Page 1

BluesSystem

Installation Manual

Manuel d’installation

This product is intended for professional use only.

Read this entire document before using this product.

Copyright © 2016 Electronic Theatre Controls, Inc.

All rights reserved. Product information and specifications subject to change.

Part Number: 7492M2100 Rev: C

Released: 2016-03

Page 2

ETC® is a registered trademark of Electronic Theatre Controls, Inc. in the United States and other

countries.

®

GDS

is a registered trademark of Global Design Solutions in Bristol, UK

All other trademarks, both marked and not marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be printed in its entirety.

Page 3

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 1

Help from ETC Technical Services. . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

System Overview . . . . . . . . . . . . . . . . . . . . . 3

Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Installation. . . . . . . . . . . . . . . . . . . . 8

Fixture Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Fixture Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Terminate Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Maximum Cable Length Charts . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Accessory Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Wall Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Terminate Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . .14

Dimming Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

System Power Up and Configuration. . . . 21

Configure DMX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Set the DMX Start Address . . . . . . . . . . . . . . . . . . . . . . . . . . .21

DMX Loss Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Set Minimum Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

System Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Power Up the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . .22

Configure Switched Output Level . . . . . . . . . . . . . . . . . . . . . . . . .23

Set Output Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Replace Input Power Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Table of Contents i

Page 4

Introduction

Congratulations on your purchase of BluesSystem products. The BluesSystem products are a

range of low-voltage LEDs that provide dimmable running lights in a compact form factor.

This manual details both BlueBeam and BlueDome LED installation instructions as well as

instructions for the installation of BluesSystem power supplies.

Document Conventions

This document uses the following conventions to draw your attention to important

information.

Note:

CAUTION:

WARNING:

WARNING:

ETC's user documents are designed for printed or electronic use. However, there are many

advantages to using the electronic (.PDF) versions. In addition to the benefits of a PDF, such

as word search, bookmarks, and commenting tools, you can click on headings in the Table of

Contents and jump to the desired page. Throughout this document, any cross-references

(indicated in blue italics like this: page 2) are links that may be clicked to jump to the specific

part of the manual.

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur,

people may be harmed, or there are serious or dangerous

consequences of an action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of electric shock.

All of ETC's documents are available for free download from our website:

www.etcconnect.com.

Please email comments about this manual to: TechComm@etcconnect.com.

1 BluesSystem Installation Manual

Page 5

Help from ETC Technical Services

If you are having difficulties, your most convenient resources are the references given in this

document. To search more widely, try the ETC website at www.etcconnect.com. If none of

these resources are sufficient, contact ETC Technical Services directly at one of the offices

identified below. Emergency service is available from all ETC offices outside of normal

business hours.

When calling for help, please:

• Have a detailed description of the problem

• Be near the equipment for troubleshooting

• Have a notification number if you have called in previously

Americas United Kingdom

Electronic Theatre Controls Inc. Electronic Theatre Controls Ltd.

Technical Services Department Technical Services Department

3031 Pleasant View Road 26-28 Victoria Industrial Estate

Middleton, WI 53562 Victoria Road,

800-775-4382 (USA, toll-free) London W3 6UU England

+1-608 831-4116 +44 (0)20 8896 1000

service@etcconnect.com service@etceurope.com

Asia Germany

Electronic Theatre Controls Asia, Ltd. Electronic Theatre Controls GmbH

Technical Services Department Technical Services Department

Room 1801, 18/F Ohmstrasse 3

Tower 1, Phase 1 Enterprise Square 83607 Holzkirchen, Germany

9 Sheung Yuet Road +49 (80 24) 47 00-0

Kowloon Bay, Kowloon, Hong Kong techserv-hoki@etcconnect.com

+852 2799 1220

service@etcasia.com

Safety

BluesSystem products are intended for professional use only. Read the entire manual

before using this equipment.

