GB

Aristo

WO100

4

Instruction manual

Valid from program version 1.60444 405 074 GB 110428

1 INTRODUCTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Selection of language 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Control panel 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 SETTING RANGE 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 WELDING PARAMETERS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Sectors 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Welding current 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Pulsed current/continuous current 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Special pulsing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Wire feed 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Rotation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Arc voltage control (AVC) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Weaving 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Gas 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Preheating 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Slope 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 MENU STRUCTURE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 MENUS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Weld area 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Parameters 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 File manager 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Information 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Joint information 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Settings 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.6 Limits 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Design area 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Settings 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Appearance 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Users settings 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Login 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

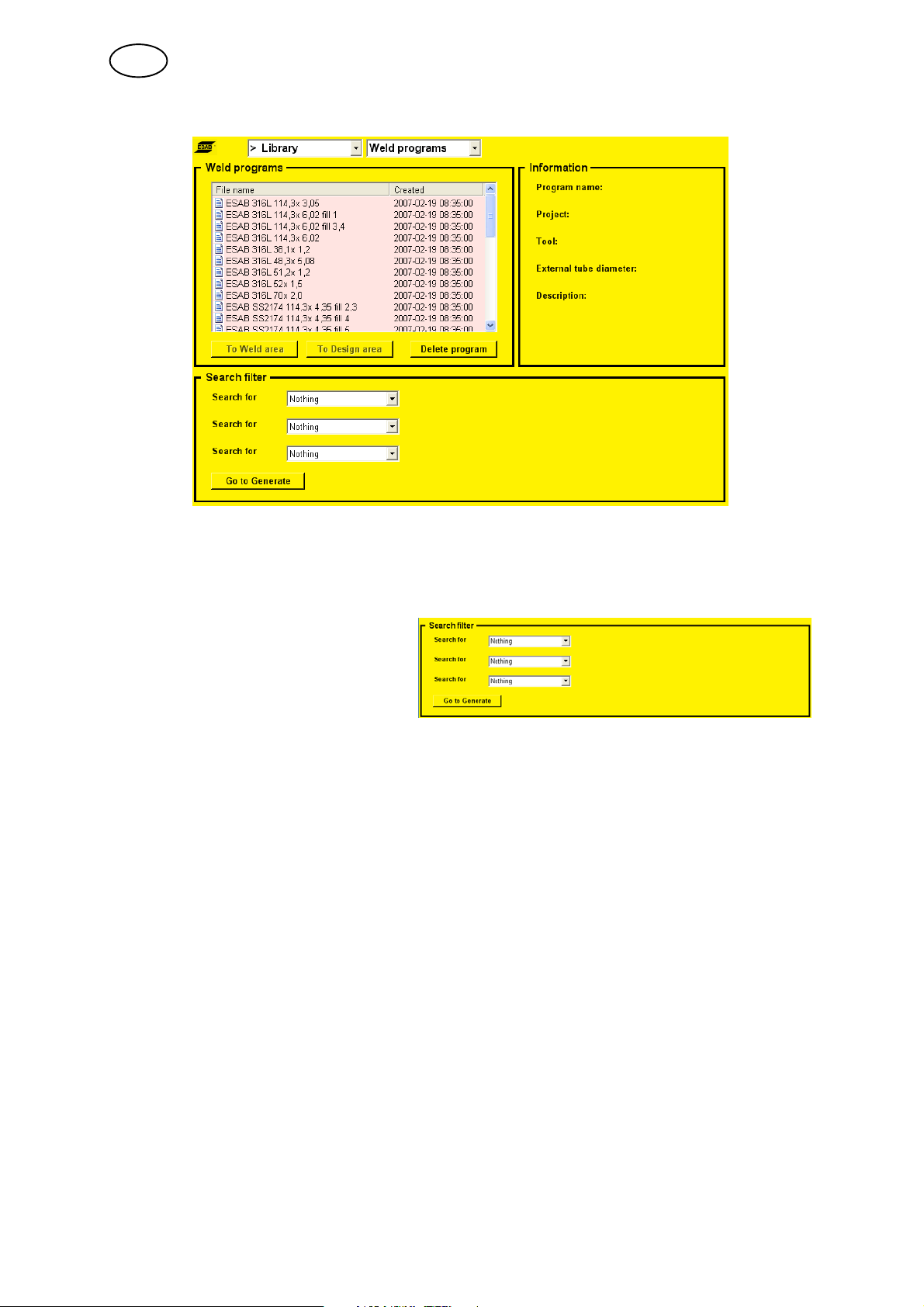

5.5 Library 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Weld programs 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Search filter 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

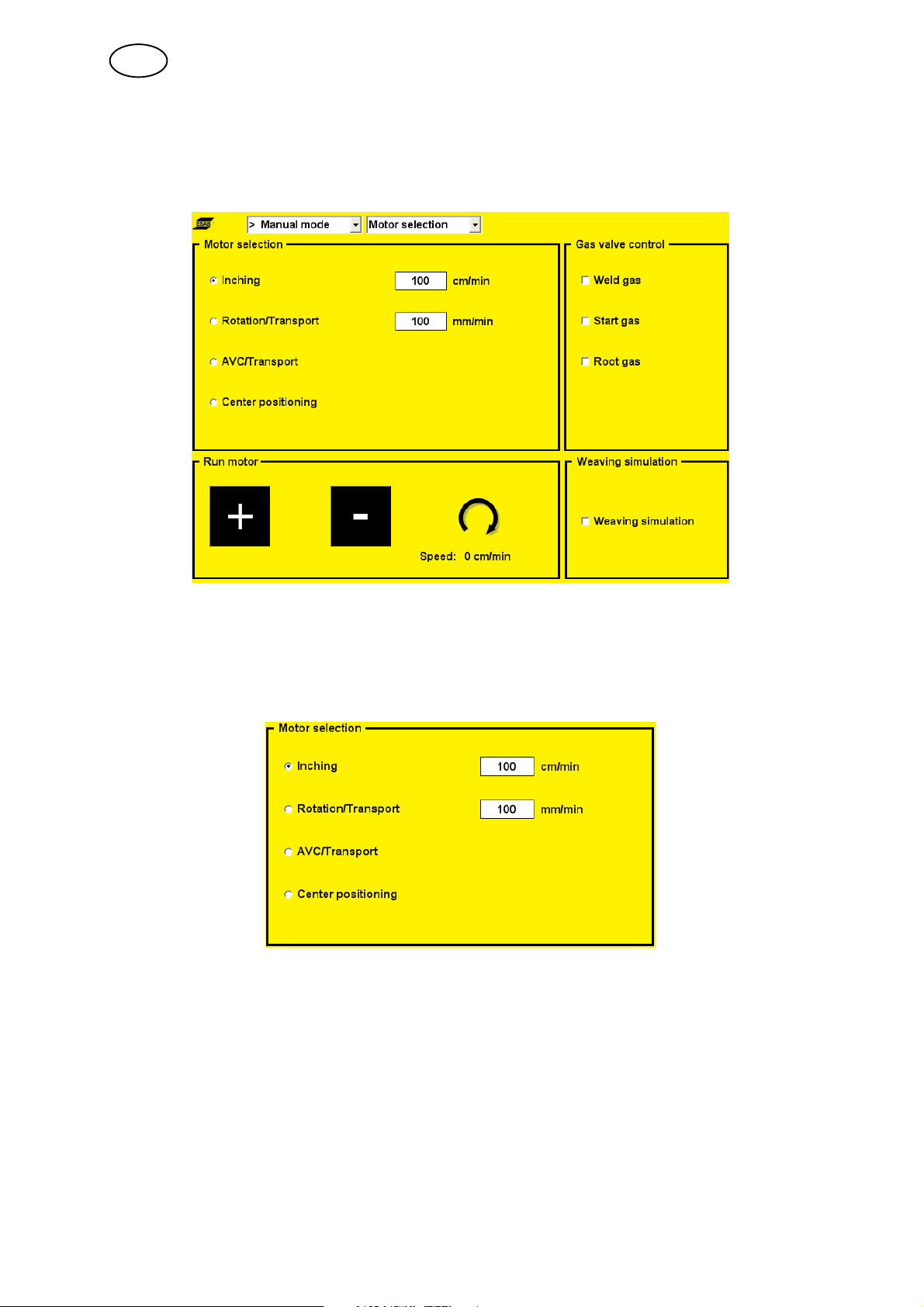

5.6 Manual mode 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Motor selection 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

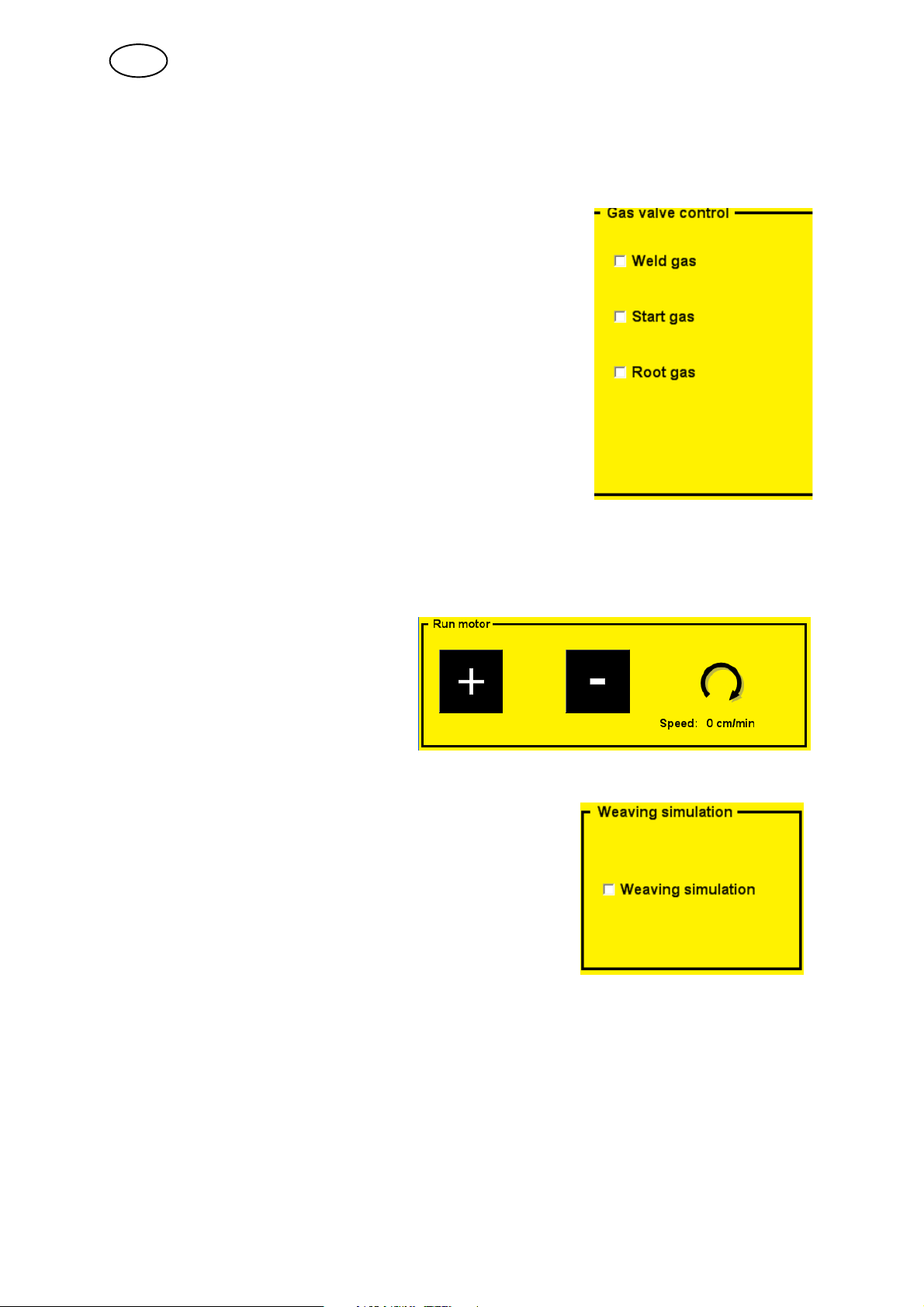

5.6.2 Gas valve control 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Run motor 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.4 Weaving simulation 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Tool editor 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Load/save 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Edit settings 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 Edit motor data 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

