Page 1

Industrial

Commercial

Owner’s Guide

• INSTALLATION

• OPERATION

• MAINTENANCE

• SERVICING

READ AND SAVE

THIS INSTRUCTION

MANUAL

EVAPORATIVE AIR COOLER

MODELS

CS11/16, CD11/16

CD21

IMPORTANT

Note any damage on the freight bill, as any damage

claim must be filed with carrier.

Motor, Motor Pulley, Pump and Belt are sold

separately

Date purchase: _____________________

Purchased from: ____________________

Manual part # 70888

REV. 1/06

1

Page 2

INSTALLATION OF EVAPORATIVE COOLERS

PREPARATION

1. All electrical and duct work must comply with local and federal codes.

2. Make arrangements to get the cooler from ground to roof (crane, hoist, etc.).

LOCATION

1. Cooler should not be mounted near exhaust openin gs or vent pipes where fumes and odors can be drawn into cooler.

2. Ensure mounting surface is strong enough to support the cooler. Operating weight will be much heavier than

shipping weight.

3. Locate cooler so that fresh air is drawn in; air is not recirculated.

ROOF MOUNT UNITS

1. Select the location, taking into account roof construction and duct requirements. If rafters are cut when the roof

opening is cut, be sure to strengthen them.

2. Purchase or construct a platform to provide a level, mounting surface for the cooler. Always mount the cooler

high enough to allow easy access to the drain fitting.

3. Measure cooler or use the spec sheet to determine size of platform. Platform must be located so that the discharge

opening of the cooler is in line with the ductwork. On pitched roofs, the platform frame may be covered with galvanized

sheet steel or other weatherproof materials. An opening or removable panel must be left to allow access to the drain

fitting. On down discharge coolers the duct should be fastened to the platform collar before cooler is set in place. The

duct should have a standing flange for the cooler discharge opening to fit. Flash and seal the duct and roof opening to

provide weather tightness.

CAUTION: TO AVOID RISK OF FIRE, ELECTRICAL SHOCK, OR SERIOUS PERSONAL INJURY, BE SURE TO

DISCONNECT POWER FROM UNIT BEFORE CLEANING OR SERVICING.

WARNING: TO REDUCE THE RISK OF FIRE OR SHOCK; DO NOT USE THIS FAN WITH ANY SOLID STATE SPEED

CONTROL DEVICE.

DUCT WORK

1. The most important rule to follow when designing duct work is: AN EVAPORATIVE COOLER DEPENDS UPON

A LARGE VOLUME OF AIR COMING OUT OF THE DUCT WORK AT HIGH VELOCITY IN ORDER TO COOL

PROPERLY.

2. Do not “reduce” the discharge opening of the cooler.

3. Do not undersize the duct work and make it much smaller than the discharge opening. (In most cases, air

conditioning duct work is too small for coolers.)

4. Extra long ducts cause static pressure and will reduce airflow. They also pick up heat and diminish the effect of

the cooled air.

5. The motor pulley may be adjusted to compensate for ductwork.

6. Sharp or abrupt bends hinder airflow.

7. Poorly designed ceiling diffusers will rui n a successful installation. Install diffusers that are designed for use with

evaporative coolers.

MOTOR INSTALLATION

After cooler is in place and level, remove the motor from the box and inspect for shipping damage. Ensure that the motor

voltage, phase and horsepower are correct. Mount motor on motor mount as shown.

Mount the motor using the slots that align the motor pulley and blower pulley.

BELT ADJUSTMENT

An improperly adjusted belt will greatly shorten motor life.

A deflection of ¾” with finger force will indicate proper adjustment.

Do not use the motor pulley to adjust belt tension.

Always use the motor mount to adjust the belt.

