Eschweiler Combi Service manual

combi n line

Blood-Gas-Electrolyte-Analyser

For In-Vitro-Diagnostic Use

!

Service Manual

Eschweiler GmbH & Co. KG

Development - Manufacturing - Sales - Technical Service

Made in Germany

Service Manual

Manual Version

Manual History

Software Copyrights

The latest Manual version is: 4.01

Order No.:

Copyright © 2010 by

Eschweiler GmbH & Co. KG, Holzkoppelweg 35, 24118 Kiel

No part of this Manual may be reproduced in any form without the

written permission of Eschweiler GmbH & Co. KG.

Manual ANALYSER-Software Revision

Version Version Date

4.01 2500 April 2010

The software for the combiline Analyser is the User and Instrument Control Software for the combiline. The combiline Software is the intellectual

property of Eschweiler GmbH & Co. KG hereafter Eschweiler.

Intellectual property rights shall remain with Eschweiler.

60 8 90 10 Print: SMe COMBILINE 401.PDF

!

Manufacturer

You are entitled to use the combiline Software and the printed accompanying material at your place of work only.

Any violations of property rights or copyright or trademark or conditions

of use may be subject to legal action.

Eschweiler GmbH & Co. KG

Holzkoppelweg 35

24118 Kiel, Germany

Phone: -49- 431-54 65 80

FAX: -49- 431-54 94 23

Internet: http://www.eschweiler-kiel.de

E-Mail: info@eschweiler-kiel.de

Service Manual

Consumable solutions and spare parts from other manufacturers used in ESCHWEILER Analysers.

We point out specifically that fault-free operation of our analysers can be

guaranteed only when original ESCHWEILER solutions and spare parts are

used.

The name ESCHWEILER with its decades of experience in the field of blood

gas analysis also stands for the quality of the spare parts and consumable

solutions. ESCHWEILER sensors and solutions form a functional unit

whose components are optimally adapted to each other. Measuring accuracy

and long life of the sensors are the goal of this system.

Through intensive development work, the chemical compositions of our

solutions have been adjusted optimally to the ESCHWEILER sensors and

guarantee, besides precise measurements, the greatest possible protection of the sensitive sensor surfaces.

For example, special wetting solutions are used which have a decisive

influence on the unconstrained contact between sensor and solution in the

measuring capillary. At the same time suitable preservatives prevent the

growth of micro-organisms in the consumable solutions and keep them from

being introduced into the measuring capillaries of the ESCHWEILER

analysers.

The characteristics and concentrations of both the wetting- and the

preservative substances are selected according to the special requirements of our sensors.

Fault-free operation of our analysers with measuring accuracy and long

sensor life are the main goals of our quality requirements. Only if

ESCHWEILER original parts and solutions are used we can meet these

requirements.

Please support us in doing this!

Service Manual

Table of Contents

Safety Issues ................................................................................................................................................ 2-5

Technical Data. ................................................................................................................................................ 6

Menue Guide. .................................................................................................................................................. 7

System Description ...................................................................................................................................... 8-11

Tubing. ....................................................................................................................................................... 12-15

Specification of Valves..................................................................................................................................... 16

Blockdiagram. .................................................................................................................................................17

Power Supply ..................................................................................................................................................18

Power Supply ESW-MVTC......................................................................................................................... 19-24

Adjustment of the operating voltage for Rollerpumps RP1 and RP2. ................................................................ 21

Adjustment of Thermostate Temperature ......................................................................................................... 23

Analog-Board ESW-ANALOG..................................................................................................................... 25-35

Adjustment of O2 Polarization Voltage and O2 Zero Point. ..............................................................................27

Circuit diagram for Sample-light-Barrier ...........................................................................................................28

Circuit Diagram for Hb-unit ..............................................................................................................................28

Testing the Airpressure Indication. ...................................................................................................................29

Adjustment of Thermostat Temperature-Indication. .......................................................................................... 30

Adjustment of the Sample Light-Barrier ...........................................................................................................31

Capillary exchange in Sample-Light-Barrier .....................................................................................................32

Hb-Measurement module ...........................................................................................................................33-35

CPU / AD-Converter CL Z80ADC. .............................................................................................................. 36-40

Serial Interface with SD Card Reader RS232 SD INT1.4 ............................................................................. 41-47

Fill Level Control CL FÜLLSTAND............................................................................................................... 48-50

Keyboard. .......................................................................................................................................................51

Display / Contrast. .......................................................................................................................................... 52

Thermoprinter GPT-4352-60 .............................................................................................................................54

Liquid-Valves .............................................................................................................................................. 55-56

Delay Circuit for Ventilation Valve ....................................................................................................................57

Suction-Pump ............................................................................................................................................ 58-59

Sensor Spare Parts and Lifetime Information. .............................................................................................60-62

Consumeables ........................................................................................................................................... 63-65

Spare Parts ................................................................................................................................................ 66-68

TÜV Certificate ................................................................................................................................................69

Declaration of Conformity ................................................................................................................................ 70

combiline Service- Manual - Version 4.01

page 1 page 1

page 1

page 1 page 1

Safety Issues

Biohazard

CAUTION

DANGER

NOTE

DANGER

Please read the Instruction Manual in its entirety prior to operating the

combi

references to technical safety in this Instruction Manual have to be followed.

! 1 Hazards and Precautions

The cautions and safety regulations in this Instruction Manual meet international classifications:

Warns of a risk of injury or of a risk to life (for example by electrical shock).

Warns of a risk of injury or of the analyser being severely damaged.

Warns of a risk of biological material like blood or other human or animal

specimen. Risk of infection! Potential infectious area/material!

lineline

line. In order to ensure a high level of performance, all warnings and

lineline

Electrical safety

Introduces rules to be observed.

The following safety issues have to be observed at all

times:

- Check that the operating voltage is set correctly before you connect the

device to the main power supply.

- To connect the analyser to the main power supply, use only sockets which

are grounded to avoid the risk of an electrical shock.

- Use only grounded extension power cords. The used power cord has to

correspond to the country specific regulations.

- Never intentionally disconnect the grounding contacts.

There is the risk of electrical shock if the protective conductor is interrupted within or outside the analyser, and/or the grounded contacts have

been disconnected from the line.

- Never remove protective guards or secured components since you could

expose electrically live parts in this way.

- Electrical connection contacts (plugs, sockets, etc.) can be electrically live.

page 2page 2

page 2 Service- Manual - Version 4.01

page 2page 2

combiline

Safety Issues

Biohazard

CAUTION

- Even after an analyser has been switched off, components (e.g. capacitors) can be under voltage as the result of an electrical charge.

- All current carrying parts are sources of danger for an electrical

shock.

- Surfaces (floors, work tables) have not to be moist when you are working

with any electrical device.

- Carry out only the maintenance work and/or the replacement of parts

described in these Instruction Manual.

- Unauthorized work on the analyser can lead to the guarantee obligation

becoming null and void with necessary expensive service work to

correct it.

- All work, which requires the analyser to be opened, have to be carried

out by an authorised technician who is familiar with the risks related

thereto.

- Use only replacement fuses of the stated type and with the stated nominal current. Never use fuses, which have been “repaired”.

- There is a Lithium battery on MAIN BOARD that have to be replaced

Mechanical Safety (Analyser is

operating)

- Never open or unscrew analyser's casing parts while it is switched ON.

Biological Material - Risk of Infection

- Wear gloves in all cases if there is a risk of infection.

- Avoid any direct contact with samples that are potentially infectious or

- If sample material (blood) or reagent is spilled onto the analyser, wipe it off

by the authorised technical service every 5 years! In case of a battery

fault, all memorised parameter might be lost.

There is a risk of injury due to moving parts as fans, pumps,

stepper-motors or any other mechanical movements.

which may generate other risks to the human body (Aids, Hepatitis etc).

In case of direct body contact go and wash the contaminated area

immediately. Use a suitable skin disinfection solution. Ask your doctor for

aid.

immediately and refer to the chapter ! 2 Maintenance and Hygiene.

- Do not open a waste bottle as long as the analyser is in process.

combiline Service- Manual - Version 4.01

page 3 page 3

page 3

page 3 page 3

Safety Issues

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Reagents and Controls

- Observe the suggestions in the package inserts for an exact use of the

- Don't use Reagents, Controls and other Liquids after expiration date!

- Avoid any liquid penetration into the analyser.

Restrictions for Samples, Reagents

and Controls

- For consumables no guarantee can be provided for any resistance against

- Do not use any other rinsing or cleaning solutions as recommended by the

- Waste liquid has to be disposed in compliance with the legislation.

Accuracy and Precision of the

Measured Results

- In order to ensure a flawless operation of the analyser measure control

reagents and quality controls. Note that reagents and quality control material can be biological material!

organic solvents. For this reason, do not use any organic solvents unless

such solvents are expressly indicated.

manufacturer or representative.

samples and watch the function of the analyser closely.

- Faulty measurement results may result in an incorrect diagnosis or range

danger for patient.

