Page 1

ESI

ESI

Excel Semiconductor inc.

ES29LV160D

16Mbit(2M x 8/1M x 16)

CMOS 3.0 Volt-only, Boot Sector Flash Memory

GENERAL FEATURES

• Single power supply operation

- 2.7V -3.6V for read, program and erase operations

•Sector Structure

- 16Kbyte x 1, 8Kbyte x 2, 32Kbyte x 1 boot sectors

- 64Kbyte x 31 sectors

• Top or Bottom boot block

- ES29LV160DT for Top boot block device

- ES29LV160DB for Bottom boot block device

• Package Options

- 48-pin TSOP

- 48-ball FBGA ( 6 x 8 mm )

- Pb-free packages

- All Pb-free products are RoHS-Compliant

• Low Vcc write inhibit

• Manufactured on 0.18um process technology

• Compatible with JEDEC standards

- Pinout and software compatible with single-power

supply flash standard

DEVICE PERFORMANCE

• Read access time

- 90ns/120n for normal Vcc range ( 2.7V - 3.6V )

- 70ns for regulated Vcc range ( 3.0V - 3.6V )

• Program and erase time

- Program time : 6us/byte, 8us/word ( typical )

- Sector erase time : 0.7sec/sector ( typical )

• Power consumption (typical values)

- 200nA in standby or automatic sleep mode

- 9mA active read current at 5 MHz

- 15mA active write current during program or erase

• Minimum 100,000 program/erase cycles per sector

• 20 Year data retention at 125

o

C

SOFTWARE FEATURES

• Erase Suspend / Erase Resume

• Data# poll and toggle for Pro gr a m/erase status

• CFI ( Common Flash Interface) supported

• Unlock Bypass program

• Autoselect mode

• Auto-sleep mode after t

ACC

+ 30ns

HARDWARE FEATURES

• Hardware reset input pin ( RESET#)

- Provides a hardware reset to device

- Any internal device operation is terminated and the

device returns to read mode by the reset

• Ready/Busy# output pin ( RY/BY#)

- Provides a program or erase operational status

about whether it is finished for read or still being

progressed

• Sector protection / unprotection ( RESET# , A9 )

- Hardware method of locking a sector to prevent

any program or erase operation within that sector

- Two methods are provided :

- In-system method by RESET# pin

- A9 high-voltage method for PROM programmers

• Temporary Sector Unprotection ( RESET# )

- Allows temporary unprotection of previously

protected sectors to change data in-system

ES29LV160D

1

Rev. 1C Jan 5 , 2006

Page 2

GENERAL PRODUCT DESCRIPTION

ESI

ESI

Excel Semiconductor inc.

The ES29LV160 is a 16 megabit, 3.0 volt-only flash

memory device, organized as 2M x 8 bits (Byte

mode) or 1M x 16 bits (Word mode) which is configurable by BYTE#. Four boot sectors and thirty one

main sectors are provided : 16Kbytes x 1, 8Kbytes

x 2, 32Kbytes x 1 and 64Kbytes x 31. The device is

manufactured with ESI’s proprietary, high performance and highly reliable 0.18um CMOS flash

technology. The device can be programmed or

erased in-system with standard 3.0 Volt Vcc supply

( 2.7V-3.6V) and can also be programmed in standard EPROM programmers. The device of fers minimum endurance of 100,000 program/erase cycles

and more than 10 years of data retention.

The ES29LV160 offers access time as fast as 70ns

or 90ns, allowing operation of high-speed microprocessors without wait states. Three separate control

pins are provided to eliminate bus contention : chip

enable (CE#), write enable (WE#) and output

enable (OE#).

All program and erase operation are automatically

and internally performed and controlled by embedded program/erase algorithms built in the device.

The device automatically generates and times the

necessary high-voltage pulses to be applied to the

cells, performs the verification, and counts the number of sequences. Some status bits (DQ7, DQ6 and

DQ5) read by data# polling or toggling between

consecutive read cycles provide to the users the

internal status of program/erase operation: whether

it is successfully done or still being progressed.

The ES29LV160 is completely compatible with the

JEDEC standard command set of single power supply Flash. Commands are written to the internal

command register using standard write timings of

microprocessor and data can be re ad out from the

cell array in the device with the same way as used i n

other EPROM or flash devices.

ES29LV160D

2

Rev. 1C Jan 5 , 2006

Page 3

PRODUCT SELECTOR GUIDE

Family Part Number ES29LV160

Voltage Range 3.0 ~ 3.6V 2.7 ~ 3.6V

Speed Option 70R 90 120

Max Access Time (ns) 70 90 120

CE# Access (ns) 70 90 120

OE# Access (ns) 35 40 50

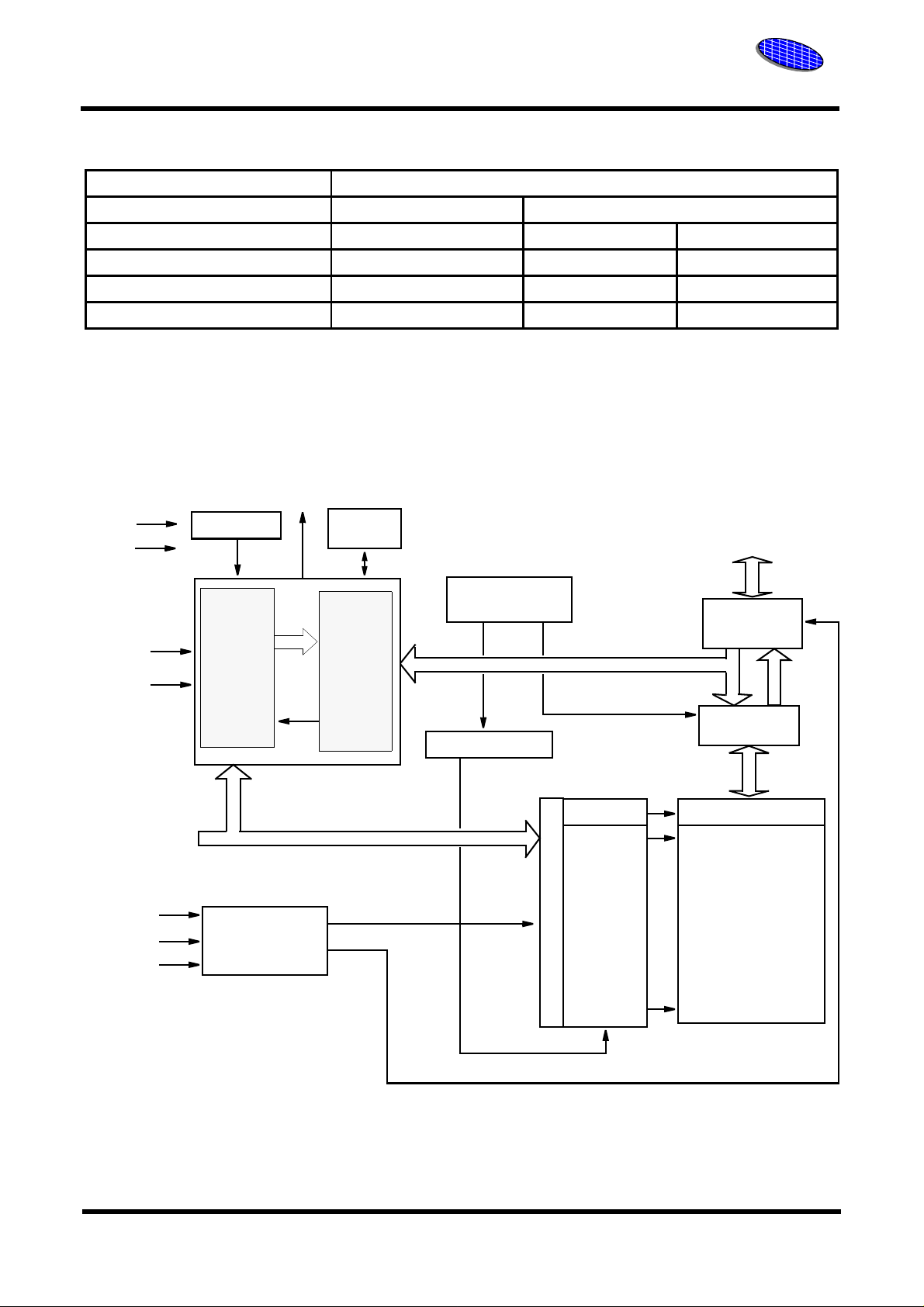

FUNCTION BLOCK DIAGRAM

RY/BY#

ESI

ESI

Excel Semiconductor inc.

Vcc

Vss

WE

RESET#

A<0:19>

CE#

OE#

BYTE#

Vcc Detector

#

Command

Register

Chip Enable

Output Enable

Logic

Timer/

Counter

Write

State

Machine

Analog Bias

Generator

Sector Switches

Y-Decoder

X-Decoder

Address Latch

DQ0-DQ15(A-1)

Input/Output

Buffers

Data Latch/

Sense Amps

Y-Decoder

Cell Array

ES29LV160D

3

Rev. 1C Jan 5 , 2006

Page 4

PIN DESCRIPTION

Pin Description

A0-A19 20 Addresses

DQ0-DQ14 15 Data Inputs/Outputs

DQ15/A-1

CE# Chip Enable

OE# Output Enable

WE# Write Enable

RESET# Hardware Reset Pin, Active Low

BYTE# Se lects 8-bit or 16-bit mode

RY/BY# Ready/Busy Output (N/A SO 044)

Vcc

Vss Device Ground

NC Pin Not Connected Internally

Excel Semiconductor inc.

DQ15 (Data Input/Output, Word Mode)

A-1 (LSB Address Input, Byte Mode)

3.0 volt-only single power supply

(see Product Selector Guide for speed options and voltage supply tolerances)

ESI

ESI

LOGIC SYMBOL

20

A0 ~ A19

CE#

OE#

WE#

RESET#

BYTE#

16 or 8

DQ0 ~ DQ15

(A-1)

RY/BY#

(N/A SO 044)

ES29LV160D

4

Rev. 1C Jan 5 , 2006

Page 5

CONNECTION DIAGRAM

ESI

ESI

Excel Semiconductor inc.

