ESAB PT-20AMX Plasmarc Cutting Torch and PT-21AMX Plasmarc Cutting Torch Installation manual / Instruction manual

December 2006

Installation, Operation and Maintenance

PT-20AMX Plasmarc Cutting Torch

and

PT-21AMX Plasmarc Cutting Torch

F15-778

The equipment described in this manual is

potentially hazardous. Use caution when installing,

operating and maintaining this equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold be ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liability.

ESAB Cutting Systems first priority is total

customer satisfaction. We constantly look for

ways to improve our products, service and

documentation. As a result, we make

enhancements and/or design changes as

required. ESAB makes every possible effort to

ensure our documentation is current. We

cannot guarantee that each piece of

documentation received by our customers

reflects the latest design enhancements.

Therefore, the information contained in this

document is subject to change without notice.

This manual is ESAB Part Number

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

F15-778

Printed in U.S.A.

© ESAB Cutting Systems, 2002

Table of Contents

Page

Safety

Introduction ........................................................................................... 1

Safety Notations And Symbols ................................................................ 2

General Safety Information ...................................................................... 3

Installation Precautions............................................................................ 3

Electrical Grounding................................................................................ 5

Operating A Plasma Cutting Machine ...................................................... 5

Service Precautions ................................................................................ 9

Safety References................................................................................... 10, 11, 12

I. Description Introduction .....................................................................

II. Accessories.......................................................................................... 14

III. Installing Front End Parts.................................................................. 16

IV. Operation – Cutting Parameters....................................................... 20

V. Maintenance........................................................................................ 21

A. General.............................................................................................

B. Dirt or Contamination........................................................................

C. Loose Consumables.........................................................................

D. Damage Caused By Loose Parts and Torch Over Heating...............

E. Consumables – Removal and Replacement.....................................

F. Measuring Torch Gas Flows.............................................................

G. Removal and Replacement of Torch Body.......................................

PT-20AMX Torch...............................................................................

PT-21AMX Torch...............................................................................

H. Removal and Replacement of Torch Cables.....................................

13

21

22

22

23

23

25

26

26

27

28

VI. Replacement Parts............................................................................ 30

PT-20AMX 4ft, 17ft, and 25 ft.................................................................

PT-20AMX 50 ft. Wire Mesh Shielded....................................................

PT-21AMX Torches................................................................................

i

30,31

32,32

34,35

Table of Contents

ii

PT-20/21 AMX Plasmarc Torches

Safety Introduction

The process of cutting metals with plasma

equipment provides industry with a valuable and

versatile tool. ESAB cutting machines are

designed to provide both operation safety and

efficiency. However, as with any machine tool,

sensible attention to operating procedures,

precautions, and safe practices is necessary to

achieve a full measure of usefulness. Whether an

individual is involved with operation, servicing, or

as an observer, compliance with established

precautions and safe practices must be

accomplished. Failure to observe certain

precautions could result in serious personnel injury

or severe equipment damage. The following

precautions are general guidelines applicable when

working with cutting machines. More explicit

precautions pertaining to the basic machine and

accessories are found in the instruction literature.

For a wide scope of safety information on the field

of cutting and welding apparatus, obtain and read

the publications listed in the Recommended

References.

1

PT-20/21 AMX Plasmarc Torches

Safety Notations And Symbols

!

DANGER

!

WARNING

!

The following words and symbols are used

throughout this manual. They indicate different

levels of required safety involvement.

ALERT or ATTENTION. Your safety is

involved or potential equipment failure exists.

Used with other symbols and information.

Used to call attention to immediate hazards

which, if not avoided, will result in serious

personal injury o r lo ss o f life.

Used to call attention to potential hazards that

could result in personal injury or loss of life.

CAUTION

!

CAUTION

NOTICE

Used to call attention to hazards that could

result in minor personal injury or equipment

damage.

Used to call attention to minor hazards to

equipment.

Used to call attention to important

installation, operation or maintenance

information not directly related to safety

hazards.

2

PT-20/21 AMX Plasmarc Torches

General Safety Information

Machinery often starts automatically.

WARNING

!

WARNING

!

This equipment moves in various directions and

speeds.

· Moving machinery can crush.

· Only qualified personnel should operate or

service this power source.

· Keep all personnel, materials, and equipment

not involved in production process clear of

entire system area.

· Fence off entire work cell to prevent personnel

from passing through area or standing in the

working envelope of the equipment.

· Post appropriate WARNING signs at every

work cell entrance.

· Follow lockout procedure before servicing any

equipment.

Failure to follow operating instructions

could result in death or serious injury.

Read and understand this operator’s manual

before using machine.

· Read entire procedure before operating or

performing any system maintenance.

· Special attention must be given to all hazard

warnings that provide essential information

regarding personnel safety and/or possible

equipment damage.

· All safety precautions relevant to electrical

equipment and process operations must be

strictly observed by all having system

responsibility or access.

· Read all safety publications made available by

your company.

3

PT-20/21 AMX Plasmarc Torches

WARNING

!

Installation Precautions

Failure to follow safety warning label

instructions could result in death or

serious injury.

Read and understand all safety warning labels on

machine.

Refer to operator’s manual for additional safety

information.

DANGER

!

Improperly Installed Equipment Can

Cause Injury Or Death.

Follow these guidelines while installing machine:

· Contact your ESAB representative before

installation. He can suggest certain

precautions regarding piping installation and

machine lifting, etc. to ensure maximum

security.

· Never attempt any machine modifications or

apparatus additions without first consulting a

qualified ESAB representative.

· Observe machine clearance requirements for

proper operation and personnel safety.

· Always have qualified personnel perform

installation, troubleshooting and maintenance

of this equipment.

· Provide a wall mounted disconnect switch with

proper fuse sizes close to the power supply.

4

PT-20/21 AMX Plasmarc Torches

Electrical Grounding

Electrical grounding is imperative for proper

machine operation and SAFETY. Refer to this

manual’s Installation section for detailed grounding

instructions.

Electric shock hazard.

WARNING

!

Operating A Plasma Cutting Machine

Improper grounding can cause severe injury or

death.

