ETAS ES415.1 User Manual

ES415.1

High Definition A/D Module with Sensor Supply

User’s Guide

Copyright

The data in this document may not be altered or amended without special notification from ETAS GmbH. ETAS GmbH undertakes no further obligation in relation to this document. The software described in it can only be used if the

customer is in possession of a general license agreement or single license. Using

and copying is only allowed in concurrence with the specifications stipulated in

the contract.

Under no circumstances may any part of this document be copied, reproduced,

transmitted, stored in a retrieval system or translated into another language

without the express written permission of ETAS GmbH.

© Copyright 2018 ETAS GmbH, Stuttgart

The names and designations used in this document are trademarks or brands

belonging to the respective owners.

ES415.1 - User’s Guide R08 EN - 04.2018

2

ETAS Contents

Contents

1 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Identification of Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Presentation of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Scope of Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Basic Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Requirements for Users and Duties for Operators . . . . . . . . . . . . . . . . . . . . . 9

2.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 ES400 Product Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Wiring Concepts in Test Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Features of the ES400 Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Advantages of the Decentral Wiring Concept . . . . . . . . . . . . . . . . 15

3.2.2 Further Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.1 “Sensor” Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.2 Daisy Chain Ports (“IN”, “OUT”) . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.1 Operational State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.2 Service State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.3 Functional State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Features of the ES415.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Sensor Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 Signal Processing and Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ES415.1 - User’s Guide 3

Contents ETAS

4.3.2 Amplifier and analog Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.3 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.4 Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.5 Maximum Input and Common-Mode Voltages . . . . . . . . . . . . . . . 23

4.3.6 Galvanically Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.7 Sensor Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 Communication Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.2 Realization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.3 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5.1 Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5.2 Supplying the ES400 Modules via the Connecting Line . . . . . . . . . 31

4.5.3 Additional Supply of the ES400 Modules via a Y-Boost Cable . . . . 31

4.6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.7 Tool Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.8 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.9 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1 General Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.1 Assembly Environment and Components for Attaching the Module 34

5.1.2 Potential Equalization in the Vehicle and Mounting the Modules . 34

5.1.3 Guarantee of Features as defined by IP67 . . . . . . . . . . . . . . . . . . . 35

5.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1 How to Connect and Attach ES400 Modules . . . . . . . . . . . . . . . . . 36

5.2.2 Connecting Several ES400 Modules Mechanically . . . . . . . . . . . . . 37

5.2.3 Attaching ES400 Modules to Other Components Using the Integrated

Assembly Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.4 Attaching ES400 Modules on DIN Rails with the Integrated Assembly

Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.5 Attaching ES400 Modules to Other Components with Screws . . . . 44

5.2.6 Attaching ES400 Modules on DIN Rails using Screws . . . . . . . . . . . 46

5.2.7 Attaching ES400 Modules to Other Components Using Cable Fasten-

ers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 Drilling Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.4 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4.2 ES415.1 with additional ETAS Modules (MC Application). . . . . . . . 51

5.4.3 ES415.1 with additional ETAS Modules (Rapid Prototyping Application)

52

5.5 Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.5.1 ES400 Modules with additional ETAS Modules (Measurement and Cal-

ibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.5.2 ES400 Modules with additional ETAS Modules and Drive Recorder

(Measurement and Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.5.3 ES400 Modules with ES910.3 (Rapid Prototyping) . . . . . . . . . . . . . 55

5.5.4 ES400 Modules with ES910.3 and Drive Recorder (Rapid Prototyping)

56

ES415.1 - User’s Guide4

ETAS Contents

5.5.5 ES400 Modules with ETAS RTPRO-PC (Rapid Prototyping) . . . . . . . 57

5.6 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6.1 “Sensor” Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6.2 Daisy Chain Ports (“IN”, “OUT”) . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 Troubleshooting Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.1 LED Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Troubleshooting ES415.1 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3 Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3.1 Network Adapter Cannot Be Selected via Network Manager . . . . . 64

6.3.2 Search for Ethernet Hardware Fails . . . . . . . . . . . . . . . . . . . . . . . . 65

6.3.3 Personal Firewall Blocks Communication . . . . . . . . . . . . . . . . . . . . 67

7 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.1 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.1.1 Product labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.1.2 Standards and Norms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.1.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1.4 Maintenance the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1.5 Cleaning the product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1.6 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1.7 Modules in one chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.2 RoHS conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.2.1 European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.2.2 China . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.4 Product return and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.5 Declarable Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.6 Use of Open Source software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.7 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.7.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.7.2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.8 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.8.1 Host Interface ("IN" Connection) . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.8.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8.3 Sensor Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8.4 Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.8.5 Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.9 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.9.1 “IN” Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.9.2 “OUT” Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.9.3 “Sensor” Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8 Cables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.1 Combined Ethernet and Power Supply Cable . . . . . . . . . . . . . . . . . . . . . . . 86

8.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.1.2 CBEP410.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.1.3 CBEP4105.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.1.4 CBEP415.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.1.5 CBEP4155.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

ES415.1 - User’s Guide 5

Contents ETAS

8.1.6 CBEP420.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.1.7 CBEP4205.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.1.8 CBEP425.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.1.9 CBEP4255.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.1.10 CBEP430.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.1.11 CBEP4305.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2 Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.1 CBE400.2 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2 CBE401.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.3 CBE430.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.2.4 CBE431.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.2.5 CBEX400.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.2.6 ES4xx_BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.3 Cable for the Connection "Sensor" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.3.1 CBAV400.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.3.2 CBAV411.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.3.3 CBAV413.1 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.4 Measurement Probes and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.4.1 CBN400.1 Isolating Measurement Probe . . . . . . . . . . . . . . . . . . . . 98

8.4.2 CBN401.1 Isolating Measurement Probe . . . . . . . . . . . . . . . . . . . . 98

8.4.3 CBN41x.1 Current Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.4.4 CBN42x.1 Sensor Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.4.5 CBN430.1 Temperature Sensor Connection Cable. . . . . . . . . . . . 101

8.5 Protective Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.5.1 Protective Caps supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.5.2 Cap CAP_LEMO_1B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.5.3 Cap CAP_LEMO_1B_LC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.5.4 Cap CAP_SOURIAU_8STA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.6 Angle Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.6.1 Angle Bracket Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.6.2 Angle Bracket Right. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.1 ES415.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2.2 Protective caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.2.3 Angle brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.2.4 Device calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10 ETAS Contact Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

ES415.1 - User’s Guide6

ETAS About this Manual

DANGER!

WARNING!

CAUTION!

1 About this Manual

This chapter contains information about the following topics:

• "Identification of Safety Notices" on page 7

• "Presentation of Information" on page 8

• "Scope of Supply" on page 8

• "Additional Information" on page 8

1.1 Identification of Safety Notices

The safety notices contained in this manual are identified with the danger symbol

shown below:

The safety notices shown below are used for this purpose. They provide notes to

extremely important information. Please read this information carefully.

indicates an immediate danger with a high risk of death or serious

injury, if not avoided.

indicates a possible danger with moderate risk of death or (serious)

injury, if not avoided.

identifies a hazard with low risk that could result in minor or medium

physical injuries or property damages if not avoided.

ES415.1 - User’s Guide 7

About this Manual ETAS

Note

1.2 Presentation of Information

All activities to be performed by the user are presented in a "Use Case" format.

That is, the goal to be accomplished is briefly defined in the heading, and the

respective steps required for reaching this goal are then presented in a list. The

presentation looks as follows:

Goal definition:

any advance information...

1. Step 1

Any explanation for step 1...

2. Step 2

Any explanation for step 2...

3. Step 3

Any explanation for step 3...

Any concluding comments...

Typographical conventions

The following typographical conventions are used:

Bold Labels of the device

Italic Particularly important text passages

Important notes for the user are presented as follows:

Important note for the user.

1.3 Scope of Supply

Prior to the initial commissioning of the module, please check whether the module was delivered with all required components and cables (see chapter 9.1

on page 104).

Additional cables and adapters can be obtained separately from ETAS. A list of

available accessories and their order designation is located in chapter "Accessories" on page 104 of this manual or in the ETAS product catalog.

1.4 Additional Information

The configuration instructions for the module under INCA can be found in the

corresponding software documentation.

ES415.1 - User’s Guide8

ETAS Basic Safety Notices

Note

2 Basic Safety Notices

This chapter contains information about the following topics:

• "General Safety Information" on page 9

• "Requirements for Users and Duties for Operators" on page 9

• "Intended Use" on page 9

2.1 General Safety Information

Please observe the Product Safety Notices ("ETAS Safety Notice") and the following safety notices to avoid health issues or damage to the device.

Carefully read the documentation (Product Safety Advice and this User's Guide)

that belongs to the product prior to the startup.

ETAS GmbH does not assume any liability for damages resulting from improper

handling, unintended use or non-observance of the safety precautions.

2.2 Requirements for Users and Duties for Operators

The product may be assembled, operated and maintained only if you have the

necessary qualification and experience for this product. Incorrect operation or

operation by users without sufficient qualification may lead to injuries or death

or property damages.

The safety of systems that are using the product is the responsibility of the system

integrator.

General safety at work

The existing regulations for safety at work and accident prevention must be followed. All applicable regulations and statutes regarding operation must be

strictly followed when using this product.

2.3 Intended Use

Application area of the product

This product was developed and approved for applications in the automotive

area. The module is suitable for use in interiors, in the passenger cell, in the

trunk, in the engine compartment or in the exterior area of vehicles.

For use in other application areas, please contact your ETAS contact partner.

Requirements for the technical state of the product

The product is designed in accordance with state-of-the-art technology and recognized safety rules. The product may be operated only in a technically flawless

condition and according to the intended purpose and with regard to safety and

dangers as stated in the respective product documentation. If the product is not

used according to its intended purpose, the protection of the product may be

impaired.

ES415.1 - User’s Guide 9

Basic Safety Notices ETAS

DANGER!

