Escalade sports P2085 User Manual

OWNER'S

MANUAL

MODEL NOS.

HERITAGE

8FT. SLATRON HOME

POOL TABLE

WITH DROP POCKETS

P2085

READ THESE

INSTRUCTIONS

CAREFULLY!

!ASSEMBLY

!OPERATION

!SERVICE

!INSTALLATION

!REPLACEMENT PARTS

!WARRANTY

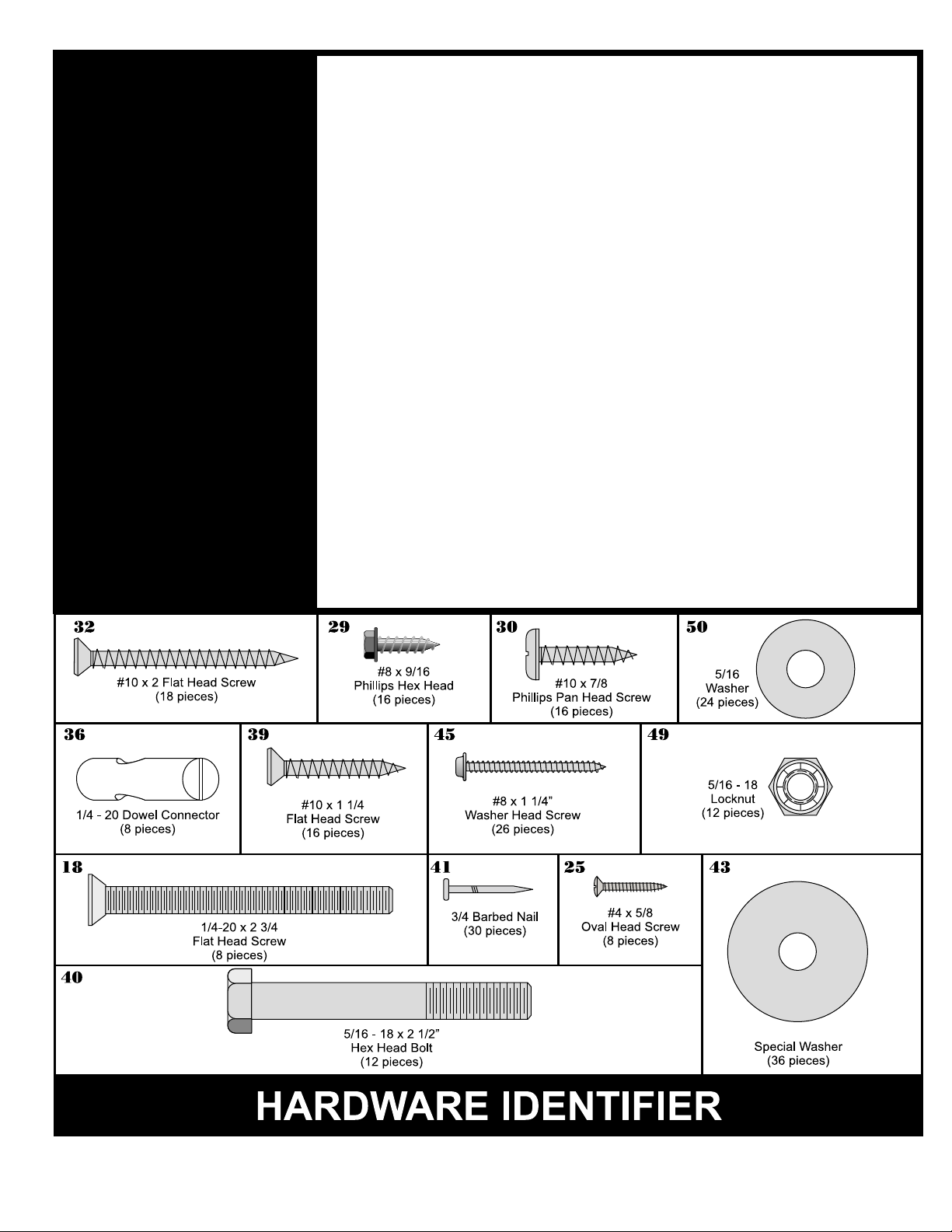

For aid in identifying the different hardware used in this assembly, use the

hardware identifier below. Each number refers to the numbers shown in the

illustrations within this manual. For more specific information about the hardware, see the replacement parts list on page 13.