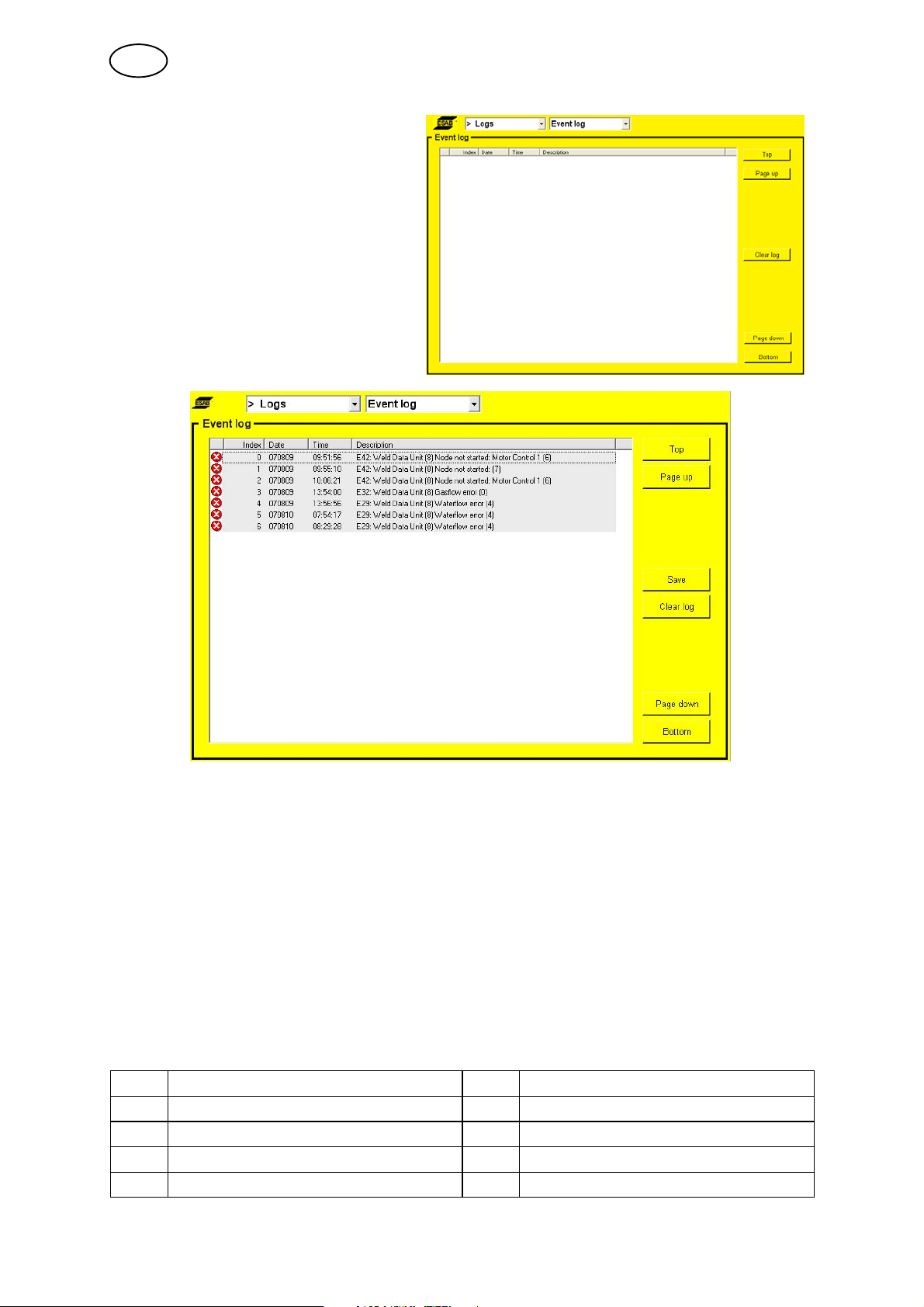

5.8 Logs 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.1 Event log 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.2 Quality data 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Manual welding 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Generate 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rights reserved to alter specifications without notice.

TOCe

- 2 -

6 TECHNICAL TERMS 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING NUMBER 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rights reserved to alter specifications without notice.

TOCe

- 3 -

GB

1 INTRODUCTION

The manual describes the use of a control panel. WO100

4

For general information about operation, see the instruction manual for the power

source and control unit.

The text displayed in the panel is available in the following languages: Swedish,

Norwegian, Danish, Finnish, English, German, French, Dutch, Spanish, Italian,

Portuguese, Greek, Polish, Czech, Hungarian, Slovenian and Russian.

1.1 Selection of language

The first time you start up the machine, the following is displayed.

On delivery the system is set to English. To select your preferred language:

S Press the ”Menu” button

so that the menu is

activated and shows the

options available at this

level.

S Turn the knob until

”Settings” is highlighted,

then press the knob.

S ”Appearance” is

highlighted, press the knob.

S ”General” is highlighted,

press the knob. The

”Language” field with the

word ”English” is framed.

Turn the knob to select

your preferred language.

S Activate your preferred language by pressing the knob.

bi16d1ea

- 4 -

© ESAB AB 2007

GB

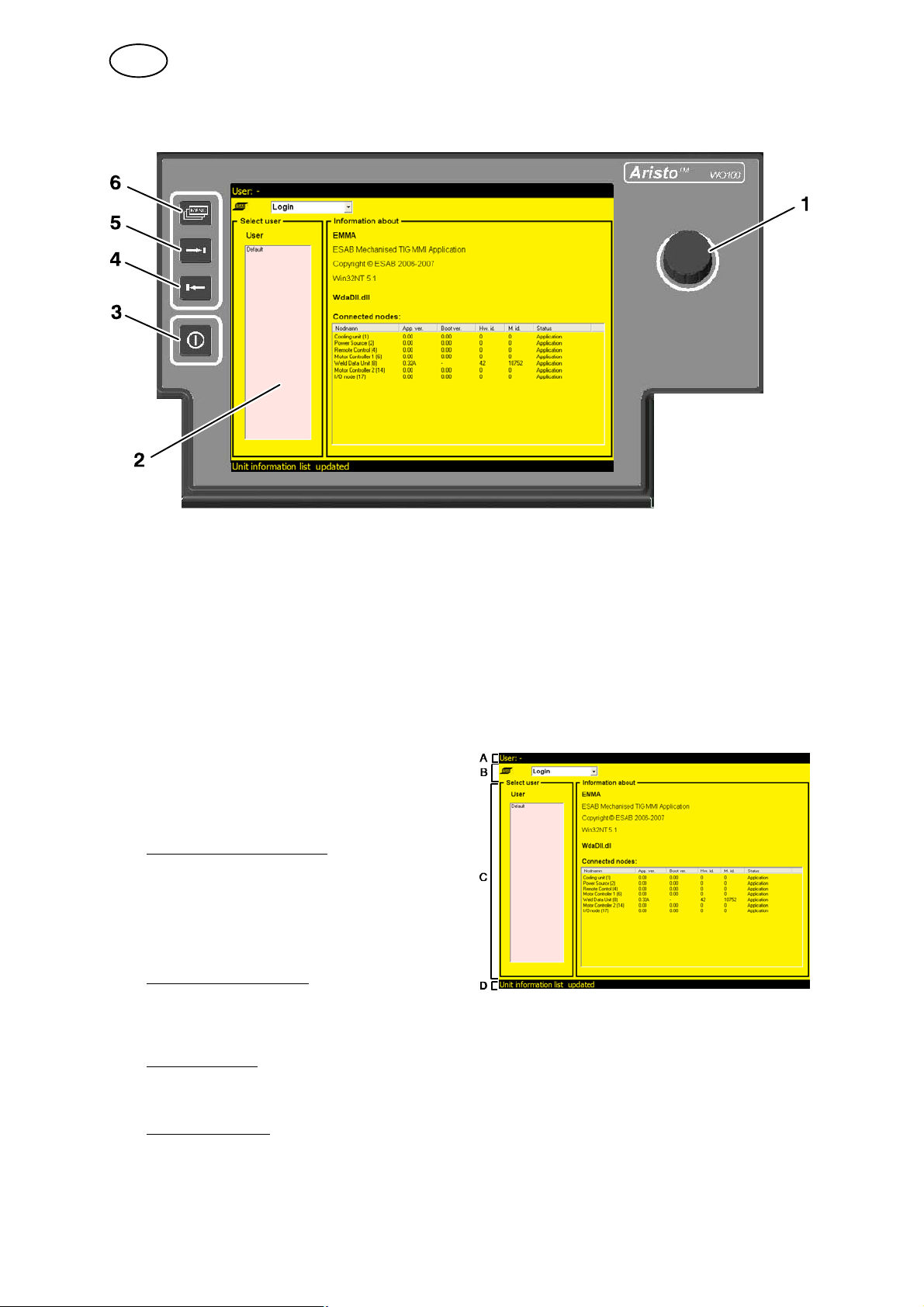

1.2 Control panel

1 Knob

For moving, activating and setting parameter values.

There are three knob functions:

S Turn to the left

S Turn to the right

S Press the knob, activate

2 Display

There are four view fields in the

display:

Upper status field (A)

Information about the weld area's

program name, user, which type of

tool is connected and the tube

dimension.

Main menu field (B)

Different menus, see chapter 5 ”Menu

Structure”.

View field (C)

For editing weld programs, saving programs, information, appearance, etc.

Status field (D)

Shows general information, error messages and current welding data (position,

voltage, current)

- 5 -

bi16d1ea

© ESAB AB 2007

GB

3 Quick stop/Restart

Immediate stop of the welding process. Gas postflow occurs according

to information from end sector.

Pressing the button again initiates restart with parameters from start

sector; the welding process continues from the point in the weld

program at which the interruption occurred.

4 Left arrow

Moving to the left in the menus and back in the main menus

5 Right arrow

Moving to the right in the menus and forward in the main menus

6 Main menu

Moving to the main menu field

2 SETTING RANGE

Parameter Setting range

Sector

Breakpoints

Degrees

Welding current

Peak current

Background current

Pulse time

Background time

Special pulsing

Wire feed

Peak wire feed speed

Background wire feed speed

Rotation

Rotation speed

Rotation direction

Pulsed rotation

1)

0 - 50

0.000 - 9.999

0 - 3599°

3 - 400 A

3 - 400 A

0.01 - 25 s

0.01 - 25 s

Off and On

15 - 250 cm/min

15 - 250 cm/min

5 - 100 % of the welding tool's maximum speed

Forwards and Backwards

0.05 - 25 s

2)

2)

AVC

Peak voltage

Background voltage

Delay time

Weaving

Weaving amplitude

Weaving speed

Pause time (right and left)

bi16d1ea

8 - 33 V

8 - 33 V

0.5 - 6000 s

0 - 12 mm (5 mm)

2 - 12 mm/s (5 mm/s)

0.1 - 10 s (1 s)

- 6 -

© ESAB AB 2007

GB

Parameter Setting range

Gas

Weld gas preflow time

Weld gas postflow time

Start gas

Root gas

Preheating

Preheating time 0 - 600 s

Slope

Slope up time

Slope down time

1)

The maximum welding current for air-cooled tube welding tools is 100 A.

