Page 1

Copyright © 2016 Electronic Theatre Controls, Inc.

All rights reserved. Product information and specifications subject to change.

Part Number: 7191M1200-1.0.0 Rev: A

Released: February 2016

Irideon

™

FPZ

User Manual

Rev A

Page 2

ETC®, Eos®, and Unison® are either registered trademarks or trademarks of

Electronic Theatre Controls, Inc. in the United States and other countries.

All other trademarks, both marked and not marked, are the property of their

respective owners.

ETC intends this document, whether printed or electronic, to be provided in its

entirety.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . 2

Basic Assembly . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . 3

Addressing . . . . . . . . . . . . . . . . . . . . . . 4

Initial Power Up . . . . . . . . . . . . . . . . . .5

Status LED . . . . . . . . . . . . . . . . . . . . . .5

Adjustments . . . . . . . . . . . . . . . . . . . . 5

Adjusting the Yoke Position . . . . . . . . 5

Shaping the Beam . . . . . . . . . . . . . . . . 6

Rotating The Lens Barrel. . . . . . . . . . .7

Integrated Media Holder . . . . . . . . . .8

Cleaning the Glass Lens. . . . . . . . . . . 9

Page 4

Page 5

User Manual 1

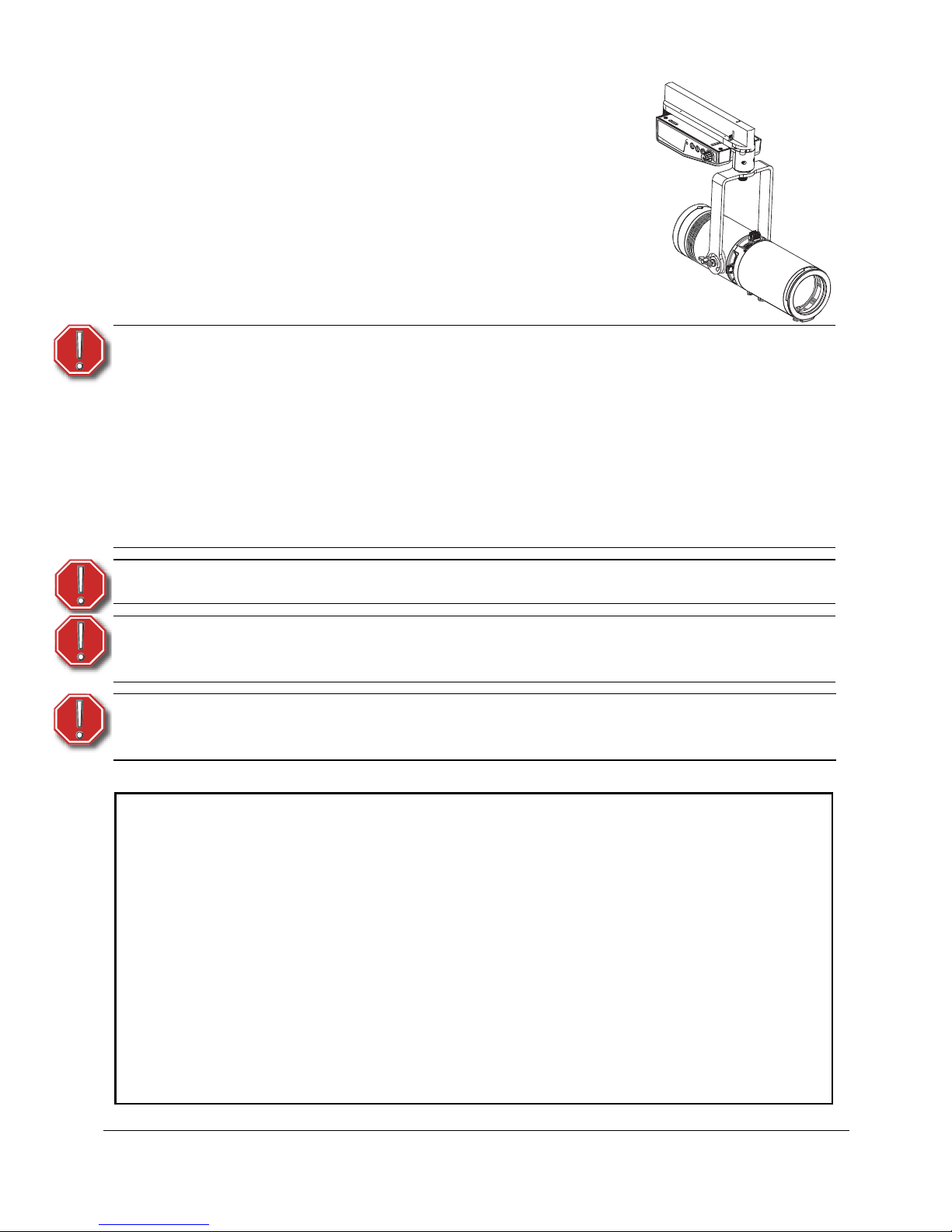

Introduction

The Irideon FPZ takes the beauty and punch of the Source

Four Mini beam and puts it into a fixture designed to work

in any architectural environment. With built in zoom optics,

three-plane shutters and a rotating barrel, the FPZ can

create a sharp or soft focused light in any shape you need.

When used with either glass or metal gobos, logos and

designs look great. With the addition of local level control

as well as individual DMX addressing, the Irideon FPZ can

do it all, and look great while doing it.

WARNING:

Please note the following safety warnings before use:

Do not mount the fixture on or near combustible surfaces.

Do not operate the fixture without a lens installed, or with

a scratch or cracked lens. Damaged lenses must be

replaced.

Use the Irideon FPZ fixture in dry locations only, where

humidity does not exceed 90 percent (non-condensing).

These fixtures are not intended for outdoor use.

WARNING:

Use with ceiling-mounted track only.

WARNING:

To reduce the risk of fire and electric shock, use the track