2L-6620-01

IMPORTANT! READ THIS

MANUAL ALL THE WAY

THROUGH BEFORE BEGINNING

TO PUT YOUR POOL TABLE

THE DRAWINGS IN THIS

MANUAL HAVE BEEN

EXAGGERATED OR MODI

TOGETHER! THEN READ EACH

TO SHOW DETAILS.

STEP COMPLETELY BEFORE

STARTING THAT STEP.

This table has been inspected to insure proper fit. Carefully unpack and examine

each shipping container and its packing material before discarding to assure all parts

have been removed. Some smaller parts may be shipped inside larger parts. Check

inside parts before assembling.

This table is contained in three separate containers

Tools Needed:

! 1/2" Open End Wrench (2)

! 7/16" Open End Wrench (2)

! 3/8" Open End Wrench

! Phillips Screwdriver

Beside the assembly tools listed above, it would be useful to have a rachet with 1/2, 7/16 and 3/8 sockets and an

electric screwdriver.

NOTE: Rails are made with cushion rubber at a height that requires 2 ¼" diameter balls. Your dealer has a complete

line of Billard Accessories.

! Hammer (Small Ball Peen Type)

! Tape Measure

! Sandpaper (80 grit)

! Sanding Block

! Awl or 8d Nail

! Carpenter's Level & 36" Straight Edge

! Needle Nose Pliers

! Scissors

! Putty Knife

NOTE: This table adds weight to any floor. Be sure floor can withstand this kind of weight. If floor sags, table will be

impossible to level!

THE CEMENT USED FOR APPLYING PLAYFIELD CLOTH IS

EXTREMELY FLAMMABLE AND UNDER PRESSURE! CAREFULLY READ CAUTIONS ON CEMENT CONTAINER!

KEEP OUT OF REACH OF CHILDREN!

DO NOT USE OR STORE CEMENT NEAR A HEAT SOURCE,

FLAMES, SPARKS OR WHEN SMOKING! WORK AREA MUST

BE WELL VENTILATED. OPEN DOORS AND WINDOWS WHEN

USING CEMENT!

