Escalade sports P2010RAIL, P2010LEG User Manual

OWNER'S

MANUAL

8 FT. DROP POCKET

HOME POOL TABLE

IF YOU PURCHASED A BALL RETURN KIT WITH

YOUR T ABLE. USE THE INSTRUCTIONS IN THAT KIT

TO ASSEMBLE YOUR TABLE.

Questions, Concerns, Comments?

Need to Purchase Replacement Parts?

Need Product Assistance?

Escalade Sports, a diversified manufacturer of fine sporting goods equipment, is here to help you in any way possible to

make your experience with this product a pleasurable one for you and your family. We always try hard to make sure that

our products are manufactured free from defects in material and workmanship to provide a lifetime of family fun. If you find

any problems with your new product such as missing parts, damaged parts, or incorrectly manufactured parts,

MODEL NOS.

P2010RAIL

527.25410

P2010LEG

527.25408

Please Do Not Return This Product to the Store!

Please contact our consumer affairs department at:

Phone 1-866-556-2757 Toll – Free !

Fax 1-866-873-3532 Toll – Free !

E-mail pooltables@escaladesports.com

Additionally, we highly recommend that you visit our web site for additional

information or possible solutions for your concern which include:

On-Line Trouble Shooting *** On-Line Parts

Requests *** Technical Assistance *** Frequently

Asked Questions *** Additional Escalade

Product Information

READ THESE

INSTRUCTIONS

CAREFULLY!

Mailing Address: Escalade Sports

PO Box 889

Evansville, IN 47706

Manufactured under one or more of the following patents:

6,345,820 6,196,953 6,179,733 6,120,397 6,117,051 5,921,227 5,919,102 5,901,692 5,899,824 5,816,957 5,769,744 5,749,351

5,718,212 5,672,144 5,498,004 5,392,757 5,318,489 5,271,625 5,213,554 5,169,360 5,158,512 5,119,741 5,071,120 5,067,728

4,911,085 4,798,381 4,717,157 4,596,228 4,546,754 4,519,374 4,515,142 4,424,968 D442,654 D425,943 D425,572 D420,563

D330,234 D330,057

2L-6717-00

1

IMPORTANT! READ THIS MANUAL ALL

THE WAY THROUGH BEFORE

BEGINNING TO PUT YOUR POOL TABLE

TOGETHER! THEN READ EACH STEP

BEFORE STARTING THAT STEP.

Model No. P2010

This table has been inspected to insure proper fit. Carefully unpack and examine each shipping container and its packing material before

discarding to assure all parts have been removed. Some smaller parts may be shipped inside larger parts. Check inside parts before

assembling.

This table is contained in three separate containers:

Container #1. . . . . . Three playfield pieces

Container #2. . . . . . Contains this owner's manual, leg assemblies, hardware kits, corner & side caps, corner posts, playfield spots,

slate shims, glue and grout kit and drop pockets.

Container #3. . . . . . Contains long and short slats; beams, top rails; aprons; playfield cloth, and additional hardware kits.

Tools Needed:

n Hammer (Claw Type) n Putty Knife n 3/8" Open End Wrench

n Needle Nose Pliers n Tape Measure n Hammer (Small Ball Peen Type)

n 7/16" Open End Wrench n Sanding Block n Carpenter's level or 36'' Straight Edge

n Standard Screwdriver n Awl or 8d Nail n ½" Open End Wrench

n Phillips Screwdriver n Scissors

n Power Screwdriver (optional but very helpful)

n In addition to the assembly tools listed above, it would be useful to

have a rachet with 3/8, 7/16 and ½ socket.

NOTE: Rails are made with cushion rubber at a height that requires standard 2 ¼" diameter balls. Your dealer has a complete line of

Billiard Accessories.

NOTE: This table adds weight to any floor. Be sure floor can withstand this kind of weight. If floor sags, table will be impossible to level.