Introduction 2

Page 6

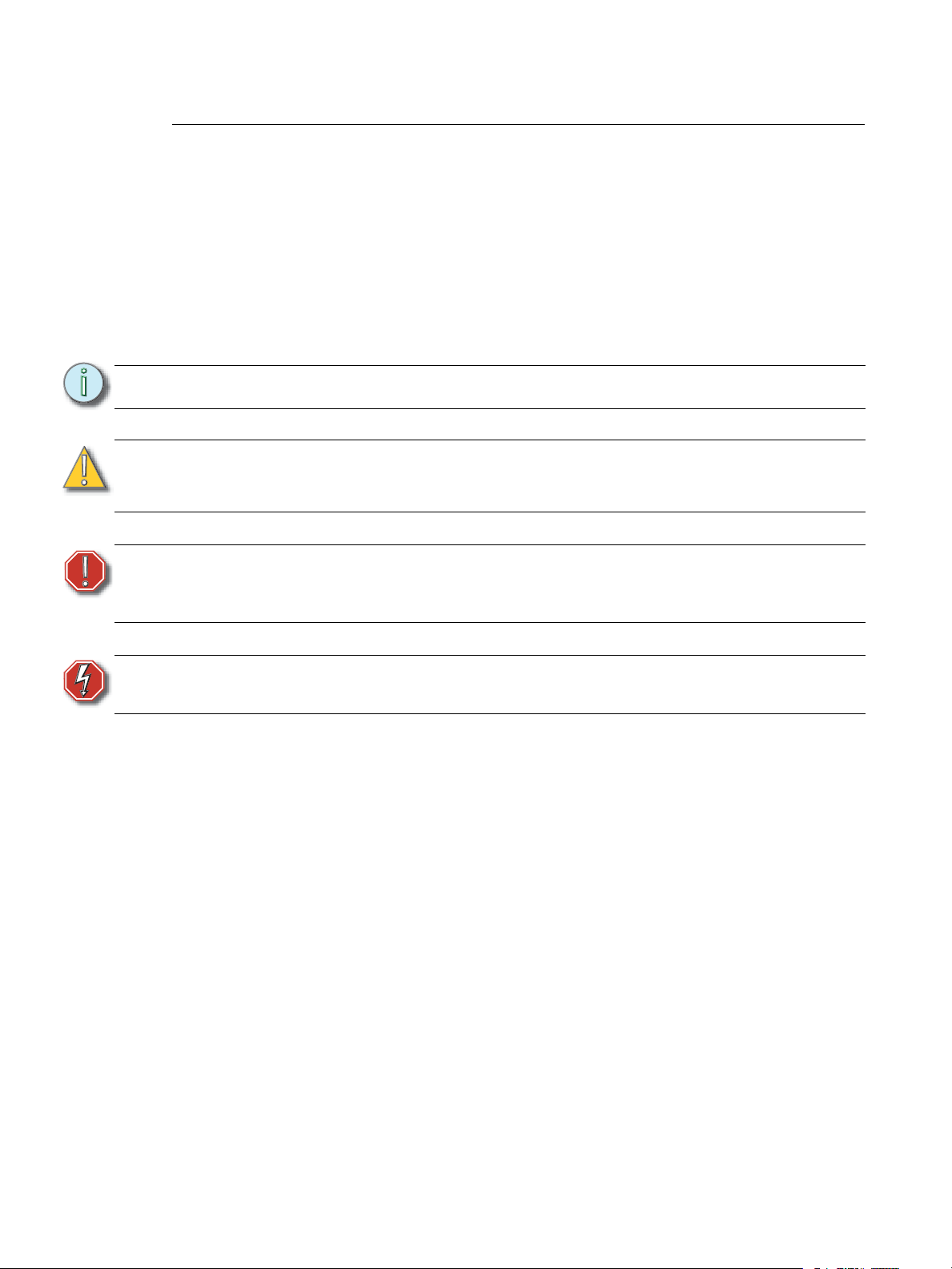

System Overview

BluesSystem is comprised of BlueDome or BlueBeam fixtures and a One-Zone or Six-Zone LV

Power Supply.

The fixtures mount directly to a junction box (either flush or surface mounted are acceptable,

but not provided) and provide focused light for corridor, stairway, lobby, and backstage

applications.

One zone power supplies are available in Switched Control or DMX512 for wall mount

installation. Six zone power supplies are available for wall mount or rack mount installation.

Models are available with DMX512, Switched Control, or 0-10 VDC Control.

Control

Power

Supply

Mains Power

PWR

O/P 1

GND

CTRL

PWR

GND

O/P 2

CTRL

Do not exceed the total load of 10 units (BlueBeam and/or BlueDome) per power zone

BlueBeam BlueBeam

BlueBeam BlueBeam

PWR

BlueBeam

GND

CTRL

BlueDome

BlueDome

BlueDome

BlueBeam

This chapter introduces you to each product and provides specification details for each

BluesSystem product.

3 BluesSystem Installation Manual

Page 7

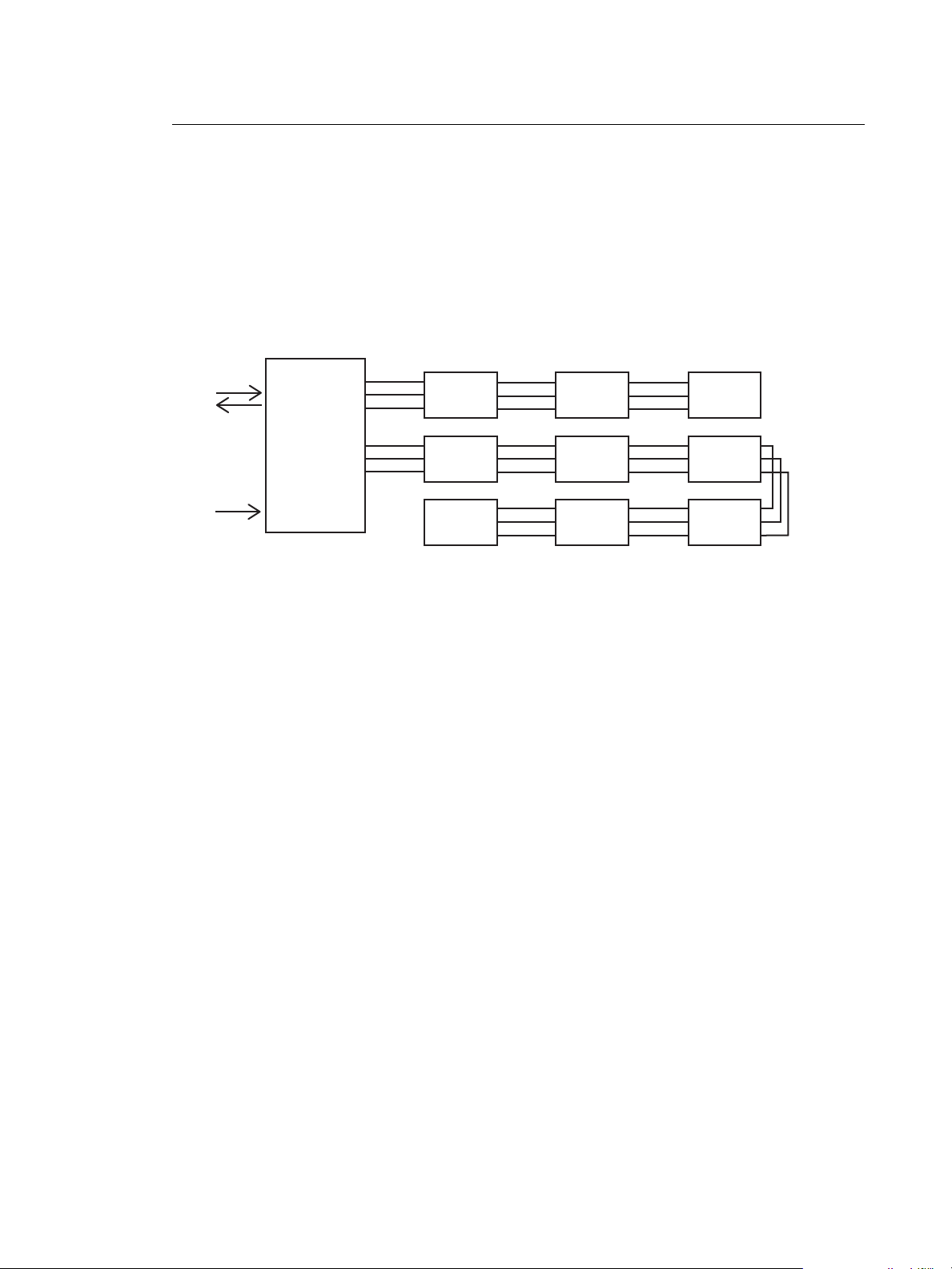

Fixtures

BlueBeam Fixture

BlueDome Fixture

Overview

Both the BlueBeam and BlueDome low-voltage LED lighting fixtures provide dimmable