The maximum welding current for water-cooled tube welding tools is 400 A.

See also the instruction manual for the tube welding tool in question.

2)

Depends on power source

0 - 6000 s

0 - 6000 s

0 - 6000 s

0 - 6000 s

0.1 - 25 s

0.1 - 25 s

3 WELDING PARAMETERS

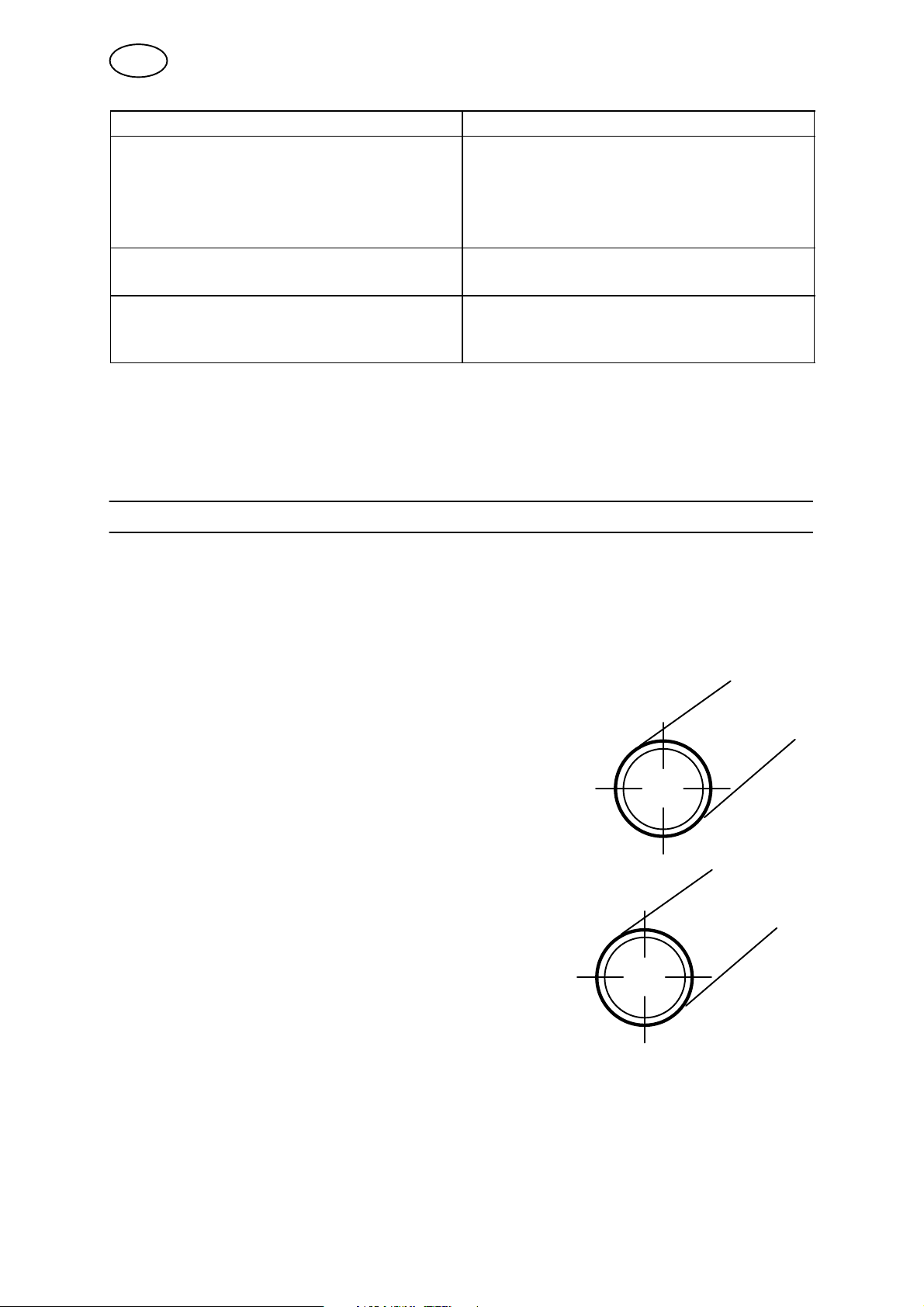

3.1 Sectors

A program for tube welding can be divided into different sections: sectors. Each

sector corresponds to one section of the tube's circumference. The maximum

number of sectors for one program is 50.

A sector can be assigned its own set of values

for different welding parameters, such as

current, rotation speed and wire feed speed, etc.

This allows the welding to be performed using

different welding parameter settings for different

sections of the tube joint.

The division into sectors is done by

indicating different breakpoints or degrees

around the circumference of the tube. Each

breakpoint or degree constitutes the starting

point for a new sector. In the figure,

breakpoint 0.000, 0 degrees, is the starting

point for sector 1, breakpoint 0.250, 90

degrees, the starting point for sector 2, and

so on.

The power source allows welding of up to

10 turns in the same weld joint. (The

welding tool can be rotated 10 times around

the tube.)

Sector 4 Sector 1

Sector 3 Sector 2

0.000

Sector 4 Sector 1

0.750 0.250

Sector 3 Sector 2

0.500

Note: A sector may not be less than 10 thousandths, or 3.6 degrees, of a turn.

bi16d1ea

- 7 -

© ESAB AB 2007

GB

S Turn 1 =

breakpoints 0.000 - 0.999

0 - 359 degrees

S Turn 3 =

breakpoints 2.000 - 2.999

720 - 1079 degrees

S Turn 5=

breakpoints 4.000 - 4.999

1440 - 1799 degrees

S Turn 7=

breakpoints 6.000 - 6.999

2160 - 2519 degrees

S Turn 9=

breakpoints 8.000 - 8.999

2880 - 3239 degrees

S Turn 2 =

breakpoints 1.000 - 1.999

360 - 719 degrees

S Turn 4 =

breakpoints 3.000 - 3.999

1080 - 1439 degrees

S Turn 6=

breakpoints 5.000 - 5.999

1800 - 2159 degrees

S Turn 8 =

breakpoints 7.000 - 7.999

2520 - 2879 degrees

S Turn 10 =

breakpoints 9.000 - 9.999

3240 - 3599 degrees

To conclude a weld program, a so-called end sector is indicated.

For a sector to be counted as an end sector the following two conditions must be

fulfilled:

S There is no subsequent sector.

S The welding current value for the sector is 0 ampere.

3.2 Welding current

Six parameters are represented in the parameter group for welding current:

S Peak current

S Background current

S Pulse time

S Background time

S Special pulsing

S Slope, see point 3.9.

Pulse time

Background time

Peak current

Background current

TIG welding with pulsed current

Welding current can be pulsed or continuous (not pulsed).

3.2.1 Pulsed current/continuous current

When welding using a pulsed current, peak current, background current, pulse

time and background time must be given a value.

When welding using a continuous current, however, you need only enter a

parameter value for peak current. Entering a value for background current will result

in a pulsed current.

bi16d1ea

- 8 -

© ESAB AB 2007

GB

The welding current (pulsed current) can be synchronized with the weaving motion

so that the peak current will start when the electrode is at the extremes of the

weaving motion. This is also called special pulsing. (Even when special pulsing is

not used, peak current still starts at the extremes of the weaving motion.)

3.2.2 Special pulsing

Special pulsing means that the welding current is synchronized with the weaving

motion, i.e. you get peak current when the electrode is at the extremes of the

weaving motion. Thus, the peak current time is determined by the pause time for

each extreme.

Special pulsing can be used in combination with both continuous and pulsed

rotation. Special pulsing with pulsed rotation, also called square-wave pulsing,

means that the gear ring rotates when the electrode is at either extreme of the

weaving motion.

A = Background current

B = Peak current

Rotation direction Rotation direction

Special pulsing with

continuous rotation

Special pulsing with

pulsed rotation

With special pulsing, the wire feed can be either continuous or pulsed. With pulsed

wire feed, synchronization with the welding current takes place in the manner

described above, see also chapter 3.3”Wire Feed Speed”.

bi16d1ea

- 9 -

© ESAB AB 2007

GB

3.3 Wire feed

Wire feed speed is used to indicate the feed speed for the filler wire in cm/minute.

Speed can be pulsed or continuous (not pulsed).

Three parameters are represented in the parameter group for wire feed:

S Peak wire feed

S Background wire feed

S Slope, see point 3.9.

For welding using a continuous (not pulsed) wire feed, only the peak wire feed

parameter needs to be entered.

For welding with a pulsed wire feed speed, both the peak wire feed and the

background wire feed parameters need to be entered.

The pulsed wire feed speed is always automatically synchronized with the welding

current so that the wire feed speed is high when using peak current and low when

using background current.

3.4 Rotation

Used to indicate the rotation speed of the electrode around the workpiece. It is

indicated in mm/min.

The rotation speed can be pulsed or continuous (not pulsed).

Four parameters are represented in the parameter group for rotation:

S Rotation speed

S Rotation direction

S Pulsed rotation

S Slope, see point 3.9.

Pulsed rotation is automatically synchronized with the welding current so that the

welding tool is stationary at peak current and rotates at background current.

3.5 Arc voltage control (AVC)

Used during welding with welding tools equipped with an AVC unit.

Arc voltage control (AVC) means that the arc voltage, and therefore the arc length

(the distance between the electrode point and workpiece), is regulated automatically

during ongoing welding.

Four parameters are represented in the parameter group for arc voltage control

(AVC):

S Peak voltage (Arc voltage at peak current)

S Background voltage (Arc voltage at background current)

S Delay time

S Slope, see point 3.9.

The parameters peak voltage and background voltage are used to enter the

reference value for arc voltage control at peak current and background current. With

continuous current, only the peak voltage parameter needs to be entered.

bi16d1ea

- 10 -

© ESAB AB 2007

GB

If no value is indicated for peak voltage, use a value measured immediately after

welding began as the reference value.

If no value is indicated for background voltage and pulsed welding current is

entered, there is no arc voltage control with background current.

Note: It is not possible to indicate a time slope in sector 1 for peak voltage and

background voltage.

It is possible to enter a delay time as a means of stablising the arc before arc

voltage control commences. During this delay time the AVC unit is completely

locked.

If you do not enter a delay time, the following happens:

S The delay time is the same (at least 5 seconds) as any slope up time for the

welding current. If the entered slope up time is less than 5 seconds, the AVC unit

will start up once the slope ends, but only by increasing the arc voltage (arc

length).

S If no slope up time has been entered for the welding current, a fixed delay time

of 5 seconds applies. The AVC unit is not completely locked but can increase the

arc voltage (arc length).