THE SPRAY ADHESIVE USED FOR APPLYING PLAYFIELD CLOTH IS

EXTREMELY FLAMMABLE AND UNDER PRESSURE! CAREFULLY READ

CAUTIONS ON SPRAY ADHESIVE CONTAINER! KEEP OUT OF REACH OF

CHILDREN! DO NOT USE OR STORE NEAR HEAT SOURCE, FLAMES,

SPARKS OR WHEN SMOKING! WORK AREA MUST BE WELL VENTILATED.

OPEN DOORS AND WINDOWS WHEN USING SPRAY ADHESIVE.

2

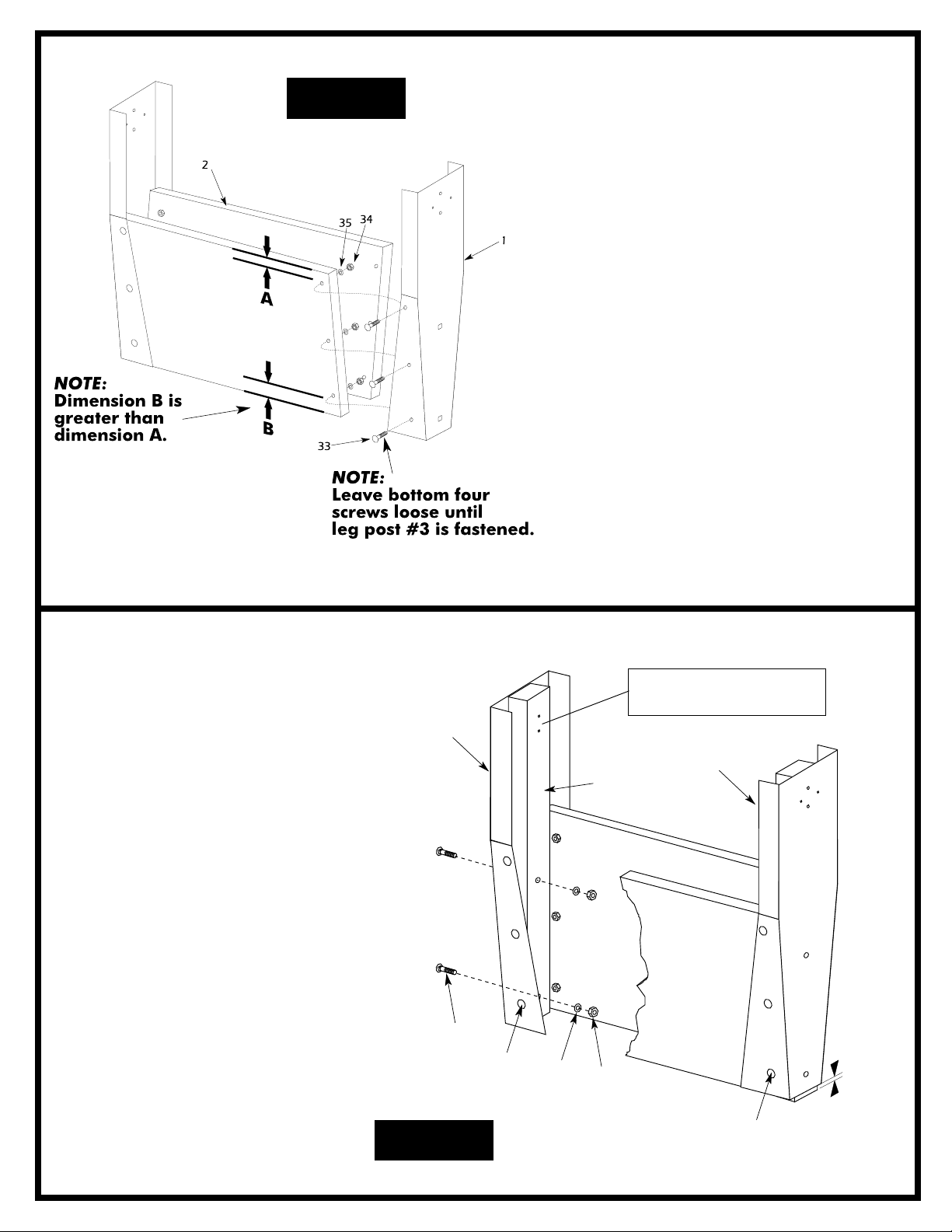

Figure 1

1. Open hardware kits and sort hardware

into "like" groups using hardware

identifier provided in this manual.