running lights for tight spaces, such as catwalks, stairways, backstage areas and hallways,

that require discrete, safe illumination during live productions.

BlueBeam and BlueDome LED lighting fixtures mount directly to a standard metal or plastic

conduit junction box (either flush mounted or surface mount is acceptable). A compatible

junction box cover plate is available from ETC in either square, round, or octagonal. Contact

ETC Customer Service for ordering information.

The fixtures must be powered by a BluesSystem Low-Voltage 1 Zone or 6 Zone Power Supply.

For more information about power supplies, reference Power Supplies on page 6.

WARNING:

The BlueBeam and BlueDome LED lighting fixtures cannot be installed

in the storage area of a clothes closet.

Low-Voltage LED Fixture Electrical Specification

• Minimum operating voltage 11 VDC

• Maximum operating voltage 36 VDC

• Nominal input voltage 24 VDC

• Nominal input power 3 watts

• Operating current 125mA @ 24 VDC

• Standby current 6-8mA

• Control line impedance 100

KΩ

System Overview 4

Page 8

Accessories

Cowl Accessory

Eyelid Accessory

The BlueBeam low-voltage LED lighting fixture provides directional blue light and is available

in 2.5, 5, 10, 20, and 50 degree variants. The beam can be masked by using a cowl accessory.

The cowl can be rotated to mask off a selected side of the fixture beam.

The BlueDome low-voltage LED lighting fixture provides omnidirectional blue light at low

levels and is available in frosted or opaque variants. Masking can be achieved using the eyelid

accessory. The eyelid is used to mask off half of the BlueDome light output. The eyelid can be

rotated to mask off the desired portion of the light.

Both the cowl and eyelid accessories mount around the lens of the fixture using a simple push

and twist motion to lock them in place.

5 BluesSystem Installation Manual

Page 9

Power Supplies

Overview

The BluesSystem Power Supply provides power for the BlueDome and BlueBeam low-voltage

LED lights. Power supplies are available in a One-Zone and Six-Zone variants.

The One-Zone LV Power Supply provides power for up to 10 BlueBeam and BlueDome

running lights and is wall mounted. The wall mounted One-Zone LV Power Supply is available

in two models either DMX512 or Switched Control, depending on control requirements.

The Six-Zone LV Power Supply provides power for up to 10 BlueBeam and BlueDome running

lights per zone. Six-Zone power supplies are available in both rack mount and wall mount

variants, and offer three control options, DMX512, Switched Control, or 0-10 VDC Control.

System Overview 6

Page 10

Power Supply Electrical Specification

One-Zone LV Power Supply

• Input voltage/frequency - 100-240 VAC / 50-60 Hz

• Maximum input current - 0.65A

• Nominal output voltage - 24 VDC

• Maximum output current - 1.6A

Six-Zone LV Power Supply

• Input voltage/frequency - 100-240 VAC / 50-60 Hz

• Maximum input current - 2.7A

• Nominal output voltage - 36 VDC

• Maximum output current - 1.25A per zone

Maximum load

• One-Zone power supplies - 10 BlueBeam/BlueDome LED fixtures

• Six-Zone power supplies - 60 BlueBeam/BlueDome LED fixtures

• Control output impedance - 10 ohm

Note:

All outputs are protected from overload and short circuits by a user replaceable fuse.

Reference Fuse Replacement on page 24 for more information.