2

Page 3

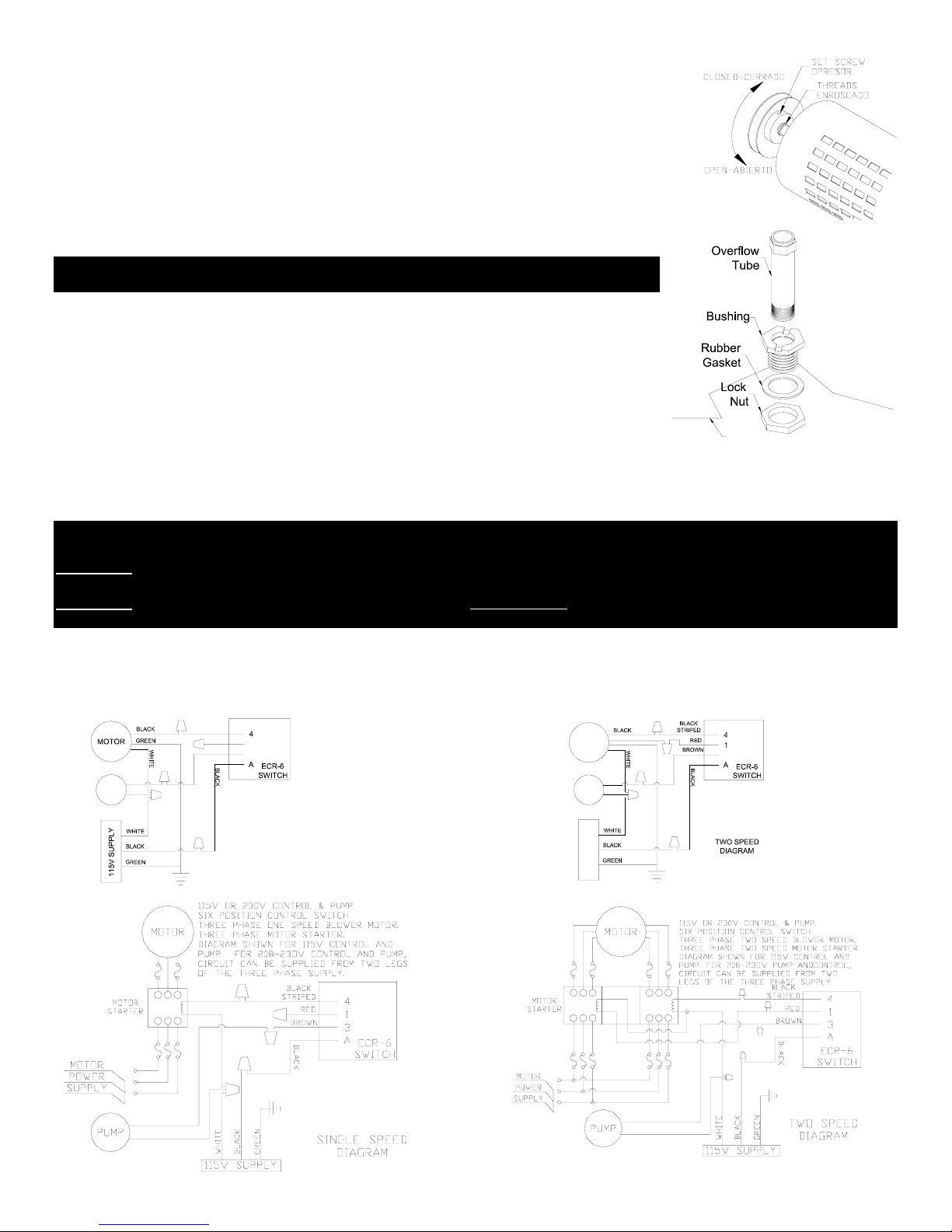

MOTOR PULLEY ADJUSTMENT

Before installing the motor pulley, loosen the set screw on the back side of the pulley and

turn the outside jaw of the pulley until it is fully closed. Position the set screw over the

closest flat spot in the thread and then open the outside jaw of the pulley 4 or 5 turns.

Position the set screw over the closest flat spot in the thread and retighten the set screw.

Place the pulley on the motor shaft and tighten the front set screw. The CD21 coolers are

equipped with double groove pulleys.

OVERFLOW PIPE INSTALLATION

Place the rubber washer onto the drain bushing. Slide the bushing through the drain

opening, in the cooler bottom, from the top side. Screw the nut onto the bushing from

under the cooler. Position the overflow tube in the bushing.

CAUTION: DO NOT HOOK THIS COOLER TO A WATER SOFTENER. THIS WILL

WATER CONNECTION

VOID THE WARRANTY.

