ESI ALL-FLEX FLEX3-SLV-V1, ALL-FLEX FLEX3-BLK-V1, ALL-FLEX FLEX3-WHT-V1 Assembly And Operation Manual

Page 1

ASSEMBLY AND OPERATION

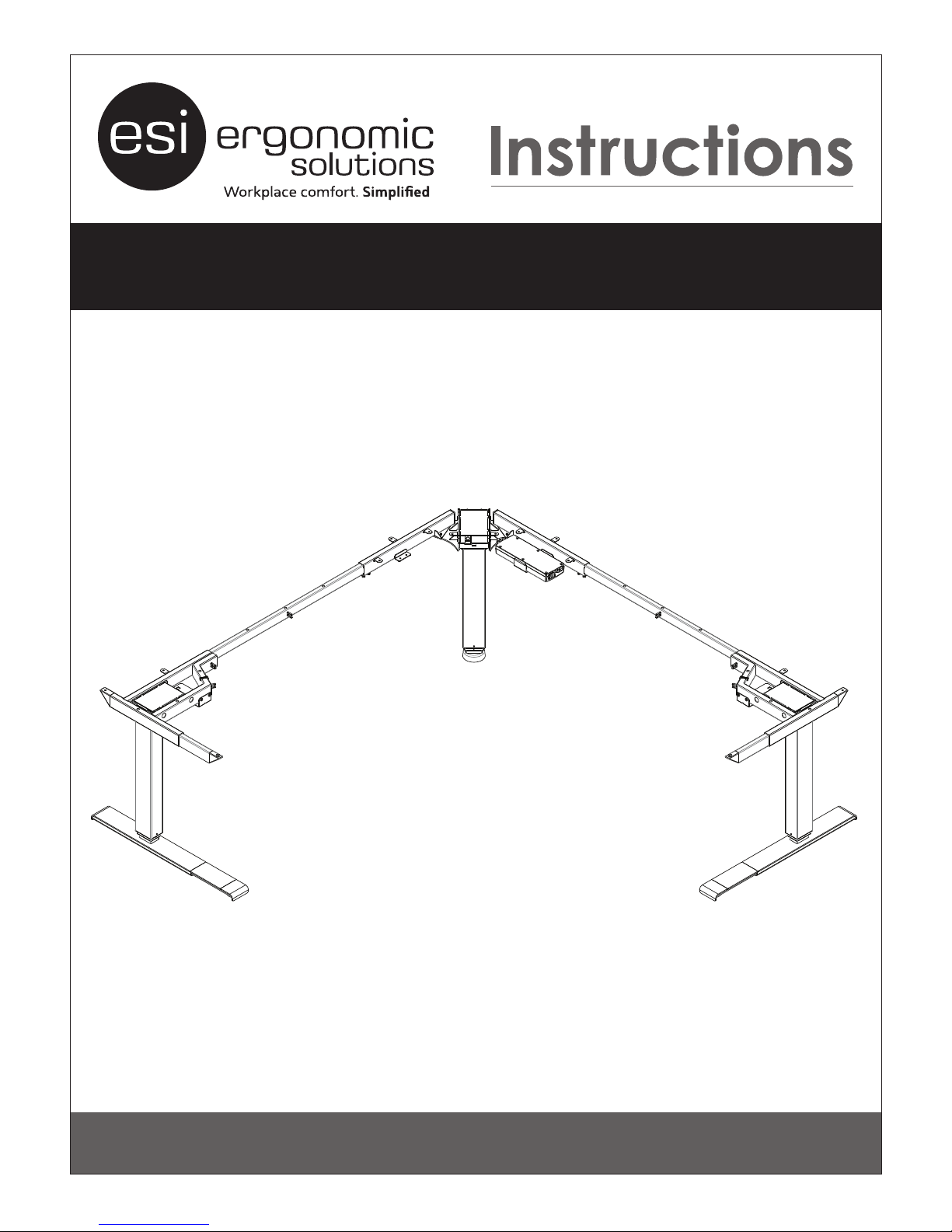

ALL-FLEX

3 LEG ELECTRIC TABLE BASE

FLEX3-V1 Rev B 6/17

™

Model FLEX3-SLV-V1

Model FLEX3-BLK-V1

Model FLEX3-WHT-V1

Page 2

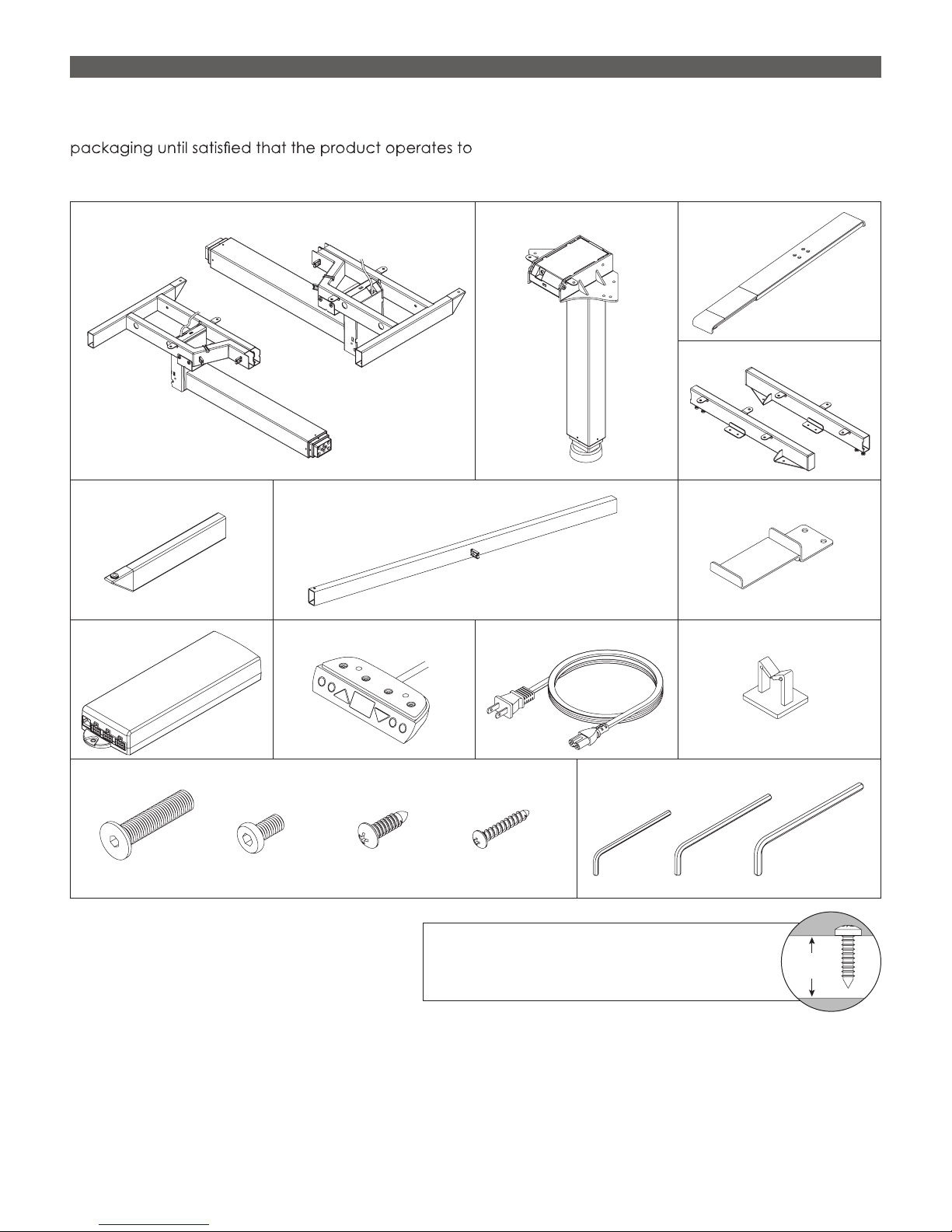

ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE PARTS AND TOOLS

Work

Surface

PLEASE REVIEW these instructions before beginning the assembly procedures. Check that all the parts shown

below were provided with your order. Contact your supplier if any materials are missing. Do not discard the

your satisfaction.