Machine must be properly grounded before put

into service.

Flying debris and loud noise

WARNING

!

hazards.

· Hot spatter can burn and injure eyes. Wear

goggles to protect eyes from burns and flying

debris generated during operation.

· Chipped slag may be hot and fly far.

Bystanders should also wear goggles and

safety glasses.

· Noise from plasma arc can damage hearing.

Wear correct ear protection when cutting

above water.

Burn hazard.

WARNING

!

Hot metal can burn.

· Do not touch metal plate or parts immediately

after cutting. Allow metal time to cool, or douse

with water.

· Do not touch plasma torch immediately after

cutting. Allow torch time to cool.

5

PT-20/21 AMX Plasmarc Torches

DANGER

!

Hazardous voltages. Electric shock

can kill.

· Do NOT touch plasma torch, cutting table or

cable connections during plasma cutting process.

· Always turn power off to plasma power

supplies before touching or servicing plasma torch.

· Always turn power off to plasma power

supplies before servicing any system component.

· Do not touch live electrical parts.

· Keep all panels and covers in place when

machine is connected to power source.

· Wear insulating gloves, shoes and clothing to

insulate yourself from workpiece and electrical

ground.

· Keep gloves, shoes, clothing, work area, and

equipment dry.

· Replace worn or damaged cables.

Fume hazard.

WARNING

!

Fumes and gases generated by the plasma cutting

process can be hazardous to your health.

· Do NOT breathe fumes.

· Do not operate plasma torch without fume

removal system operating properly.

· Use additional ventilation to remove fumes if

necessary.

· Use approved respirator if ventilation is not

adequate.

· Provide positive mechanical ventilation when

cutting galvanized steel, stainless steel, copper,

zinc, beryllium, or cadmium. Do not breathe these

fumes.

·

operations. Heat or arc rays can react with

chlorinated hydrocarbon vapors to form phosgene,

a highly toxic gas and other irritant gases.

Do not operate near degreasing and spraying

6

PT-20/21 AMX Plasmarc Torches

WARNING

!

Radiation hazard.

Arc rays can injure eyes and burn skin.

· Wear correct eye and body protection.

· Wear dark safety glasses or goggles with side

shields. Refer to following chart for recommended

lens shades for plasma cutting:

Arc Current Lens Shade

Up to 100 Amps Shade No. 8

100-200 Amps Shade No. 10

200-400 Amps Shade No. 12

Over 400 Amps Shade No. 14

· Replace glasses/goggles when lenses are

pitted or broken

· Warn others in area not to look directly at the

arc unless wearing appropriate safety glasses.

· Prepare cutting area to reduce reflection and

transmission of ultraviolet light.

§ Use special paint on walls to absorb UV

light.

§ Install protective screens or curtains to

reduce ultraviolet transmission.

7

PT-20/21 AMX Plasmarc Torches

WARNING

!

Burn Hazard.

Heat, spatter, and sparks cause fire and burns.

· Do not cut near combustible material.

· Do not have on your person any combustibles

(e.g. butane lighter).

· Pilot arc can cause burns. Keep torch nozzle

away from yourself and others when activating

plasma process.

· Wear correct eye and body protection.

· Wear gauntlet gloves, safety shoes and hat.

· Wear flame-retardant clothing covering all

exposed areas.

· Wear cuffless trousers to prevent entry of

sparks and slag.

· Have fire extinguishing equipment available for

use.

Explosion hazard.

WARNING

!

· Certain molten aluminum-lithium (Al-Li) alloys

can cause explosions when plasma cut OVER

water.

§ These alloys should only be dry cut on a

dry table.

§ DO NOT dry cut over water.

§ Contact your aluminum supplier for

additional safety information regarding

hazards associated with these alloys

Do not cut in atmospheres containing

·

explosive dust or vapors.

·

Do not carry any combustibles on your person

(e.g. butane lighter)

· Do not cut containers that have held

combustibles.

.

8

PT-20/21 AMX Plasmarc Torches

Service Precautions

DANGER

!

Hazardous voltages. Electric shock

can kill.

· Do NOT touch plasma torch, cutting table or

cable connections during plasma cutting process.

· Always turn power off to plasma power

supplies before touching or servicing plasma torch.

· Always turn power off to plasma power

supplies before removing covers or panels to

service any system component.

· Do not touch live electrical parts.

· Keep all panels and covers in place when

machine is connected to power source.

· Keep gloves, shoes, clothing, work area, and

equipment dry.

· Inspect power and ground leads cables for

wear or cracking. Replace worn or damaged

cables. Do not use if damaged.

· Never bypass safety interlocks.

· Follow lock-out procedures.

Establish and adhere to preventive maintenance.

CAUTION

CAUTION

!

A composite program can be established from

recommended schedules.

Avoid leaving test equipment or hand tools on

machine. Severe electrical or mechanical damage

could occur to equipment or machine.

Extreme caution should be used when probing

circuitry with an oscilloscope or voltmeter.

Integrated circuits are susceptible to over voltage

damage. Power off before using test probes to

prevent accidental shorting of components.

All circuit boards securely seated in sockets, all

cables properly connected, all cabinets closed and

locked, all guards and covers replaced before

power is turned on.

9

PT-20/21 AMX Plasmarc Torches

Safety References -- Regulations, Standards, Guidelines

USA

The following recognized publications on safety in welding and cutting

operations are recommended. These publications have been prepared

to protect persons from injury or illness and to protect property from

damage, which could result from unsafe practices. Although some of

these publications are not related specifically to this type of industrial

cutting apparatus, the principles of safety apply equally.

· “Precautions and Safe Practices in Welding and Cutting with

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB Cutting

Systems.

· “Precautions and Safe Practices for Electric Welding and Cutting,”

Form 52-529. ESAB Cutting Systems.

· “Safety in Welding and Cutting” - ANSI Z 49.1, American Welding

Society, 2501 NW 7th Street, Miami, Florida, 33125.

· “Recommended Safe Practices for Shielded Gases for Welding and

Plasma Arc Cutting” - AWS C5.10-94, American Welding Society.