The float mounts in a hole provided in the corner post (down draft) or front panel (side

draft). The water level should remain at least ½” below the top of the overflow tube. A

screw is provided in the float to adjust water level; or the float rod may be bent to adjust

the level.

BLEEDOFF

In hard water areas, a bleed off kit may be installed to dispose of small amounts of

mineralized water, allowing fresh water to replace it.

Reservoir

ELECTRICAL POWER

1. The installation of electrical wiring must conform to all local and federal codes and should be done by a certified

electrician.

2. Connecting the motor and/or pump to the wrong voltage will void the warranty.

Notice to Installer: The motor amperage must be set as close as possible to motor nameplate amps without the pump

running.

WARNING: To avoid risk of electrical shock, disconnect the power before opening or attempting service on this unit.

WARNING: TO REDUCE THE RISK OF FIRE OR SHOCK; DO NOT USE THIS FAN WITH ANY SOLID STATE SPEED

CONTROL DEVICE.

WIRING DIAGRAMS

Three phase; one and two speed. Motor starter to be equipped with overload

relay sized to accommodate motor full load amps.

Motor starters and overloads are not supplied with units.

BLACK

STRIPED

BROWN

RED

1

3

MOTOR

RED

GREEN

3

PUMP

SINGLE SPEED

DIAGRAM

PUMP

115V SUPPLY

3

Page 4

START UP

After installing cooler and before filling with water:

1. Open windows and doors or other exhaust opening s in building.

2. Turn on cooler and check amperage at the incoming white lead, using clam p on ammeter. If amperage reads above

motor name plate, refer to the motor pulley adjustment instructions (page 2) and open the pulley ½ turn. Restart

cooler and recheck amperage. If amperage reads below motor name plate, close the pull ey ½ turn. Restart cooler

and recheck amperage.

3. Turn on water to cooler and ensure that connections do not leak.

4. Fill pan to ½” below top of overflow tube and ensure that the float cuts off water completely.

5. Turn the switch to cool and check that water is coming from the water trays and that the pads are wetting evenly.

There are screws at the top of the louvers to level the water trays.

MAINTENANCE

CAUTION: Turn off all electrical power to this unit before opening or attempting any service.

Occasionally inspect your cooler for leaks, loose belt, blocked water lines, correct

belt alignment or excessive residue buildup on the pads. Inspect cabinet for rust. If

rust spots appear, sand and paint with a high-grade, corrosion resistant paint.

OILING

Lube the blower bearings twice per year- 2-3 drops per bearing. Use SAE 20W or

30W, non-detergent oil on bearings with oil cups and standard bearing grease o n

ball bearings. Oil the blower motor if it is equipped with oil holes. Some motors are

permanently lubricated at the factory.

PAD REPLACEMENT

It is best to change pads at the end of the season. When old pads (covered by

minerals and salts) are left in the cooler during the wet winter months, there is a

greater possibility for corrosion.

1. Remove the louver from the cooler.

2. Unhook pad retainers from the sides of the louver and remove.

3. Remove the old pad and discard.

4. Clean any dirt or sediment that has built up on louver. Inspect the water tray

and clean any dirt or sediment that has built up in the water slots. If louver

has rust spots, sand and paint with a high-grade, corrosion resistant paint.

5.

Tuck new pad into louver, ensuring that there are no gaps to allow hot air

to bypass the pad

6. Replace the pad retainers.

LIMITED WARRANTY

This warranty is extended to the original purchaser only. It does not cover damages incurred during shipping or through accident,

neglect, or abuse by the owner. Essick Air Products does not authorize any person or representative to assume any other or different

liability in connection with this cooler.

TERMS AND CONDITIONS OF WARRANTY

The BOTTOM PAN is guaranteed against leakage due to rusting out for Five Years. All other original parts provided by Essick Air

Products are warranted against defects in material or factory workmanship for One Year.

EXCLUSIONS FROM THE WARRANTY

Essick Air Products is not responsible for incidental or consequential damage resulting from any malfunction.

Essick Air Products is not responsible for any damage occurring from the use of water softeners, chemicals, descale material, or if a

higher horsepower motor than what Essick Air Products recommends is used in the unit.