Requirements for operation

• Use the product only according to the specifications in the corresponding

User's Guide. With any deviating operation, the product safety is no longer ensured.

• Observe the requirements on the ambient conditions.

• Do not use the product in potentially explosive atmospheres.

Electrical safety and power supply

• Observe the regulations applicable at the operating location concerning

electrical safety as well as the laws and regulations concerning work

safety!

• Connect only current circuits with safety extra-low voltage in accordance

with EN 61140 (degree of protection III) to the connections of the module.

• Ensure the compliance with the connection and adjustment values (see

the information in the chapter "Technical Data").

• Do not apply any voltages to the connections of the module that do not

correspond to the specifications of the respective connection.

Power supply

• The power supply for the product must be safely disconnected from the

supply voltage. For example, use a car battery or a suitable lab power supply.

• Use exclusively lab power supplies with double protection to the supply

system (with double insulation / with reinforced insulation (DI/ RI)).

• The lab power supply must be approved for an operating altitude of

5,000 m and for an ambient temperature of up to 120 °C.

• For normal operation of the modules as well as for very long standby operation, it is possible that the vehicle battery will be drained.

Connection to the power supply

• The power cable may not be connected directly to the vehicle battery or

the lab power supply, but only via a suitable fuse.

• Ensure that the connections of the lab power supply, the power supply at

the module and the vehicle battery are easily accessible!

• Route the power cable in such a way that it is protected against abrasion,

damages, deformation and kinking. Do not place any objects on the

power cable!

Dangerous electrical voltage!

Connect the power cable only with a suitable vehicle battery or with

a suitable lab power supply! The connection to power outlets is not

allowed!

To prevent an inadvertent insertion in power outlets, ETAS recommends to equip the power cables with safety banana plugs in areas

with power outlets.

ES415.1 - User’s Guide10

ETAS Basic Safety Notices

CAUTION!

CAUTION!

CAUTION!

De-energizing the module

The module does not have an operating voltage switch. The module can be deenergized as follows:

• Disconnecting the cables from the measurement inputs

and

• Disconnecting the module from the power supply

– Switching off the lab power supply

or

– Disconnecting the module from the lab power supply

Separating device is the lab plug of the power cable or the plug of the

power cable at the connection of the module

or

– Disconnecting the module from the vehicle battery

Separating device is the lab plug of the power cable or the plug of the

power cable at the connection of the module

or

– Disconnecting the vehicle battery.

Cabling

Approved cables:

• Use exclusively ETAS cables at the connections of the module!

• Adhere to the maximum permissible cable lengths!

• Do not use any damaged cables! Cables may be repaired only by ETAS!

Never apply force to insert a plug into a socket.

Ensure that there is no contamination in and on the connection, that

the plug fits the socket, and that you correctly aligned the plugs with

the connection.

Damage possible to connectors of the modules or the

ES4xx_BRIDGE!

Fasten the two modules with screws to the stop inside the module

without canting them.

For detailed information about cabling, see the User's Guide of the module.

Potential equalization in the vehicle is possible via the shield of

the connecting cables of the modules!

Install the modules only at locations with the same electrical potential

or isolate the modules from the installation location.

ES415.1 - User’s Guide 11

Basic Safety Notices ETAS

CAUTION!

CAUTION!

CAUTION!

Requirements for the place of installation

• Place the module or the module block on a smooth, even and firm foundation.

• The module or module block must always be securely fastened.

Requirements on the ventilation

• Keep the module away from heat sources and protect it against direct

exposure to the sun.

• The free space above and behind the module must be selected so that

sufficient air circulation is ensured.

Fixing the module on a carrier system

When selecting the carrier system, observe the static and dynamic forces that

could be created by the module or the module block at the carrier system.

Damage or destruction of the module is possible.

The modules of series ES400 are approved only for installation and

operation at components or locations that ensure compliance with

the technical data of the modules, such as:

• the resistance to vibration of the modules (for example, install

modules only on spring-loaded bodies, not on wheel suspensions

or directly at the motor) and

• the temperature resistance of the modules (for example, do not

install modules on the motor, turbocharger, exhaust manifold or

their environments).

During the installation of the modules, observe the permissible temperature range of the cable ties being used!

Damage of the module and loss of properties acc. to IP67

Loss of Features as defined by IP67!

Water standing at the pressure balance element damages the membrane!

Please observe which way the module is pointing when installing vertically!

Transport

• Mount and connect the modules only at the location of their startup!

• Do not transport the modules at the cable of the module or any other

cables.

ES415.1 - User’s Guide12

ETAS Basic Safety Notices

Maintenance

The product is maintenance-free.

Repair

If a repair of an ETAS hardware product should become necessary, send the product to ETAS.

Cleaning the module housing

• Use a dry or lightly moistened, soft, lint-free cloth for cleaning the module

housing.

• Do not user any sprays, solvents or abrasive cleaners which could damage

the housing.

• Ensure that no moisture enters the housing. Never spray cleaning agents

directly onto the module.

ES415.1 - User’s Guide 13

ES400 Product Family ETAS

Sensor 1

Sensor 2

Sensor 3

Sensor n

Sensor 1

Sensor 2

Sensor 3

Sensor n

Sensor 1

Sensor 2

Sensor 3

Sensor n

Sensor 1

Sensor 2

Sensor 3

Sensor n

Sensor 1

Sensor 2

Sensor 3

Sensor n

3 ES400 Product Family

This chapter contains information on the following topics:

• "Wiring Concepts in Test Vehicles" on page 14

• "Features of the ES400 Line" on page 15

• "Housing" on page 16

• "Ports" on page 17

• "LED" on page 18

3.1 Wiring Concepts in Test Vehicles

For the test phase, several hundred sensors must be installed in a test vehicle in

various areas, e.g. in the engine compartment and in the floor area. The sensors,

which are positioned all over the vehicle, then have to be connected to the measuring instruments of the test setup.

Today’s standard solutions with their central setup of measuring instruments

inside the vehicle require complex cabling to connect the widely distributed sensors with the measuring instruments. Numerous, usually long connection cables

between the sensors and the measuring instruments, bundled together to form

several fat wiring harnesses, require a highly modified splash wall of the test

vehicle. This involves long setting-up times as well as high costs.

Fig. 3-1 Central and Decentral Sensor Cabling

With the ES400 modules, ETAS provides a decentral solution which considerably

simplifies the test setup of the sensors.

The basic idea of this concept is to install the modules of the ES400 family as

close as possible to the sensors, to concatenate the modules with each other and

to connect just the first module of this chain with the laptop in the vehicle.

ES415.1 - User’s Guide14

ETAS ES400 Product Family

3.2 Features of the ES400 Line

3.2.1 Advantages of the Decentral Wiring Concept

• The compact ES400 modules can be mounted close to the sensors with

short connection cables.

• The simple assembly and wiring principle (daisy chain topology) of the

modules

– requires only one common cable between the modules for power sup-

ply and data transfer

– considerably reduces the setting-up times for tests

– simplifies the maintenance and the extension of the test setup

• The only item in the vehicle is the laptop which is connected to the modules with just one cable.

• Test vehicles equipped with an ES400 measurement system can be used

flexibly because the vehicles do not have to be modified for changed or

new test tasks.

3.2.2 Further Features

This list provides an overview of the other features of the ES400 line in addition

to decentral cabling:

• The ES400 modules have a very compact design.

• Each module has an LED for localizing the module.

• The High Definition A/D Module with Sensor Supplys of the ES400 family

use a XCP-based protocol which is compatible to the existing ETAS Ethernet topology.

The concept fulfills the following requirements:

– high bandwidth to be able to realize lots of channels with high resolu-

tions (typical in measuring and calibration applications) with fast sampling rates

– simple application based on the Ethernet integration in INCA, no com-

plicated setting of bus parameters,

– simple to integrate in measurement and calibration tools manufac-

tured by third-party suppliers due to the use of XCP as application protocol

– support of all probes and pressure sensors used in the automotive

industry

• Innovative, battery-saving power supply management

– automatic power-saving feature (“Standby”)

– “Wake Up” via the Ethernet interface

• Part of the ETAS Tool Suite

• Daisy Chain Configuration Tool (stand-alone operation)

ES415.1 - User’s Guide 15

ES400 Product Family ETAS

CAUTION!

• Modules suitable for use in automotive applications; suitable for use in the

development environment and in the vehicle on test drives:

– Housing, connectors and cables waterproof and dustproof in acc. with

IP65 or IP67; designed for use in the engine compartment or the outside area of the vehicle

– rugged to acceleration or mechanical damage

– rugged to extreme environmental conditions (temperature, dampness,

EMC)

– very low temperature coefficients contribute to the reduction in the

number of measurement errors

For the complete technical data of the ES415.1, refer to the chapter "Technical

Data" on page 70.

3.3 Housing

A sturdy metal housing is used for the ES415.1; it has ports on the front of the

device so it can fit into tight spaces. The ES415.1 is specifically designed to be

installed in engine compartment, but also in the passenger cell.

The housings of the ES400 family can quickly and easily be connected to one

another to create a measurement system (see section 5.2 on page 36). The modules can easily be screwed directly to a carrier system or attached to it using cable

fasteners both in the vehicle and in the lab.

These simple and uncomplicated ways of attaching the modules make them flexible in terms of assembly. These methods of attachment can also be used in harsh

environmental conditions (salt fog, dirt).

Loss of Features as defined by IP67!

Do not open or change the module housing!

Works on the module housing may be executed only by qualified

technical personnel.

