OPERATING INSTRUCTIONS for

®

October, 2000

R-522

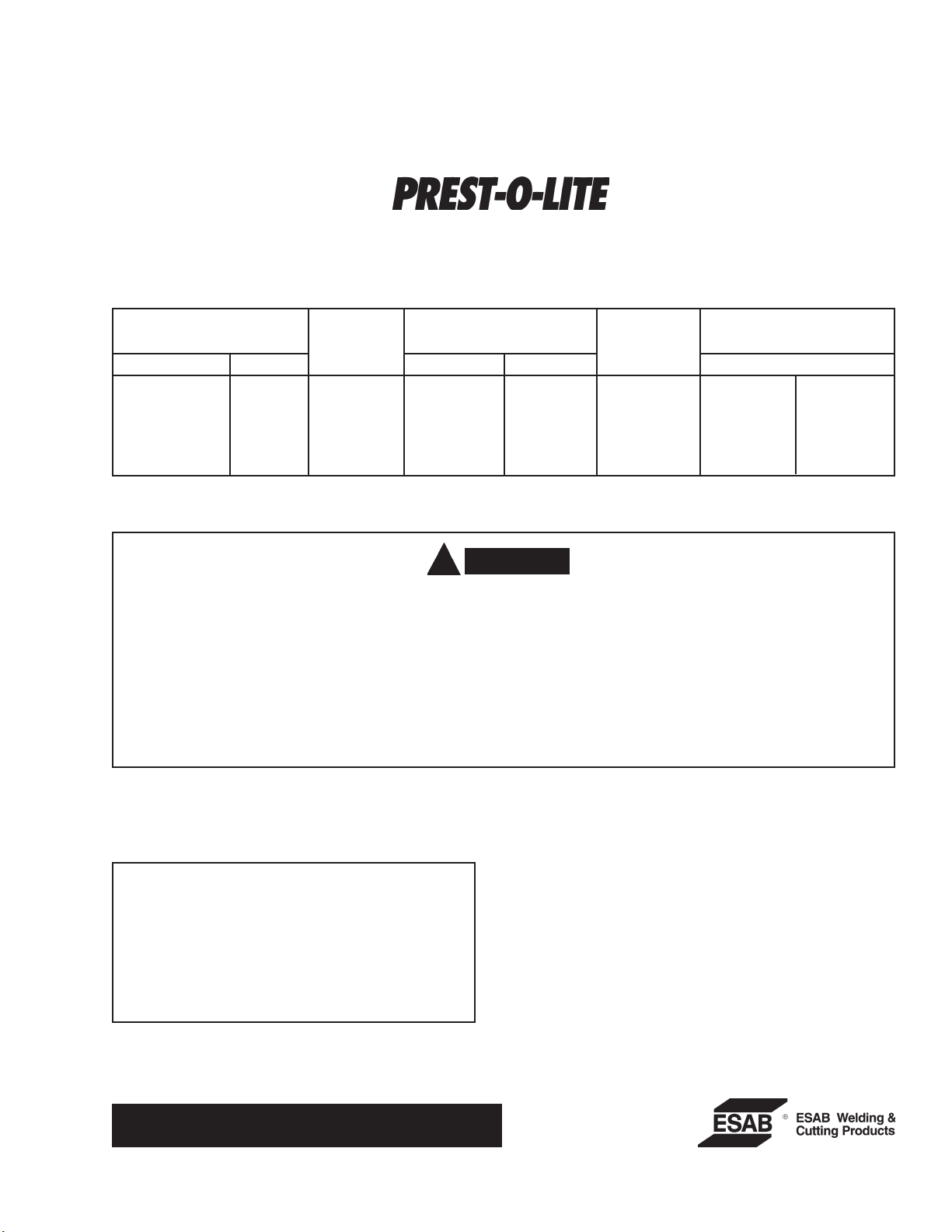

CYLINDER REGULATORS

Rated Max.