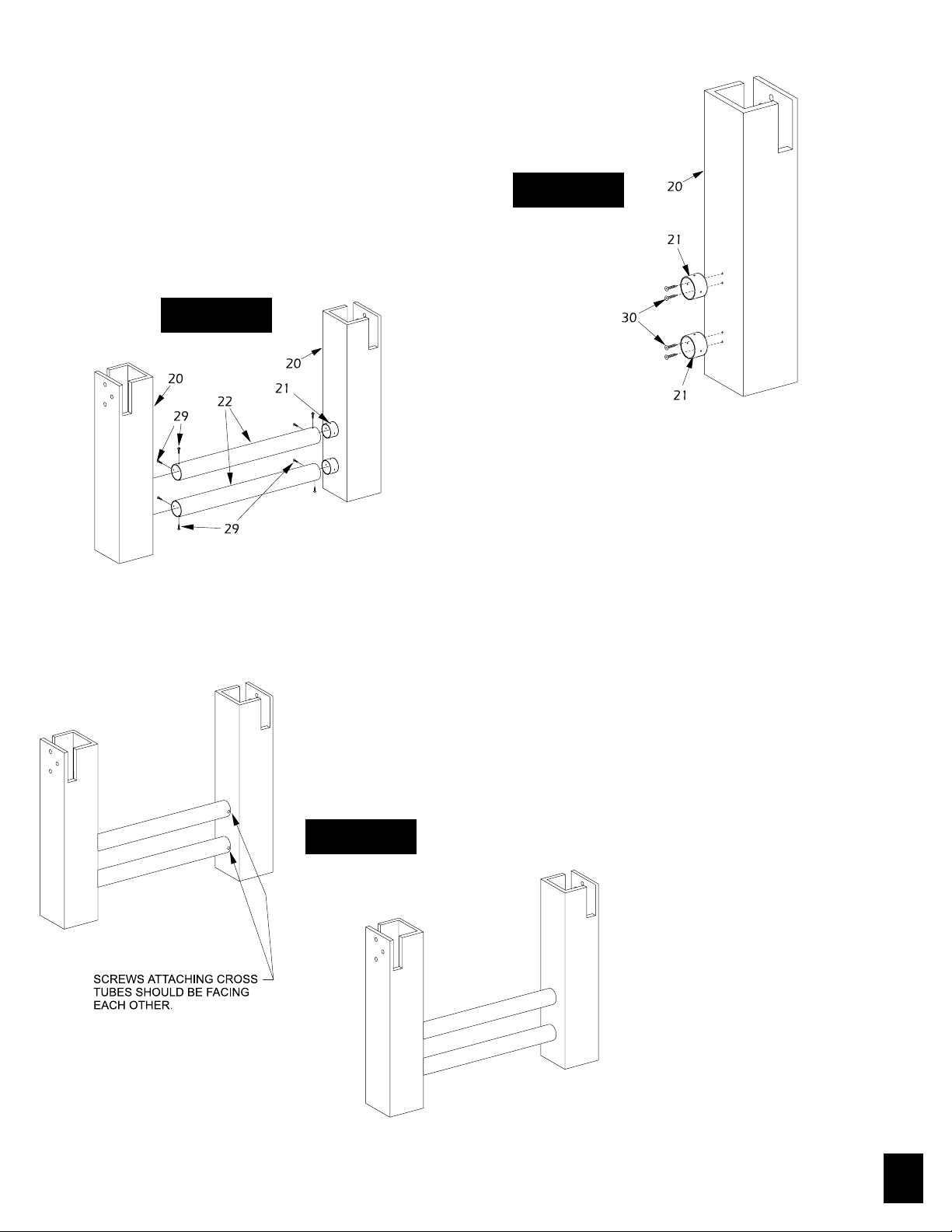

ASSEMBLE TWO LEG PEDESTALS AS FOLLOWS:

1. Begin by opening hardware kits and sort

hardware. Attach two tube brackets #21 to

each leg #20 using screws #30 and the predrilled starter holes in leg #20. (See Figure 1)

Figure 2

Figure 1

Figure 3

2. Connect two legs #20 together by putting two cross

tubes #22 over tube brackets #21 between legs.

Secure each tube with four screws #29. See figure 2.

Repeat for other two legs #20. NOTE: Attach top

tube first, with screws #29, from one side and top

of tube. Attach bottom tube second with screws

#29 from same side as top tube and bottom of

tube.

3. Set up leg assemblies so that screws attaching cross

tubes face each other. See figure 3.