Fire and Explosion Hazards

- Do not place any flammable or hazardous explosive material in the

proximity of the device. Electrical sparks could cause fire or explosions.

Operator Qualification

- The analyser should only be operated by trained personnel. Improper

operation of the analyser might cause inaccurate measuring results!

! 2 Maintenance and Hygiene

- No organic acid based cleaning substances should be applied. Instead

use cleaner designed for cleaning and disinfecting laboratory analysers.

Only use a dampened cloth to clean the analyser.

- Never spray or pour cleaning solution directly onto the analyser, that may

negatively impact the analyser’s functions significantly.

- Keep the analyser clean and do not spill liquids onto it.

- In case liquids were spilled onto the analyser, immediately absorb liquid

with a suitable cloth.

- Contact your distributor if your control measurements do not produce the

expected results.

page 4page 4

page 4 Service- Manual - Version 4.01

page 4page 4

combi

line

Safety Issues

CAUTION

NOTE

Recommended Disinfectant

Solutions.

A suitable disinfectant is available by BODE Chemie, Hamburg:

Bacillol®, is recommended for areas at risk of infection, where rapid

contact times and drying times are necessary.

BODE Chemie GmbH & Co

Melachtonstr. 27 - 22525 Hamburg, Germany

Phone: +49- (0)40-54 00 60 - Internet: www. bode-chemie.de

Another suitable disinfectant is available by S&M Schülke & Mayr:

TERRALIN® Liquid

Schülke & Mayr GmbH

Robert-Koch-Str. 2 - 22851 Norderstedt, Germany

Phone: + 49- (0)40-521 00-0 - Internet: www.schuelke-mayr.com

See the website for your nearest representation. Ask for an EC Material

Safety Data Sheet according to EC 91/155.

! 3 First-Aid Measures

! 4 Repairs

Useful hint

If a person swallowed any chemical solution may be while servicing,

wash out mouth with water.

If provided person is unconscious, than call a physician.

If inhaled, remove to fresh air. If breathing becomes difficult, than call a phy-

sician.

In case of contact, immediately wash skin with soap and copious amount of

water.

In case of contact with eyes, flush with copious amounts of water for at least

15 minutes.

Assure adequate flushing by separating the eyelids with fingers, than call a

physician.

- Repairs to the analyser may only be carried out by trained personnel, and

replacement parts have to comply with the analyser specifications.

- In case of analyser problems contact your representative.

In this Manual a bullet "•" draws your attention to an instruction.

Example:

• Press enter-key to confirm ...