PARTS AND TOOLS PROVIDED

Leg Hinged to Frame (2)

Center Leg (1)

Adjustable Feet (2)

Fasteners

Left

Right

Cross Channel (2)Side Leg Top Support (2) Control Unit Bracket (1)

Digital Keypad (1)Control Unit (1) Cable Clip (4)Power Cable (1)

Allen Keys (1 each))

Center Leg Top Support (2)

Right

Left

M6x15 (14)M10x45 (8)

NOTE: This install requires a power tool or

cordless drill. Except for the hex head

screws, which is not a hand tool install.

ADDITIONAL TOOLS REQUIRED

•

#2 Phillips drill bit

• Power Driver

2

M5x18 (18) M4x23 (2)

CAUTION: Always check that screws used to

attach components to the work surface are

not too long for the thickness of the surface.

3mm 5mm4mm

Page 3

ASSEMBLY ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE

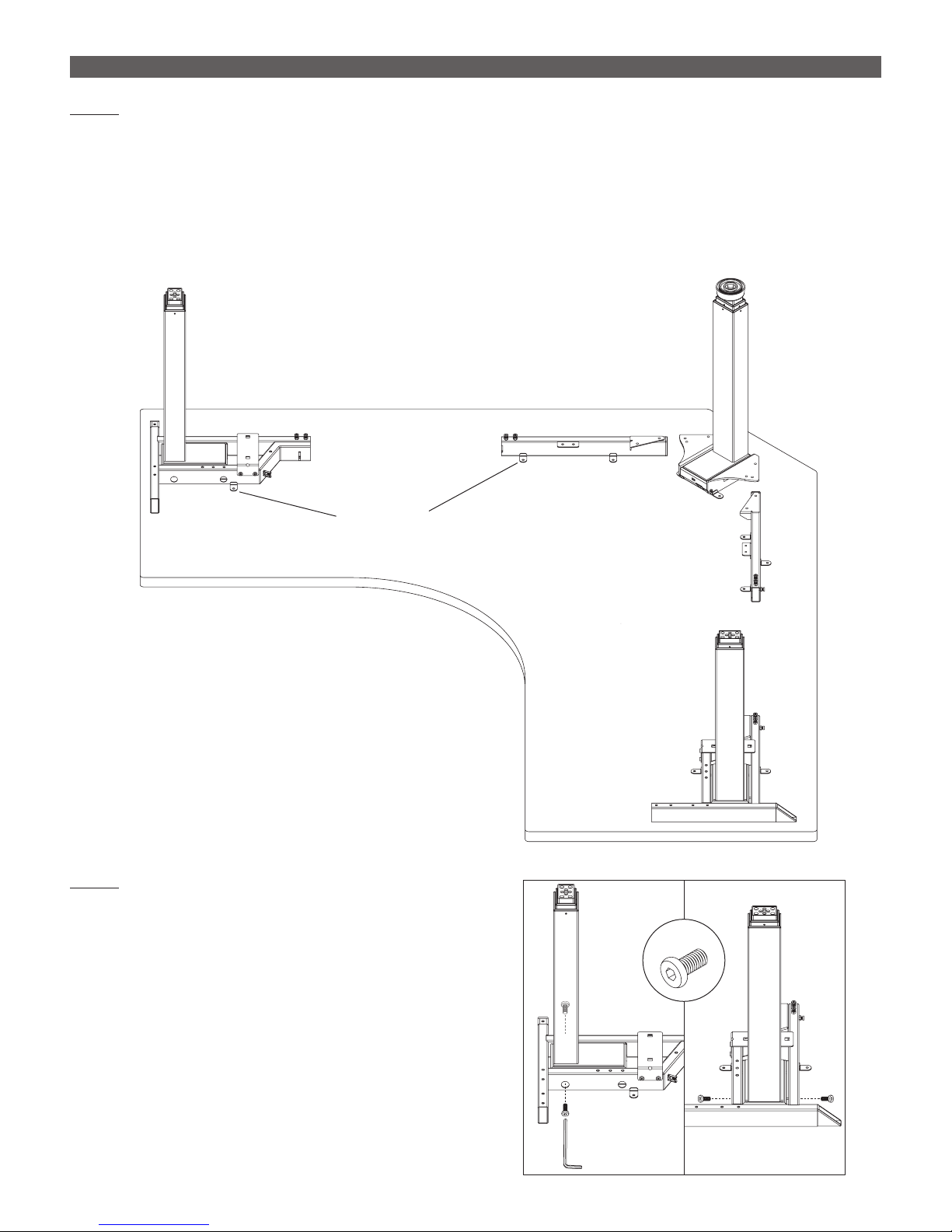

STEP 1

With the work surface facing down on a soft, clean surface, arrange the leg columns and center leg top

supports as shown.