ES415.1 - User’s Guide16

ETAS ES400 Product Family

IN

OUT

Se n so r

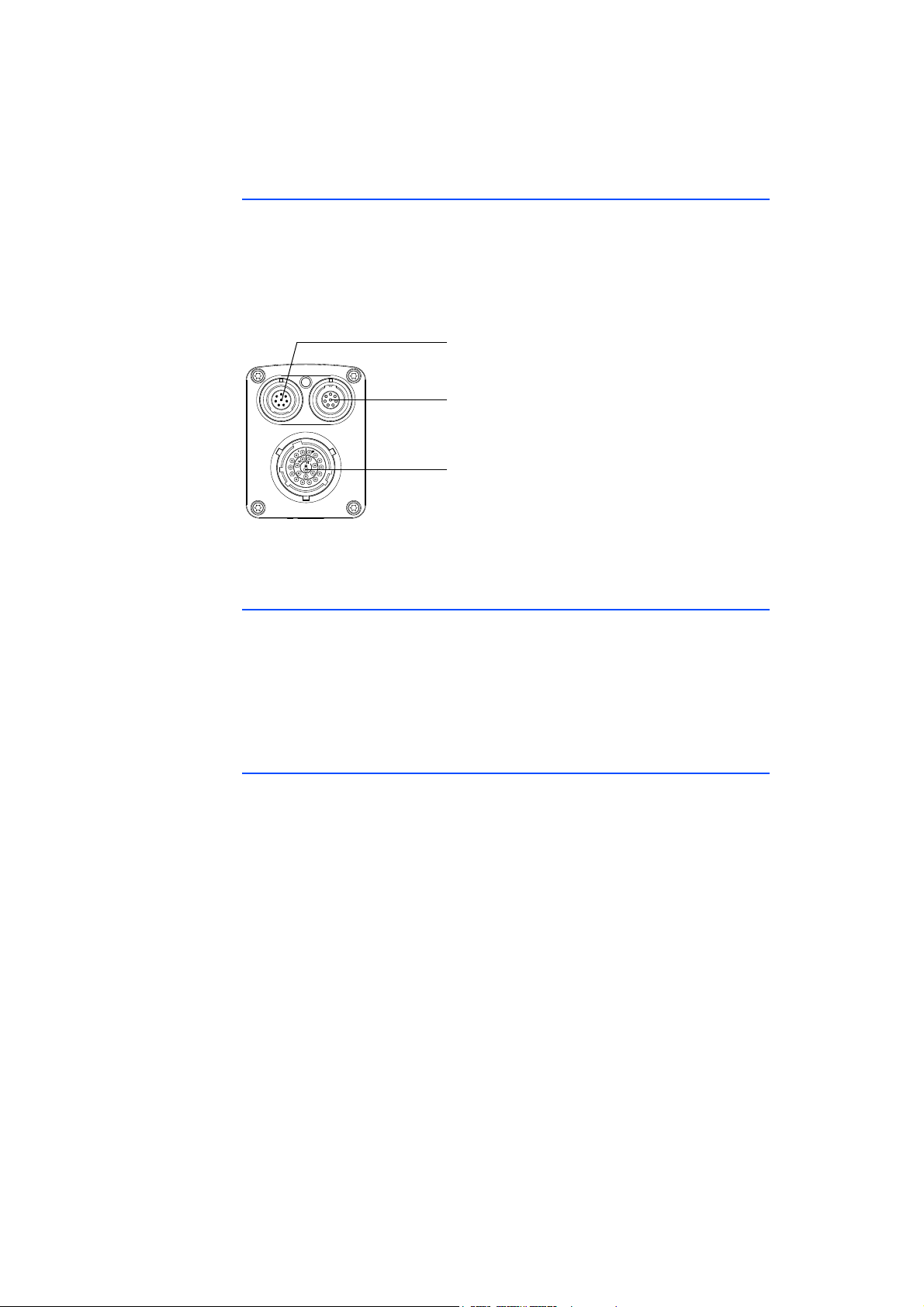

3.4 Ports

All ports of the ES400 measuring modules are on the front of the device (see

Fig. 3-2 on page 17).

The LEMO and Souriau connectors used adhere to protection class IP67. All ports

are reverse-polarity protected due to the exclusive use of coded LEMO or Souriau

connectors.

Fig. 3-2 Front

3.4.1 “Sensor” Port

The front of the ES415.1 features a 22-pin Souriau port to which four sensors

can be connected using a adapter cable. An individual sensor power supply port

is available for each sensor.

The use of a “cable tail” or “whip” solution with just one connector makes it

possible to change the modules quickly within complex test setups.

3.4.2 Daisy Chain Ports (“IN”, “OUT”)

The modules are connected using a daisy chain topology. This means each module has an explicit input socket and an explicit output socket. The Ethernet data

line and the supply voltage are routed through the daisy chain ports of the module:

• “IN” (input)

• “OUT” (output)

The PC, the modules ES523, ES59x, ES600.2, ES891, ES910.3 or the Drive

Recorder ES720 are connected at the “IN” port (input). The “OUT” port (output)

is connected to the following module of the ES400 line or remains free on the

last module of the chain.

ES415.1 - User’s Guide 17

ES400 Product Family ETAS

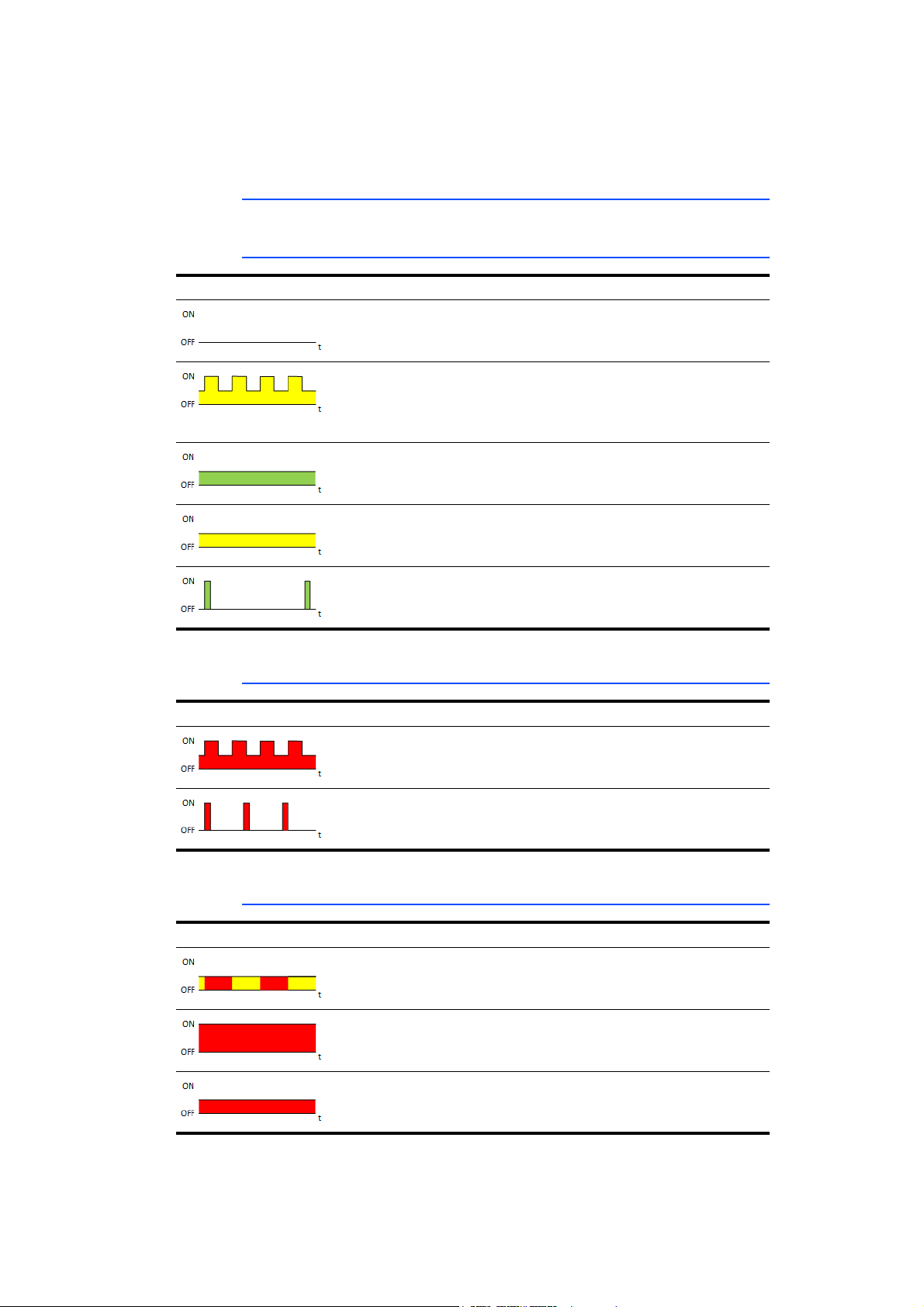

3.5 LED

Every module has an LED. It indicates the following states of the module:

3.5.1 Operational State

Display State

off No power supply to the

module

yellow flashing

0,25 s on / 0,25 s reduced

green illuminated

semi bright

yellow illuminated

semi bright

green flashing

0,1 s on / 1,9 s off

3.5.2 Service State

Display State

red flashing

0,25 s on / 0,25 s reduced

red flashing

0,1 s on / 0,6 s off

Initialization of the module

not yet complete Further modules in a chain

not initialized yet

Normal

At least one sensor supply

voltage is activated.

Standby

No Ethernet connection

established

Module identification

Update of the firmware /

HDC

3.5.3 Functional State

Display State

yellow-red flashing

0,5 s yellow reduced /

0,5 s red reduced

red illuminated

fully bright

red illuminated

semi bright

Warning

Overload on a sensor supply

voltage channel

Error during self-test

Internal error

ES415.1 - User’s Guide18

ETAS Hardware Description

4 Hardware Description

This chapter contains information on the following topics:

• "Features of the ES415.1" on page 19

• "Block Diagram" on page 20

• "Sensor Channels" on page 21

• "Data Transfer" on page 26

• "Power Supply" on page 31

• "Configuration" on page 33

• "Tool Integration" on page 33

• "Firmware Update" on page 33

• "Calibration" on page 33

4.1 Features of the ES415.1

Fig. 4-1 ES415.1 Housing

The ES415.1 High Definition A/D Module with Sensor Supply is a member of the

family of ES400-Modules. The ES415.1 can acquire analog voltages at four input

channels. There is a sensor supply for every channel.