2. Attach two wooden leg panels #2 (be

sure wood grain faces out) to the

inside of two leg facades #1 using six

screws #33, six washers #35 and six

locknuts #34 per leg panel. Make sure

that dimension B is at the bottom of the

leg panel. (See Figure 1)

NOTE: Leave all four bottom screws

#33 loose until the leg post #3 is

installed. Leg post #3 CANNOT be

attached if the four bottom screws

#33 are tight. Tighten finger tight

only.

3. Repeat step 2 to put together other leg

assembly.

4. Attach leg posts #3 to the inside

face of metal leg facades #1 on

both leg assemblies (from steps 2

& 3). Use two carriage bolts #30,

two washers #22 and two locknuts

#21 per leg post.

NOTE: There is a set of holes at

one end of the leg posts that are

grouped close together. Make sure

that these holes go to the top of the

wooden posts. About 1/8 inch of

leg posts #3 will extend below the

metal facade #1. (Figure 2)

5. Once the leg post is securely fastened, tighten the four bottom

screws #33 on the leg panels.

This set of holes grouped close

together goes toward the top.

1

1

3

30

33

22

21

1/8''

Figure 2

33

3

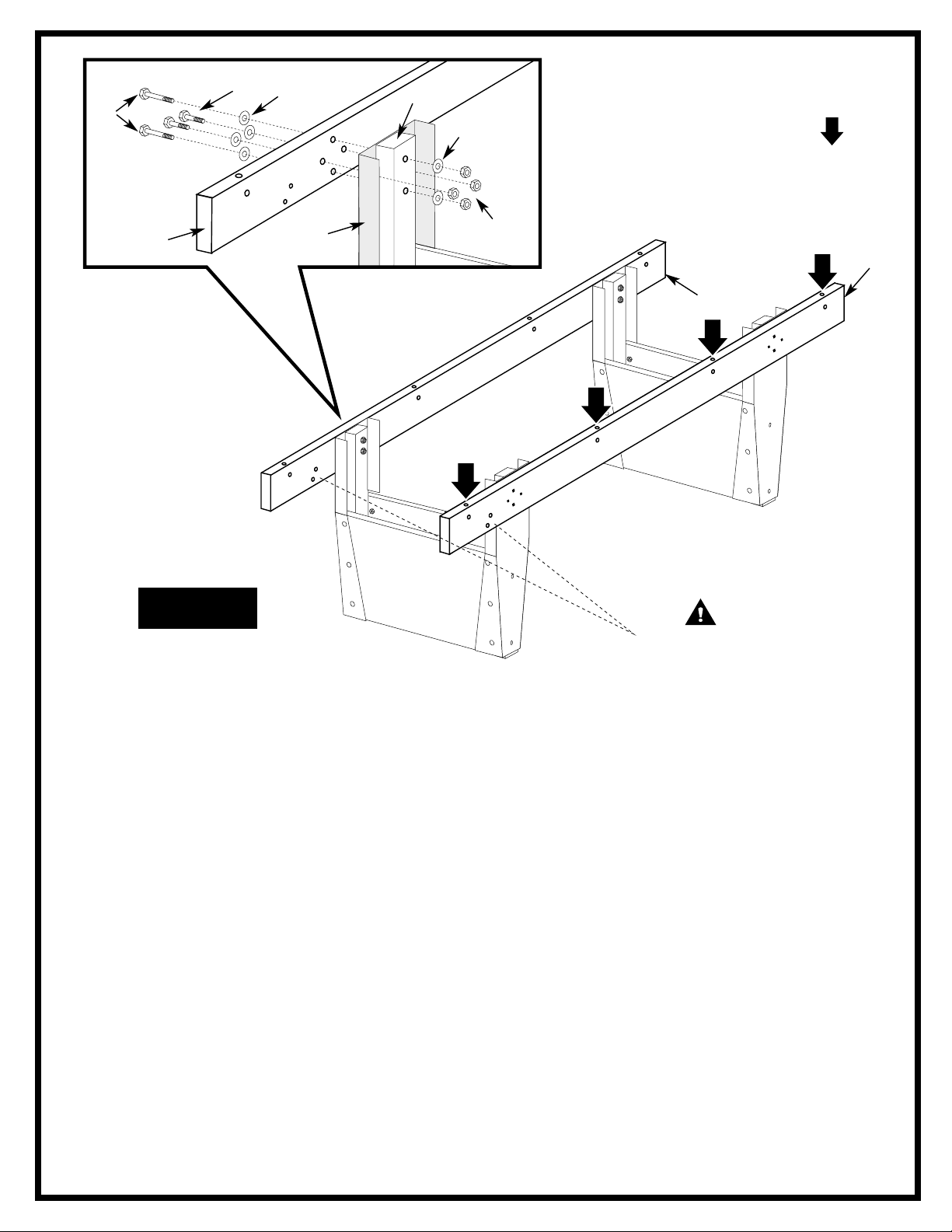

These holes are for ball return

attachment. Be sure both

beams #4 have these holes

at same end of table