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48-Pin Standard TSOP

ES29LV160

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

Vss

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

Vcc

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

Vss

CE#

A0

48-Ball FBGA (6 x 8 mm)

(Top View, Balls Facing Down)

A B C D E F G H

6

5

4

3

2

1

A13 A12

A9

WE#

RY/

BY#

A7

A3

A8

RESET#

NC

A17

A4

A14

A10

NC

A18

A6

A2

A15

A16

A11 DQ7

A19

NC

A5

DQ5

DQ2

DQ0

A0A1

BYTE#

DQ14

DQ12

DQ10 DQ11 DQ3

DQ8 DQ9 DQ1

DQ15/

A-1

DQ13

Vcc

OE#CE#

Vss

DQ6

DQ4

Vss

ES29LV160D

5

Rev. 1C Jan 5 , 2006

Page 6

DEVICE BUS OPERATIONS

ESI

ESI

Excel Semiconductor inc.

Several device operational modes are provided in

the ES29LV160 device. Commands are used to initiate the device operations. They are latched and

stored into internal registers with the address and

data information needed to execute the device

operation.

The available device operational modes are listed

in Table 1 with the required inputs, controls, and the

resulting outputs. Each operational mode is

described in further detail in the following subsections.

Read

The internal state of the device is set for the read

mode and the device is ready for reading arra y da t a

upon device power-up, or after a hardware reset. To

read the stored data from the cell array of the

device, CE# and OE# pins should be driven to V

while WE# pin remains at VIH. CE# is the power

control and selects the device. OE# is the output

control and gates array data to the output pins.

Word or byte mode of output data is determined by

the BYTE# pin. No additional command is needed

in this mode to obtain array data. Standard microprocessor read cycles that assert valid addresses

on the device address inputs produce valid data on

the device data outputs. The device st ays at the read

mode until another operation is activated by writing

commands into the internal command register. Refer

to the AC read cycle timing diagrams for further

details ( Fig. 16 ).

Word/Byte Mode Configuration ( BYTE# )

The device data output can be configured by BYTE#

into one of two modes : word and byte modes. If the

BYTE# pin is set at logic ‘1’, the device is configured

in word mode, DQ0 - DQ15 are active and controlled

by CE# and OE#. If the BYTE# pin is set at logic ‘0’,

the device is configured in byte mode, and only data

I/O pins DQ0 - DQ7 are active and controlled by CE#

and OE#. The data I/O pins DQ8 - DQ14 are tristated, and the DQ15 pin is used as an input for the

LSB (A-1) address.

IL

Standby Mode

When the device is not selected or activated in a

system, it needs to stay at the standby mode, in

which current consumption is greatly reduced with

outputs in the high impedance state.

ES29LV160D

6

Rev. 1C Jan 5 , 2006

Page 7

ESI

ESI

Excel Semiconductor inc.

The device enters the CMOS standby mode when

CE# and RESET# pins are both held at Vcc

(Note that this is a more restricted voltage range

than V

not within Vcc

standby mode, but the standby current will be

greater than the CMOS standby current (0.2uA typically). When the device is in the standby mode, only

standard access time (t

access, before it is ready for read data. And even if

the device is deselected by CE# pin during erase or

programming operation, the device draws active cur rent until the operation is completely done. While the

device stays in the standby mode, the output is

placed in the high impedance state, independent of

the OE# input.

The device can enter the deep power-down mode

where current consumption is greatly reduced down

to less than 0.2uA typically by the following three

ways:

- CMOS standby ( CE#, RESET# = Vcc + 0.3V )

Refer to the CMOS DC characteristics Table11 for

further current specification .

) If CE# and RESET# are held at VIH, but

IH.

+

0.3V, the device will be still in the

) is required for read

CE

- During the device reset ( RESET# = Vss

- In Autosleep Mode ( after t

ACC

+ 30ns )

+

0.3V.

+ 0.3V )

Autosleep Mode

The device automatically enters a deep power-down

mode called the autosleep mode when addresses

remain stable for t

consumption is greatly reduced ( less than 0.2uA

typical ), regardless of CE#, WE# and OE# control

signals.

+30ns. In this mode, current

ACC

Writing Commands

To write a command or command sequences to initiate some operations such as program or erase, the

system must drive WE# and CE# to V

. For program operations, the BYTE# pin deter-

V

IH

mines whether the device accepts pro gram data in

bytes or words. Refer to “BYTE# timings for Write

Operations” in the Fig. 19 for more information.

, and OE# to

IL

Unlock Bypass Mode

To reduce more the programming time, an unlockbypass mode is provided. Once the device enters

this mode, only two write cycles are required to initiate the programming operation instead of four

cycles in the normal program command sequences

which are composed of two unlock cycles, program

set-up cycle and the last cycle with the program data

and addresses. In this mode, two unlock cycles are

saved ( or bypassed ).

Sector Addresses

The entire memory space of cell array is divided into

a many of small sectors: 16Kbytes x 1, 8Kbytes x 2,

32Kbytes x 1 and 64Kbytes x 31 main sectors. In

erase operation, a single sector, multiple sectors, or

the entire device (chip erase) can be selected for

erase. The address space that each sector occupies

is shown in detail in the Table 3-4.

Autoselect Mode

Flash memories are intended for use in applications

where the local CPU alters memory contents. In

such applications, manufacturer and device identification (ID) codes must be accessible while the

device resides in the target system ( the so called

“in-system program”). On the other hand, signature

codes have been typically accessed by raising A9

pin to a high voltage in PROM programmers. However, multiplexing high voltage onto address lines is

not the generally desired system design practice.

Therefore, in the ES29LV160 device an autoselect

command is provided to allow the system to access

the signature codes without any high voltage. The

conventional A9 high-voltage method used in the

PROM programers for signature codes are still supported in this device.

If the system writes the autoselect command

sequence, the device enters the Autoselect mode.

The system can then read some useful codes such

as manufacturer and device ID from the int er na l re gisters on DQ7 - DQ0. Standard read cycle timings

apply in this mode. In the Autoselect mode, the following three informations can be acc essed through

either autoselect command method or A9 high-voltage autoselect method. Refer to the Table 2.

-

-

-

Manufacturer ID

Device ID

Sector protection verify

Hardware Device Reset ( RESET# )

The RESET# pin provides a hardware method of

resetting the device to read array data. When the

RESET# pin is driven low for at least a period of t

RP

,

ES29LV160D

7

Rev. 1C Jan 5 , 2006

Page 8

ESI

ESI

Excel Semiconductor inc.

the device immediately terminates any operation in

progress, tristates all output pins, and ignores all

read/write commands for the duration of the

RESET# pulse The device also resets the internal

state machine to reading array data. The operation

that was interrupted should be reinitiated once after

the device is ready to accept another command

sequence, to ensure data integrity.

CMOS Standby during Device Reset

Current is reduced for the duration of the RESET#

pulse. When RESET# is held at Vss

device draws the greatly reduced CMOS standby

current ( I

within Vss

). If RESET# is held at VIL but not

CC4

+

0.3V, the standby current will be greater.

+

0.3V, the

RY/BY# and Terminating Operations

If RESET# is asserted during a program or erase

operation, the RY/BY# pin remains a “0” (busy) until

the internal reset operation is completed, which

requires a time of t

rithms). The system can thus monitor RY/BY# to

determine whether the reset operation is completed.

If RESET# is asserted when a program or erase

operation is not executing (RY/BY# pin is “1”), the

reset operation is completed within a time of t

(not during Embedded Algorithms). The system can

read data after the RESET# pin returns to V

requires a time of t

READY

RH.

(during Embedded Algo-

READY

, which

IH

Sector protection can be implemented via two

methods.

-

-

To check whether the sector protection was successfully executed or not, another operation called

“protect verification” needs to be performed after

the protection operation on a sector. All protection

and protect verifications provided in the device are

summarized in detail at the Table 1.

In-system protection

A9 High-voltage protection

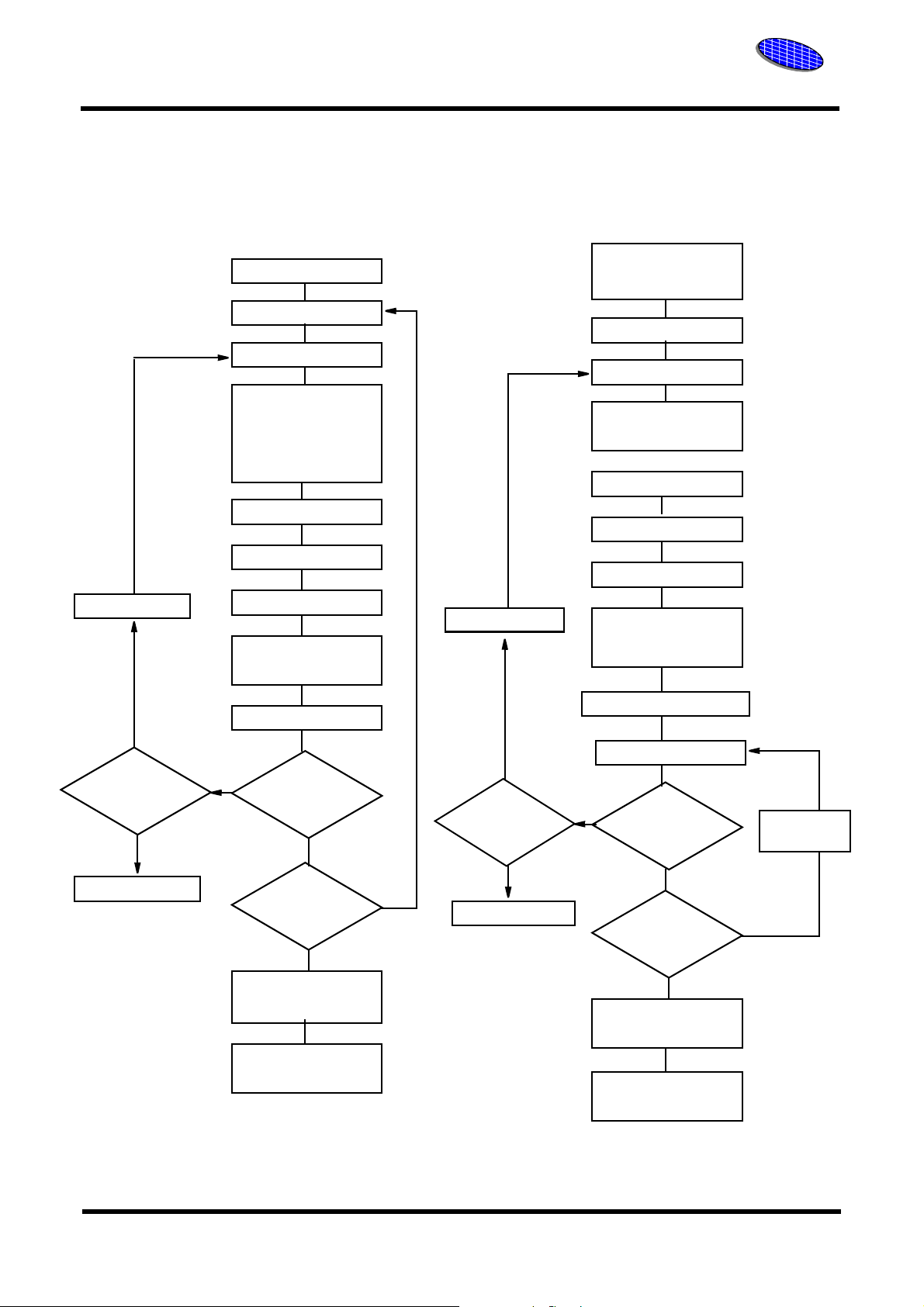

In-System Protection

“In-system protection”, the primary method,

requires V

A6=0, A1=1, and A0=0. This method can be implemented either in-system or via programming equipment. This method uses standard microprocessor

bus cycle timing. Refer to Fig. 26 for timing diagram

and Fig. 2 for the protection algorithm.