combiline Service- Manual - Version 4.01

page 5 page 5

page 5

page 5 page 5

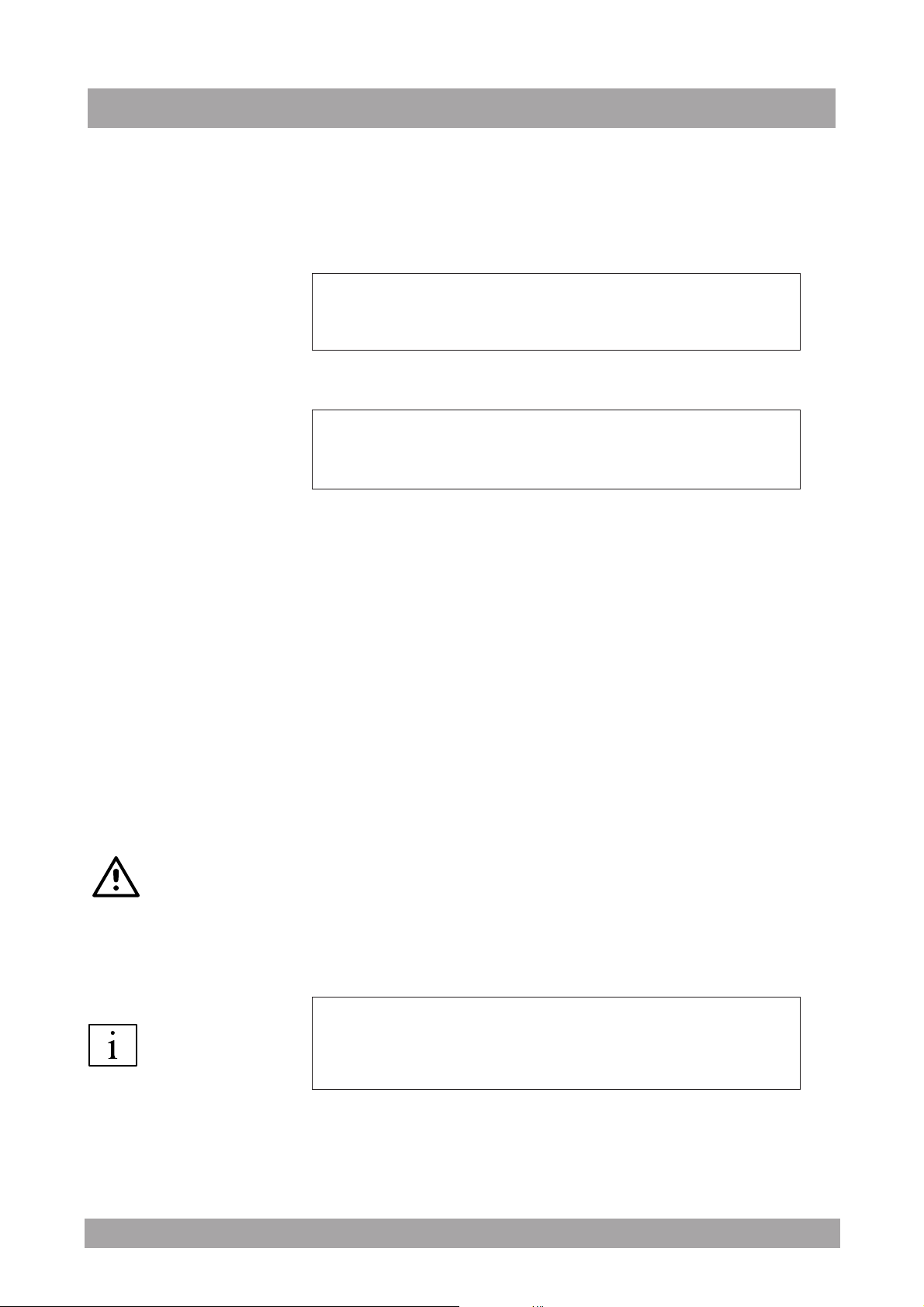

Technical Data

page 6page 6

page 6 Service- Manual - Version 4.01

page 6page 6

combi

line

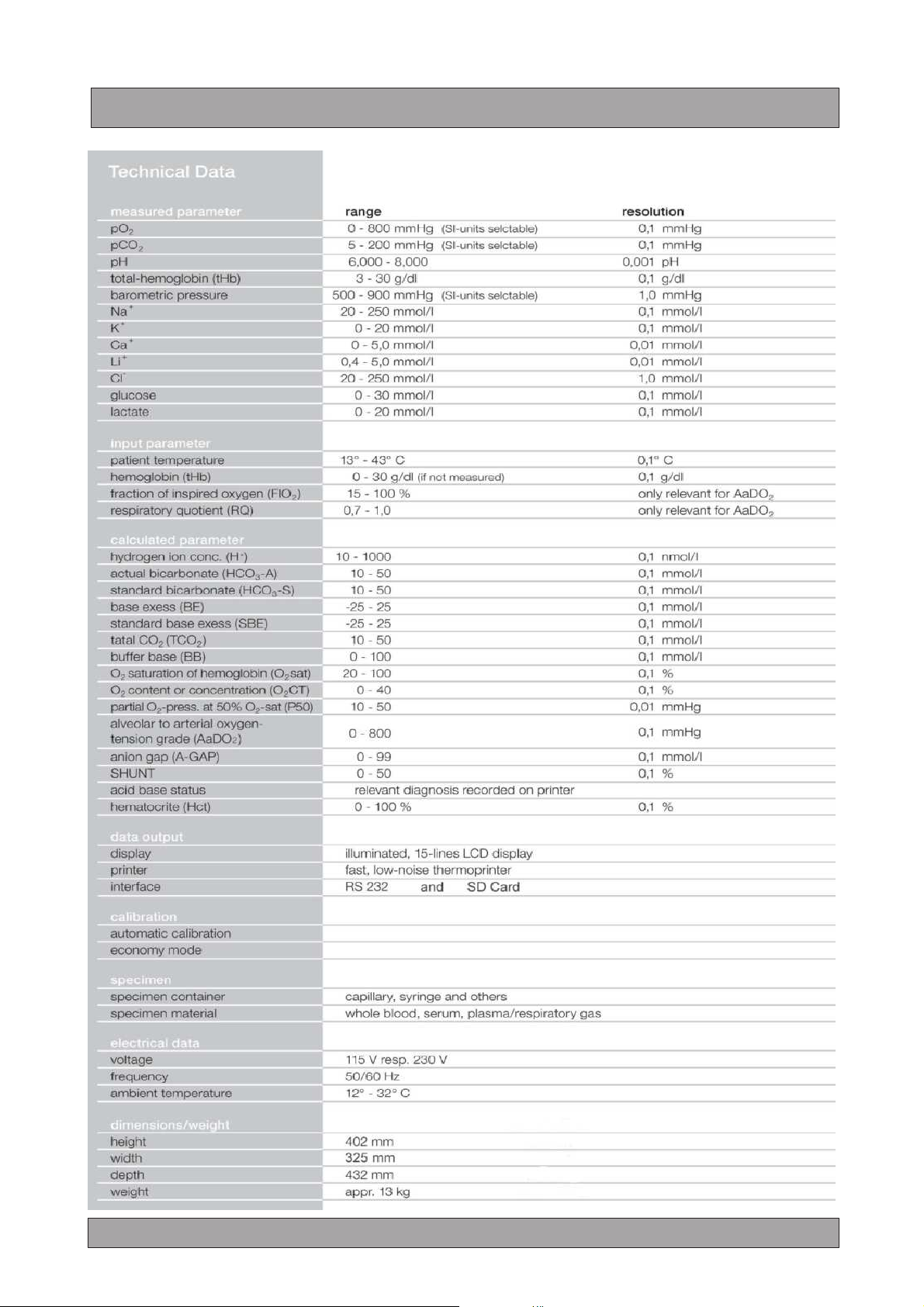

SERVICE - TEST

1 = BGA 1 / 3 ***

2 = BGA 2 / 4 ***

3 = CAL 3 **

4 = CAL 4 **

5 = GAS ***

6 = AIR / TEMP

7 = LIGHT BARRIER

8 = PROTEIN *

9 = REAGENT TEST

STANDARD DATA

1 = CALIBRATION DATA ***

2 = DATE / TIME

3 = CORRELATION

4 = SETTINGS

5 = SENSOR SELECTION

6 = AB-PARAMETER ***

Sample introduction by

selection of:

MEASURE

(SYRINGE or CAPILLARY)

specify:

- BGA and meta values only

- ISE and meta values only

QC specify:

- LEVEL 1

- LEVEL 2

- LEVEL 3

- LEVEL 4

ASPIRATION GAS

POWER UP COMBILINE

STAND BY

DIALOGUE

WARM UP PHASE

OF 1 HOUR

AUTO-CALIBRATION

OF SENSORS

DISPLAY

MEASURED

ECONOMY

PROGRAM

PRINT

MEASURING DIALOGUES

press 1 x

OPERATION key

to select Menu

Rev. 2.500

Attention!

Sofware functions marked with *

are not accessible during Warming Up!

Software functions marked with **

are not available in BGA types!

Software functions marked with ***

are not available in ISE types!

1 = RINSE

2 = CALIBRATION *

3 = CALIBRATION BGA * **

4 = CALIBRATION ISE * **

5 = ACTIVATION HB *

6 = SENSOR PARAMETER *

OPERATION

7= ECONOMY MODE *

8 = DISPLAY MEASURED

press 2 x

OPERATION key

to select Menu

press 3 x

OPERATION key

to select Menu

Menue-Guide

combiline Service- Manual - Version 4.01

page 7 page 7

page 7

page 7 page 7

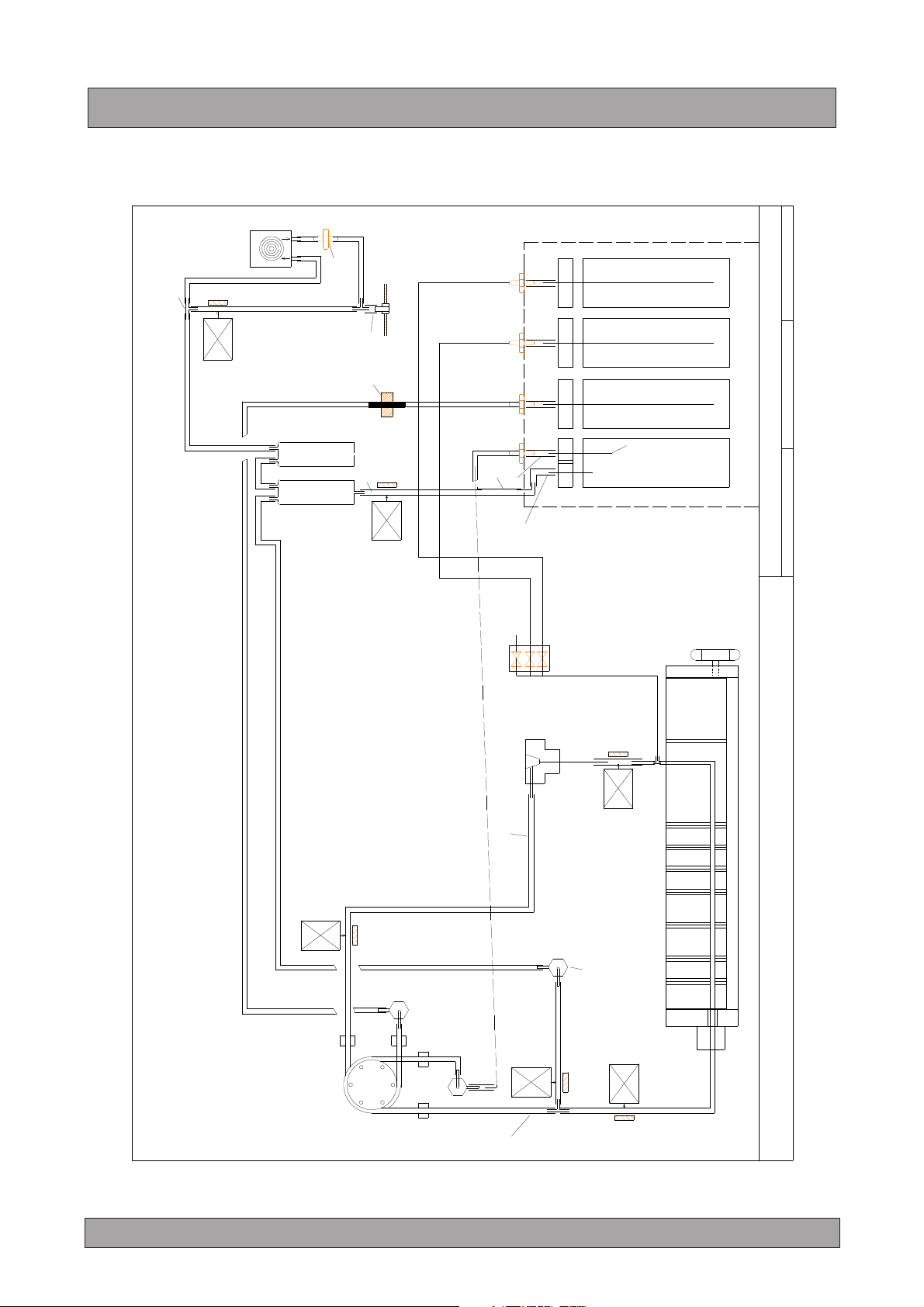

System Description

Opened front cover

Order no.

1 - LCD-Display F100.4.2

2 - Function keys 50 8 20 70 (keyboard compl.)

3 - Numerical keys 50 8 20 70 (keyboard compl.)

4 - Screw joint of Reagentwall

5 - Display-Contrast

6 - Peristaltic Pump meta 50 7 40 00

7 - Peristaltic Pump 50 7 40 00

8 - WASH-Valve F200.25

9 - Sampleport-Insert 1-8.106

10- Liquid-Valves for Cal.Solutions 50 8 30 20

page 8page 8

page 8 Service- Manual - Version 4.01

page 8page 8

11- Suction-Valve F200.25

12- Sampleport-Valve F200.28

13- Input-Valve F200.25

14- Sample Light-Barrier 40 7 10 20

15- Thermostat with Sensors

16- Hb-Sensor type II 50 2 10 01

17- Sensorcatch 50 7 20 10

18- Panel for therm. illumination 50 7 20 21

19- Metabolite valve F200.25

20- Metabolite unit

Order no.

