Estyma iGNEO COMPACT User Manual

BOILER CONTROLLER

COMPACT

page 2

PL20110629

Index

Index

1 General information 5

1.1 Introduction 5

1.2 Features 5

1.3 Safety precautions 7

1.4 Disposal of old equipment 8

2 Connecting to the system 9

2.1 General requirements 9

2.2 Location 9

2.3 Assembly 10

2.4 Connecting 11

2.4.1 Direct connection of devices............................................................................. 11

2.4.2 Connecting using burner wire........................................................................... 13

3 Overview of the basic functions 15

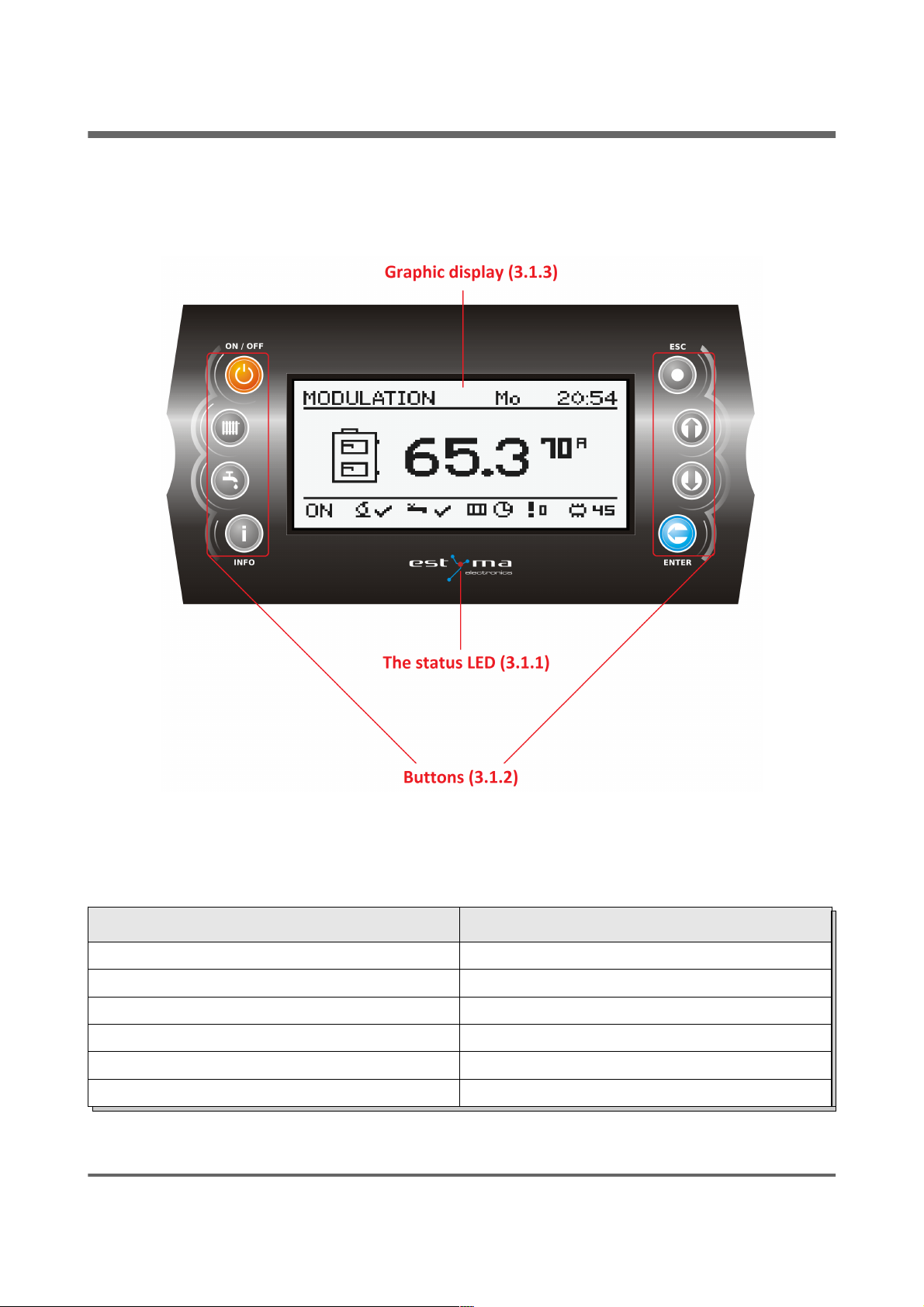

3.1 Control panel 15

3.1.1 The status LED............................................................................................... 15

3.1.2 Buttons......................................................................................................... 16