· “Recommended Practices for Plasma Arc Welding” - AWS C5.1,

American Welding Society.

· “Recommended Practices for Arc Cutting” - AWS C5.2, American

Welding Society.

· “Safe Practices” - AWS SP, American Welding Society.

· “Standard for Fire Protection in Use of Cutting and Welding

Procedures” - NFPA 51B, National Fire Protection Association, 60

Batterymarch Street, Boston, Massachusetts, 02110.

· “Standard for Installation and Operation of Oxygen - Fuel Gas

Systems for Welding and Cutting” - NFPA 51, National Fire

Protection Association.

· “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB Cutting

Systems. Obtainable through your ESAB representative or local

distributor.

· "Design and Installation of Oxygen Piping Systems," Form 5110.

ESAB Cutting Systems.

· “Precautions for Safe Handling of Compressed Gases in

Cylinders”, CGA Standard P-1, Compressed Gas Association.

Literature applicable to safe practices in welding and cutting with

gaseous materials is also available from the Compressed Gas

Association, Inc., 500 Fifth Ave., New York, NY 10036.

10

PT-20/21 AMX Plasmarc Torches

International

Accident Prevention

VBG 1 General Provisions

VDE Regulations

VBG 4 Electrical Equipment and operating

Equipment

VBG 15 Welding, Cutting and related working

methods

VBG 48 Shot Blasting Works

VBG 61 Gases

VBG 62 Oxygen

VBG 87 Operating liquid jet cutting machines

VBG 93 Laser beams, accident prevention and

Electro-technology

VBG 121 Noise

VDE 0100 Erection of power installations with normal

voltages up to 1000 volts

VDE0113 Electrical equipment of industrial machines

VDE 0837 Radiation safety of laser products; users

guide (DIN EN 60825)

VDE 0837-

Specification for laser guards

50

TRAC Technical Rules for Acetylene and Carbide Stores

TRAC-204 Acetylene lines

TRG Technical Rules for Pressure gases

TRAC-206 Acetylene cylinder battery systems

TRAC-207 Safety devices

TRG 100 General regulations for pressure gases

TRG 101 Pressure gases

TRG 102 Technical gas mixtures

TRG 104 Pressure gases; alterative use of

compressed gas tanks

11

PT-20/21 AMX Plasmarc Torches

DIN Standards

DIN 2310

DIN 2310

DIN 2310

DIN 2310

DIN 4844

DIN EN ISO Harmonized Standards

292/1 and 2

DIN EN 559 Hoses for welding, cutting and allied

DIN EN 560 Hose connections and hose couplings for

DIN EN 561 Gas welding equipment hose couplings

Part 1

Part 2

Part 4

Part 5

Part 1

DIN EN

Thermal cutting; terminology and

nomenclature

Thermal cutting; determination of quality of cut

faces

Thermal cutting; arc plasma cutting; process

principles, quality, dimensional tolerances

Thermal cutting; laser beam cutting of metallic

materials; process principles

Safety markings (DIN EN 7287)

Safety of machinery

processes

equipment for welding, cutting and allied

processes

VDI Guidelines

DIN EN

626-1

DIN EN

848-1

DIN EN

1829

DIN EN

9013

DIN EN

12584

DIN EN

12626

DIN EN

28206

DIN EN

31252

DIN EN

31553

DIN EN

60204-1

DIN EN

60825

DIN EN 999 Arrangement of protection devices

Safety of machines, reduction of risks to

health

Single spindle vertical milling machines

High pressure water jet machines

Thermal cutting, oxygen cutting, process

principles, dimensional tolerances

Imperfections in oxy/fuel flame cuts, laser

beam cuts and plasma

Laser processing machines

Acceptance testing for oxygen cutting

machines

Laser Equipment

Laser and laser related equipment

Electrical equipment of machines

Radiation safety of laser products

VDI 2906 Quality of cut faces on metallic workpieces;

abrasive water jet cutting and arc plasma

cutting

VDI 2084 Room air; Technical systems for welding

workshops

12

PT-20/21 AMX Plasmarc Torches

· The plasma arc cutting process employs

WARNING

!

I. Description Introduction

PT-20AMX

PT-20 AMX

Without Rack; 25 ft. 0558003426

With Rack; 25 ft. 0558003427

WARNING

!

Without Rack; 50 ft. 0558003422

With Rack; 50 ft. 0558003421

RAS; With Rack, 4 ft. 0558003424

RAS, With Rack, 17 ft. 0558003425

PT-21 AMX (for use with PowerCut 1250 and PowerCut 1500)

Without Rack; 50 ft. 0558003615

With Rack; 50 ft. 0558003614

Without Rack; 25 ft. 0558003617

With Rack; 25 ft. 0558003616

extremely high voltages. Avoid contact with

"live" parts of the torch and machine.

· The improper use of any of the gases

employed can present a safety hazard.

· Before beginning operation with the PT20AM torch, read and understand all safety

precautions covered in this instruction

manual.

This booklet covers mainly accessories,

maintenance, and parts information for the PT20AMX and PT-21AMX plasma torches. For

installation and operating instructions for your

cutting package, refer to your power source

instruction manual.

The patented PT-20AMX is a 100 amp capacity,

pilot-arc mechanized torch available in 6 different

versions. The torch uses clean, dry air as the cut

gas for cutting carbon steel, aluminum, or stainless

steel.

PT-21 AMX Torch is identical to the PT-20 AMX torch

except it is specifically designed to connect to the

PowerCut 1250 and 1500 plasma power sources.

DO NOT use oxygen with this torch!

A hazardous fire may result.

13

PT-20/21 AMX Plasmarc Torches

Dimensional Data – PT-20AMX

1.375 inches

Without Rack

7.63 inches

II. Accessories

14.5 inches

17.125 inches

With Rack

PT-20AMX Torch Spare Parts Kits - The following

three spare parts kits are available for maintaining

the PT-20AMX torch with minimum downtime.

50 Amps - 21370

70 Amps - 21369

100 Amps – 21376

PT-21 AMX torch uses the same spare parts as

the PT-20AMX.

