Page 1

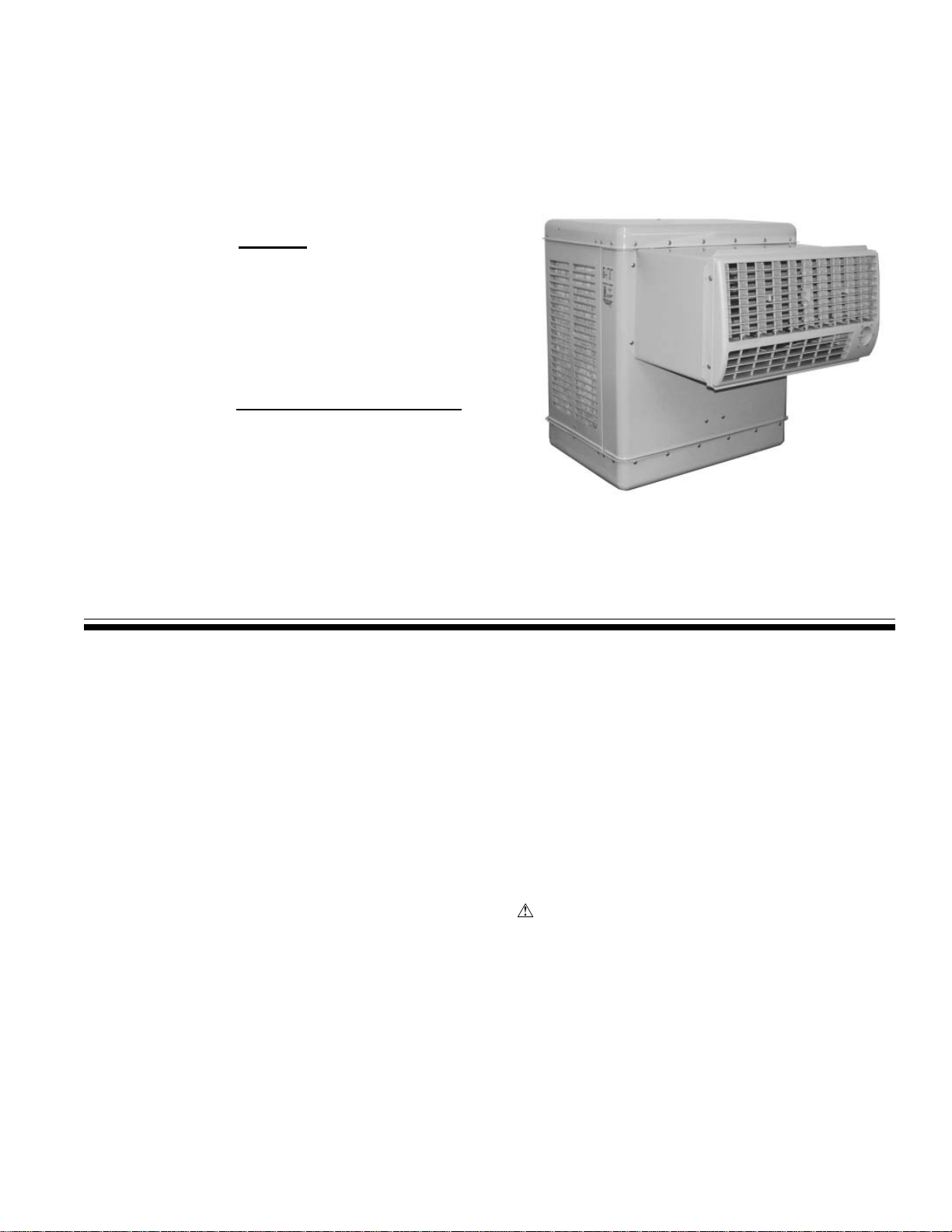

CHAMPION•ESSICK

Window Evaporative Cooler

Models

WCM28

N28W

Serial #

Número De Serie

Read Carefully All Of This Manual

Before Installing The Unit

Manual

Lea Con Cuidado Todo Este Manual Antes

De Instalar La Unidad

Read And Save These Instructions

Vea el español en el interior.

Evaporative Cooling

With this unit being a fresh air system, you are not trapped with

recirculating air that can become stale, laden with smoke and odors,

as happens with refrigerated air conditioning systems. Instead,

you are completely replacing the air every 2 to 4 minutes by either

opening doors or windows or a combination of both to exhaust the

air continually.

How much should you open your windows? T o obtain the maximum

cooling capacity of your cooler, you should open your windows until

the air inside the house is nearly balanced with the air outside. As

you open your windows you decrease the pressure buildup inside the

home, and the cooler is able to output increasingly more air until the

capacity of the cooler is reached.

Safety Rules

1. Read instructions carefully.

2. Unit must be in the OFF POSITION and UNPLUGGED from

power receptacle when installing or performing any maintenance.

3. Your cooler will run on 120 volt AC., 60 Hz (cycle) current

only.

4. Motor and pump are grounded and have an automatic thermal

overload switch which will shut motor off when it overheats. The

motor will restart automatically when it cools down.

WARNING: T o reduce the risk of fi re or electric shock, do not

use this fan with any “solid-state fan speed control device.”

Operation

One method to determine when the air is reasonably balanced is to

place a piece of tissue paper up against the screen of the window

furthest from the cooler and adjust the opening of the windows in the

house until the tissue paper stays lightly on the screen. If the tissue

plasters itself to the screen, open the windows more. If it falls, close

the windows more.