Page

3

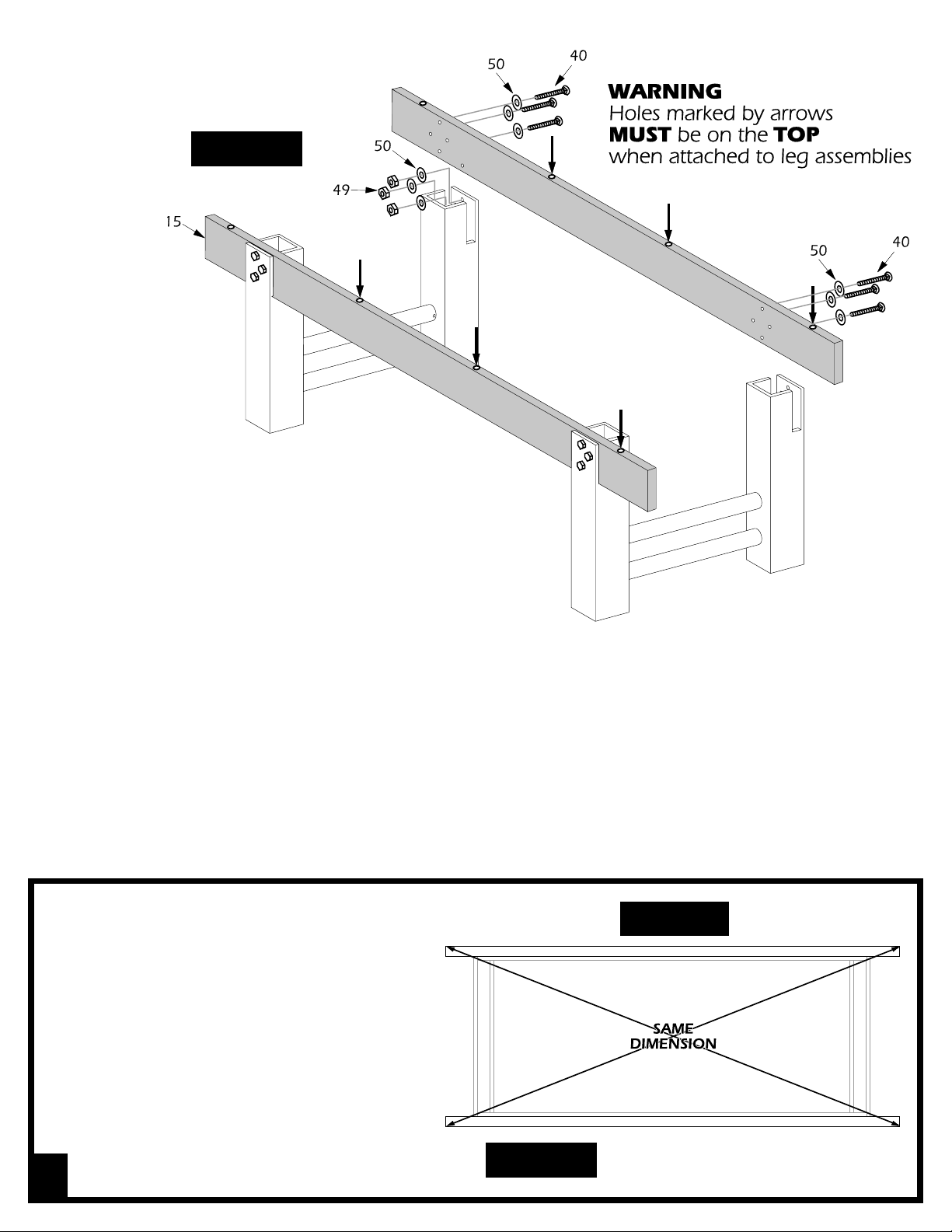

Figure 4

5. Attach beam #15 by using three bolts #40, six washers

#50, and three locknuts #49 for each of the legs post

#20. Place one washer between the bolts and leg and

one between beam and locknuts. Tighten these bolts

securely. (See figure 4)

6. Attach other beam #15 to the other side the same way.

(See figure 4)

Make sure the holes in the edge of the beams #15 are on

the top of the beams when attached.

7. Place the frame in its final loca-

tion. Square the base frame assembly by measuring diagonally from

the corner of one beam to the opposite corner of the other beam.

(See Figure 5) Nudge the frame

until both diagonals are equal

(within 1/16 inch).

8. Go back and tighten all loose

screws, nuts and bolts.