(11.5V~12.5V) on the RESET# with

ID

A9 High-Voltage Protection

“High-voltage protection”, the alternate method

intended only for programming equipment, must

force V

trol pin OE# with A6=0, A1=1 and A0=0. Refer to

Fig. 28 for timing diagram and Fig. 4 for the protection algorithm.

(11.5~12.5V) on address pin A9 and con-

ID

RESET# tied to the System Reset

The RESET# pin may be tied to the system reset circuitry. A system reset would thus also reset the

Flash memory , enab ling the system to read the bootup firmware from the Flash memory.Refer to the AC

Characteristics tables for RESET# parameters and

to Fig. 17 for the timing diagram.

SECTOR PROTECTION

The ES29LV160 features hardware sector protection. In the device, sector protection is performed on

the sector previously defined in the Table 3-4. Once

after a sector is protected, any program or erase

operation is not allowed in the protected sector. The

previously protected sectors must be unprotected by

one of the unprotect methods provided here before

changing data in those sectors.

SECTOR UNPROTECTION

The previously protected sectors must be unprotected before modifying any data in the sectors.

The sector unprotection algorithm unprotects all

sectors in parallel. All unprotected sectors must first

be protected prior to the first sector unprotection

write cycle to avoid any over-erase due to the intrinsic erase characteristics of the protection cell. After

the unprotection operation, all previously protected

sectors will need to be individually re-protected.

Standard microprocessor bus cycle timings are

used in the unprotection and unprotect verification

operations. Three unprotect methods are provided

in the ES29LV160 device. All unprotection and

unprotect verification cycles are summarized in

detail at the Table 1.

-

-

-

In-system unprotection

A9 High-voltage unprotection

T emporary sector unprotection

ES29LV160D

8

Rev. 1C Jan 5 , 2006

Page 9

ESI

ESI

Excel Semiconductor inc.

In-System Unprotection

“In-system unprotection”, the primary method,

requires V

(11.5V~12.5V) on the RESET# with

ID

A6=1, A1=1, and A0=0. This method can be implemented either in-system or via programming equipment. This method uses standard microprocessor

bus cycle timing. Refer to Fig. 26 for timing diagram

and Fig. 3 for the unprotection algorithm.

A9 High-Voltage Unprotection

“High-voltage unprotection”, the alternate method

intended only for programming equipment, must

force V

(11.5~12.5V) on address pin A9 and con-

ID

trol pin OE# with A6=1, A1=1 and A0=0. Refer to

Fig. 29 for timing diagram and Fig. 5 for the unprotection algorithm.

Temporary Sector Unprotect

This feature allows temporary unprotection of previously protected sectors to change data in-system.

The Sector Unprotect mode is activated by setting

the RESET# pin to V

(11.5V-12.5V). During this

ID

mode, formerly protected sectors can be programmed or erased by selecting the sector

addresses. Once V

is removed from the RESET#

ID

pin, all the previously protected sectors are protected again. Fig. 1 shows the algorithm, and Fig. 25

shows the timing diagrams for this feature.

HARDWARE DATA PROTECTION

The command register and all internal program/

erase circuits are disabled, and the devi ce resets to

the read mode. Subsequent writes are ignored until

Vcc is greater than V

. The system must provide

LKO

proper signals to the control pins to prevent unintentional writes when Vcc is greater than V

LKO

.

Write Pulse “Glitch” Protection

Noise pulses of less than 5ns (typical) on OE#, CE#

or WE# do not initiate a write cycle.

Logical inhibit

Write cycles are inhibited by holding any one of

OE#=V

, CE#=VIH or WE#=VIH. To initiate a write

IL

cycle, CE# and WE# must be a logical zero while

OE# is a logical one.

Power-up Write Inhibit

If WE#=CE#=VIL and OE#=VIH during power up,

the device does not accept any commands on the

rising edge of WE#. The internal state machine is

automatically reset to the read mode on power-up.

START

RESET# = V

(Note 1)

ID

The ES29LV160 device provides some protection

measures against accidental erasure or programming caused by spurious system level signals that

may exist during power transition. During power-up,

all internal registers and latches in the device are

cleared and the device automatically resets to the

read mode. In addition, with its internal state

machine built-in the device, any alteration of the

memory contents or any initiation of new operationcan only occur after successful completion of specific command sequences. And several features are

incorporated to prevent inadvertent write cycles

resulting from Vcc power-up and power -dow n tr an sition or system noise.

Low Vcc Write inhibit

When Vcc is less than V

accept any write cycles. This protects data during

Vcc power-up and power-down.

ES29LV160D

, the device does not

LKO

9

Perform Erase or

Program Operations

RESET# = V

Temporary Sector

Unprotect Completed

(Note 2)

Notes:

1. All protected sectors are unprotected .

2. All previously protected sectors are protected once again.

IH

Figure 1. Temporary Sector Unprotect

Operation

Rev. 1C Jan 5 , 2006

Page 10

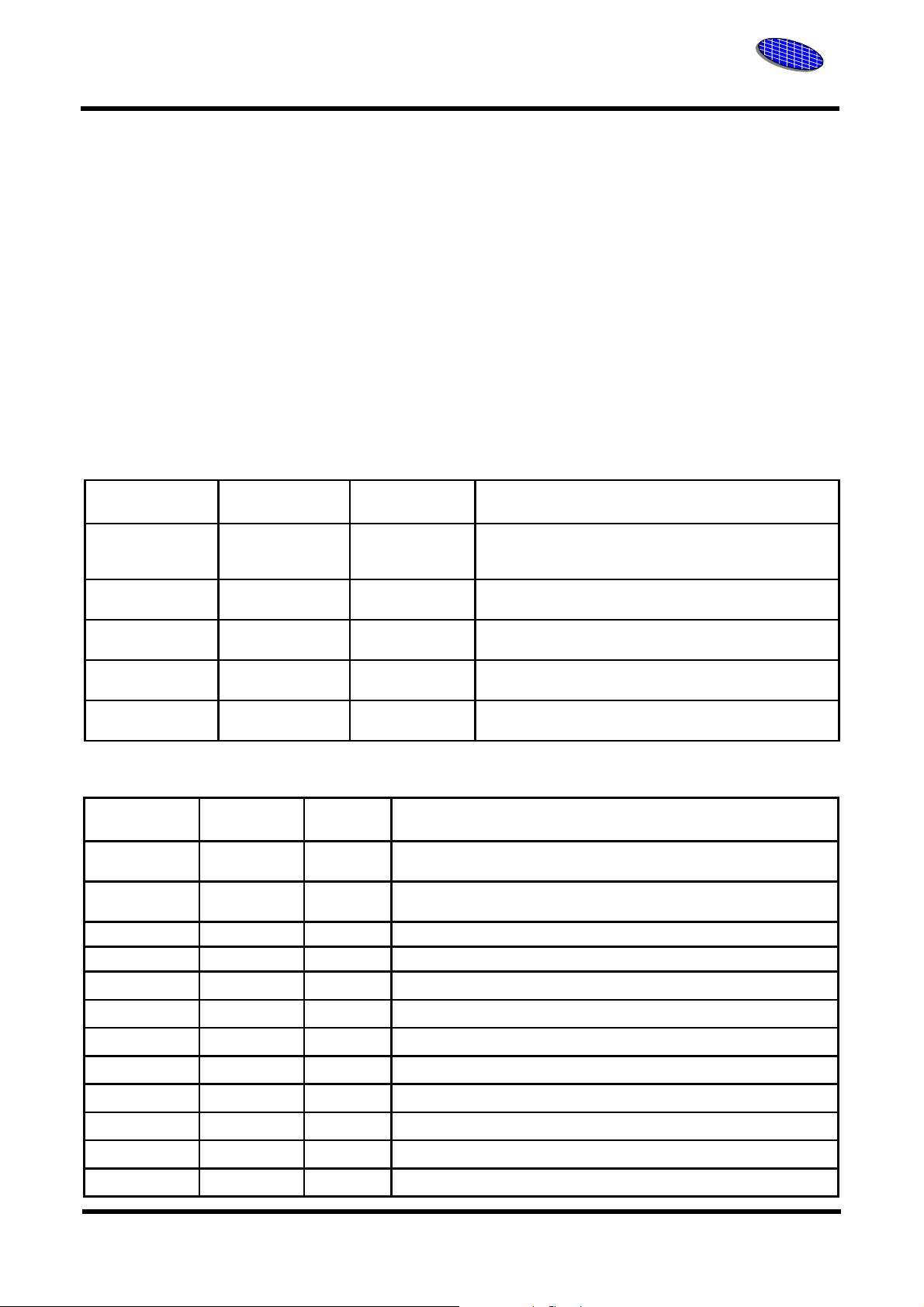

Table 1. ES29LV160 Device Bus Operations

ESI

ESI

Excel Semiconductor inc.