Description

50 AMP 21370 70 AMP 21369 100 AMP 21376

Quantity

Heat Shield (70/100 A), 21326 - 2 2

Heat Shield (50 A), 21447 2 1 1

Cutting Nozzle (50 A), 21330 5 5 5

Cutting Nozzle (70 A), 21329 - 5 5

Cutting Nozzle (100 A), 21328 - - 5

Electrode, 21150 5 5 5

Electrode 50Hz, 0558001617 5** 5** 5**

Electrode Seat, 21372

1 1 1

Electrode Insulator, 21373 1 1 1

Electrode Holder Assy, 21332 1 1 1

Baffle Tube, 21374 1 1 1

Pilot Arc Adaptor, 19497 1 1 1

O-ring, 488157 5 5 5

Lubricant (1 oz.), 17672 1 1 1

Seat/Baffle Wrench, 21375 1 1 1

1/16: Hex-Key Wrench, 93750006 1 1 1

14

PT-20/21 AMX Plasmarc Torches

Torch Holder Assembly – 0558005926

Plasma Flow Measuring Kit -- 19765

Remote Hand Control Switch with 7,6m lead

For PT-20 AMX -- 680982

For PT-21 AMX -- 0558003612

Adaptor for PCM-875 and PCM-1125 -- 19500

15

PT-20/21 AMX Plasmarc Torches

III. Installing Front End Parts

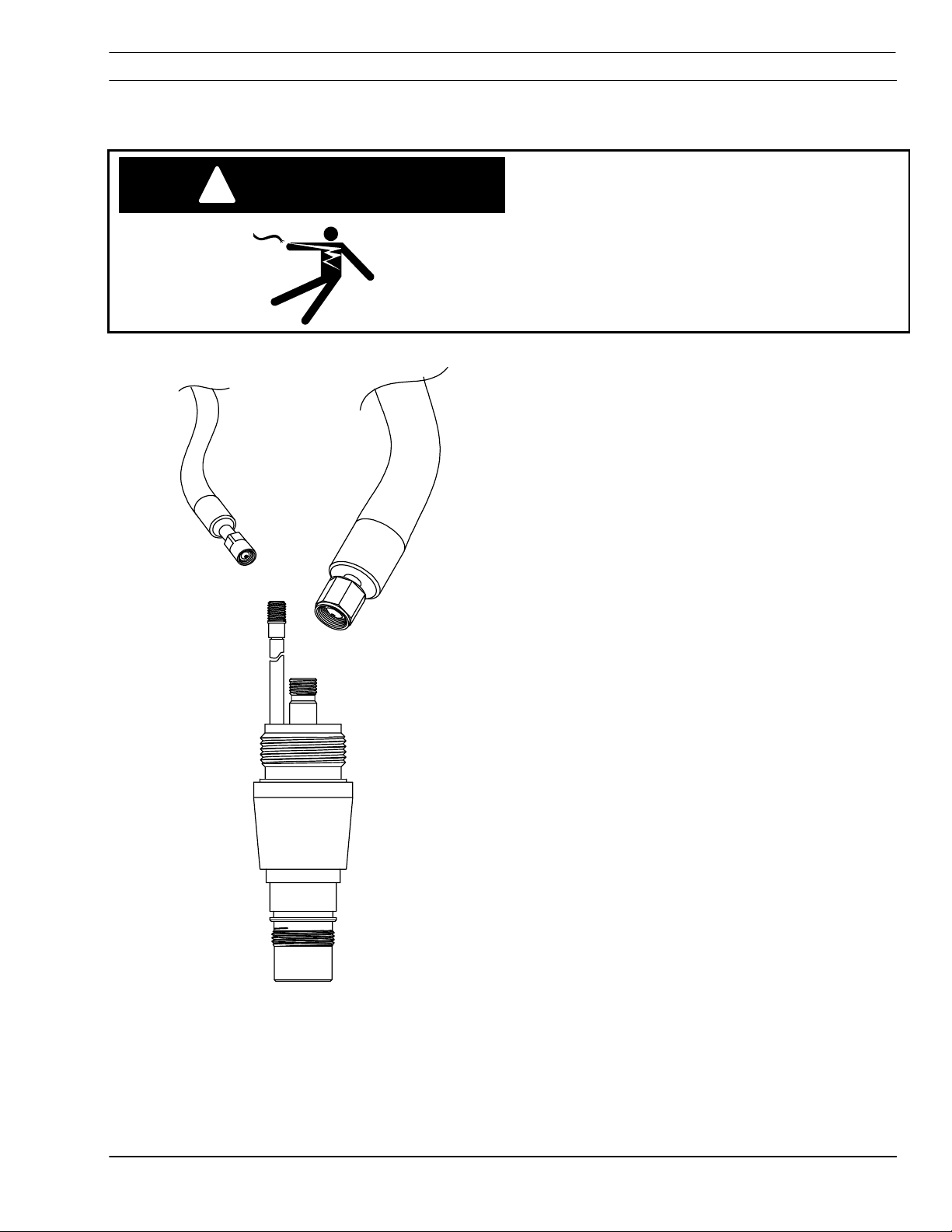

WARNING

!

Seat

Make sure power switch on console is in

OFF position and primary input power is

de-energized.

1. The seat comes assembled to the front end

of the torch. IF the seat becomes damaged, the

torch body must be replaced. DO NOT attempt

to remove the seat from torch body.

