dimming systems operating within 10 degrees C of the

upper or lower temperature limits must strictly follow

installation and operation guidelines to operate reliably.

Relative humidity: 30-90% non-condensing

Altitude: Below 2000 metres.

Mechanical

Rugged 16-gauge steel construction

Fine-textured, scratch-resistant, epoxy paint

ESR3-12 uses wall mount installation

ESR3-24 can be wall or pedestal mounted

ESR3-36 and ESR3-48 are floor mounted

Top and bottom cabling access through removable panels

Screwdriver required for module removal or installation

Keyed module slots prevent insertion of inappropriate

module types

Front access to all wiring and terminations

Full height locking door

Electrostatic air filter easily removed from door for periodic

cleaning

High efficiency cooling system with airflow sensor

High visibility LED status beacon

Electrical

ESR3 racks accept:

Single phase 230V AC (3-wire)

ESR3-36: restricted to a max.600A across all circuits

ESR3-48: restricted to a max. 800A across all circuits

Three phase 230/415 V AC (3-wire)

Line feed frequencies from 47-63Hz

Maximum current ratings:

ESR3-12 – 200 amps per phase (3 phase max.)

ESR3-24 – 400 amps per phase (3 phase max.)

ESR3-36 – 600 amps per phase (3 phase max.)

ESR3-48 – 800 amps per phase (3 phase max.)

These are absolute maximum current ratings. You may use

less dependant on the type and number of dimmer

modules.

Operational Voltage (U

Insulation Voltage (U

Impulse Withstand Voltage (U

Short-circuit current: 10kA Minimum (Consult Factory)

Degree of Protection: IP20

Types of Electrical Connection: W.W.W

): 230V +/-10% (3p + N + E)

e

): 400V

i

): 4000V

imp

EMC Environment: 1

Pollution Degree: 2

Complies with Low Voltage Directive 73/23/EC

Electromagnetic Compatibility Directive 89/336/83/EC

Complies with all applicable European

Directives and associated Standards for

product safety and electromagnetic

compatibility.

Control

Sensor3 Control Electronics Module (CEM3) electronics

Redundant Tracking of dual control modules available in

ESR3-24, ESR3-36 and ESR3-48

Single Ethernet control signal input

Two DMX512 inputs

Standard diagnostic reporting

Options

Advanced Features™ dimmer-specific load and diagnostic

reporting (included with ESRAFN3 racks)

Vibration reduction kits available for all racks

SSSH Hood for noise reduction

Empty Rack Weights

Model Weight (kg)

ESR3-12 31

ESR3-12 Door* 5

ESR3-24 60

ESR3-24 Door* 8

ESR33-6 75

ESR3-36 Door* 11

ESR3-48 113

ESR3-48 Door* 14

* Racks ship with door unattached, but in same crate.

Installed Rack Weights*

Model Weight (kg)

ESR3-12 66

ESR3-24 128

ESR3-36 176

ESR3-48 247

Typical - ED15 modules (2.5kg/slot)

Refer to module datasheets to calculate total rack weight for

other module types

Load Wiring Lug Capacity

Connection Wire Size

6/10/15A, 25A and 50A lugs 16mm

2

Max.

Rack Dimensions

Installation Rack Dimensions - Including Door

Model Height (cm) Width (cm) Depth (cm)

ESR3-12 65 37.5 42.5

ESR3-24 124 37.5 50.5

ESR3-36 170.5 37.5 50.5

ESR3-48 217 37.5 58.1

34 Sensor3 CE Rack (ESR3) Installation Manual

Page 43

Appendix B

Sensor3 Installation Checklist

CAUTION:

Job Number

Job Name

Rack of

Place a tick in each box to confirm item has been

checked and is OK. Write NA if Not Applicable.

This checklist is for use by authorised ETC trained personnel when energising

ETC Sensor3 racks. Do not attempt to energise a Sensor3 system unless you are

authorised and qualified to do so.

Beforehand

All material on site. Advise ETC of shortages

ASAP.

Electrical Contractor wiring OK

Confirm time and personnel for training.

DMX

Belden 9729 and ETC specified cables.

Daisy chain DMX.

Termination DIPs set correctly

Measure DMX termination from far end

Phase-Phase high impedance (>500k ohms)

Load-Neutral impedance > 1 ohm: no “shorts”

Rack clear of dust and debris

Dimmer modules: Chokes tight, hardware

tight, circuit breakers OK

Install dimmer modules

Install CEM3s

End User Training

Who received end-user training?

Contact ETC to return unused/defective

goods

Detail any open items

Ethernet

Network star topology and using CAT5 or

better cable

Longest ethernet Run < 100m

Cable correctly terminated

Rack - Power Off

Top/bottom access plates in place and air

gaps sealed

Side plates in place and air gaps sealed

All air gaps, connections to conduit, and

trunking sealed

All bolts tightened to specification

Rack bolted to floor or wall

Neutral per load, no floating neutrals/earths

in system

All load wires and lugs tight

Fan spins freely

Phase-Earth high impedance (>500k ohms)

B Sensor3 Installation Checklist 35

Page 44

Appendix C

Figure 35: Emergency Module Circuit

Module Circuit Breaker

Dimming or Relay Circuit

Dimmed or Switched Output

Constant Output

Figure 36: Emergency Module Connections

Constant live

line is landed

on the neutral

lugs

Dimmed or

switched line is

landed on live

lugs

Emergency Modules

About Emergency Modules

Sensor3 CE Emergency modules provide two live outputs, one of which is dimmed or

switched, and one of which is live whenever the breaker is turned on. This allows the

modules to control battery backed lighting which requires a constant and a switched or

dimmed feed.

There are two varieties of Emergency Module - ED15AFE (15A Dimmer), and

ER15AFE(15A Relay). They are painted red for easy identification.

Connection

The constant output from the module is connected to the neutral lugs at the left of the rack.

Therefore, unlike neutral disconnect modules, emergency modules provide a live output at

these lugs, not a neutral connection. There is no neutral disconnect or RCD version of the

emergency modules.

Step 1: Locate the slot where the Emergency module is to be fitted.

Step 2: Terminate the outgoing dimmed line to the terminals at the right hand side of the

Step 3: Terminate the outgoing constant feed line to the terminals at the left hand side of

Step 4: Terminate the outgoing earth to the earth bar terminals.

rack.

the rack.

36 Sensor3 CE Rack (ESR3) Installation Manual

Page 45

Step 5: Terminate the neutral as described below dependant on your rack type.

CAUTION:

It is important to correctly identify the Constant Live, Dimmed Live and Neutral

wires, as incorrect termination can cause damage to the fixture and/or dimmer

rack.

Single Pole Racks

For racks which have neutral jumpers fitted, the neutral of the load fed by the emergency

module should be connected to the neutral terminal of an adjacent module.

Neutral Disconnect Racks

In racks without neutral jumpers (Neutral Disconnect racks) the neutral of the load should

not be connected to another load’s neutral terminal. This can cause unwanted tripping of

RCD modules. Instead, an auxiliary neutral terminal must be fitted to the neutral plate and

the loads should be connected to the terminal. If your rack was ordered with Emergency

Modules the auxiliary neutral terminal should be factory fitted. If you require an auxiliary

neutral terminal, please contact ETC as shown using the details in Contacting ETC, page 2.

C Emergency Modules 37

Page 46

Page 47

Page 48

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Pieve Torina, 48, 00156 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0) 20 8752 8486

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Room 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7144M2100

Rev F Released 2013-05

Copyright © 2013 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...