Page 1

ECP

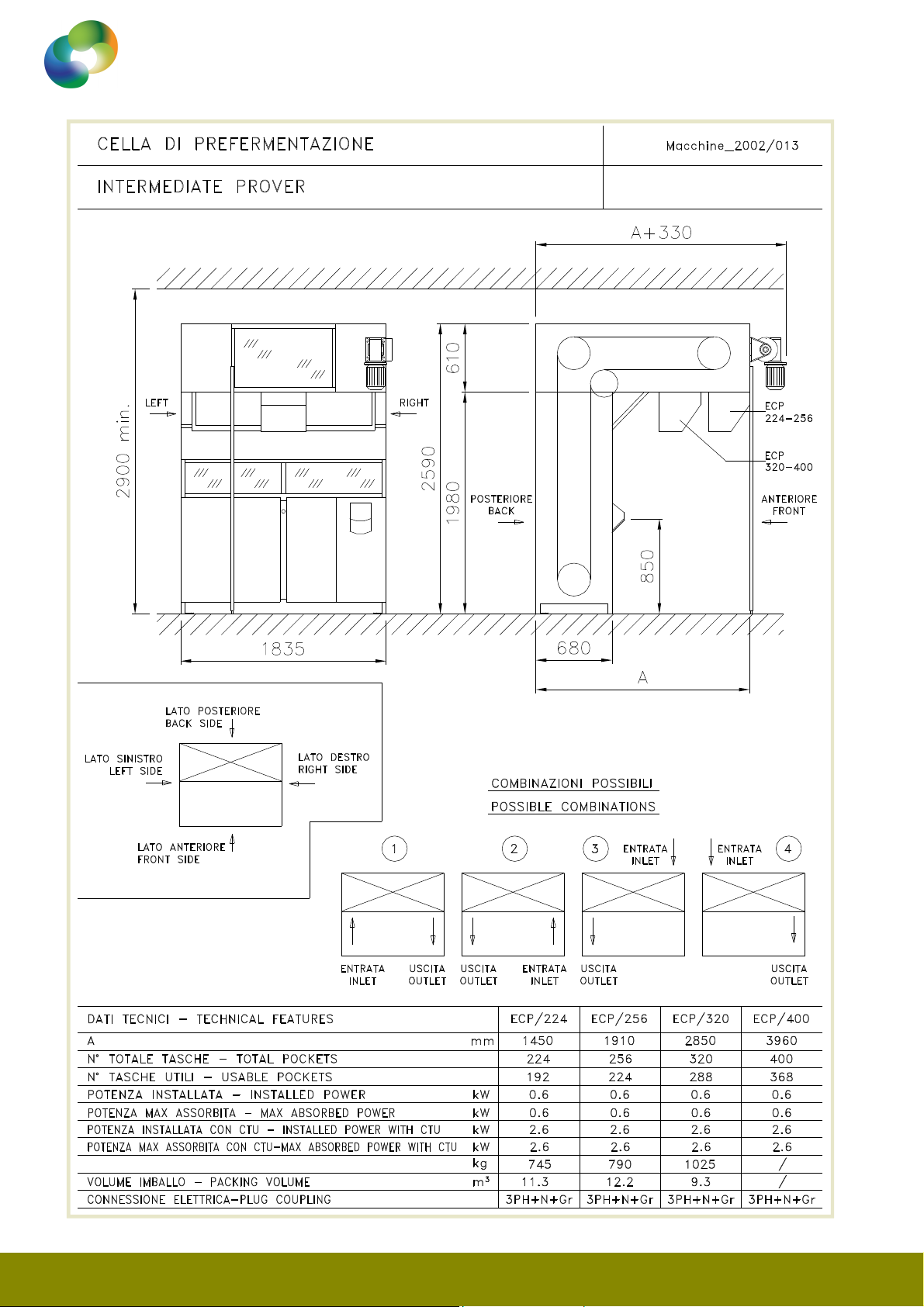

Automatic intermediate proofer

The ECP prover is generally used in automatic bread-making lines for proving portions of dough after dividing and rounding

operations and before moulding and final leavening, thus ensuring the continuity of the production cycle at the preset production

rhythm. The ECP prover is therefore designed and dimensioned - depending on needs - to give the portions an adequate rest

time, inside a closed structure, with controlled conditioning on request.

The ECP prover is usually fed by AC conical rounders and AT

counter-moving belt rounders, or directly by volumetric

dividers with built-in roller device. The discharge end is usually

combined with long moulders for baguettes, long moulders for

small loaves and tin bread and moulders for large soave.

ECP provers are supplied in four standard models. However,

as it is a machine prevalently ordered to specific customer

1/1 version 00 december 2014

needs, the provers can be built in special versions whose

performance differs from the other models; in these cases, the

dimensions and number of pockets for every gutter, the

number of gutters and the automatic loading system are

defined on the basis of the requested portions, the rest times

and working rhythm.

Standard features

The support structure and casings are made of steel

sections and sheets painted with dual cycle anticorrosion treatment using epoxy powders (food contact).

The pocket gutters are made of galvanized steel tubing.

The pockets containing dough portions are made of

nylon mesh.

The motor drive, connected to the microswitch-

controlled automatic loading device, adjusts the

intermittent feed of gutters with a chain transmission

system.

24V low voltage electric control panel, with three sockets

for the connection of other machines.

Germicide lamp with UV ray.

MODELS

ECP 224 Intermediate prover with 224 pocket capacity - 192 useful.

ECP/256 Intermediate prover with 256 pocket capacity - 224 useful.

ECP/320 Intermediate prover with 320 pocket capacity - 288 useful.

ECP/400 Intermediate prover with 400 pocket capacity - 368 useful.

Description

ECP proofer in an automatic line for baguettes

Standard performance

Dough portion weight from 200/300 up to 1300 gr

Maximum working rhythm 1200 pcs./h. according to the rest

time.

Possibility to anticipate the piece unloading of 1/8 or 2/8 of

the maximum rest time.

Unloading chute allowing to receive the dough piece from the

last three exits.

CALCULATION OF THE MAX. REST TIME WITH

REFERENCE TO THE HOURLY OUTPUT:

Example: ECP/224 (192 useful pockets) and hourly output = 900

pieces.

900 pieces/hour : 60 = 15 pieces/minute

192 useful pockets: 15= 12,8 rest minutes

Option

CTU Automatic device for humidity and heating production and control

ESMACH S.p.A. Tel. + 039 0444 419777 sales@esmach.com - www.esmach.com

Description

Page 2

Intermediate prover ECP

MASSA/WEIGHT

ESMACH S.p.A. Tel. + 039 0444 419777 sales@esmach.com - www.esmach.com

Loading...

Loading...