Operation CE# OE# WE# RESET# Addresses

Read

Write

Standby

Output Disable

Reset

In-system

A9 High-Voltage Method

L

L

Vcc+

0.3V

L H H H X High-Z High-Z

X X X L X High-Z High-Z

Sector Protect

(Note 2)

Sector Unprotect

(Note 2) L H L V

Temporary Sector

Unprotect X X X

Sector protect

Sector unprotect

LHL

L

L

H

L

L

H

XX Vcc+

V

L

ID

V

L

ID

H

H

0.3V

V

V

H

H

DQ0

~

(Note 1)

A

IN

A

IN

X High-Z High-Z

ID

ID

ID

SA,A6=L,

A1=H,A0=L

SA,A6=H,

A1=H,A0=L

A

IN

SA,A9=V

A6=L,

A1=H,A0=L

SA,A9=V

A6=H,

A1=H,A0=L

DQ7

D

OUT

(Note 3) (Note 3)

(Note 3) X X

(Note 3) X X

(Note 3) (Note 3) High-Z

,

ID

(Note 3) (Note 3) High-Z

,

ID

BYTE#

= V

D

OUT

DQ8~DQ15

IH

BYTE#

= V

IL

DQ8~DQ14 = High-Z,

DQ15 = A-1

High-Z

Legend:

D

L=Logic Low=VIL, H=Logic High=VIH, VID=11. 5-12.5V, X=Don’t Care, SA=Sector Address, AIN=Address In, DIN=Data In,

=Data Out

OUT

Notes:

1. Addresses are A19:A0 in word mode (BYTE#=VIH) , A19:A-1 in byte mode (BYTE#=VIL).

2. The sector protect and sector unprotect functions may also be implemented via programming equipment. See the “Sector Pro tection and Unprotection” section.

3. D

IN

or D

as required by command sequence, data polling, or sector protection algorithm.

OUT

Table 2. Autoselect Codes (A9 High-Voltage Method)

A19

Description CE# OE# WE#

ManufactureID:ESI

Device ID:

ES29LV160

Sector Protection

Verification

Legend:

T= Top Boot Block, B = Bottom Boot Block, L=Logic Low=VIL, H=Logic High=VIH, SA=Sector Address, X = Don’t care

L

L

LLHX X

LLHSAX

A12

H

A11

to

to

A10

XX

A9A8toA7A6

V

XLXLL X

ID

V

X L X L H 22h X C4h(T),49h(B)

ID

V

XLXHL X X

ID

A5

toA2A1 A0

DQ8~DQ15

BYTE#

= V

IH

BYTE#

= V

IL

X4Ah

DQ7~DQ0

01h(protected)

00h(unprotected)

ES29LV160D

10

Rev. 1C Jan 5 , 2006

Page 11

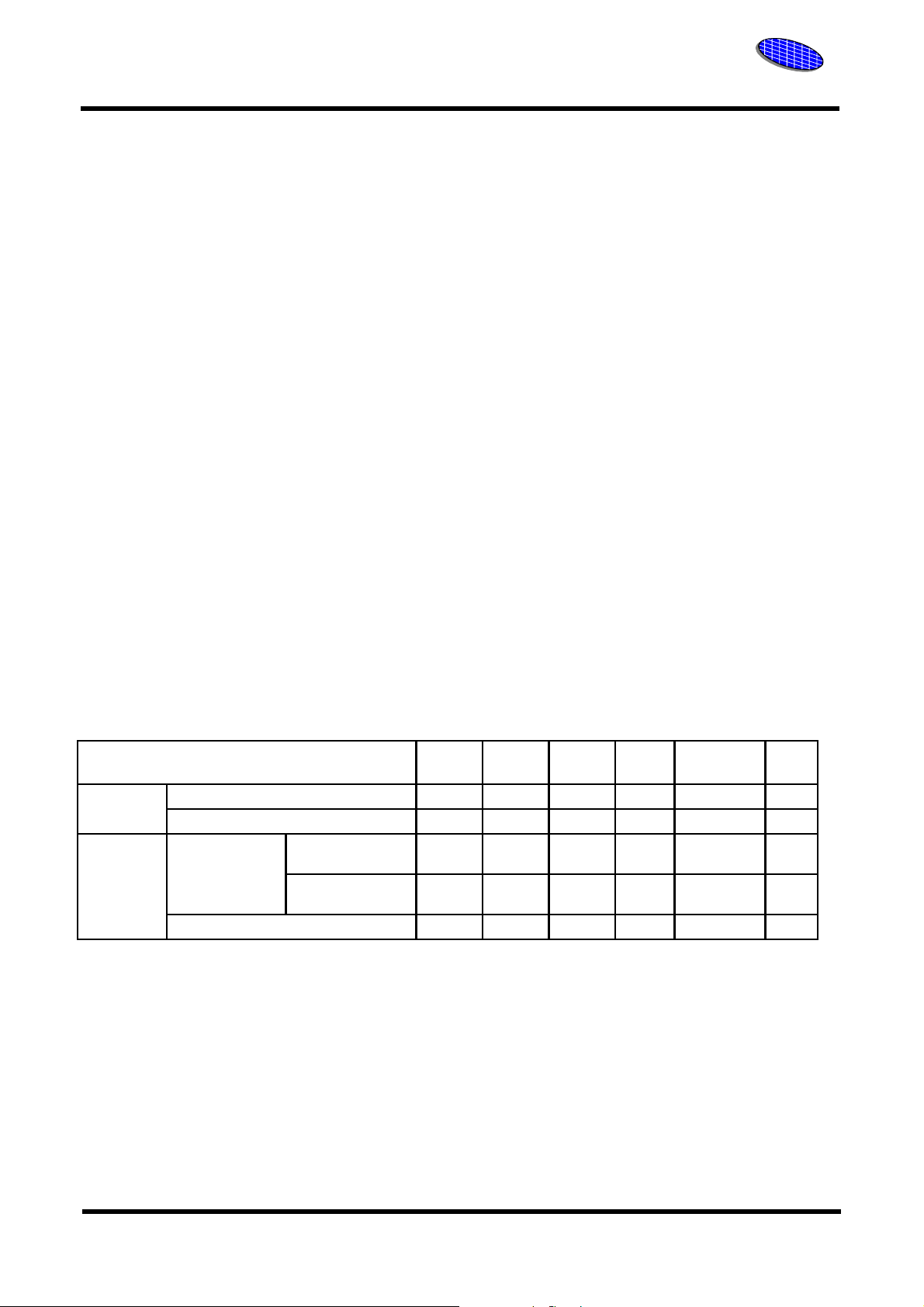

Table 3. Top Boot Sector Addresses (ES29LV160DT)

ESI

ESI

Excel Semiconductor inc.

Sector

SA0 00000XXX 64/32 000000h~00FFFFh 00000h~07FFFh

SA1 00001XXX 64/32 010000h~01FFFFh 08000h~0FFFFh

SA2 00010XXX 64/32 020000h~02FFFFh 10000h~17FFFh

SA3 00011XXX 64/32 030000h~03FFFFh 18000h~1FFFFh

SA4 00100XXX 64/32 040000h~04FFFFh 20000h~27FFFh

SA5 00101XXX 64/32 050000h~05FFFFh 28000h~2FFFFh

SA6 00110XXX 64/32 060000h~06FFFFh 30000h~37FFFh

SA7 00111XXX 64/32 070000h~07FFFFh 38000h~3FFFFh

SA8 01000XXX 64/32 080000h~08FFFFh 40000h~47FFFh

SA9 01001XXX 64/32 090000h~09FFFFh 48000h~4FFFFh

SA10 01010XXX 64/32 0A0000h~0AFFFFh 50000h~57FFFh

SA11 01011XXX 64/32 0B0000h~0BFFFFh 58000h~5FFFFh

SA12 01100XXX 64/32 0C0000h~0CFFFFh 60000h~67FFFh

SA13 01101XXX 64/32 0D0000h~0DFFFFh 68000h~6FFFFh

SA14 01110XXX 64/32 0E0000h~0EFFFFh 70000h~77FFFh

SA15 01111XXX 64/32 0F0000h~0FFFFFh 78000h~7FFFFh

SA16 10000XXX 64/32 100000h~10FFFFh 80000h~87FFFh

SA17 10001XXX 64/32 110000h~11FFFFh 88000h~8FFFFh

SA18 10010XXX 64/32 120000h~12FFFFh 90000h~97FFFh

SA19 10011XXX 64/32 130000h~13FFFFh 98000h~9FFFFh

SA20 10100XXX 64/32 140000h~14FFFFh A0000h~A7FFFh

SA21 10101XXX 64/32 150000h~15FFFFh A8000h~AFFFFh

SA22 10110XXX 64/32 160000h~16FFFFh B0000h~B7FFFh

SA23 10111XXX 64/32 170000h~17FFFFh B8000h~BFFFFh

SA24 11000XXX 64/32 180000h~18FFFFh C0000h~C7FFFh

SA25 11001XXX 64/32 190000h~19FFFFh C8000h~CFFFFh

SA26 11010XXX 64/32 1A0000h~1AFFFFh D0000h~D7FFFh

SA27 11011XXX 64/32 1B0000h~1BFFFFh D8000h~DFFFFh

SA28 11100XXX 64/32 1C0000h~1CFFFFh E0000h~E7FFFh

SA29 11101XXX 64/32 1D0000h~1DFFFFh E8000h~EFFFFh

SA30 11110XXX 64/32 1E0000h~1EFFFFh F0000h~F7FFFh

SA31 111110XX 32/16 1F0000h~1F7FFFh F8000h~FBFFFh

SA32 11111100 8/4 1F8000h~1F9FFFh FC000h~FCFFFh

SA33 11111101 8/4 1FA000h~1FBFFFh FD000h~FDFFFh

SA34 1111111X 16/8 1FC000h~1FFFFFh FE000h~FFFFFh

Sector address

A19~A12

Sector Size

(Kbytes/Kwords)

(X8)

Address Range

(X16)

Address Range

Remark

Main Sector

Boot Sector

Note:

The addresses range is A19:A-1 in byte mode (BYTE#=VIL) or A19:A0 in word mode (BYTE#=VIH).

ES29LV160D

11

Rev. 1C Jan 5 , 2006

Page 12

Table 4. Bottom Boot Sector Addresses (ES29LV160DB)

ESI

ESI

Excel Semiconductor inc.