7 BluesSystem Installation Manual

Page 11

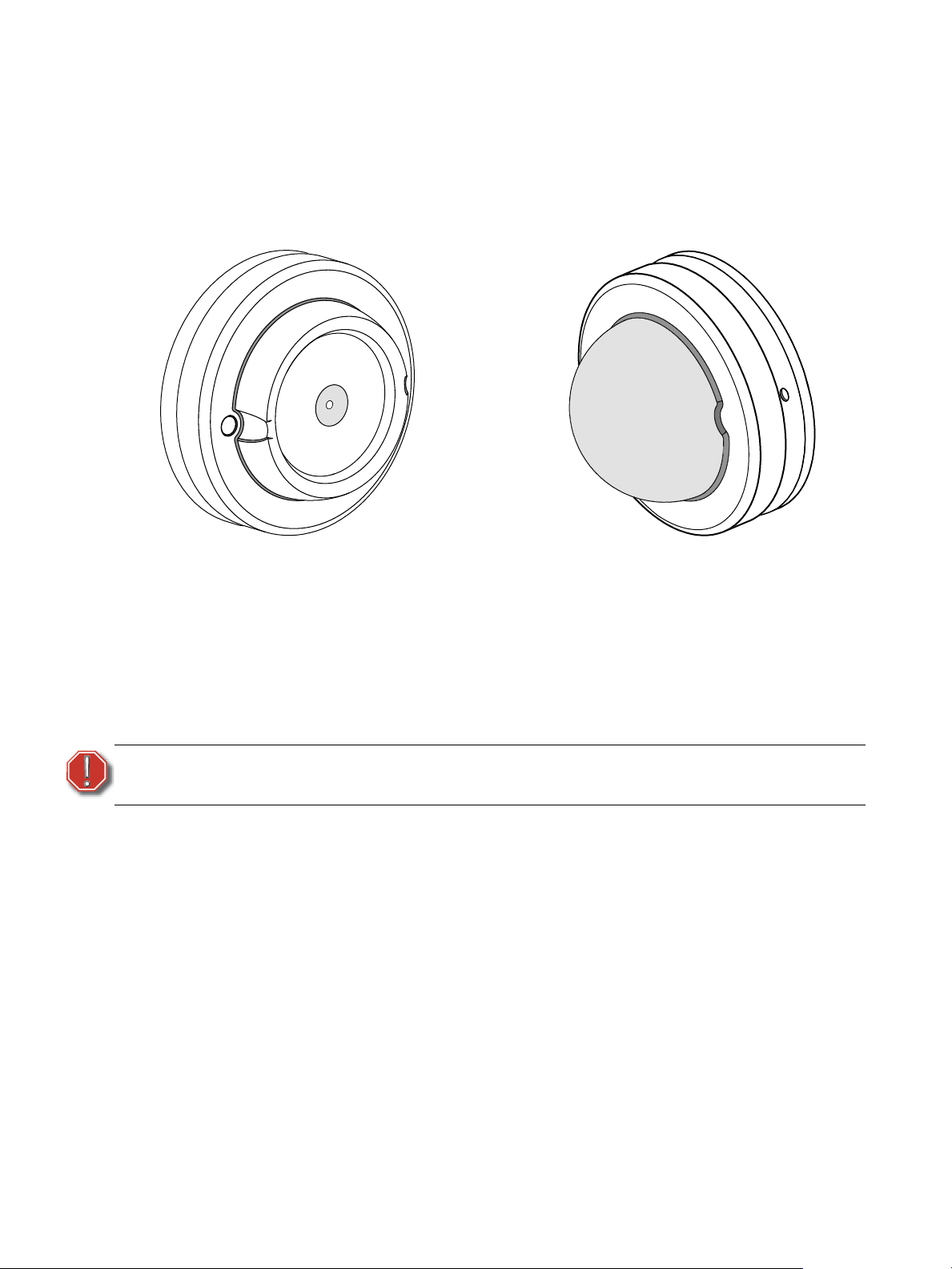

System Installation

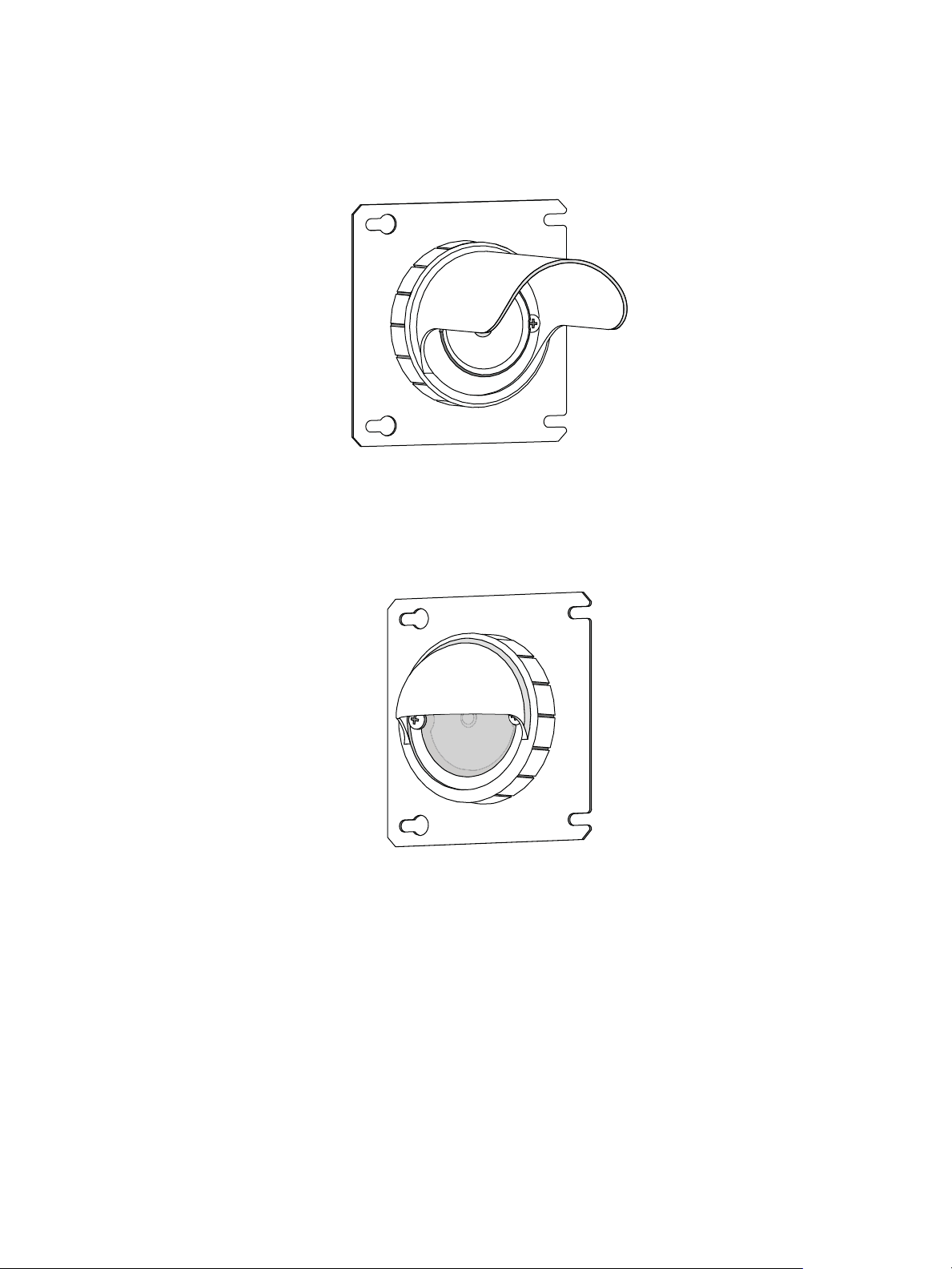

BlueBeam Fixture

with Octagonal

Mounting Bracket

BlueDome Fixture

with Round

Mounting Bracket

This chapter details the installation and wire termination for each BluesSystem product.

