A21 PRG 25- 45

101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Valid for Serial NO 452 XXX--XXXX0443 415 001 990803

SVENSKA 3..............................................

DANSK 14................................................

NORSK 25................................................

SUOMI 36................................................

ENGLISH 47..............................................

DEUTSCH 58.............................................

FRANÇAIS 69.............................................

NEDERLANDS 80.........................................

ESPAÑOL 91..............................................

ITALIANO 102..............................................

PORTUGUÊS 113..........................................

ЕЛЛЗНЙКБ 124.............................................

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

-- 2 --

ENGLISH

1 DIRECTIVE 48........................................................

2SAFETY 48...........................................................

3 INTRODUCTION 49...................................................

3.1 General 49..................................................................

3.2 Technical data 52............................................................

4 INSTALLATION 52....................................................

4.1 General 52..................................................................

5 OPERATION 53.......................................................

5.1 General 53..................................................................

6 MAINTENANCE 53....................................................

6.1 General 53..................................................................

6.2 Replacement of worn or damaged parts. 54......................................

6.3 General maintenance 54......................................................

7 ACCESSORIES 54....................................................

8 WEAR COMPONENTS 57..............................................

9 ORDERING OF SPARE PARTS 57......................................

DIMENSION DRAWING 135................................................

SPARE PARTS LIST 137...................................................

TOCe

-- 4 7 --

GB

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, 695 81 Laxå, Sweden, declares that tube welding tool

A21 PRG 25--45 from serial number 452 onwards, conforms to standard EN 60292,

in accordance with the requirements of directive (89/392/EEC) and appendix

(93/68/EEC) and standard EN 50199 in accordance with the requirements of directive (89/336/EEC) and appendix (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Laxå 1999--08--12

Anders Birgersson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 411924

2SAFETY

Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions.

Safety precautions must meet the requirements that apply to this type of welding equipment.

The following recommendations should be observed in addition to the standard regulations that apply

to the work place.

All work must be carried out by trained personnel well familiar with the operation of the welding equipment.

Incorrect operation of the equipment may lead to hazardous situations which can result in injury to the

operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment when it is

started up.

S that no--one is unprotected when the arc is struck

3. The work place must:

S be suitable for the purpose

S be free from draughts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely .

S Work on high voltage equipment shall only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