mount version only with the EUTRAC track system.

AVERTIR:

Pour éviter le risque d'incendie ou de choc électrique

utiliser seulement avec une alimentation par rail EUTRAC.

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS:

1) Keep lamp away from materials that may burn.

2) External temperature after 5 minutes of full-brightness operation

34°C (93°F)

3) External temperature when steady state is achieved 54°C (129°F).

SAVE THESE INSTRUCTIONS

Page 6

2 FPZ

Specifications

Physical • IP20 rated

• Die-cast aluminum construction (A380

grade)

• Magnetically held media holder

• Fine-texture, high-temperature powdercoated paint

• Zoom range to suit a variety of throw

distances

• Steel yoke with 0.406” diameter

mounting hole

• Tool-free tilt and beam adjustment

• Rotating shutter assembly ±175°

• High-impact resistant, thermally

insulated knobs and shutter handles

• E-size gobo pattern holder (included)

37.5mm with a 25.4mm image area

• Captive accessory slot for pattern

holder (included)

• Track mount

-- Compatible and ETL-listed for DataTrack

(EUTRAC) brand track

-- DataTrack color matching track adapter

included

• Locking, stainless steel, full hard

shutters in a tri-plane assembly,

0.40mm (A301 grade)

Electrical • Power at full intensity: 20W max

• Input voltage options:

-- 100-240V, 50/60Hz

• Inrush (first half-cycle)

-- 120V: 11A

-- 240V: 24A

LEDs

• Long-life LED: 35,000 hours L70

lumen maintenance

• Cree LED source

-- Irideon FPZ 3000K: 80+ CRI

-- Irideon FPZ 3000K Gallery: 90+ CRI

-- Irideon FPZ 4000K: 80+ CRI

-- Irideon FPZ 5000K: 80+ CRI

Optical

• Beam edge continually adjustable

hard to soft

• Built-in zoom optics (25-50 degree fieldangle)

• Projector-quality, high-contrast lenses

Thermal

• 0°C to 40°C (32°F to 104°F) ambient

operating temperature

Page 7

User Manual 3

Basic Assembly

Installation

Step 1: Insert the DataTrack adapter

into the track. The adapter only

fits into the track one way with

the tabs nesting into the track’s

groove.

Step 2: Rotate the locking mechanisms

to lock the adapter into place.

Step 3: Use the circuit selection lock to

select the circuit. The desired

circuit number should point

toward the center of the

adaptor.

Step 4: Focus the fixture. See Adjustments on page 5.

