April 2007

Installation, Operation, and Maintenance for the

SmartFlow 2.5

Plasma System Plumbing Box

F-15-732

The equipment described in this manual is

potentially hazardous. Use caution when

installing, operating and maintaining this

equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold be ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liability.

ESAB Cutting Systems first priority is total

customer satisfaction. We constantly look for

ways to improve our products, service and

documentation. As a result, we make

enhancements and/or design changes as

required. ESAB makes every possible effort to

ensure our documentation is current. We

cannot guarantee that each piece of

documentation received by our customers

reflects the latest design enhancements.

Therefore, the information contained in this

document is subject to change without notice.

This manual is ESAB Part Number F15732

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

© ESAB Cutting Systems, 2003 ,2004

All rights reserved

Printed in U.S.A.

Table Of Contents

Safety (Section 1)

1.1 Introduction.........................................................................................................1-1

1.2 Safety Notations And Symbols...........................................................................1-2

1.3 General Safety Information.................................................................................1-3

1.4 Installation Precautions ......................................................................................1-4

1.5 Electrical Grounding...........................................................................................1-5

1.6 Operating A Plasma Cutting Machine ................................................................1-6

1.8 Safety References............................................................................................1-13

1.8.1 USA Domestic............................................................................................1-14

1.8.2 International ...............................................................................................1-15

Description (Section 2)

2.1 Introduction.........................................................................................................2-1

2.2 SmartFlow II

2.3 SmartFlow II

2.4 SmartFlow II

2.5 Gas Requirements..............................................................................................2-2

2.6 Water Supply Requirements...............................................................................2-3

2.7 Electrical Input Requirements.............................................................................2-3

2.8 Dimensions.........................................................................................................2-4

V

and PT-15XL................................................................................2-1

V

and PT-19XLS/PT-600.................................................................2-2

V

Options ........................................................................................2-2

Installation (Section 3)

3.1 Introduction.........................................................................................................3-1

3.2 Box Mounting (Bottom View)..............................................................................3-1

3.3 Hose and Cable Connections.............................................................................3-2

3.3.1 Starter Box Connections..............................................................................3-4

3.3.2 PC Board Connections.................................................................................3-5

3.3.3 Torch Cooling Water Connections...............................................................3-6

3.3.4 Power Source To SMF II

3.4 Nomex Insulation................................................................................................3-8

3.5 Gas Connections................................................................................................3-8

3.5.1 Gas Lines From Supply................................................................................3-8

3.5.2 Gas Pressure Setup...................................................................................3-10

3.6 Cut Water Setup (PT-15XL) .............................................................................3-10

3.7 Secondary Shield Gas Setup (PT-19XLS/PT-600)...........................................3-11

3.8 A Component Relationship Block Diagram ......................................................3-12

3.9 Fluid Schematic – SmartFlow II

V

Buss Connection................................................3-7

V

Standard and H-35 Versions........................3-14

SmartFlow 2.5

Table Of Contents

Operation (Section 4)

4.1 Operation Introduction........................................................................................4-1

Maintenance (Section 5)

5.1 SmartFlow II

5.2 Pressure Switches...............................................................................................5-2

5.3 Spark Gap Of the Arc Starter..............................................................................5-3

5.4 Spark Adjustment Procedure ..............................................................................5-4

5.5 Gas Proportional Valves......................................................................................5-5

5.6 Cutwater/Secondary Shield Proportional Valve ..................................................5-5

5.7 Cooling Water Flow Switch .................................................................................5-6

5.8 Gas Filters...........................................................................................................5-7

Troubleshooting (Section 6)

6.1 Troubleshooting Introduction...............................................................................6-1

6.2 Cooling Water Circuit .........................................................................................6-2

6.3 Cut Water and Auxiliary Cut Water ....................................................................6-3

6.4 Plasma Gas........................................................................................................6-4

6.5 Secondary Shield...............................................................................................6-5

6.6 Arc Start .............................................................................................................6-6

6.6.1 Setting the Spark Gap..................................................................................6-6

6.6.2 Spark Gap Size Attributes............................................................................6-7

6.6.3 Spark Viewing..............................................................................................6-8

6.7 Fluid Schematic..................................................................................................6-9

6.8 SmartFlow II

6.9 SmartFlow II Secondary Shield Gas Proportional Valve Calibration................6-13

Replacement Parts (Section 7)

7.1 General...............................................................................................................7-1

7.2 Ordering .............................................................................................................7-1

7.3 Inside Right View – SF 2.5 (without H-35 capability) DISCONTINUED.............7-2

7.4 Inside Right View – SF 2.5 (with H-35 capability) ..............................................7-4

7.5 Outside Front View.............................................................................................7-6

7.6 Inside Left View..................................................................................................7-8

7.7 Outside Back View...........................................................................................7-10

V

Maintenance Introduction.............................................................5-1

V

Interface PCB Schematic (3 pages) ..........................................6-10

SmartFlow 2.5

SECTION 1 SAFETY

1.1 Introduction

ESAB cutting machines are designed to provide

both operational safety and efficiency. However,

as with any machine tool, sensible attention to

operating procedures, precautions, and safe

practices is necessary. Whether an individual is

involved with operation, servicing, or as an

observer, compliance with established

precautions and safe practices must be carried

out. Failure to observe warnings/ precautions

could result in death/serious personal injury or

severe equipment damage. The following are

general guidelines applicable when working with

cutting machines. Additional precautions

pertaining to this equipment are found throughout

this literature. For a wide scope of safety

information on the field of cutting and welding,

obtain and read the publications listed in the

Recommended References at the end of this

section.

SmartFlow 2.5

1-1

SECTION 1 SAFETY

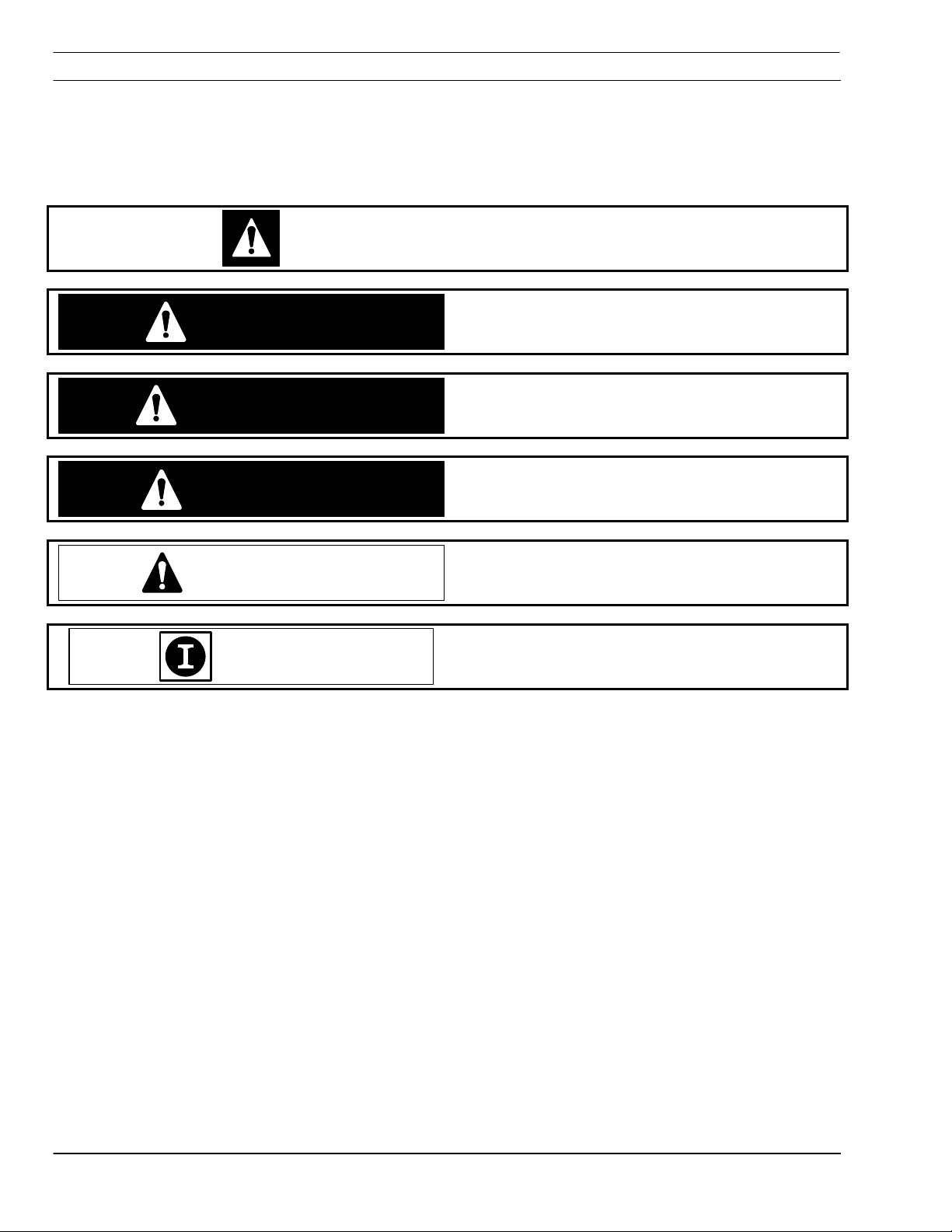

1.2 Safety Notations and Symbols

DANGER

WARNING

The following words and symbols are used

throughout this manual. They indicate different

levels of required safety involvement.

ALERT or ATTENTION. Your safety is involved or

potential equipment failure exists. Used with

other symbols and information.

Used to call attention to immediate hazards which,

if not avoided, will result in serious personal injury

or loss of life.

Used to call attention to potential hazards that

could result in personal injury or loss of life.

CAUTION

CAUTION

NOTICE

Used to call attention to hazards that could result

in minor personal injury or equipment damage.

Used to call attention to minor hazards to

equipment.

Used to call attention to important installation,

operation or maintenance information not directly

related to safety hazards.

1-2

SmartFlow 2.5

SECTION 1 SAFETY

1.3 General Safety Information

Failure to follow operating instructions

WARNING

could result in death or serious injury.

Read and understand this operator’s manual

before using machine.

• Read entire procedure before operating or

performing any system maintenance.

• Special attention must be given to all

hazard warnings that provide essential

information regarding personnel safety

and/or possible equipment damage.

• All safety precautions relevant to electrical

equipment and process operations must

be strictly observed by all having system

responsibility or access.

• Read all safety publications made

available by your company.

Failure to follow safety warning label

WARNING

instructions could result in death or

serious injury.

Read and understand all safety warning labels

on machine.

Refer to operator’s manual for additional

safety information.

SmartFlow 2.5

1-3

SECTION 1 SAFETY

1.4 Installation Precautions

Improperly Installed Equipment Can

WARNING

Cause Injury Or Death.

Follow these guidelines while installing

machine:

• Do not connect a cylinder directly to

machine inlet. An appropriate cylinder

regulator must be installed on a fuel gas

cylinder to reduce pressure to a

reasonable inlet supply pressure.

Machine regulator is then used to obtain

pressure required by torches.

• Contact your ESAB representative before

installation. He can suggest certain

precautions regarding piping installation

and machine lifting, etc. to ensure

maximum security.

• Never attempt any machine modifications

or apparatus additions without first

consulting a qualified ESAB

representative.

• Observe machine clearance requirements

for proper operation and personnel safety.

• Always have qualified personnel perform

installation, troubleshooting and

maintenance of this equipment.

• Provide a wall mounted disconnect switch

with proper fuse sizes close to the power

supply.

1-4

SmartFlow 2.5

SECTION 1 SAFETY

1.5 Electrical Grounding

Electrical grounding is imperative for proper

machine operation and SAFETY. Refer to this

manual’s Installation section for detailed

grounding instructions.

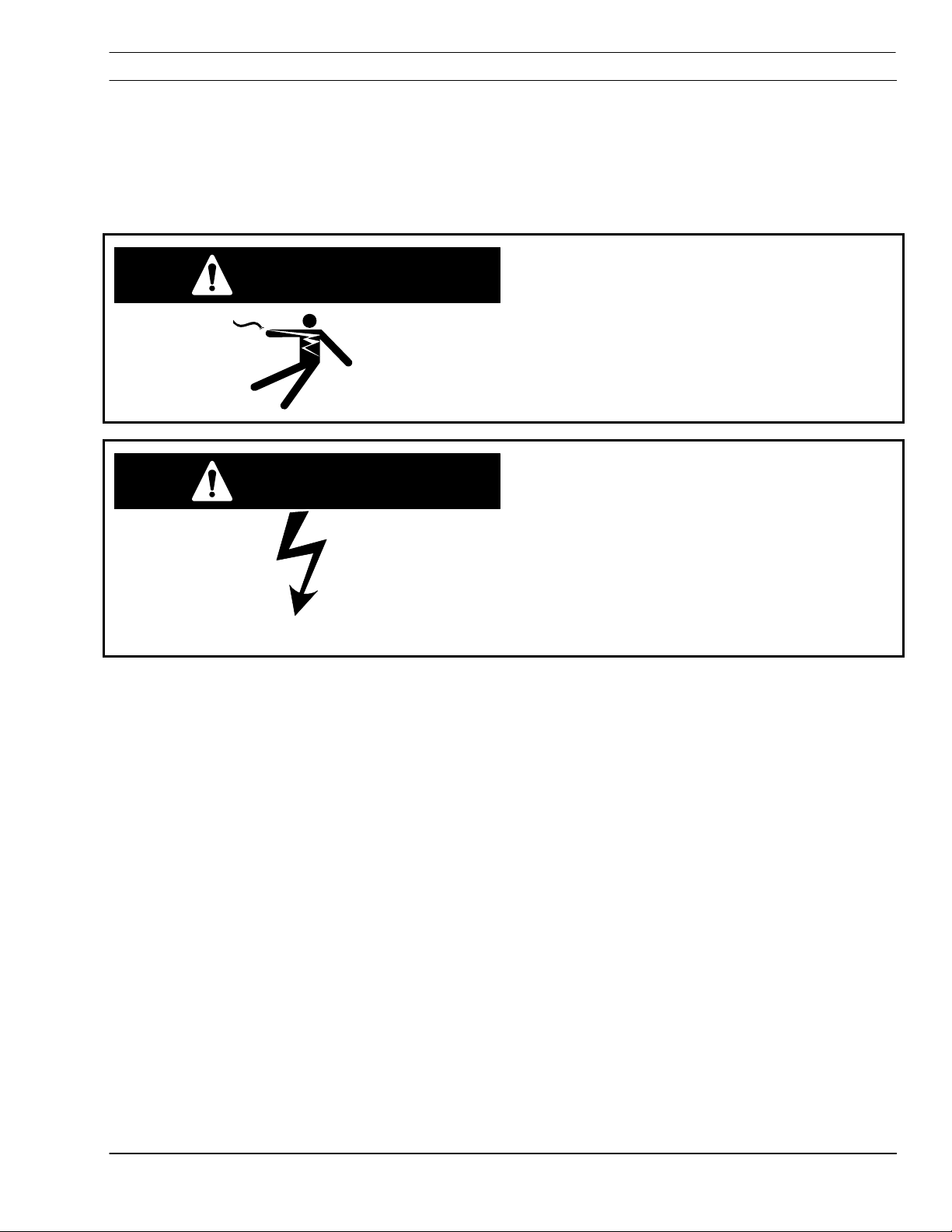

Electric shock hazard.

WARNING

Improper grounding can cause severe injury

or death.

Machine must be properly grounded before

put into service.