• 4 electrically isolated A/D channels, separately configurable

• Measure range 100 mV to 60 V

• Signal conditioning cable available for expanded measure ranges

• Sample rate 0.5 Hz to 100 kHz (measuring and calibrating)

• Adjustable short circuit-proof sensor supply voltage (5 V to 15 V)

• Auto detect and configuration of sensors possible with TEDS (Transducer

Electronic Data Sheet)

For the complete technical data of the ES415.1, refer to the chapter "Technical

Data" on page 70.

ES415.1 - User’s Guide 19

Hardware Description ETAS

Channel 4

...

Synchronous Sampling

Channel 1

+/-0,1 V

+/-1 V

+/-10 V

+/-60 V

16-Bit A/D

Converter

Digital Filter

16-Bit D/A

Converter

Sp l i t t e r

Cab l e

Connector

TEDS Inter face

(cable recognit ion)

IN

(Host direction)

100 MBit /s

Overload

Detection

TEDS Inter face

(sensors and transducer

configuration)

Volt age

Regulator

Diagn ost ic

Unit

100 MBit /s

Et h e r n e t

Traffic

Detect ion

On

Automatic

OUT

(Next module)

Measurem ent Cont roll er

Tim e

Synchronization

Unit

Et h e r n e t

Ph y

Et h e r n et

Ph y

Protocol Engine

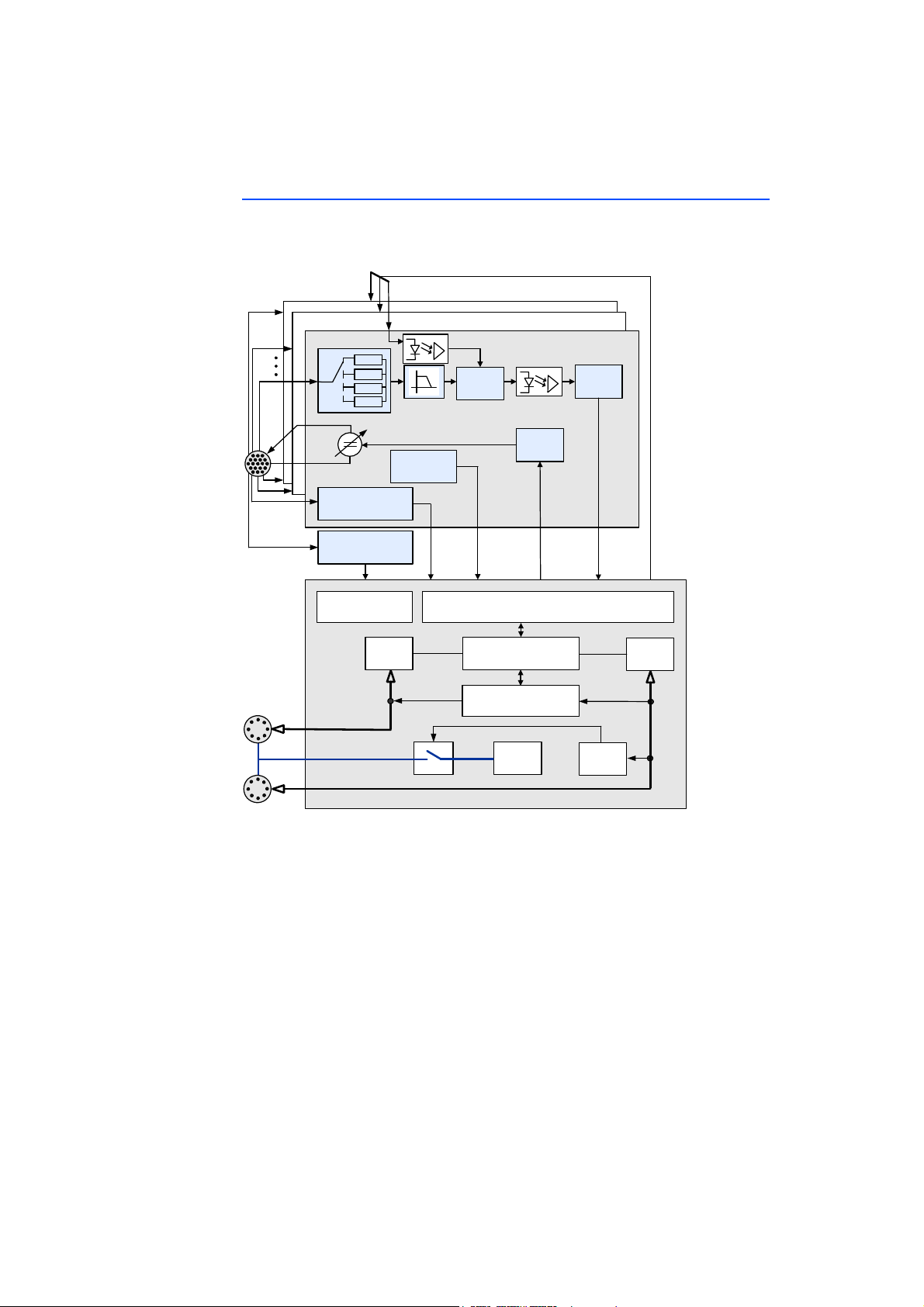

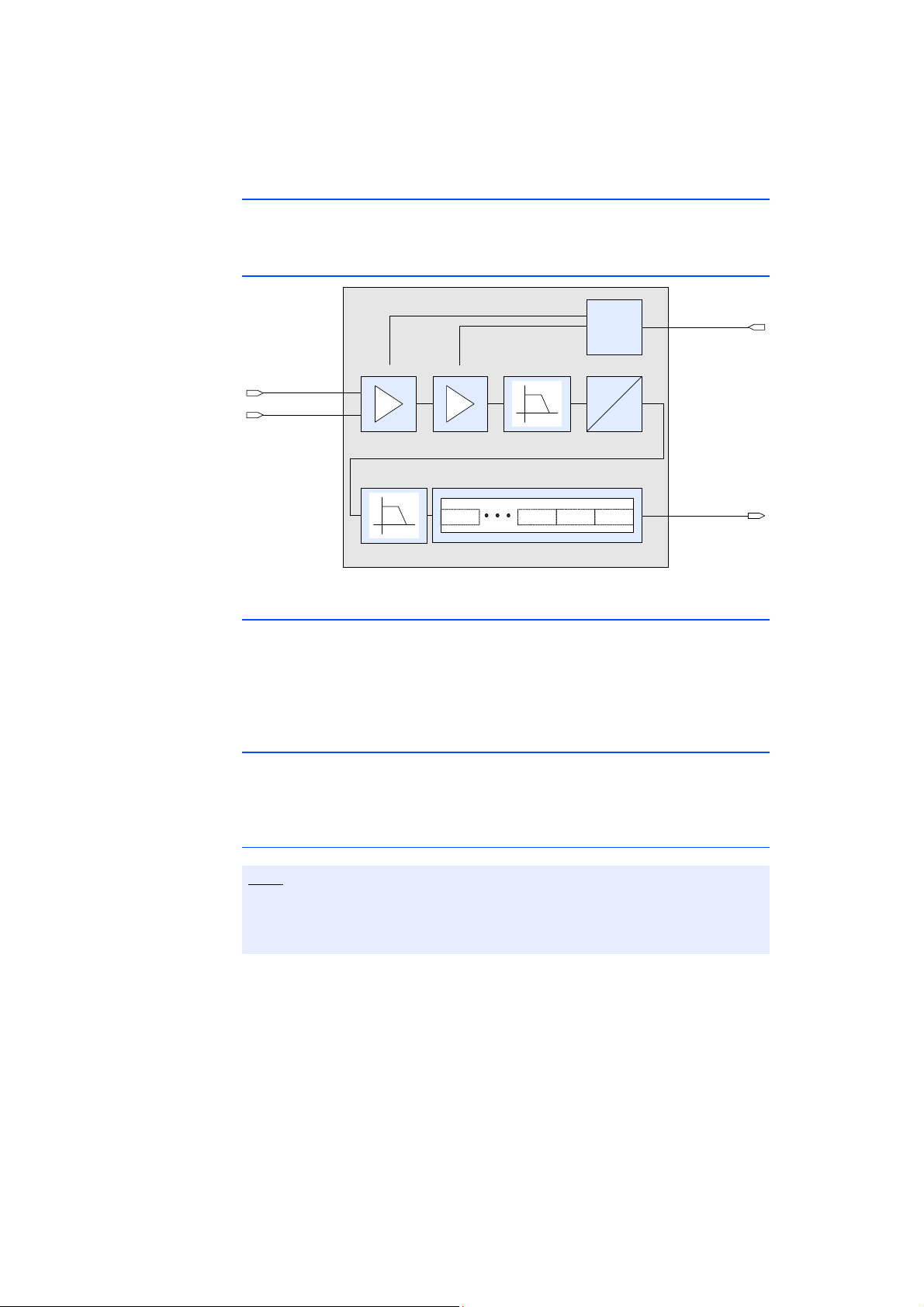

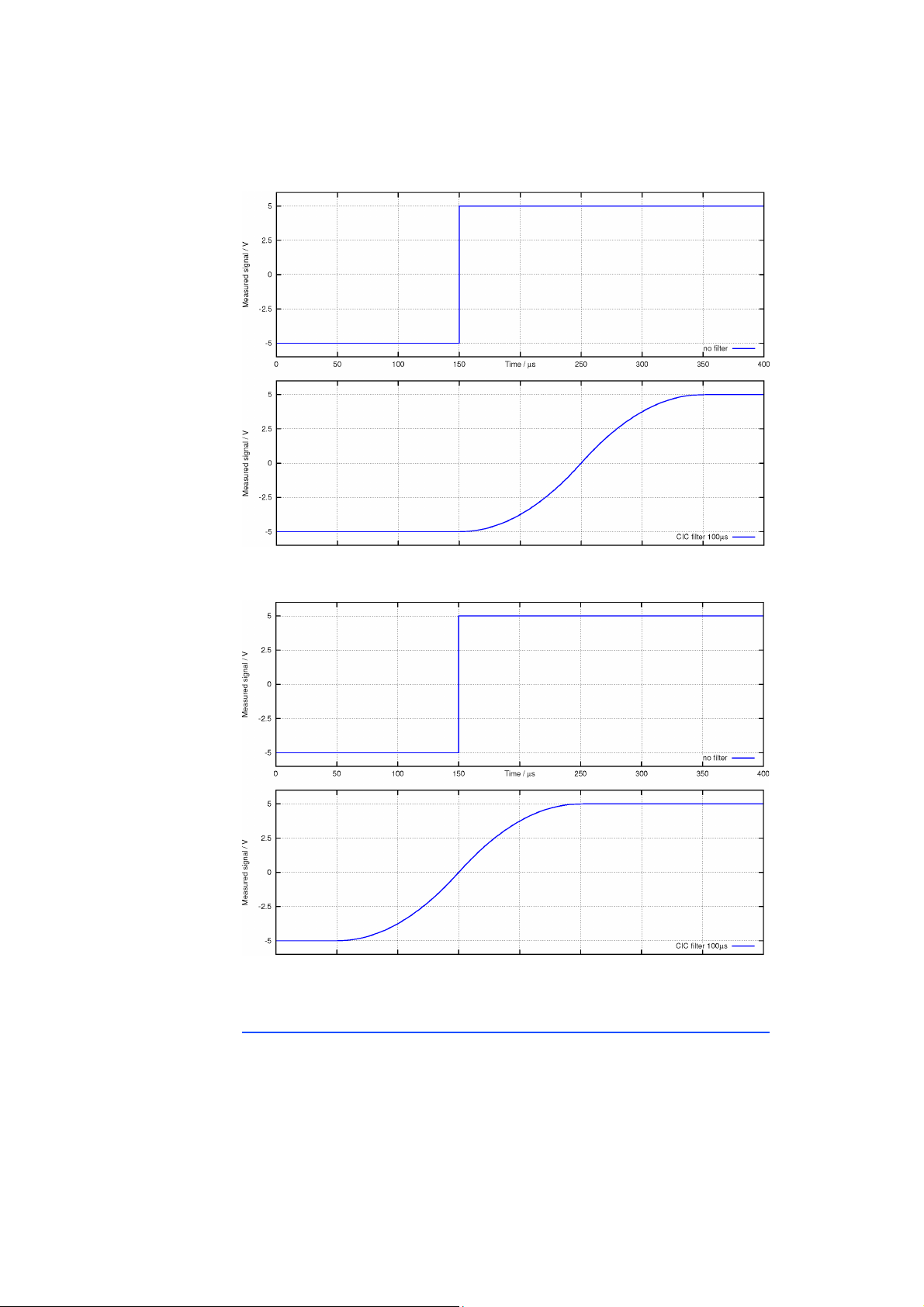

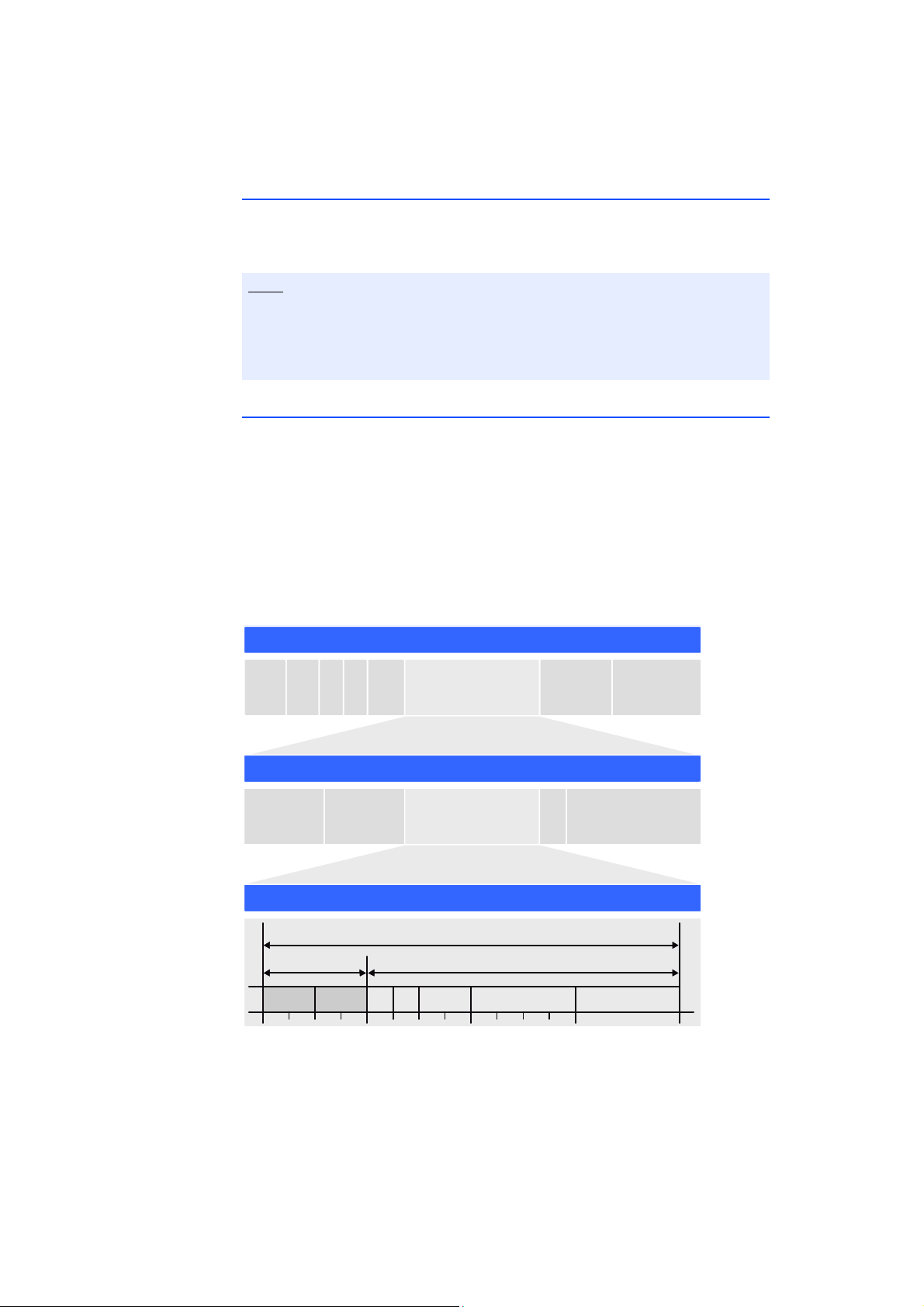

4.2 Block Diagram

The ES415.1 is a module with four identical sensor channels, two shared Ethernet interfaces and a power supply.

Fig. 4-2 Block Diagram

ES415.1 - User’s Guide20

ETAS Hardware Description

Note

Bypass

f

C,FIR

AnalogInput+

LowpassFilter

A

D

AdjustableGain A/DConverter

AnalogInput‐

VoltageRange

f

C,AAF

f

S,AD

Control

DigitalFilter,

Decimator

Buffer

Sample1Sample2Sample3Samplen

f

S,INCA

CTRL

ADC

4.3 Sensor Channels

All sensor channels of the ES415.1 are identical. Every sensor channel consists of

the function groups Signal Processing and Filter as well as Sensor Power Supply.