Sector

SA0 0000000X 16/8 000000h~003FFFh 00000h~01FFFh

SA1 00000010 8/4 004000h~005FFFh 02000h~02FFFh

SA2 00000011 8/4 006000h~007FFFh 03000h~03FFFh

SA3 000001XX 32/16 008000h~00FFFFh 04000h~07FFFh

SA4 00001XXX 64/32 010000h~01FFFFh 08000h~0FFFFh

SA5 00010XXX 64/32 020000h~02FFFFh 10000h~17FFFh

SA6 00011XXX 64/32 030000h~03FFFFh 18000h~1FFFFh

SA7 00100XXX 64/32 040000h~04FFFFh 20000h~27FFFh

SA8 00101XXX 64/32 050000h~05FFFFh 28000h~2FFFFh

SA9 00110XXX 64/32 060000h~06FFFFh 30000h~37FFFh

SA10 00111XXX 64/32 070000h~07FFFFh 38000h~3FFFFh

SA11 01000XXX 64/32 080000h~08FFFFh 40000h~47FFFh

SA12 01001XXX 64/32 090000h~09FFFFh 48000h~4FFFFh

SA13 01010XXX 64/32 0A0000h~0AFFFFh 50000h~57FFFh

SA14 01011XXX 64/32 0B0000h~0BFFFFh 58000h~5FFFFh

SA15 01100XXX 64/32 0C0000h~0CFFFFh 60000h~67FFFh

SA16 01101XXX 64/32 0D0000h~0DFFFFh 68000h~6FFFFh

SA17 01110XXX 64/32 0E0000h~0EFFFFh 70000h~77FFFh

SA18 01111XXX 64/32 0F0000h~0FFFFFh 78000h~7FFFFh

SA19 10000XXX 64/32 100000h~10FFFFh 80000h~87FFFh

SA20 10001XXX 64/32 110000h~11FFFFh 88000h~8FFFFh

SA21 10010XXX 64/32 120000h~12FFFFh 90000h~97FFFh

SA22 10011XXX 64/32 130000h~13FFFFh 98000h~9FFFFh

SA23 10100XXX 64/32 140000h~14FFFFh A0000h~A7FFFh

SA24 10101XXX 64/32 150000h~15FFFFh A8000h~AFFFFh

SA25 10110XXX 64/32 160000h~16FFFFh B0000h~B7FFFh

SA26 10111XXX 64/32 170000h~17FFFFh B8000h~BFFFFh

SA27 11000XXX 64/32 180000h~18FFFFh C0000h~C7FFFh

SA28 11001XXX 64/32 190000h~19FFFFh C8000h~CFFFFh

SA29 11010XXX 64/32 1A0000h~1AFFFFh D0000h~D7FFFh

SA30 11011XXX 64/32 1B0000h~1BFFFFh D8000h~DFFFFh

SA31 11100XXX 64/32 1C0000h~1CFFFFh E0000h~E7FFFh

SA32 11101XXX 64/32 1D0000h~1DFFFFh E8000h~EFFFFh

SA33 11110XXX 64/32 1E0000h~1EFFFFh F0000h~F7FFFh

SA34 11111XXX 64/32 1F0000h~1FFFFFh F8000h~FFFFFh

Sector address

A19~A12

Sector Size

(Kbytes/Kwords)

(X8)

Address Range

(X16)

Address Range

Remark

Boot Sector

Main Sector

Note:

The addresses range is A19:A-1 in byte mode (BYTE#=VIL) or A19:A0 in word mode (BYTE#=VIH).

ES29LV160D

12

Rev. 1C Jan 5 , 2006

Page 13

ESI

ESI

Excel Semiconductor inc.

Temporary Sector

Unprotect Mode

Increment

COUNT

No

COUNT=25?

Yes Yes

Device failed

No

Set up sector

address

Sector Protect:

Write 60h to sector address with

A6 = 0, A1 = 1,

A0 = 0

Write 40h to sec-

tor address with

A6 = 0, A1 = 1,

Read from sec-

tor address with

A6 = 0, A1 = 1,

No

Sector Protect

In-System Protection / Unprotection Method

START

COUNT = 1

RESET# = V

Wait 1us

First Write

Cycle = 60h?

Yes

Wait 150us

Verify Se ctor

Protect:

A0 = 0

A0 = 0

Data = 01h?

Protect another

sector?

No

Remove VID

from RESET#

Write reset

command

complete

Protect all sectors:

The indicated portion of the sector

ID

Reset

COUNT = 1

Yes

protect algorithm

must be performed

for all unprotected

sectors prior to

issuing the first

sector unprotect

address

Increment

COUNT

No

COUNT

=1000?

Yes Yes

Device failed

No

No

START

COUNT = 1

RESET# = V

Wait 1us

First Write

Cycle = 60h?

All sectors

protected ?

Set up first sector

address

Sector Unprotect:

Write 60h to sector address with

A6 = 1, A1 = 1,

Wait 15ms

Verify Se ctor

Unprotect:

Write 40h to sector address with

A6 = 1, A1 = 1,

A0 = 0

Read from sector address with

A6 = 1, A1 = 1,

A0 = 0

Data = 00h?

Last sector

verified?

Remove VID from

RESET#

Write reset

command

Yes

Yes

Yes

ID

No

Temporary Sector

Unprotect Mode

Set up next

sector address

No

Figure 2. In-System Sector

Protect Algorithm

ES29LV160D

13

Sector Unprotect

complete

Figure 3. In-System Sector

Unprotect Algorithm

Rev. 1C Jan 5 , 2006

Page 14

ESI

ESI

Excel Semiconductor inc.

A9 High-Voltage Method

Start

Start

COUNT = 1

SET A9=OE#=V

ID

Note: All sectors must be

previously protected.

COUNT = 1

SET A9=OE#=V

ID

Increase COUNT

No

COUNT= 25?

Yes

Device failed

CE#,OE#,A6,A0=V

RESET#, A1 = V

No

Set Sector Address

A<19 :12>

CE#, A6, A0=V

RESET#, A1=V

SET WE# = V

Wait 150 us

SET WE# = V

Read Data

Data = 01h?

Protect Another

Sector ?

Remove VID from

A9 and Write

Reset Command

IL

IH

IL

IH

IH

Yes

No

CE#, A0=V

RESET#,

A6, A1=V

SET WE# = V

Wait 15ms

SET WE# = V

Increase COUNT

IL

No

COUNT=1000?

Yes

Yes

Device failed

CE#,OE#, A0=V

RESET#, A6, A1=V

Set Sector AddressA<19 :12>

Read Data

No

Data = 00h?

Yes

The Last Sector

Address ?

Remove VID from A9 and

Write Reset Command

IH

Yes

,

IL

IL

IH

IL

IH

Increase Sector

Address

No

Sector Protection

Complete

Figure 4. Sector Protection Algorithm

(A9 High-Voltage Method)

ES29LV160D

14

Sector Unprotection

Complete

Figure 5. Sector Un-Protection Algorithm

(A9 High-Voltage Method)

Rev. 1C Jan 5 , 2006

Page 15

ESI

ESI

Excel Semiconductor inc.

Common Flash Memory

Interface (CFI)

CFI is supported in the ES29LV160 device. The

Common Flash Interface (CFI) specification outlines device and host system software interrogation

handshake, which allows specific vendor-specified

software algorithms to be used for entire families of

devices. Software support can then be device-independent, JEDEC ID-independent, and forward- and

backward-compatible for the specified flash device

families. Flash vendors can standardize their existing interfaces for long-term compatibility.

Table 5. CFI Query Identification String

Addresses

(Word Mode)

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

Addresses

(Byte Mode)

20h

22h

24h

26h

28h

2Ah

2Ch

2Eh

30h

32h

34h

Data Description

0051h

0052h

0059h

0002h

0000h

0040h

0000h

0000h

0000h

0000h

0000h

This device enters the CFI Query mode when the

system writes the CFI query command, 98h, to

address 55h in word mode (or address AAh in byte

mode), any time the device is ready to read array

data. The system can read CFI information at the

addresses given in Tables 5-8. To termin ate reading

CFI data, the system must write the reset com-

mand.The CFI query command can be written to the

system when the device is in the autoselect mode

or the erase-suspend-read mode. The device

enters the CFI query mode, and the system can read

CFI data at the addresses given in Tables 5-8.

When the reset command is written, the device

returns respectively to the read mode or erase-suspend-read mode.

Query Unique ASCII string “QRY”

Primary OEM Command Set

Address for Primary Extended Table

Alternate OEM Command Set(00h = none exists)

Address for Alternate OEM Extended Table (00h = none exists)

Table 6. System Interface String

Addresses

(Word Mode)

1Bh 36h 0027h

1Ch 38h 0036h

1Dh 3Ah 0000h Vpp Min. voltage (00h = no Vpp pin present)

1Eh 3Ch 0000h Vpp Max. voltage (00h = no Vpp pin present)

1Fh 3Eh 0004h

20h 40h 0000h

21h 42h 000Ah

22h 44h 0000h

23h 46h 0005h

24h 48h 0000h

25h 4Ah 0004h

26h 4Ch 0000h

Addresses

(Byte Mode)

Data Description

Vcc Min. (write/erase)

D7-D4: volt, D3-D0: 100 millivolt

Vcc Max. (write/erase)

D7-D4: volt, D3-D0: 100 millivolt

Typical timeout per single byte/word write 2

Typical timeout for Min. size buffer write 2

Typical timeout per individual block erase 2

Typical timeout for full chip erase 2

Max. timeout for byte/word write 2

Max. timeout for buffer write 2

Max. timeout per individual block erase 2

Max. timeout for full chip erase 2

N

N

times typical

N

times typical (00h = not supported)

N

N

us (00h = not supported)

N

N

ms (00h = not supported)

times typical

N

times typical

us

ms

ES29LV160D

15

Rev. 1C Jan 5 , 2006

Page 16

Table 7. Device Geometry Definition

ESI

ESI

Excel Semiconductor inc.

Addresses

(Word Mode)

27h 4Eh 0015h

28h

29h

2Ah

2Bh

2Ch 58h 0004h Number of Erase Block Regions within device

2Dh

2Eh

2Fh

30h

31h

32h

33h

34h

35h

36h

37h

38h

39h

3Ah

Addresses

(Byte Mode)

50h

52h

54h

56h

5Ah

5Ch

5Eh

60h

62h

64h

66h

68h

6Ah

6Ch

6Eh

70h

72h

74h

Data Description

N

byte

0002h

0000h

0000h

0000h

0000h

0000h

0040h

0000h

0001h

0000h

0020h

0000h

0000h

0000h

0080h

0000h

001Eh

0000h

Device Size = 2

Flash Device Interface description

02 = x8, x16 Asynchronous

Max. number of bytes multi-byte write = 2

(00h = not supported)

Erase Block Region 1 Information

Number of identical size erase block = 0000h+1 = 1

Erase Block Region 1 Information

Block size in Region 1 = 0040h * 256 byte = 16 Kbyte

Erase Block Region 2 Information

Number of identical size erase block = 0001h+1 =2

Erase Block Region 2 Information

Block size in Region 2 = 0020h * 256 byte = 8 Kbyte

Erase Block Region 3 Information

Number of identical size erase block = 0000h+1 =1

Erase Block Region 3 Information

Block size in Region 3 = 0080h * 256 byte = 32 Kbyte

Erase Block Region 4 Information

Number of identical size erase block = 001Eh+1 =31

N

3Bh

3Ch

76h

78h

0000h

0001h

Erase Block Region 4 Information

Block size in Region 4 = 0100h * 256 byte = 64 Kbyte

ES29LV160D

16

Rev. 1C Jan 5 , 2006

Page 17

Table 8. Primary Vendor-Specific Extended Query

ESI

ESI

Excel Semiconductor inc.