3.1.3 Graphic display ............................................................................................. 17

3.2 Statuses of furnace 17

4 Handling 18

4.1 Navigation in the menu 18

4.2 Starting regulator - ON 18

4.3 Switching off the regulator - OFF 18

4.4 Time scheduling 19

4.5 Service password 20

5 Simple menu 21

5.1 Simple menu screens 21

6 Main menu 23

6.1 Heating 24

6.1.1 Selection of circuit.......................................................................................... 24

6.1.2 State............................................................................................................ 24

6.1.3 Settings........................................................................................................ 25

6.1.4 Time program................................................................................................ 25

6.1.5 Service......................................................................................................... 26

6.2 Hot water 28

estyma electronics

www.estyma.pl

page 3

PL20110629

Index

6.2.1 Selection of circuit.......................................................................................... 28

6.2.2 State............................................................................................................ 28

6.2.3 Settings........................................................................................................ 29

6.2.4 Time program................................................................................................ 29

6.2.5 Service......................................................................................................... 30

6.3 Buffer 31

6.3.1 State............................................................................................................ 31

6.3.2 Settings........................................................................................................ 31

6.3.3 Time program................................................................................................ 32

6.3.4 Service......................................................................................................... 32

6.4 Boiler 33

6.4.1 State............................................................................................................ 33

6.4.2 Settings........................................................................................................ 33

6.4.3 Service......................................................................................................... 34

6.5 Settings 35

6.5.1 Date and time................................................................................................ 35

6.5.2 Language...................................................................................................... 35

6.5.3 General settings............................................................................................. 35

6.5.4 Service......................................................................................................... 35

6.6 Burner 38

6.6.1 State............................................................................................................ 38

6.6.2 Settings........................................................................................................ 38

6.6.3 Service......................................................................................................... 39

6.7 Alarms 40

6.7.1 Alarm codes.................................................................................................. 40

6.8 Solar 46

6.8.1 State............................................................................................................ 46

6.8.2 Settings........................................................................................................ 46

6.8.3 Service......................................................................................................... 47

6.9 Info 47

7 Expansion of the system - CAN bus 48

7.1 Sonda Lambda 51

7.2 Solars 53

8 Specification 55

page 4

PL20110629

1 General information

1 General information

Thank you for choosing our product and congratulations on a good decision. We will be

grateful for comments concerning the unit’s performance.

ESTYMA electronics

Team

1.1 Introduction

Controller IGNEO Compact is a modern microprocessor system, which controls not only

the boiler, but also the central heating system and domestic hot water.

The device controls the burning process by providing the appropriate amount of air and

fuel. By using solid state relays the power of blower is regulated smoothly.

Thanks to the advanced algorithm and possibility to regulation of many parameters, the

system can be very flexible to adapt to the needs of the heating system.

1.2 Features

Graphic display – thanks to a large graphic display FSTN handling device is intuitive.

Large fonts and icon - to improve ease of handling equipment for elderly people.

Two types of menus - menus simple and sophisticated. During the daily operation of the

device can support is easily accessible from the simple menu.

Info button - the controller is equipped with the function of intelligent assistance. Each

parameter is described, calling the description is done by pushing the info button.

estyma electronics

www.estyma.pl

page 5

PL20110629

1 General information

The modular construction of the CAN - using industrial CAN bus data exchange (mainly

used in the demanding automotive industry), it is possible to expansion of the system. The

maximum extension is 16 heating circuits, two circuits of hot water, energy buffers and solars.

Buffer - controlling the heating system in combination with heat storage reservoir.

Solars - the controller controls the solar system.

Powerful modern 32-bit ARM processor (ARM family is widely used in mobile phones) -

enables advanced controlling algorithm device Fuzzy Logic II generation.

The history of alarms and errors - the controller keeps a history of the last 20 errors and

alarms with a description, date of creation and the date of confirmation.

Clock with calendar - the clock allows to program in a weekly cycle required temperatures in

the rooms and hot water which contributes to a reduction in expenditure on fuel.

Statistics - in memory controller stores statistical data of the system, so it is possible to

observe the work and reduce fuel consumption. For example, monitoring temperature and

power boiler burner. Feeder operating time of the fuel.

Beep sound alarm - built-in piezoelectric loudspeaker signals the occurrence of an alarm in

the boiler, which increases operational safety of the device.

Resetting - function allows you to restore factory settings of the controller.

page 6

PL20110629

1 General information

1.3 Safety precautions

Warning – risk of electric shock!

• Read this operation manual carefully and thoroughly before using the unit.

• Keep this operation manual and refer to it whenever you work with this unit in the

future.

• Apply all the rules and heed all the warnings included in the unit operation manual.