Improper Grounding Can Damage

WARNING

Machine And Electrical

Components.

• Machine must be properly grounded

before put into service.

• Cutting table must be properly grounded

to

a good Earth ground rod.

SmartFlow 2.5

1-5

SECTION 1 SAFETY

1.6 Operating a Plasma Cutting Machine

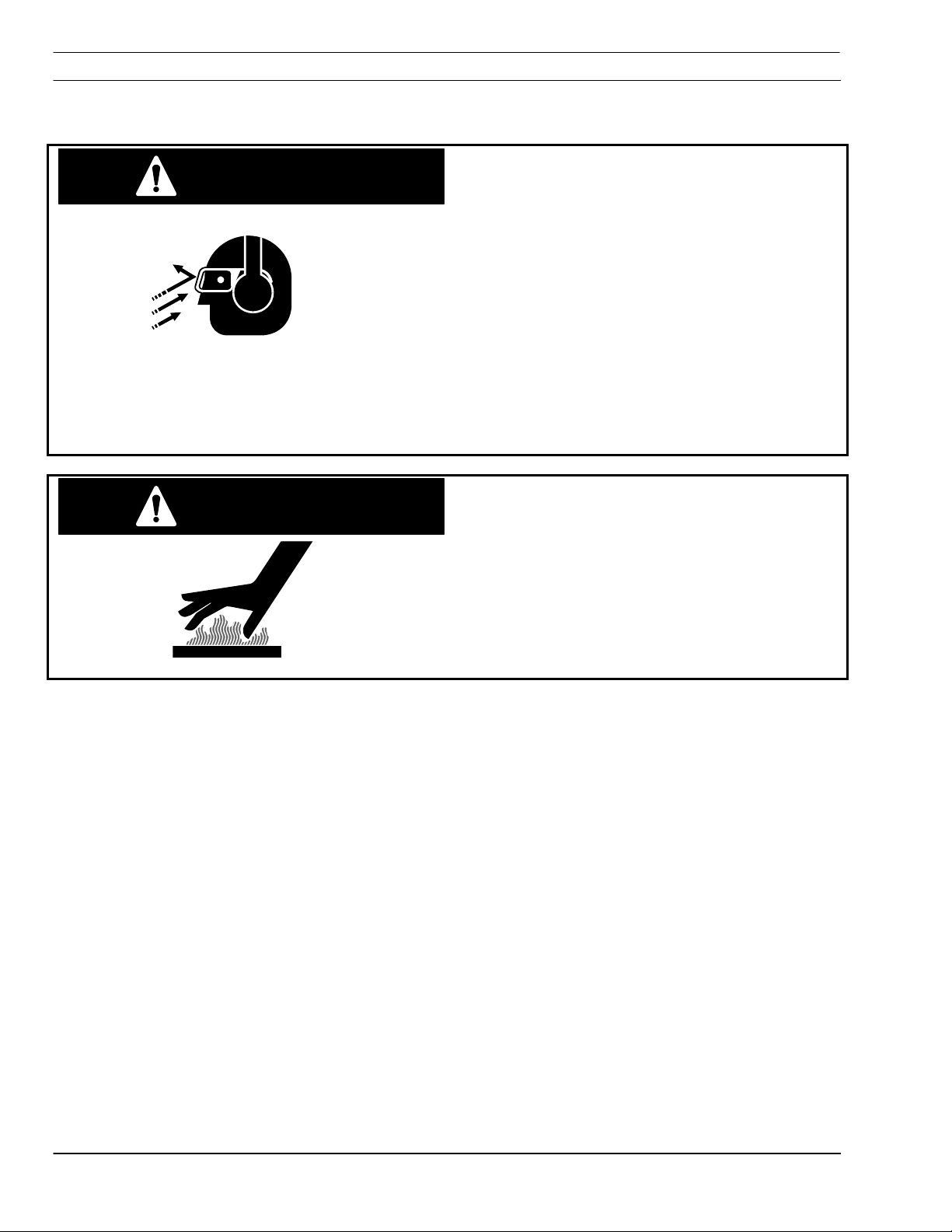

WARNING

hazards.

• Hot spatter can burn and injure eyes.

Wear goggles to protect eyes from burns

and flying debris generated during

operation.

• Chipped slag may be hot and fly far.

Bystanders should also wear goggles and

safety glasses.

• Noise from plasma arc can damage

hearing. Wear correct ear protection when

cutting above water.

Burn hazard.

WARNING

Hot metal can burn.

• Do not touch metal plate or parts

immediately after cutting. Allow metal time

to cool, or douse with water.

Flying debris and loud noise

• Do not touch plasma torch immediately

after cutting. Allow torch time to cool.

1-6

SmartFlow 2.5

SECTION 1 SAFETY

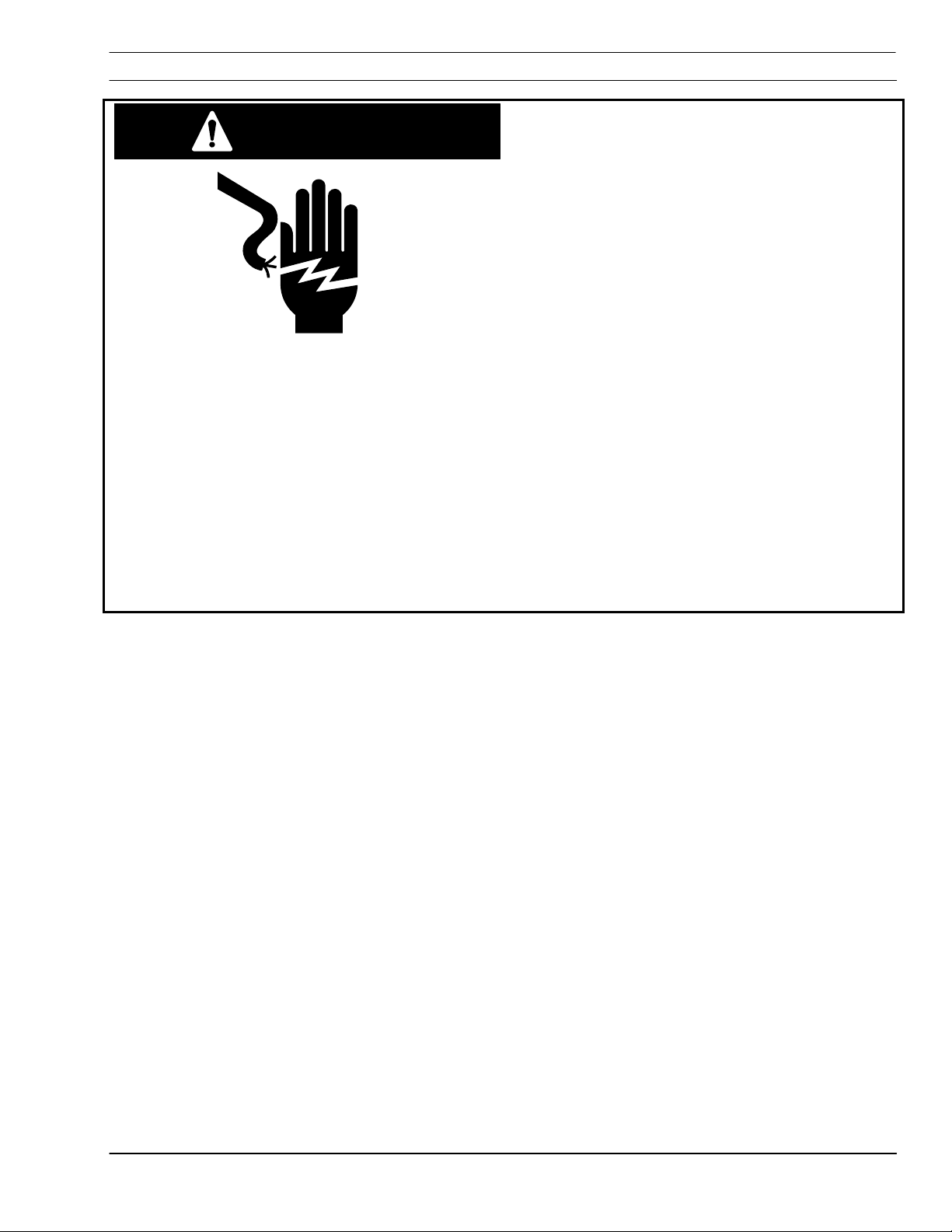

WARNING

Hazardous voltages. Electric shock

can kill.

• Do NOT touch plasma torch, cutting table

or cable connections during plasma

cutting process.

• Always turn power off to plasma power

supplies before touching or servicing

plasma torch.

• Always turn power off to plasma power

supplies before servicing any system

component.

• Do not touch live electrical parts.

• Keep all panels and covers in place when

machine is connected to power source.

• Wear insulating gloves, shoes, and

clothing to insulate yourself from the

workpiece and electrical ground.

• Keep gloves, shoes, clothing, work area,

and equipment dry.

• Replace worn or damaged cables.

SmartFlow 2.5

1-7

SECTION 1 SAFETY

Fume hazard.

WARNING

Fumes and gases generated by the plasma

cutting process can be hazardous to your

health.

• Do NOT breathe fumes.

• Do not operate plasma torch without fume

removal system operating properly.

• Use additional ventilation to remove

fumes if necessary.

• Use approved respirator if ventilation is

not adequate.

• Provide positive mechanical ventilation

when cutting galvanized steel, stainless

steel, copper, zinc, beryllium, or cadmium.

Do not breathe these fumes.

• Do not operate near degreasing and

spraying operations. Heat or arc rays can

react with chlorinated hydrocarbon vapors

to form phosgene, a highly toxic gas and

other irritant gases.

1-8

SmartFlow 2.5

SECTION 1 SAFETY

Radiation hazard.

WARNING

Arc rays can injure eyes and burn skin.

• Wear correct eye and body protection.

• Wear dark safety glasses or goggles with

side shields. Refer to following chart for

recommended lens shades for plasma

cutting:

Arc Current Lens Shade

Up to 100 Amps Shade No. 8

100-200 Amps Shade No. 10

200-400 Amps Shade No. 12

Over 400 Amps Shade No. 14

• Replace glasses/goggles when lenses are

pitted or broken

• Warn others in area not to look directly at

the arc unless wearing appropriate safety

glasses.

• Prepare cutting area to reduce reflection

and transmission of ultraviolet light.

Paint walls and other surfaces with

dark colors to reduce reflections.

Install protective screens or curtains

to reduce ultraviolet transmission.

SmartFlow 2.5

1-9

SECTION 1 SAFETY

Ruptured Gas Cylinders Can Kill

WARNING

Mishandling gas cylinders can rupture and

violently release gas.

• Avoid rough handling of cylinders.

• Keep cylinder valves closed when not in

use.

• Maintain hoses and fittings in good

condition.

• Always secure cylinders in an upright

position by chain or strap to a suitable

stable object not part of an electrical

circuit.

• Locate cylinders away from heat, sparks

and flames. Never strike an arc on a

cylinder.

• Use approved pressure reducing regulator

for the specific gas.

• Refer to CGA Standard P-1, “Precautions

for Safe Handling of Compressed Gases in

Cylinders”, available from Compressed

Gas Association.

Explosion hazard.

WARNING

• Certain molten aluminum-lithium (Al-Li)

alloys can cause explosions when plasma

cut OVER water.

These alloys should only be dry cut

on a dry table.

DO NOT dry cut over water.

Contact your aluminum supplier for

additional safety information

regarding hazards associated with

these alloys

• Do not cut in atmospheres containing

explosive dust or vapors.

• Do not carry any combustibles on your

person (e.g. butane lighter)

.

1-10

• Do not cut containers that have held

combustibles.

SmartFlow 2.5

SECTION 1 SAFETY

WARNING

Burn Hazard.

Heat, spatter, and sparks cause fire and

burns.

• Do not cut near combustible material.

• Do not have on your person any

combustibles (e.g. butane lighter).

• Pilot arc can cause burns. Keep torch

nozzle away from yourself and others

when activating plasma process.

• Wear correct eye and body protection.

• Wear gauntlet gloves, safety shoes and

hat.

• Wear flame-retardant clothing covering all

exposed areas.

• Wear cuff-less trousers to prevent entry of

sparks and slag.

• Have fire extinguishing equipment

available for use.

SmartFlow 2.5

1-11

SECTION 1 SAFETY

1.7 Service Precautions

WARNING

Hazardous voltages. Electric shock

can kill.

• Do NOT touch plasma torch, cutting table

or cable connections during plasma

cutting process.

• Always turn power off to plasma power

supplies before touching or servicing

plasma torch.

• Always turn power off to plasma power

supplies before removing covers or

panels to service any system component.

• Do not touch live electrical parts.

• Keep all panels and covers in place when

machine is connected to power source.

• Keep gloves, shoes, clothing, work area,

and equipment dry.

• Inspect power and ground leads cables for

wear or cracking. Replace worn or

damaged cables. Do not use if damaged.

• Never bypass safety interlocks.

• Follow lock-out procedures.

Establish and adhere to preventive

CAUTION

maintenance. A composite program can be

established from recommended schedules.

Avoid leaving test equipment or hand tools on

machine. Severe electrical or mechanical

damage could occur to equipment or

machine.

1-12

SmartFlow 2.5

SECTION 1 SAFETY

Extreme caution should be used when

CAUTION

probing circuitry with an oscilloscope or

voltmeter. Integrated circuits are susceptible

to over voltage damage. Power off before

using test probes to prevent accidental

shorting of components.

All circuit boards securely seated in sockets,

all cables properly connected, all cabinets

closed and locked, all guards and covers

replaced before power is turned on.

1.8 Safety References

The following nationally recognized publications on

safety in welding and cutting operations are

recommended. These publications have been

prepared to protect persons from injury or illness and

to protect property from damage, which could result

from unsafe practices. Although some of these

publications are not related specifically to this type of

industrial cutting apparatus, the principles of safety

apply equally.

SmartFlow 2.5

1-13

SECTION 1 SAFETY

1.8.1 USA Domestic

• “Precautions and Safe Practices in Welding and

Cutting with Oxygen-Fuel Gas Equipment,” Form

2035. ESAB Cutting Systems.

• “Precautions and Safe Practices for Electric

Welding and Cutting,” Form 52-529. ESAB Cutting

Systems.

• “Safety in Welding and Cutting” - ANSI Z 49.1,

American Welding Society, 2501 NW 7th Street,

Miami, Florida, 33125.

• “Recommended Safe Practices for Shielded

Gases for Welding and Plasma Arc Cutting” - AWS

C5.10-94, American Welding Society.

• “Recommended Practices for Plasma Arc

Welding” - AWS C5.1, American Welding Society.

• “Recommended Practices for Arc Cutting” -

AWS C5.2, American Welding Society.

• “Safe Practices” - AWS SP, American Welding

Society.

• “Standard for Fire Protection in Use of Cutting

and Welding Procedures” - NFPA 51B, National

Fire Protection Association, 60 Batterymarch

Street, Boston, Massachusetts, 02110.

• “Standard for Installation and Operation of

Oxygen - Fuel Gas Systems for Welding and

Cutting” - NFPA 51, National Fire Protection

Association.

• “Safety Precautions for Oxygen, Nitrogen,

Argon, Helium, Carbon Dioxide, Hydrogen, and

Acetylene,” Form 3499. ESAB Cutting Systems.

Obtainable through your ESAB representative or

local distributor.

• "Design and Installation of Oxygen Piping

Systems," Form 5110. ESAB Cutting Systems.

• “Precautions for Safe Handling of Compressed

Gases in Cylinders”, CGA Standard P-1,

Compressed Gas Association.