Top View

Page

4

Figure 5

Figure 6

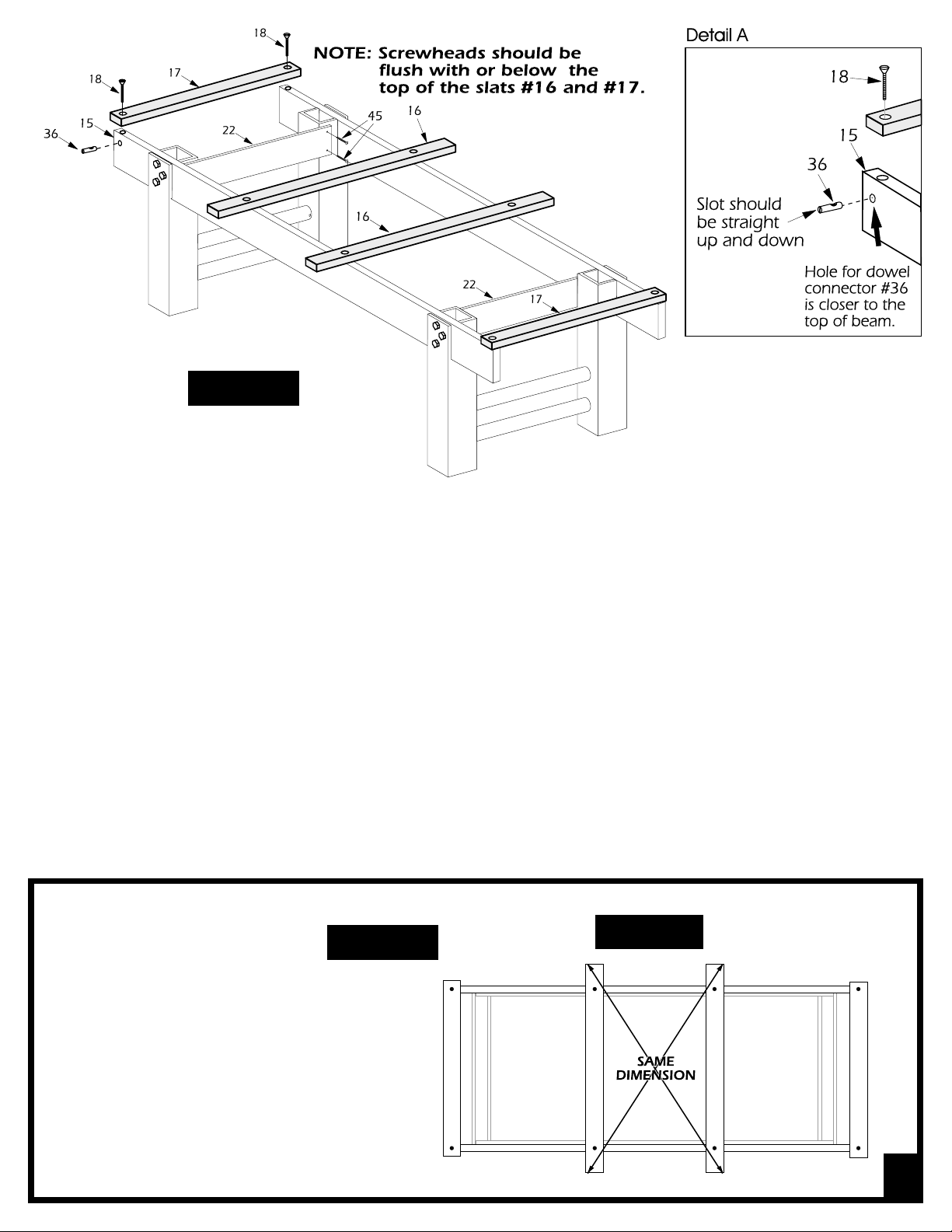

9. Place long slats #16 (50 inches long) and short slats #17 (36 inches long) across table from beam

to beam as shown in figure 6. Make sure to use the two shorter slats #17 on the ends of the beams

and the two longer slats #16 in the center as shown. Insert four dowel connectors #36 into the four

holes in the side of each of the beams #15 these holes should be closer to the top of the beams #4.

(See Detail A). Attach the slats #16, and #17 to the wooden beams #15 by placing screws #18 through

the slats and into the dowel connectors #36 that are in the beams #15 and tighten, make sure not

to over tighten them. (See figure 4 and detail A))

HINT: When holes are lined up, the slot in the dowel connector should be vertical. After holes line

up, insert screws #18 into slats and down into dowel connectors. It is recommended to start the

screws by hand and not forcing them with power tools until you are sure threads are engaged

properly. Do not tighten completely yet.

10.Attach cross supports #22 to inside surface of legs, as shown in figure 6, using four screws #45 for

each cross support. NOTE: No pilot holes are provided for screws #45. Hold cross support

approximately 1/2" from top of leg and drive screws #45 through holes in cross support and

into leg.

Figure 7

11.Square up the long slats #16 by

measuring diagonally, similar to

the method used earlier to square

up base frame. (See Figure 7) After

squaring up slats, tighten all the

screws holding slats #16 and #17

to the beams.

Top View

Page

5

Loading...

Loading...