Essick Air Products is not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace

HOW TO OBTAIN SERVICE UNDER THIS WARRANTY

Contact the Dealer where you purchased the evaporative cooler. If for any reason you ar e not satisfied with the response from the

dealer, contact Customer Service Department: Essick Air Products Inc. 5800 Murray Street, Little Rock, Arkansas 72209.

Phone 1-800-643-8341

parts.

4

Page 5

CS11/16, CD11/16 & CD21 REPLACEMENT PARTS / PIEZAS DE RECAMBIO

To order replacement parts, please call “The Cooler Hotline” at 1-800-643-8341. To ensure prompt service, have the

following information available.

Cooler Model #____________________________ __ Serial # ____________________________________

Manual # and Revision Date____________________ Purchased From_____________________________

5

Page 6

CS11/16, CD11/16 & CD21 REPLACEMENT PARTS / PIEZAS DE RECAMBIO

ITEM

1 FRONT FRENTE 70697 1 N/A ***

2 BOTTOM BANDEJA INFERIOR 70702 1 70681 1

3

4 CUTOFF LIMITADOR DE AIRE 70705 1 70694 1

5 TOP BANDEJA SUPERIOR 500220 1 500219 1

6

7 WATER DISTRIBUTOR DISTRIBUIDOR DE AGUA 512522 1 512523 1

8 BLOWER BRACE SOPORTE DEL VENTILADOR 500852 2 500852 2

9 CENTER POST POSTE CENTRO 501466 3 501466 4

10 PAD RETAINER SUJETADOR DE LOS FILTROS 500603 6 500603 8

11 FILTER FILTRO 524093 6 524093 8

12 LOUVER LA REJILLA 501352 6 501352 8

13 WATER TRAY LA CHAROLA PARA AGUA 500677 6 500677 8

* LOUVER ASSEMBLY JUEGO DE REJILLA 503396 6 503396 8

14 CORNER POST POSTE DE ESQUINA 500098 1 500098 2

15 WATER HOSE MANGUERA DEL AGUA 598400 60” 598400 60”

16 PUMP BRACKET ABRAZADERA DE LA BOMBA 70488 1 70488 1

17 OVERFLOW KIT EQUIPO DE DESBORDIMENTO 515100 1 515100 1

18 FLOAT VALVE VÁLVULA FLOTADORA 524198 1 524198 1

19 SET COLLAR COLLAR FIJO 501242 2 501242 2

20 BLOWER WHEEL EL SOPLADOR LA RUEDA 70640 1 70640 1

21 BLOWER SHAFT EJE DEL VENTILADOR 70672 1 70672 1

22 KEY CHAVETA 589041 2 589041 2

23 BLOWER PULLEY POLEA DEL VENTILADOR 583095 1 583095 1

23

24 BEARING (CS/CD11/16) CONJINETE (CS/CD11/16) 583005 2 583005 2

24 BEARING (CD21) CONJINETE (CD21) 583001 2 583001 2

25 BEARING ANGLE SOPORTE PARA COJINETE 514498 2 514498 2

26

27 MOTOR MOUNT (CD21) MONTAJE DEL MOTOR (CD21) *** *** 512491 1

28 SPLASH BAFFLE DEFLECTOR N/A *** 501464 2

29

DESCRIPTION DESCRIPCIÓN

BLOWER HOUSING

(CS11/16)

MOTOR MOUNT

(CS/CD11/16)

BLOWER PULLEY

DOUBLE GROOVE

(CD21)

BLOWER HOUSING

(CD11/16 &21)

PUMP (SOLD

SEPARATELY)

CAJA DEL VENTILADOR (CS11/16) 70703 1 *** ***

MONTAJE DEL MOTOR (CS/CD11/16) 70686 1 70686 1

POLEA DEL VENTILADOR (CD21)

SURCO DOBLE

CAJA DEL VENTILADOR (CD11/16 &21) *** *** 70692 1

BOMBA (se venden por separado)

Motor, pulley and belt sold separately.

*Louver assembly includes louver, water tray, pad and

pad retainers.

CS11/16 CD11/16 & CD21

PART NO.

NO. DE REF.