• Make sure that the unit is not damaged. In case of any doubts, do not use the unit and

contact the supplier.

• In case of any doubts concerning the safe operation of the unit, contact the supplier.

• Pay special attention to all warning signs on the unit casing and its package.

• Use the unit as intended.

• The unit is not a toy. Do not allow children to play with it.

• Under no circumstances children should be allowed to play with any parts of the

package of the unit.

• Access to small parts such as clamping screws or bolts should be secured against

children. Such elements may be delivered with the unit and may result in choking when

swallowed by a child.

• Do not make any mechanical or electrical changes to the unit. Such changes may cause

the unit to malfunction and fail to meet the relevant standards, leading to an adverse

impact on the performance of the unit.

• Do not insert any objects into the unit through openings (e.g. ventilation grills), as this

may cause short circuiting, electric shock, fire or damage to the unit.

• Do not allow water, humidity or dust to enter the unit, as this may cause short

circuiting, electric shock, fire or damage to the unit.

• Provide adequate ventilation of the unit, do not cover or block the ventilation grills, and

ensure that there is free flow of air around the unit.

• The unit should be installed indoors unless it is adapted for outdoor operation.

• Do not expose the unit to mechanical impacts and vibrations.

• When connecting the unit to power supply, make sure that the parameters of the supply

network are within the unit’s operating range.

• All electrical connections must be as shown in the electrical assembly drawings and

must comply with national and/or local regulations concerning electrical connections.

estyma electronics

www.estyma.pl

page 7

PL20110629

1 General information

• This unit contains no parts that may be replaced by the user. All maintenance work

except for cleaning, fuse replacement (when the unit is de-energized), and function

setting, should be performed by an authorized service provider.

• Before doing any maintenance work, you must cut off the power supply to the unit.

• Do not clean the casing of the unit with petrol, solvents or any other chemicals that

may damage the casing of the unit. Using a soft cloth is recommended.

1.4 Disposal of old equipment

This electronic equipment is made of materials which are partly recyclable. Therefore,

when the equipment has reached the end of its service life, take it to an electrical and

electronic equipment recycling centre or to the manufacturer. The equipment must not be

disposed of with other household waste.

page 8

PL20110629

2 Connecting to the system

2 Connecting to the system

2.1 General requirements

Read this operation manual carefully and thoroughly before you start using the unit.

The person installing the unit should have sufficient technical experience.

Copper wire connections should be designed to work in temperatures of up to +75ºC .

All connections made must be as shown in the electrical wiring assembly drawings and must be

compliant with national and/or local regulations concerning electrical connections.

WARNING !!! The device must be connected to a separate electrical circuit

equipped with an appropriately sized circuit breaker and residual current circuit breaker.

2.2 Location

The unit is intended for indoor installation only. After selecting the location, make sure

that it meets the following requirements:

1. The location must be free from excessive humidity and from flammable or corrosive

vapours.

2. The unit must not be installed near high power electrical equipment, electrical

machines or welding equipment.

3. The temperature in the location must not exceed 60ºC and should not be lower than

0ºC. Humidity should be within the range from 5% to 95%, with no vapour condensation

taking place.