110499 3-09

www.championcooler.com

To eliminate delivery of hot air when starting cooler, turn on pump

only for the fi rst few minutes, then turn on the blower motor.

These coolers may be used without water for ventilation purposes.

When outside air is cool (for example, at night) or when humidity is

high the water pump can be turned off.

Page 2

Cooler Installation

be broken off. Apply pressure on the edge of the panel that extends

over the edge of the surface and break off unwanted piece.

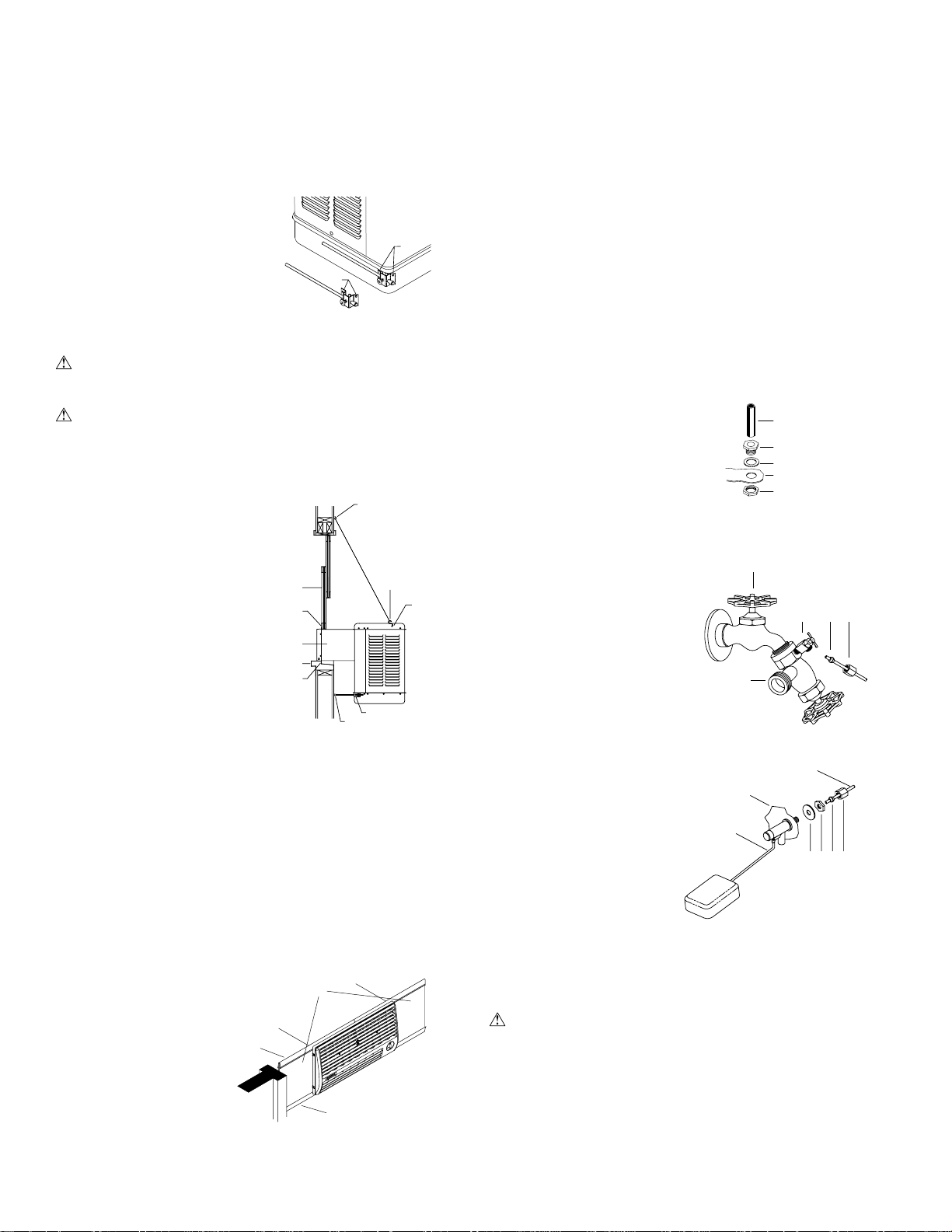

Installing House Legs

• NOTE: If installing unit without the use of the installation kit,

omit these directions and those pertaining to Fig. 2.

• Remove two corner screws in bottom pan (A-Fig. 1).

• Place house leg bracket at corner of bottom pan, using two top

holes in bracket (B-Fig. 1). Replace

the two previously removed screws to

hold house leg bracket in place (As

shown by dotted house leg bracket).

A

• Mount other side in same manner.

• Refer to the instructions “Adjust

B

house legs” below for adjusting house

leg .

Fig. 1

Mounting Cooler

CAUTION: Make sure that the mounting surface is strong

enough to support the operating weight of the cooler when in use.

(For operating weight, see Specifi ca tion Table.)

CAUTION: Never plug in cooler until installation is complete

and unit has been tested for rigidity.

• Lift out all removable louvered sides.

• Screw chain hooks into win-

dow facing. Position the two

chain hooks above the neck of

the cooler a distance equal to

the width of the cooler apart

(A-Fig. 2). Hook one hanger

chain in each hook and then

one “S” hook in the other

end of each chain. NOTE:

Chain hooks supplied with this

mounting kit have wood screw

threads for wood walls. Con-

D

C

Window

Neck

H

E

crete, brick walls or concrete

blocks require sufficiently

strong wing nuts or anchors

with mating hooks.