Addresses

(Word Mode)

40h

41h

42h

43h 86h 0031h Major version number, ASCII

44h 88h 0030h Minor version number, ASCII

45h 8Ah 0000h

46h 8Ch 0002h

47h 8Eh 0001h

48h 90h 0001h

49h 92h 0004h

4Ah 94h 0000h

4Bh 96h 0000h

4Ch 98h 0000h

Addresses

(Byte Mode)

80h

82h

84h

Data Description

0050h

0052h

0049h

Query-unique ASCII string “PRI”

Address Sensitive Unlock (Bits 1-0)

0 = Required, 1 = Not required

Silicon Revision Number (Bits 7-2)

Erase Suspend

0 = Not Supported, 1 = To Read Only, 2 = To Read & Write

Sector Protect

0 = Not Supported, X = Number of sectors in per group

Sector Temporary Unprotect

00 = Not Supported, 01 = Supported

Sector Protect/Unprotect scheme

04 = In-System Method and A9 High-Voltage Method

Simultaneous Operation

00 = Not Supported

Burst Mode Type

00 = Not Supported, 01 = Supported

Page Mode Type

00 = Not Supported, 01 = 4 Word Page, 02 = 8 Word Page

ES29LV160D

17

Rev. 1C Jan 5 , 2006

Page 18

COMMAND DEFINITIONS

ESI

ESI

Excel Semiconductor inc.

Writing specific address and data commands or

sequences into the command register initiates

device operations. Table 9 defines the valid register

command sequences. Note that writing incorrect

address and data values or writing them in the

improper sequence may place the device in an

unknown state. A reset command is required to

return the device to normal operation.

All addresses are latched on the falling edge of WE#

or CE#, whichever happens later. All data is latched

on the rising edge of WE# or CE#, whichever happens first. Refer to the AC Characteristics section for

timing diagrams.

READING ARRAY DATA

The device is automatically set to reading array data

after device power-up. No commands are required

to retrieve data. The device is ready to read array

data after completing an Embedded Program or

Embedded Erase algorithm.

After the device accepts an Erase Suspend command, the device enters the erase-suspend-read

mode, after which the system can read data from

any non-erase-suspended sector. After completing a

programming operation in the Erase Suspend mode,

the system may once again read array data with the

same exception. See the Erase Suspend/Erase

Resume Commands section for more information.

The system must issue the reset command to return

the device to the read (or erase-suspend-read)

mode if DQ5 goes high during an active program or

erase operation, or if the device is in the autoselect

mode. See the next section, Reset Command, for

more information.

See also Requirements for Reading Array Data in

the Device Bus Operations section for more information.The Read-Only Operations table provides the

read parameters, and Fig. 16 shows the timing diagram

RESET COMMAND

Writing the reset command resets the device to the

read or erase-suspend-read mode. Address bits are

don’t cares for this command.

The reset command may be written between the

sequence cycles in an erase command sequence

before erasing begins. This resets the device to

which the system was writing to the read mode.

Once erasure begins, however, the device ignores

reset commands until the operation is complete.

The reset command may be written between the

sequence cycles in a program command sequence

before programming begins. This resets the device

to which the system was writing to the read mode. If

the program command sequence is written to a sector that is in the Erase Suspend mode, writing the

reset command returns the device to the erase-suspend-read mode. Once programming begins, however, the device ignores reset commands until the

operation is complete.

The reset command may be written between the

sequence cycles in an autoselect command

sequence. Once in the autoselect mode, the reset

command must be written to return to the read

mode. If the device entered the autoselect mode

while in the Erase Suspend mode, writing the reset

command returns the device to th e erase-suspendread mode.

If DQ5 goes high during a program or erase operation, writing the reset command returns the device to

the read mode (or erase- suspend-read mode if the

device was in Erase-Suspend).

ES29LV160D

18

Rev. 1C Jan 5 , 2006

Page 19

Command Definitions

Table 9. ES29LV160 Command Definitions

ESI

ESI

Excel Semiconductor inc.

Command

Sequence

(Note 1)

Read (Note 6) 1 RA RD

Reset (Note 7) 1 XXX F0

Manufacturer ID

Device ID (Top)

Device ID (Bottom)

Sector Protect Verify

Autoselect (Note 8)

(Note 9)

Program

Unlock Bypass

Unlock Bypass Program (Note 10) 2 XXX A0 PA PD

Unlock Bypass Reset (Note 11) 2 XXX 90 XXX 00

Chip Erase

Sector Erase

Erase Suspend (Note 12) 1 XXX B0

Erase Resume (Note 13) 1 XXX 30

CFI Query (Note 14)

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA X02

Word

Byte AAA 555 AAA X02

Word

Byte AAA 555 AAA (SA)X04

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555

Word

Byte AA

First Second Third Fourth Fifth Sixth

Cycles

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

555

4

555

4

555

4

555

4

555

4

555

3

555

6

555

6

55

1

AA

AA

AA

AA

AA

AA

AA

AA

98

2AA

2AA

2AA

2AA

2AA

2AA

2AA

2AA

Bus Cycles (Notes 2~5)

555

55

55

55

55

55

55

55

55

90 X00 4A

555

90

555

90

555

90

555

A0 PA PD

555

20

555

80

555

80

X01

X01

(SA)X02

555

555

C4

49

00/01

AA

AA

2AA

2AA

555

55

55 SA 30

10

Legend:

X = Don’t care

RA = Address of the memory location to be read.

RD = Data read from location RA during read operation

PA = Address of the memory location to be programmed.

Addresses latch on the falling edge of the WE# or CE# pulse,

whichever happens later.

Notes:

1. See Table 1 for description of bus operations.

2. All values are in hexadecimal.

3. Except for the read cycle and the fourth cycle of the autoselect

command sequence, all bus cycles are write cycles.

4. Data bits DQ15-DQ8 are don’t care in command sequences,

except for RD and PD

5. Unless otherwise noted, address bits A19-A11 are don’t cares.

6. No unlock or command cycles required when device is in

read mode.

7. The Reset command is required to return to the read mode

(or to the erase-suspend-read mode if previously in Erase

Suspend) when a device is in the autoselect mode, or if DQ5

goes high (while the device is providing status information).

8. The fourth cycle of the autoselect command sequence

is a read cycle. Data bits DQ15-DQ8 are don’t care. See the

Autoselect Command Sequence section for more information.

PD = Data to be programmed at location PA. Data latches on the

rising edge of WE# or CE# pulse, whichever happens first.

SA = Address of the sector to be verified (in autoselect mode) or

erased. Address bits A19-A12 uniquely select any sector.

9. The data is 00h for an unprotected sector and 01h for a

protected sector.

10. The Unlock Bypass command is required prior to the Unlock Bypass Program command.

11. The Unlock Bypass Reset command is required to return

to the read mode when the device is in the unlock bypass

mode.

12. The system may read and program in non-erasing sectors,

or enter the autoselect mode, when in the Erase Suspend

mode. The Erase Suspend command is valid only during

a sector erase operation.

13. The Erase Resume command is valid only during the Erase

Suspend mode.

14. Command is valid when device is ready to read array data

or when device is in autoselect mode.

ES29LV160D

19

Rev. 1C Jan 5 , 2006

Page 20

ESI

ESI

Excel Semiconductor inc.

AUTOSELECT COMMAND

The autoselect command sequence allows the host

system to access the manufacturer and device

codes, and determine whether or not a sector is

protected, including information about factorylocked or customer lockable version.

Identifier Code Address Data

Manufacturer ID 00h 4Ah

Device ID 01h C4h(T),

49h(B)

Sector Protect Verify (SA)02h 00 / 01

Table 9 shows the address and data requirements.

This method is an alternative to “A9 high-voltage

method” shown in Table 2, which is intended for

PROM programmers and require s V

pin A9. The autoselect command sequence may be

written to an address within sector that is either in

the read mode or erase-suspend-read mode. The

auto-select command may not be written while the

device is actively programming or erasing. The

autoselect command sequence is initiated by first

writing two unlock cycles. This is followed by a third

write cycle that contains the autoselect command.

The device then enters the autoselect mode. The

system may read at any address any number of

times without initiating another autoselect command sequence.

Once after the device enters the auto-select mode,

the manufacture ID code ( 4Ah ) can be accessed

by one of two ways. Just one read cycle ( with A6,

A1 and A0 = 0 ) can be used. Or four consecutive

read cycles ( with A6 = 1 and A1, A0 = 0 ) for continuation codes (7Fh) and then another last cycle

for the code (4Ah) (with A6, A1 and A0 = 0) can be

used for reading the manufacturer code.

on address

ID

BYTE / WORD PROGRAM

The system may program the device by word or

byte, depending on the state of the BYTE# pin.

Programming is a four-bus-cycle operation. The

program command sequence is initiated by writing

two unlock write cycles, followed by the program

set-up command. The program address and data

are written next, which in turn initiate the Embedded

Program algorithm. The system is not required to

provide further controls or timings. The device auto matically provides internally generated program

pulses and verifies the programmed cell margin.

Table 9 shows the address and data requirements

for the byte program command sequence. Note that

the autoselect and CFI modes are unavailable

while a programming operation is in progress.

START

Write Program Com-

mand Sequence

Embedded

Program

algorithm in

progress

No

Increment Address

Data Poll

from System

Verify Data

Yes

Last Address?

No

?

- 4Ah (one-cycle read)

- 7Fh 7Fh 7Fh 7Fh 4Ah (Five-cycle read)

The system must write the reset command to return

to the read mode (or erase-suspend-read mode if

the device was previously in Erase Suspend).