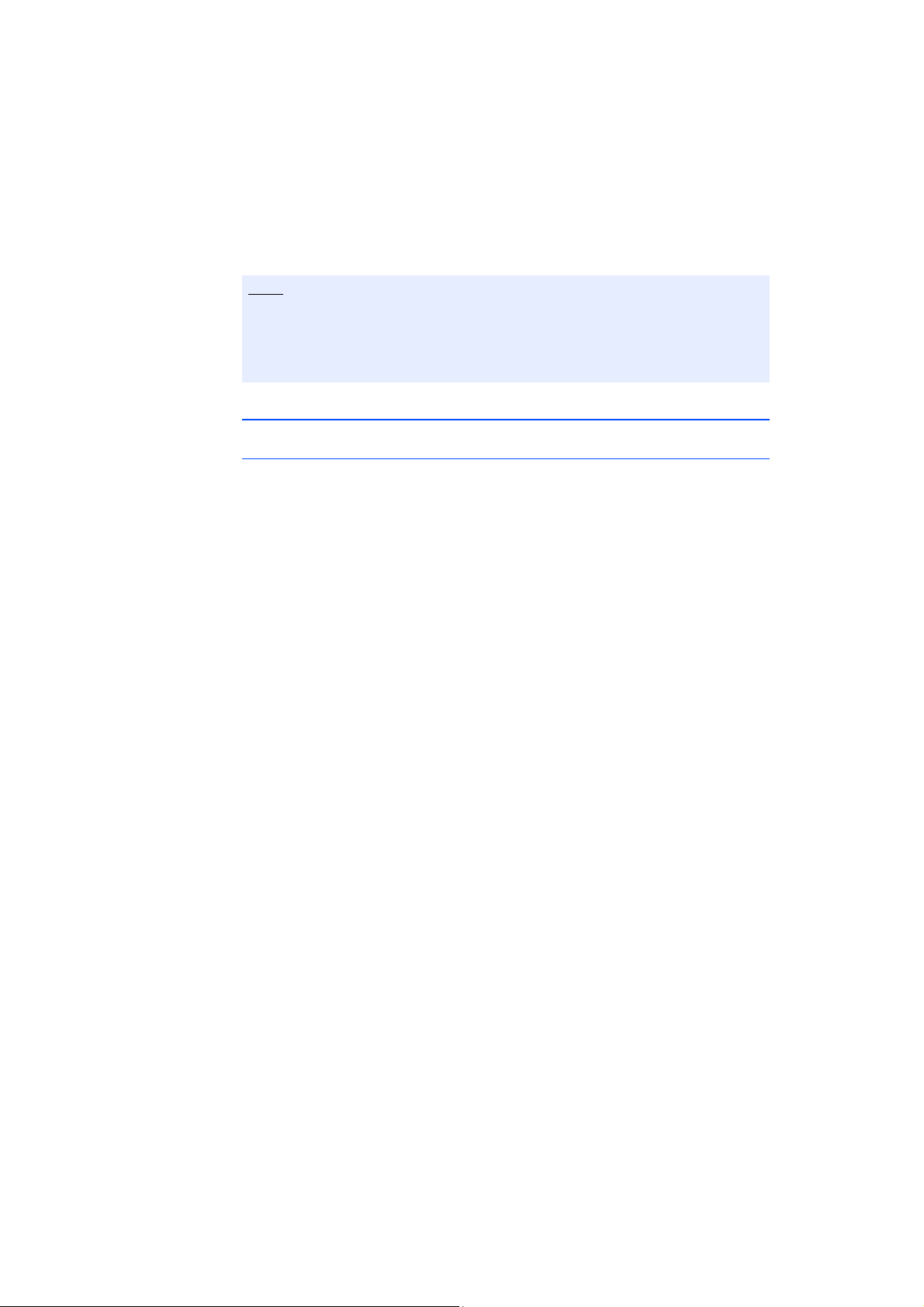

4.3.1 Signal Processing and Filters

Fig. 4-3 Signal Processing and Filters of a Sensor Channel

4.3.2 Amplifier and analog Filter

The level of the input signal is limited in every sensor channel after the overvoltage protection by a capacitively compensated voltage divider. An amplifier

adjusts the input signal to the following analog anti-aliasing filter according to

the selection of the input voltage range. This 4th order analog filter with Butterworth characteristics has a cutoff frequency of 50 kHz.

4.3.3 A/D Converter

An A/D converter digitizes the output signal of the analog filter. The individual A/

D converter available in every sensor channel guarantees synchronous sampling

of the measure signals.

Sample Rates for Rapid Prototyping Applications

For Rapid Prototyping applications, the sample rate of the ES415.1 module is

limited to a maximum of 10 kHz. The sample rates 100 kHz, 50 kHz and

20 kHz are available only for measurement and calibration applications.

Sample rates to 10 kHz can be configured for measurement and calibration

applications as well as for Rapid Prototyping applications in the application software.

To avoid the IRQ overload at the I/O port of the ES910.3, the sample rate of the

ES415.1 module in this mode is automatically limited to 10 kHz.

If the ES415.1 would be operated at high sample rates for Rapid Prototyping

applications, the ES910.3 could no longer process the data of the ES415.1 or

other ETAS daisy chain modules due to IRQ overload at its I/O port and would

discard the data.

ES415.1 - User’s Guide 21

Hardware Description ETAS

If the user selects a higher sample rate in this mode (100 kHz, 50 kHz and

20 kHz), the application software prevents the initialization of the hardware and

points to the limited selection of sample rates.

4.3.4 Digital Filter

A digital filter then processes the digital signal. The parameters of the CIC filter

(Cascaded-Integrator-Comb filter) are automatically set upon selecting the sample rate in the configuration software. The digital filter can be switched off,

parameters of the filter cannot be configured.

The data is written to a data buffer at the output of the digital filter. It can be

queried there by the application program.

Compensating Group Delay

The group delay is the time it takes the input signal of an analog or digital filter

to pass the filter. In the application program (e.g. INCA MDA), the signal must be

delayed to compensate for the group delay.

A special feature of the ES415.1 is the compensation of the group delay within

the module. The group delays of the analog anti-aliasing filter and the configurable digital filter are taken into consideration in this process. The signal in the

application program (e.g. in MDA) no longer has to be delayed to compensate

for the group delay.

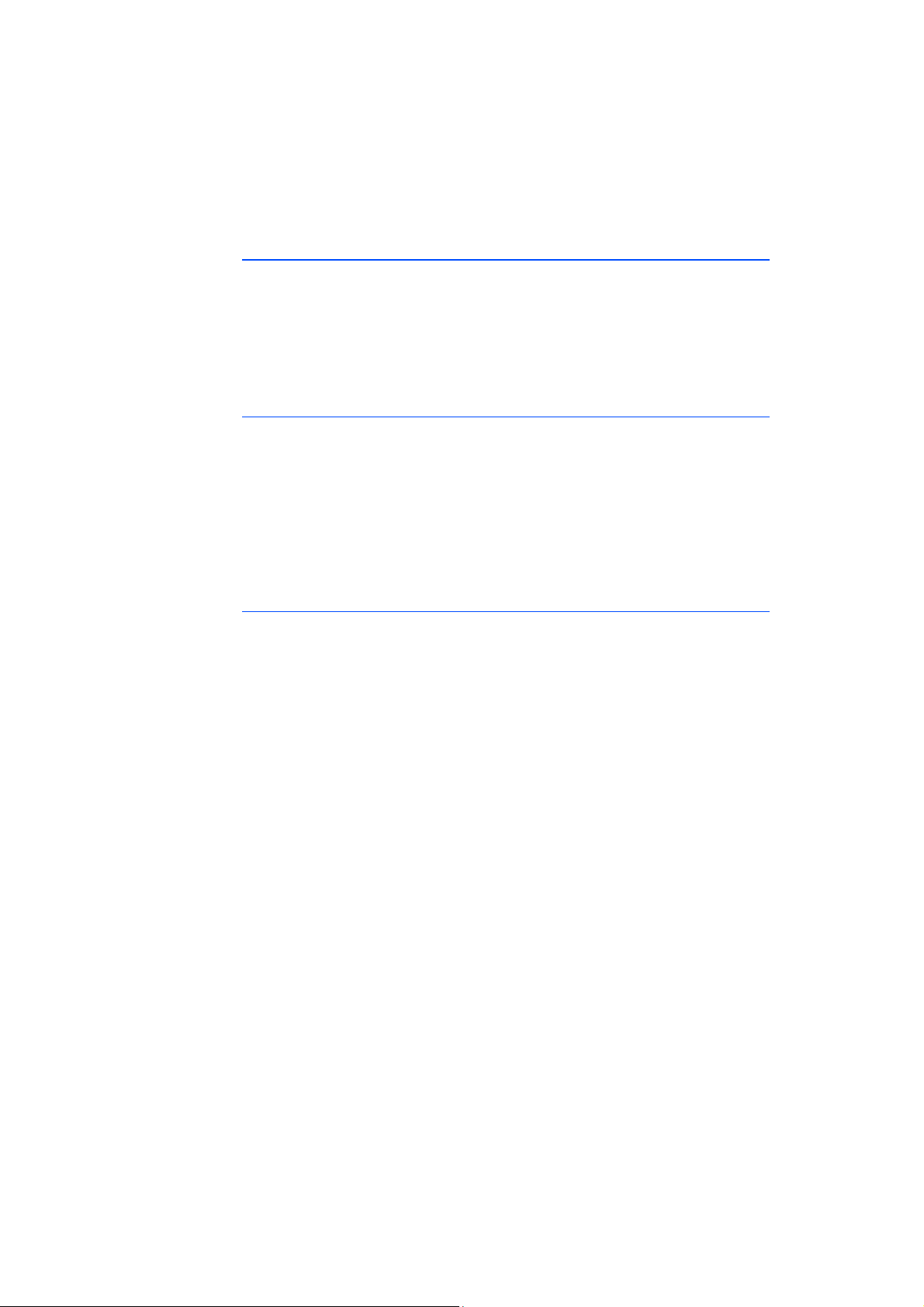

Examples

To represent the group delay with digital filters, a test signal was sent to two

filters of the same type:

• Filter A without compensation of the group delay

• Filter B with compensation of the group delay

The configuration of both filters is identical. The test signal is sampled with the

sampling rate f

quency f

= 200 Hz.

C,CIC

= 2 kHz (0.5 ms). The filter channel was set to a cutoff fre-

S,INCA

Fig. 4-4 and Fig. 4-5 on page 23 show the relevant signal trace - in the upper

part of the figure without a filter, in the lower part of the figures with a filter and

without or with group delay compensation respectively.