Electrode Holder Assembly

Wrench

21375

Baffle Tube

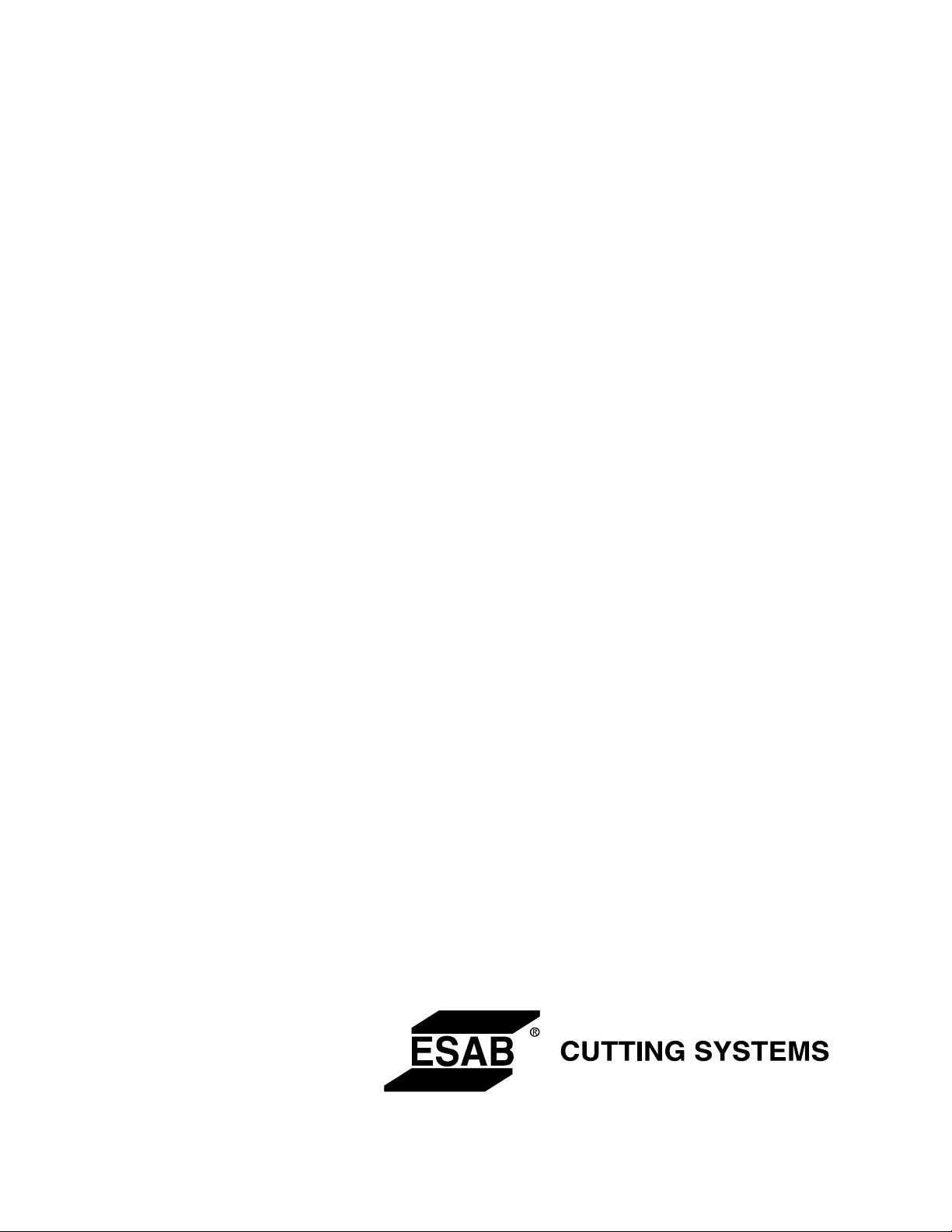

2. Electrode holder assembly (21332) includes

the baffle tube (21374). If baffle tube becomes

damaged, it can be replaced by un-threading the

damaged tube out of the holder. Use small hex

end of the wrench (21375) in hex broach on the

tube. Tighten tube securely but do not overtighten.

16

PT-20/21 AMX Plasmarc Torches

3. Install the electrode insulator (21373) onto

electrode holder assembly (21332) and then thread

electrode (21150) onto the electrode holder

assembly. Assemble electrode firmly by hand. Do

not use wrenches or pliers. These three parts

combined are the electrode assembly.

21332

21373

21150

4. Install nozzle onto the electrode assembly by

inserting small shoulder on electrode insulator into

nozzle’s rear opening. Place nozzle and electrode

assembly into the heat shield as shown in page 6.

If front end of the torch is facing down as normal in

a setup, the nozzle and electrode assembly can be

stacked in the heat shield and then assembled to

the torch. Be sure to use proper heat shield and

nozzle combination as noted in page 18.

O-ring (488157)

5. Apply a thin film of lubricant (17672) to O-ring

(488157).

17672

17

PT-20/21 AMX Plasmarc Torches

6.Tighten heat shield fully to hold the parts in firm

contact with each other and to the torch head.

“Fully” means at least 3/16 inch rotation after

electrode seat contacts electrode holder.

IMPORTANT: See Maintenance section.

CAUTION

!

Follow all instructions in the booklet

packed with your unit. DO NOT install or

attempt to operate this torch without

following these instructions.

To connect PT-20AMX torch to the console,

connect the power cable of the torch to the

‘‘NEG’’ terminal and pilot arc cable to the ‘‘POS’’

terminal of the unit using pilot arc adaptor (19497 supplied with spare parts kit). A separate remote

control switch cable is required for connecting to

the switch receptacle on the console.

The front end of the torch contains a gas flow

check valve that acts in conjunction with the

circuitry provided in the power supply. This

patented system provides a safety interlock

preventing the torch from being accidentally

energized with high voltage when the heat shield is

removed and the torch switch is accidentally

closed.