• Install window panel retainers. Place two panel retainer strips

onto bottom of neck fl ange and position to the width of the window.

Cut the strips to fi t if necessary. These strips hold the window fi ll-

in panels (Fig. 3).

• Position cooler in window. Position neck of cooler so that the

fl ange (E-Fig. 2) is snug against edge of sill (H-Fig. 2). With cooler

in position, hook the “S” hooks into the holes of the top pan near

the back of the cooler (B-Fig. 2).

F

A

“S” Hook

B

G

Fig. 2

• Install fi ll-in panels. Place one window fi ll-in panel on each side

of grill and into panel retainer strip at bottom of grill. Place the

other panel retainer strips onto top of neck fl ange and fi ll-in panels.

Be sure the panels are snug up against cooler neck.

• Place window behind retainer strip. Raise back of cooler so that

the window (D-Fig. 2) may be brought down behind top of panel

retainer strip (C-Fig. 2).

• Level Cooler. Adjust the chains to level the cooler.

• Adjust house legs. Pull out house legs so that the rubber bumpers

rest against house siding (F-Fig. 2). Tighten screw in retaining

collar. (G-Fig. 2).

Connecting Water

• Install overfl ow assembly. Place the

nipple through the hole in the pan, with

the rubber washer between the pan

and the head of the drain nipple (Fig.

4). Screw the nut onto the nipple and

draw up tight against bottom of pan.

Insert the overfl ow pipe in the nipple

to retain water. The overfl ow pipe

may be removed to drain pan when

necessary. A garden hose may

be screwed onto the drain nipple

to drain water away from your

unit.

• Connect water supply line.

Install a sillcock and water valve

on a faucet as shown by fi gure 5.

Run 1/4 inch tubing from sillcock

valve to cooler. Place the nut and

ferrule on the tubing and tighten

the nut until water tight.

• Install fl oat valve. Install

valve in the provided hole in

the louvered side (Fig. 6) and

attach water supply line.

• Fill pan. Allow water to fi ll

to within 1” of top of pan

and ad just fl oat to maintain

this water level. This can be

accomplished by bending the

fl oat rod (Fig. 6).

Sillcock

Fig. 5

Louvered Side

Float Rod

Fig. 4

Faucet

Water Supply

Fig. 6

Overfl ow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Water Supply

Valve

Line

Nut

Washer

Ferrule

Nut

Ferrule

Nut

• Break fill-in panels

to fi t. With cooler in-

stalled, as described

above, measure for each

window fill-in panel

and score with sharp

knife and straight edge

guide to desired width.

To break window fi ll-

in panels, the panel

should be laid over the

edge of a straight fl at

surface at the point to

2

Top Panel

Retainer

Window Fill-In

Panels

Fig. 3

Bottom Panel

Retainer

Maintenance

WARNING: Before doing any maintenance be sure power is

off and unit is unplugged. This is for your safety.

Spring Start-Up

• Change Pads. Aspen pads should be replaced once or twice a

season, depending upon the length of the season. At the beginning

and at mid season a clean pad is more absorbent and effi cient and

will deliver substantially more cool air.

110499

Page 3

• Clean pump. Cleaning the pump is necessary once a year at

start-up. For your safety, turn unit off and unplug from power

receptacle. Remove the pump from the mount slot. Remove the

base of the pump (Fig. 7). Clean the pump and turn the impeller

to ensure free operation. Remove the pump spout and check for

any blockage. After cleaning,

reinstall the base onto the pump.

Press fi rmly to make sure it is

Remove

Base

secure. Reattach the pump to

the mount in the cooler using

the plastic retainer to ensure that

the pump will not overturn. Do

Impeller

not forget to replace the spout

and water delivery tube onto the

Fig. 7

pump outlet.

• Cover unit. To protect the life of the fi nish, a cover for the unit is

suggested in extended periods of non use.

• Unplug unit from power supply during extended periods of non

use.

By following the operating, installation, and maintenance suggestions as outlined, you can get many years of effi cient and satisfactory

service from your cooler. In the event additional information is

desired, your dealer will be more than glad to assist you in every

possible way.