• Literature applicable to safe practices in welding

and cutting with gaseous materials is also available

from the Compressed Gas Association, Inc., 500

Fifth Ave., New York, NY 10036.

1-14

SmartFlow 2.5

SECTION 1 SAFETY

1.8.2 International

Accident Prevention

VBG 1 General Provisions

VDE Regulations

TRAC Technical Rules for Acetylene and Carbide Stores

VBG 4 Electrical Equipment and operating

Equipment

VBG 15 Welding, Cutting and related working

methods

VBG 48 Shot Blasting Works

VBG 61 Gases

VBG 62 Oxygen

VBG 87 Operating liquid jet cutting machines

VBG 93 Laser beams, accident prevention and

Electro-technology

VBG 121 Noise

VDE 0100 Erection of power installations with normal

voltages up to 1000 volts

VDE0113 Electrical equipment of industrial machines

VDE 0837 Radiation safety of laser products; users

guide (DIN EN 60825)

VDE 0837-

50

TRAC-204 Acetylene lines

Specification for laser guards

TRAC-206 Acetylene cylinder battery systems

TRAC-207 Safety devices

TRG Technical Rules for Pressure gases

TRG 100 General regulations for pressure gases

TRG 101 Pressure gases

TRG 102 Technical gas mixtures

TRG 104 Pressure gases; alterative use of

compressed gas tanks

SmartFlow 2.5

1-15

SECTION 1 SAFETY

DIN Standards

DIN EN ISO Harmonized Standards

DIN 2310

Part 1

DIN 2310

Part 2

DIN 2310

Part 4

DIN 2310

Part 5

DIN 4844

Part 1

DIN EN

292/1 and 2

DIN EN 559 Hoses for welding, cutting and allied

DIN EN 560 Hose connections and hose couplings for

DIN EN 561 Gas welding equipment hose couplings

Thermal cutting; terminology and

nomenclature

Thermal cutting; determination of quality of cut

faces

Thermal cutting; arc plasma cutting; process

principles, quality, dimensional tolerances

Thermal cutting; laser beam cutting of metallic

materials; process principles

Safety markings (DIN EN 7287)

Safety of machinery

processes

equipment for welding, cutting and allied

processes

DIN EN

626-1

DIN EN

848-1

DIN EN

1829

DIN EN

9013

DIN EN

12584

DIN EN

12626

DIN EN

28206

DIN EN

31252

DIN EN

31553

DIN EN

60204-1

DIN EN

60825

DIN EN 999 Arrangement of protection devices

Safety of machines, reduction of risks to

health

Single spindle vertical milling machines

High pressure water jet machines

Thermal cutting, oxygen cutting, process

principles, dimensional tolerances

Imperfections in oxy/fuel flame cuts, laser

beam cuts and plasma

Laser processing machines

Acceptance testing for oxygen cutting

machines

Laser Equipment

Laser and laser related equipment

Electrical equipment of machines

Radiation safety of laser products

VDI Guidelines

1-16

VDI 2906 Quality of cut faces on metallic workpieces;

VDI 2084 Room air; Technical systems for welding

SmartFlow 2.5

abrasive water jet cutting and arc plasma

cutting

workshops

SECTION 2 DESCRIPTION

2.1 Introduction

The SmartFlow 2.5 Cutting System is a

streamlined, high performance-cutting package

designed for use exclusively with the ESAB Vision

CNC. This advanced technology integrates gas

and water control into the machine CNC.

Using a system of proportional valves driven by

CNC outputs, this system:

• dramatically reduces the amount of plumbing

hardware necessary to control the plasma

torch

• reduced purge time/increased part throughput

• simplified operation with gas and water flow

rates manually controlled at the Vision CNC

process parameter screen

• allows for programmed/automated control of

gas and water flow rates using SDP Files

(SchneidDatenPaket = Cutting Data Package,

see Vision control and programming manuals

for details on SDP Files. Data used to

generate SDP files can be found in your model

specific torch manual.)

• can be used with either a PT-15XL water

injection torch or a PT-600/PT-19XLS dry

cutting torch with secondary shield gas. (The

PT-600 and the PT-19XLS are both dry cutting

torches of similar design.)

2.2 SmartFlow 2.5 and PT-15XL

When the PT-15XL water injection torch is used,

the complete cutting system also requires the

following components:

• PT-15XL plasma torch

• a plasma power supply

• a recirculating water cooler

• coolant pump

• cut water pump

• air curtain regulator

• Vision CNC.

SmartFlow 2.5

2-1

SECTION 2 DESCRIPTION

2.3 SmartFlow

2.5

and PT-19XLS/PT-600

When a dry torch (no water injection) is used, the

SmartFlow 2.5 water injection components are

used to control the secondary shield pressure.

The components of The SmartFlow II Cutting

System with dry torch requires the following

components:

• Vision CNC,

• PT-19XLS or PT-600 plasma torch,

• power supply,

• a recirculating water cooler,

• and coolant pump.

2.4 SmartFlow

2.5

Options

SmartFlow 2.5 with H-35 capability

(H-35 is industry accepted nomenclature

for a gas mixture of 65% argon and 35%

2.5 Gas Requirements

Nitrogen

Oxygen

Compressed Air

SmartFlow 2.5 without H-35 capability

(DISCONTINUED)

hydrogen)

P/N 0560935258 P/N 0560935257

• 125 PSI (8,63 bar) with 0.5”

NPT

• 99.999% purity

• Filtered to 25 microns

• 125 PSI (8,63 bar) with 0.5”

NPT

• 99.999% purity

• Filtered to 25 microns

• 100 PSI (6,9 bar) with 0.5” NPT

• Clean, dry and filtered to 25

microns

2-2

• 150 PSI (10,4 bar)

H-35 (argon/hydrogen)

• Filtered to 25 microns

SmartFlow 2.5

SECTION 2 DESCRIPTION

2.6 Water Supply Requirements

Cooling Water

Deionized Water

(PT-15XL only)

2.7 Electrical Input Requirements

Voltage Supply

Voltage Signals

• 120 PSI (8,28 bar)

• 1.5 gallons per minute (5.68 liters/minute)

• 35 PSI (2,42 bar)

• >200,000 ohms (resistance)

• .5 gallons/minute (1,89 liters/minute) for up to

600A cutting

• 1.5 gallons/minute (5,68 liters/minute) for

600A to 1000A cutting

• +24 VDC for proportional valves, flow and

pressure switches

• +15 VDC for pressure switch

• 120 VAC input to start gas solenoid valve

• 120 VAC input to cut gas solenoid valve

• 120 VAC input to arc starter

• 0-10 VDC input to proportional valves

SmartFlow 2.5

2-3

SECTION 2 DESCRIPTION

2.8 Dimensions

12.12"

(308mm)

15.62" (396.8mm)

7.5 " (190,5mm)

2-4

SmartFlow 2.5

SECTION 3 INSTALLATION

Electricity Can Kill!

WARNING

Before performing any maintenance or

assembly of this equipment, ensure the

power source (ESP) is turned off and

disconnected.

3.1 Introduction

The SmartFlow 2.5 is a plumbing box that

interfaces with the ESAB Vision machine controls

and the ESP product line of plasma power

sources. An interface pc board receives voltage

signals from the machine CNC that control

proportional and solenoid valves. The result is

CNC management of gas and cutwater or shield

gas delivery to the plasma torch. Analog signal

feedback is sent back to the CNC, creating a

control loop.

The SmartFlow 2.5 can be used with the PT-15

water injection plasma torch or both the dry cutting

PT-19XLS and PT-600 plasma torches with

secondary shield gas.

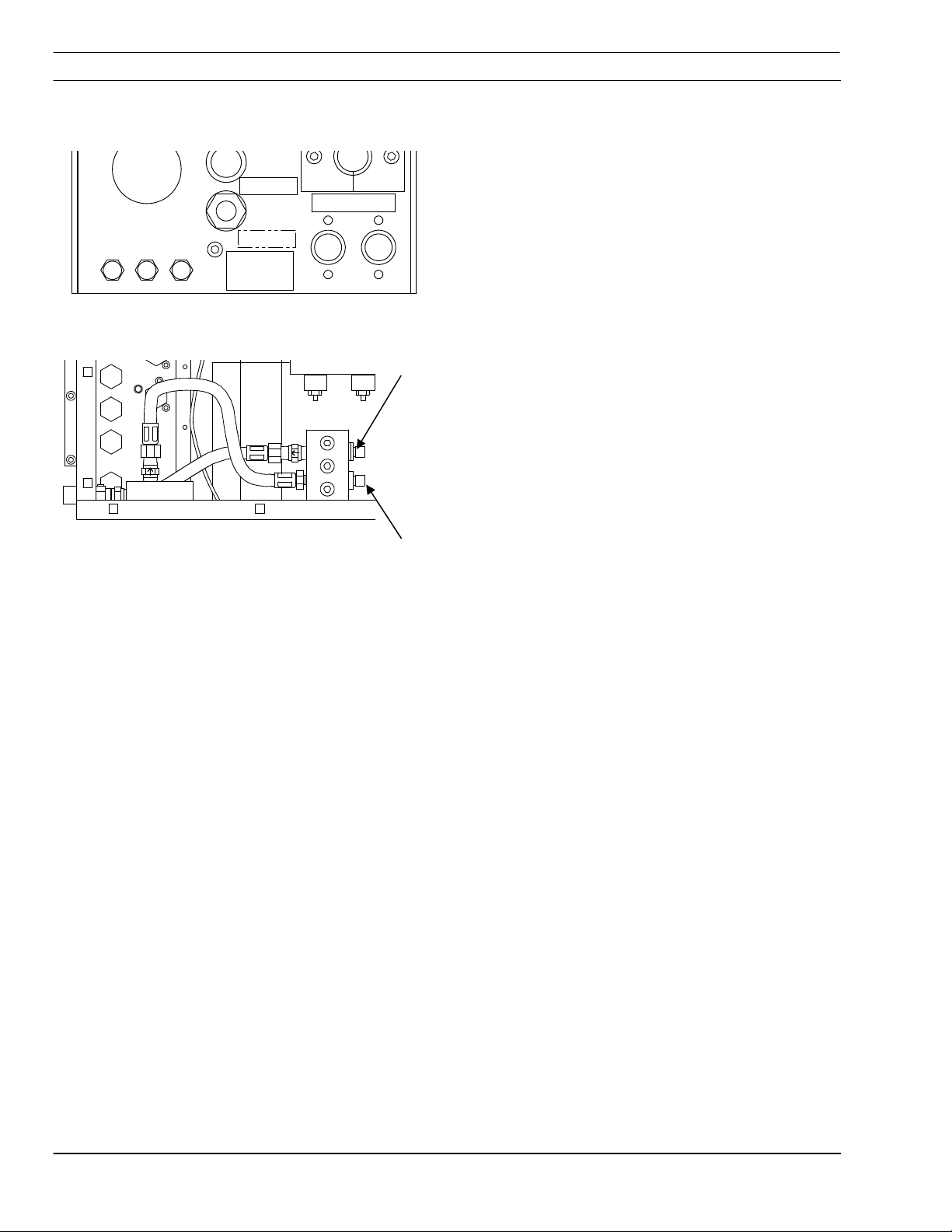

3.2 Box Mounting (Bottom View)

7.25"

184.2 mm

6.515"

165.5 mm

Cable Clamp

2.015"

51.2 mm

0

(Ref)

Gauges (Ref)

0

2.125"

54 mm

If mounting the box is required:

The box has four 6 mm threaded mounting holes

in a pattern offset from longitudinal center. Note

13.125"

333.4 mm

15.125"

384.2 mm

relationship of hole pattern to gauges and cable

clamp.

SmartFlow 2.5

3-1

SECTION 3 INSTALLATION

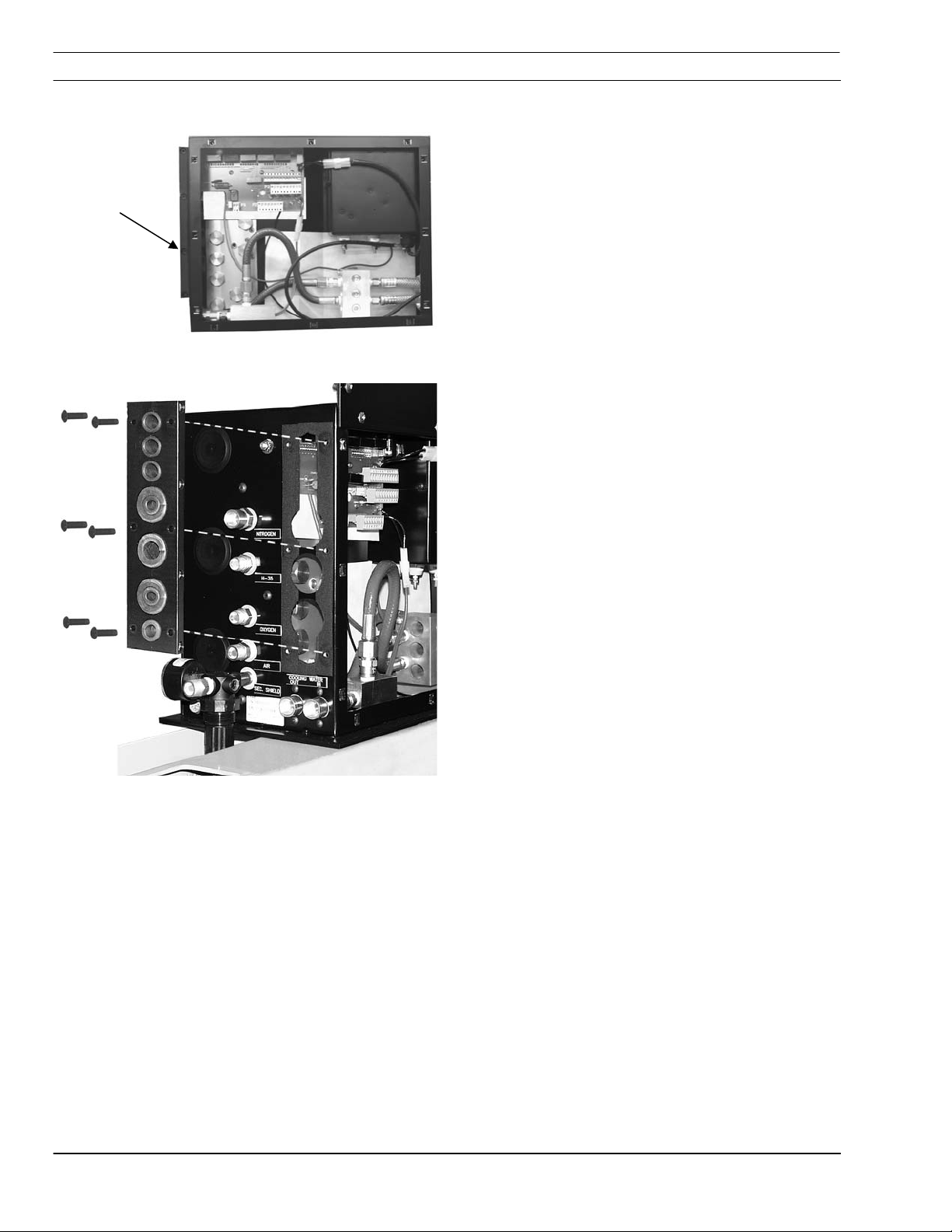

3.3 Hose and Cable Connections

Control Cable

Clamp/Strain

Relief

1. Remove left side panel of the SmartFlow 2.5

box. Rotate ¼ turn fasteners

counterclockwise.