ES415.1 - User’s Guide22

ETAS Hardware Description

Fig. 4-4 Filter A: f

Fig. 4-5 ES415.1 Filter B: f

= 10 kHz (without compensation of the group delay)

C,CIC

= 10 kHz (with compensation of the group

C,CIC

delay)

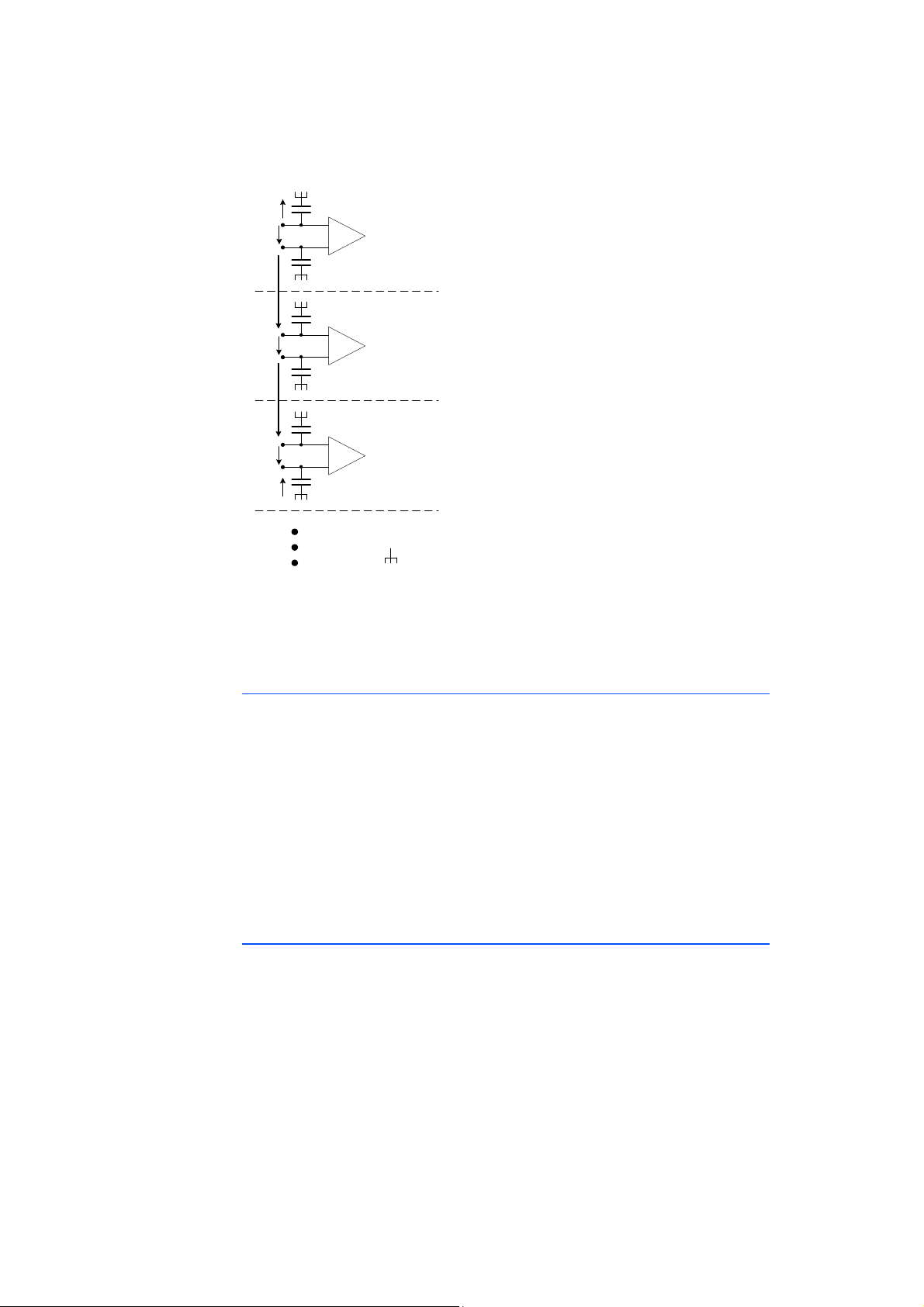

4.3.5 Maximum Input and Common-Mode Voltages

The maximum input voltage between two inputs and the maximum voltage

between an input and the case ground is 60 V DC/ 30 V AC. For an explanation

of the maximum input and common-mode voltages, see Fig. 4-6 on page 24 and

the example.

ES415.1 - User’s Guide 23

Hardware Description ETAS

+

-

+

-

+

-

Kanal x

Kanal y

Kanal z

Galvanische Trennung

Galvanische Trennung

Gehäusemasse

C

C

C

C

C

C

U

in+

U

in+

U

in+

U

in-

U

in-

U

in-

U

inx

U

iny

U

inz

U

CMx y

U

CMy z

U

c

U

c

Fig. 4-6 Maximum Input and Common-Mode Voltages

All capacitors between the inputs (U

and U

in+

) and case ground have the same

in-

capacity. The maximum voltage between any input and case ground is also 60 V

DC/ 30 V AC.

Example

For the given input voltages U

the maximum allowed common-mode voltage U

U

= 10 V

inx

U

= 5 V

iny

U

= 10 V

inz

U

= 15 V

CMxy

max (U

inx

+ U

iny

+ U

inz

+ U

10 V + 5 V + 10 V + 15 V + max (U

max (U

) = 60 V - 40 V = 20 V

CMyz

CMxy

inx

+ U

, U

, U

and the common-mode voltage U

iny

CMyz

CMyz

inz

) = 60 V

) = 60 V

is to be calculated.

CMyz

CMxy

,

4.3.6 Galvanically Isolation

The sensor channels are galvanically isolated from each other and from the

power supply. The digitized transfer of the measurements on an Ethernet connection implicitly results in a separation of the sensor channels from the supply

voltage.

ES415.1 - User’s Guide24

ETAS Hardware Description

Note

4.3.7 Sensor Supply

Every sensor that can be switched to the ES415.1 has an individual sensor supply

voltage which can be set separately.

The cable connected to the sensor port of the ES415.1 transfers both the sensor

supply voltage and the sensor output voltage for the sensor. Additional cables or

an additional external power supply for the sensor supply voltage are not

required.

The sensor supply voltage is generated from the module operating voltage in

every sensor channel. The sensor supply voltage can be modified in steps. The

user can switch off the sensor supply voltage of each sensor channel in the application program, select one of the defined values between +5 V and +15 V or

enter or define any value within the value range.

Behavior for Rapid Prototyping Applications

The already existing sensor voltage is briefly interrupted at the start of the Rapid

Prototyping model on the ES910.3.

Electrical Isolation

The ground of the sensor supply voltage channels is connected with the ground

of the operating voltage of the module and protected with a fuse.

The supply voltages of the sensors are not galvanically isolated towards the

operating voltage of the module.

Overvoltage Protection

Each sensor supply output is protected against overvoltages. Exceeding the maximum value trips a fuse.

Fuses

If a sensor supply output (ground) is connected with the supply voltage (positive)

of the module, it trips a fuse.

Defective fuses cannot be replaced by the user. Please return defective modules

to ETAS. Notes about the process are available from the local ETAS sales and

service offices. The contact information is located in the chapter "ETAS Contact

Addresses" on page 108.

Overload

Upon exceeding the maximum output of a channel, the output voltage of this

channel is reduced.

Short-circuit Detection

In case of a short circuit of a sensor supply output (positive) to ground, the sensor

power supply automatically switches off this channel.

Information in the Application Program

In case of short circuits and tripped fuse, the application program receives analyzable channel-specific information.

ES415.1 - User’s Guide 25

4.4 Data Transfer

Note

SA

48

UDP Head er

IFG

min. 96

IP Head er

DA

48

Pr e56So F

8

CRC

32

Typ e

16

DATA

n*8

XCP M essa g e 1 XCP M essa g e n

...

XCP on Ethernet Message

XCP Header XCP Package

DATATIM E STAM PDAQFI LLPI DCTRLEN

Embedded UDP/IP

Embedded XCP

IEEE802.3 (Ether net)

For data transfer, the ES930.1 as well as the ES4xx and ES63x modules use a

100 Mbit/s Ethernet network connection in duplex operation. The data transfer

can be adapted flexibly to suit the test setup and the measurement task.

The complete Ethernet bandwidth is available for both measure data and control variables.

Calibration procedures can take place in a Rapid Prototyping application without delay with measure data being acquired at the same time.

4.4.1 Communication Protocols

The universal ASAM measure and calibration protocol XCP is used for serial communication. On the Ethernet transport and network layer, the UDP/IP protocol is

used (see Fig. 4-7 on page 26).

Within the XCP protocol, the modules transfer, among other things, module ID,

time stamp and measure and/or stimulation data in an extremely precise and

predictable time pattern. The communication protocol used for the modules

avoids repeated transfer of protocol data, which takes place, for example, in

handshake-based systems. This makes a high bandwidth available for reference

data.

ETAS

Fig. 4-7 Message Format “XCP on UDP” (Schematic)

Using the UDP/IP standard for data transfer makes it possible to connect the

modules directly to a PC, a router or a switch. In XCP communication, the PC has

the master function.

ES415.1 - User’s Guide26

ETAS

Note

No real-time requirements are made. Data acquisition on a PC, which generally

does not have to fulfil high real-time requirements, can thus be connected

directly to an ES400 chain. With a real-time-capable master, such as, for example, a Rapid Prototyping system, lots of different kinds of I/O signal can be

accessed with extremely short cycle times.

The communication protocol used by the ES400 family makes it possible for

third-party suppliers to use the communication protocol for their own, nonETAS applications once the modules have been configured with the „ES4xx

Configuration Tool from ES4xx_DRV_SW“ .

4.4.2 Realization

Time Slice Procedure

The modules in the daisy chain transfer the data to the master using a 100 MBit/

s Ethernet connection time-controlled, i.e. without being prompted. The PC

assumes the function of the master. In the network, the modules respond like a

single Ethernet device with one MAC address.

All daisy chained modules have a generator which is only activated in the last

module of each chain after the test setup has been connected to the PC. The

frequency of the generator or the period duration of the time slices generated

can be set in the application program. It corresponds to the measuring frequency

of the measurement channel with the highest acquisition rate in the chain.

A binary counter linked to the generator periodically counts the time slices generated (value range: 2

vant number of time slices in the IP header. The Ethernet frames are transferred

from module to module within the chain.

Each module in the chain receives bandwidth to transfer its measure data in

freely selectable time slices assigned within the period of the binary counter. The

module uses the number of the time slice to determine whether it can insert an

XCP message with its measure data into the current time slice.