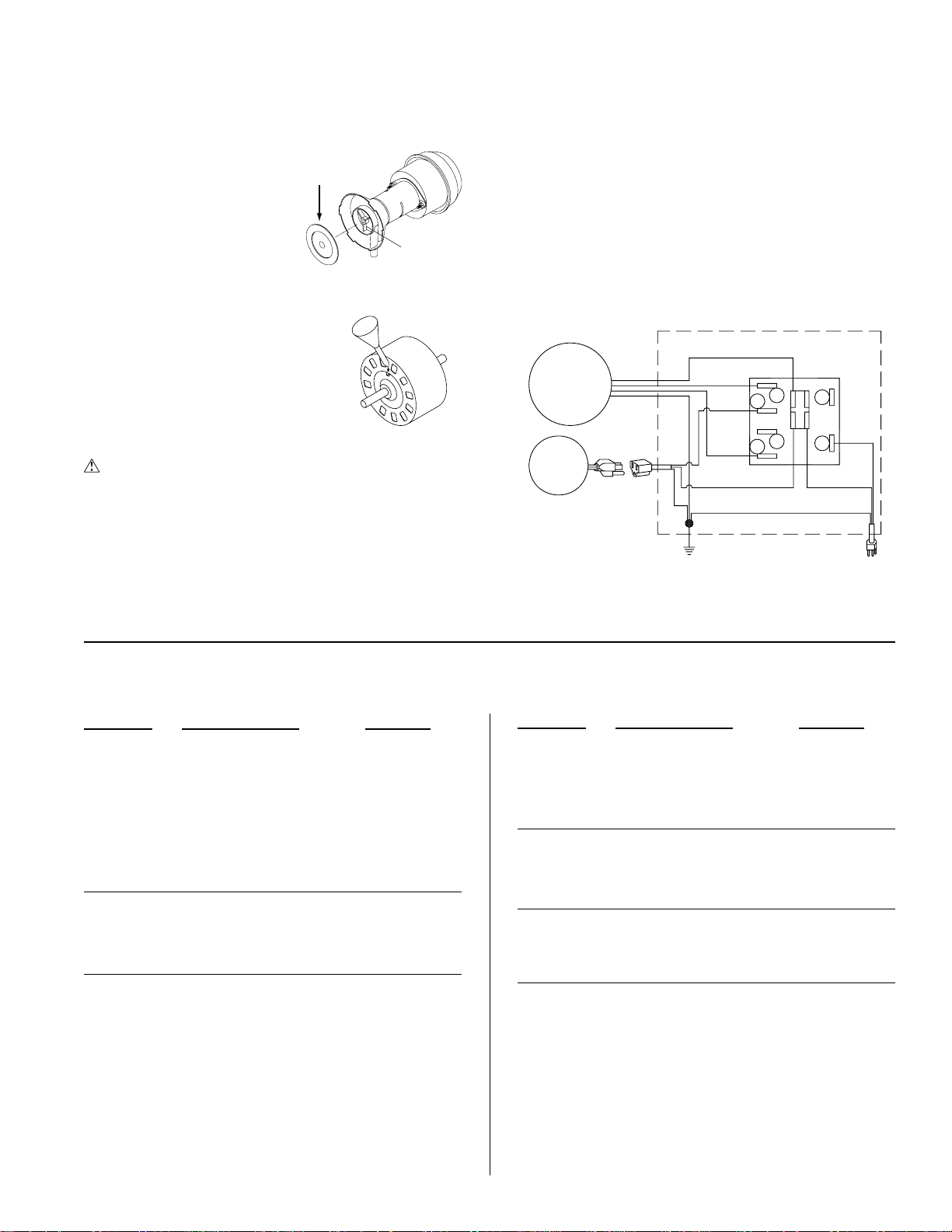

Wiring Diagram

• Oil motor. The cooler motor in this unit

Oil

should be oiled with a few drops of nondetergent 20/30 weight oil once each year.

The oil ports are located on each side of

the motor (Fig. 8). Motors that have no oil

ports are lifetime oiled at the factory and

require no further oiling for the life of the

Fig. 8

unit.

CAUTION: Do not over oil. Over oiling can cause motor burn

out, due to excessive oil getting into motor winding.

Winter Shut Down

• Drain water. Always drain all of the water out of the cooler and

water supply line when not in use for prolonged periods, and

par ticularly at the end of the season. Keep the water line disconnected from both the unit and water supply so that it does not

freeze.

Troubleshooting Guide

Problem Possible Cause Remedy

Failure to

start or no

air delivery

Inadequate

air delivery

with cooler

running

1. No electrical power to

unit

• Fuse blown

• Circuit breaker tripped

• Electric cord damage

2. Motor overheated

• Bearings dry

3. Motor locked

1. Insuffi cient air exhaust

2. Pads plugged

1. Check power

• Replace fuse

• Reset breaker

• Replace cord

2. Determine cause of

overheating

• Oil bearings

3. Replace motor

1. Open windows or

doors to increase air

fl ow

2. Replace pads

White-Com.

Blower

Motor

Pump

Motor

Green

Black-Hi

Plain

Green

Red-Lo

Ribbed-Com.

Green-Ground

Switch

4

2

B

Plain

A

Ribbed-Com.

3

1

Problem Possible Cause Remedy

Motor

cycles on

and off

Noisy

Excessive

humidity in

house

1. Low voltage

2. Motor bearings dry

3. Wheel rubbing blower

housing

4. Faulty motor

1. Motor bearings dry

2. Wheel rubbing blower

housing

3. Loose parts

1. Inadequate exhaust

1. Check voltage

2. Oil bearings

3. Inspect and realign

(Unplug unit)

4. Replace motor

1. Oil bearings

2. Inspect and realign

(Unplug unit)

3. Tighten loose parts

1. Open doors or windows

Inadequate

cooling

110499

1. Inadequate exhaust in

house

2. Pads not wet

• Pads plugged

• Open spots in pads

• Trough holes or Dis-

tributor system clogged

• Pump not working

properly

1. Open windows or

doors to increase air

fl ow

2. Check water distribution system

• Replace pads

• Repack pads

• Clean

• Replace or clean

pump (Unplug unit)

Musty or

unpleasant

odor

1. Stale or stagnate water

in cooler

2. Pads not wetting

properly

• Trough holes clogged

• Pump not wetting

properly

• Insuffi cient water fl ow

over pads

1. Drain pan and clean

pads

2. Check water distribution system

• Clean

• Replace or clean

pump (Unplug unit)

• Clean distribution

system and trough

openings

3

Page 4

Replacement Parts List / Lista De Piezas De Recambio

When ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your order. /

Al pedir piezas, incluya toda la información siguiente con su pedido. El no proporcionar toda esta información resultará en una demora.