18

PT-20/21 AMX Plasmarc Torches

2

1

4

5

3

6

7

Front End Assembly

1 Wrench Seat/Baffle 21375

2 Baffle Tube 21374

3 Electrode 21150

Electrode 50Hz 0558001617

4 Electrode Insulator 21373

5 Electrode Holder Assembly 21332

6 Heat Shield (70 and 100 Amp – Blue) 21326

Heat Shield (50 Amp – White) 21447

7 Nozzle (100 Amp) 21328

Nozzle (70 Amp) 21329

Nozzle (50 Amp) 21330

8 O-Ring 488157

8

19

PT-20/21 AMX Plasmarc Torches

Cutting Parameters for the PT-20AMX Torch

100AMP Data, Nozzle P/N 21328, Heat Shield P/N 21 326

Travel Speed

Metal

Thickness

(in.) (mm) psig bar (in.) (mm) DC volts (sec.) ipm mm/m ipm mm/m ipm mm/m

0.25 6 85 6 0.25 6 110 0,1 100 2540 105 2667 80 2032

0.50 13 85 6 0.25 6 120 0,3 45 1143 50 1270 30 762

0.75 19 85 6 0.25 6 125 1,0 27 686 35 889 15 381

1.00 25 85 6 0.25 6 130 2,75 15 381 20 508 10 254

1.25 32 85 6 0.32 8 140 NR 10 254 13 330 7 178

1.50 38 85 6 0.32 8 145 NR 7 178 10 254 5 127

Metal

Thickness

(in.) (mm) psig bar (in.) (mm) DC volts (sec.) ipm mm/m ipm mm/m ipm mm/m

0.13 3 75 5 0.19 5 105 0,1 190 4826 180 4572 80 2032

0.25 6 75 5 0.19 5 110 0,2 80 2032 85 2159 55 1397

0.50 13 85 6 0.25 6 115 0,6 30 762 30 762 20 508

0.75 19 85 6 0.25 6 130 2,3 15 381 25 635 8 203

1.00 25 85 6 0.32 8 140 NR 7 178 12 305 6 152

1.25 32 85 6 0.32 8 155 NR 5 127 10 254 3 76

Metal

Thickness

(in.) (mm) psig bar (in.) (mm) DC volts Amps ipm mm/m ipm mm/m ipm mm/m

0.06 2 75 5 0.13 3 110 40 150 3810 150 3810 130 3302

0.13 3 75 5 0.13 3 110 40 100 2540 105 2667 75 1905

0.19 5 85 6 0.13 3 110 50 100 2540 90 2286 50 1270

0.25 6 85 6 0.19 5 120 50 65 1651 75 1905 30 762

0.38 10 85 6 0.25 6 130 50 40 1016 30 762 8 203

0.50 13 85 6 0.32 8 150 50 18 457 8 203 6 152

“NR” indicates piercing is not recommended

Air

Pressure

Air

Pressure

Air

Pressure

Stand-Off Arc

Voltage

70AMP Data, Nozzle P/N 21329, Heat Shield P/N 21326

Stand-Off Arc

Voltage

50AMP Data, Nozzle P/N 21330, Heat Shield P/N 21447

Stand-Off Arc

Voltage

Pierce

Time

Pierce

Time

Arc

Current

Mild Steel Aluminum Stainless

Mild Steel Aluminum Stainless

Mild Steel Aluminum Stainless

20

PT-20/21 AMX Plasmarc Torches

IV. Maintenance

WARNING

!

A. General

Before any maintenance is attempted on

this torch, make sure the POWER SWITCH

on the console is in the OFF position and

the PRIMARY INPUT POWER is

DEENERGIZED.

1. The gas flow check valve is part of the safety

interlock and is permanently assembled in the

torch head. The head must be replaced if this valve

malfunctions.

2. Periodically check heat shield, electrode holder

assembly, electrode nozzle seat, and electrode

insulator. Replace if worn or damaged.

3. Apply a thin film of lubricant 17672 (supplied in

spare parts kit) to O-ring. Check O-ring for damage

whenever shield is removed. Replace if necessary.

4. Power and pilot arc cables should be inspected

periodically. If cuts through protective sheath or if

gas leaks are noted, replace damaged component.

21

PT-20/21 AMX Plasmarc Torches

B. Dirt or Contamination

Dirt or other contamination in the torch and loose

consumable parts can cause premature failure of

the PT-20AM Torch through internal arcing. To

avoid this, users are instructed to do the following:

1. Ensure that clean, dry, or oil-free air is being

used.

2. Avoid excessive use of the silicone o-ring

grease used to lubricate the torch o-ring. A thin

film is sufficient.

3. Wipe the torch body insulator clean with a

cloth before installing each fresh set of

consumables. The ability of the insulator to resist

arc tracking over its surface is reduced when dirt

or other contamination is allowed to collect there.

C. Loose Consumables

Tests have shown that with proper use of the torch

within rated operating conditions (especially arc

current and gas flow rate), the torch consumable

parts do not become loose if they are firmly

installed in the first place.

1. Tighten heat shield fully at each consumable

change or inspection. “Fully” means at least 5

mm of rotation after electrode seat contacts

electrode holder.

2. Check consumable tightness at beginning of

each work shift, even if everything was working

normally at the end of the previous shift.

3. Ensure that the torch electrode seat and

electrode holder are clean and free of dust or dirt

Debris may prevent mating surfaces from having

solid contact.

22

PT-20/21 AMX Plasmarc Torches

The torch requires good electrical contact

CAUTION

D. Damage Caused by Loose Parts and Torch Overheating.

between the electrode seat and electrode

holder. If good contact is not maintained,

then the resulting potential difference

causes internal arcing and possible torch

damage.

Electrode Insulator (21373)

Deformation at this edge indicates

torch overheating. Check gas

pressure, gas flowrate and current

setting. Deformation leads to loose

parts and internal arcing. Do not

operate torch with a deformed

insulator.

E. Consumables- Remove and Replace

1. Bring torch to a position where it is easily

Arc tracking indicates loose parts. Make sure heat

shield is tightened fully, at least 5mm of rotation

after electrode seat contacts electrode holder.

Check tightness again after a few minutes of use.

Parts damaged by arcing will cause destruction of

torch. Parts damaged by arcing must be replaced.

accessed by machine operator, in its normal

vertical position and at least 6 inches above the

workpiece or the edge of the water table.

Make sure that the power source has been

WARNING

!

turned off and that the power cable has

been unplugged at the wall receptacle

before proceeding.

2. Unscrew the heat shield and lower it away

from the torch, allowing nozzle and electrode

assembly to remain with shield.

23

PT-20/21 AMX Plasmarc Torches

3. Remove the nozzle and electrode assembly

from the shield and inspect for wear. The nozzle

orifice should be round at both the entrance and

the exit. If the nozzle orifice is worn in an oval

shape or shows other signs of damage at either

end, it should be replaced. The inside of the nozzle

may have light gray deposits from the electrode.

These may be removed with steel wool but care

must be taken to remove all traces of the steel

wool afterward.