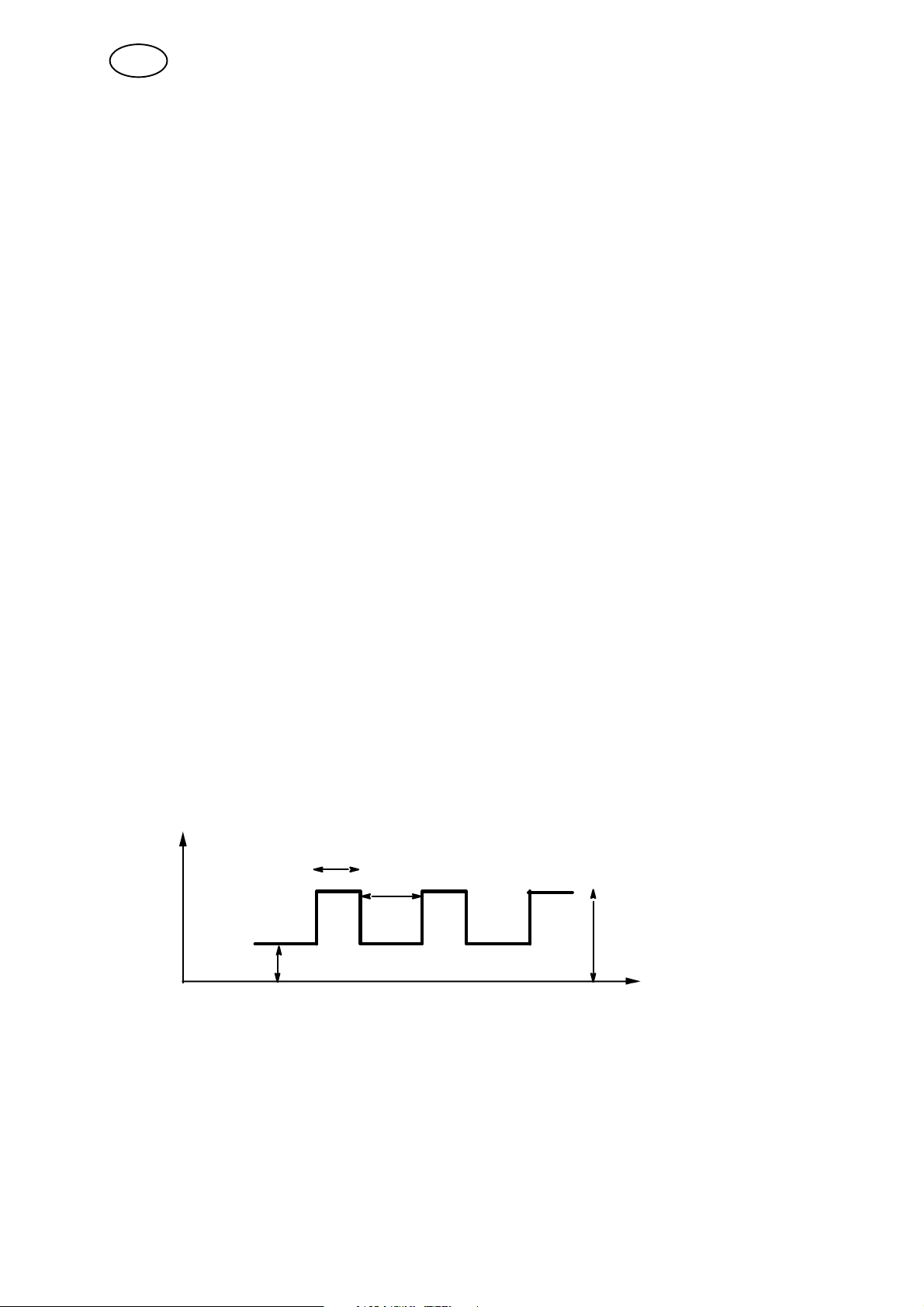

3.6 Weaving

Used if you want to weave the electrode sideways during welding when using

welding tools equipped with a weaving unit.

Five parameters are represented in the parameter group for weaving:

S Weaving amplitude

S Weaving speed

S Left pause time

S Right pause time

S Slope, see point 3.9.

Amplitude (mm)

Left pause time (s)

Right pause time (s)

Weaving speed (mm/s)

Weaving

The weaving motion can be synchronized with the welding current (pulsed current)

so that the peak current will start when the electrode reaches the extremes of the

weaving motion. This is also called `special pulsing' and is described further in

chapter 3.2.2 ”Special Pulsing”.

bi16d1ea

- 11 -

© ESAB AB 2007

GB

3.7 Gas

Three parameters are represented in the parameter group for shielding gas:

S Weld gas

S Start gas

S Root gas

Weld gas refers to the shielding gas on the upper side of the weld joint. The weld

gas parameter indicates how long the shielding gas is to flow on the upper side of

the joint before and after welding. The weld gas is monitored by a flow guard min.

4.5 l/min.

Some shielding gases, for example, helium (He), can cause problems with regard to

igniting the arc. If this type of shielding gas is to be used as weld gas, it may be

advisable to use a different gas mixture at the actual instance of starting, a so-called

start gas.

Root gas refers to the shielding gas on the underside of the weld joint. The root gas

parameter indicates how long the shielding gas is to flow on the underside of the

joint before and after welding.

If one value is entered for weld gas and another for start gas in sector 1, only the

start gas will flow. The weld gas starts flowing once the arc is ignited.

3.8 Preheating

Preheating is used to heat the workpiece at the starting point in order to ensure

correct penetration of the molten pool and is defined as the time elapsing between

arc ignition and the start of the rotary motion. If no value has been entered for

preheating, rotation will start as soon as the arc ignites.

3.9 Slope

A slope may be indicated for certain parameters. A slope is the time during which the

value of the parameter gradually changes from the value in the preceding sector to

the value entered for the current sector.

Slope up = gradual increase, if the preceding value is lower than the entered value.

Slope down = gradual decrease, if the preceding value is higher than the entered

value.

The maximum period a slope can run depends on the duration of a particular sector.

If the slope time is of the same duration as the sector, this is called a `sector slope'.

bi16d1ea

- 12 -

© ESAB AB 2007

GB

4 MENU STRUCTURE

Weld area

Parameters File manager Information Joint info. Settings Limits

Table

· Edit table

· Show/hide

· Weld

control

· Edit

Parameters File manager Information Joint info. Settings Limits

Graphical

· Current

· Wire feed

· Rotation

· Weaving

· AVC

· Gas

· General

· Description

· Tube

· Electrode

· Wire

· Gas

Design area

· Visualization

· Parameter

values

· Tool

settings

· Tube

settings

Table

· Edit table

· Show/hide

· Edit

Graphical

· Current

· Wire feed

· Rotation

· Weaving

· AVC

· Gas

· General

· Description

· Tube

· Electrode

· Wire

· Gas

· Visualization

· Parameter

values

· Tool

settings

· Tube

settings

bi16d1ea

- 13 -

© ESAB AB 2007

GB

Settings Login Library Manual

mode

Appearance User · Weld

program

· Search filter · Run motor

· General

· Quality

data

Tool

editor

Load/

save

· Tool

selection

· Tool

action

Change

settings

· General

· Parameter

limits

Change

motor data

· Change

parameter

· Show para

meters

· Motor selection

· Gas valve control

· Weaving simulation

Logs Manual

Event

log

Generate

welding

Quality data

· Quality data

files

· Contents

5 MENUS

There are two work areas where you can view and edit welding parameters, Weld

area (see chapter 5.1) and Design area (see chapter 5.2).

5.1 Weld area

In this view, you can view and edit parameters in a weld program and control the

welding process. The weld program in the weld area controls the welding process.

You can enter the weld area's parameters by loading a weld program from the

library, generating a basic weld program or editing the parameters manually.

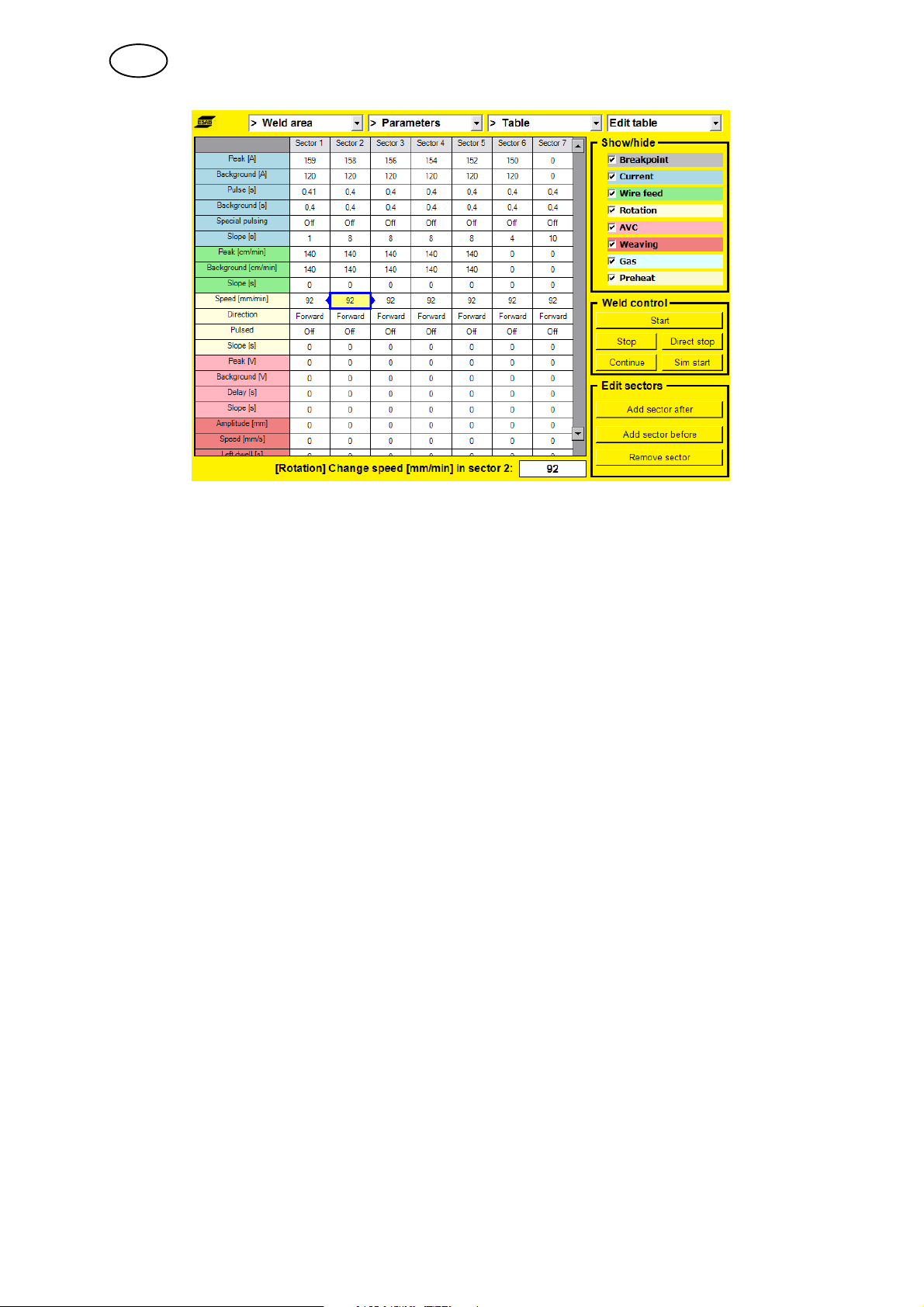

5.1.1 Parameters

This menu option is solely an archive for other menu options.

Weld area --> Parameters --> Table

Here you can view and edit welding parameters in table form and start and stop the

welding process.

bi16d1ea

- 14 -

© ESAB AB 2007

GB

Each parameter in a parameter group is highlighted in the group's colour.

A selected welding parameter in the table is indicated by a blue box with two arrows.

S To move through the table, turn the knob.

S To change direction, press the knob.

S To change a parameter value, click on the right arrow and change the parameter

values using the knob.

Menu shortcuts:

S Edit table

Highlights the table with welding parameters

S Show/hide

Shows or hides groups of welding parameters in the table.

Here you can choose which parameters are to be shown in the table by selecting

groups of parameters.

S Weld control

Highlights the start button in the weld control box.

The buttons in this box control the welding process. You can start, stop, direct

stop, continue or simulate the start of the welding process.

S Edit sectors

Highlights the button 'Add sector after' in the Edit sectors box.

The number of sectors can be increased or decreased using this box. It is

possible to add new sectors before or after an existing sector and remove

sectors in the weld program.

- 15 -

bi16d1ea

© ESAB AB 2007

GB

Weld area --> Parameters --> Graphical--> Current

In this view, you can view and edit welding parameters for current in a graphical

representation.