27

WARNING:

MUST TOP

Holes marked by arrows

be on the when

attached to the legs!

40

All Washers

#23

3

#23

WARNING:

Holes marked by arrows

MUST TOP

be on the when

attached to the legs!

4

Figure 3

1

All locknuts

#26

4

4

CAUTION:

These holes are for ball return

attachment. Be sure both

beams #4 have these holes

at same end of table

6. Before starting this part of the assembly, orient

beams #4 with ball return attachment holes at

the same end of the table and the holes marked

by arrows in figure 3 facing up.

7. Attach wooden beams #4 to the leg assemblies

(that you just put together). Use two long bolts

#27, two short bolts #40, six washers #23 and

four locknuts #26 as shown. Repeat for other

beam #4.

NOTE: The two longer bolts #27 go through

top and bottom mounting holes in beam #4,

metal facade #1 and leg post #3. These bolts

require a washer between the bolt and beam

#4 as well as between leg post #3 and the

locknut.

NOTE: The two shorter bolts #40 go through

the other two mounting holes in beam #4 and

metal facade #1. They only require a washer

between the bolt and beam #4.

4

Figure 4

Countersink

goes up.

4

5

24

6

24

6

24

5

4

39

39

NOTE: Screwheads must

be flush or below the top of

the slats #5 and #6.