1. Cooler serial number / Número de serie de la unidad

2. Description and part number / Descripción y número de pieza

3. Cooler model number / Modelo de la unidad

4. Date of purchase / Fecha de compra

No. N28W

N° Description / Descripción WCM 28

1. Top Pan / Tapa De La Caja --------------------------------------------------------------------------------------------------222901-002

2. Bottom Pan / Base De La Caja ----------------------------------------------------------------------------------------------222902-002

3. Louvered Back Assembly / Montaje De Reja Posterior -----------------------------------------------------------------324102-203

4. Aspen Pads, Back / Esponjas De Paja, Posterior -------------------------------------------------------------------------110088

5. Pad Retainer, Back / Soporte Para La Esponja, Posterior ---------------------------------------------------------------3PW-2 (2)

6. Louvered Side, Right / Reja Lateral, Derecha ----------------------------------------------------------------------------324102-102

7. Louvered Side, Left / Reja Lateral, Izquierda -----------------------------------------------------------------------------324102-202

8. Aspen Pads, Side / Esponjas De Paja, Lateral -----------------------------------------------------------------------------110087 (2)

9. Pad Retainer, Side / Soporte Para La Esponja, Lateral ------------------------------------------------------------------3PW-1 (4)

10. Blower Housing / Caja De La Rueda ---------------------------------------------------------------------------------------324102-005

11. Blower Wheel, Right / Rueda Derecha -------------------------------------------------------------------------------------110748

12. Blower Wheel, Left / Rueda Izquierda -------------------------------------------------------------------------------------110747

13. Motor / Motor ------------------------------------------------------------------------------------------------------------------110441-C*

14. Motor Mounts / Monturas Del Motor---------------------------------------------------------------------------------------216002-001 (2)

15. Front Panel / Panel De Frente -----------------------------------------------------------------------------------------------224102-001

16. Tunnel / Túnel (Cuello De La Unidad) -------------------------------------------------------------------------------------324102-006

17. Pump Mount / Montura De La Bomba -------------------------------------------------------------------------------------218001-032

18. Pump Receptacle Cord / Cable Con Tomacorriente Para La Bomba --------------------------------------------------110395

19. Pump Retainer / Sujetador De La Bomba ----------------------------------------------------------------------------------110714

20. Pump / Bomba ----------------------------------------------------------------------------------------------------------------- 110436

21. Pump Screen / Malla Para La Bomba --------------------------------------------------------------------------------------281001-001

22. Tube, Water Delivery / Tubo De Agua --------------------------------------------------------------------------------------310716

24. Water Distributor Assembly / Sistema Del Distribuidor De Agua ------------------------------------------------------3D-1

25. Over Flow Assembly / Montaje De Desagüe ------------------------------------------------------------------------------3OA-1

26. Grill Assembly / Rejilla Completa ------------------------------------------------------------------------------------------110843

27. Switch Cover / Cubierta Del Interruptor-----------------------------------------------------------------------------------222006-003

28. Switch / Interruptor -----------------------------------------------------------------------------------------------------------110425

29. Knob, Switch / Perilla Del Interruptor -------------------------------------------------------------------------------------110839-006

30. Outer Electrical Cord / Cable Eléctrico Exterior ------------------------------------------------------------------------- 110394

31. Float Valve / Flotador De Agua ---------------------------------------------------------------------------------------------FL-C

32. Window Fill-In Panels / Paneles De Relleno Para La Ventana ---------------------------------------------------------110604 (2)

33. Retainers, Window Panels / Guarda De Retención Para Los Paneles -------------------------------------------------110599 (4)

34. House Leg Assembly / Equipo De Collar De La Pata -------------------------------------------------------------------3HL-2 (2)

35. House Leg / Pata --------------------------------------------------------------------------------------------------------------310811 (2)

* See electrical specifi cation table. / Vea la tabla de especifi caciones eléctricas.

NOTE: Standard hardware items may be purchased from your local hardware store. /

NOTA: Artículos de uso corriente pueden comprarse en la ferretería de su localidad.

General Specifi cations / Especifi caciones Generales

Weight (lbs.)

Model No.

Modelo

Peso (libras)

Dry

Seco

Operating

Lleno

WCM28, N28W 65 105 27 24 17 21 1/4 11

Cabinet Dimensions (in.)

Dimensiones De La Caja (pulgadas)

Height

Altura

Width

Anchura

Profundidad

Depth

Window Opening Req’d (in.)

Abertura Requerida (pulgadas)

Width

Anchura

Electrical Specifi cations / Especifi caciones Eléctricas

Model No.

Modelo

WCM28, N28W 115 2 4.0 0.7

4

Volts

Voltios

Motor Speed

Velocidad del Motor

Motor Amperage

Amperaje Del Motor

Pump Amperage

Amperaje De La Bomba

Height

Altura

110499

Page 5

Parts Drawing / Dibujo De Piezas

Register your product online at www.championcooler.com/eac/onlineregistration-eac.htm

Limited W arranty

This warranty is extended to the original purchaser of an evaporative cooler installed and used under normal conditions. It does not cover damages incurred through accident,

neglect, or abuse by the owner. We do not authorize any person or representative to assume for us any other or different liability in connection with this product.