Left Side Panel

Removed

2. Disassemble the strain relief/clamp block.

(When apart, this strain relief will allow

placement of cables and hoses without

removing plugs and fittings.)

A. Remove six screws holding block to back of

the SM box.

B. Remove four side clamping screws.

3-2

SmartFlow 2.5

SECTION 3 INSTALLATION

Control Cables

3. Place cables in block.

4. Replace four side clamp screws. Do not

tighten.

Power Source Leads

(4/0 Cable)

Pilot Arc Cable

5. Reattach block using three mount screws

along a vertical line.

6. Adjust cable length and tighten the four side

clamp screws.

7. Finish attaching the block to the box with the

other three mount screws.

8. Tighten all screws.

SmartFlow 2.5

3-3

SECTION 3 INSTALLATION

3.3.1 Starter Box Connections

Connection Point

TB4/Buss

TB1 – Pilot arc ground cable from the plasma

power source (ESP).

TB4 – Connected to buss bar (brass block just

below starter box) inside the SmartFlow box.

TB2 – Pilot Arc Torch cable from the torch leads.

3-4

SmartFlow 2.5

SECTION 3 INSTALLATION

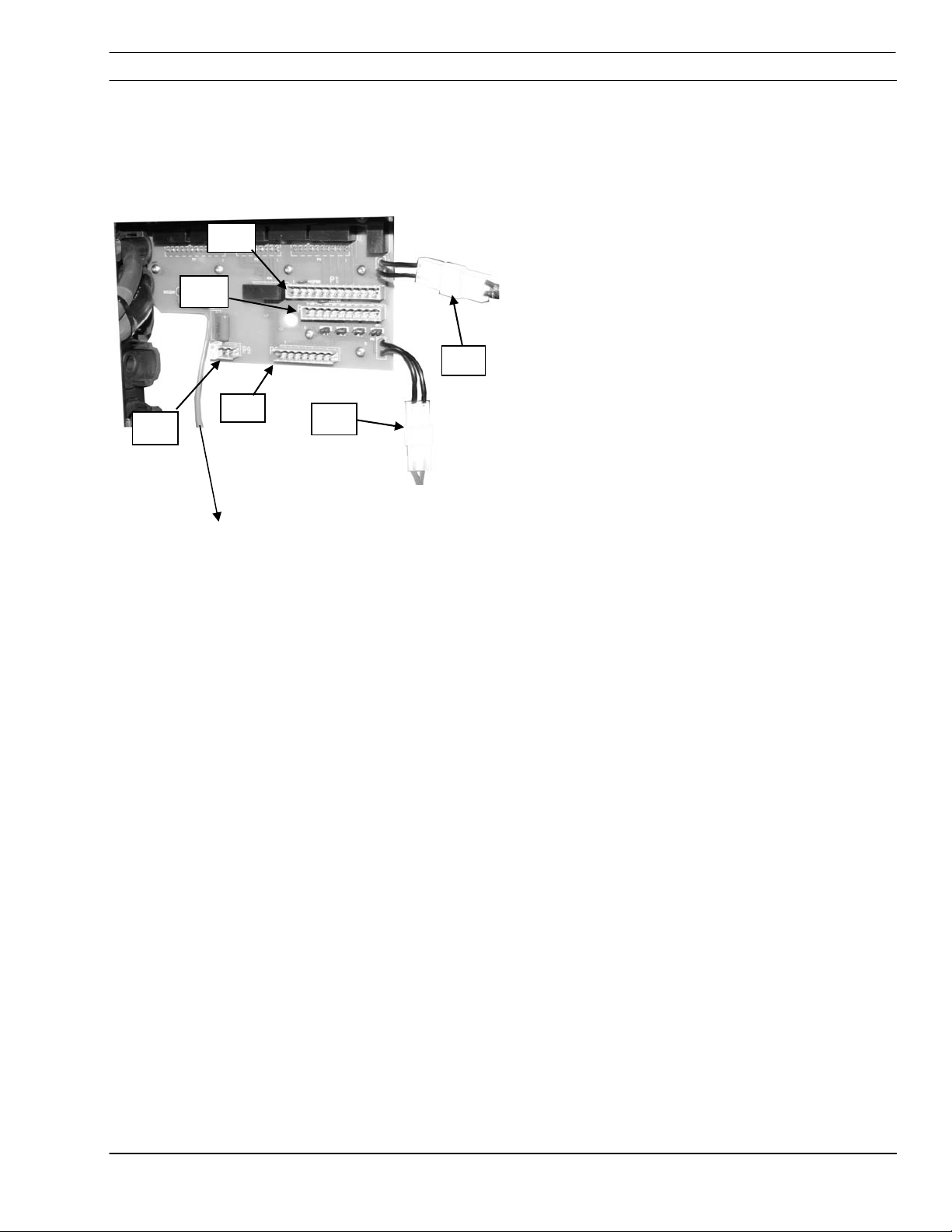

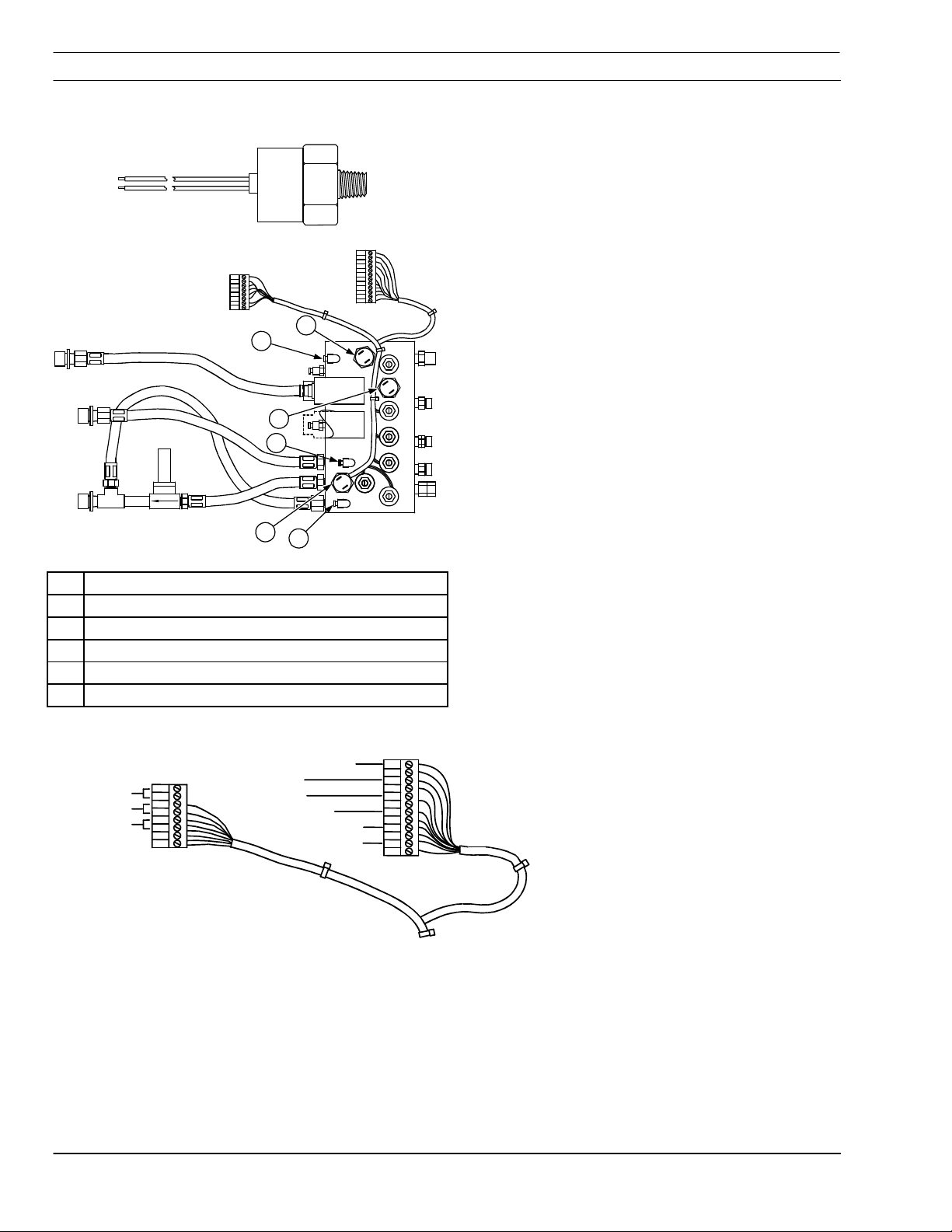

3.3.2 PC Board Connections

P1

P3

P1 – 12 pin connector, CNC control lead (valves)

P2 – 8 pin connector, CNC control lead (cutwater/

secondary shield)

P3 – 10 pin connector, CNC control lead (cut gas)

P6 – Cooling water flow switch

P8 – High frequency arc start AC power

P9 – Voltage divider

P9

To arc start buss

P2

P6

P8

Reverse side (not shown)

P4 – 10 pin connector, valve control lead (valves)

P5 – 8 pin connector, manifold control lead

(cutwater/ secondary shield)

P7 – 12 pin connector, manifold control lead (cut

gas)

Note:

For more detailed information, refer to PC

board schematic in Section 6.

SmartFlow 2.5

3-5

SECTION 3 INSTALLATION

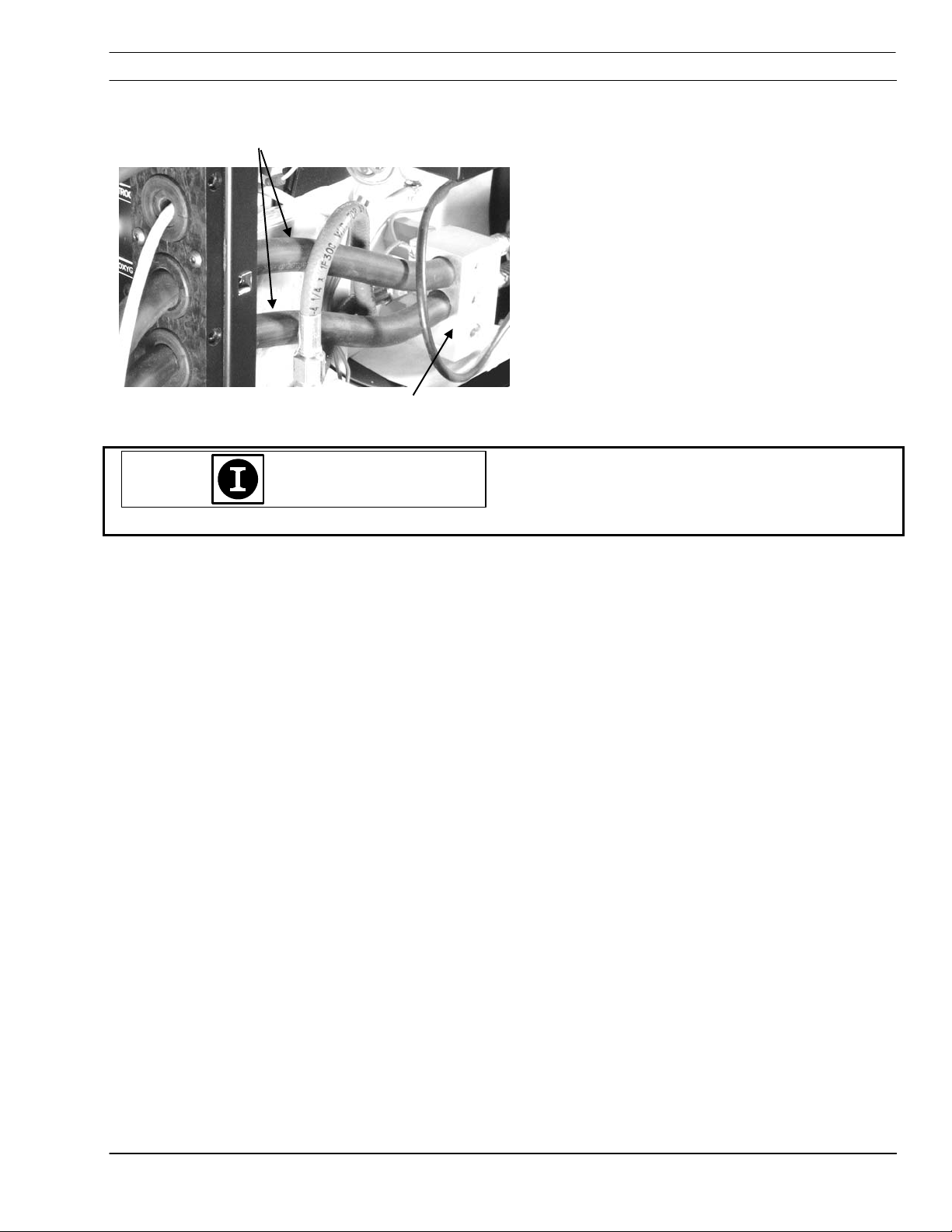

3.3.3 Torch Cooling Water Connections

Coolant Connections To and From Power

Source

AIR

COOLING WATER

OUT

IN

When packaged with a torch and power supply at

the factory, connections are labeled. Additional

CUT WATER

SERIAL

NUMBER

labels are available if re-labeling becomes

necessary. Tracing Smart Flow 2.5 interior lines

can identify the proper connections. Flow switch is

located on the “IN” line.

Coolant OUT (from

torch)

Coolant Connections To And From Torch

Note arrows on fittings indicating coolant flow

OUT

IN

Left Side Panel

Removed

Coolant IN (to torch)

direction.

Coolant Out has right-hand threads.

Coolant In has left-hand threads

3-6

SmartFlow 2.5

SECTION 3 INSTALLATION

3.3.4 Power Source To SMF 2.5 Buss Connection

4/0 power source cables

1. Strip 4/0 insulation, approximately 38 mm.

2. Insert 4/0 cable in buss hole until copper

extends to the edge of the buss block.

Buss

3. Tighten locking screw(s) on cable.

Note:

The buss will accommodate three cables.

(1) 4/0 – 400 amps

(2) 4/0 – 750 amps

(3) 4/0 – 1000 amps

Careful attention while stripping insulation

NOTICE

will make installation of the 4/0 cable in the

buss easier. Do not spread or flare the

copper conductors.