estyma electronics

www.estyma.pl

page 9

PL20110629

2 Connecting to the system

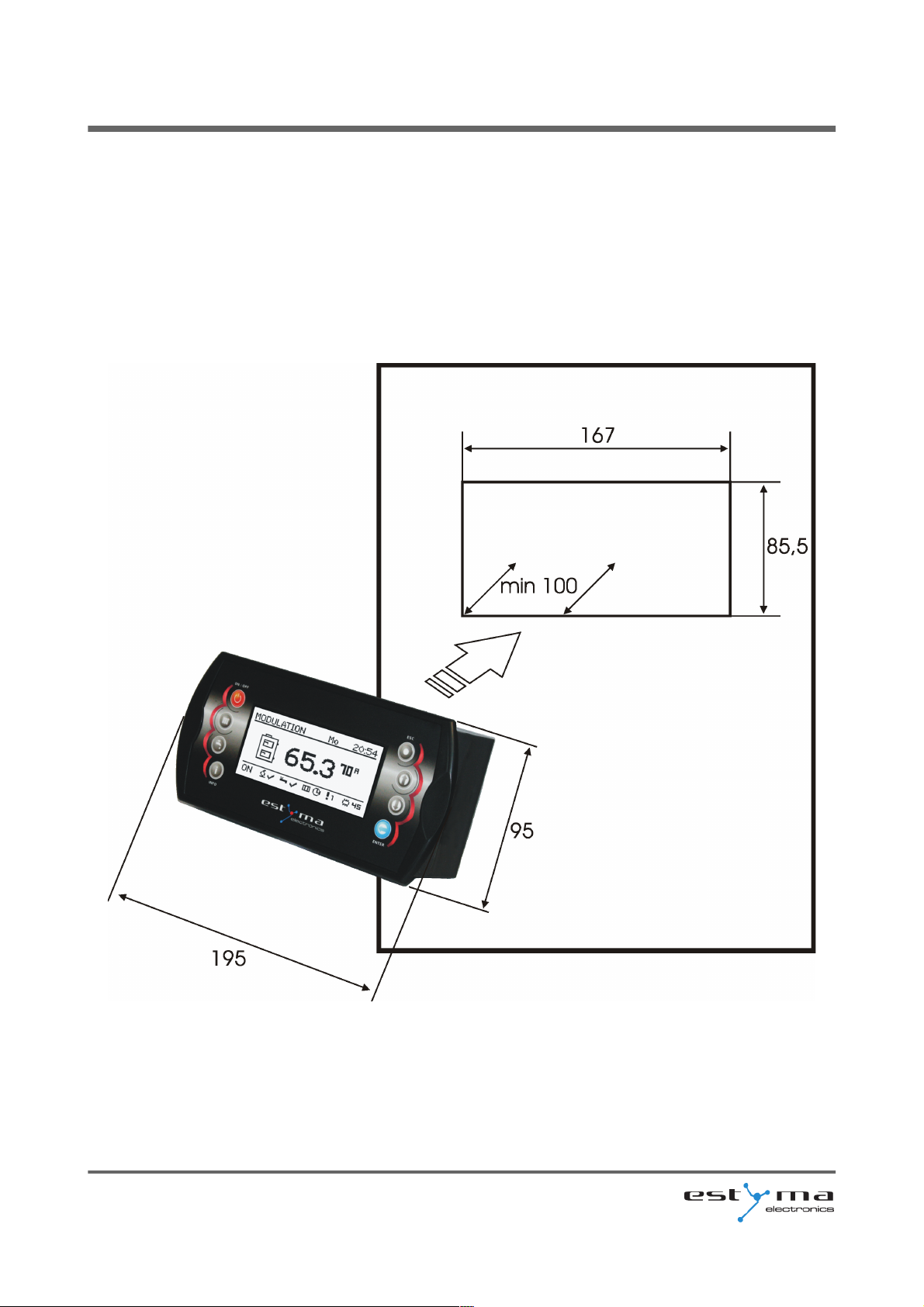

2.3 Assembly

The controller is designed for mounting in a wall or plate mounting. Plate thickness

should not exceed 3mm. The minimum depth of the mounting hole is 100mm. The dimensions

of the hole and controller are indicated in the figure below.

After placing the panel in the hole, always install the mounting frame.

page 10

PL20110629

2 Connecting to the system

2.4 Connecting

The device supply voltage is ~ 230V/50Hz. Plug the power cord to the controller in

accordance with the posted signs.

Be attached to the controller for operating the boiler sensors and actuators as needed.

The drawings shows the connection scheme of equipment. In the tables, a description of the

inputs and outputs.

Warning !!! Under no circumstances connect the protective conductor (PE) with a

neutral (N).

Warning !!! Wiring must be done with the device disconnected from the mains.

Connections should be exercised by a person possessing adequate powers in this regard.