Terms And Conditions Of The Warranty

For Eight Years from date of purchase, we will replace the original base assembly if water leakage should occur due to rust out.

For One Year from date of purchase, we will replace any original component provided by Champion Cooler which fails due to any defect in material or factory workmanship only.

Exclusions From The Warranty

We are not responsible for replacement of cooler pads. These are disposable components and should be replaced periodically. W e are not responsible for any incidental

or consequential damage resulting from any malfunction.

We are not responsible for any damage received from the use of water softeners, chemicals, descale material, plastic wrap, or if a motor of a higher horsepower than

what is shown on the serial plate is used in the unit.

We are not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace parts.

How To Obtain Service Under This Warranty

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfi ed with the response from the dealer, contact the Customer Service

Department: Champion Cooler, 5800 Murray Street, Little Rock, Arkansas 72209. 1-800-643-8341. info@championcooler.com

This limited warranty applies to original purchaser only.

110499

5

Page 6

Lea Y Conserve Estas Instrucciones

Reglas De Seguridad

1. Lea las instrucciones con cuidado.

2. La unidad debe estar APAGADA y DESCONECTADA de la

electricidad cuando se instale o haga cualquier mantenimiento.

3. Su enfriador funciona sólo con corriente alterna de 120 voltios, 60

Hz. (ciclos).

4. El motor y la bomba están conectados con la tierra, y se apagarán

automáticamente en caso de sobrecalentamiento. Los motores

volverán a funcionar cuando se enfrían.

ADVERTENCIA: Para reducir el riesgo de incendio o toques

eléctricos, no use este ventilador con ningún “dispositivo de estado

sólido para controlar la velocidad del ventilador.”

Enfriamiento Por Evaporación

Este enfriador evaporativo funciona circulando el aire fresco; Usted no

tiene aire recirculado que esté viciado, cargado de humo y olores como

ocurre con los sistemas de aire acondicionado a base de refrigeración.

En cambio, se reemplaza el aire completamente cada 2 a 4 minutos,

abriendo las puertas o las ventanas o una combinación de ambas para

agotar el aire continuamente.

¿Cuánta abertura requiere su unidad? Para obtener la máxima

capacidad de enfriamiento del enfriador, abra las ventanas hasta

que el aire interior esté bastante equilibrado con el aire exterior. La

más abertura que tenga, la menos acumulación de presión del aire

interior, y más la producción del aire del enfriador será hasta llegar

a la capacidad de la unidad.

Hay un método para saber cuando el aire está bastante equilibrado.

Ponga un papel de seda contra la pantalla de la ventana a lo más lejos

del enfriador. Ajuste la abertura de las ventanas hasta que el papel

de seda queda ligeramente contra la pantalla. Abra más las ventanas

si el papel se queda contra la pantalla con fuerza. Cierre más las

ventanas si el papel se caiga.

Operación

Para que no salga aire caliente al principio, prenda sólo la bomba

durante unos cuantos minutos; luego prenda también el motor del

ventilador.

Su enfriador puede ser utilizada sin agua para proporcionar ventilación

solamente. Cuando hace fresco (por ejemplo, de noche) o cuando la

humedad es alta, la bomba de agua puede ser apagada.

Instalación

Instalar Las Patas

• NOTA: Si instale la unidad sin el uso del equipo de instalación,

omite las direcciones siguientes y las de la fi gura 2.

• Quite los tornillos de la esquina de la bandeja (A-fi g. 1).

• Coloque la ménsula en la esquina de

la bandeja usando los dos agujeros

de la parte superior de la ménsula

(B-fi g. 1) y los dos tornillos que

antes había quitado.

• Coloque la ménsula del otro lado de

la misma manera.

• Vea la instrucción abajo de “Ajuste

las patas” para ajustar las patas.

B

A

Fig. 1

Instalar El Enfriador

PRECAUCION: La superfi cie en que ha de colocarse el

enfriador deberá aguantar el peso completo de la unidad cuando

ésta está en funcionamiento. (Para saber este peso, vea la tabla

de especifi caciones.)

PRECAUCION: No conecte el enfriador hasta que la

instalación esté completa y se haya comprobado la estabilidad

del mismo.

• Quite todas las rejas de los costados.

• Fije los ganchos en la pared.

Ponga los dos ganchos para

la cadena arriba del cuello del

enfriador, separados por una distancia equivalente al ancho de la

unidad (A-fi g. 2). Enganche una

cadena en cada gancho y luego

enganche un gancho “S” en cada

cadena. NOTA: Los ganchos

que vienen con ésta unidad tienen

rosca de tornillo para madera y

son para uso en paredes de ma-

D

C

Cuello

H

E

dera. Las paredes de concreto

o ladrillo requieren el uso de

tuercas mariposas de sufi ciente

fuerza o anclas con ganchos de

acoplamientos.

• Instale las guardas

Paneles De

Relleno

de retención. Coloque dos guardas de

retención en la parte

inferior de la pestaña

del cuello y ajústelas

Guarda De

Retención

Superior

al ancho de la ventana.

Corte las guardas si

es necessario. Éstas

sujetan a los paneles

de relleno (fi g. 3).

Fig. 3

• Coloque el enfriador en la ventana. Coloque el cuello del en-

friador dentro de la ventana para que la parte inferior de la pestaña

del cuello se asiente en la repisa de la ventana y la pestaña (E-fi g.