SmartFlow 2.5

3-7

SECTION 3 INSTALLATION

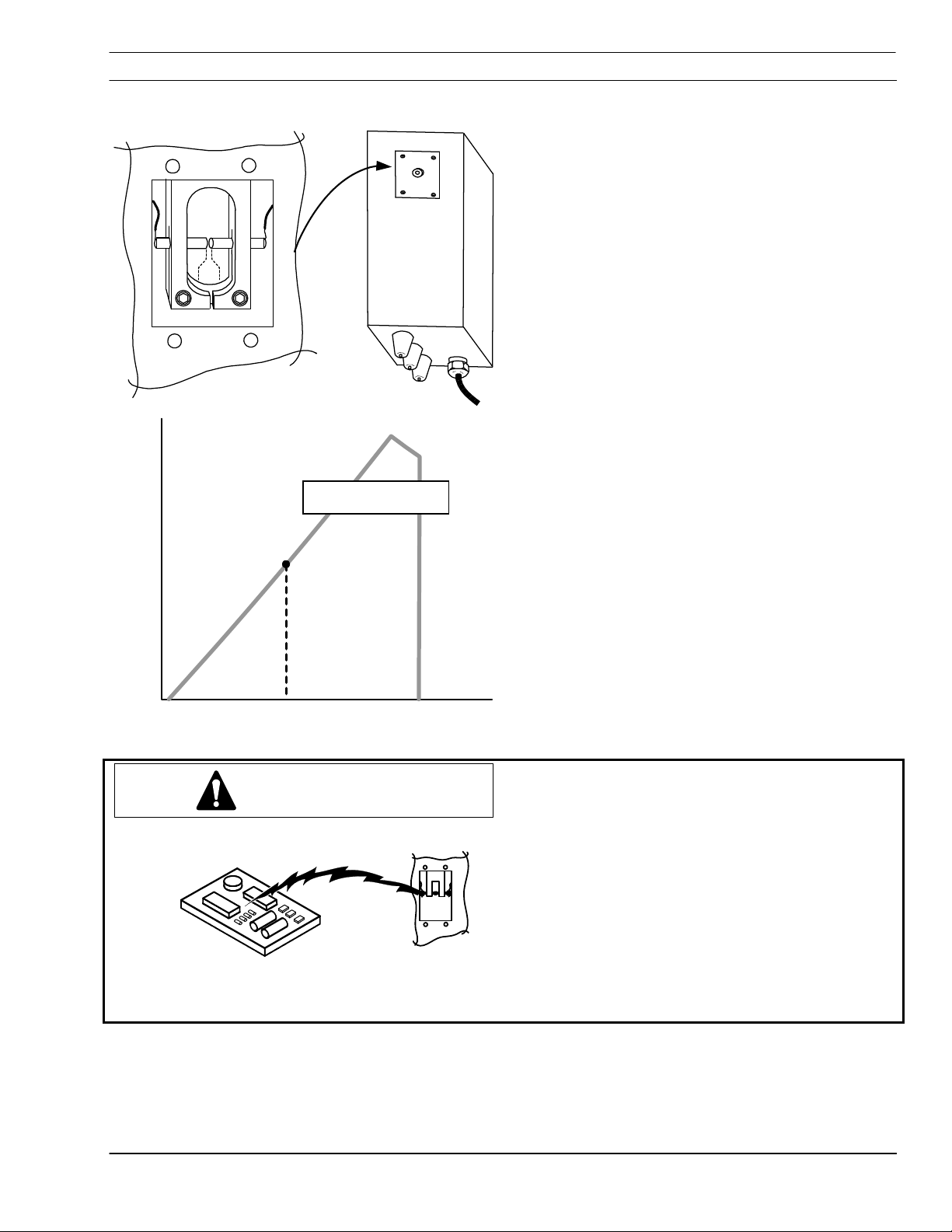

3.4 Nomex Insulation

Arc Start Box

Nomex

Insulation

High Frequency Cable from ESP

Plasma Power Source

Buss

3.5 Gas Connections

3.5.1 Gas Lines From Supply.

Position Nomex insulation to prevent any possible

arcing between the buss and arc start box

terminals.

Replace side panels of SmartFlow 2.5 enclosure.

Gas Connections are made on the exterior of the

SM box. Gas lines are connected to the back

from supply sources and the front for the torch.

Unfiltered Gas Will Clog Proportional

CAUTION

Valves

Dirt particles will clog small orifices in proportional

valves.

3-8

All gas supplies must have a 25 micron filter

installed between supply and gas regulator panel.

EASB Filter P/N 56998133 (replacement filter

element P/N 0560988406)

When using the PT-19XLS or PT-600 torch with a

secondary shield, air supply must be filtered and

dry using a minimum 25 micron filter.

Proportional valves contain no serviceable parts.

Replace valve assembly with factory parts.

SmartFlow 2.5

SECTION 3 INSTALLATION

Gas Line Contamination Will Damage

CAUTION

1

2

NITROGEN

Proportional Valves

Purge Gas Lines

Before connecting gas delivery lines to the

SmartFlow 2.5V, purge all lines thoroughly.

Residue from the hose manufacturing process

may clog/damage the proportional valves in

your SmartFlow 2.5.

1. Purge gas and air lines completely before

connecting to 25 micron gas filters.

3

H-35

AIR

4

5

OXYGEN

AIR

SECONDARY

SHIELD

SERIAL

NUMBER

COOLING WATER

OUT

IN

Back of SM 2.5 Plumbing Box

1 Nitrogen (N2)

2 Alternate Cut Gas Air or H-35. Units differ on

thread type. Standard version (air) have right hand

threads. The H-35 version has left hand threads.

3

Oxygen (O

4 Torch Air

5 Secondary Shield or Cutwater (depends on torch)

)

2

2. Connect oxygen, H-35, nitrogen and airlines to

gas filters.

3. Purge gas/air lines between regulator panel

and SmartFlow 2.5 plumbing box.

4. Connect gas/air lines to back of plumbing box.

SmartFlow 2.5

3-9

SECTION 3 INSTALLATION

3.5.2 Gas Pressure Setup

Adjust pressure at the regulator panel while gas is

flowing.

3.6 Cut Water Setup (PT-15XL)

See system requirements for description of

cutwater.

Gas Type Pressure

Oxygen 125 PSI (8,63 Bar)

Nitrogen 125 PSI (8,63 Bar)

H-35 150 PSI (10,4 Bar)

A supply of deionized water is required for the

installation of cutwater when using the PT-15XL.

A minimum regulated pressure of 30 psi (2,07 bar)

supply is required to prevent cavitation in the

cutwater pump.

Pressure from the cutwater pump to the

SmartFlow should be adjusted to 120 psi (8,28

bar). Refer to the cutwater pump manual for this

procedure.

3-10

SmartFlow 2.5

SECTION 3 INSTALLATION

3.7 Secondary Shield Gas Setup (PT-19XLS/PT-600)

Secondary shield gas (air or N2) must be dry and

filtered to a minimum of 25 microns and regulated

to 60 PSI (4,14 bar). Excess moisture in shield

gas may cause arcing inside the torch and/or poor

consumable life. This gas supply (pre-filtered)

uses the same fitting as the cutwater hose in back

of the plumbing box.

Secondary shield gas regulator

Air regulator

SmartFlow 2.5

3-11

SECTION 3 INSTALLATION

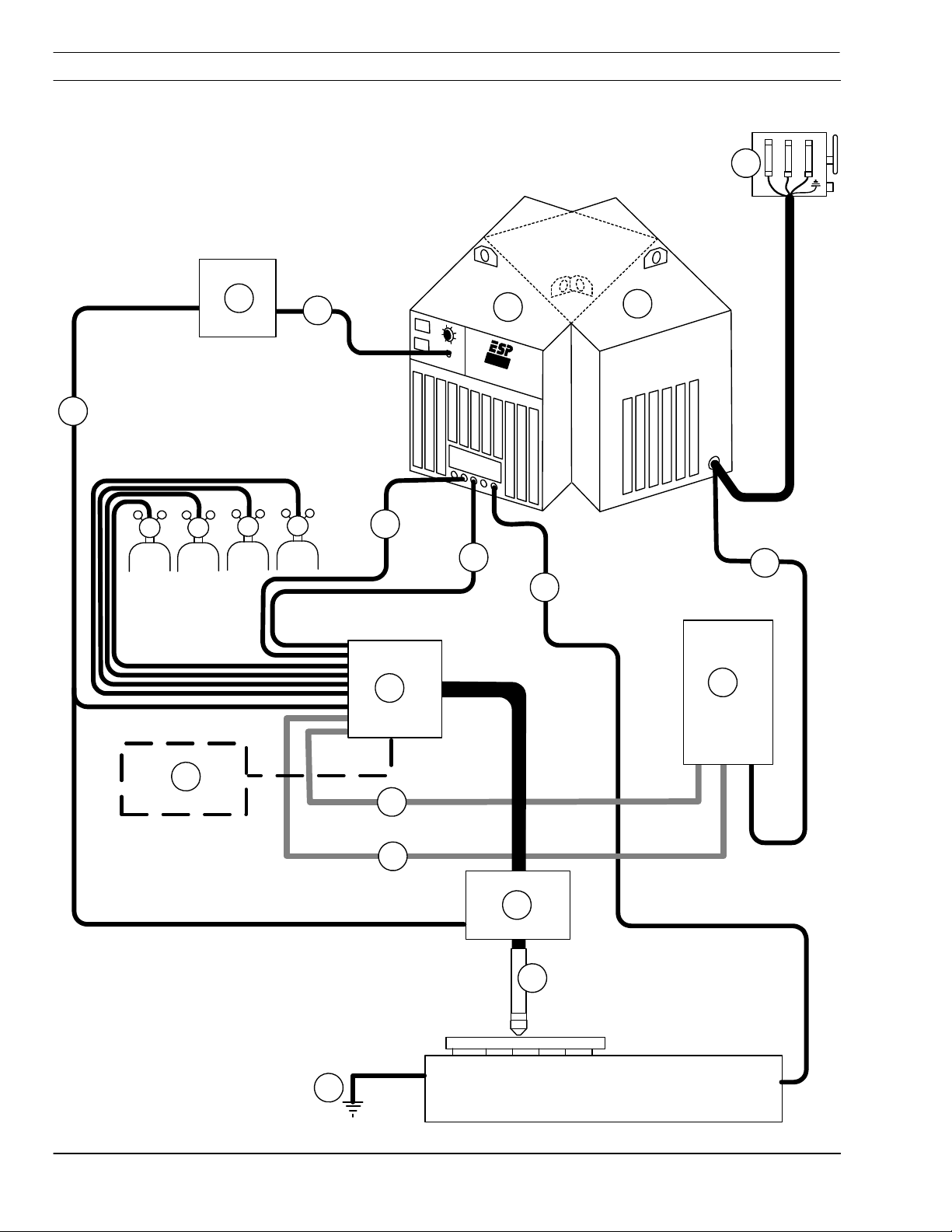

3.8 A Component Relationship Block Diagram

1

5

4

2

4

0

0

C

3

6

7

N2

O2

Air

H-35

8

17

9

10

18

3-12

11

12

13

14

15

16

SmartFlow 2.5

SECTION 3 INSTALLATION

System Interconnecting Block Diagram with Smart Flow 2.5

1

3 phase with ground (wall disconnect)

2

Front view of plasma power source

3

Rear view of plasma power source

4

Remote to CNC

5

CNC

6

CNC Input/Output to Smart Flow 2.5

7

Torch Lead (-)

8

Pilot Arc Lead

9

Work Lead (+)

10

11

12

13

14

15

16

17

18

SmartFlow 2.5

Cut Water Pump (required for PT-15)

Cooling Water to Torch

Cooling Water from Torch

Voltage Height Control

Plasma Torch Lead Bundle and Torch

Earth Ground

On/Off Control

WC-7C Water Cooling

SmartFlow 2.5

3-13

SECTION 3 INSTALLATION

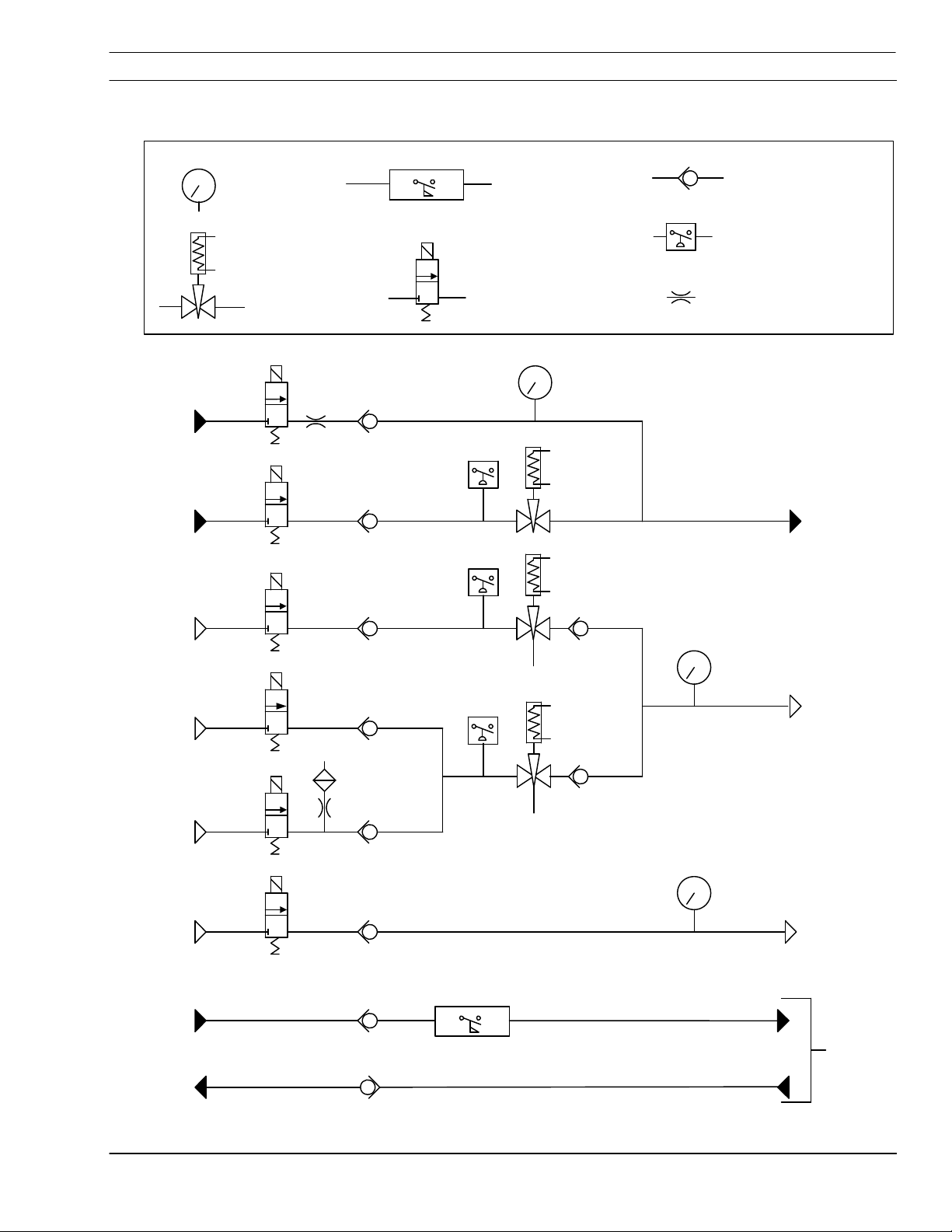

3.9 Fluid Schematic – SmartFlow 2.5 Standard and H-35 Versions – See note

Gauge

Proportional

Valve

Auxilery

Cut Water

Valve 3

Secondary

Shield/

Cut Water

IN

Vent

Oxygen

IN

Vent

Air/H-35

IN

See note.

Nitrogen

IN

Valve 2

N

2

Orifice

Vent

Air IN

Flow Switch

Cooling

Water IN

Cooling

Water OUT

3-14

Flow Switch

2 way Solenoid

Valve

0-100 PSI (6,9 bar)

PS2

PS

PS3

Valve 1

PS

See note.

PS1

PS

Purge

IN OUT

SmartFlow 2.5

Check Valve

PS

Pressure Switch

Flow Restriction Orifice

Secondary

Shield/

Cut Water

OUT

0-100 PSI (6,9 bar)

Plasma

Gas

H-35 Version valve 2 is rated

Note:

for fuel gas. Inlet has left-hand

threads and a louvered cover.

The Standard Version valve 2 is rated for

non-fuel gas, Unit has a right-hand

threaded inlet and no louvers on the cover.