ES29LV160D

20

Programming

Completed

Note:

See Table 9 for program command sequence

Figure 6. Program Operation

Rev. 1C Jan 5 , 2006

Yes

Page 21

ESI

ESI

Excel Semiconductor inc.

Program Status Bits : DQ7, DQ6 or RY/BY#

When the Embedded Program algorithm is complete, the device then returns to the read mode and

addresses are no longer latched. The system can

determine the status of the program operation by

using DQ7, DQ6, or RY/BY#. Refer to the Write

Operation Status section Table 10 for information on

these status bits.

Any Commands Ignored during Programming Operation

Any commands written to the device during the

Embedded Program algorithm are ig nored. Note tha t

a hardware reset can immediately terminates the

program operation. The program command

sequence should be reinitiated once the device has

returned to the read mode, to ensure data integrity.

Programming from “0” back to “1”

Programming is allowed in any sequence and

across sector boundaries. But a bit cannot be programmed from “0” back to a ”1”. Attempting to do so

may cause the device to set DQ5 = 1, or cause the

DQ7 and DQ6 status bits to indicate the operation

was successful. However, a succeeding read will

show that the data is still “0”. Only erase operations

can convert a “0” to a “1”

Unlock Bypass

In the ES29LV160 device, an unlock bypass program mode is provided for faster programming operation. In this mode, two cycles of program command

sequences can be saved. To enter this mode, an

unlock bypass enter command should be first written

to the system. The unlock bypass enter command

sequence is initiated by first writing two unlock

cycles. This is followed by a third write cycle containing the unlock bypass command, 20h. The device

then enters the unlock-bypass program mode. A

two-cycle unlock bypass program command

sequence is all that is required to program in this

mode. The first cycle in this sequence contains the

unlock bypass program set-up command, A0h; the

second cycle contains the program address and

data. Additional data is programmed in the same

manner. This mode dispenses with the initial two

unlock cycles required in the standard program command sequence, resulting in faster total programming time. Table 9 shows the requirements for the

command sequence.

During the unlock-bypass mode, only the unlockbypass program and unlock-bypass reset commands are valid. To exit the unlock-bypass mode,

the system must issue the two-cycle unlock-bypass

reset command sequence. The first cycle must contain the data 90h. The second cycle need to only

contain the data 00h. The device then returns to the

read mode.

- Unlock Bypass Enter Command

- Unlock Bypass Reset Command

- Unlock Bypass Program Command

CHIP ERASE COMMAND

To erase the entire memory, a chip erase command

is used. This command is a six bus cycle operation.

The chip erase command sequence is initiated by

writing two unlock cycles, followed by a set-up command. Two additional unlock write cycles are then

followed by the chip erase command, which in turn

invokes the Embedded Erase algorithm. The chip

erase command erases the entire memory including all other sectors except the protected sectors,

but the internal erase operation is performed on a

single sector base.

Embedded Erase Algorithm

The device does not require the system to preprogram prior to erase. The Embedded Erase algorithm automatically preprograms and verifies the

entire memory for an all zero data pattern prior to

electrical erase. The system is not required to provide any controls or timings during these operations. Table 9 shows the address and data

requirements for the chip erase command

sequence. Note that the autoselect, and CFI modes

are unavailable while an erase operation is in

progress

Erase Status Bits : DQ7, DQ6, DQ2, or RY/

BY#

When the Embedded Erase algorithm is complete,

the device returns to the read mode and addresses

are no longer latched. The system can determine

the status of the erase operation by using DQ7,

DQ6, DQ2, or RY/BY#. Refer to the Write Operation St atus section Table 10 for information on these

status bits.

Commands Ignored during Erase Operation

Any command written during the chip erase operation are ignored. However, note that a hardware

ES29LV160D

21

Rev. 1C Jan 5 , 2006

Page 22

ESI

ESI

Excel Semiconductor inc.

reset immediately terminates the erase operation.If

that occurs, the chip erase command sequence

should be reinitiated once the device has returned to

reading array data. to ensure data integrity. Fig. 7

illustrates the algorithm for the erase operation.

Refer to the Erase and Program Operations tables in

the AC Characteristics section for parameters, and

Fig. 21 section for timing diagrams.

SECTOR ERASE COMMAND

By using a sector erase command, a sing le sector or

multiple sectors can be erased. The sector erase

command is a six bus cycle operation. The sector

erase command sequence is initiated by writing two

unlock cycles, followed by a set-up command. Two

additional unlock cycles are written, and are then followed by the address of the secto r to be eras ed, and

the sector erase command. Table 9 shows the

address and data requirements for the sector erase

command sequence. Note that the autoselect, and

CFI modes are unavailable while an erase operation

is in progress.

Embedded Sector Erase Algorithm

to the read mode. The system must rewrite the

command sequence and any additional addresses

and commands.

Status Bits : DQ7,DQ6,DQ2, or RY/BY#

When the Sector Erase Embedded Erase algorithm

is complete, the device returns to reading array

data and addresses are no longer latched. Note

that while the Embedded Erase operation is in

progress, the system can read data from the nonerasing sector. The system can determine the status of the erase operation by reading

DQ7,DQ6,DQ2, or RY/BY# in the erasing sector.

Refer to the Write Operation Status section Table

10 for information on these status bits.

Valid Command during Sector Erase

Once the sector erase operation has begun, only

the Erase Suspend command is valid. All other

commands are ignored. However, note that a hard-

ware reset immediately terminates the erase operation. If that occurs, the sector erase command

The device does not require the system to preprogram prior to erase. The Embedded Erase algorithm

automatically programs and verifies the entire memory for an all zero data pattern prior to electrical

erase. The system is not required to provide any controls or timings these operations.

Sector Erase Time-out Window and DQ3

After the command sequence is written, a sector

erase time-out of 50us occurs. During the time-out

period, additional sector addresses and sector erase

commands may be written. Loading the sector erase

buffer may be done in any sequence, and the number of sectors may be from one sector to all sectors.

The time between these additional cycles must be

less than 50 us, otherwise the last address and command may not be accept ed, and eras ure may beg in.

It is recommended that processor interrupts be disabled during this time to ensure all commands are

accepted. The interrupts can be re-enabled after the

last Sector Erase command is written. The system

can monitor DQ3 to determine if the sector erase

timer has timed out (See the section on DQ3:Sector

Erase Timer.). The time-out begins from the rising

edge of the final WE# pulse in the command

sequence.

START

Write Erase

Command Sequence

(Notes 1,2)

Embedded

Erase

algorithm in

progress

No

Notes:

1. See Table 9 for erase command sequence

2. See the section on DQ3 for information on the sector erase timer

Data Poll to

Erasing Bank

from System

No

Data = FFh?

Yes

Erasure Completed

Figure 7. Erase Operation

Any command other than Sector Erase or Erase Suspend during the time-out period resets the device

ES29LV160D

22

Rev. 1C Jan 5 , 2006

Page 23

ESI

ESI

Excel Semiconductor inc.

sequence should be reinitiated once the device has

returned to reading array data, to ensure data integrity.

Fig. 7 illustrates the algorithm for the erase operation. Refer to the Erase and Program Operations

tables in the AC Characteristics section for parameters, and Fig. 21 section for timing diagra ms .

ERASE SUSPEND/ERASE RESUME

An erase operation is a long-time operation so that

two useful commands are provided in the

ES29LV160 device Erase Suspend and Erase

Resume Commands. Through the two commands,

erase operation can be suspended for a while and

the suspended operation can be resumed later when

it is required. While the erase is suspended, read or

program operations can be performed by the system.

Erase Suspend Command, (B0h)

The Erase Suspend command, B0h, allows the system to interrupt a sector erase operation and then

read data from, or program data to, any sector not

selected for erasure. This command is valid only during the sector erase operation, including the 50us

time-out period during the sector erase command

sequence. The Erase Suspend command is ignored

if written during the chip erase operation or Embedded Program algorithm. When the Erase Suspend

command is written during the sector erase operation, the device requires a maximum of 20us to suspend the erase operation. However, when the Erase

Suspend command is written during the sector erase

time-out, the device immediately terminates the timeout period and suspends the erase operation.

After an erase-suspended program operation is

complete, the device returns to the erase-suspendread mode. The system can determine the sta tus for

the program operation using the DQ7 or DQ6 status

bits, just as in the standard Byte Program operation.

Refer to the Write Operation Status section for more

information.

Autoselect during Erase-Suspend- Read

Mode

In the erase-suspend-read mode, the system can

also issue the autoselected command sequence.

Refer to the Autoselect Mode and Autoselect Command Sequence section for details (Table 9).

Erase Resume Command

To resume the sector erase operation, the system

must write the Erase Resume command. Further

writes of the Resume command are ignored.

Another Erase Suspend command can be written

after the chip has resumed erasing.

Read and Program during Erase-SuspendRead Mode

After the erase operation has been suspended, the

device enters the erase-suspend-read mode. The

system can read data from or program data to any

sector not selected for erasure. (The device “erase

suspends” all sectors selected for erasure.)

Reading at any address within erase-suspended sectors produces status information on DQ7-DQ0. The

system can use DQ7, or DQ6 and DQ2 together, to

determine if a sector is actively erasing or is erasesuspended. Refer to the Write Operation Status section for information on these status bits (Table 10).

ES29LV160D

23

Rev. 1C Jan 5 , 2006

Page 24

ESI

ESI

Excel Semiconductor inc.

COMMAND DIAGRAM

Done

90

Program

Unlock

Bypass

98

PA/PD

20

90

Autoselect

F0

A0

55

AA

80

AA

Chip

Erase

10

55

SA/30

00

CFI

Read

F0

98

Erasesuspend

Read

Figure 8. Command Diagram

Done

Resume

30

Done

SA/30

50us

Sector

Erase

B0

Suspend

ES29LV160D

24

Rev. 1C Jan 5 , 2006

Page 25

WRITE OPERATION STATUS

ESI

ESI

Excel Semiconductor inc.

In the ES29LV160 device, several bits are provided

to determine the status of a program or erase operation: DQ2, DQ3, DQ5, DQ6, DQ7 and RY/BY#.

Table 10 and the following subsections describe the

function of these bits. DQ7 and DQ6 each offer a

method for determining whether a program or erase

operation is complete or in progress. The device

also provides a hardware-based output signal, RY/

BY#, to determine whether an Embedded Program

or Erase operation is in progress or has been completed.

DQ7 (DATA# POLLING)

The Data# Polling bit, DQ7, indicates to the host

system whether an Embedded Program or Erase

algorithm is in progress or complete d, or whether a

device is in Erase Suspend. Data# Polling is valid

after the rising edge of the final WE# pulse in the

command sequence.