1,5 mm

If the electrode has a pit which is more than

1.5mm deep at its center, replace it. This is done

by unscrewing the electrode from the electrode

holder. Grasp the electrode holder with the fingers

using the two flats and grasp the electrode

between the thumb and finger of the other hand

and twist.

Inspect electrode insulator and electrode holder

assembly for signs of damage such as arc tracking

or cracking and replace them if any are found.

Insure that the baffle tube is securely threaded into

the electrode holder, but do not overtighten. Use

the small hex end of the plastic wrench in the

spare parts kit.

After installing the electrode insulator onto the

electrode holder assembly, install electrode by

reversing the procedure used to remove it. Note

that firm tightening of the electrode by hand is

sufficient, the use of tools such as wrenches or

pliers is not required or recommended.

4. Inspect heat shield for signs of damage or

wear. The gas holes inside shield should not be

blocked by debris, and there should be no signs of

arcing anywhere inside the shield. The outer

insulating jacket of the shield should not be

severely charred or eroded. Replace the heat

shield if any of the above damage is found.

.

24

PT-20/21 AMX Plasmarc Torches

Inspect o-ring of torch

6. Install the nozzle and the electrode assembly

F. Measuring Torch Gas Flows

5. Inspect the o-ring on the torch. If it shows

signs of wear or damage, replace it. If it is dry,

lubricate it with a thin film of lubricant supplied with

spare parts kit

into heat shield and thread heat shield onto torch.

The shield should be tightened fully to insure good

electrical contact for electrode and nozzle. "Fully"

means at least 3/16 inch of rotation after electrode

seat contacts electrode holder.

If low gas flow is suspected of causing poor cutting

performance or short consumable life, the flow can

be checked by using Plasma Torch Flow

Measuring Kit (19765). The kit includes a hand

held rotameter (flowmeter) which will indicate the

gas flow rate exiting the torch. The kit also includes

a set of instructions which should be followed

exactly to insure safe and accurate use of the

rotameter.

Total air flow rate in the PT-20AMX should be

325cfh minimum with any nozzle at 75 psi.

Flow Measuring Kit -- P/N 19765

25

PT-20/21 AMX Plasmarc Torches

G. Removal and Replacement of the Torch Body

Make sure that the power source has been

WARNING

!

turned off and that the power cable has

been unplugged at the wall receptacle

before proceeding.

PT-20AMX Torch

1. Cut and remove the shrink wrap at the back

end of the torch handle. Unscrew the handle from

the torch body and slide it back onto the torch

cable assembly in order to expose the torch

connections.

2. Remove the electrical tape which secures the

short piece of vinyl tubing on the pilot arc cable.

Slide the tubing away from the torch and onto the

pilot arc cable to expose the pilot arc connector.

3. Use the 1/16" Allen Wrench supplied in the

spare parts kit to loosen the pilot arc connector set

screw closest to the torch body, being careful not

to totally remove the screw. Slip the torch’s pilot arc

lead out of the connector.

4. Unscrew the power cable fitting from the

torch’s power lead using a 7/16" open-end wrench

and remove the torch body.

5. Connect the pilot arc cable and the power

cable to the new torch body’s pilot arc lead and

power lead by reversing the steps taken to

disconnect them. Tighten the pilot arc connector

set screw fitting firmly but do not overtighten.

Torque the power fitting to 20 lb. in..

26

6. Slide the vinyl tubing forward to cover the pilot

arc connector and secure in place with electrical

tape.

7. Slide the handle forward and thread it firmly

onto the torch body.

8. Slide the new piece of shrink tube over the

torch handle and shrink in place over the handle’s

end and the cable sheath.

PT-20/21 AMX Plasmarc Torches

PT-21AMX Torch body Removal and Replacement

Make sure that the power source has been

WARNING

!

turned off and that the power cable has

been unplugged at the wall receptacle

before proceeding.

1. Remove shrink wrap or electrical tape from lead

2. Remove lock ring and slide up on torch lead.

3. Holding torch body steady, unscrew handle

end of torch handle (if any).

from torch body and slide back onto the

braided shield cable assembly to expose torch

connections.

4. Unscrew the power cable fitting from the torch

power lead connector using a 7/16” open end

wrench.

5. Unscrew Pilot arc connector using a ¼”

wrench.

6. Remove torch body and reverse procedure.

Note: Tighten handle on torch body hand tight.

Note: Tighten lock ring on handle with pliers.

27

PT-20/21 AMX Plasmarc Torches

H. Removal and Replacement of the Torch Cables

Make sure that the power source has been

WARNING

!

turned off and that the power cable has

been unplugged at the wall receptacle

before proceeding.

ESAB Welding &

PT-20AMX

1. Disconnect the torch cable assembly from the

power source. Refer to your power source

instruction booklet for detailed instructions.

2. Remove the torch body and handle from the

cable assembly as described in the previous

section.

3. Lay the cable assembly on the floor and

stretch it out completely. This should be done in an

area that is approximately 1-1/2 times as long as

the cable assembly.

4. Using a piece of cord or sturdy twine about

1/2 the length of the torch cables, secure one end

of the cord around the cables at the torch end and

secure the other end of the cord to a stationary

object.

5. Remove the tape securing the cable sheath

to the cables at both ends.

6. Secure the torch cables at the power source

end and pull the sheath completely off the cables

and onto the cord used in step 4.

28

7. Untie the cord from the cables and replace

the damaged cable or cables. Be sure to retain the

vinyl tube used to insulate the pilot arc connector.

PT-20/21 AMX Plasmarc Torches

8. Resecure the torch ends of the cables with

the cord, and pull the cable sheath back off of the

cord and onto the cables.

9. Untie the cord from the cables and

temporarily secure the torch body to the cable

connections.

10. Secure the sheath to the cables using

electrical tape at both ends.

11. Remove the torch body (temporarily installed

in step 9) from the cables and slide the handle over

the cables and cable sheath. Install the vinyl tube

over the pilot arc cable.

12. Reconnect the torch body to the cables as

described in the previous section and reinstall the

torch handle onto the torch body.