combi

line

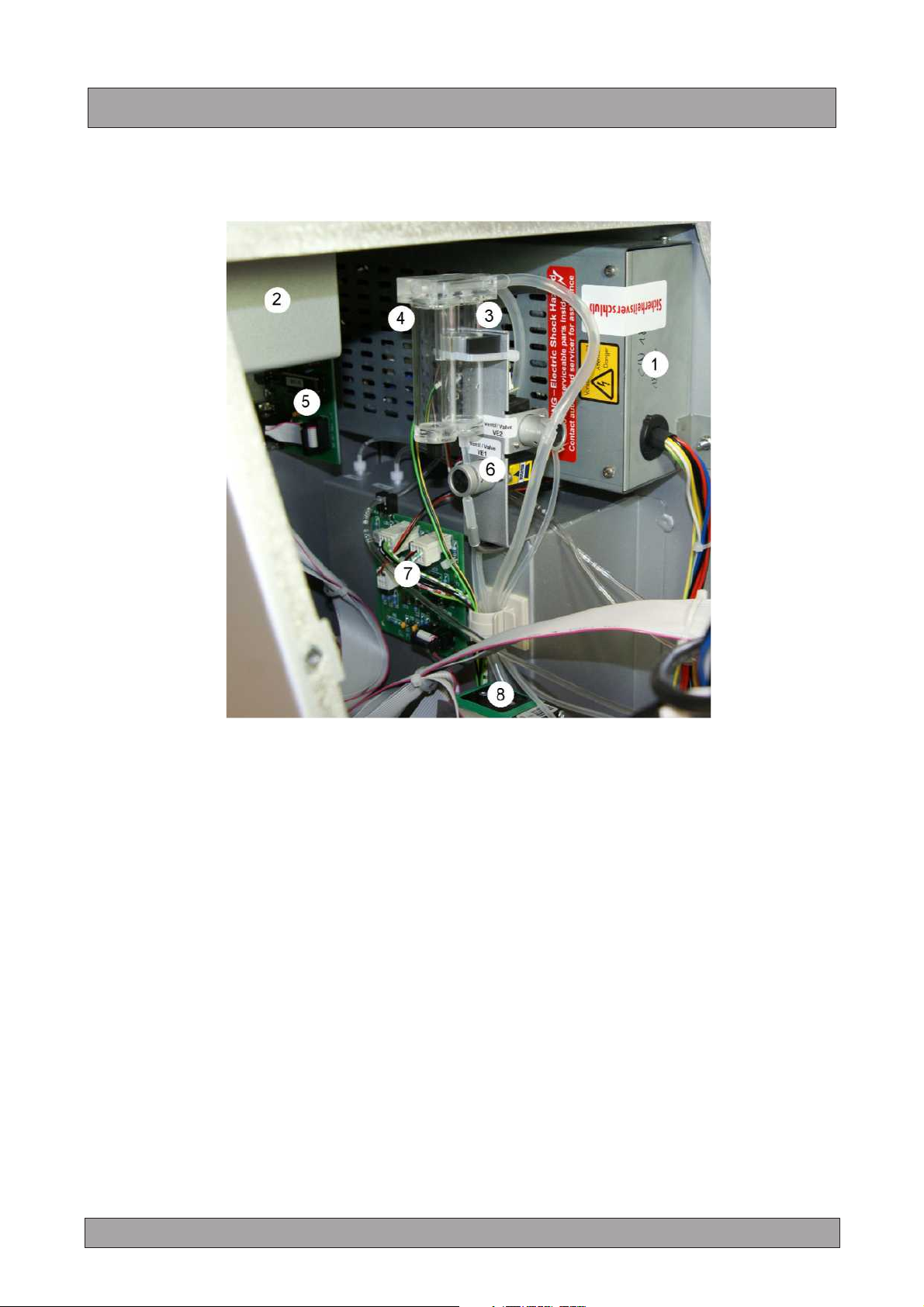

System Description

Opened Front

1 - Switching power supply 60 8 10 90

2 - Thermoprinter GPT-4352-60 60 8 20 90

3 - Intermediate Vessel for suction 40 7 10 50

4 - Dampness Absorber 40 7 10 50

5 - Interface RS232 with SD-Card Reader 60 8 20 40

6 - Pinch Valve VE1 and VE2 F200.25

7 - Filling Level Control board CL-FÜLLSTAND 40 8 20 00

8 - Suction Pump F10.19

combiline Service- Manual - Version 4.01

Order no.

page 9 page 9

page 9

page 9 page 9

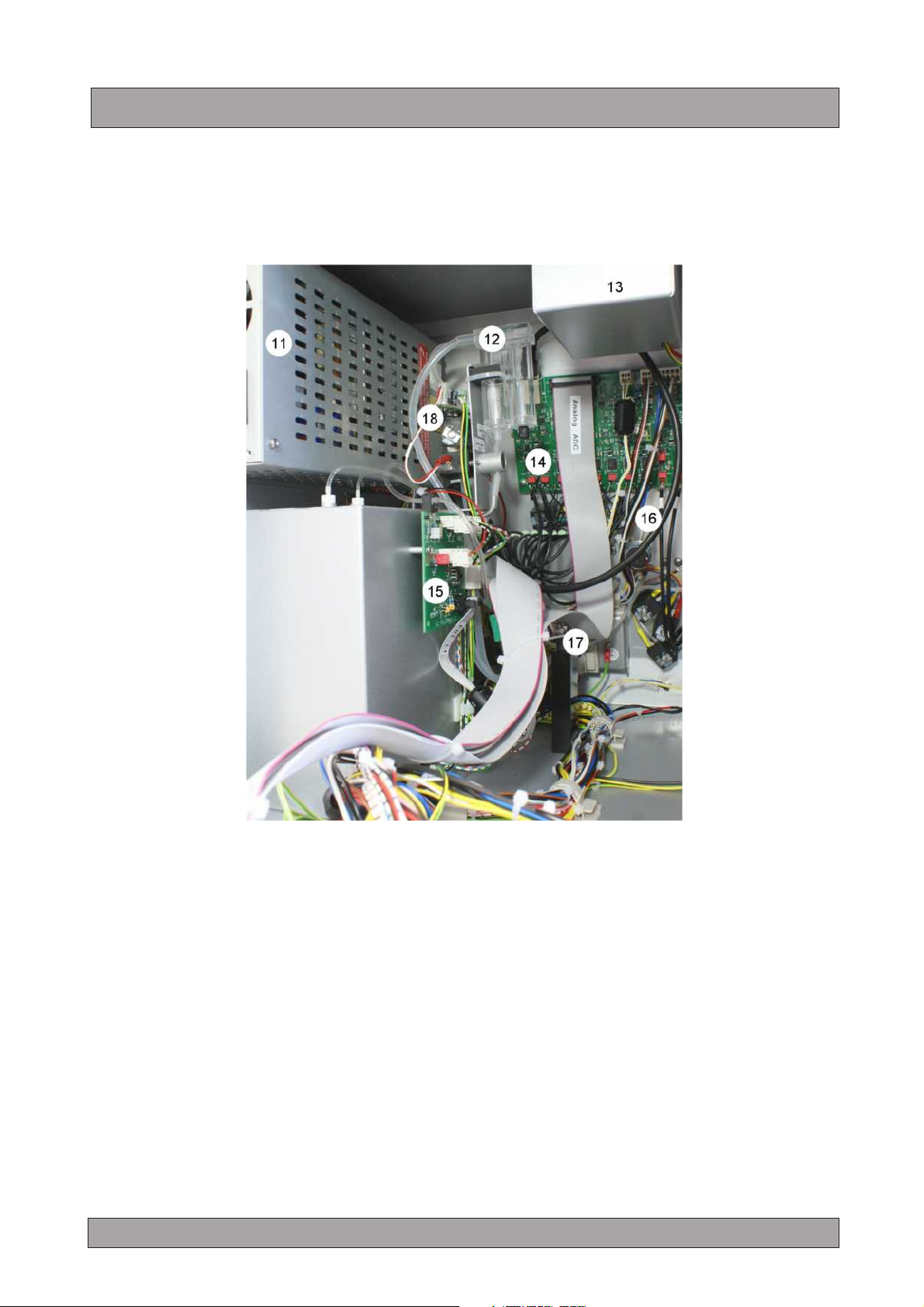

System Description

Opened Rear Wall

11 - Switching Power Supply 60 8 10 90

12 - Intermediate Vessel 40 7 10 50

13 - Thermoprinter GPT-4352-60 60 8 20 90

14 - Analogboard ESW-ANALOG 60 8 10 xx / 60 8 11 xx

15 - Filling Level Control board CL-FÜLLSTAND 40 8 20 00

16 - Rollerpump Motor with gear 50 7 40 10

17 - Suction Pump F10.19

page 10page 10

page 10 Service- Manual - Version 4.01

page 10page 10

Order no.

