Page 1

ETC Installation Guide

Unison Paradigm® Occupancy Sensor

Occupancy Sensor Installation Guide Page 1 of 8 Electronic Theatre Controls, Inc.

Corporate Headquarters Middleton, Wisconsin, USA Tel +608 831 4116 Service: (Americas) service@etcconnect.com

London, UK Tel +44 (0)20 8896 1000 Service: (UK) service@etceurope.com

Rome, IT Tel +39 (06) 32 111 683 Service: (UK) service@etceurope.com

Holzkirchen, DE Tel +49 (80 24) 47 00-0

Service: (DE) techserv-hoki@etcconnect.com

Hong Kong Tel +852 2799 1220 Service: (Asia) service@etcasia.com

Web: www.etcconnect.com

Copyright © 2016 ETC. All Rights Reserved.

Product information and specifications subject to change

. ETC intends this document to be provided in its entirety.

7184M2160 Rev C Released 2016-07

Overview

The Unison Paradigm® Occupancy Sensor is a ceiling mounted sensor that

utilizes passive infrared (PIR) technology, providing reliable vacancy and

occupancy detection for lighting control. Paradigm Occupancy Sensors

integrate with Paradigm lighting control systems, providing energy efficient

lighting control solutions.

Each sensor is available in neutral white or black finish. Lens masks are

provided to allow customized occupancy detection fields as required by each

installation.

Wire Specification

The Paradigm Occupancy Sensor utilizes LinkConnect to power the sensor and

to provide data to and from the connected Paradigm control system.

LinkConnect is topology-free and polarity independent. You can install your

data runs in any desired combination of bus, star, loop, and home-run. ETC

recommends using Belden 8471 (or equivalent) wire. The total combined

length of a LinkConnect wire run may not exceed 1,640 feet (500m), with a

maximum distance of 1,312 feet (400m) between any two devices.

All control wiring should be installed and terminated by a qualified installer

and should follow standard wiring installation practices and meet local codes.

Leave approximately 10 inches (254mm) of wiring in the junction box or tied

back in the ceiling to allow for wiring connections and future service needs.

Note:

ETC requires that all sensors be grounded by using a 14 AWG

(2.5mm

2

) ESD drain wire.

The Paradigm Occupancy Sensor provides 360 degree coverage

of the installed location and is available in three models:

• P-OCC-SR- Occupancy Sensor with small room lens

covers 450 sq. ft. at 8 ft. (41.8m

2

at 2.4m) / 800 sq. ft. at

12 ft (74.3m2 at 6.65m).

• P-OCC - Occupancy Sensor with standard room lens

covers 1,800 sq. ft. at 8 ft. (167m

2

at 2.4m)/ 3,000 sq. ft.

at 12 ft. (279m2 at 6.65m).

• P-OCC-HC - Occupancy Sensor with high ceiling lens

covers 350 sq. ft. at 12 ft. (32.5m

2

at 2.4m)/ 7,000 sq. ft.

at 40 ft. (650m2 at 12.2m)

Page 2

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 2 of 8 Electronic Theatre Controls, Inc.

Installation Environment

Paradigm Occupancy Sensors are intended for installation to a finished ceiling

surface, ceiling tile mounted, attached to a round fixture junction box or

single-gang RACO switch box. The sensor operates in ambient temperatures

of -10°C to 40°C, non-condensing humidity.

ETC recommends paying special attention to the installation environment:

• The sensor must have an unobstructed view of the room. Do not mount

behind or near tall cabinets, shelves, hanging light fixtures, etc.

• Do not install the sensor within eight feet from an HVAC airflow duct /

vent.

• Install the sensor where it cannot easily sense movement in areas

outside of the intended space, such as hallways, glass partitions, or

adjacent rooms. If the installation location cannot avoid these

conditions, portions of the lens can be masked to block the sensor view

of these undesired areas. Reference Lens Masking on page 5.

Parts and Supplies

The following parts and supplies are included with the Unison Paradigm®

Occupancy Sensor ordered:

Installation

The Paradigm Occupancy Sensor is provided with a twist-lock mounting plate

that can be mounted to a junction box, finished ceiling or soft ceiling tile.

Determine the installation method and follow the detailed instructions:

• See “Junction Box Installation” on page 3.

• See “Soft Ceiling Tile Installation” on page 4.

• soft ceiling tile adapter • 3 position WAGO connectors

• LinkConnect & ESD ground

wire pigtails

• 2 each screws, 6-32 x 3/4” and

1 3/4”

• 3 each lens masks (spare)

Note:

The LinkConnect pigtail and WAGO connectors (provided) are

only required when the sensor is installed in series with other

stations or sensors. If you are not continuing the data run, direct

termination on the control board is recommended.