During Programming

During the Embedded Program algorithm, the

device outputs on DQ7 the complement of the

datum programmed to DQ7. This DQ 7 status also

applies to programming during Erase Suspend.

When the Embedded Program algorithm is complete, the device outputs the datum programmed to

DQ7. The system must provide the program

address to read valid status information on DQ7. If

a program address falls within a protected sector,

Data# Polling on DQ7 is active for approximately

250ns, then the device returns to the read mode.

During Erase

Erase algorithm is complete, or if the device enters

the Erase Suspend mode, Data# polling produces a

“1” on DQ7. The system must provide an address

within any of the sectors selected for erasure to read

valid status information on DQ7.

Erase on the Protected Sectors

After an erase command sequence is written, if all

sectors selected for erasing are protected, Data#

Polling on DQ7 is active for approximately 1.8us,

then the device returns to the read mode. If not all

selected sectors are protected, the Embedded Erase

algorithm erases the unprotected sectors, and

ignores the selected sectors that are protected.

ever, if the system reads DQ7 at an address within a

protected sector, the status may not be valid.

How-

Data# Polling Algorithm

Just prior to the completion of an Embedded

Program or Ease operation, DQ7 may change

asynchronously with DQ0-DQ6 while Output

Enable(OE#) is asserted low. That is, this device

may change from providing status information to

valid data on DQ7. Depending on when the system

samples the DQ7 output, it may read the status or

valid data. Even if the device has completed the

program or erase operation and DQ7 has valid data,

the data outputs on DQ0-DQ7 will appear on

successive read cycles.

Table 10 shows the outputs for Data# Polling on

DQ7. Fig. 9 shows the Data# Polling algorithm. Fig.

22 in the AC Characteristics section shows the

Data# Polling timing diagram.

During the Embedded Erase algorithm, Data# Polling produces a “0” on DQ7. When the Embedded

ES29LV160D

25

Rev. 1C Jan 5 , 2006

Page 26

ESI

ESI

Excel Semiconductor inc.

Erase Suspend mode. Toggle Bit I may be read at

START

Read DQ7-DQ0

Addr = VA

any address, and is valid after the rising edge of the

final WE# pulse in the command sequence ( prior to

the program or erase operation), and during the sector erase time-out. During an Em bedde d Prog ram or

Erase algorithm operation, successive read cycles to

any address cause DQ6 to toggle. The system may

DQ7 = Data ?

Yes

use either OE# or CE# to control the read cycles.

No

No

DQ5 = 1 ?

When the operation is complete, DQ6 stops toggling.

Yes

Read DQ7-DQ0

Addr = VA

DQ7 = Data ?

FAIL

Notes:

1. VA = Valid address for programming. During a sector erase

operation, a valid address is any sector address within the

sector being erased. During chip erase, a valid address in

any non-protected sector address.

2. DQ7 should be rechecked even if DQ5 = “1” because

DQ7 may change simultaneously with DQ5

Yes

No

PASS

Figure 9. Data# Polling Algorithm

RY/BY# ( READY/BUSY# )

The RY/BY# is a dedicated, open-drain output pin

which indicates whether an Embedded Algorithm is

in progress or complete. The RY/BY# status is valid

after the rising edge of the final W E# pulse in the

command sequence. Since RY/BY# is an opendrain output, several RY/BY# pins can be tied

together in parallel with a pull-up resistor to Vcc. If

the output is low (Busy), the device is actively erasing or programming. (This includes programming in

the Erase Suspend mode.) If the output is high

(Ready), the device is in the read mode, the

standby mode, or in the erase-susp en d- re a d m od e .

Table 10 shows the outputs for RY/BY#.

DQ6 ( TOGGLE BIT I )

Toggle Bit I on DQ6 indicates whether an Embedded Program or Erase algorithm is in progress or

complete, or whether the device has entered the

The system can use DQ6 and DQ2 together to

determine whether a sector is actively erasing or is

erase-suspended. When the device is actively erasing (that is, the Embedded Erase algorithm is in

progress), DQ6 toggles. When the device enters the

Erase Suspend mode, DQ6 stops toggling. However, the system must also use DQ2 to determine

which sectors are erasing or erase-suspended.

Alternatively, the system can use DQ7(see the subsection on DQ7:Data# Polling). DQ6 also toggles

during the erase-suspend-program mode, and stops

toggling once the Embedded Program algorithm is

complete.

Table 10 shows the outputs for Toggle Bit I on DQ6.

Fig. 10 shows the toggle bit algorithm. Fig. 23 in the

“AC Characteristics” section shows the toggle bit

timing diagrams. Fig. 24 shows the differences

between DQ2 and DQ6 in graphical form. See also

the subsection on DQ2 : (Toggle Bit II).

Toggling on the Protected Sectors

After an erase command sequence is written, if all

sectors selected for erasing are pr otected, DQ6 to ggles for approximately 1.8us, then returns to reading

array data. If not all selected sectors are protected,

the Embedded Erase algorithm erases the unprotected sectors, and ignores the selected sectors that

are protected. If a program address falls within a

protected sector, DQ6 toggles for approximately

250ns after the program command sequence is written, then returns to reading array data.

DQ2 ( TOGGLE BIT II )

The “Toggle Bit II” on DQ2, when used with DQ6,

indicates whether a particular sector is actively erasing (that is, the Embedded Erase algorithm is in

progress), or whether that sector is erase-suspended. Toggle Bit II is valid after the rising edge of

the final WE# pulse in the command sequence DQ2

ES29LV160D

26

Rev. 1C Jan 5 , 2006

Page 27

toggles when the system reads at addresses within

those sectors that have been selected for erasure.

(The system may use either OE# or CE# to control

the read cycles.) But DQ2 cannot distinguish

whether the sector is actively erasing or is erasesuspended. DQ6, by comparison, indicates

whether the device is actively erasing, or is in Erase

Suspend, but cannot distinguish which sectors are

selected for erasure. Thus, both status bits are

required for sector and mode information. Refer to

Table 10 to compare output s fo r DQ2 an d DQ6. Fig.

10 shows the toggle bit algorithm in flowchart form,

and the section “DQ2: Toggle Bit II” explains the

algorithm. See also the DQ6: Toggle Bit I subsection. Fig. 23 shows the toggle bit timing diagram.

Fig. 24 shows how differently DQ2 operates compared with DQ6.

No

START

Read DQ7-DQ0

Read DQ7-DQ0

Toggle Bit

= Toggle ?

Yes

DQ5 = 1 ?

Yes

Read DQ7-DQ0

Twice

ESI

ESI

Excel Semiconductor inc.

No

Reading Toggle Bits DQ6/DQ2

Refer to Fig. 10 for the following dis cussion. Whenever the system initially begins reading toggle bit

status, it must read DQ7-DQ0 at least twice in a row

to determine whether a toggle bit is toggling. Typically, the system would note and store the value of

the toggle bit after the first read. After the second

read, the system would compare the new value of

the toggle bit with the first. If the toggle bit is not

toggling, the device has completed the program or

erase operation. The system can read array data

on DQ7-DQ0 on the following read cycle. However,

if after the initial two read cycles, the system determines that the toggle bit is still toggling, the system

also should note whether the value of DQ5 is high

(see the section on DQ5). If it is, the system should

then determine again whether the toggle bit is toggling, since the toggle bit may have stopped toggling just as DQ5 went high. If the toggle bit is no

longer toggling, the device has successfully completed the program or erase operation. If it is still

toggling, the device did not completed the operation

successfully, and the system must write the reset

command to return to reading array data. The

remaining scenario is that the system initially determines that the toggle bit is toggling and DQ5 has

not gone high. The system may continue to monitor

the toggle bit and DQ5 through successive read

cycles, determining the status as described in the

previous paragraph. Alternatively, it may choose to

perform other system tasks. In this case, this system must start at the beginning of the algorithm

when it returns to determine the st atus of the o peration (top of Fig. 10).

Yes

No

Program/Erase

Operation

Complete

Toggle Bit

= Toggle ?

Program/Erase

Operation Not

Complete, Write

Reset Command

Note:

The system should recheck the toggle bit even if DQ5 = “1”

because the toggle bit may stop toggling as DQ5 changes to “1”.

See the subsections on DQ6 and DQ2 for more information.

Figure 10. Toggle Bit Algorithm

ES29LV160D

27

Rev. 1C Jan 5 , 2006

Page 28

ESI

ESI

Excel Semiconductor inc.

DQ5 ( EXCEEDED TIMING LIMITS )

DQ5 indicates whether the program or erase time

has exceeded a specified internal pulse count limit.

Under these conditions DQ5 produces a “1”, indicating that the program or erase cycle was not successfully completed. The device may output a “1”

on DQ5 if the system tries to program a “1” to a

location that was previously programmed to “0”

Only an erase operation can change a “0” back to a

“1”. Under this condition, the device halts the operation, and when the timing limit has been exceeded,

DQ5 produces a ”1”. Under both these conditions,

the system must write the reset command to return

to the read mode.

DQ3 ( SECTOR ERASE TIMER )

After writing a sector erase command sequence,

the system may read DQ3 to determine whether or

not erasure has begun. (The sector erase time

does not apply to the chip erase command.)

If additional sectors are selected for erasure, the

entire time-out also applies after each additional

sector erase command. When the time-out period is

complete, DQ3 switches from a “0” to a”1”. If the

time between additional sector erase commands

from the system can be assumed to be less than

50us, the system need not monitor DQ3. See also

the Sector Erase Command Sequence section. After

the sector erase command is written, the system

should read the status of DQ7 (Data# Polling) or

DQ6 (Toggle Bit I) to ensure that the device has

accepted the command sequence, and then read

DQ3. If DQ3 is “1”, the Embedded Erase algorithm

has begun; all further commands (except Erase Suspend) are ignored until the erasure operation is complete. If DQ3 is “0”, the device will accept additional

sector erase commands. To ensure the command

has been accepted, the system software should

check the status of DQ3 prior to and following each

subsequent sector erase command. If DQ3 is high

on the second status check, the last command might

not have been accepted. In Table 10, DQ3 status

operation is well defined and summarized with other

status bits, DQ7, DQ6, DQ5, and DQ2.

Table 10. Write Operation Status

DQ7

(Note 2)

Data Data Data Data Data 1

DQ6

1 No toggle 0 N/A Toggle 1

Standard

Mode

Erase Suspend Mode

Status