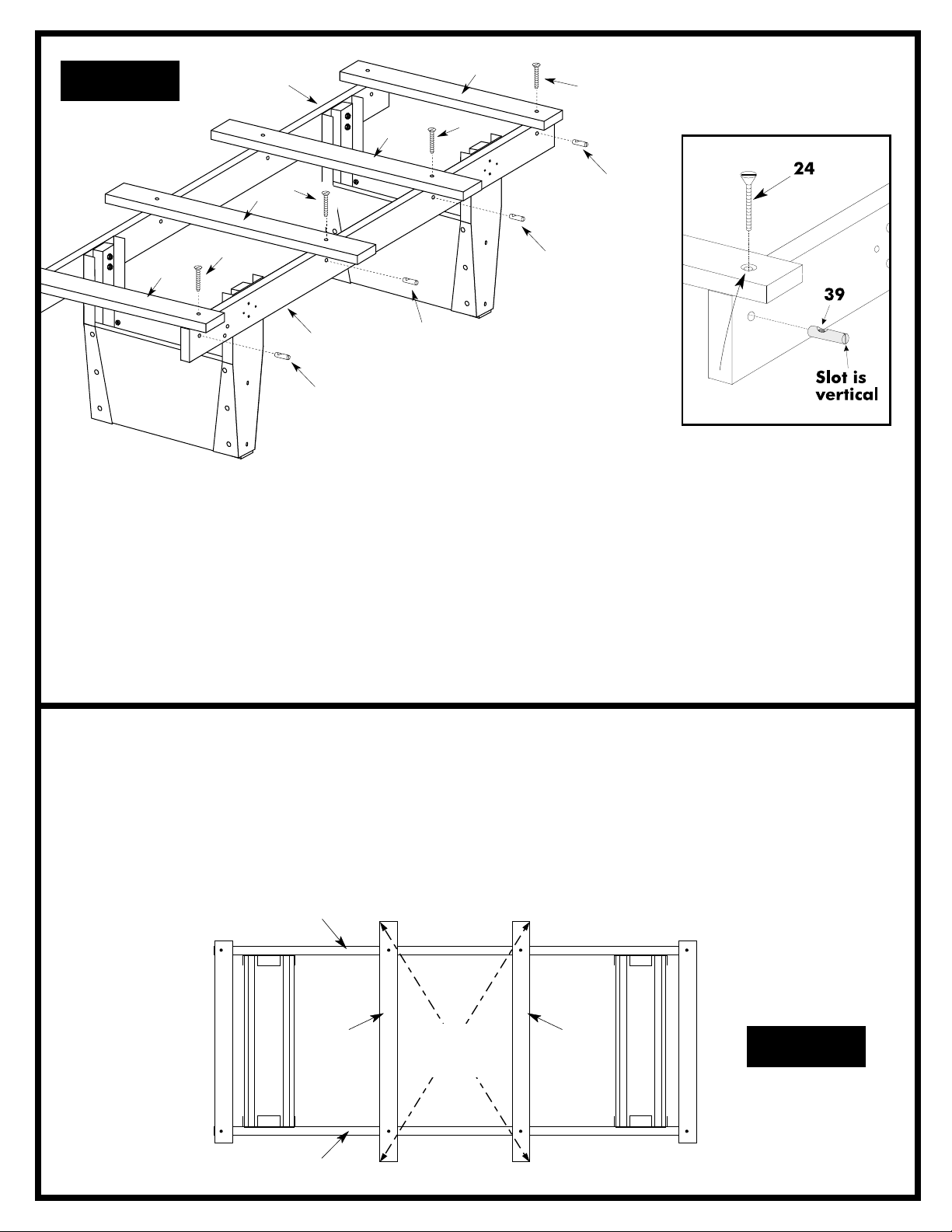

8. Place slats #5 and #6 across beams #4 as shown

in figure 4. Make sure the two shorter slats #5 go

on the ends of the beams and that the two longer

slats #6 go in the center as shown. The side of the

slats with the countersink around each hole faces

up. (See detail A).

24

39

39

Detail A

Countersink

goes up.

9. Insert four dowel connectors #39 into the holes

in side of beams #4 just below the slats. Note

that the slot in the end of dowel connectors

should be vertical. (See Figure 4 and Detail A).

Start screws #24 the dowel connectors by hand

until you are sure threads are engaged properly.

Do not force them with power tools. Do not

tighten screws completely yet.

10.Square up long slats #6 by measuring diagonally

as shown in figure 5. Diagonals should be the

same length within 1/8". Check to make sure the

table is square. If frame is not square, the

adjustment can be made by moving table beams

#4 in opposite directions. Usually only a slight

adjustment if any should be required.

4

6

4

11.Once frame is square, tighten screws #24

SAME

DIMENSION

(within 1/8")

holding slats to beams. Be sure the heads of

screws #24 are flush with or below the top of

the slats.