0-50 PSI (3,45 bar)

Air Curtain

To torch

SECTION 4 OPERATION

4.1 Operation Introduction

A major advantage of the SmartFlow 2.5 is that

NOTICE

4.2 Pressure Gauges

operating parameters are managed by the

machine CNC. There are no operating procedures

necessary with the SmartFlow 2.5. Management

is accomplished either with manual inputs on the

Vision cutting parameter screen or using the

ESAB system of Process Parameter Files.

Note:

Process Parameter Files (know by the acronym …

SDP for SchneidDatkenPaket) are files stored in

the Vision Control memory containing all

necessary information for cutting a thickness and

a material type. It is specific to material, thickness,

torch model, gas and material type. The

information used to create SDP files can be found

in your torch manual under Cutting Data,

Operation, Section 4. Refer to Vision CNC Part

Programming manual for more detail on the

creation and use of SDP files.

See your specific torch manual for cutting

parameter settings for using the

SmartFlow 2.5 Plumbing Box. These

settings can be found in the form of

cutting data charts located in the operation

section of the torch manual.

Pressure gauges display actual pressure to the

torch. They provide visual feedback to the

operator, and can be helpful in spotting torch

problems.

4.3 Pressure Switches.

Pressure switches monitor line pressure and

Smart Flow 2.5

provide inputs to the CNC. If the pressure drops

below a preset level, the CNC can shut the

process down. Switches are in-line between the

solenoid and the proportional valve for cut water

(or secondary shield), H-35, and oxygen/nitrogen

lines.

4-1

SECTION 4 OPERATION

This page intentionally left blank.

4-2

Smart Flow 2.5

SECTION 5 Maintenance

5.1 SmartFlow 2.5 Maintenance Introduction

This section provides adjustment or replacement

procedures for those serviceable parts inside the

SmartFlow 2.5 plumbing box.

Only trained personnel should perform

maintenance on this equipment.

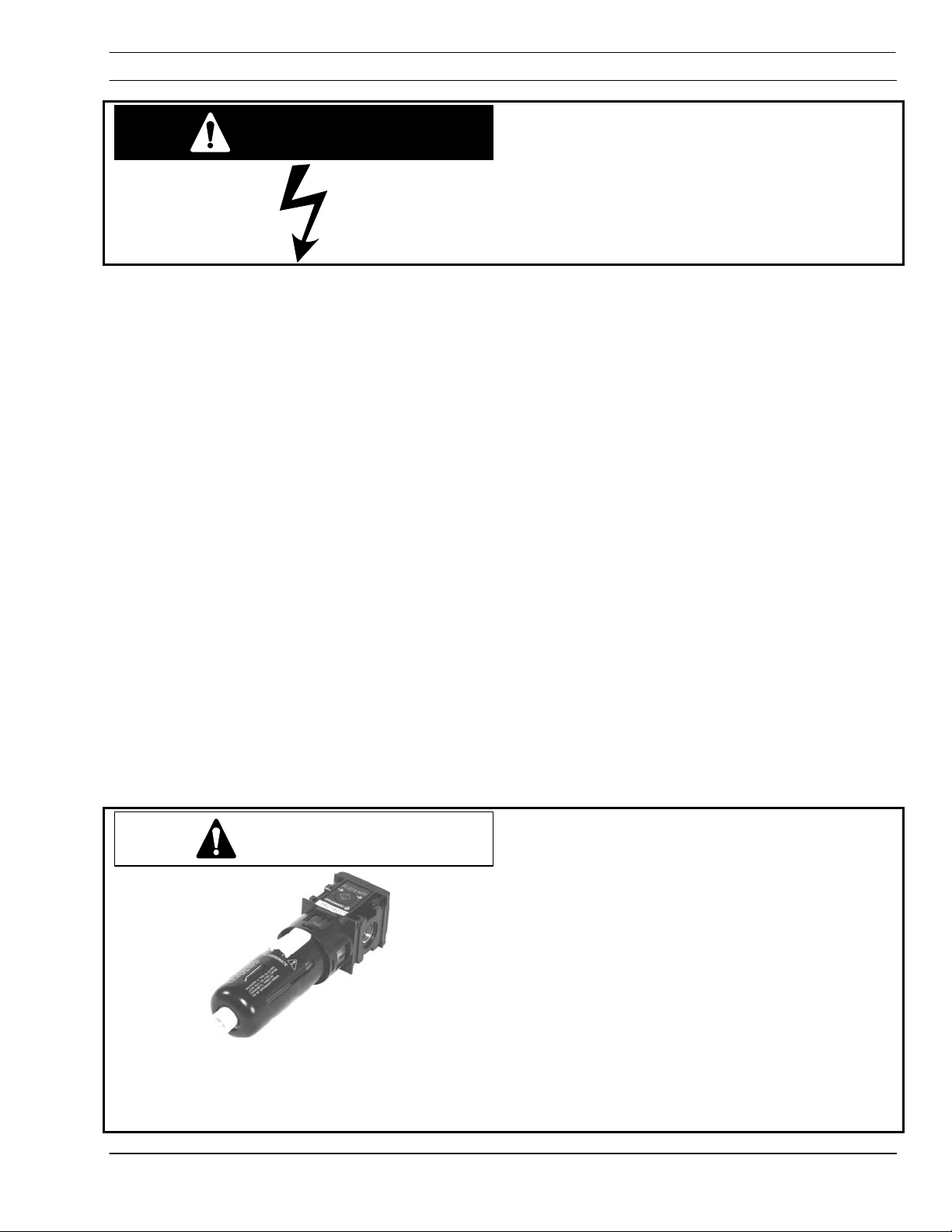

Electric Shock Can Kill!

WARNING

CAUTION

Always disconnect power from the ESP

power source and the cutting machine

before opening or servicing the SmartFlow

2.5 plumbing box.

Only Qualified Maintenance Personnel

Should Repair And Maintain This

Equipment.

Smart Flow 2.5

5-1

SECTION 5 Maintenance

5.2 Pressure Switches

P5

1

2

3

4

5

6

P7

Gas Pressure Switch monitors the pressure of

plasma gas supply to the plumbing box. One

switch monitors O

monitoring the alternate gas: Air or H-35 / N

. The other switch is used for

2

.

2

Note:

H-35 is an industry name for a mixture of 65 %

argon and 35% hydrogen.

Cut Water/Secondary Shield Switch monitors

the pressure of either cutwater or secondary

shield gas, depending on the torch application.

These switches are wired as an input to the CNC.

Logic codes in the control look for a change of

state (low/high) of the input signals, therefore

these switches cannot be jumpered out of the

circuit.

Both pressure switches are factory set and nonadjustable to close at 50 PSI (3.45 Bar). They

contain no serviceable parts. Replacement P/N

952920.

1 Oxygen Pressure Switch

2 Plasma Gas Pressure Gauge Tap

3 Air or H-35 / N2 Plasma Gas Pressure Switch

4 Air Curtain Pressure Gauge Tap

5 Cut Water/Secondary Shield Pressure Switch

6 Cut Water Pressure Gauge Tap

P5 and P7 Wiring

N2

AIR

O2

N2

AIR 1

P7

12

11

10

9

8

7

6

5

4

3

2

CUT WATER

O2

Air or H-35/N2

O2

8

7

6

5

4

3

2

1

CUT H2O AUX

CUT H2O

Air or H-35

CUT H2O AUX

CUT H2O

Air or H-35

P5

5-2

Smart Flow 2.5

SECTION 5 Maintenance

5.3 Spark Gap Of the Arc Starter

The SmartFlow 2.5 uses a high frequency arc

starter to initiate the plasma arc within the cutting

torch.

The arc starter box is mounted in the upper right

corner of the plumbing box. The arc starter box

contains an adjustable spark gap.

The recommended spark gap setting is

0.040" (1,0 mm).

HIGH

Decreased Spark Gap from 0.040” (1 mm):

Starting

decreased

• Positive Effect – smaller risk of high frequency

• Negative Effect- starting reliability is

interference

Increased Spark Gap from 0.040” (1 mm):

• Negative Effect – increased damage risk from

Risk of High Frequency

Interference Damage

LOW

0

.040"

(1 mm)

Spark Gap

high frequency interference

• Positive Effect - starting reliability increased (to

a point where it doesn’t work at all).

High Frequency Interference Can Damage

CAUTION

Machine Electronic Components

Potentially damaging high frequency interference

may result from increasing the spark gap beyond

recommendation. This electrical interference may

find its’ way to pc boards in the electronics cabinet

or Vision control. The result will be failure of some

portion of machine function.

Do not set spark gap beyond

recommended distance of 0.040” (1,0 mm)

Smart Flow 2.5

5-3

SECTION 5 Maintenance

5.3.1 Arc Starter Box Troubleshooting

Arc Starter Box schematic

If it is determined that the arc starter box has

failed, contact ESAB for replacement box.

To remove the arc starter box, locate the eight (8)

mounting screws on the interior mounting wall.

The air curtain and cut gas gauges will need to be

moved to access mounting screws. Loosen clamp

screws on gauges and slide gauges forward to

access arc starter box screws. Remove arc starter

box mounting screws and disconnect wires at

TB1, TB2, TB4 and the black lead 120 vac input.

Make sure to note proper wire connection

locations for reassembly. Reassemble arc starter

box, make wire connections and replace gauges.

5-4

(8) Arc Starter Box mounting screws

Air Curtain gauge

Clamp screws

Cut Gas Gauge

Smart Flow 2.5

SECTION 5 Maintenance

Electric Shock Can Kill!

WARNING

Always turn power off before opening and

servicing the SmartFlow 2.5 plumbing box.

5.4 Spark Adjustment Procedure

1. Disconnect input power to plasma power

source (ESP) and cutting machine.

2. Remove left and right side covers from the

SmartFlow 2.5. Mounting screws for the arc

starter box are accessed from the manifold

side (right side) of the SM II.

1

Spark Gap Access

2

Fiber Optic Cable

3

Spark Gap of 0.040” (1 mm)

3. Disconnect fiber optic cable from arc starter

box.

4. Remove arc starter box. Mounting screws are

accessed from the opposite side of the SM

2.5. Removal of gauge(s) may be necessary to

see some screws.

1

2

3

ARC Starter Box

5. Remove access cover from the arc starter.

6. Use a 0.040” (1 mm) feeler gauge or shim to

measure the spark gap setting.

7. Adjust as required. When correctly adjusted,

there should be slight pressure felt when a

back and forth motion is applied to the shim.

8. Replace access cover and remount arc starter

box.

9. Replace side panels.

Smart Flow 2.5

5-5

SECTION 5 Maintenance

5.5 Gas Proportional Valves

P/N 0558001068

O2 Proportional Valve

Oxygen rated.

Gas proportional valves contain no user

serviceable parts. In case of failure, the valve

must be replaced.

P/N 0558001065

H-35 / N2 Proportional Valve

Fuel gas rated.

Easily distinguishable with nickel-plated valve

body. Gas proportional valves contain no user

serviceable parts. In case of failure, the valve

must be replaced.

5.6 Cutwater/Secondary Shield Proportional Valve

P/N 56997044

This proportional valve contains no user

serviceable parts. The valve must be replaced in

case of failure. This is the only valve that can be

calibrated if necessary. See troubleshooting

section for calibration procedure.

5-6

Smart Flow 2.5

SECTION 5 Maintenance

5.7 Cooling Water Flow Switch

2

P/N 636383

The cooling water circuit uses a 1.0 gallon (3.8

liters) flow switch to monitor cooling water flow. It

measures actual flow through the torch in the

cooling water return line.

The switch is wired as an input to the CNC. The

control looks for a change of state of the input

1

signal when the plasma station is turned on. This

switch cannot be jumpered out of the circuit.

Type of cooling water problems:

• Insufficient flow due to a restriction in the

cooling water circuit.

2

The switch may be disassembled and cleaned

if found to have a restriction.

3

• Sufficient flow but no flow closure.

If measurement of the actual cooling water

4

flow rate indicates more than 1.0 gallon

(3.8 liters) per minute, but the switch does

not close, the switch may be damaged or

clogged. Clean or replace as necessary.

1

1 Retainer Ring

2 Flow Switch

3 Spring

4 Piston

Smart Flow 2.5

5-7

SECTION 5 Maintenance

5.8 Gas Filters

Nitrogen, oxygen, and secondary shield gases

must be filtered before entering the SmartFlow II.

Check these filters regularly (dependent on usage

and cleanliness of supply). Replace filter as

required.

Unfiltered Gas Will Clog Proportional

CAUTION

Valves

Gas filters must be installed in the gas

supply lines in front of the gas regulator

panel. A 25 micron filter is required.

P/N 56998133. Replacement filter element

P/N 0560988406

5-8

Smart Flow 2.5

SECTION 6 TROUBLESHOOTING

Electric Shock Can Kill!

WARNING

Disconnect power before removing side

panels.

6.1 Troubleshooting Introduction

The SmartFlow 2.5 has proven to be a very

reliable product. Regular maintenance is important

for many years of trouble free use.

This section contains a brief description of the

most common problems, schematics, and

technical diagnostic tools.

• Cooling Water Circuit

• Cut Water

• Plasma Gas

• Secondary Shield

• Spark

• Process Diagnostics

The SmartFlow 2.5 is designed to support the PT15XL, PT-19XLS and PT-600 plasma torches.

• The PT-15XL torch uses cutwater.

• PT-19XLS and PT-600 torches introduce a

secondary gas shield. Secondary shield

utilizes the same solenoid and proportional

valve used for the cutwater on the PT15XL.

All gases supplied to the SmartFlow 2.5

CAUTION

must be filtered to 25 microns. Small

orifices in proportional valves will become

clogged if filters are neglected or bypassed.

Do Not Attempt to Clean. Replacement of

manifold assembly may be necessary.

Replacement of proportional valves only is

possible. Thoroughly flush manifold and gas

lines with N

before reassembly.

2

Because proportional valves contain the

smallest gas passages, replacement or

cleaning of check valves is not recommended.

Avoid any potential problems by

appropriately filtering plasma and shield

gases.

SmartFlow 2.5

6-1

SECTION 6 TROUBLESHOOTING

6.2 Cooling Water Circuit

The cooling water circuit consists of two reverse

5

1 Torch

2 To torch check valve

3 Flow Switch

4 Return coolant check valve

5 Water cooler

4

2

3

1

flow check valves and a flow switch. It is a closed

loop re-circulating system which cools the

electrode

and torch body of the PT-15XL torch. The PT19XLS and PT-600 torches have electrode,

nozzle, nozzle retaining cup, and torch body

cooled by this system.

The primary concern of the cooling water system

is the flow rate. Insufficient cooling flow can result

in severe damage to the consumables and torch

body.

The cooling water flow switch is calibrated to close

at or above a flow rate of 1 gallon (3.8 liters) per

minute. If the flow rate drops below this rate, a

signal is sent to the CNC and the plasma system

is shut down.

3

2

6

4

1 Buss Block

2 Coolant line – to torch (from cooler)

3 Coolant line – from torch (to cooler)

4 Flow switch

5 Check Valve – from torch

6 Check Valve – to torch

6-2

5

1

SmartFlow 2.5

SECTION 6 TROUBLESHOOTING

6.3 Cut Water and Auxiliary Cut Water

SmartFlow 2.5 Manifold

9

8

7

6

5

3

4

1

2

• Cutwater is used with the PT-15 XL torch.

• Deionized water is supplied to the

plumbing box cutwater solenoid valve.

• Check valves built into the manifold are

positioned to prevent back flow to the

solenoids. See Schematic below.