13. Reconnect the torch cables to the power

source.

29

PT-20/21 AMX Plasmarc Torches

V. Replacement Parts – PT-20AMX Torches 4ft. – 17 ft. – 25 ft.

(0558003424, 0558003425, 0558003426, 0558003427)

1

4

5

10

6

1

7

8

9

15

30

11

13

12

14

PT-20/21 AMX Plasmarc Torches

.

PT-20 AMX Plasma Torch with Coaxial Pilot Arc Cable

With 4 ft. torch leads, without handle rack P/N 0558003424

With 17 ft. torch leads, without handle rack P/N 0558003425

With 25 ft. torch leads, without handle rack P/N 0558003426

With 25 ft. torch leads, with handle rack P/N 0558003427

Ref. Description...................................................................................................

1 Torch Lead Assembly – 4 ft. ...............................................................

Torch Lead Assembly – 17 ft. .............................................................

Torch Lead Assembly – 25 ft. .............................................................

4 Lock Ring .......................................................................................... 57N70

5 Rubber Boot ...................................................................................... 0558001157

6 Wrap with electrical tape as shown.............................................................. Reference

7 H.F. Connector .................................................................................. 17974

8 Set screw 6-32 X 3/16 ................................................................................Reference

9 Insulate with vinyl tubing and secure with electrical tape............................... Reference

Handle and sleeve without rack .......................................................... 22329

10

Handle and sleeve with rack............................................................... 0558003419

Part Number

0558002638

0558002639

0558003383

11 Handle........................................................................................................Reference

12 Basic Torch Body Assembly............................................................... 21359

13 O-ring supplied with torch body.......................................................... 5W92

14 O-ring supplied with torch body.......................................................... 488157

15 Shield Shroud – 25 ft.......................................................................... 72020003

16 Lubricant ........................................................................................... 17672

31

PT-20/21 AMX Plasmarc Torches

PT-20 AMX Plasmarc Torches 50 ft. (0558003422, 0558003421)

15

16

5

4

6

ESAB Welding &

PT-20AMX

9

8

7

3

1

2

10

11

13

12

14

32

PT-20/21 AMX Plasmarc Torches

.

PT-20 AMX Plasma Torch -- wire mesh shielded

With 50 ft. torch leads, without handle rack P/N 0558003422

With 50 ft. torch leads, with handle rack P/N 0558003421

Ref. Description...................................................................................................

1 Pilot Arc Cable Assy. – 50 ft. ............................................................. 948163

2 .875-14 L.H. ...............................................................................................Reference

3 Power Cable Assembly – 50 ft............................................................ 20621

4 Lock Ring .......................................................................................... 57N70

5 Sheath – 50 ft. ................................................................................... 995829

6 Wrap with electrical tape as shown.............................................................. Reference

7 H.F. Connector .................................................................................. 17974

8 Set screw 6-32 X 3/16 ................................................................................Reference

9 Insulate with vinyl tubing and secure with electrical tape............................... Reference

Handle and sleeve without rack .......................................................... 22329

10

Handle and sleeve with rack............................................................... 0558003419

Part Number

11 Handle........................................................................................................Reference

12 Basic Torch Body Assembly............................................................... 21359

13 O-ring supplied with torch body.......................................................... 5W92

14 O-ring supplied with torch body.......................................................... 488157

15 Shield Shroud – 25 ft.......................................................................... 72020003

16 Lubricant ........................................................................................... 17672

33

PT-20/21 AMX Plasmarc Torches

PT-21 AMX Plasmarc Torches 25 ft.and 50 ft.(0558003614, 0558003615, 0558003616, 0558003617)

4

5

6

8

14

15

9

6

10

1

3

7

12

11

2

13

34

PT-20/21 AMX Plasmarc Torches

.

PT-21 AMX Torch Used with PowerCut 1250 and PowerCut 1500 Power Sources

With 25 ft. m torch leads, without handle rack P/N 0558003617

With 25 ft torch leads, with handle rack P/N 0558003616

With 50 ft. torch leads, without handle rack P/N 0558003615

With 50 ft. torch leads, with handle rack P/N 0558003614

Ref. Description...................................................................................................

Pilot Arc Cable Assy. – 25 ft. ............................................................. 0558003609

1

Pilot Arc Cable Assy. – 50 ft. ............................................................. 0558003610

2 0,375 – 14 L.H. A/I-G.................................................................................. Reference

Power Cable Assembly – 25 ft............................................................ 0558003606

3

Power Cable Assembly – 50 ft............................................................ 0558003607

4 Lock Ring .......................................................................................... 57N70

5 Sheath – 25 ft./ 50 ft. ......................................................................... 72020003

6 Wrap with electrical tape as shown.............................................................. Reference

7 Shield Ground............................................................................................. Reference

8 Handle........................................................................................................Reference

Part Number

9 Insulate with vinyl tubing and secure with electrical tape............................... Reference

Handle and sleeve without rack .......................................................... 22329

10

Handle and sleeve with rack............................................................... 0558003419

11 Basic Torch Assembly – PT-21........................................................... 0558003611

12 O-ring supplied with torch body.......................................................... 5W92

13 O-ring supplied with torch body.......................................................... 488157

Shield Shroud – 25 ft.......................................................................... 995832

14

Shield Shroud – 50 ft.......................................................................... 995826

15 Lubricant ........................................................................................... 17672

35

Customer // Technical Support

(843) 664-4405

(800) ESAB-123 (372-2123)

ESAB Welding and Cutting Products

PO BOX 100545 Ebenezer Road

Florence, SC 29501-0545

http://www.esab.com

ESAB Cutting Systems – Canada

6010 Tomken Road

Mississauga, Ontario Canada L5T 1X9

Phone: (905) 670-0220

Fax: (905) 670-4879

ESAB-Hancock GmbH

Cutting Technologies

P.O Box 1128

D-61174 Karben

Robert-Bosch-Strasse 20

D-61184 Karben

Phone + 49 60 39 40-0

Fax + 49 60 39 40 301_302

http://www.esab.com

esab_info@compuserve.com

Printed in U.S.A

Loading...

Loading...