combiline

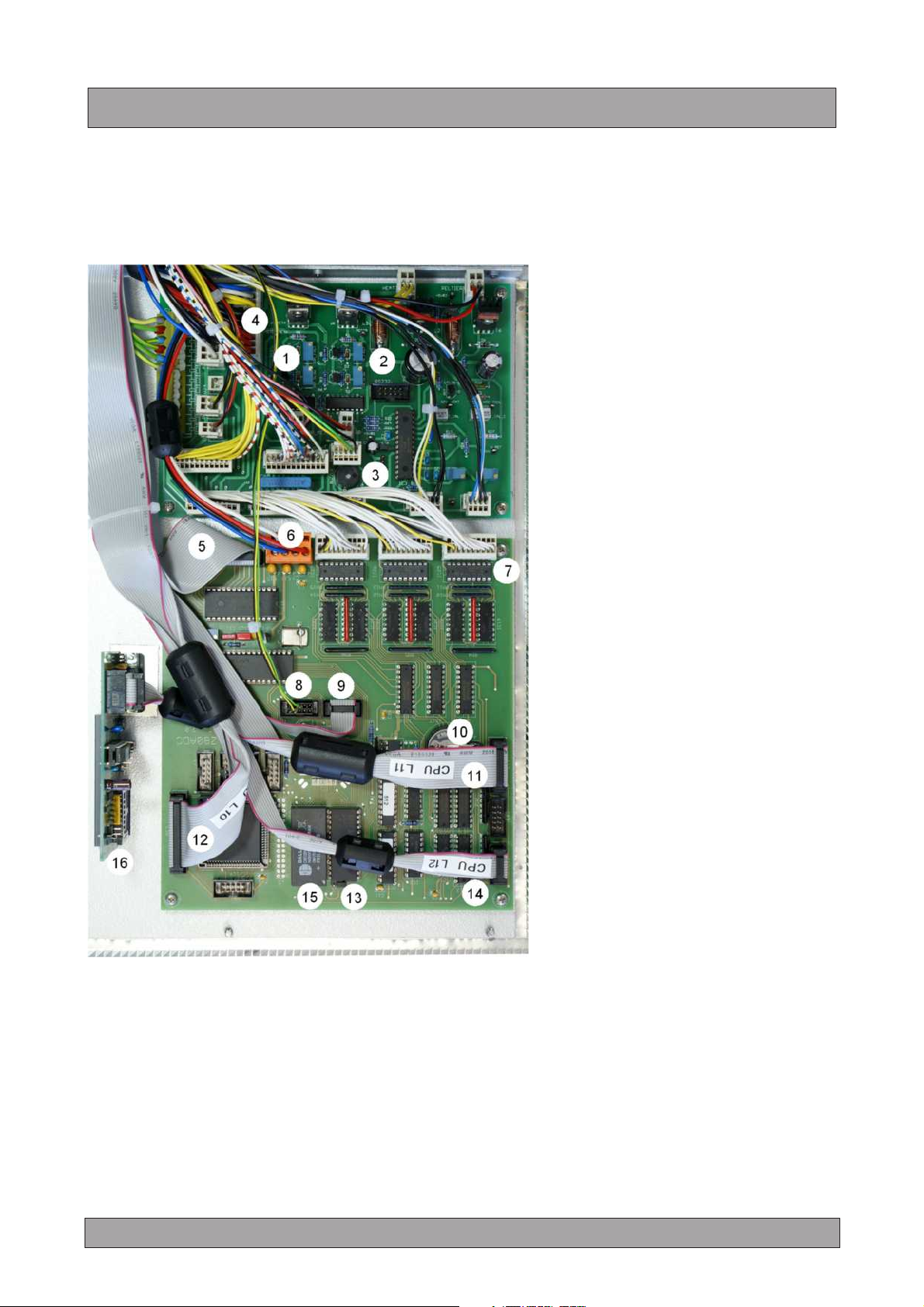

System Description

Opened Rearwall, inside

CPU Board Z80ADC 1.2 and Power Supply ESW_MVTC

ESW_MVTC 2.0 60 8 10 80

1 - Potentiometer Rollerpump 2

2 - Potentiometer Rollerpump 1

3 - Buzzer

4 - Voltage input from Switching Power Supply

CPU CL Z80ADC 1.2 60 8 10 70

5 - L4 Connector for Analogboard ESW ANALOG

6 - Connector for DC-Supply (+5V)