2) se ajuste contra el borde de la repisa (H-fi g. 2). Con el enfriador

situado en la ventana, enganche los ganchos “S” en los agujeros

encontrado en la esquina trasera superior de la unidad (B-fi g. 2).

• Rompa los paneles de relleno. Con el enfriador instalado según el

método de arriba, mida el ancho requerido para cada panel. Marque

el panel con un cuchillo fi loso y una regla al ancho correcto. Apoye

el panel en el borde de una superfi cie lisa y plana y presione sobre

la parte del panel que se extienda sobre el borde de la superfi cie,

para que se desprenda la parte sobrante.

• Instale los paneles de relleno. Coloque un panel de relleno a cada

lado de la rejilla y dentro de la banda de retención situada en la

parte inferior de la rejilla. Coloque las otras guardas de retención

en la parte superior de la pestaña del cuello y los paneles de relleno.

Compruebe que los paneles queden bien ajustados contra el cuello.

(Véase Fig. 3).

• Coloque la ventana detrás de la guarda de retención. Levante

la parte trasera del enfriador para que la ventana (D-fi g. 2) pueda

bajarse y quedar detrás de la parte superior de la guarda de retención

(C-fi g. 2).

A

Gancho “S”

G

F

Fig. 2

Guarda De Retención

Inferior

B

6

110499

Page 7

• Nivele el enfriador. Ajuste las cadenas hasta que el enfriador esté

nivel.

• Ajuste las patas. Saque las patas (F-fi g. 2) para que los topes de

hule descansen contra el costado de la pared. Apriete el tornillo

del collar (G-fi g. 2).

Conectar El Agua

• Instale el montaje de desagüe. Pase

la boquilla roscada por el agujero de

la bandeja, colocando la arandela de

goma entre la bandeja y la cabeza de

la boquilla (fi g. 4). Coloque la tuerca

en la boquilla y atorníllela hasta que

quede apretada contra la parte inferior de la bandeja. Inserte el tubo de

desagüe en la boquilla para retener el

agua. El tubo de desagüe se puede quitar para desaguar el agua de

la bandeja cuando sea necesario. Se puede conectar una manguera

de jardín a la boquilla para desaguar el agua hacia otra parte.

• Conecte el tubo de abastecimiento de agua. Instale la llave de

paso y la válvula de agua en el

grifo de agua según indica la

fi gura 5. Coloque la tuerca y la

férula en el tubo y apriete bien

la tuerca para impedir que gotee

Llave De

el agua.

Fig. 4

Grifo

Paso

Tubo De Desagüe

Boquilla Roscada

Arandela De Goma

Bandeja

Tuerca

Válvula

De Agua

Férula

Tuerca

• Limpie la bomba. Es necesario limpiar la bomba una vez al

principio de cada año. Por su propia seguridad, apague la unidad

y desconéctela de la electricidad. Quite el sujetador de plástico de

la montura y quite la bomba, deslizándola hacia usted. Quite la

base de la bomba (véase fi g. 7). Limpie la bomba. Dé la vuelta a

la hélice para verifi car que se mueve libremente. Quite el pico de la

bomba y vea si está obstruido. Después de limpiar, reinstale la base

en la bomba. Presione fi rmemente

para asegurarse de que es segura.

Vuelva a colocar la bomba en

Quite La

Base

la unidad y fíjela en su montura

con el sujetador de plástico. Esto

impedirá que se caiga la bomba al

agua, lo que dañaría el motor. No

Hélice

se olvide de volver a conectar el

tubo de agua a la bomba.

• Lubrique el motor. El motor del ventilador

Fig. 7

Aceite

debe ser lubricado usando unas gotas de

un aceite no detergente de densidad 20/30

una vez al año. Las aberturas para aceite

están situadas en cada lado del motor (fi g.

8). Motores que no tengan una abertura

para aceite son lubricados en la fábrica

de por vida y no requieren nunca ninguna

Fig. 8

lubricación.

PRECAUCION: No lubrique demás. El agregar demasiado

aceite puede ocasionar que se queme el motor, a causa del aceite

entrando al interior del motor.

• Instale la válvula del fl otador.

Fig. 5

Instale la válvula en el agujero

que se encuentra en la reja

lateral (fi g. 6) y conecte el tubo

de agua.

• Llene la bandeja con agua.

Permita que se llene la bandeja

con agua hasta una altura de

Varilla Del

Tubo De Abastec-

imiento De Agua

Reja Lateral

Flotador

una pulgada por debajo del

borde superior de la bandeja y

ajuste el fl otador para que man-

tenga este nivel. Esto se puede

lograr torciendo la varilla para

Fig. 6

Férula

Tuerca

Arandela

Tuerca

arriba o para abajo (fi g. 6).

Mantenimiento

ADVERTENCIA: Antes de hacer cualquier mantenimiento,

compruebe que la unidad esté apagada y desconectada de la

electricidad. Esto es por su seguridad.

Puesta En Marcha En La Primavera

• Cambie las esponjas. Debe cambiar las esponjas de paja una o

dos veces durante cada temporada, según la duración de ésta. Al

principio y a mediados de la temporada, una esponja limpia es más

absorbente y efi ciente y producirá un mayor volumen de aire frío.