WARNING:

When using the circuit selection lock, ensure the

selected circuit is a constant power circuit. Dialing into

a dimmable circuit may cause fixture damage that will

void the ETC warranty.

Yoke

Integrated Media

Holder

Shutters x4

Beam Zoom and

Focus Knobs

Pattern Holder

Slot

Circuit

Selection

Lock

Locking

Mechanism

Page 8

4 FPZ

Addressing

Fixture addresses must be

set between 1 and 512.

There are three addressing

dials on the track adapter.

To address, use a small flat

head screwdriver to move

the arrow to the desired

address number.

Each Irideon FPZ fixture must

be considered a separate

DMX device for the purpose

of DMX line-loading

calculations. The Irideon FPZ

only has an intensity

channel.

Alternative DMX Addressing Functions

Certain DMX addresses are reserved for special functions. Addresses 700 and above

can be used for setting the intensity level of the fixture. The second and third address

numbers set the intensity level. The intensity knob is ignored when using these DMX

addresses. See the following chart for examples:

Note:

No more than 32 DMX devices can be daisy-chained

together on a single run. For runs of fixtures totaling more

than 32 DMX devices, a DMX splitter will need to be used to

split the DMX runs.

When using RDM with track fixtures, ETC recommends

connecting no more than 20 fixtures on a single run.

DMX Address Function

701 Intensity at 1%

710 Intensity at 10%

725 Intensity at 25%

799 Intensity at 99%

800 Intensity at 100%

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

Local Intensity

Control Knob

DMX Addressing

Dials

Status LED

In this addressing example, the fixture is

addressed to 503.

Page 9

User Manual 5

Using the Local Intensity Knob

A local intensity knob is located on the track adapter. This can be used to adjust the

intensity with or without DMX being present.

• When DMX is not present, the intensity will be controlled by the knob.

• When DMX is present, the maximum light output can be set by the knob.

Dimming will begin from that setting. When the knob is set to off, the

maximum light level over DMX is 100%.

• When the knob is set to off, data loss behavior is instant, and the light will go

dark.

When the knob is set to a level greater than 0, the data loss behavior goes to the

setting of the local knob.

Initial Power Up

Control and configuration of the Irideon FPZ can be achieved over a DMX/RDM

control network, or directly from a connected computer running appropriate

software. When controlling the Irideon FPZ directly from a PC, a Gadget Interface or

DMX/RDM gateway is required.

Status LED

The status LED indicates the DMX status. When DMX is present, the LED will be on

solid for 10 seconds, and then it will go into an off time out state.

When the local intensity knob is set to off, the status LED will flash when there is a

loss of DMX.

With the local intensity knob set to any other position, the status LED will flash for 10

seconds when there is a loss of DMX. Then the LED will go into an off time out state.

Adjustments

Adjusting the Yoke Position

The Irideon FPZ provides multi-positioning capabilities within its yoke for overall

fixture angle.

Note:

Changing the address via RDM will override the local DMX

addressing dials. However after the address has been set via

RDM, changing the dials will then override the RDM setting.

Note:

Changing the DMX start address, the local intensity knob, or

a change in DMX presence will wake the status LED from its

time out state.

Page 10

6 FPZ

Setting the angle with the

yoke

Step 1: Loosen the yoke locking knob.

Do not remove the knob.

Step 2: Tilt the fixture to the desired

position.

Step 3: Tighten the yoke locking knob

to secure position.

Zooming and Focusing

the Beam

Step 1: Loosen the beam

focus or zoom knob

located under the

barrel. Do not remove

the knob(s).

Step 2: Slide the lens forward

or backward to

achieve the desired

beam edge or angle.

Step 3: Once the fixture is focused, tighten the knob(s).

Shaping the Beam

The beam can be shaped using the four shutters or with a pattern.

The Irideon FPZ has four shutters: left, right, top, and bottom. Each shutter can be

pulled out or pushed in to create the desired beam shape.

Once the shutters are set, you can lock the shutters in place by using a 3mm Allen

wrench (provided).

Yoke

Locking

Knob

Beam Focus

Knob

Zoom Knob

Shutter Lock

Page 11

User Manual 7

Rotating The Lens Barrel

Step 1: Unlock the rotating barrel lock

using the 2mm Allen wrench

(provided).