• A port inside the manifold re-routes

additional cutwater to the auxiliary cutwater

solenoid. This option is used when cutting

with N2 / H-35 to provide additional

cutwater flow. Maximum water flow, with

auxiliary water solenoid open and the

cutwater proportional valve set to

maximum, is 1.5 gpm.

1 De-ionized cutwater supply connection

2 Cutwater solenoid

3 Aux. Cutwater solenoid

4 Cutwater pressure tap

5 Cutwater Pressure switch

6 Aux cutwater supply hose

7 Cutwater hose manifold to proportional valve

8 Cutwater proportional valve

9 Cutwater torch connection

10 Check valve

11 Cutwater Gage

12 Aux. Cutwater Restriction Orifice

Cutwater Flow Schematic

11

4

• Back pressure thru the auxiliary cutwater

hose provides pressure to the cutwater

pressure tap and line to the cutwater

gauge.

• Cutwater pressure switch is preset and

nonadjustable to 50 psi. If pressure drops

below 50 psi, a signal is sent to the

machine control and process is shut down.

• Cutwater proportional valve provides a

means of controlling flow at the CNC. This

value is automatically set if using SDP files

to control cutting parameters. (SDP

SchneidDatenPaket = cutting data

package contain all the same information

that can be individually adjusted on the

Vision control process parameter screen.

See Vision Programming Manual.)

12

3

PS

9

8

5

10

2

1

SmartFlow 2.5

6-3

SECTION 6 TROUBLESHOOTING

6.4 Plasma Gas

Plasma gases are controlled with proportional

valves mounted on the manifold.

15

14

13

9101112

PS

1

PS

2

3

Oxygen supply connection

1

Air or H-35 connection

2

Nitrogen supply connection

3

Air curtain supply connection

4

Solenoid

5

Check valve

6

Nitrogen purge orifice

7

Air gage 0-50 psi

8

Air or H-35 / Nitrogen pressure switch

9

Oxygen pressure switch

10

Oxygen proportional valve

11

Air or H-35 / Nitrogen proportional valve

12

Plasma gas gage 0-100 psi

13

Plasma gas

14

Air curtain

15

6-4

4

8

567

Note:

Part number 0560935258, SmartFlow

includes all of the components listed at left. Item 2

for H-35 is a connection with left-hand threads.

Part number 0560935257, SmartFlow

with air as alternate plasma gas.

Item 2 for air is a right-hand threaded bulkhead

fitting. The auxiliary water is not removed because

of improved piercing of thicker materials when using

PT-19 and PT-600. Squarer cuts in thicker

materials are also possible using the auxiliary

cutwater path for additional shield gas flow.

SmartFlow 2.5

2.5 with H-35,

2.5 Standard

SECTION 6 TROUBLESHOOTING

6.5 Secondary Shield

SmartFlow 2.5 Manifold

• Secondary shield gas is used with the PT19XLS and PT-600 torches (dry torches)

• Shield gas (nitrogen or air) is supplied to

the shield gas solenoid valve.

• Check valves built into the manifold are

positioned to prevent back flow to the

solenoids. See Schematic below.

• A port inside the manifold re-routes

additional shield gas to the secondary

shield gas solenoid. This option is used

when piercing may require an addition

“blast”.

9

1 Shield Gas Supply Connection

2 Secondary Shield Gas Solenoid

3 Auxiliary Shield Gas Solenoid

4 Secondary Shield Pressure Tap

5 Secondary Shield Pressure Switch

6 Secondary Shield Supply Hose

7 Shield Gas Hose To Proportional Valve

8 Secondary Shield Gas Proportional Valve

9 Shield Gas Torch Connection

10 Check Valve

11 Shield Gas Gage

8

6

7

5

11

4

3

4

• Back flow thru the secondary shield gas

1

2

hose provides pressure to the shield gas

pressure tap.

• Secondary Shield pressure switch is preset

and nonadjustable to 50 psi. If pressure

drops below 50 psi, a signal is sent to the

machine control and process is shut down.

• Shield gas proportional valve provides a

means of controlling flow at the CNC. This

value will be automatically set if using SDP

files to control cutting parameters. (SDP

SchneidDatenPaket = cutting data

package contain all the same information

that can be individually adjusted on the

Vision control process parameter screen.

See Vision Programming Manual.

12

3

9

8

Shield Gas Fluid Schematic

PS

5

10

2

1

SmartFlow 2.5

6-5

SECTION 6 TROUBLESHOOTING

6.6 Arc Start

WARNING

6.6.1 Setting the Spark Gap

The Arc Spark Gap inside the spark box should be

Electric Shock Can Kill

Disconnect Power before attempting any

repairs, disassembly or adjustments.

set to 0.040".

Note: Evidence of a spark can be confirmed at

the front of the plumbing box during normal

operations. See 6.6.3.

Procedure

1. Disconnect electricity to plasma power source

(ESP) and cutting machine.

2. Remove left and right side covers from the

SmartFlow II. Mounting screws for the arc

starter box are accessed from the manifold

side (right side) of the SM II.

1

2

3

3. Remove arc starter box, being careful not to

damage the fiber optic cable.

4. Remove access cover from the arc starter.

5. Use a 0.040" (1 mm) feeler gauge or shim to

measure the spark gap setting.

6. Adjust as required. When correctly adjusted,

there should be slight pressure felt when a

back and forth motion is applied to the shim.

7. Replace access cover and remount arc starter

box.

1 Spark Gap Access

2 Fiber Optic Cable

3 Spark Gap of 0.040" (1 mm)

6-6

8. Replace side panels.

ARC Starter Box

SmartFlow 2.5

SECTION 6 TROUBLESHOOTING

6.6.2 Spark Gap Size Attributes

HIGH

Decreased Spark Gap of 0.040" (1 mm):

Starting

decreased

• Positive Effect – smaller risk of high frequency

• Negative Effect- starting reliability is

interference

Increased Spark Gap of 0.040" (1 mm):

• Negative Effect – increased risk of damage

Risk of High Frequency

Interference Damage

LOW

0

.040"

(1 mm)

Spark Gap

from high frequency interference

• Positive Effect - starting reliability increased (to

a point where it doesn’t work at all).

High Frequency Interference Can Damage

CAUTION

Machine Electronic Components

Potentially damaging high frequency interference

may result from increasing the spark gap beyond

recommendation. This electrical interference may

find its way to pc boards in the electronics cabinet

or Vision control. The result can be failure of

some portion of machine function.

Do not set spark gap beyond

recommended distance of 0.040" (1,0 mm)

SmartFlow 2.5

6-7

SECTION 6 TROUBLESHOOTING

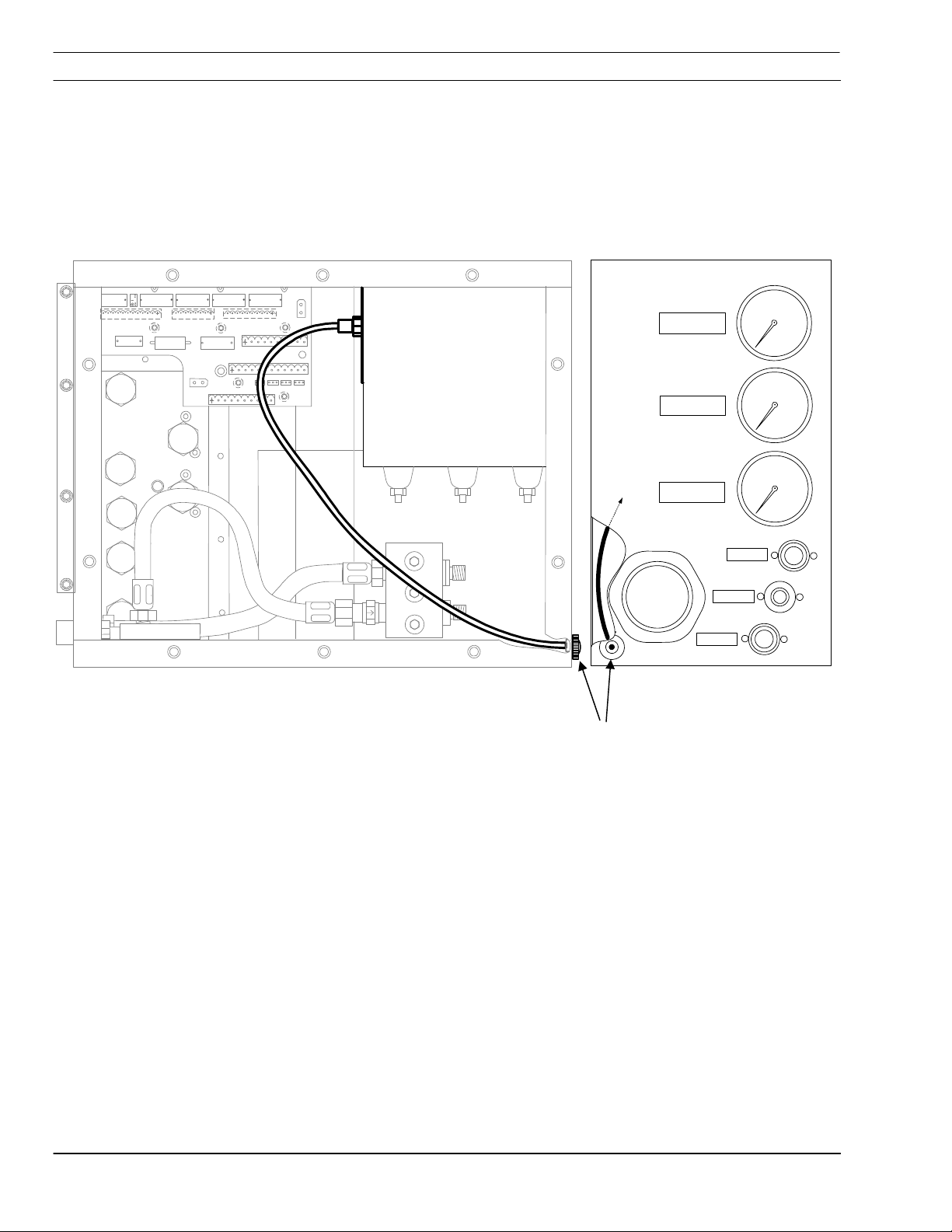

6.6.3 Spark Viewing

The spark can be seen from the front of the

plumbing box without removing any covers.

An optical cable is connected from the arc start

box to a view port on the bottom left front corner of

the plumbing box

AIR CURTAIN

60

CUT GAS

100

To Pilot Arc

Start Box

CUT WATER

100

AIR CURTAIN

CUT GAS

CUT WATER

Spark View Port

6-8

SmartFlow 2.5

SECTION 6 TROUBLESHOOTING

6.7 Fluid Schematic

Gauge

Proportional

Valve

Auxilery

Cut Water

Valve 3

Secondary

Shield/

Cut Water

IN

Vent

Oxygen

IN

Vent

Air/H-35

IN

* See note.

Nitrogen

IN

Valve 2

N

2

Orifice

Vent

Air IN

Flow Switch

Cooling

Water IN

Cooling

Water OUT

Flow Switch

2 way Solenoid

PS2

PS3

PS1

Purge

IN OUT

Valve

Flow Restriction Orifice

0-100 PSI (6,9 bar)

PS

Valve 1

PS

PS

* See note.

threads and has a louvered cover.

Standard version valve 2 is rated for

non-fuel gas. Unit has a right-handed

threaded inlet and no louvers on the cover.

Check Valve

PS

Pressure Switch

Secondary

Shield/

Cut Water

OUT

0-100 PSI (6,9 bar)

Plasma

Gas

H-35 Version valve 2 is rated

for fuel gas. Inlet is left-hand

*Note:

0-50 PSI (3,45 bar)

Air Curtain

To torch

SmartFlow 2.5

6-9

SECTION 6 TROUBLESHOOTING

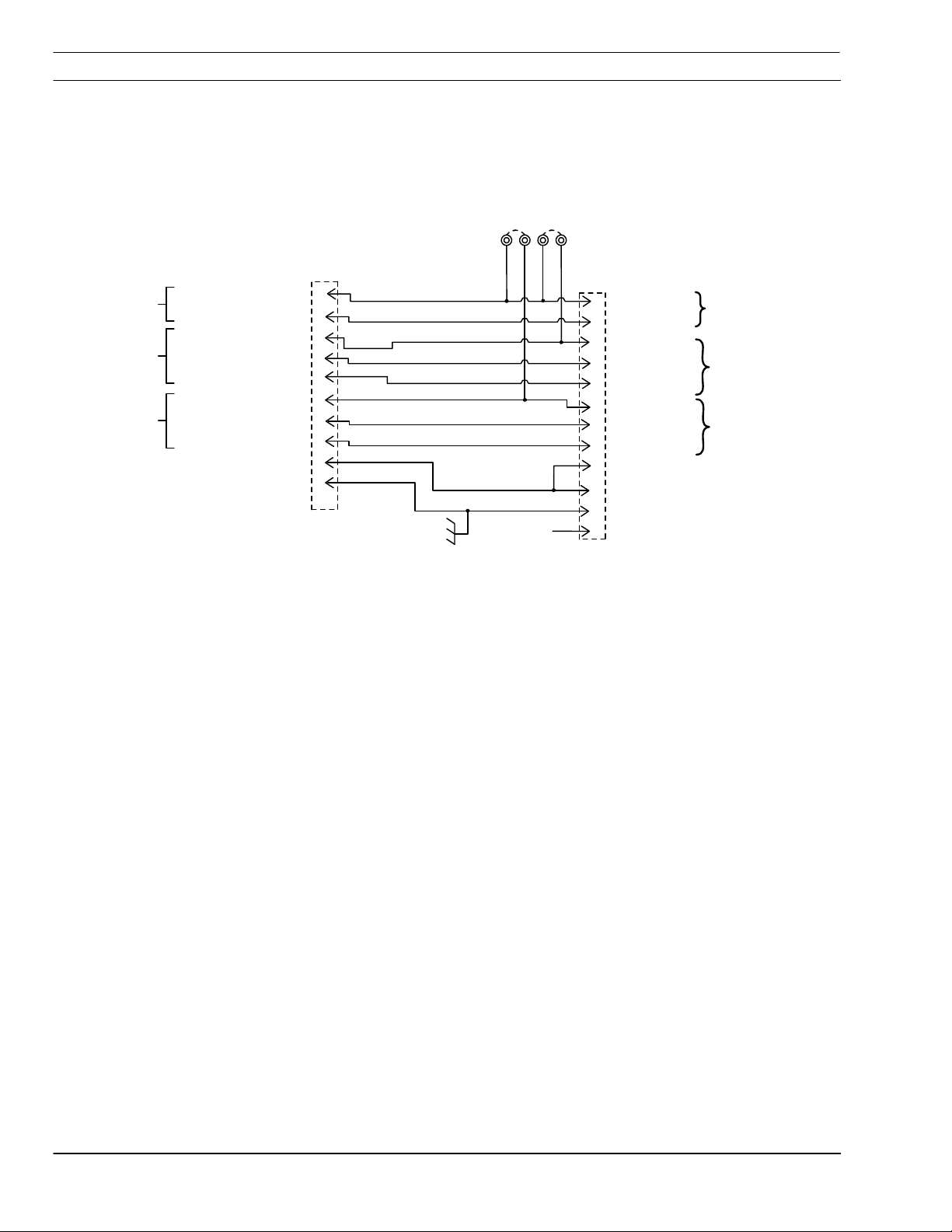

6.8 SmartFlow 2.5 Interface PCB Schematic (3 pages)

Proportional Valve Interface Schematic

V2PWR

V1PWR

P4

1

(RED)

1

A

V

L

V

3

E

+

2

V

4

L

O

T

H

A

R

S

S

N

E

3

E

V

AL

V

H

A

A

V

HARNESS

V

source file:

3

1

R

N

E

S

S

6

L

E

V

2

3

1

6

A

L

V

1

E

3

2

(WHITE)

VALVE 2 +24 VOLTS

(RED)

A

V

(WHITE)

(GREEN)

(RED)

A

V

(WHITE)

VALVE 1 P-SENSOR

(GREEN)

(BLACK)

V

AL

L

2

E

V

V

AL

E

V

L

1

L

A

V

VALVE GNDS

VALVE SHIELDS

S

10

V

E

3

S

E

T

P

T

P

-

S

V

E

P

T

2

+

4

E

V

1

T

P

9

.