583018 1 583018 1

506605/115V

506606/230V

QTY.

CAN.

1

PART NO.

NO. DE REF.

506605/115V

506606/230V

El motor, la polea y la banda se venden por separado.

*El juego de rejilla incluye la rejilla, la charola para agua,

filtro y sujetadores de los filtros.

QTY.

CAN.

1

6

Page 7

Guía Del Propietario

Industrial y

Comercial

• INSTALACIÓN

• OPERACIÓN

• MANTENIMIENTO

• SERVICIO

LEA Y CONSERVE

ESTE MANUAL DE

ENFRIADOR EVAPORATIVO

MODELOS

INSTRUCCIÓN

IMPORTANTE

Anote cualquier daño en el recibo del transporte.

Cualquier demanda de daños por transporte se debe

presentar directamente con la compañía de

transportes.

El motor, la polea y la correa se venden por

separado.

CS11/16, CD11/16

CD21

Fecha de compra: _____________________

Comprado de: ____________________

1

Manual No. 70888

REV. 2/06

Page 8

INSTALACIÓN DEL ENFRIADOR EVAPORATIVO

PREPARACIÓN

1. Todo el trabajo eléctrico y de los conductos debe cumplir con los códigos locales y federales.

1. Haga los arreglos necesarios para subir el enfriador al techo (grúa, polea, etc.).

UBICACIÓN

1. No instale el enfriador cerca de salidas de extractores o de tubos de ventilación para evit ar que los humos y los olores penetren el

enfriador.

2. Asegure que la superficie de montaje sea lo suficientemente fuerte para soportar el peso del enfriador. El peso total del enfriador ya

instalado es mucho mayor del peso de transporte.

3. Coloque el enfriador de manera que entre aire fresco; pues el enfriador no recircula el aire.

UNIDADES DE MONTAJE PARA TECHO

1. Al seleccionar el lugar adecuado, tome en cuenta el tipo de construcción del techo y sigue las instrucciones para la instalación de

los conductos. Si al hacer el corte de abertura en el techo se afecta alguna viga de soporte, hay que reforzarla.

2. Compre o construya una plataforma de montaje para que el enfriador quede nivelado. Instale el enfriador dejando suficiente

espacio para permitir fácil acceso al sistema de desagüe.

Hay que medir el enfriador o ver la hoja de especificaciones para determinar el tamaño de la pl ataforma. La plataforma debe

3.

estar colocada de manera que la abertura de desagüe del enfriador este alineada con los conductos. En techos con

inclinación, la estructura de la plataforma puede recubrirse con lámina de acero galvanizado o con otras materiales a prueba de

agua. Hay que dejar una abertura o un panel de quita para permitir el acceso al sistema d e desa güe. En los enfriadores con

descarga hacia abajo, los conductos deben fijarse a la plataforma antes de poner el e nfria dor en su lugar. El conducto debe

tener una ceja para conectar la abertura de descarga del enfriador. Selle herméticamente la abertura en el techo donde entra

el conducto para que quede protegida de los elementos.

PRECAUCIÓN: PARA EVITAR RIESGO DE INCENDIO, CHOQUE ELÉCTRICO, O GRAVES DAÑOS PERSONALES, ASEGÚRESE

DE DESCONECTAR LA FUENTE DE PODER ANTES DE LIMPIAR O DAR SERVICIO AL ENFRIADOR

ADVERTENCIA: PARA REDUCIR EL RIESGO DE INCENDIO O CHOQUE ELÉCTRICO; NO USE ESTE ENFRIADOR CON NINGÚN

CONTROL DE VELOCIDAD DE ESTADO SÓLIDO.

CONDUCTOS

1. La regla mas importante a seguir al diseñar los conductos es: PARA QUE EL ENFRIADOR FUNCIONE ÓPTIMAMENTE ES

NECESARIO QUE EL CONDUCTO PERMITA PASAR UN GRAN VOLUMEN DE AIRE A ALTA VELOCIDAD.

2. No “reduzca” la abertura de descarga del enfriador

3. No permita que los conductos sean menores a la abertura de la salida de la descarga. (En la mayoría de los casos, los conductos

para aire acondicionado son demasiado pequeños para los enfriadores).