Note:

WARNING:

WARNING:

Read this chapter in full before beginning your system installation.

A system without an accessible power disconnect device cannot be

serviced or operated safely. Follow all local codes and restrictions.

The BlueBeam and BlueDome LED lighting fixtures cannot be installed

in the storage area of a clothes closet.

Fixture Installation

BlueBeam and BlueDome LED lighting fixtures mount directly to a standard metal or plastic

conduit junction box (either flush mounted or surface mount is acceptable). They must be

powered by a low-voltage power supply, such as a BluesSystem One-Zone or Six-Zone Power

Supply. For more information about power supplies, reference Power Supplies on page 13.

WARNING:

• Do not connect to a mains supply. The fixture requires 11-36 VDC only.

• Do not overtighten mounting screws.

• Always use the supplied gasket.

• Do not allow moisture into rear terminal area.

ETC recommends that you install all wiring in grounded metal conduit. When calculating

cable sizes, each fixture consumes 0.13A at 24 VDC or 0.8A at 36V.

Note:

System Installation 8

All low voltage cables must run in separate conduit from higher voltage (power)

wires. Follow all local codes and restrictions.

Page 12

Supplies

The following supplies are included:

• (1) Junction box cover plate (available in round, square, or octagonal)

• (2) M4 screws for mounting the fixture to the junction box

• (1) Sealing gasket

• Wiring pigtail for power, ground, and control

The following supplies are not included (provided by others):

• Conduit and conduit fittings

• Junction box

Fixture Installation

WARNING:

RISK OF DEATH BY ELECTRIC SHOCK! Failure to disconnect all power

to the system before installation, maintenance, cleaning or any other

system modification, could result in serious injury or death.

De-energize the main feed to BluesSystem and follow appropriate

Lockout/ Tagout procedures as described in NFPA Standard 70E. It is

important to note that electrical equipment such as relay panels, can

present an arc flash safety hazard if improperly serviced. This is due

to available large short circuit currents on the feeders of the

equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

Step 1: Install conduit between the BluesSystem power supply and the fixture installation

location, following your installation wiring plan. It is acceptable to continue the wiring

run up to 10 fixtures per zone on a power supply.

Step 2: Run wiring to the fixture, leaving approximately 8" (203mm) of wiring in the box for

future servicing as needed.

Step 3: Align the mounting plate.

Step 4: Align the provided gasket to the back side of the fixture.

Step 5: Pull wiring through the mounting plate and gasket.

9 BluesSystem Installation Manual

Page 13

Terminate Wiring

op

t

i

o

n

a

l

C

T

R

L

wi

re

pr

e-s

t

r

ipped

PWR wire

from power suppl

y

to the next f

ix

ture

Wire terminations are made to the terminals located on the back side of the fixture.

Dry Locaons Only

Note:

It is acceptable to continue the wiring run for up to 10 fixtures per zone on a power

supply.

Step 1: Locate the provided fixture termination kit.

Step 2: Connect ground.

a: Locate the pre-stripped black wire with spade terminal.

b: Loosen but do not remove the GND terminal screw on the back of the fixture.

c: Insert the spade terminal under the screw and tighten the screw firmly to secure.

d: Locate a 3 position WAGO inside the termination kit and open all terminal levers.

e: Insert the pre-stripped end of the pigtail into a terminal and close the lever.

f: Strip the ground wire from the power supply to .35-.39” (9-10mm), then insert it

into a terminal and close the lever.

g: If continuing to another fixture in the run, strip the wire .35-.39” (9-10mm) and

insert it into the third terminal and close the lever.

Step 3: Connect power.

a: Locate the pre-stripped red wire inside of the termination kit.

b: Loosen but do not remove the PWR terminal screw on the back of the fixture.

c: Insert the spade terminal under the screw and tighten the screw firmly to secure.

d: Locate a 5 position WAGO inside the termination kit and open all terminal levers.

e: Insert the pre-stripped end of the pigtail into a terminal and close the lever.

f: Strip the power wire from the power supply .35-.39” (9-10mm), then insert it into

a terminal and close the lever.

g: If continuing to another fixture in the run, strip the wire .35-.39” (9-10mm) and

insert it into the third terminal and close the lever.

System Installation 10

Page 14

Step 4: Connect control.

pre-

s

tri

pp

e

d

C

T

RL wire

f

r

o

m

power

s

u

p

p

ly

t

o

th

e

next

fixture

a: Locate the pre-stripped violet wire inside of the termination kit.

b: Loosen but do not remove the CTRL terminal screw on the back of the fixture.

c: Insert the spade terminal under the screw and tighten the screw firmly to secure.

d: Locate a 3 position WAGO inside the termination kit and open all terminal levers.

e: Insert the pre-stripped end of the pigtail into a terminal and close the lever.

f: Strip the control wire from the power supply .35-.39” (9-10mm), then insert it into

a terminal and close the lever.

g: If continuing to another fixture in the run, strip the wire .35-.39” (9-10mm) and

insert it into the third terminal and close the lever.

Step 5: Push all terminated wiring through to the junction box.

Step 6: Install the BlueBeam/BlueDome LED fixture to the installed junction box using the

provided hardware.

Maximum Cable Length Charts

One-Zone LV Power Supply at 24 VDC

AWG Max run in ft Max run with double ground

12 396 792

2.5mm

2

14 249 498

16 157 313

18 99 197

307 614

Six-Zone LV Power Supply at 36 VDC

AWG Max run in ft Max run with double ground

12 594 1188

2.5mm

2

14 374 747

16 235 470

18 148 296

460 920

11 BluesSystem Installation Manual

Page 15

Accessory Installation

BluesSystem provides the cowl and the eyelid accessory options for masking unwanted light

on the BlueBeam and the BlueDome low-voltage LED fixtures. Both accessories come with a

provided plastic accessory ring that allows the cowl or eyelid to snap onto the fixture.