The current's peak and background values are represented in a coordinate system.

The Y-axis represents the current's value in ampere, while the X-axis represents

time.

The current's various values per sector are connected and form a line.

Green indicates the peak current value per sector, while blue indicates the

background current value per sector.

Slope is represented as an angled line from the start of the sector, which ends where

the slope time stops on the X-axis.

S Zoom

Here you can adjust the scale of the X-axis in the coordinate system.

S Weld control

The buttons in this box control the welding process. You can start, stop, direct

stop, continue or simulate the start of the welding process.

S Sector information

The figures in this field show the other parameters concerned with the parameter

group for current. The sector's breakpoint is represented by a dash in a circle

(cross-section of a tube).

If the weld program extends over more than one turn, these turns are shown as

a sequence of slightly smaller circles.

The preheating time is shown in tenths of a second under the breakpoint

information.

Special pulsing on or off is shown as an image, where a red cross indicates that

special pulsing is not being used.

The relationship between pulse times is shown as a pulse cycle. Separate times

for peak and background pulse.

bi16d1ea

- 16 -

© ESAB AB 2007

GB

S Figure for breakpoints

It is possible to move, add or remove breakpoints using the knob in the figure for

breakpoints. By skipping forward to the figure and highlighting it, you can turn the

knob and move a white dash or `cursor'.

Moving a breakpoint:

S Press the knob once the cursor is on or directly next to the breakpoint cursor

(black) to be moved.

The breakpoint is `collected' by the cursor and follows this when it is turned

around in the circle.

S To confirm the new breakpoint, press the knob.

Creating a new breakpoint

S Move the cursor by turning the knob and press the knob once at the point

where you want the new breakpoint to be created.

Removing a breakpoint:

S Press the knob once the cursor is on or directly next to the breakpoint cursor

to be removed.

The breakpoint is `collected' by the cursor and follows this when it is turned

around in the circle.

S Turn the knob to the previous or next breakpoint and press the knob once.

Weld area --> Parameters --> Graphical--> Wire feed

Here you can view and edit parameters that control wire feed per sector.

The coordinate system shows the speed at which the wire will be fed out at the peak

and background value per sector.

Slope is represented as an angled line from the start of the sector for the duration

entered for the slope.

bi16d1ea

- 17 -

© ESAB AB 2007

GB

Weld area --> Parameters --> Graphical--> Rotation

Rotation speed is viewed and edited in a coordinate system with one line for each

value and time slope. The coordinate system shows breakpoints as dashed lines.

If pulsed rotation is off, this is shown by a pulse that is crossed out.

Weld area --> Parameters --> Graphical--> Weaving

This view shows the parameters that affect weaving. The amplitude is viewed and

edited in the coordinate system. Speed and pause times are viewed and edited in

the sector information field.

bi16d1ea

- 18 -

© ESAB AB 2007

GB

Weld area --> Parameters --> Graphical--> AVC

Here you can view and edit parameters that control AVC. Peak and background

voltage are shown in the coordinate system.

Delay time is viewed and edited in the sector information field.

Weld area --> Parameters --> Graphical--> Gas

Times for weld, start and root gas are viewed and edited in this view.

bi16d1ea

- 19 -

© ESAB AB 2007

GB

5.1.2 File manager

This view is used to save, copy, clear and verify weld programs.

S Save weld program

To save a weld program, select where you want the program to be saved, either

on the control unit (User defined programs) or on a USB memory device

(External memory).

Specify a file name and click the 'Save weld program' button using the knob.

S Copy weld program to another area

Depending on which work area is active, it is possible to copy the contents of

one area to another area by clicking the 'Copy this wld program to design area'

button or 'Copy this weld program to weld area' button.

S Clear, reset weld program

If you want to begin a brand new weld program, click the 'Clear weld area'

button or 'Clear design area' button.

S Verify

This function is used to check whether the weld program in the current work area

fulfils the system's requirements as follows:

S A tool is selected for the weld program.

S The connected tool is the same as the one the program is designed for (only

applies to weld area).

S The program has at least two sectors (start and stop sector).

S The final sector in the program is a stop sector (the welding current is zero).

S Selected tube diameter is supported by the selected tool.

S The welding parameters in each sector are within the limits (min. and max.

values) for the selected tool.

bi16d1ea

- 20 -

© ESAB AB 2007

GB

5.1.3 Information

Used to enter information about the weld program. This information does not affect

the welding process, but is an aid for describing the program in words.

S General

Program name is shown at the top of the list. This is not the same as file name in

file manager. If a program name is assigned, this is the suggestion offered for

the file name.

S Description

S Tube

S Electrode

S Wire

S Gas

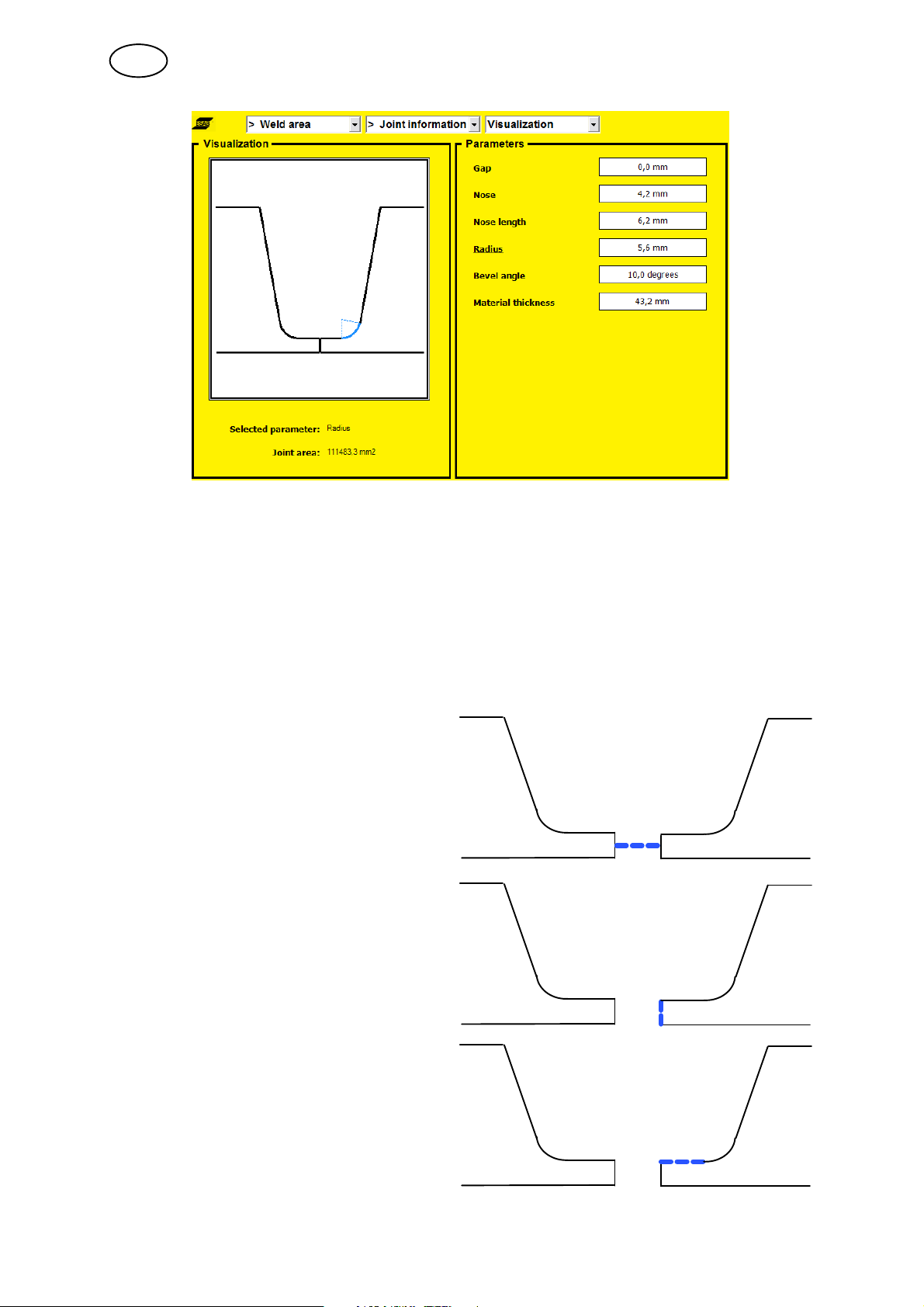

5.1.4 Joint information

In this view, you can view and change how the joint will look to suit the weld

program. This is only information about the weld program. It does not affect the

welding process.

In the ”Visualization, Visualization” field, it is possible to view a graphical

representation of the joint. In the ”Parameters” field, you can view those values

relevant to the joint. Values that affect the joint can be changed in both fields.

bi16d1ea

- 21 -

© ESAB AB 2007

GB

Visualization

S Turn the knob and a blue line will indicate which parameter has been selected.

S Press the knob and the line will turn red. The value can be changed by turning

the knob.

Parameter

S Use the arrows to move between the various parameters.

S Turn the knob to change the value.

Gap

Nose

Nose length

bi16d1ea

- 22 -

© ESAB AB 2007

GB

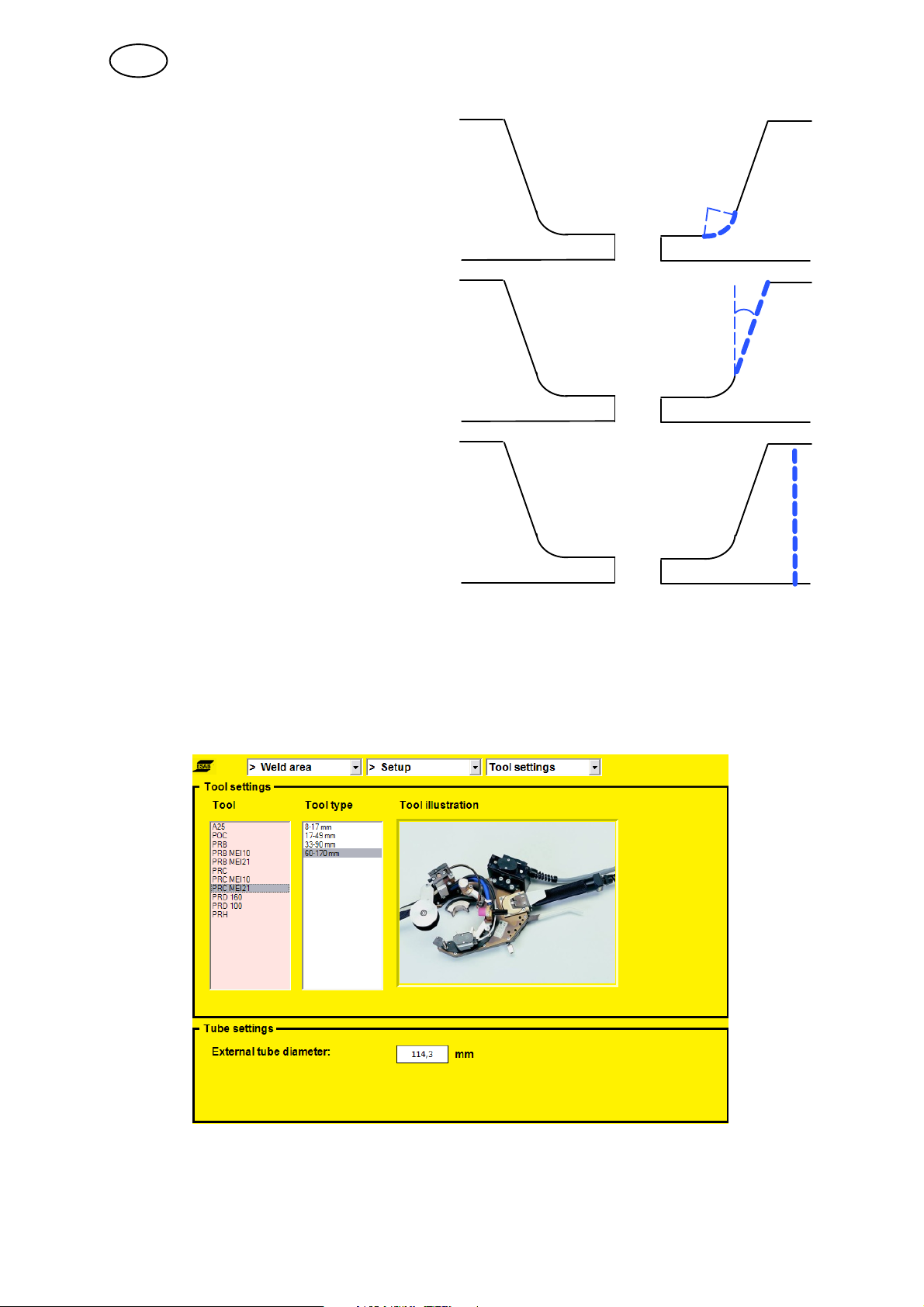

Radius

Bevel angle

Material thickness

5.1.5 Settings

This view allows you to select tools and the external tube dimension for which the

weld program has been created. In the ”Tool settings” field, you can scroll through

the tools and look at an overview of the tools under ”Tool illustration”. To select a

tool, press the knob and then select the type of tool by turning and pressing the

knob.