4. Conductos demasiado largos causan presión estática, reducen el flujo de aire y también absorben calor y disminuyen la efectividad

del aire frío.

5.

Los ángulos o dobleces abruptos obstruyen el flujo de aire.

6.

Los difusores de techo mal diseñados estropean una buena instalación. Instale difus ores diseñados exclusivamente para uso en

enfriadores evaporativos.

7.

La polea del motor puede ajustarse para compensar el sistema de conductos.

INSTALACIÓN DEL MOTOR

Una vez que el enfriador este en su lagar y nivelado, saque el motor de su caja y revis e si hay daños de transporte. Asegúrese que el

voltaje del motor, fase y caballaje sean los correctos. Coloque el motor sobre la base para motor según lo mostrado. Use las ranuras

para alinear la polea del motor con la polea del ventilador.

AJUSTE DE LA CORREA

Una correa mal ajustada acortara la vida del motor. La tensión óptima de la correa es una desviación de ¾ pulgad as al hacer presión

con el dedo de la mano. No use la polea del motor para ajustar la tensión de la correa. Siempre use la base del motor para hacer el

ajuste de la correa.

2

Page 9

AJUSTES DE LA POLEA DEL MOTOR

Antes de instalar la polea del motor, afloje el tornillo de fijación en la parte interna de la pole a y gire la

parte exterior de la polea hasta que quede completamente cerrada. Coloque el tornillo d e fijación en

la superficie plana más cercana en la rosca y luego gire 4 o 5 vueltas la parte exterior de la polea.

Coloque el tornillo de fijación en la superficie plana más cercana en la rosc a y apriete el tornillo de

fijación. Coloque la polea en el eje del motor y apriete el tornillo de fijación del antero.

equipado con una polea de dos acanaladuras.

El CD21 es

INSTALACIÓN DEL TUBO DE DESBORDAMIENTO

Coloque la arandela de goma en la boquilla de desagüe. Deslice de arriba hacia abajo, el boquilla a través de la abertura del desagüe

en el fondo del enfriador. Apriete la tuerca en el boquilla por la parte de abajo del enfriador. Coloque e l tubo de desbordamiento a la

boquilla.

PRECAUCIÓN: NO INSTALE ESTE ENFRIADOR A NINGÚN SISTEMA DE SUAVIZADOR DE AGUA. ESTO CANCELARÁ LA

GARANTÍA.

CONEXIÓN DE AGUA

El flotador montaje en un agujero in el poste esquina (descarga debajo) o en el panel frente (descarga lateral).

El nivel de agua debe permanecer ½ pulgadas por debajo de la parte superior del tub o d e desbordamiento.

Para ajustar el nivel de agua se puede usar el tornillo que esta en el flota dor o doblar la varilla del flotador.

EQUIPO ANTISARRO

En áreas con agua dura se puede instalar un equipo antisarro para disolv er pequeños residuos de minerales y

así permitir el flujo de agua fresca.

CORRIENTE ELÉCTRICA

1. La instalación del cableado eléctrico debe cumplir con todos los requisitos locales y federales y debe

efectuada por un electricista certificado.

2.

Conectar el motor y/o bomba al voltaje equivocado cancelará la garantía.

Advertencia: Para evitar el riesgo de choque eléctrico, desconecte la fuente de poder antes de abrir o de iniciar el servicio de esta

DEPOSITO

unidad.

Noticia al Instalador: El amperaje del motor debe ser menos del amperaje que indica la placa del motor si n manejar la

DIAGRAMAS DEL CABLEADO

Monofásico; una y dos velocidades

Trifásico, una y dos velocidades. El arrancador del motor debe tener protector de sobrecarga de la capacid ad adecuada para recibir el

amperaje total del motor.

Los arrancadores y sobrecargas del motor no se proveen con las unidades.

bomba.