Step 1: To install cowl and eyelid accessories, remove screws from the fixture.

Step 2: Align the holes on the fixture with the holes on the provided plastic accessory ring and

slide the ring down for an easy, secure fit.

Step 3: Reinstall the original screws back into the fixture.

Step 4: Snap the eyelid or cowl accessory over the plastic accessory ring.

System Installation 12

Page 16

Power Supplies

WARNING:

A system without an accessible power disconnect device cannot be

serviced or operated safely. Follow all local codes and restrictions.

BluesSystem Power Supplies are available in a One-Zone and a Six-Zone variant and provide

low voltage 24 or 36 VDC power to connected BlueBeam and BlueDome lighting fixtures.

Model Description Notes

BS-PS1-W-S Switched Power Supply Supports a maximum of 10 fixtures.

BS-PS1-W-D DMX Power Supply Supports a maximum of 10 fixtures.

BS-PS6-W

BS-PS6-R

6 Zone Power Supply,

Wall Mount

6 Zone Power Supply,

Rack Mount

Each zone supports a maximum of ten fixtures.

The 6 Zone Power Supply supports up to 60 fixtures

maximum.

Control input terminations are made inside of the power supply for the One-Zone and SixZone wall mounted versions and are continued to the lighting fixtures.

Supplies

The following supplies are required, but not provided, for installation.

• Conduit and conduit fittings.

• Phillips head screw driver.

• Four each mounting bolts or screws and wall anchors as needed. Mounting hardware must hold

at least 2.6 lbs for the one zone power supply and 8.5lbs for the six zone wall-mounted power

supply.

Wiring Requirements

Power

• Terminals accept 12 to 22 AWG

• max 0.5 Nm screw tightening torque

• wire strip length 7 to 7.5 mm

Control

Control

Type

DMX Belden 9729 (or approved equal)

Switched 12 to 30 AWG

0-10V 12 to 30 AWG

Wire Specification Notes

A 120 ohm resistor is required (not

provided) to terminate the last DMX

device in a control run.

13 BluesSystem Installation Manual

Page 17

Wall Mount Installation

Four mounting holes are provided on the rear panel of the power supply and provide for easy

mounting options.The power supply can be mounted to a wall or other smooth, supported,

vertical surface.

Step 1: Each non-vented edge of the power supply offers conduit knock outs. Knock out the

required holes based on your installation wire plan.

Step 2: Using a Phillips head screw driver, remove the two screws that secure the cover to the

power supply tray. Set screws aside for later re-installation. The cover is grounded by a

tether to the power supply enclosure.

Step 3: Align the power supply in its desired installation location and mark, then pre-drill the

four mounting holes.

Step 4: Install wall anchors (as needed) and the mounting hardware. Leave approximately 3/4”

(19mm) of the mounting hardware exposed to mount the power supply.

Step 5: Install the power supply to the mounting hardware and tighten the hardware for a

secure fit.

Rack Mounting

The BluesSystem 6 zone power supply can be ordered with rack mounted brackets for

installation into a standard 19" equipment rack.

Terminate Power Supply Wiring

WARNING:

RISK OF DEATH BY ELECTRIC SHOCK! Failure to disconnect all power

to the system before installation, maintenance, cleaning or any other

system modification, could result in serious injury or death.

De-energize the main feed to BluesSystem and follow appropriate

Lockout/Tagout procedures as described in NFPA Standard 70E. It is

important to note that electrical equipment such as relay panels, can

present an arc flash safety hazard if improperly serviced. This is due

to available large short circuit currents on the feeders of the

equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

Mains Input Power for Wall Mounted Units

Step 1: Make sure power is off at the main breaker.

Step 2: Loosen the three screw terminals for ground, neutral, and line connections.

Step 3: Strip each wire 5/16” (7.9mm).

Step 4: Terminate the incoming ground wire (typically green/yellow) into the GROUND terminal

and tighten the screw firmly onto the wire.

Step 5: Terminate the neutral wire (typically white) into the NEUTRAL (N) terminal and tighten

the screw firmly onto the wire.

Step 6: Terminate the line (hot) wire (typically black) into the HOT (L) terminal and tighten the

screw firmly onto the wire.

System Installation 14

Page 18

Low Voltage Outputs

OUTPUT 1 OUTPUT 2

PW

R

PW

R

G

N

D

G

N

D

CTRL

CTRL

Power supply outputs (also known as Zones) can control a maximum of 10 BlueBeam or

BlueDome fixtures installed in a single wire run.

Cable Specification

Output

Term i na l s

Power

Ground

Control

30-12 AWG (.2-4mm2 solid or

.2-2.5mm2 stranded)

Wire Torq ue Notes

Supports up to 10 fixtures per

output. For the one zone power

0.5 NM

supply, the 10 fixtures can be

split between both outputs, or

utilize only one.

To connect the installed fixture(s) to the power supply Output terminals:

Step 1: Loosen the three “Output” screw terminals.

Step 2: Strip each wire to .27" (6.9mm) and label them according to the system installation

wiring plan:

• GND typically uses black

• PWR typically uses red

• CTRL when used is typically violet

Step 3: Terminate ground.

a: Terminate into the Output GND terminal.

b: Tighten the screw firmly onto the wire.

Step 4: Terminate the power wire (typically red) into the PWR terminal and tighten the screw

firmly onto the wire.

Step 5: Terminate the control wire (typically violet) into the CTRL terminal and tighten the screw

firmly onto the wire. When control is not required from the power supply, do not

terminate.

Step 6: Reference Termi n a t e W iring on page 10 for instructions to terminate wiring at the

fixture.

.

15 BluesSystem Installation Manual

Page 19

Connect Control

Power Supplies are available in DMX, 0-10 VDC control, or Switched control models.