8

N

S

E

R

O

7

2

S

E

T

6

.

S

T

L

O

V

5

4

T

E

S

3

.

2

1

135c001c.dxf (modified for SmartFlow 2.5

N.C.

P

1

V

L

A

V

E

2

E

V

L

V

A

3

VALVE 2 +24 VDC

4

VALVE 2 P-SENSOR

PROVISIONAL

5

L

V

V

A

E

6

E

A

V

L

V

7

V

L

A

V

E

PROVISIONAL

8

VALVE 1 SET PT.

4

2

C

D

V

9

10

4

2

V

DC

11

CHASSIS GROUND

12

3

4

+

2

V

T

E

S

3

S

2

E

T

V

1

2

4

+

-

1

P

E

S

G

R

O

U

G

RO

UND

CUT

C

D

H2O

.

T

P

2

/

N

-

H

3

5

/

i

A

r

P

T

.

D

C

S

N

O

R

2

O

N

D

6-10

SmartFlow 2.5

SECTION 6 TROUBLESHOOTING

Pressure Switch (PS) Interface Schematic

2

C1

0.1MFD

P

1

CUT WATER P-SENSOR +

2

CUT WATER P-SENSOR -

3

PRES. SW. 15 V. SOURCE (SR1)

4

PRES. SW. 24 V. SOURCE (SR2)

5

PS1 (N2 /ALT)

6

P

S

U

(

2

C

T

H

O

2

)

7

PS3 (O2)

2

G

H

N

O

O

I

L

C

1

(

S

F

8

P

9

2

V-Divide Arc Volts

V-Divide Work

1

O

)

P

PROVISIONAL

source file:

CUT WATER P-SENSOR +

CUT WATER P-SENSOR -

5

/

i

A

H

2

O

O

(

)

2

PS1

r

)

PS1

PS2

)

PS2

PS3

PS3

FS2

FS2

BUSS BAR

2

/

-

H

3

(

N

C

(

U

T

(COOLING H2O)

135c001c.dxf (modified for SmartFlow 2.5

5

1

2

3

4

5

6

7

8

1

2

6

P

JP1

JP2

JP3

Jumpers JP1 -- JP4

select either 24 vdc or

15 vdc input

JP4

requirements

1K 0.5W

CW

R1

R2

15K 8W

SmartFlow 2.5

6-11

SECTION 6 TROUBLESHOOTING

Solenoid Valve Interface Schematic

P

P7

AIR

1

2

AIR

3

N2

4

N2

H-35/Air

-

H

CUT H2O

CUT H2O

CUT H2O AUX

CUT H2O AUX

ARC START AC PWR

ARC START AC PWR

source file:

135c001c.dxf (modified for SmartFlow 2.5

5

6

3

5

/

i

A

r

7

8

9

10

O

2

11

O

2

12

1

2

8

P

RC1

RC2

RC3

RC4

RC5

RC6

RC7

N.C.

Note:

Alternate Gas can be H-35 or Air

3

1

SELECTOR VALVE COMMON

2

AIR

3

N2

120 VAC 50/60 HZ. 7 WATTS

4

5

/

A

H

3

-

5

CUT H2O

6

C

U

T

H

7

O

2

8

ARC START AC PWR

9

ARC START AC PWR

10

ALL SELECTOR

i

r

2

O

A

U

X

VALVES

6-12

SmartFlow 2.5

SECTION 6 TROUBLESHOOTING

6.9 SmartFlow 2.5 Secondary Shield Gas Proportional Valve Calibration

The Secondary Shield Gas (and Cutwater)

NOTICE

P3 P4

P1

S1, S2, S3, S4

P2

Cutwater/Secondary

Shield Proportional

Valve

Proportional valve is the only proportional

valve that can be calibrated.

Plasma Gas proportional valves are

calibrated by the valve manufacturer to

ESAB specifications. Do not attempt to

calibrate.

The following instructions are for calibrating single

or multiple station machines to ensure a

consistent value for the Cut Water/Shield

proportional valve. This calibration procedure will

ensure the SDP files developed in the factory

conform to the same screen values and output

pressures as factory settings.

These instructions are tested for PT19XLS

and PT-600 Secondary Shield only.

1. Calibrate the frequency of the proportional

valve using Pin2 to Pin3 for 300 Hz for gas and

water using P4 (potentiometer).

2. Check voltage on Pin2 to Pin3 on

Cutwater/Shield proportional valve. At 100 on

Vision Parameter Window for "Cut Water or

Shield" the voltage should be approximately 10

VDC.

3. Set shield gas regulator to 80 psi on the back

of the plumbing box with screen value for

"Cutwater/Shield" set to 100.

4. Check shield gas gauge (on front of plumbing

box) for max output pressure equal to about 32

psi. Adjust P3 (potentiometer) on proportional

valve board to maximum value by turning

clockwise until the pressure peaks out. Then

turn counterclockwise until the pressure begins

to drop. This will insure the valve is at the

maximum opening for the voltage.

5. Recheck shield input gas regulator is at 80 psi

at 100 on screen. Reset to 80 psi if necessary

and recheck for maximum output pressure of

32 psi.

SmartFlow 2.5

6-13

SECTION 6 TROUBLESHOOTING

P1 (potentiometer)

6. Set screen value for "Cut Water or Shield" to

20. Check voltage on Pins 2 to 3 on Cut

Water/Shield proportional valve. The voltage

should be approximately 2 volts. Check Shield

gas gauge for minimum output pressure equal

to 4 psi approximately (this is the first tick mark

on the gauge above the needle rest). Adjust P1

on proportional valve board to 4 psi. Use a

similar procedure to step 4) to reach a

consistent value on the gauge. This will result

in a minimum opening of the valve at low

settings.

7. Check the gauge pressure for Secondary

Shield set at 50 on the screen. This should be

approximately 14 psi on the plumbing box

gauge (adjust P2 to obtain 14-16 psi ).

8. Lower the inlet gas regulator to 60 psi with the

screen value set to 100. This should result in a

gauge pressure of approximately 22 psi. This

will insure the SDP files generated since

January 2000 will be consistent in the field.

6-14

SmartFlow 2.5

SECTION 7 REPLACEMENT PARTS

7.1 General

Always provide the serial number of the unit on

which the parts will be used. The serial number is

stamped on the unit nameplate.

7.2 Ordering

To ensure proper operation, it is recommended

that only genuine ESAB parts and products be

used with this equipment. The use of non-ESAB

parts may void your warranty.

Replacement parts may be ordered from your

ESAB Distributor or from:

ESAB Welding and Cutting Products

ATTN: Customer Service Department

PO Box 100545 Ebenezer Road

Florence, SC USA 29501-0545

Phone (843) 664-4405

(800) ESAB-123 (372-3123)

ESAB Cutting Systems - Canada

6010 Tomken Road

Mississauga, Ontario, Canada L5T 1X9

Phone (905) 670-0220

Fax (905) 670-4879

ESAB Cutting Systems GmbH

Robert-Bosch-Strasse 20

Postfach 1128

D-61184 Karben

Phone 011-49-6039-400

Fax 011-49-6039-403-02

http://www.esab.de

Be sure to indicate any special shipping

instructions when ordering replacement parts.

Refer to the Communications Guide located on

the last page of this manual for a list of customer

service phone numbers.

SmartFlow 2.5

7-1

SECTION 7 REPLACEMENT PARTS

7.3 Inside Right View – Smartflow 2.5 (w/o H-35 capability)

PN 0560935257 Replacement Parts (DISCONTINUED)

7-2

SmartFlow 2.5

SECTION 7 REPLACEMENT PARTS

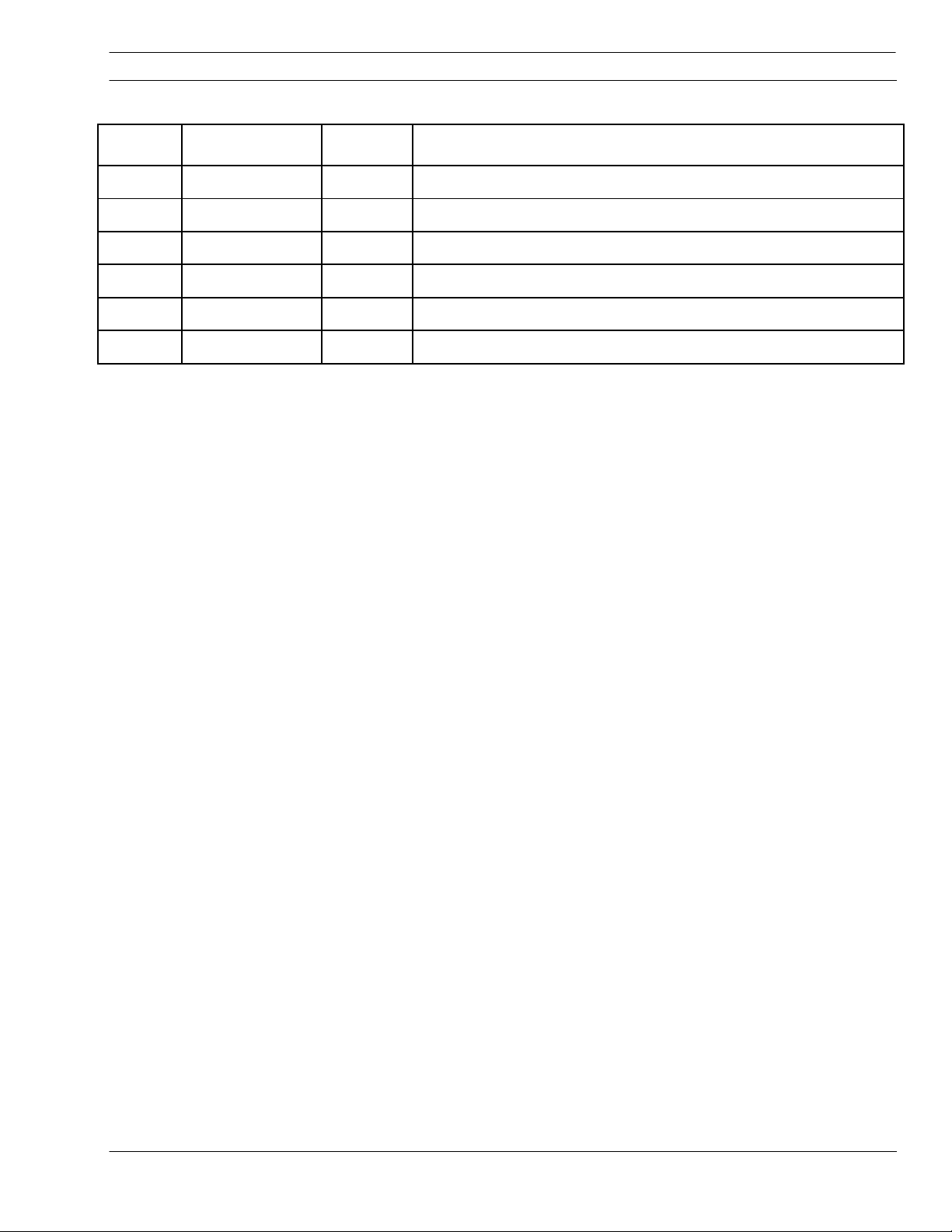

SmartFlow 2.5 (without H-35 Capability) – Assembly P/N 0560935257 (DISCONTINUED)

Item

Number

1 0558001056 1 Manifold Assembly without H-35 proportional valve

2 0558001068 2 Valve Sentronic 0-6 bar Manifold Mount (Oxygen)

0558001282 4 O-Ring…Proportional valve 5mm ID X 1mm

0558001283 2 O-Ring…Proportional valve 4mm ID X 1mm

3 0558001066 5 Valve solenoid, 2 way series 2, 120vac 150 mopd 1/8 orifice

4 952920 2 Pressure Switch 50 psi non-adj

5 0558001064 1 Hose ¼ NPT M X ¼ NPT F X Swivel Ball 13.5" long

6 0558001063 1 Hose ¼ NPT M X ¼ NPT F X 10.75" long

7 0558001062 1 Hose ¼ NPT M X ¼ NPT F X 6" long

8 56998261 1 Valve Proportional Water Pulse Width Modulator

56997044 1 Valve Proportional Water 24VDC

9 0558001067 1 Hose ¼ NPT M X ¼ NPT F X 13.5" long

10 37538 1 Smartflow II Plumbing Box Assembly

Part Number Quantity Description

SmartFlow 2.5

7-3

SECTION 7 REPLACEMENT PARTS

7.4 Inside Right View – Smartflow 2.5 (w/ H-35 capability)

PN 0560935258 Replacement Parts

7-4

SmartFlow 2.5

SECTION 7 REPLACEMENT PARTS

SmartFlow 2.5 (with H-35 Capability) – Assembly P/N 0560935258

Item

Number

1 0558001061 1 Manifold Assembly with H-35 proportional valve

2 0558001065 1 Valve Sentronic 0-6 bar Manifold Mount (Fuel Gas Rated)

0558001282 2 O-Ring…Proportional valve 5mm ID X 1mm

0558001283 1 O-Ring…Proportional valve 4mm ID X 1mm

3 0558001066 6 Valve solenoid, 2 way series 2, 120vac 150 mopd 1/8 orifice

4 952920 3 Pressure Switch 50 psi non-adj

5 0558001064 1 Hose ¼ NPT M X ¼ NPT F X Swivel Ball 13.5" long

6 0558001063 1 Hose ¼ NPT M X ¼ NPT F X 10.75" long

7 0558001062 1 Hose ¼ NPT M X ¼ NPT F X 6" long

8 56998261 1 Valve Proportional Water Pulse Width Modulator

56997044 1 Valve Proportional Water 24VDC

Part Number Quantity Description

9 0558001067 1 Hose ¼ NPT M X ¼ NPT F X 13.5" long

10 37538 1 SmartFlow II Plumbing Box Assembly

11 0558001068 1 Valve Sentronic 0-6 bar Manifold Mount (Oxygen)

0558001282 2 O-Ring…Proportional valve 5mm ID X 1mm

0558001283 1 O-Ring…Proportional valve 4mm ID X 1mm

SmartFlow 2.5

7-5

SECTION 7 REPLACEMENT PARTS

7.5 Outside Front View – SmartFlow 2.5 Replacement Parts

1

AIR CURTAIN

60

2

CUT GAS

To Pilot Arc

Start Box

100

CUT WATER

100

AIR CURTAIN

CUT GAS

CUT WATER

7-6

6

5

4

3

SmartFlow 2.5

SECTION 7 REPLACEMENT PARTS

Item

Number

1 0558001060 1 Pressure Gauge 2½" 60 psi

2 0558001059 2 Pressure Gauge 2½" 100 psi

3 0558001054 1 Label Set

4 33053 1 Strain Relief 2" Torch

5 0558001057 1 Knurled Nut-Fiber Optic Cable Holder