The external tube dimension is selected by turning the knob. To confirm, press the

knob. The selected tool (”Tool ”) and dimension (”Ø:”) are visible in the top status

field, when using views from a work area.

bi16d1ea

- 23 -

© ESAB AB 2007

GB

5.1.6 Limits

This view can be used to limit how much a user can change preset parameter values

in a weld program.

In order for the restrictions to be activated, the check box ”Limits activated” must be

checked.

5.2 Design area

Weld programs can be created in the design area for use in the weld area or saved

in the library for subsequent use. To see how the design area works, refer to chapter

5.1Weld Area. The design area works in a similar way to the weld area.

The greatest difference between the two areas is that you cannot control the welding

process from the design area.

5.3 Settings

You can change the appearance of the panel and manage users in the system via

the Settings menu.

bi16d1ea

- 24 -

© ESAB AB 2007

GB

5.3.1 Appearance

Settings --> Appearance --> General

S Language

Choose from Swedish, Norwegian, Danish, Finnish, English, German, French,

Dutch, Spanish, Italian, Portuguese, Greek, Polish, Czech, Hungarian, Slovenian

and Russian.

S Angle system

Choose between thousandth points or degrees.

S Start view

Choose between starting the panel with the login menu or last viewed menu.

bi16d1ea

- 25 -

© ESAB AB 2007

GB

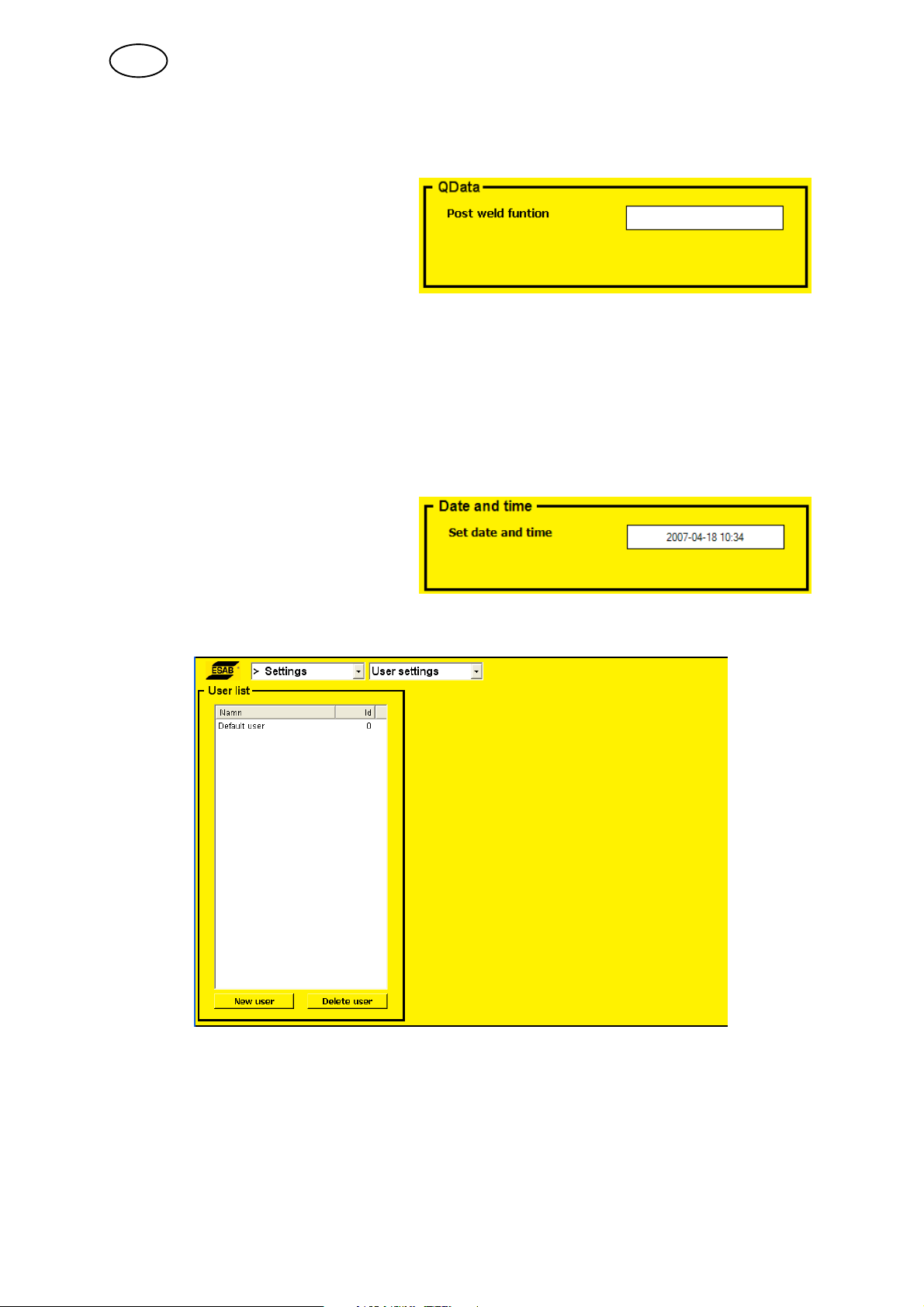

Settings --> Appearance --> QData

S Post weld function

Choose from:

S None

S Print

S Save

S Print + save

The values that are saved and printed out are set values and the measurement

values from the concluded welding process. Printing uses the integral printer in

the control unit.

The values are saved in the control panel under the ”quality data” menu, see

chapter 5.8.

Settings --> Appearance --> Date and time

Here you can view and enter the

date and time used in the system.

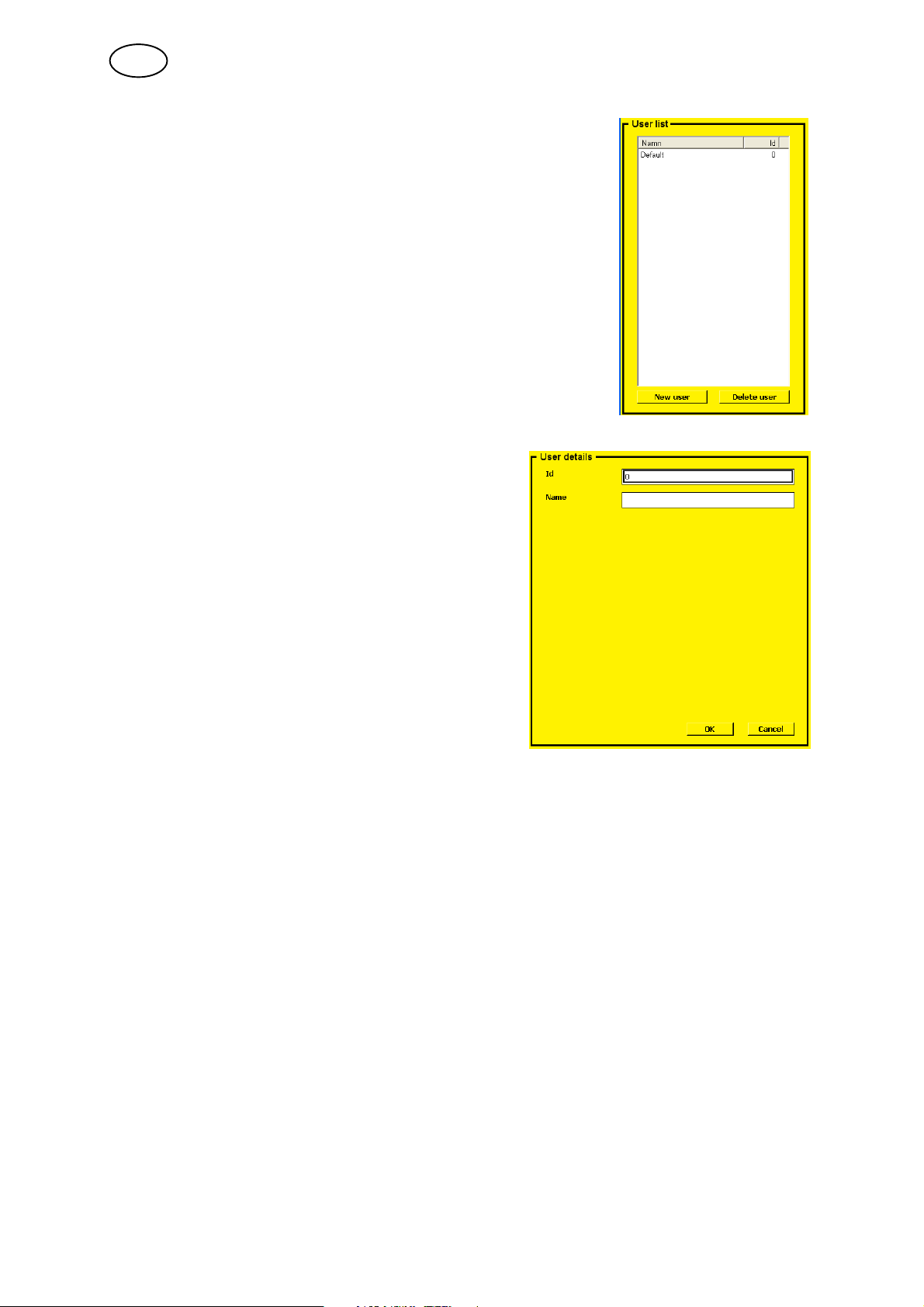

5.3.2 Users settings

In this view, you can add, change and delete users.

bi16d1ea

- 26 -

© ESAB AB 2007

GB

”Default user” appears the first time this menu is accessed.

To add a new user:

S Press the right or left arrow until ”New user” is

highlighted.

S Press the knob.

S Turn the knob until a suitable ID appears.

S Press the knob. The next box will be

highlighted.

S Turn the knob until a suitable letter appears,

press the knob, and so on.

S Once the name is ready, press the right

arrow until ”ok” is highlighted.

S Press the knob.

A new user appears in the list.

To change a user:

S Highlight the user list (by pressing the arrow keys).

S Turn the knob to select the user you want to change and press the knob.

A new field appears at the side of the user list, which allows you to change the

selected user's name or ID. Confirm the changes using ”OK”.

To delete a user:

S Highlight the user.