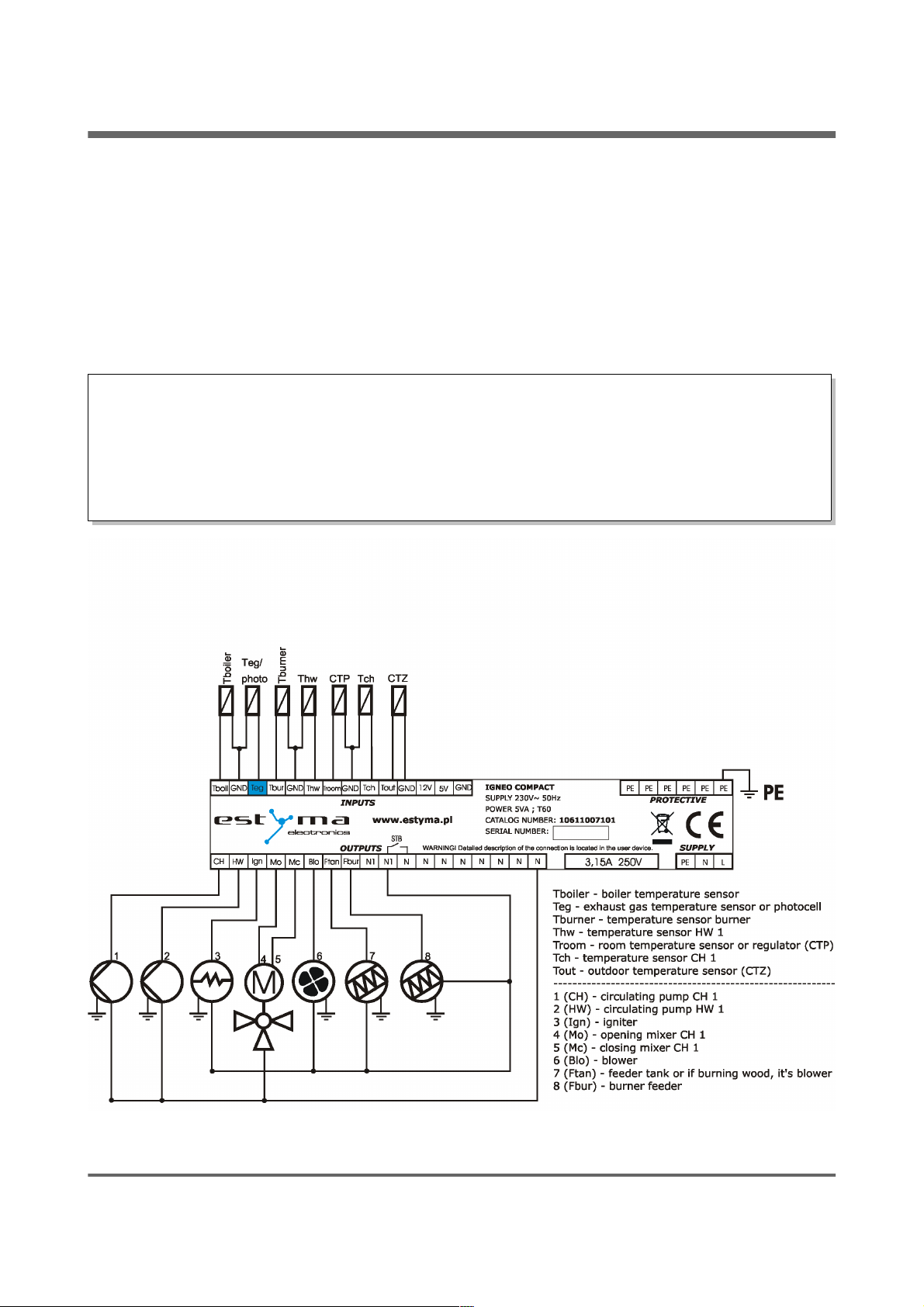

2.4.1 Direct connection of devices

estyma electronics

www.estyma.pl

page 11

PL20110629

2 Connecting to the system

INPUTS

Description Explanation

Tboiler Boiler temperature sensor

Teg / photo Exhaust gas temperature sensor or photocell

Tburner The temperature sensor burner

Thw The temperature sensor hot water

Troom Room temperature sensor / regulator (CTP)

Tch The temperature sensor central heating

Tout Outdoor temperature sensor (CTZ)