3

Page 10

INICIO DE OPERACIONES

Después de instalar el enfriador y antes de llenarlo con agua:

1. Abra las ventanas y las puertas u otras salidas de ventilación del edificio.

2. Encienda el enfriador y revise el amperaje en la línea de entrada blanca, usando un amperímetro. Si la lectura del amperaje es

mayor que el indicado en la placa del motor, vea las instrucciones del ajuste de la polea del motor (pagina 3) y abra la polea ½

vuelta. Vuelva a encender el enfriador y revise el amperaje otra vez. Si la lectura del amperaje es menor que el indicado en la

placa del motor, cierra la polea ½ vuelta. Vuelva a encender el enfriador y revise el amperaje otra vez.

3. Abra el suministro de agua hacia el enfriador y revise que no haya fugas.

4. Llene el deposito de agua ½ pulgadas por debajo de la parte alta del tubo de desbordamiento y asegúrese que el flotador corte

completamente el flujo de agua.

Ponga el encendido en frío y revise que el agua este saliendo de las charolas para agua y que los filtros se humedezcan

5.

uniformemente. En la parte superior de las rejillas se encuentran los tornillos para nivelar las charolas de agua.

MANTENIMIENTO

PRECAUCIÓN: Desconecte la corriente eléctrica que alimente esta unidad antes de abrir o iniciar servicio.

Revise regularmente el enfriador por fugas, correas flojas, tuberías tapadas, alineamiento de la correa y exceso de sarro en los filtros.

Inspeccione si hay oxidación en el gabinete. Si aparecen manchas de oxido, líje las y píntelas con pintura anticorrosiva.

LUBRICACIÓN

Lubrique los recipientes para aceite localizados en las chumaceras del ventilador. Use SAE 20W

o 30W aceite sin acción detergente. Lubrique el motor del ventilador si esté equipado con

receptáculos para aceite. Algunos motores están permanente prelubricados de fábrica.

CAMBIO DE FILTROS

Es el mejor cambiar los filtros al fin de la temperada. Cuando filtros viejos (cubiertos con los

minerales y las sales) se dejan en el enfriador durante los meses mojados del inv ierno, hay una

mayor posibilidad de la corrosión.

1. Retire la rejilla del enfriador.

2. Desenganche los sujetadores de los lados de las rejillas y quítelos.

3. Quite el filtro usado y deséchelo

4. Limpie todos los residuos y sedimentos que se hayan acumulado en las rejillas. Revise la

charlo para agua y limpie los residuos y sedimentos que se hayan acumu lado en las

ranuras para agua. Si las rejillas tienen manchas de oxido, líjelas y píntelas con

pintura anticorrosiva.

5. Coloque el filtro nuevo en la rejilla, asegurando que no queden espacios que perm itan que

pase aire caliente sin ser filtrado y vuelva a enganchar los sujetadores.

6.

Recoloque las sujetadores.

Esta garantía se extiende solamente al comprador original. No cubre daños ocurridos durante el transporte por causa de

accidentes, negligencia o abuso por el propietario. Essick Air Products no autoriza a ninguna p ersona o representante para asumir

cualquier otra o diferente responsabilidad civil en relación a este enfria dor.

Garantía por cinco años sobre la cubeta de agua por filtraciones causadas por corrosión. Todas las demás piezas originales

suministradas por Essick Air Products están garantizadas contra defectos del material o de mano de obra por un año.

Essick Air Products no es responsable por daños incidentales o consecuentes como resultado de un funcionamiento defectuoso.

Essick Air Products no es responsable por ningún daño causado por el uso de ablanda dores de agua, productos químicos, material

anticorrosivo, o si se utiliza un motor con más caballos de fuerza de los recomendados por Essick Air Products para esta unidad.

Essick Air Products no es responsable por el costo de las visitas de servicio para diagnosticar la causa del problema, o los costos por

la mano de obra para reparar y/o reemplazar piezas.

Contactar al concesionario donde compró el enfriador evaporativ o. Si por alguna razón no está satisfecho con la

respuesta del concesionario, contactar el Servicio de Atención al Cliente; Essick Air Products Inc.; 5800 Murray Street,

Little Rock, Arkansas 72209. Teléfono 1-800-643-8341.

GARANTÍA LIMITADA

TÉRMINOS Y CONDICIONES DE LA GARANTÍA

EXCLUSIONES DE LA GARANTÍA

COMO OBTENER SERVICIO BAJO ESTA GARANTÍA

4

Loading...

Loading...