Step 2: Rotate the barrel to the desired

location.

Step 3: Lock the rotating barrel lock

using the 2mm Allen wrench

(provided).

Rotating Barrel

Lock

Pattern Projection

The Irideon FPZ has a pattern holder slot on the top side

of the shutter barrel, in front of the shutter. It

accommodates an E-size (37.5mm with a 25.4mm

image area) pattern. The maximum pattern thickness

that can be accommodated is 4mm (0.158”).

When the slot is not in use, a small plastic cover

prevents light leakage.

Step 1: Slide the cover knob completely to the

side to expose the slot.

Step 2: Insert the pattern holder.

Step 3: Slide the slot cover back toward the

shutters until it meets the pattern

handle. Leave enough space to move

the handle.

1” Diameter

Page 12

8 FPZ

Integrated Media Holder

The Irideon FPZ comes equipped with an integrated media holder, which is a metal

frame used to hold color media (often referred to as gel) or diffusion in front of the

lens. The media holder is equipped with a magnetic retaining clip that prevents the

media from falling out. The integrated media holder can take color media or diffusion

with a 3” diameter.

Step 1: Release the magnetic retaining clip by

gently pushing it up.

Step 2: Insert the media.

Step 3: Replace the media holder by lining up

the magnets.

Installing Dichroic Glass

.

Step 1: Release the magnetic

retaining clip by gently

pushing it up.

Step 2: Place the dichroic glass into

the groove.

Step 3: Replace the media holder by

lining up the magnets.

WARNING:

Make sure the media holder is locked in position with

the magnetic retaining clip.

Magnetic

Retaining

Clip

Integrated

Media

Holder

Dichroic

Glass

Orange

Rubber

Pads

Magnet

Page 13

User Manual 9

Cleaning the Glass Lens

A fixture diagram is available on page 10.

Step 1: Remove the integrated media holder.

Step 2: Use a Phillips screwdriver to remove the three screws from the front

of the fixture.

Step 3: Remove the front casting and the metal shaft.

Step 4: Remove the light block bracket.

Step 5: Remove the lens adjustment knobs.

Step 6: Remove the front and rear lens holders.

Step 7: Remove dust with a blast of oil-free air or wipe with a clean, lint-free

cloth. Isopropyl alcohol, distilled water, or a 50%-50% mixture of

each can be used to clean the glass surface.

Step 8: Replace the lens.

Step 9: Replace the lens adjustment knobs.

Step 10: Replace the light block bracket. Make sure that it fits into its pocket

of each lens.

Step 11: Replace the metal shaft if you have not previously done so.

Step 12: Replace the front casting.

Step 13: Replace the three screws, which hold the casting onto the fixture.

Step 14: Replace the integrated media holder.

WARNING:

Do not use ammonia-based or other harsh commercial

cleaners. Clean lens only as directed.

Commercially available glass cleaning agents should be

avoided as they may contain ammonia, other harsh

chemical detergents, or abrasive agents. These cleaners

may damage the glass surface and the Anti-Reflective

coatings. Do not immerse or soak the glass in any

cleaning solution.

Note:

You may find it easier to insert the metal shaft into its pocket

of each lens before replacing the lens.

Page 14

10 FPZ

Integrated

Media

Holder

Front

Casting

Metal

Shaft

Light Block

Bracket

Front

Lens

Rear

Lens

Lens Adjustment

Knobs

Three

Screws

Page 15

Page 16

Corporate Headquarters Middleton, Wisconsin, USA Tel +608 831 4116 Service: (Americas)

service@etcconnect.com

London, UK Tel +44 (0)20 8896 1000 Service: (UK)

service@etceurope.com

Rome, IT Tel +39 (06) 32 111 683 Service: (UK)

service@etceurope.com

Holzkirchen, DE Tel +49 (80 24) 47 00-0

Service: (DE)

techserv-hoki@etcconnect.com

Hong Kong Tel +852 2799 1220 Service: (Asia)

service@etcasia.com

Web:

www.etcconnect.com Copyright © 2016 ETC. All Rights Reserved.

Product information and specifications subject to change

. ETC intends this document to be provided in its entirety.

7191M1200-1.0.0 Rev A Released 2016-02

Loading...

Loading...