Page 3

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 3 of 8 Electronic Theatre Controls, Inc.

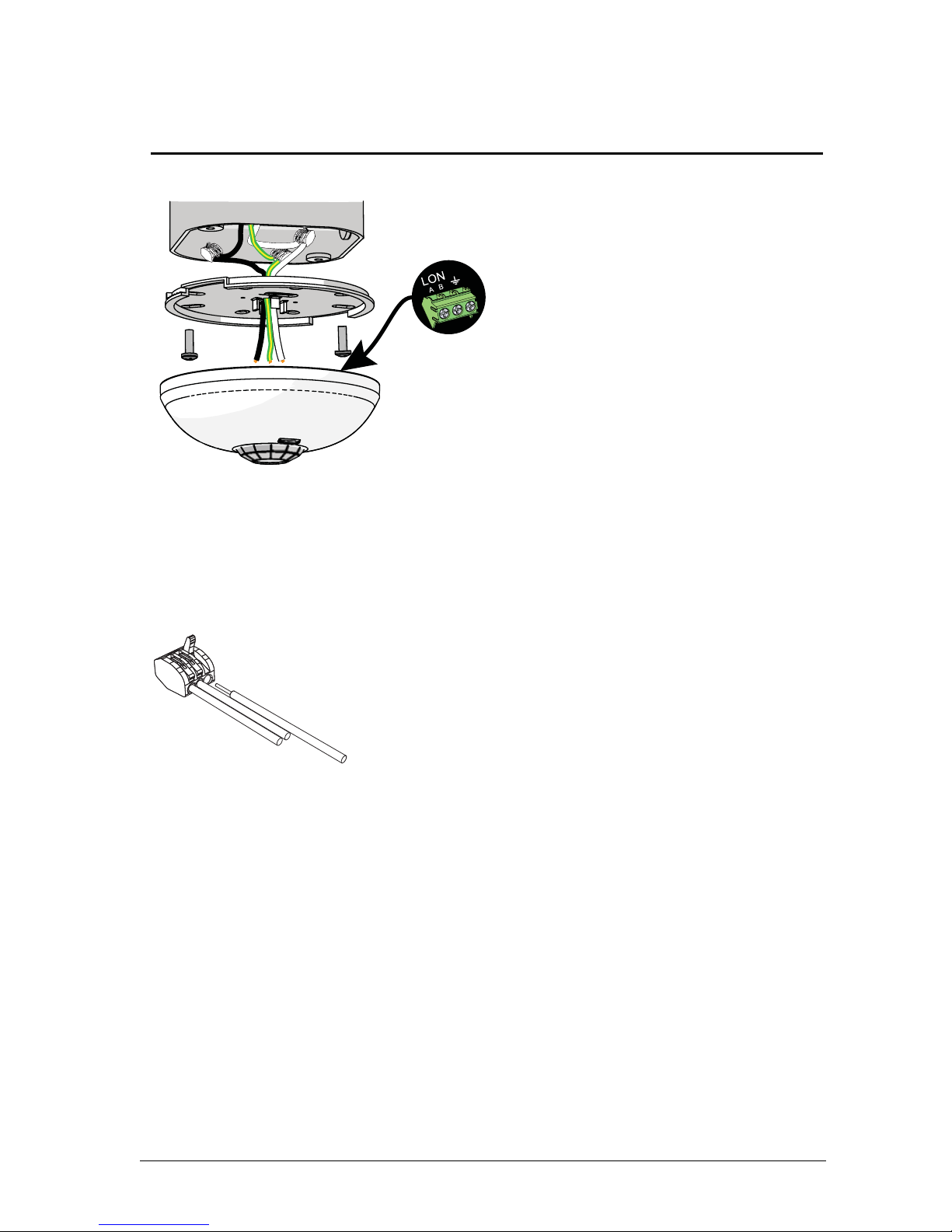

Junction Box Installation

Step 2: If you are installing the sensor in series with other sensors

or stations (continuing the data run), use the provided

LinkConnect pigtail, ESD ground pigtail and WAGO connectors

to make the terminations. If you are not continuing the data

run, proceed to step 3.

a: Strip 3/16” (5mm) of insulation from each installed LON

wire.

b: Open the three terminal levers on a WAGO connector

and insert the installed (typically black) Belden 8471

LinkConnect wire, the black lead from the sensor pigtail,

and the continuing Belden 8471 (typically black) wire into

the terminals.

c: Close the levers onto the wires.

d: Repeat the above for the installed (typically white) Belden

8471 LinkConnect wire and the remaining pigtail from

the sensor, and repeat for the ESD ground wires. Use a

new WAGO connector for each termination type.