Preparar La Unidad Para El Invierno

• Drene el agua. Drene siempre toda el agua del enfriador y del

tubo de abastecimiento de agua cuando no use el enfriador durante

períodos prolongados, especialmente al fi n de la temporada. El tubo

debe quedarse desconectado del enfriador y del abastecimiento de

agua para que no lo congele.

• Cubra la unidad. Para proteger y alargar la vida útil del acabado,

se sugiere cubrir el enfriador durante períodos largos cuando no

sea utilizado.

• Desconecte la unidad de la electricidad cuando no sea utilizada

durante períodos extendidos.

Si usted sigue estas sugerencias en cuanto a instalación, operación

y mantenimiento, podrá disfrutar de muchos años de servicio

efi ciente y satisfactorio de este enfriador. Si desea más información,

su concesionario tendrá mucho gusto en ayudarle con respecto a

cualquier duda o pregunta.

Esquema Del Cableado

Blanco-Común

Motor De

La Rueda

Bomba

Verde

Verde

Negro-Alto

Negro

RojoBajo

Blanco-Común

Verde-Tierra

Interruptor

4

2

B

Liso

A

AcanaladoComún

3

1

110499

7

Page 8

La Localización De Averías

Problema Causa Posible Remedio

No arranca o

no sale aire

Sale poco

aire cuando

la unidad

está funcionando

Enfriamiento

inadecuado

1. No llega corriente

• Fusible fundido

• Cortacircuito desactivado

• Cable eléctrico dañado

2. Motor recalentado

• Cojinetes están secos

3. Motor parado

1. Insufi ciente abertura

para que salga el aire

2. Esponjas obstruidas

1. Insufi ciente abertura

para que salga aire

2. Las esponjas no están

mojadas

• Esponjas obstruidas

• Esponjas agujereadas

• El sistema de distribución o los agujeros de

los canales obstruidos

• Bomba no funciona

1. Revise la corriente

• Cambie el fusible

• Restablecer el cortacircuito

• Reemplace el cable

2. Determine la causa

• Lubrique los cojinetes

3. Cambie el motor

1. Abra ventanas o

puertas para aumentar fl ujo de aire

2. Cambie las esponjas

1. Abra más las venta-

nas o puertas

2. Revise la distribu-

ción de agua

• Cambie las esponjas

• Acomode la paja en

la esponja

• Límpielos

• Cámbiela o límpiela

(Desconecte la

unidad)

Problema Causa Posible Remedio

Motor se

apaga y se

enciende

Hace Ruido

Demasiada

humedad en

la casa

Olor a encerrado, olor

desagradable

1. Voltaje defi ciente

2. Cojinetes del motor

están secos

3. Rueda roza contra

caja de la rueda

4. Motor defectuoso

1. Cojinetes del motor

están secos

2. Rueda roza contra

caja de la rueda

3. Partes sueltas

1. Insufi ciente salida

de aire

1. Agua estancado en la

unidad

2. Esponjas secos

• Agujeros del canal

tapados

• Bomba no trabaja

adecuada

• Insufi ciente fl ujo de

agua

Registre su producto en línea a: www.championcooler.com/eac/onlineregistration-eac.htm

1. Compruebe el

voltaje

2. Lubrique los cojinetes

3. Inspeccione y alinee

(Desconecte la

unidad)

4. Cámbielo

1. Lubrique los cojinetes

2. Inspeccione y alinee

(Desconecte la

unidad)

3. Apriételas

1. Abra puertas o

ventanas

1. Desagüe y limpie las

esponjas

2. Revise la distribución de agua

• Límpielos

• Reemplace o limpie

la bomba (Desconecte la unidad)

• Limpie el sistema

de distribución y

agujeros de los

canales

Garantía Limitada

La presente garantía se extiende al comprador original de un enfriador evaporativo instalado y utilizado bajo condiciones normales. No cubre daños

ocurridos por accidente, descuido o abuso por parte del propietario. No autorizamos que ninguna otra persona o representante asuma por nosotros

cualquier otra o diferente responsabilidad en relación con este producto.

Términos Y Condiciones De La Garantía

Durante Ocho Años a partir de la fecha de compra, nosotros reemplazaremos la base original del enfriador en caso de que goteara agua debido a

oxidación.

Durante Un Año a partir de la fecha de compra, reemplazaremos cualquier componente original proporcionado por Champion Cooler que falle debido

a cualquier defecto de material o mano de obra en la fábrica solamente.

Exclusiones De La Garantía

No somos responsables por reemplazar las esponjas del enfriador. Estas son componentes desechables y deben cambiarse periódicamente. No somos

responsables por daños que resulten a consecuencia de alguna falla de funcionamiento.

No somos responsables por cualquier daño producido por el uso de suavizadores de agua, productos químicos, materiales desincrustantes, envolturas

de plástico, o si se usa en esta unidad un motor de mayor potencia de la que se indica en la placa de número de serie.

No somos responsables por el costo del servicio para diagnosticar la causa del problema ni por la mano de obra necesaria para reparar y/o reemplazar

piezas.

Como Obtener Servicio Bajo Esta Garantía

Póngase en contacto con el Concesionario que le vendió el enfriador. Si por alguna razón usted no queda satisfecho con la respuesta por parte del

Concesionario, comuníquese con el departamento de servicio al cliente: Champion Cooler, 5800 Murray Street, Little Rock, Arkansas 72209. 1800-643-8341. info@championcooler.com

Esta garantía limitada se aplica al comprador original solamente.

8

110499

Loading...

Loading...