7 - Driver ICs for Valve and Motor Control

8 - Printer Interface 9600 Baud

9 - Connector for RS232 Interface, 9600 Baud

10- Lithium Battery 3V Type BR2325

11- L11 LCD-Display

12- L10 Keyboard

13- Eprom with Analyser Software

14- L12 Filling Level board CL FÜLLSTAND

15 -RAM

16 - SD-Card Reader with RS232 Interface

combiline Service- Manual - Version 4.01

page 11 page 11

page 11

page 11 page 11

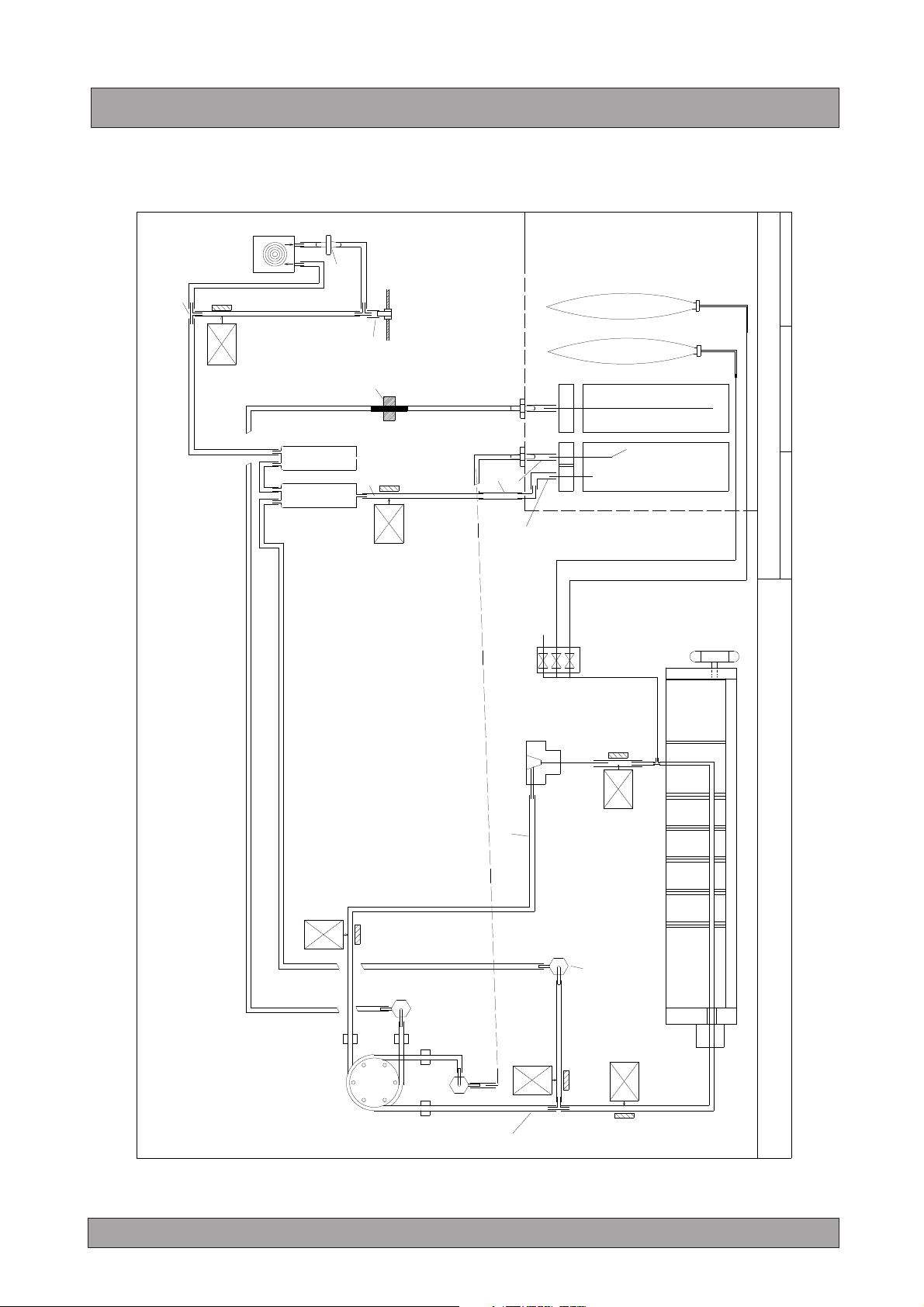

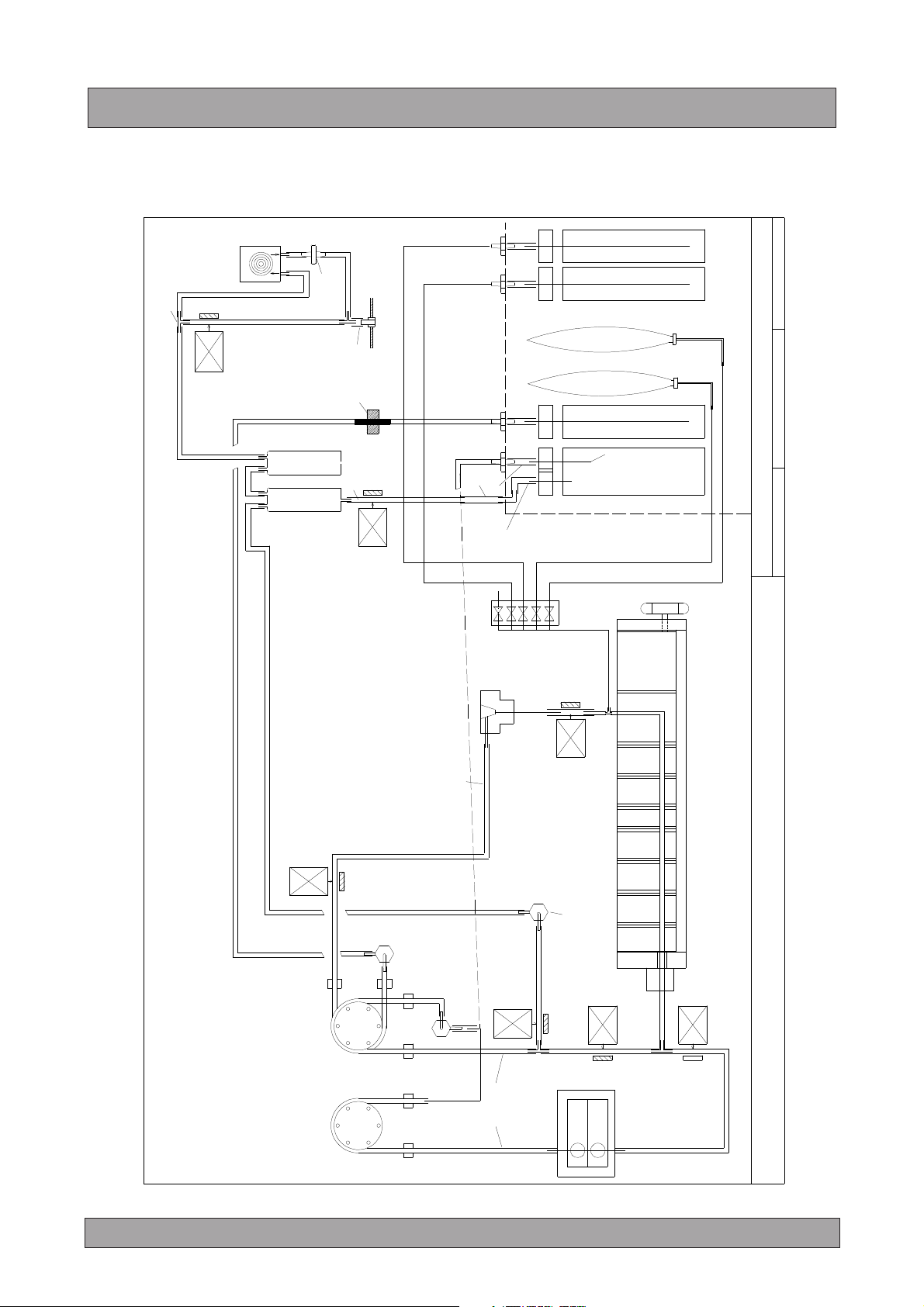

Reagent-Transport

Ref

Zwischengefäß

Intermediate-Vessel

R20.28

SR20.8

Absaugpumpe

SP

Entlüftungsventil

EV

Entlüftungsventil

SR20.3

pH

ABS

SR20.12

R20.8

R20.8

R20.8

DATUM:

RP

SR20.18

SR20.19

SR20.20

SR20.17

SR20.16

BEZ.:

SV20.7

SR20.24

SR20.13

suction-pump

SV20.6

S204-06

S204-06

S204-06

S204-06

S104-08

ESCHWEILER GmbH & CO. KG KIEL GERMANY

SR20.12

SR20.19

Abfallflasche

BGA 1 BGA 2

SR20.23

pCO2 pO2

LS

HB

COMBILINE BGA

SR20.22

SR30.14

WASH

VE1

VE2

SP-COMBILINE BGA+HB.TCD

28.07.2008

BGA 2

BGA 1

LV

PV

S204-06

Feuchtefilter

Dampness Absorber

VERSCHLAUCHUNG / TUBING REV 1.1

VERSION: 1.1

waste bottle

Kalibrierlösung

Calibration-Solution

Ventilblock

Valve-block

F200.26

40-8.101 (set)

F200.25

F200.25

F200.25

35-8.101 (set)

F200.25

Rollerpump

(peristaltic-pump)

Rollerpumpe

F200.25

ventilation valve

ventilation valve

F200.25

F10.19

Light barrier for

level control

(CL Füllstand)

stromlos offen

normally open

stromlos offen

normally opened

normally open

stromlos offen

normally open

stromlos offen

normally open

stromlos offen

sample-port

Probenport

1-8.106

normally open

stromlos offen

Rm100.21

combiline BGA

page 12page 12

page 12 Service- Manual - Version 4.01

page 12page 12

combiline

Reagent-Transport

Ref

Zwischengefäß

Intermediate-Vessel

R20.28

SR20.8

Absaugpumpe

SP

Entlüftungsventil

EV

Entlüftungsventil

SR20.3

pH

ABS

SR20.12

R20.8

R20.8

R20.8

DATUM:

RP

SR20.18

SR20.19

SR20.20

SR20.17

SR20.16

BEZ.:

SV20.7

SR20.24

SR20.13

suction-pump

SV20.6

S204-06

S204-06

S204-06

S204-06

S104-08

ESCHWEILER GmbH & CO. KG KIEL GERMANY

SR20.12

SR20.19

Abfallflasche

Kalibrierlösung

Calibration-Solution

SR20.23

SR20.9

CAL 4CAL 3

Na

Li

K

LS

E

COMBILINE ISE

SR20.22

SR30.14

WASH 2

VE1

VE2

SP-COMBILINE ISE.TCD

06.10.2006

CAL 4

CAL 3

LV

PV

S204-06

Feuchtefilter

Dampness Absorber

VERSCHLAUCHUNG / TUBING REV 1

VERSION: 1.1

waste bottle

Ventilblock

Valve-block

F200.26

35-8.101 (set)

F200.25

F200.25

F200.25

35-8.101 (set)

F200.25

Rollerpump

(peristaltic-pump)

Rollerpumpe

F200.25

ventilation valve

ventilation valve

F200.25

F10.19

Rm100.21

Rm100.21

Light barrier for

level control

(CL Füllstand)

stromlos offen

normally open

stromlos offen

normally opened

normally open

stromlos offen

normally open

stromlos offen

normally open

stromlos offen

sample-port

Probenport

1-8.106

normally open

stromlos offen

Ca

Rm100.21

Cl

combiline ISE

combiline Service- Manual - Version 4.01

page 13 page 13

page 13

page 13 page 13

Reagent-Transport

Ref

Zwischengefäß

Intermediate-Vessel

R20.28

SR20.8

Absaugpumpe

SP

Entlüftungsventil

EV

Entlüftungsventil

SR20.3

pH

ABS

SR20.12

R20.8

R20.8

R20.8

DATUM:

RP

SR20.18

SR20.19

SR20.20

SR20.17

SR20.16

BEZ.:

SV20.7

SR20.24

SR20.13

suction-pump

SV20.6

S204-06

S204-06

S204-06

S204-06

S104-08

ESCHWEILER GmbH & CO. KG KIEL GERMANY

SR20.12

SR20.19

Abfallflasche

Kalibrierlösung

BGA 3 BGA 4

SR20.23

SR20.9

CAL 4CAL 3

Na

pCO2 pO2

K

LS

HB

calibration solution ISE

COMBILINE BGA+E

SR20.22

SR30.14

WASH 2

VE1

VE2

SP-COMBILINE BGA +E+HB.TCD

28.07.08

BGA 4

BGA 3

CAL 4

CAL 3

LV

PV

S204-06

Feuchtefilter

Dampness Absorber

VERSCHLAUCHUNG / TUBING REV 1.1

VERSION: 1.1

waste bottle

Calibration-Solution

Ventilblock

Valve-block

F200.26

40-8.101 (set)

F200.25

F200.25

F200.25

35-8.101 (set)

F200.25

Roll erpump

(peristalt ic-pump)

Rollerpum pe

F200.25

ventilatio n valve

ventilatio n valve

F200.25

F10.19

Rm100.31

Rm100.31

Light barrier for

level control

(CL Füllstand)

stromlos offen

normally open

stromlos offen

normally opened

normally open

stromlos offen

normally open

stromlos o ffen

normally open

stromlos offen

sample-p ort

Probenpor t

1-8.106

normally open

stromlos o ffen

Ca

Rm100.30

combiline BGA+E

page 14page 14

page 14 Service- Manual - Version 4.01

page 14page 14

combiline

Reagent-Transport

Ref

Zwischengefäß

Intermediate-Vessel

R20.28

SR20.8

Absaugpumpe

SP

Entlüftungsventil

EV

Entlüftungsventil

SR20.3

pH

ABS

SR20.12

R20.8

R20.8

R20.8

DATUM:

RP 1

SR20.18

SR20.19

SR20.20

SR20.17

SR20.16

BEZ.:

SV20.7

SR20.24

SR20.13

suction-pump

SV20.6

S204-06

S204-06

S204-06

S204-06

S104-08

ESCHWEILER GmbH & CO. KG KIEL GERMANY

SR20.12

SR20.19

Abfallflasche

Kalibrierlösung

BGA 3 BGA 4

SR20.23

SR20.9

CAL 4+M

CAL 3

Na

pCO2 pO2

K

LS

HB

calibration solution ISE

COMBILINE meta BGA+E

SR20.22

SR30.14

WASH

2 + M

VE1

VE2

SP-COMBILINE II BGA+E HBI I.TCD

01.09.2008

BGA 4

BGA 3

CAL 4+M

CAL 3

LV

PV

S204-06

Feuchtefilter

Dampness Absorber

VERSCHLAUCHUNG / TUBING REV 1.1

VERSION: 1.1

waste bottle

Calibration-Solution

Ventilblock

Valve-block

F200.26

40-8.102 (set)

F200.25

F200.25

F200.25

40-8.102 (set)

F200.25

Rollerpump

(peristaltic-pump)

Rollerpumpe

F200.25

ventilation valve

ventilation valve

F200.25

F10.19

Rm100.31

Rm100.31

Light barrier for

level control

(CL Füllstand)

stromlos offen

normally open

stromlos offen

normally opened

normally open

stromlos offen

normally open

stromlos offen

normally open

stromlos offen

sample-port

Probenport

1-8.106

normally open

stromlos offen

Ca

Rm100.30

RP 2

Rollerpump

(peristaltic-pump)

Rollerpumpe

META

S204-06

F200.25

normally open

stromlos offen

GLU

LAC

combiline meta

combiline Service- Manual - Version 4.01

page 15 page 15

page 15

page 15 page 15

Valves

Determination of Valves

EV Input-valve, module holder (one stage pinch valve, normally open)

BGA1 Liquid-valve for calibration solution BGA 1 (normally closed)

BGA2 Liquid-valve for calibration solution BGA 2 (normally closed)

BGA 3 Liquid-valve for calibration solution BGA 3 (normally closed)

BGA 4 Liquid-valve for calibration solution BGA 4 (normally closed)

CAL 3 Liquid-valve for calibration solution CAL 3 (normally closed)

CAL 4 Liquid-valve for calibration solution CAL 4 (normally closed)

LV Liquid-valve for ventilation (normally closed)

1

1

2

2

2

2

ABS Suction-valve (one stage pinch valve, normally open)

META Valve for triggering of the metabolite sensors

3

VE1 Ventilation-valve, intermediate vessel (one stage pinch valve, norm. open)

VE2 Ventilation-valve, suction pump (one stage pinch valve, normally open)

PV Sample port valve (one stage pinch valve, normally open)

SP Rinsing solution valve (one stage pinch valve, normally closed)