S Press the knob, move to the ”Delete user” button and click on the button.

The user disappears from the list.

bi16d1ea

- 27 -

© ESAB AB 2007

GB

5.4 Login

The login menu is used to select users and view which program version applies for

the panel and which units are connected. It is also possible to view version

information on the connected units/nodes.

The user name is shown in the top status field, see chapter Control Panel 1.2.

5.5 Library

Programs can be erased and retrieved for the weld area or the design area using the

library menu.

Please note that each program stored in the library is 4 - 6 Kb. The control unit's

internal memory is 1 Gb, so there is only a very small risk of the library becoming full.

NOTE! Predefined programs that begin with ESAB cannot be erased. These

programs are tested and are intended to serve as start data for similar dimensions.

bi16d1ea

- 28 -

© ESAB AB 2007

GB

5.5.1 Weld programs

5.5.2 Search filter

Using the search filter menu it is possible to search by the following criteria in the

programs stored in the library:

S Nothing

S Name

S Project

S Material

S External tube diameter

S Tube wall thickness

If there are programs that match the criteria, these programs are displayed in the

”Weld programs” menu.

If there are no programs that match the selected criteria, continue on to ”Go to

Generate”, see chapter Generate 5.10.

bi16d1ea

- 29 -

© ESAB AB 2007

GB

5.6 Manual mode

All motors can be checked using this menu.

5.6.1 Motor selection

Here you can choose which motor to run and also enter the motor speed.

Note: This view only shows those motors available in the system. The tool selected

in ”Weld area --> Settings” affects the information shown.

S Wire inching

Used when loading a new wire bobbin, for example.

S Rotation/Transport

Used to move the welding tool around the workpiece.

S AVC/Transport

Used to move the electrode holder up and down.

S Center positioning

Used to offset the centre point.

- 30 -

bi16d1ea

© ESAB AB 2007

GB

5.6.2 Gas valve control

Used when measuring the gas flow or to flush any air or moisture from the gas

hoses before welding begins.

Starts and stops the flow of gas.

If you exit this view, the gas valves close automatically.

5.6.3 Run motor

Used to view the current value of the motors.

Note! Hold in the knob to activate motor drive.

Run selected motor forwards ”+” or

backwards ”-”, and view current

speed for selected motor.

5.6.4 Weaving simulation

Used to run simulated weaving.

5.7 Tool editor

This menu is used for viewing and editing tool parameters. You can create new tools

from scratch or use predefined tools. Tools that are created by a user can be

removed, changed and saved. Predefined tools supplied with the system cannot be

changed or removed.

Please note that the tool currently being used is designated a specific work area, a

tool area. All changes performed in the views described below only affect the tool

area and are not saved until this is requested by the user.

bi16d1ea

- 31 -

© ESAB AB 2007

GB

5.7.1 Load/save

In this view, you can load a tool to work from when creating a new tool, clear

user-defined tools and save tools.

Select a tool to use (enter parameters in the tool area) by moving to the list of tools

using the left or right arrow. Turn the knob to select (highlight) a tool.

Move to the button ”Load tool”, press the knob and confirm that this is the tool you

want to use.

It is also possible to use a tool specification (tool type), for example, a tool with a

particular diameter range.

Delete a created tool by selecting it in the list, press the knob on ”Delete tool, Delete

tool” and confirm that you want to delete it using ”Yes”. It is not possible to delete

any tools supplied with the system.

You can save the created tool as a new tool or in place of an existing tool (you

cannot replace tools supplied with the system).

To save the tool as a new tool (or new tool type):

S Move to the list of tools (or tool types) using the arrow keys.

S Turn the knob to highlight ”New.... ” in the list.

S Click the menu button and select ”Tool action”.

S Move to the ”Save tooll” button.

S Press the knob and confirm that you want to save the tool as a new tool using

the ”Yes” button.

To replace an existing tool, use the same procedure as above but instead select an

existing tool from the list of tools.

You can upload tools to the system from a USB memory device, if you have a

”MechTIG_Tools.xml” tool file at the root of the file structure.

bi16d1ea

- 32 -

© ESAB AB 2007

GB

Proceed as follows:

S Connect a USB memory device to the panel's USB terminal, where the

”MechTIG_Tools.xml” file is at the very root of the file structure.

S Move to the ”Load tools from usb-memory” button using the arrow keys.

S Press the knob and confirm using ”Yes” to invalidate all the changes made to the

tool.

Clear or reset all parameters in the tool area by moving to the ”Clear tooll” button

and pressing the knob. Confirm using ”Yes” to invalidate any changes made in the

tool area.

To save all your tools to a USB memory device:

S Connect a USB memory device to the panel's USB terminal.

S Move to the ”Save tools to usb-memory” button and press the knob.

S Confirm using ”Yes” to save the tools and overwrite any tools stored on the USB

memory device.

5.7.2 Edit settings

This view is used once you have loaded a tool or when you want to create a brand

new tool. Here you can view and edit all parameter values for a tool.

The ”General settings” field contains general settings for the tool, while the

”Parameter limits” field defines the highest and lowest values for a parameter.

For min. values the value 0 means that the minimum value has not been set, while

for max. values 65535 means that the maximum value has not been set. (In some

instances, where decimals are used, 655,30 or 6553,5 may indicate not set).

bi16d1ea

- 33 -

© ESAB AB 2007

GB

5.7.3 Edit motor data

In this view, you can view and edit specific motor settings. There are motor settings

for each motor (rotation, wire feed, weaving and AVC). There are currently three

parameters per motor. The parameters are ”Setting parameter”, ”Scalefactor

position” (”numerator” and ”denominator”) and ”Scalefactor speed” (”numerator” and

”denominator”).

Add the value 100 for the parameter ”Scalefactor position (numerator)” for the motor

that controls rotation.

Proceed as follows:

S Move to the text field under ”Motor parameter” using the arrow keys.

S Turn the knob until ”Scalefactor position (numerator)” is visible in the text field

and press the knob.

S Change the value to 100 by turning the knob. Press the knob to continue.

S Turn the knob so that ”Rotation” appears in the text field. Confirm by pressing

the knob.

S Press the knob to add (or edit) the value in the list of parameters for the rotation

motor.

You can remove motor parameters by highlighting a parameter in the list of motor

parameters, pressing the knob, moving to the ”Delete” button and pressing the knob

to delete the selected parameter from the list.

5.8 Logs

This menu allows you to view logs compiled by the system.

5.8.1 Event log

Event log

When a fault occurs, this is indicated by the symbol , which is displayed to the

right of the ESAB logo. When you go into the Event log menu, the symbol

disappears.

bi16d1ea

- 34 -

© ESAB AB 2007

GB

Used to display operating messages

In order to clear or remove all operating messages from the log, move the focus to

the ”Clear log” button with the arrow keys and press the knob. Confirm that you want

to remove all events by pressing ”Yes” with the knob. The event log is reloaded and

is now empty.

It is also possible to save the event log onto an external USB memory.

Proceed as follows:

S Insert a USB memory in the panel's USB contact, move the focus with the arrow

keys to the ”Save” button.

S Press the knob. The text ”Event log saved” appears in the lower status bar if the

log was saved correctly.

Operating messages

Unit Unit

1 = cooling unit 8 = weld data unit

2 = power source 14 = motor control 2, AVC, oscillation

4 = remote control 17 = I/O node

6 = motor control 1, rotation, wire feed

bi16d1ea

- 35 -

© ESAB AB 2007

GB

Below describes event codes which the user can take action by him self. Is any other

code shown, send for a service technician.

Code Description

5 Intermediate DC voltage outside limits

The voltage is too high or too low. Too high a voltage can be due to severe transients on

the mains power supply or to a weak power supply (high inductance of the supply or a

phase missing).

The power unit is stopped and cannot be started.

Action: Turn off the mains power supply to reset the unit. If the fault persists, send for a

service technician.

6 High temperature

The thermal overload cut-out has tripped.

The current welding process is stopped and cannot be restarted until the cut-out has reset.

Action: Check that the cooling air inlets or outlets are not blocked or clogged with dirt.

Check the duty cycle being used, to make sure that the equipment is not being overloaded.

If the fault is repeated, send for a service technician.

11 Motor servo fault, (rotation, wire feed, oscillation, AVC)

When a motor cannot maintain its speed. Welding stops.

Action: Check that the tool / wire feed unit has not become trapped or is moving too

slowly. Check that the weaving unit's oscillating movement has not reached the outer limit.

If so, adjust the centre position. If the fault persists, send for a service technician.

11 Current servo fault, (power source)

The voltage is too high or too low. Too high a voltage can be due to severe transients on

the mains power supply or to a weak power supply (high inductance of the supply or a

phase missing).

The power unit is stopped and cannot be started.

Action:Turn off the mains power supply to reset the unit. If the fault persists, send for a

service technician.

12 Internal communication error (warning)

The load on the system's CAN-bus is temporarily too high.

The power unit may have lost contact with the panel.

Action: Check that all the equipment is correctly connected.

If the fault persists, send for a service technician.

14 Communication error

The system's CAN-bus has temporarily stopped working due to the load being too high.

The current welding process stops.

Action: Check that all the equipment is correctly connected. Turn off the mains power

supply to reset the unit. If the fault persists, send for a service technician.

17 Lost contact with unit

Lost contact with unit. The gas is not turned off; it must be turned off manually.

Start is prevented

Action: Check the cables. If the fault persists, send for a service technician.

19 Battery voltage low

Battery voltage too low. If the battery is not replaced, all stored data will be lost.

This fault does not disable any functions.

Action: Send for a service technician to replace the battery.

20 Incorrect set values stored in welding program

Non-permitted values have been discovered at start-up.

Action: Change parameters in the welding program. If the fault persists, send for a service

technician.

bi16d1ea

- 36 -

© ESAB AB 2007

GB

Code Description

29 No cooling water flow

The flow monitor switch has tripped.

The current welding process is stopped and starting is prevented.

Action: Check cooling water circuit, pump and hoses.

32 No gas flow

The gas flow is less than 3.5 l/min. Start prevented.

Action: Check the gas valve, hoses and connectors.

41 Failed welding start

The power source does not manage to light the welding arc.

Action: Check welding cables and tool.

5.8.2 Quality data

Here you can view data saved

under the post weld function, see

chapter 5.3.

Logs --> QData --> QData files

The QData file is saved with the

date and a serial number.

The files can be saved to a USB

memory device using ”Save”.