12V +12V output to supply optional equipment

5V +5V output to supply optional equipment

GND Mass electric to connect sensors

OUTPUTS

Description Explanation

1 (CH) Central heating circulating pump

2 (HW) Circulating pump for hot water

3 (Ign) Burner igniter

4 (Mo) Opening the central heating mixer

5 (Mc) Closing the central heating mixer

6 (Blo) Burner blower

7 (Ftan) Feeder tank, or if burning wood, it's blower

8 (Fbur) Burner feeder

STB Protection STB

N Neutral standing

N1 Neutral separable such as by STB

PE Protective

page 12

PL20110629

2 Connecting to the system

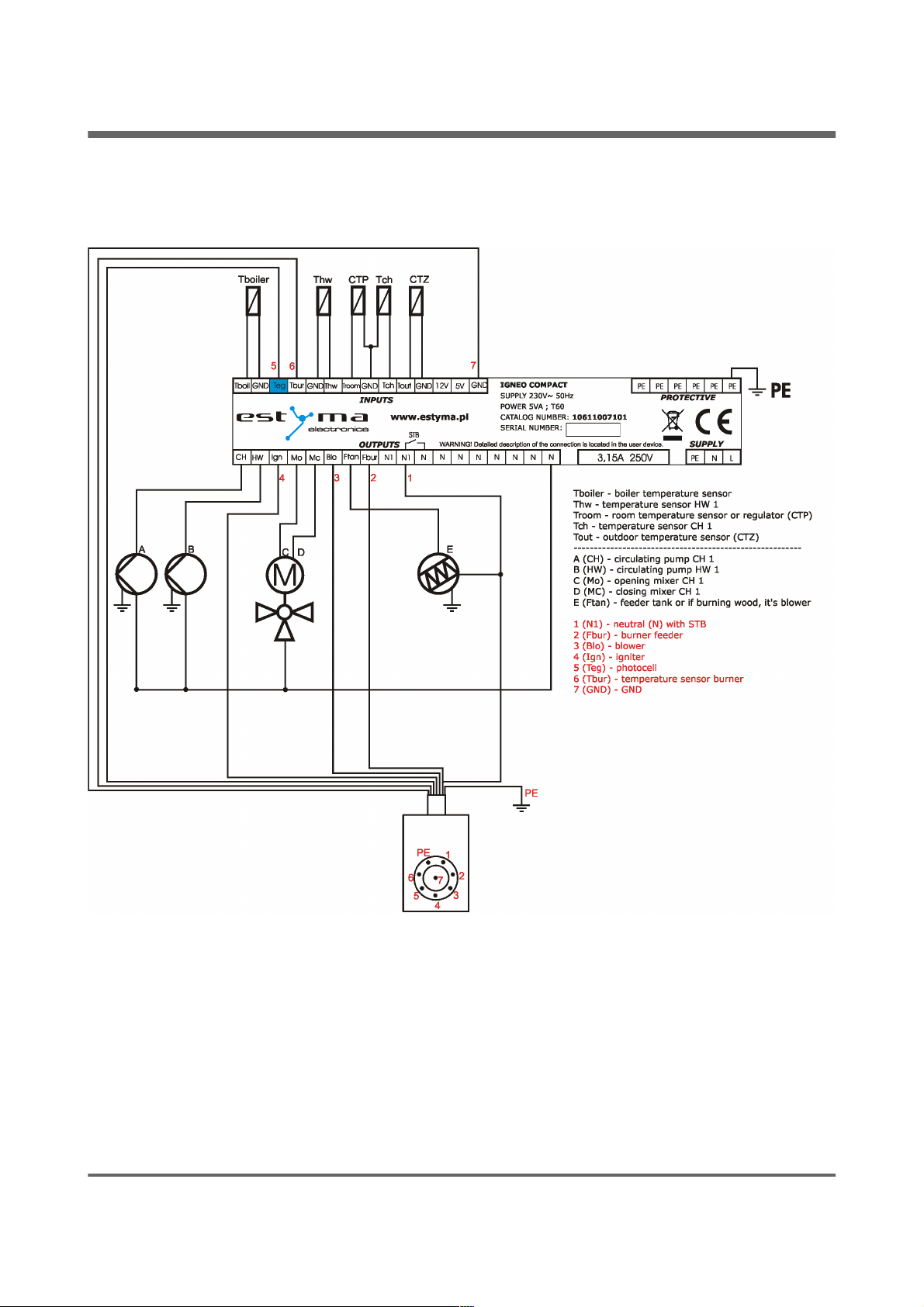

2.4.2 Connecting using burner wire

estyma electronics

www.estyma.pl

page 13

PL20110629

2 Connecting to the system

INPUTS

Description Explanation

Tboiler Boiler temperature sensor

5 (Teg) Photocell

6 (Tbur) The temperature sensor burner

Thw The temperature sensor hot water

Troom Room temperature sensor / regulator (CTP)

Tch The temperature sensor central heating

Tout Outdoor temperature sensor (CTZ)