DMX Cable Preparation

Step 1: Cut cable (if necessary) so that an

8” (20.3cm) tail extends from the edge

of the box.

Step 2: Strip 7” (17.8cm) of the outer jacket

off.

Step 3: Label the cable with the data type and

run designation. (DMX1, DMX2, etc.)

Step 4: Strip the foil shielding from each wire

set back to within 1/4” (6.3mm) of the

outer jacket.

Step 5: Untwist the shield wire from each pair

and apply a piece of 1/16” (1.5mm)

clear heat shrink to each shield wire.

Step 6: Twist each shield wire back onto its data

pair, then apply a 1.5” (38mm) piece of

3/16” (4.8mm) heat shrink all the way

down each 3-wire set. Make sure to

capture the foil shielding at the base.

Step 7: Apply the 2” (51mm) of the 3/

8” (9.5mm) heat shrink centered on the

end of the cable jacket and the bases of

all the wires in the cable.

Step 8: Cap the ends of the unused pair of wires

with a 1” (25.4mm) of 3/16” (4.8mm)

heat shrink centered over the end of the

wires.

Step 9: Strip 3/16” (4.8mm) of insulation off all

of the wires to be used.

3

D1

7

6

13

8

12

11

5

Note:

Step 10: Maintain the wire pair twist going as close to the connector as possible and terminate

Step 11: Bend back the unused set of wires.

Step 12: Secure the unused set of wires to the cable with a wire tie.

Step 13: Secure the terminated wire set(s) together with a wire tie 2” (51mm) from the

System Installation 16

In the case of two wires landing at the same terminal, strip both wires to 3/4”

(19mm), twist them together tightly and then trim them to 3/16” (4.8mm).

the wires as required.

connector.

Page 20

Terminate DMX In

Label is mounted on inside

cover of the 6 zone wallmounted power supply

Step 1: Insert the Ground (Common) wire into the Ground terminal on the DMX In connector

and tighten the screw firmly onto the wire.

Step 2: Insert the Data - wire into the Data - terminal on the DMX In connector and tighten the

screw firmly onto the wire.

Step 3: Insert the Data + wire into the Data + terminal on the DMX In connector and tighten the

screw firmly onto the wire.

DMX IN DMX THRU

Note:

Use a 120 ohm resistor (not provided) to terminate the last DMX device in a control

run.

Terminate DMX Thru

Step 1: Insert the Common wire into the Common terminal on

the DMX Thru connector and tighten the screw firmly

onto the wire.

Step 2: Insert the Data - wire into the Data - terminal on the

DMX Thru connector and tighten the screw firmly onto

the wire.

Step 3: Insert the Data + wire into the Data + terminal on the

DMX Thru connector and tighten the screw firmly onto the wire.

n

ee

Scr

n

+

-

+

a

ee

ata

ata

at

ata

Scr

D

D

D

D

17 BluesSystem Installation Manual

Page 21

Terminate Remote Switch Wiring

Ch.1

Ch.2

Ch.3

Ch.4

Ch.5

Ch.6

Ch.1

Ch.2

Ch.3

Ch.4

Ch.5

Ch.6

COM

Ch.1

Ch.2

Ch.3

Ch.4

Ch.5

Ch.6

Ch.1

Ch.2

Ch.3

Ch.4

Ch.5

Ch.6

COM

REMOTE

SWITCH

12

Note:

Switched connection requires a dry contact such as a switch or relay. Wires with

voltage present should not be landed here.

One-Zone LV Power Supply

Step 1: Insert the wire from one side of the dry contact into terminal 1 and tighten the screw

firmly onto the wire.

Step 2: Insert the wire from the other side of the dry contact into terminal 2 and tighten the

screw firmly onto the wire.

Six-Zone LV Power Supply

Step 1: Remove the connector from the unit.

Step 2: Insert the wire from one side of the dry contact into the removable connector at Ch.1

and tighten the screw firmly onto the wire.

Step 3: Insert the wire from the other side of the dry contact into the removable connector at

COM and tighten the screw firmly onto the wire.

Step 4: Repeat Steps 1-2 for all of the dry contacts.

Step 5: Install the connector into the unit.

System Installation 18

Page 22

Terminate 0-10 VDC Wiring

CAUTION:

For Sink Control

Note:

Control wires are polarity dependent. Crossing the + and – wires while

combining drivers will result in improper performance.

Sink control refers to control voltage being provided by the BluesSystem Power

Supply to the 0-10VDC controller to set the light output.

Step 1: Insert the wire from one side of the 0-10 VDC controller into the +10V terminal on the

BluesSystem power supply and tighten the screw firmly onto the wire.

Step 2: Insert the wire from the other side of the 0-10 VDC controller into the CH.1 terminal on

the BlueSystem power supply and tighten the screw firmly onto the wire.

Step 3: Repeat Steps 1 and 2 for all 0-10 VDC connections

Step 4: Set all corresponding dip switches to Sink.

For Source Control

Note:

Step 1: Insert the wire from one side of the 0-10 VDC controller into the COM terminal on the

Step 2: Insert the wire from the other side of the 0-10 VDC controller into the CH.1 terminal on

Step 3: Repeat Steps 1 and 2 for all 0-10 VDC connections

Step 4: Set all corresponding dip switches to Source.

Source control refers to control voltage being sent from the 0-10 VDC controller to

the BluesSystem Power Supply to set the light output.

BluesSystem power supply and tighten the screw firmly onto the wire.

the BluesSystem power supply and tighten the screw firmly onto the wire.

19 BluesSystem Installation Manual

Page 23

Dimming Module

BlueBeam BlueBeamBlueBeam

Mains Power

PWR

GND

PWR

GND

CTRL

PWR

GND

CTRL

Power

Supply

O/P 1

Switch

BS-DM1

Dimming

Module

BS-DM1

Dimming

Module

BS-DM1

Dimming

Module

CTRL

CTRL

CTRL

PWR

PWR

PWR PWR

GND

GND

GND

GND

CTRL

The BS-DM1 Dimmer Module is designed to allow intensity control of the BlueDome or

BlueBeam light Fittings. The Dimmer Module can be fitted anywhere in series with the

BlueDome or BlueBeam fixtures, simply connect the Dimming Module as you would connect

another Beam or Dome to the system.