• Unfold the hinged side legs and place them motor-side down at the ends of the work surface.

• Place the center leg motor side down near the 90° or 120° angle of the table.

• The mounting tabs on the leg columns and top supports must be face down so that they are against the

work surface.

Leg Column

with Frame

(Right)

Mounting Tabs

Center Leg

Top Support

(Right)

Center Leg

Center Leg

Top Support

(Left)

Leg Column

with Frame

(Left)

STEP 2

Lock the side leg columns in the upright position.

• Use the 4mm Allen key to install M6x15 hex head

screws into the frame and motor.

M6x15

4mm

Allen Key

3

Page 4

ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE ASSEMBLY

90°

120°

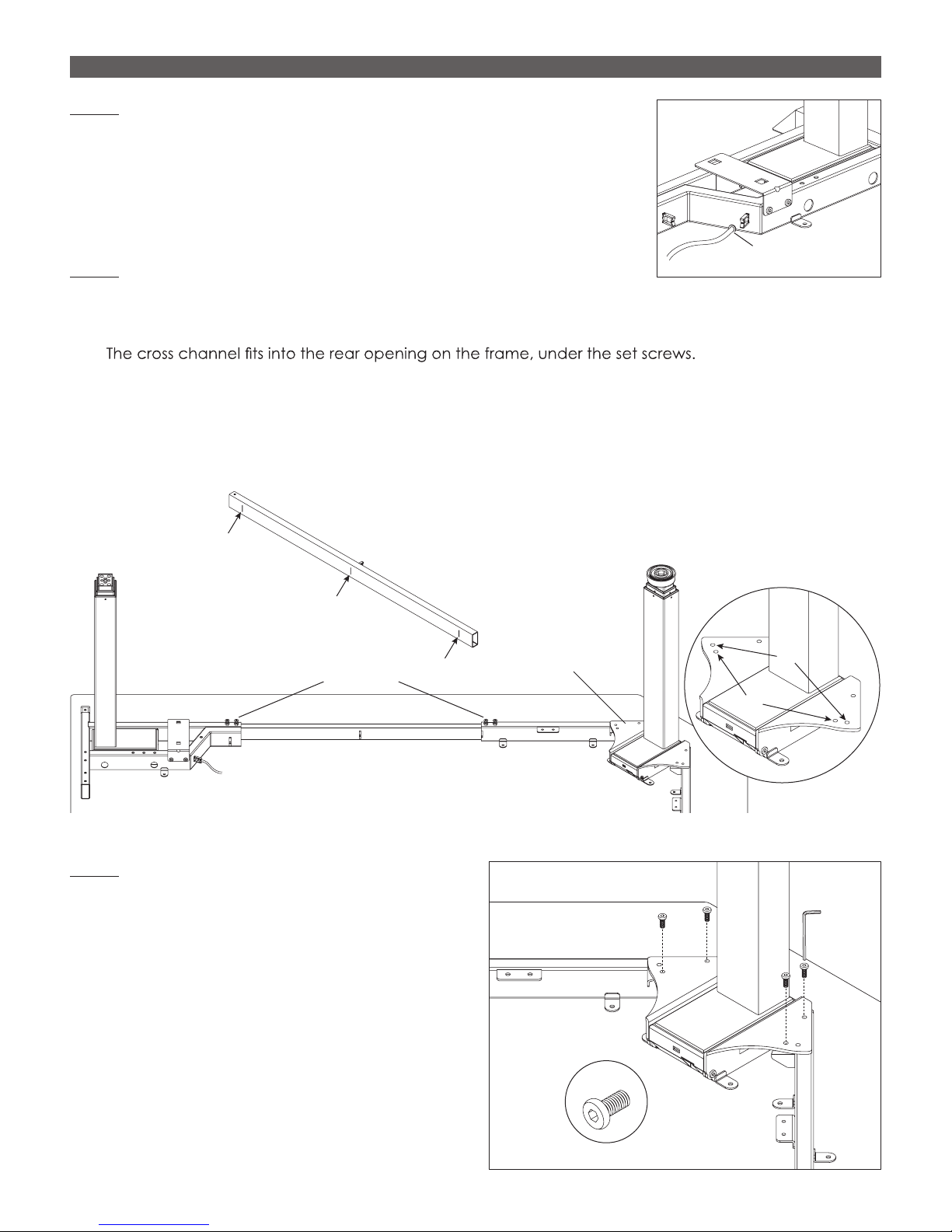

STEP 3

Route the side column motor cables under the notch on the angled

portion of each frame.

Route Cable

STEP 4

Install the cross channels.

• Insert each cross channel into the frame and center leg top support.

—

• Slide the top supports under the center leg brackets. Align the holes on the top supports with the 90° or

120° holes in the brackets. See the illustration below.

• Position each cross channel so that its center line is centered between the frame and the top support.

• The MAX lines must not extend beyond the frame and top support.

Under Notch

Cross Channel

MAX

Frame Top Support

Rear

Center Line

MAX

Set Screws

Cross Channel

STEP 5

Attach the top supports to the center leg brackets.

• Use the 4mm Allen key and four M6x15 hex head

screws.

• Use the inner hole on the bracket for 90° tables

and the outer hole for 120° tables.

Center Leg

Bracket

Top Support

4mm

Allen

Key

4

M6x15

Top

Support

Page 5

ASSEMBLY ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE

3mm

Allen Key

Set

Screws

Store

Adjustment

Plates

STEP 6

Attach the two-piece side top supports. One piece is attached to the frame; the other piece is separate.

• Insert the separate piece of the top support into the top support attached to the frame.

• Align the holes on the inserted piece with the rear set of two holes on the integral top support if the table

depth is less than 30" (76cm). Align the holes with the front set if the table depth is 30" or more.

4mm

Allen Key

Two-Piece

Top Channel

Use Rear Set of Holes

STEP 7