The fastest module, which determines the period duration of the time slices generated, transfers data in every time slice. An Ethernet frame then contains at least

one XCP-on-Ethernet data package. The length of the Ethernet frame transferred inside a time slice increases with the number of modules which can insert

their data into this time slice.

The numbering of the time slices ensures, for example, that two modules which

work with half the sampling rate of the generator never attach their data to the

same Ethernet frame. One module uses only the odd frame numbers and the

other only the even ones. This mechanism also ensures for certain that the

assigned frames do not exceed the length of a time slice.

The measure data is automatically distributed to the frames so that the available

bandwidth is used perfectly.

The time slice procedure makes both measurements of fast signals and the acquisition of a large number of channels with a low sampling rate possible.

16

= 65536). The last module in the chain sends the rele-

ES415.1 - User’s Guide 27

ETAS

Note

If a few fast signals and lots of slow ones are acquired in a chain, the slow signals

can be transferred in time multiplex procedure.

Due to data transfer by Ethernet, there are virtually no limitations in terms of

the number of modules in a module chain even with fast sampling rates.

Clock Generator for Synchronizing Modules

The clock generator for the synchronization of the modules is either the first

module in an module chain or the network module ES600. In both cases, the

measure data is synchronized with a tolerance of one microsecond. Using an

ES600 network module, several ES4xx/ES63x/ES93x chains can be synchronized

with each other or with the modules of the ES600 series. The ES4xx/ES63x/ES93x

and ES600 modules add the relevant time stamp to the Ethernet data package

for every measure value. The exact assignment in terms of time of the measure

data of the ES4xx/ES63x/ES93x and ES600 modules used resulting from this

makes precise analysis of the correlations of measure signals possible.

Synchronizing the Modules and INCA Signal Processing

Data transfer does not require synchronization of the local timebases of the

ES4xx/ES63x/ES93x modules. The time stamps are still synchronized by the system to be able to correlate measure data and sampling times of different modules in terms of time after data transfer. A precise time and drift synchronization

takes place in the modules via a hardware connection.

No bandwidth is required for this, unlike time synchronization in acc. with

IEEE1588 (Precision Time Protocol). The modules add the time stamp to the

Ethernet data package for every measure date.

The combination of time stamp synchronization, full duplex and time slice procedure results in a very high reference data rate of the modules.

ES415.1 - User’s Guide28

ES415.1 - User’s Guide 29

Cont rol variables

Measured

values M1

Rate: 10 kHz

Signal injection

Signal extract ion

Fr am e

Gen era t or

(inak tiv)

MODULE 1

Control variables

Measured

values M2

Rate: 10 kHz

Signal injection

Fr am e

Gen era to r

(inak tiv)

MODULE 2

Signal extract ion

Control variables

Measured

values M3

Rate: 10 kHz

Signal injection

Si gnal ext raction

Fr am e

Gen era to r

(10 kHz)

MODULE 3

Et h e rn e t

100 Mb it/s

PC

Ethernet Frame 1

M3 M2 M1H R M3 M2 M1H RM3 M2 M1H R

t [µs]

2000 100

Ethern et Frame 2

Ethernet Frame 65536

Periode Frame Generat or

M3 M2 M1H R

Ethernet Frame 3

M3 M2 M1H R

Ethernet Frame 4

M3 M2 M1H R

Ethernet Frame 5

300

500

400

H UDP/IP Header

R

Reserved for additional

com mu ni cat io n

Mn Measured values of module n

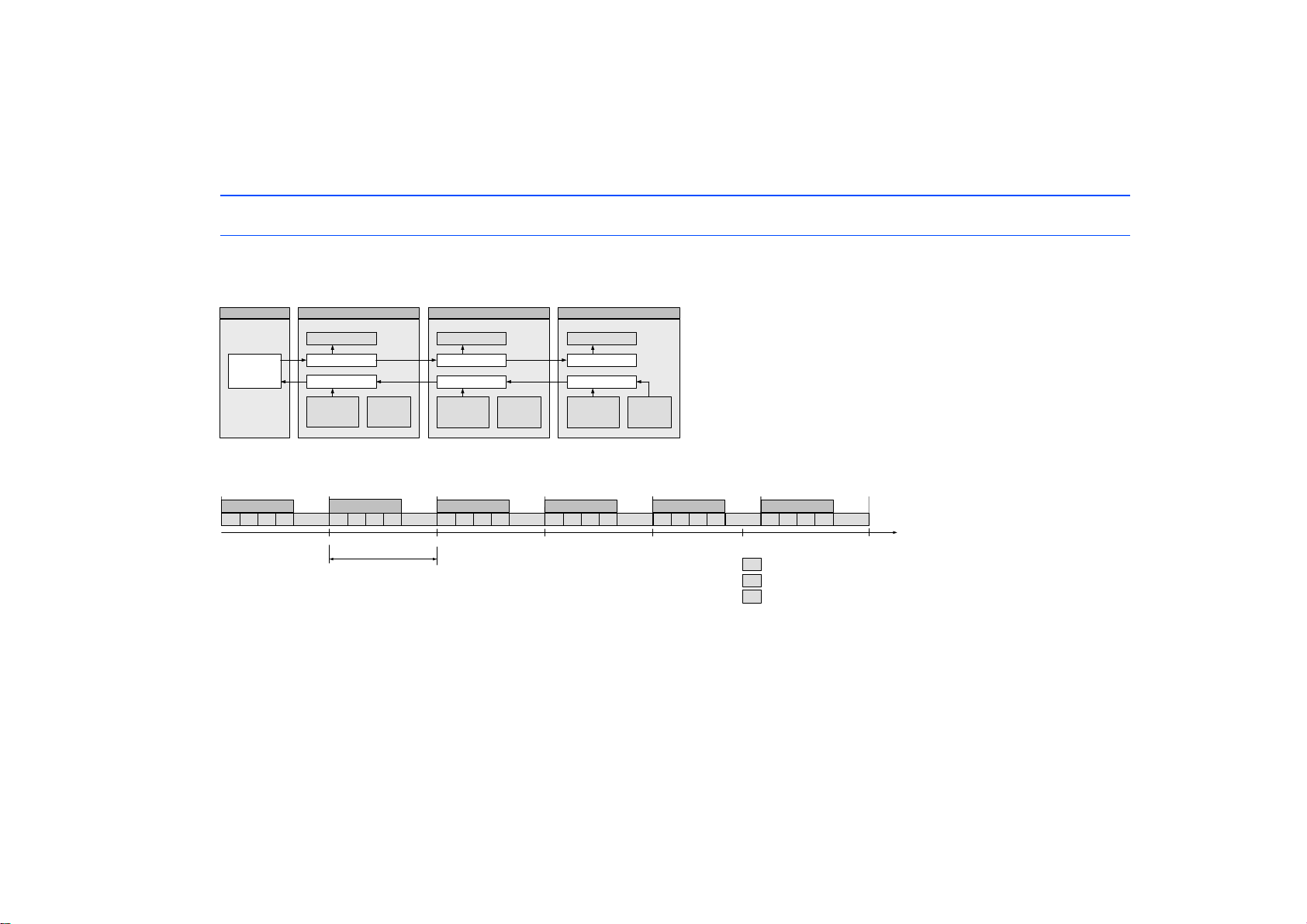

4.4.3 Examples

Example 1

Fig. 4-8 on page 29 shows an example of an application with three concatenated ES400 modules with the same acquisition rates. The

transfer scheme for this configuration is shown in Fig. 4-9 on page 29.

Fig. 4-8 Time-Multiplex Data Transfer Between an ES400 Module Chain and a PC

ETAS

Fig. 4-9 Transfer Scheme for Example 1 (Simplified, Not True to Scale)

In this example, the third module periodically generates 2

16

(65536) time slices each 100 microseconds long. Modules 1, 2 and 3 acquire

measurements with the same rate of 10 kHz each. Module 1, Module 2 and Module 3 link their measurements to each time slice (see

Fig. 4-9 on page 29).

Independently of this, control variables can be transferred at the same time from the PC to the modules.

ES415.1 - User’s Guide30

Co ntrol variables

Measured

values M1

Rate: 10 kHz

Signal injection

Si gnal ext raction

Fr am e

Gen era t or

(inakt iv)

MODULE 1

Co ntrol variables

Measured

values M2

Rat e : 2 kH z

Signal injection

Fr am e

Gen era t or

(inakt iv)

MODULE 2

Si gnal ext raction

Co ntrol variables

Measured

values M3

Rat e : 5 k Hz

Signal injection

Si gnal ext raction

Fr am e

Gen erat o r

(10 kHz)

MODULE 3

Et h e rn e t

100 Mb it/s

PC

Ethern et Frame 1

M1H R M1H RM3 M2 M1HR

t [µs]

2000 100

Frame 2Fr. 65536

Periode Frame Generator

M3 M1H R

Frame 3

M1H R

Frame 4

M3 M2 M1H R

Ethern et Frame 5

300

500

400

H UDP/IP Header

R

Reserved for additional

communication

Mn Measured values of module n

Example 2

Fig. 4-10 on page 30 shows an example in which three modules with different acquisition rates are linked to each other. The transfer

scheme for this configuration is shown in Fig. 4-11 on page 30.

Fig. 4-10 Time-Multiplex Data Transfer Between an ES400 Module Chain and a PC

Fig. 4-11 Transfer Scheme for Example 2 (Simplified, Not True to Scale)

In this example, the third module periodically generates 2

16

(65536) time slices (Ethernet frames) each 100 microseconds long. The ES400

modules 1, 2 and 3 acquire measurements at a rate of 10 kHz, 2 kHz and 5 kHz. Module 1 links its measurements to each Ethernet frame,

module 2 to every fifth Ethernet frame and module 3 to every second Ethernet frame (bottom figure).

Independently of this, control variables can be transferred at the same time from the PC to the modules.

ETAS

Loading...

Loading...