Connection Examples

The schematic below shows the use of 3 BS-DM1 modules on a single power supply. This

allows individual control of each fitting.

This schematic below shows that by connecting a BS-DM1 and removing the CTRL line from

the power supply, the second set of fittings can be dimmed using the BS-DM1. These will not

be affected by the switch on the BS-PS1.

Switch

Power

Supply

Mains Power

System Installation 20

O/P 1

O/P 2

PWR

GND

CTRL

PWR

GND

PWR

BlueBeam BlueBeam

BlueBeam BlueBeam

BS-DM1

Dimming

Module

GND

CTRL

PWR

GND

CTRL

PWR

GND

CTRL

BlueDome

BlueDome

BlueDome

BlueBeam

Page 24

System Power Up and Configuration

100

10 1

DMX START ADDRESS

This chapter provides details for system power up and configuration.

Note:

WARNING:

Read this chapter in full before powering up the system.

A system without an accessible power disconnect device cannot be

serviced or operated safely. Follow all local codes and restrictions.

Configure DMX

Set the DMX Start Address

Set the DMX start address using the rotary encoders on the power supply board labeled DMX

Start Address.

The valid range is between 001 and 512 for the 1 zone power supply and between 001 and

506 for the 6 zone power supply.

DMX Loss Behavior

The DMX Power Supply has three options that can be set to change the behavior of the

output upon loss of DMX. These can be set and stored in the unit at any time during

installation or commissioning.

Step 1: To set any of the DMX Loss Behavior options, ensure the power is switched to Off and

that a DMX source is connected to the unit.

Step 2: Using the encoder wheels, set the address to any of the functions available in the table

below.

Address Function

901 Hold last look (default)

911 Channel to full on DMX loss

921 Channel fades down to 0% on DMX loss

Step 3: Switch the power on. The DMX power supply will store the new DMX Loss Behavior

operating mode in memory.

Step 4: Turn the power off and set the DMX start address for power supply operation. See Set

the DMX Start Address.

21 BluesSystem Installation Manual

Page 25

Set Minimum Level

The DMX Power Supply has the ability to set the minimum output level, which stops the DMX

signal from switching the outputs completely off.

Step 1: To set the minimum output level of the DMX Power Supply, ensure the power is

switched to Off and you have a DMX source connected to the unit.

Step 2: Set the address to 931. This will put the card into Minimum Level Capture mode.

Step 3: Set your DMX source to output 0% on DMX channel 1.

Step 4: Switch the power on. While the DMX Power Supply is in this mode, it will respond to

DMX channel 1 and output this level to the fixtures.

a: Slowly increase the DMX control level until you see the desired level, then turn the

power supply off for five seconds and then turn it on again. It will now capture the

level on DMX channel 1 and store this as the new minimum level.

Step 5: Turn the power off and set the power supply to the required DMX address.

Step 6: If a minimum level of 0% is required, set the DMX source to output 0% on channel 1

and repeat the procedure above.

System Power Up

Power Up the Power Supply

Apply power to the power supply from the main breaker. Depending on the power supply

type, the connected fixtures will respond accordingly:

• DMX power supply will turn loads on if the DMX control level is greater than 0.

• Switched power supply will turn loads on if the switch is closed.

System Power Up and Configuration 22

Page 26

Configure Switched Output Level

TOPSET

VR1

Set Output Level

A rotary potentiometer is provided on Switched power supplies to set the intensity level for

connected BlueBeam and BlueDome fixtures when the unit is switched to On.

WARNING:

Note:

Step 1: To set the output level, power the BlueBeam and BlueDome fixtures and switch the

Step 2: Use a precision screwdriver to change the rotary potentiometer (labeled TopSet) until the

RISK OF ELECTRIC SHOCK! Mains voltage is present inside the power

supply during this procedure. It is important to note that electrical

equipment can present an arc flash safety hazard if improperly

serviced. Any work on energized equipment must comply with OSHA

Electrical Safe Working Practices.

To effectively use this feature, you will need to have line of sight between power

supply and the connected fixtures.

fixtures to On.

desired intensity level on the fixtures is reached.

23 BluesSystem Installation Manual

Page 27

Fuse Replacement

WARNING:

RISK OF DEATH BY ELECTRIC SHOCK! Failure to disconnect all power

to the system before installation, maintenance, cleaning or any other

system modification, could result in serious injury or death.

Replace Input Power Fuse

The input power circuit is protected from overload and short circuits by a user replaceable

fuse.

• Replace the One-Zone LV Power Supply input fuse with a 5 x 20mm 1.25A, 250V time delay fuse.

• Replace the Six-Zone LV Power Supply input fuse with a 5 x 20mm 3A, 250V time delay fuse.

Replace Outputs Fuse

All outputs are protected from

overload and short circuits by a user

replaceable fuse.

• Replace the One-Zone LV Power

Supply output fuse with a 1.6A,

250V fuse.

• Replace the Six-Zone LV Power Supply

output fuse with a 1.25A, 250V fuse.

System Power Up and Configuration 24

Page 28

Corporate Headquarters Middleton, WI, USA Tel +608 831 4116 Service: (Americas)

London, UK Tel +44 (0)20 8896 1000 Service: (UK)

Rome, IT Tel +39 (06) 32 111 683 Service: (UK)

Holzkirchen, DE Tel +49 (80 24) 47 00-0 Service: (DE)

Hong Kong Tel +852 2799 1220 Service: (Asia)

Web:

www.etcconnect.com

7492M2100

Rev C Released 2016-03 Product information and specifications subject to change.

Copyright © 2016 ETC. All Rights Reserved.

service@etceurope.com

service@etceurope.com

techserv-hoki@etcconnect.com

service@etcasia.com

service@etcconnect.com

Loading...

Loading...