Change the length of the adjustable feet, if necessary.

• The length of the feet may be either 22" (55.9cm) or 28"

(71.2cm). The feet are shipped in the 28" length. They

should be changed to the shorter length if the work

surface depth is less than 28".

• To change the length to 22":

A. Remove the two plastic Phillips screws holding

the adjustment plate in place.

B. Use the 5mm Allen key to remove the four hex

head screws.

C. Use the 3mm Allen key to loosen the two set

screws.

D. Slide the feet to the 22" length. Reinstall the four

hex head screws and tighten the set screws.

• Store unused adjustment plates in the brackets

attached to the frame, securing them with the two

plastic Phillips screws.

24" Table

Adjustable

A

Allen Key

30" Table

Use Front Set of Holes

28"

22"

Length

C

B

5mm

D

5

Page 6

ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE ASSEMBLY

STEP 8

Attach a foot to each of the legs.

• Use four M10x45 screws per foot.

• Tighten the screws with an 5mm Allen key.

5mm Allen Key

M10x45

STEP 9

Adjust the position of the frame before attaching it to the work surface.

• Align the rear of the feet with the rear of the table.

• Center the center leg on the 90° or 120° angle.

• Check that the top supports on each side are approximately 1" (25mm) from the ends of the table.

• The rear of the feet should align with the rear of the table. With that alignment, the center leg top

supports will be 6½" from the rear of the table.

• Check that each cross channel’s center line is centered between the frame and top support, and that

the MAX lines do not extend beyond the frame and top support.

6½"

Align Rear of Feet

with Rear of Table

90°

1" 1"

1"

6½"

120°

6

Page 7

ASSEMBLY ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE

STEP 10

Once the frame is in its nal position, attach it to the work surface using the M5x18 screws (16 total required).

• Attach the screws through the mounting tabs on the frame, center leg column, and center leg top

supports, as well as the holes at the ends of the side column top supports.

• Use a power drill with #2 Phillips bit. This is not a hand tool install.

• After attaching the frame, tighten all 12 set screws, as shown below.

M5x18

Tighten All 12

Set Screws

STEP 11

Attach the control unit bracket to one of the center

leg top suports.