1

not available in combiline with electrolytes or metabolites

2

not available in combiline BGA

3

available in combiline meta only

page 16page 16

page 16 Service- Manual - Version 4.01

page 16page 16

combiline

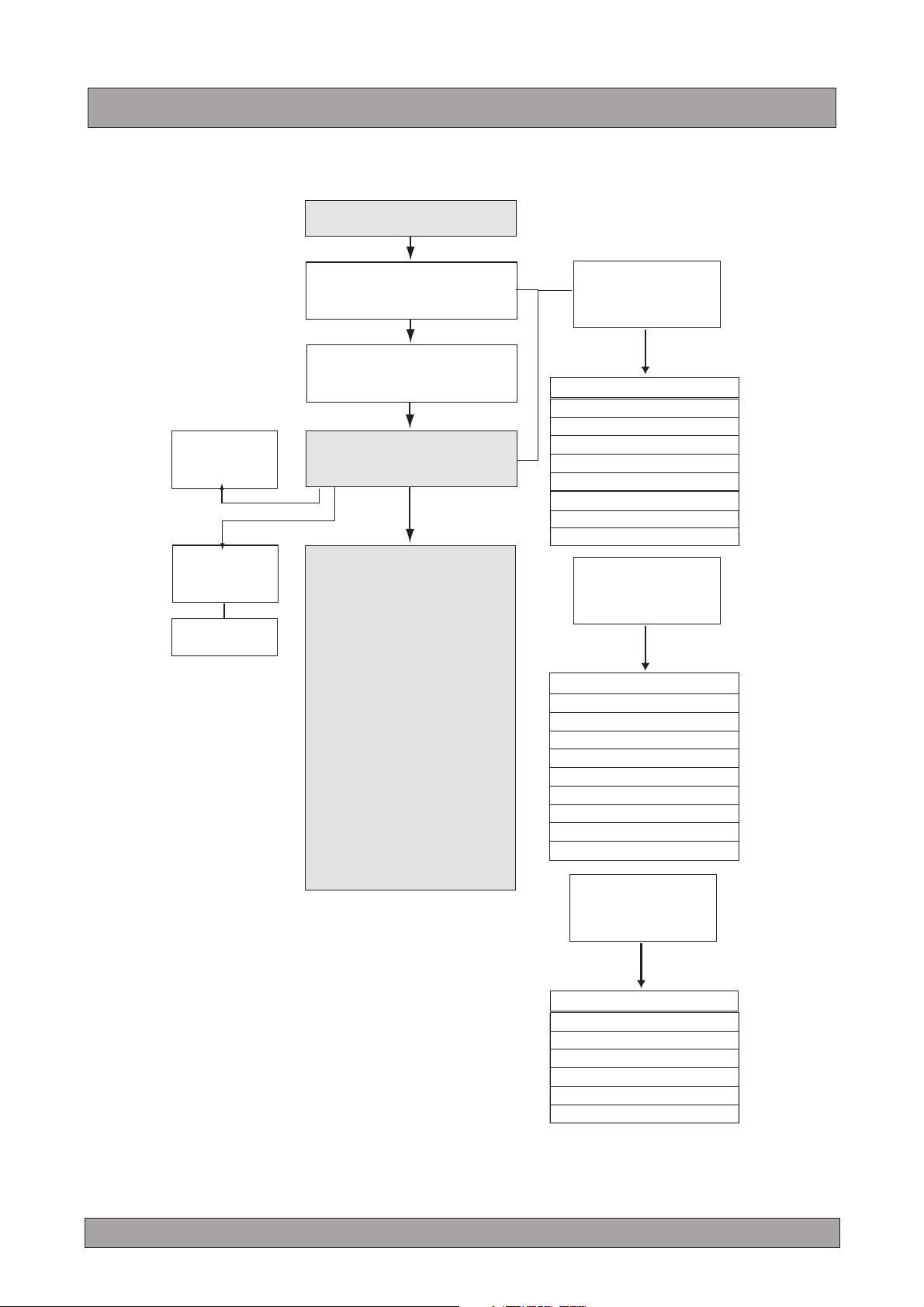

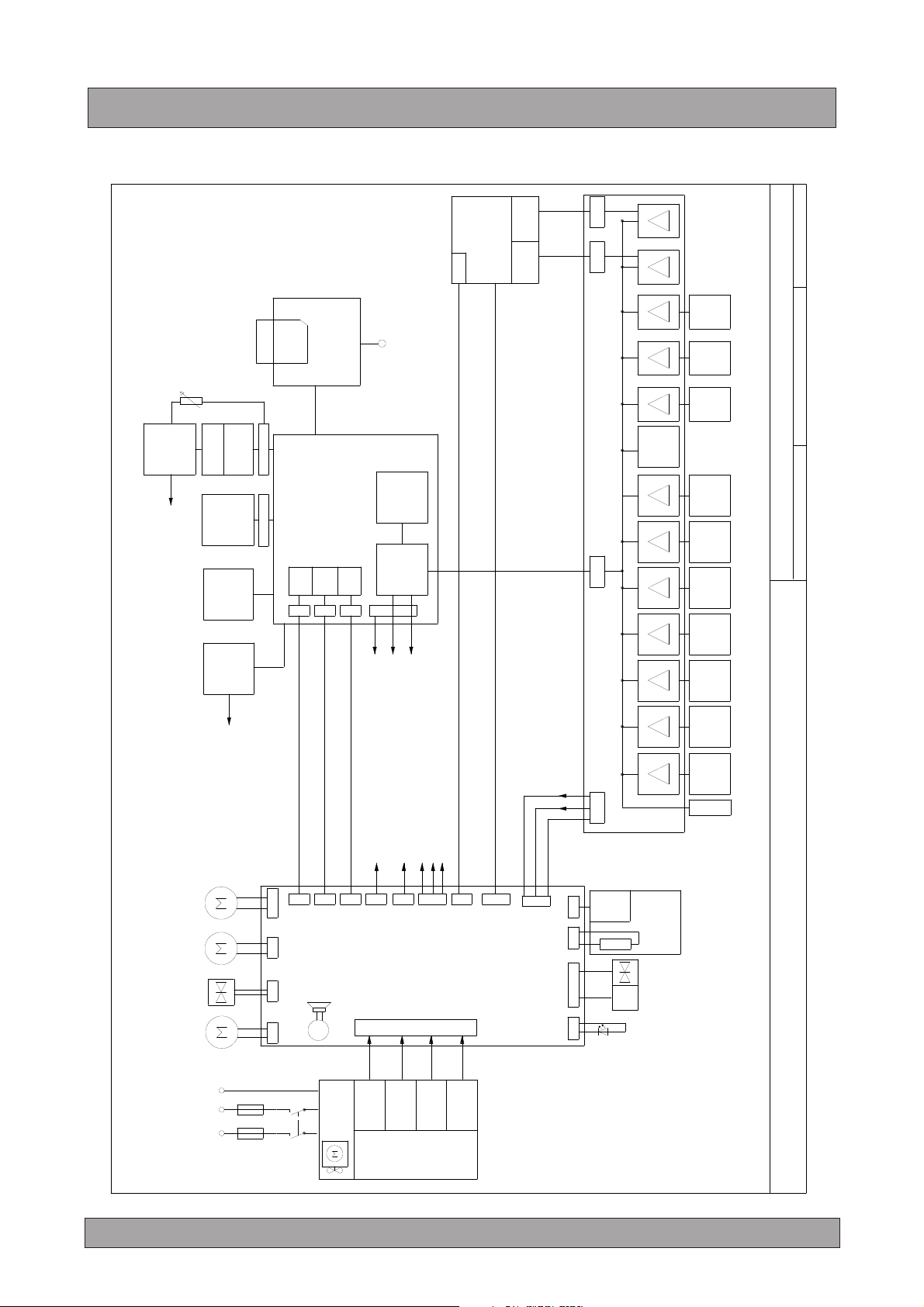

Blockdiagram

MUX

ADC

TASTATUR

L12

L3

L11

L10

Treiber

drivers

IC25

IC26

IC27

CPU Z80 ADC

Ventile

Valves

Absaugpumpe

Suction-Pump

Rollerpumpe 1

Roller-Pump 1

ESW-MVCT

Drucker

Printer

GPT-4352

Füllstands-

kontrolle

Level-Control

CL FÜLLSTAND

M1

M2

M3

BUZZER

M1

M2

M3

+12V

+5V

-12V

Schaltnetzteil

switching power-supply

PM110-45-2A

L4

DATUM: BEZ.:

Heizer

Heater

KEYBOARD

LCD

CONVERTER

DISPLAY

LMBHT014GC

DISP INT

illumination

Beleuchtung

Blockschaltbild / Blockdiagram 4.0

ESCHWEILER GmbH & CO. KG KIEL GERMANY

2 x 250V / 2.5A T

100 - 250 V~

50 - 60HZ

VERSION:Block CL 2 BGA+E+M+HBII 40.tcd

COMBILINE II

26.01.2010 4.0

CL Tastatur

L2

Kontrast

Contrast

Lüfter

Fan

Thermostat-

illumination

24V (LED)

Rollerpumpe 2

Roller-Pump 2

for metabolites

GLU

LAC

Peltier-Element

NTC

Sensor Sensor

SD CARD INT

SD Card Reader

SER-TTL

RS232

Data-Output 9600Baud 8N1

9600Baud 8N1

SD-CARD

HB

Sensoren / Sensors

K Na CaTEMPLS

pH

Luftdruck

Air-

pressure

pCO pO

2 2

ESW ANALOG

Analog-Verstärker / Analog-Amplifiers

Cl Li

+24V

24V DC

1.0W

V1

COOLPELTIER

HEAT

RP RP-METAM4B M4B

Ventil VE2

Valve VE2

VE

ASV

M4B

+5V

-12V

+12V

+12V

-12V

+24V

+5V

V1 ADC LAC GLU

+24V

+5V

+12V

-12V

TEMP

NTC

Thermostat

-15V

ANALOG

HB-Enable

Z80

+5V

+12V

-12V

CPUZ80ADC

PRINT LCD

+24V

+5V

Printer

LCD-Converter

M1

L1

V1

combiline Service- Manual - Version 4.01

page 17 page 17

page 17

page 17 page 17

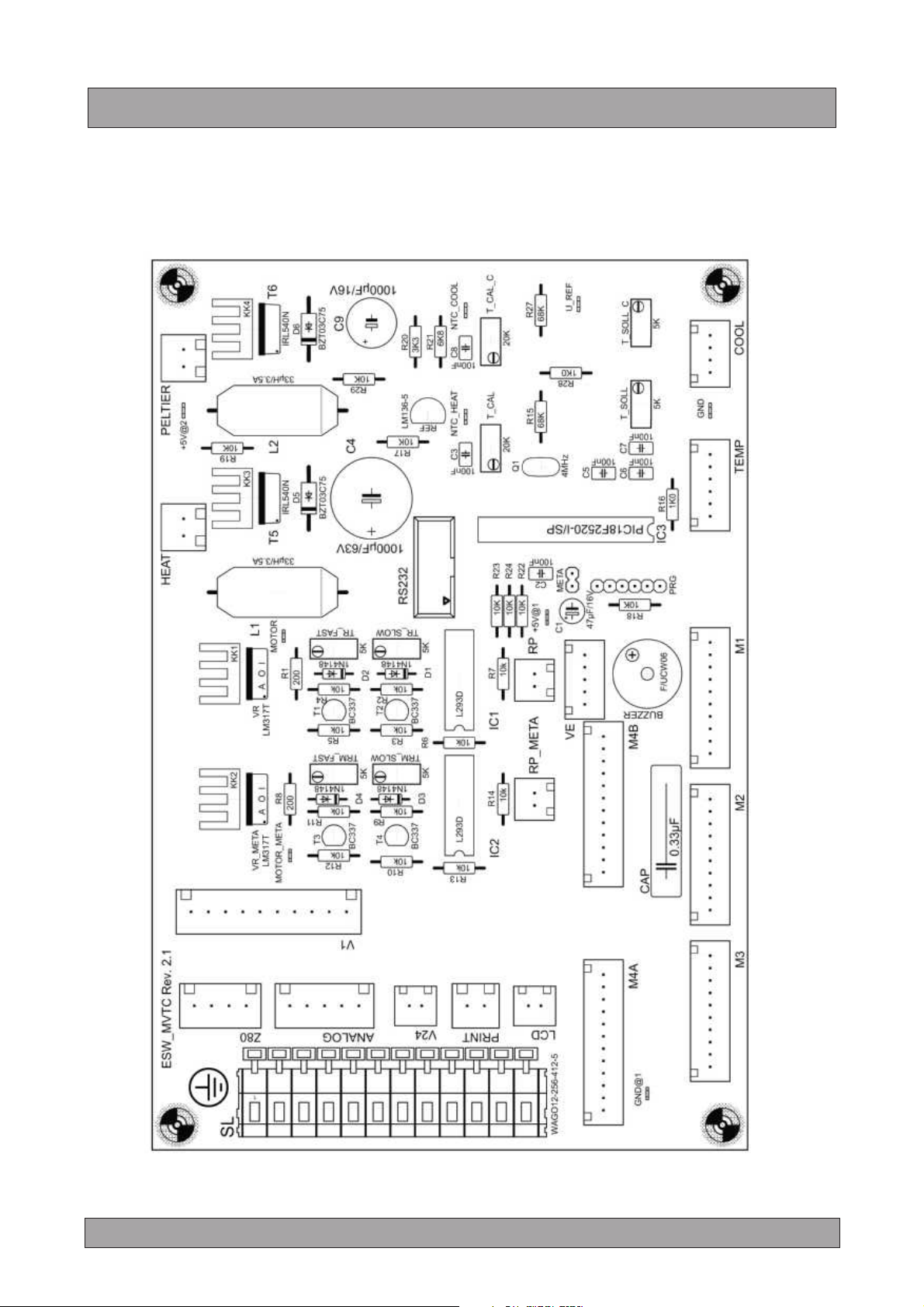

Switching Power-Supply

Type: PM110-45-2A

+5V Supply for Logic (with Protection Diode1N5630A): Z80 ADC, Level Control board CL Füllstand,

LCD Converter

±12V Analogboard ESW- ANALOG, CL Z80 ADC Multiplexer

+24V Printer, Valves, Suction-Pump, Thermostat-Heating

Power Supply für Pumps, Valves and Heating

Type: ESW-MVTC

Rollerpump 1

+6,2V (E slow) Rollerpump 1 - slow speed (Testpoint MOTOR)

+11,5V (E fast) Rollerpump 1 - fast speed (Testpoint MOTOR)

Rollerpump 2 (available in meta version only)

+6,0V (E slow) Rollerpump 2 - slow speed (Testpoint MOTOR_META)

+8,0V (E fast) Rollerpump 2 - fast speed (Testpoint MOTOR_META)

page 18page 18

page 18 Service- Manual - Version 4.01

page 18page 18

combi

line

Power-Supply ESW-MVTC

Voltage Supply for Pumps and Valves

combiline Service- Manual - Version 4.01

page 19 page 19

page 19

page 19 page 19

Loading...

Loading...