Step 3: Orient the smooth side of the mounting plate to the junction

box and pull the Belden 8471 and the 14 AWG (2.5mm

2

) ESD

ground wire from the junction box through the provided holes

near the center of the mounting plate.

Step 4: Secure the mounting place to the junction box using the screws

provided (both short and long screws are included for

convenience).

terminate

wires here

Step 1: Pull the Belden 8471 (or equivalent)

and 14 AWG (2.5mm

2

) ground wire

to the junction box.

in

s

t

a

l

le

d c

o

n

trol

w

ire

i

n

st

a

l

l

e

d con

trol

wire

t

o

ne

x

t st

ati

on

sensor pigtail

Page 4

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 4 of 8 Electronic Theatre Controls, Inc.

Step 5: Strip each wire 5/16” (8mm) and terminate the white, black,

and green (ground) wires to the terminal block located on the

sensor control board. Torque each termination

to 3.1-3.5 in-lb.

a: Terminate the white incoming wire to terminal A.

b: Terminate the black incoming wire to terminal B.

c: Terminate the green wire to the ground terminal.

Step 6: Attach the sensor to the mounting plate by aligning the tabs on

the sensor with the slots on the mounting plate, then twist

clockwise until the two are locked into place.

Soft Ceiling Tile Installation

Step 1: Pull the Belden 8471 (or equivalent) and 14 AWG (2.5mm2)

ground wire to the installation location.

Step 2: Orient the smooth side of the mounting plate to the ceiling tile

and insert the soft ceiling tile adapter through the two small

holes near the center of the mounting plate.

Step 3: Poke the adapter tines through the ceiling tile, then bend each

tine over in opposite directions for a secure fit.

poke the adapter through the ceiling tile, then bend

it over for a secure fit.

LinkConnect pigtail and

WAGO connectors

(optional use)

terminate

wires here

Page 5

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 5 of 8 Electronic Theatre Controls, Inc.

Step 4: If you are installing the sensor in series with other sensors

or stations (continuing the data run), use the provided

LinkConnect pigtail, ESD ground wire pigtail and WAGO

connectors to make the terminations. If you are not

continuing the data run, proceed to step 5.

a: Strip 3/16” (5mm) of insulation from each installed wire.

b: Open the three terminal levers on a WAGO connector

and insert the installed (typically black) Belden 8471

LinkConnect wire, the black lead from the sensor pigtail,

and the continuing Belden 8471 (typically black) wire into

the terminals.

c: Close the levers onto the wires.

d: Repeat the above for the installed (typically white) Belden

8471 LinkConnect wire and the remaining pigtail from

the sensor, as well as the ESD ground wires using a new

WAGO connector for each termination type.

Step 5: Create a hole for wire pass-through in the ceiling tile by poking

through the center hole or oblong hole of the mounting plate,

then pull the wires through.

Step 6: Strip each wire 5/16” (8mm) and terminate the white, black,

and green (ground) wires to the LON terminal block located on

the sensor control board. Torque each termination

to 3.1-3.5 in-lb.

a: Terminate the white incoming wire to terminal A.

b: Terminate the black incoming wire to terminal B.

c: Terminate the green wire to the labeled ground terminal.

Step 7: Attach the sensor to the mounting plate by aligning the tabs on

the sensor with the slots on the mounting plate, then twist

clockwise until the two are locked into place.

Lens Masking

Lens masks are provided in the packaging for your convenience.

in

s

tal

le

d c

o

n

trol

w

ire

i

n

st

a

l

l

e

d control

wire

t

o

ne

x

t st

ati

on

sensor pigta

il

Step 1: As needed, trim the lens mask to fit

the desired area to be blocked.

Step 2: Gently press down on the sensor

lens, which will give only slightly,

and insert the lens mask.

Step 3: Rotate the lens mask around the

dome to block the required area

from occupancy sensing.

Page 6

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 6 of 8 Electronic Theatre Controls, Inc.

Power Up and Test

Power Up

For power to be applied to the Paradigm Occupancy Sensor, any additional

LinkConnect terminations for the system must also be made. In addition, the

Paradigm Architectural Control Processor (P-ACP) and Station Power

Module (P-SPM) must be installed in the host DRd or ERn rack enclosure.