dsa7d1ea

-- 4 8 --

GB

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

3 INTRODUCTION

3.1 General

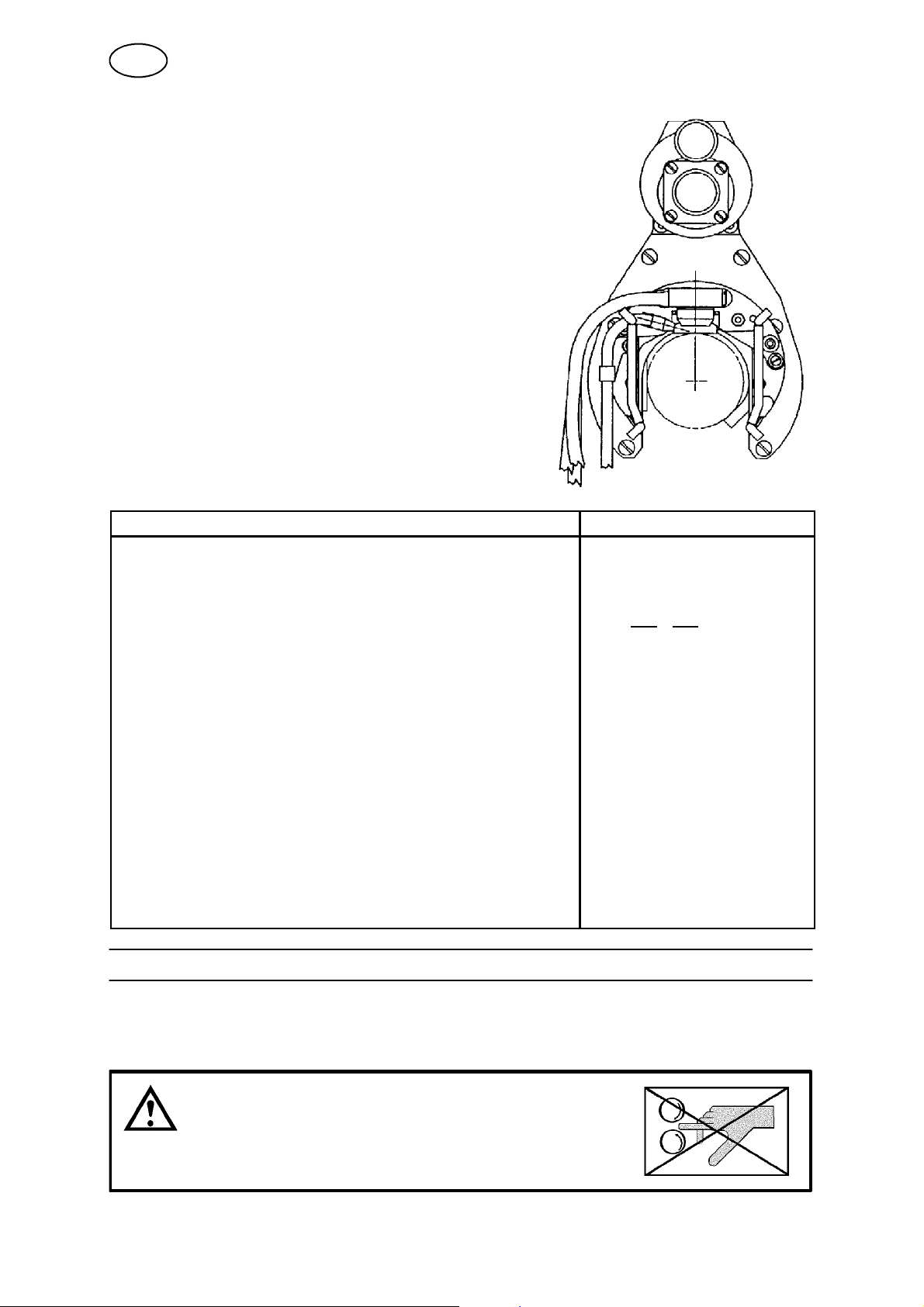

A21 PRG is an equipment intended for automatic TIG welding of tube joints, particularly adapted for the ESAB power sources PROTIG 315 and MECHTIG 315.

The A21 PRG 25--45 tube welding tool has been developed for the welding of heat

exchangers. The working range is 25--40 mm.

dsa7d1ea

-- 4 9 --

GB

Space required for tubes arranged acc. to As to straight rows of tubes

figure, see diagram below. C--C is limited by the width of the

tool -- 100 mm. See dimension draw

ing.

dsa7d002

In case of welding with cold filler wire the wire feed unit MEI 20 can be connected.

The tube welding tool A21 PRG (see fig. below) is adapted to the tool diameter by

way of exchangeable jaws ( 1) forming a V--block.

The opposite movable jaw (2) is pulled against the tube while turning the blocking

shaft (3), and by that the tool is fixed to the tube.

dsa7d1ea

-- 5 0 --

GB

Only the open gear ring (4) with the fitted components is rotating during welding. The

gear ring is rotated by the drive unit (5) consisting of a permanently magnetized DC

motor with a planetary gear. To obtain the necessary speed control accuracy a feed-back system with tachometer generator is used.

The drive unit is connected to the gear unit (6) that drives the open gear ring by way

of two wheels (7). Before dismounting the tool from the tube, the gear ring must be

rotated until the opening coincides with the opening of the fork (9). This is done over

the control box.

dsa7d1ea

dsa7d003

-- 5 1 --

GB

The welding head is designed so as to keep the wire

distance constant in relation to the envelope surface

during welding.

The distance of the wire to the joint as well as its lateral

position can be fine--adjusted, see instructions under

OPERATION

3.2 Technical data

Tube welding tool A21 PRG

Maximum welding current (60% duty cycle) 200 A

Working range 25 -- 45 mm

Rotation speed 0,18 -- 2,75 r/min

Ratio, motor armature/gear ring 288 x 115 = 1104:1

130

Electrode diameter 2,4 mm

Weight (without SGV cable) 3kg

Filler wire 0,6 -- 0,8 mm

Rotation unit

Armature voltage 24 V DC max.

Armature current 0,5 A DC max.

Armature rotation speed 3000 rpm at 20 V

Ratio 288:1

Tachometer

Voltage at 3000 rpm 1,8 V

Continuous A--weighted noise pressure 68 db

dsa7d004

4 INSTALLATION

4.1 General

The installation shall be executed by a professional.

WARNING!

Rotating parts can cause injury, take great care.

dsa7d1ea

-- 5 2 --

GB

S Welding power source Protig 315, see operating manual 0443 419 xxx.

S Welding power source Mechtig 315, see operaring manual 0443 420 xxx.

5 OPERATION

5.1 General

General safety regulations for the handling of the equipment appear from

page 48. Read through before you start using the equipment!

Adjustment to the diamter of the tube:

S Select jawssee WEAR COMPONENTS

on page 57.

S Loosen the screws (1).

S Push the welding head towards the

tube so that the arm (2) lifts from the

clamp (3) one mm or two.

The distance of the electrode to the joint.

S Loosen the screw (4).

S InserttheAllenwrenchintothe

hole (5).

S Prise sideways for the desired

electrode distance.

S Tighten the screw (4).

The lateral position of the electrode.

S Fine--adjust with the screw (6).

The position of the filler wire.

S Loosen the nozzle (7) with the screw (8) and adjust.

Dismounting from the tube.

S Rotate the gear ring by means of the control box so that the opening of the ring

coincides with the opening of the fork.