6

Figure 5

5

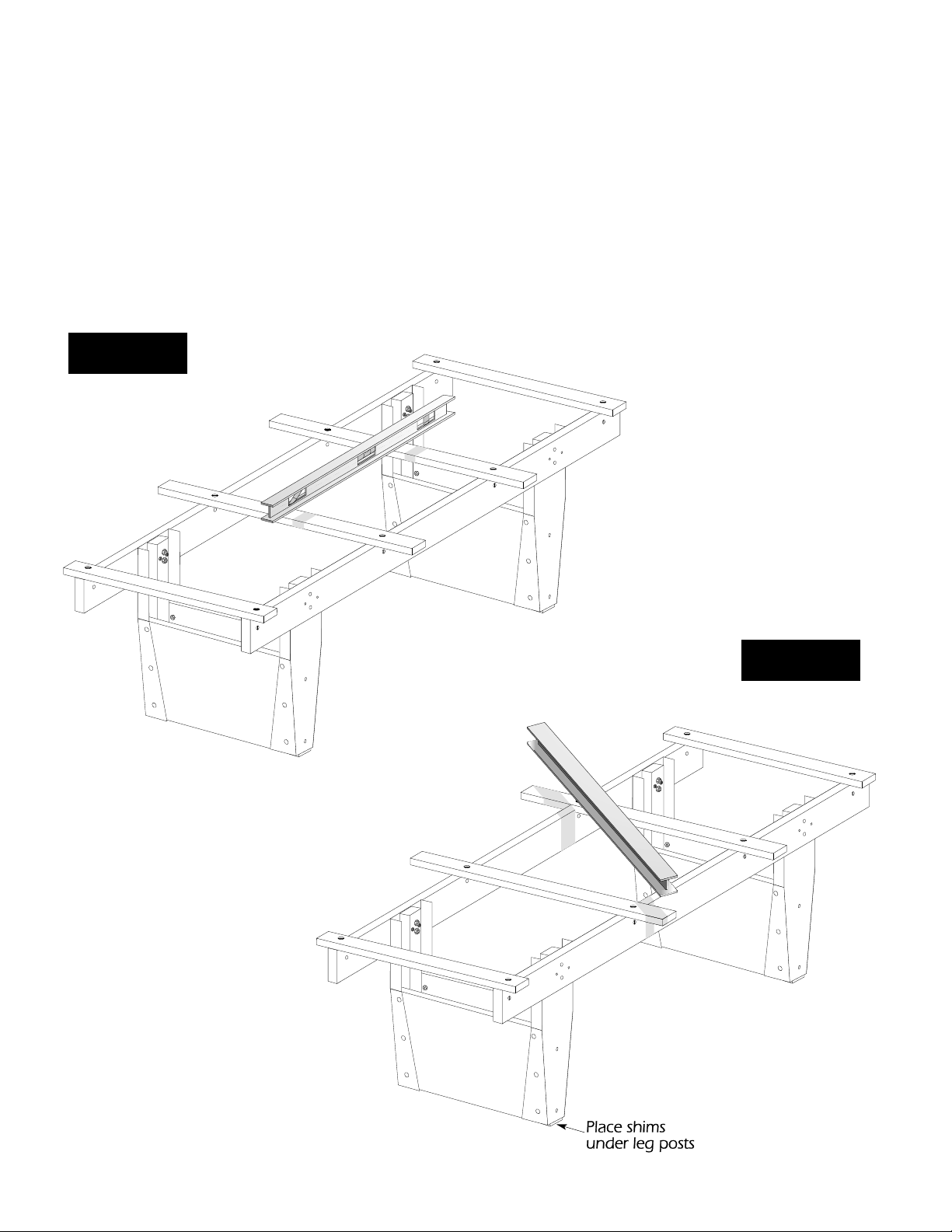

LEVELING BASE FRAME

Use a carpenter's level to level table as close as possible.

It is easier to do it now rather than after the playfield has

been attached to the frame.

12. Determine the highest corner of the frame by placing

the level in following two ways:

n Check frame from end to end as shown in figure 6.

n Then check the table diagonally as shown in fig. 7.

Figure 6

13. Once you have determined the highest corner,

raise other three corners by shimming. To do

this place one shim at a time under the lower

corners until the table is level. Leg shim stock

is provided in the slatron bed kit and must be

cut to the desired size. Shims must be placed

directly under leg post.

Figure 7

6

Loading...

Loading...