• Secure the control unit bracket to the frame using

two M6x15 screws and the 4mm Allen key.

• The bracket may be attached on either side of

the center column. (Note that the digital keypad

will be attached on the same side.)

M6x15

4mm Allen Key

Control Unit

Bracket

7

Page 8

ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE ASSEMBLY

Cables

STEP 12

Attach the control unit to the work surface.

• Slide the control unit under the bracket and

attach it using M5x18 wood screws. The motor

cable and keypad ports should face away from

the center column.

• Allow at least 2¼” (57mm) between the back of

the control unit and the center column assembly

to allow room for power cord attachment.

STEP 13

Attach the digital keypad flush with the front edge of

the work surface.

• Use the two M4x23 wood screws.

• Attach the keypad on the same side as

the control unit.

M5x18

Control Unit

M4x23

STEP 14

Make connections to the control unit.

• Connect the cable from the digital keypad.

• Connect the motor cables from the three motors.

• Connect the power cord to the control unit.

• Plug the power cord into an AC outlet.

CAUTION: Do not operate the table until after

“zero setting” the system. See the following step.

Digital Keypad

flush with the work

surface edge

Digital

Keypad

Cable

Motor

Power

Cable

Control

Unit

8

Page 9

ASSEMBLY ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE

Press and Hold Both Buttons

STEP 15

“Zero set” the system before testing operation. (Note that with the table and keypad will be upside-down,

the UP ▲ and DOWN ▼ buttons face their opposite directions.)

• Press and hold the UP ▲ and DOWN ▼ buttons at

the same time. Continue to hold the buttons. The

legs will retract until they reach their bottom point.

• Release the buttons once the system beeps. If it

Digital Keypad

does not beep, continue to hold the buttons for

Work Surface

3 seconds after the legs reach the lowest point. The

system is now “zero set.”

• Press the UP ▲ or DOWN ▼ buttons to test operation. End your test with the legs lowered and unplug the

power cord.

• If there are problems with operation, check that all cable and cord connections are secure. If problems

continue, call ESI Customer Service.

STEP 16

Use the pre-installed cable clips plus the additional clips provided, to secure the cables in position.

• Cables must not interfere with table operation.

• Cables must not interfere with the user.

Pre-Installed

Cable Clip

Cable Clip

9

Page 10

ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE ASSEMBLY

STEP 17

With the assistance of a helper, turn the table upright and place it in its nal position.

IMPORTANT: There must be 1" (25mm) of clearance on all sides of the work surface (and other moving parts)

to ensure free, unobstructed movement.

• Adjust the leveling glides on the feet to level the work surface, if necessary.

• Plug the power cord into an AC outlet.

• See the following page for operating procedures.

10

Page 11

OPERATION ALL-FLEX™ 3 LEG ELECTRIC TABLE BASE

Memory

Table

UP

Memory

DOWN

Buttons

Button

Height

Button

Buttons

CAUTION: The “zero setting” procedure

must be completed before operating the

table. See Step 15 on page 9.

GENERAL OPERATION

Move the table up or down by pressing UP s or DOWN t until

the work surface reaches the desired height.

The table will continue to move up or down until you release the

button or until the maximum or minimum height is reached.

IMPORTANT: Be sure there are no obstructions to table

movement along its full range of travel.

SETTING A MEMORY POSITION

The memory buttons allow you to save up to four specic

positions of the work surface. To set a memory position:

• Adjust the work surface to the position you want to save. (The

display on the control pad shows the work surface height.)

• Press the UP s button and one of the memory buttons at the

same time for 3 to 5 seconds.

Table movement stops when you

release the UP s or DOWN t button.

Example: Press the UP s button and

memory button number 3 at the

same time for 3 to 5 seconds. The

display will ash “P3” indicating that

the current table position has been

saved in memory.

• The display will ash “P” and the number of the memory

button.

• Repeat for the other memory buttons, if desired.

MOVING TO A MEMORY POSITION

• Press and hold the desired memory button.

• The work surface will move to the preset position.

Continue to press the memory button

until table movement stops.

11

Page 12

800.833.3746 esiergo.com

© 2017 ESI Ergonomic Solutions. All rights reserved. FLEX3-V1 Rev B 6/17

Loading...

Loading...