12V +12V output to supply optional equipment

5V +5V output to supply optional equipment

7 (GND) Mass electric to connect sensors

OUTPUTS

Description Explanation

A (CH) Central heating circulating pump

B (HW) Circulating pump for hot water

4 (Ign) Burner igniter

C (Mo) Opening the central heating mixer

D (Mc) Closing the central heating mixer

3 (Blo) Burner blower

E (Ftan) Feeder tank, or if burning wood, it's blower

2 (Fbur) Burner feeder

1 (N1) Neutral separable such as by STB

STB Protection STB

N Neutral standing

PE Protective

page 14

PL20110629

3 Overview of the basic functions

3 Overview of the basic functions

3.1 Control panel

3.1.1 The status LED

Status Importance

Green light continuously Controller OFF

Green blinks Controller enabled, burner OFF

Orange light continuously Controller enabled, burner enabled

Orange blinks Burner works

Red light continuously There is an alarm to be confirmed

Red blinks Alarm active

estyma electronics

www.estyma.pl

page 15

PL20110629

3 Overview of the basic functions

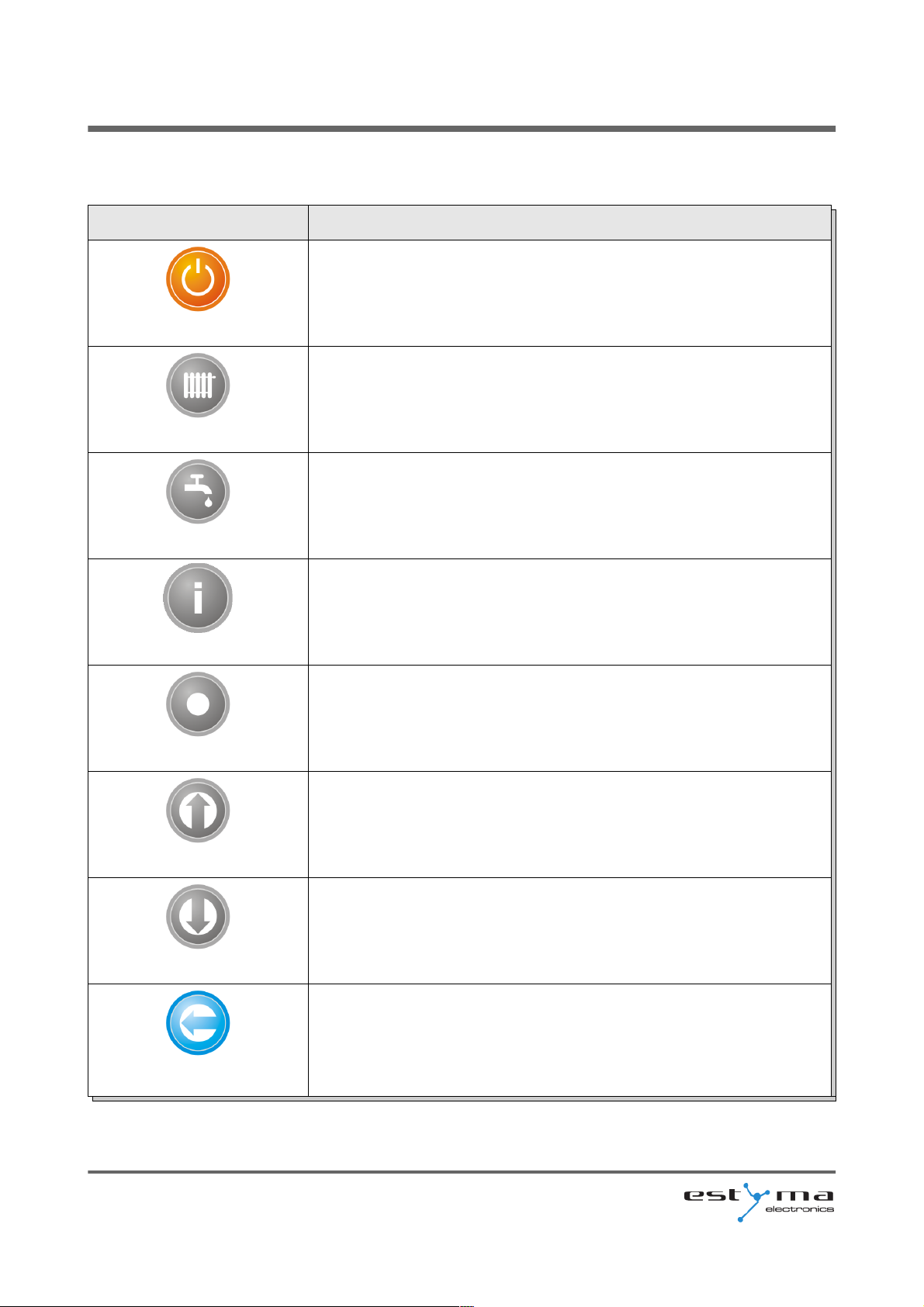

3.1.2 Buttons

Button Function

ON / OFF

Long press on the main screen (>3 seconds) changes the state

of the ON/OFF (on/off).

CH

Quick access to the full configuration settings for the central

heating.

HW

Quick access to the full configuration settings for hot water.

INFO

Shows the navigation information and descriptions of the

regulated parameters.

ESC

Back one level up in the menu, the resignation of the parameter

change.

Up arrow

Navigating through the menus, increasing the value of the

parameter being edited.

On main screen, enter the menu simple.

Down arrow

Navigating through the menus, reducing the value of the

parameter being edited.

On main screen, enter the menu simple.

ENTER

Access to the menu.

Acceptance of changes in the value of the parameter being

edited.