Logs --> QData --> QData content

The QData file's set values and

measurement values are visible in

this field.

bi16d1ea

- 37 -

© ESAB AB 2007

GB

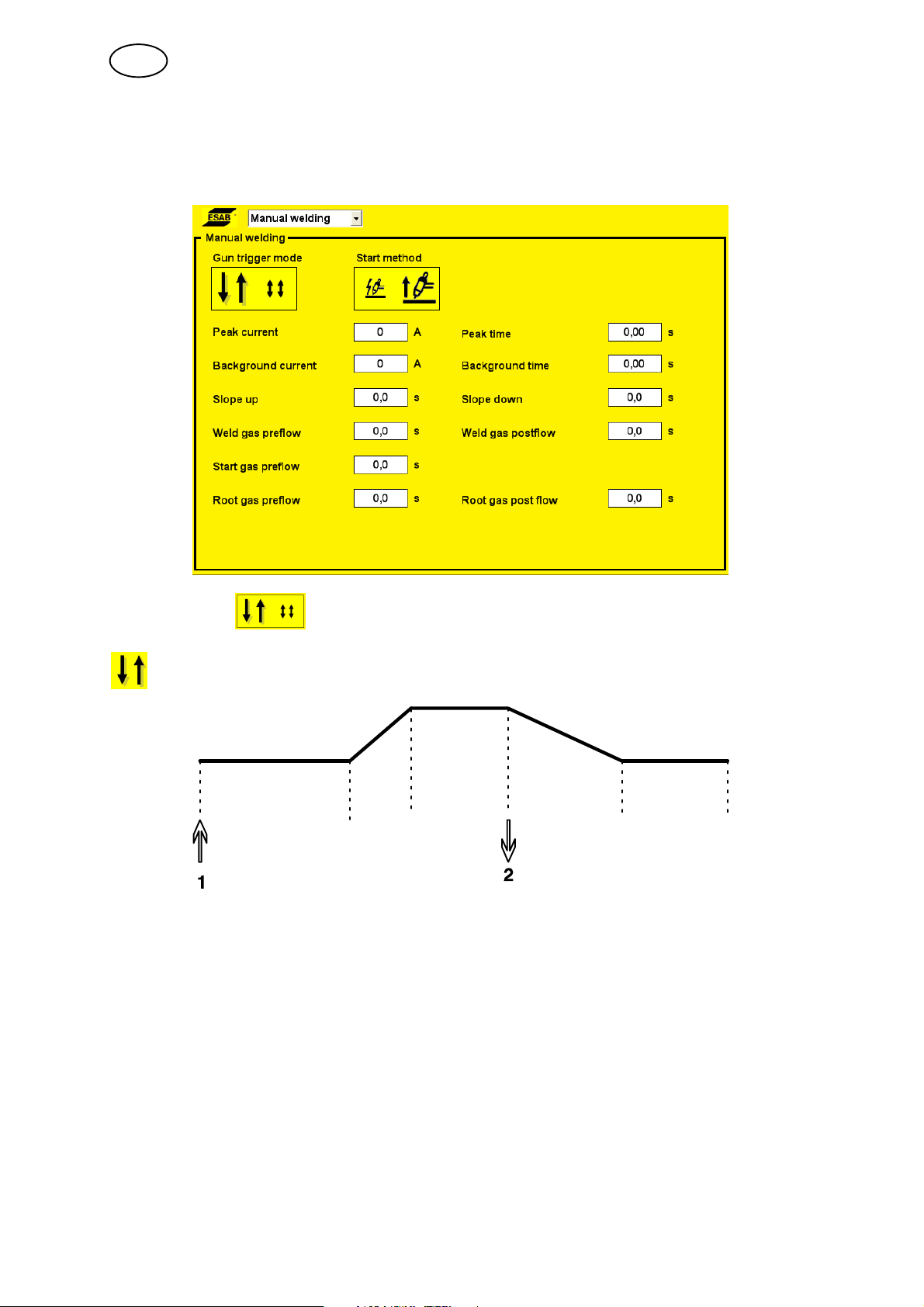

5.9 Manual welding

This menu is used for welding performed with a manual TIG torch.

Trigger mode

2 stroke

Gas preflow Slope

up

Functions when using 2-stroke control of the welding torch.

Slope down Gas postflow

In 2-stroke control mode, pressing the TIG torch trigger switch (1) starts gas preflow

(if used) and ignites the arc. The current rises to the set value (as controlled by the

slope up function, if in operation). Releasing the trigger switch (2) reduces the

current (as controlled by the slope down function, if in operation) and extinguishes

the arc. Gas postflow follows, if in operation.

bi16d1ea

- 38 -

© ESAB AB 2007

GB

4 stroke

Gas preflow Slope

up

Functions when using 4-stroke control of the welding torch.

Slope down Gas postflow

In 4-stroke control mode, pressing the trigger switch (1) starts gas preflow (if used).

At the end of the gas preflow time, the current rises to the pilot level (a few

amperes), and the arc is ignited. Releasing the trigger switch (2) increases the

current to the set value (as controlled by the slope up function, if in operation). When

the trigger switch is next pressed (3), the current is reduced to pilot level again (as

controlled by the slope down function, if in operation). Releasing the switch again (4)

extinguishes the arc and starts gas postflow.

Start method

HF

The HF function ignites the arc by means of a spark produced when the electrode is

brought closer to the workpiece.

LiftArct

The LiftArct function ignites the arc when the electrode is brought into contact with

the workpiece and then lifted away from it.

Igniting the arc using the LiftArc functiont. Step 1: the electrode is held against the workpiece. Step

2: the trigger switch is pressed, and a low current starts to flow. Step 3: the welder lifts the electrode

from the workpiece; the arc ignites, and the current rises automatically to the set value.

bi16d1ea

- 39 -

© ESAB AB 2007

GB

Peak current

The higher of two current values in the event of pulsed current.

Background current

The lower of two current values in the event of pulsed current.

Peak time

The time the pulse current is on during a pulse period.

Background time

Background current time that together with the pulse current time produces the pulse

period.

Pulse time

Background time

Peak current

Background current

TIG welding with pulsed current

Slope up

The slope up function means that when the TIG arc ignites the current rises slowly to

the set value. This provides `gentler' heating of the electrode, and gives the welder a

chance to position the electrode properly before the full current value is reached.

Slope down

TIG welding uses ”slope down”, where the current falls slowly over a controlled time,

to avoid craters and/or cracks in a completed weld.

Gas preflow

This controls the time during which shielding gas flows before the arc is ignited. Also

see information under chapter 3.7.

Gas postflow

This controls the time during which shielding gas flows after the arc is extinguished.

Also see information under chapter 3.7.

bi16d1ea

- 40 -

© ESAB AB 2007

GB

5.10 Generate

A complete basic weld program can be generated here that can be added to the

design area or directly to the weld area. The program can be used as the basis for

creating your own program.

Specify:

S Tube material

S Tube wall thickness

Max. 3 mm for stainless steel and max. 2.7 mm for carbon steel.

S External tube diameter

S Tool and tool type

Activate by pressing ”Generate in weld area” or ”Generate in design area”.

Automatically opens the weld area or design area menu.

It is now possible to continue working on the program in the weld area or design

area. See chapter ”Weld Area” 5.1 or ”Design Area” 5.2.

bi16d1ea

- 41 -

© ESAB AB 2007

6 TECHNICAL TERMS

2 stroke 2-stroke control of the welding torch.

4 stroke 4-stroke control of the welding torch.

Amplitude Weave.

Arc voltage

control, AVC

Background current The lower of two current values when using pulsed current.

Background time Background current time that together with the peak current time produces

Background voltage Arc voltage control when using background current.

Background wire feed

speed

Breakpoint Starting point for a new sector.

Delay time The time it takes for the arc voltage to stabilize before arc voltage control

Design area Weld programs are created in this menu.

End sector Last welding sector in a welding sequence.

Generate Search for a complete basic weld program.

Library Memory for storing weld programs.

Peak current The higher of two current values when using pulsed current, or the current

Peak voltage Arc voltage control at peak current.

Peak wire feed speed Wire feed speed at peak current.

Preheating time Delay time for welding movement when preheating the workpiece.

Pulse time The time the current is ”on” during a pulse period.

Root gas Shielding gas for the underside of the weld joint (root side).

Rotation speed The rotation speed of the electrode around the workpiece.

Sector A specific section of tube.

Sector system How the division into sectors is displayed, by degrees or breakpoints.

Slope down Gradual reduction of a value.

Slope up Gradual increase in a value.

Special pulsing Welding current synchronizes with the weaving motion.

Square-wave pulsing Special pulsing with pulsed rotation.

Start gas Special shielding gas with high ionizing qualities, which facilitates arc

Start sector First welding sector in a welding sequence.

Verify Check whether the program stays within the limit values.

Weaving Weave tungsten electrode sideways.

Weld area Programs in the weld area control the welding process.

Weld gas Shielding gas for the upper side of the weld joint.

Automatic regulation of the electrode distance.

the pulse period.

Wire feed speed during specified background time.

begins.

value when using continuous current.

ignition.

bi16d1eb

- 42 -

© ESAB AB 2007

WO100

4

Ordering number

Ordering no. Denomination

0444 405 070 Instruction manual SE

0444 405 071 Instruction manual DK

0444 405 072 Instruction manual NO

0444 405 073 Instruction manual FI

0444 405 074 Instruction manual GB

0444 405 075 Instruction manual DE

0444 405 076 Instruction manual FR

0444 405 077 Instruction manual NL

0444 405 078 Instruction manual ES

0444 405 079 Instruction manual IT

0444 405 080 Instruction manual PT

0444 405 081 Instruction manual GR

0444 405 082 Instruction manual PL

0444 405 083 Instruction manual HU

0444 405 084 Instruction manual CZ

0444 405 086 Instruction manual RU

Instruction manuals and the spare parts list are available on the Internet at www.esab.com

- 43 -

bi16o4

© ESAB AB 2007

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

- 44 -

notes

© ESAB AB 2007

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

- 45 -

notes

© ESAB AB 2007

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna-Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 745 11 28

BULGARIA

ESAB Kft Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Vamberk

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Herlev

Tel: +45 36 30 01 11

Fax: +45 36 30 40 03

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel: +33 1 30 75 55 00

Fax: +33 1 30 75 55 24

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 218

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel: +36 1 20 44 182

Fax: +36 1 20 44 186

ITALY

ESAB Saldatura S.p.A.

Bareggio (Mi)

Tel: +39 02 97 96 8.1

Fax: +39 02 97 96 87 01

NORWAY

AS ESAB

Larvik

Tel: +47 33 12 10 00

Fax: +47 33 11 52 03

POLAND

ESAB Sp.zo.o.

Katowice

Tel: +48 32 351 11 00

Fax: +48 32 351 11 20

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 8 310 960

Fax: +351 1 859 1277

ROMANIA

ESAB Romania Trading SRL

Bucharest

Tel: +40 316 900 600

Fax: +40 316 900 601

RUSSIA

LLC ESAB

Moscow

Tel: +7 (495) 663 20 08

Fax: +7 (495) 663 20 09

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel: +421 7 44 88 24 26

Fax: +421 7 44 88 87 41

SPAIN

ESAB Ibérica S.A.

Alcalá de Henares (MADRID)

Tel: +34 91 878 3600

Fax: +34 91 802 3461

SWEDEN

ESAB Sverige AB

Gothenburg

Tel: +46 31 50 95 00

Fax: +46 31 50 92 22

ESAB international AB

Gothenburg

Tel: +46 31 50 90 00

Fax: +46 31 50 93 60

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

UKRAINE

ESAB Ukraine LLC

Kiev

Tel: +38 (044) 501 23 24

Fax: +38 (044) 575 21 88

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem-MG

Tel: +55 31 2191 4333

Fax: +55 31 2191 4440

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 57 48

Asia/Pacific

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 2326 3000

Fax: +86 21 6566 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. ESABindo Pratama

Jakarta

Tel: +62 21 460 0188

Fax: +62 21 461 2929

JAPAN

ESAB Japan

Tokyo

Tel: +81 45 670 7073

Fax: +81 45 670 7001

MALAYSIA

ESAB (Malaysia) Snd Bhd

USJ

Tel: +603 8023 7835

Fax: +603 8023 0225

SINGAPORE

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 6861 43 22

Fax: +65 6861 31 95

SOUTH KOREA

ESAB SeAH Corporation

Kyungnam

Tel: +82 55 269 8170

Fax: +82 55 289 8864

UNITED ARAB EMIRATES

ESAB Middle East FZE

Dubai

Tel: +971 4 887 21 11

Fax: +971 4 887 22 63

Africa

EGYPT

ESAB Egypt

Dokki-Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

SOUTH AFRICA

ESAB Africa Welding & Cutting Ltd

Durbanvill 7570 - Cape Town

Tel: +27 (0)21 975 8924

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

THE NETHERLANDS

ESAB Nederland B.V.

Amersfoort

Tel: +31 33 422 35 55

Fax: +31 33 422 35 44

www.esab.com

110426© ESAB AB

Loading...

Loading...