Sliding shoe (10)

dsa7o001

6 MAINTENANCE

6.1 General

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

dsa7d1ea

-- 5 3 --

GB

6.2 Replacement of worn or damaged parts.

Electrode:

S Loosen the screw (1).

S Replace the electrode.

Current/water cable:

S Remove the screws (2) of the

damaged cable on the elctrode holder

and the adapter.

S Replace the cable.

Gas hose (5):

S Remove the screws (3) and the

ones corresponding to (2) of the

adapter.

S Replace the hose.

S Press the gas sleeve (4) home when remounting so that one of

the holes comes just opposite screw (3). Lock with screw (3).

dsa7m001

Gas lens, electrode sleeve, sealing washer:

S Loosen screw (1) and dismount nut (8). The above parts can now be replaced.

When mounting the parts, see to it that the side hole of the electrode sleeve

comes just opposite the screw.

Sliding shoe, turning or replacing: See fig. under OPERATION

S Loosen the insulation (9) and turn or replace the sliding shoe (10).

6.3 General maintenance

S Grease all sliding surfaces regularly using Molycote G Rapid Pasta.

S Check that hoses and hose connections are intact and do not leak.

7 ACCESSORIES

PROTIG 315 !!!! A21 PRG 25--45

A Tube welding tool PRG

B Programming unit

C Remote control, start/stop

D PROTIG 315, front connection

E PROTIG 315, rear connection

G Wire feed unit MEI 20

H Emergency stop

dsa7d1ea

-- 5 4 --

GB

1 Extension cable, programming unit 0333 076 880.....................................

2 Extension cable, return cable 0333 562 880..........................................

3 Extension cable, electric conductor 0333 562 880.....................................

4 Extension set, water hoses 0333 558 880............................................

5 Extension cable, remote control 0333 077 880........................................

6 Extension cable, MEI 20 0333 078 880..............................................

7 Extension cable, emergency stop 0333 077 881......................................

8 Extension-- och control cable PRG 0333 079 880.....................................

9 Extension set, protective gas 0333 557 880..........................................

10 SVG cable 0332 863 880..........................................................

11 Control cable 0157 339 880........................................................

12 Connection cable 0157 189 880....................................................

14 OKC--clutch 0317 082 880.........................................................

15 Check valve 0317 088 880.........................................................

16 Return cable 0262 613 601.........................................................

17 SV--cable 0441 740 880...........................................................

18 Hose 0441 738 104...............................................................

Sleeve 0441 768 001..............................................................

dsa7d1ea

-- 5 5 --

GB

MECHTIG 315 !!!! A21 PRG 25--45

A Tube welding tool PRG

B Programming unit

D MECHTIG 315, front connection

E MECHTIG 315, rear connection

G Wire feed unit MEI 20

1 Extension cable, programming unit 0369 143 885.....................................

Extension cable, programming unit 0369 143 884.....................................

2 Extension cable, return cable 0333 562 880..........................................

3 Extension cable, electric conductor 0333 562 880.....................................

4 Extension set, water hoses 0333 558 880............................................

5 Extension set, protective gas 0333 557 880..........................................

6 Extension cable, MEI 20 0442 549 881..............................................

7 Extension cable, rotation 0442 548 881.............................................

8 Control cable, MEI 20 0442 357 880.................................................

9 Control cable, rotation 0442 360 880................................................

10 SVG cable 0332 863 880..........................................................

11 OKC--clutch 0317 082 880.........................................................

12 Check valve 0317 088 880.........................................................

13 Return cable 0262 613 601.........................................................

14 SV--cable 0441 740 880...........................................................

15 Hose 0441 738 104...............................................................

Sleeve 0441 768 001..............................................................

dsa7d1ea

-- 5 6 --

GB

8 WEAR COMPONENTS

dsa7o002

Order no.

0441 917 880 25 15.5 0441 917 890 35 10.5

0441 917 881 25.4 15.3 0441 917 891 38 --38.1 9

0441 917 882 26.67 -- 26.9 14.6 0441 917 892 40 8

0441 917 883 28 14 0441 917 893 41.3 7.35

0441 917 884 28.6 13.7 0441 917 894 42 7

0441 917 885 30 13 0441 917 895 42.16 -- 42.4 6.85

0441 917 886 31.8 12.1 0441 917 896 43 6.5

0441 917 887 32 12 0441 917 897 44 6

0441 917 888 33.4 11.3 0441 917 898 44.4 -- 44.5 5.8

0441 917 889 33.7 -- 33.9 11.1 0441 917 899 45 5.5

Tube ø

A Order no.

Tube ø

N.B. Each position consists of two jaws.

9 ORDERING OF SPARE PARTS

A

A21 PRG 25--45 is designed and tested in accordance with the EN 60 292

(IEC 292) international standard.

It is the obligation of the service unit which has carried out the service or repair work to make sure that the product still conforms to the said standard.

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list on page 137.

This will simplify dispatch and ensure you get the right part.

dsa7d1ea

-- 5 7 --

Loading...

Loading...