Confirmation of the alarm.

page 16

PL20110629

3 Overview of the basic functions

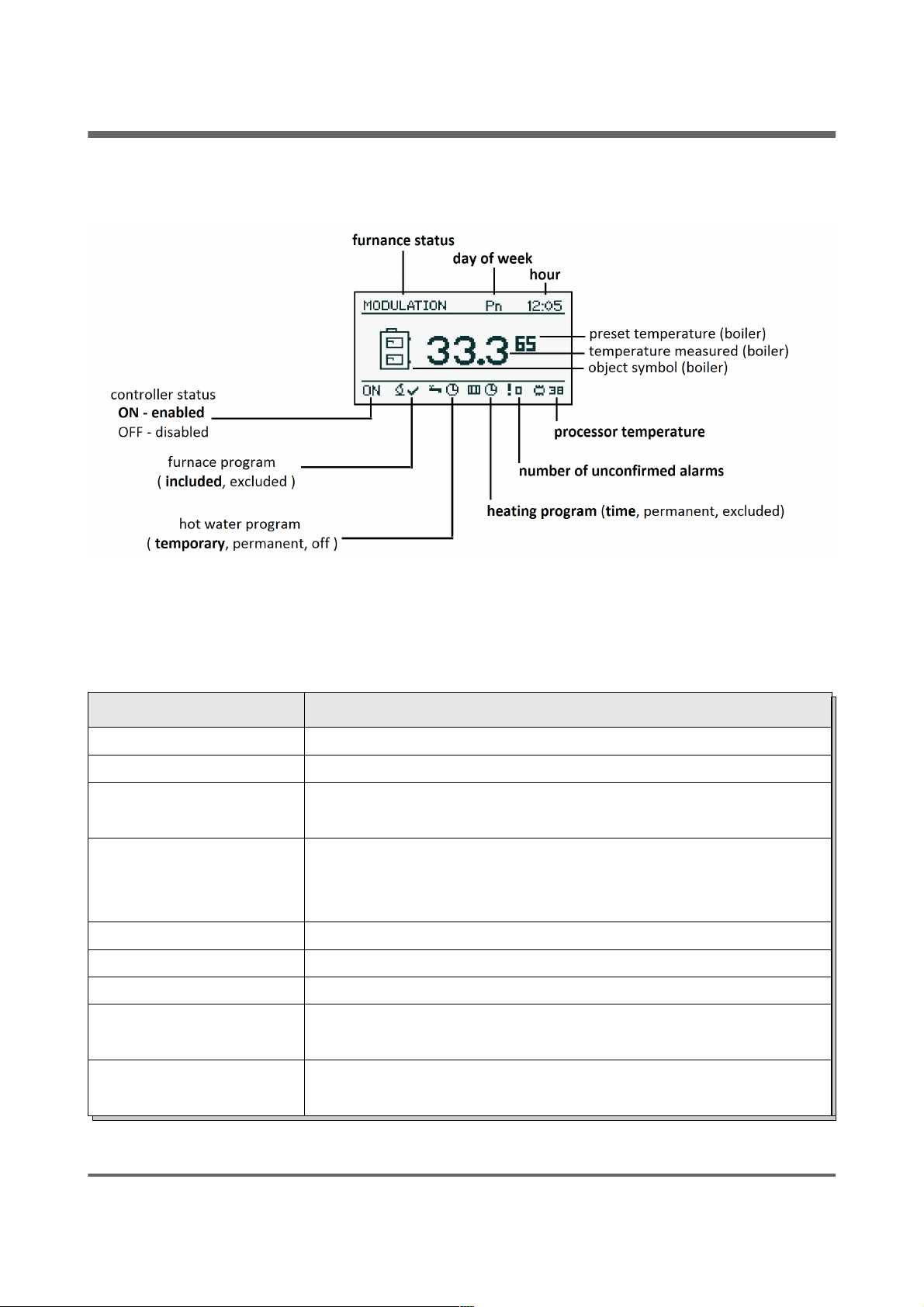

3.1.3 Graphic display

3.2 Statuses of furnace

Status Description

TURNED OFF The burner is not working. Permission to work off.

CLEANING Cleaning the burner by strong stream of air.

FIRING UP Firing up fuel.

Providing the initial dose of fuel to run igniter and blower.

INCANDESCING When the flame in phase of the firing up is discovered, starts

providing additional portions of fuel and increase the power of

blower for arcing furnace.

POWER 1 The burner works with the power first.

POWER 2 The burner works with the power of a second.

MODULATION The burner works with a modulated power.

BURNING OFF Quenching of the furnace. Work of burner and blower tray until

the complete disappearance of the flame.

STOP Burner does not work but it is to agree to his work. The required

boiler temperature is reached.

estyma electronics

www.estyma.pl

page 17

PL20110629

Loading...

Loading...