When the sensor is powered up the PIR LED will illuminate for one minute for

calibration and warm-up, then will return to normal operation and enter walk

test mode if desired.

Binding Sensors to Paradigm

The Paradigm Architectural Control Processor (P-ACP) to which this sensor is

physically wired to must learn, or be told, the station hardware address

(known as a neuron ID). When the sensor is unbound from the connected

P-ACP, the service pin LED blinks.

The neuron ID is labeled on the sensor control board and can be manually

entered into the configuration using LightDesigner software. Alternatively, the

sensor can be identified using the [Service Pin] button (designated with “S”

on the button) and by the connected Paradigm ACP using its [LonWorks

Connections] menu. Reference the related source documentation, either the

LightDesigner Online Help System or the Unison Paradigm Architectural

Control Processor Configuration Manual, specifically the section on Arch Setup

Menu, LonWorks Connections.

Test

Unison Paradigm Occupancy Sensors offer a Walk Test mode which shortens

the vacancy / no occupancy timer to 10 seconds, allowing for simple and quick

verification of the sensors coverage and range in the installed space.

Walk-Test mode automatically exits and the sensor returns to normal

operation after five minutes and can be manually terminated early by pressing

the [Walk Test] or [Service Pin] button on the sensor or alternatively by

clicking on the “Wink” command in LightDesigner.

Page 7

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 7 of 8 Electronic Theatre Controls, Inc.

Enable Walk Test Mode

Step 1: Prepare the site for configuration.

a: Make certain the sensor and lighting loads are powered

and connected for control by the Paradigm control

system.

b: You will need direct access to the Paradigm Occupancy

Sensor in order to place it into walk test mode.

Alternatively, you can invoke the walk test mode by

sending a Wink command from the connected Paradigm

control system. Reference the LightDesigner Online Help

System for instructions to send a Wink command.

Step 2: Press the [Walk Test] button on

the front of the sensor to enable

the walk test feature at the

sensor. A green LED will begin to

flash, indicating the walk test is

enabled and the vacancy / no

vacancy occupancy timer will be

shortened to 10 seconds.

Step 3: Move throughout the space

including corners and areas that

may specifically be obscured

from line of sight to the sensor. Each time the sensor detects

movement, the lens will illuminate red.

Step 4: Adjust the lens masking, if installed, blocking certain areas of

the installed space from sensor detection. See Lens Masking on

page 5.

Step 5: Walk test mode will automatically exit after five minutes from

the time it was enabled. To manually exit the walk test mode,

press either of the buttons on the sensor.

Note:

The sensor must be connected and bound to the Paradigm

Architectural Control Processor (P-ACP) in order to enable Walk

Test Mode. See “Binding Sensors to Paradigm” on page 6.

service

button

service

button

walk test

button

walk test

button

Page 8

ETC Installation Guide

Occupancy Sensor

Occupancy Sensor Installation Guide Page 8 of 8 Electronic Theatre Controls, Inc.

Verify Vacancy Operation

For systems that have been configured for the installed sensor to control

specific lighting circuits, walk test mode can also be used to verify vacancy

operation.

Step 1: Confirm the installing technician has programmed the lighting

control system.

Step 2: Enable walk test mode using the instruction above (see Enable

Walk Test Mode).

Step 3: With walk test mode enabled, exit the room for 15 seconds to

allow the 10 second timer to expire.

Step 4: Re-enter the room and confirm the configured vacancy / no

occupancy state was properly recalled.

Step 5: Walk test mode will automatically exit after five minutes from

the time it was enabled. To manually exit the walk test mode,

press either of the buttons on the sensor.

Note:

When in walk test mode, status LEDs will always behave as

indicated above, even if they have been programmed to be

off by the system configuration.

High Ceiling side view

0

3.0m

10ft

3.0m

10ft

6.1m

20ft

6.1m

20ft

9.1m

30ft

9.1m

30ft

12.2m

40ft

12.2m

40ft

0

12.2m

40ft

9.1m

30ft

6.1m

20ft

Small Room side view

0

0

1.5m

5ft

1.5m

5ft

3.0m

10ft

3.0m

10ft

4.6m

15ft

4.6m

15ft

6.1m

20ft

6.1m

20ft

8ft

2.4m

10ft

3.0m

12ft

3.7m

Side view

0

1.5m

5ft

1.5m

5ft

3.0m

10ft

3.0m

10ft

4.6m

15ft

4.6m

15ft

6.1m

20ft

0

8ft

2.4m

10ft

3.0m

12ft

3.7m

6.1m

20ft

Loading...

Loading...