Regulator Gas Connection,CGA No Delivery Pressure Gauges, PSIG

Model P/N Service Inlet Outlet Press. PSIG Cylinder Delivery

R-522-75-540 22237 Oxygen 540 022 75 4000 100

R-522-15-510 22241 Acetylene 510 023 15 400 30

R-522-15-520 22238 Acetylene 520(B) 023 15 400 30

R-522-15-200 22239 Acetylene 200(MC) 023 15 400 30

R-522-15-200 22240 Acetylene 300 023 15 400 30

• CGA-022 (formerly "B" oxygen) - 9/16"- 18 RH male conn.

CGA-023 (formerly "B" Acet.) - 9/16"-18 LH male conn.

•

F-15-454

CAUTION

!

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe

practices for oxy-fuel gas equipment, we urge you to read our booklet "Precautions and Safe Practices for Gas Welding,

Cutting and Heating," Form 2035. Do NOT permit untrained persons to install, operate, or maintain this equipment. Do NOT

attempt to install or operate this equipment until you have read and fully understand these Instructions. If you do not fully

understand these Instructions, contact your supplier for further information.

The regulators covered by these Instructions are listed by Underwriter's Laboratories only when using parts manufactured

by ESAB Welding & Cutting Products to the specifications on file with Underwriter's Laboratories, Inc., and when they are

used in the gas service for which they are designed and listed. The use of other parts that cause damage or failure to the

equipment will void the manufacturer's warranty.

IMPORT ANT : For packing purposes, the pressureadjusting screw of the regulator may be either

turned in or packed separately . If installed in regulator, back out screw (turn counterclockwise) until

it turns freely . If packed separately , install the screw

in the regulator cap and turn it in (clockwise) only

one or two turns.

For Safety Precautions, Installation & Operating

Instructions, see other side.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Safety Precautions

! !

n OXYGEN causes many metals and other materials

to burn violently .

n INERT GAS OR CARBON DIOXIDE can cause suf-

focation in confined spaces.

n FUEL GAS can explode in air or oxygen.

l Keep regulator clean and in good repair. Do NOT

oil or grease regulator. Grease and oil on regulator or valve parts can cause regulator fires.

l Always work in a well-ventilated area.

l Prevent leaks and keep away from heat, flame,

and sparks.

l Do not change CGA inlet connection from number

stamped on regulator body .

l Follow Operating Instructions on this sheet.

l This regulator must be installed, operated and

maintained only by trained servicemen.

l For complete safety information on welding equip-

ment, read Form 2035 (oxy-fuel gas) and 52-529

(arc welding). For safety information on gases,

see your supplier.

n DO NOT remove internal part from inlet connection

or R-522-75-540 Oxygen Model.

TO CONNECT:

1.Open the cylinder or station valve slightly, for an instant (this is termed 'cracking the valve'). This will

blow out dust or dirt that may have collected in the

valve outlet. Be sure to keep your face away from

the valve outlet to protect your eyes from dust or dirt.

Never crack a fuel gas valve near sparks, flames,

or another possible source of ignition.

2.Make sure the regulator pressure-adjusting screw is

released by turning it counterclockwise until it turns

freely .

3.Attach the regulator to the valve and tighten the connection nut with a wrench.

4.Open the cylinder valve slowly. (Open acetylene

cylinder valves no more than 1-1/2 turns.) Never

stand in front of or behind the regulator when

opening the valve. Always stand to one side.

5.Attach the hose to the regulator outlet and to the

equipment with which it is to be used.

TO ADJUST PRESSURE:

1.To increase delivery pressure, turn the pressureadjusting screw clockwise. To decrease delivery

pressure, turn the pressure-adjusting screw counterclockwise.

2.When making the initial delivery pressure adjustment,

all valves downstream of the regulator must be open

or you will not get a true working-pressure reading

on the delivery-pressure gauge.

IMPORTANT: Before starting operations, test all con-

nections with a leak T est Solution that is

suitable for oxygen service, such as

P/N 998771 (8oz. container). Correct

any leaks before starting work. Testing

should be performed after torch or other

gas-using device has been properly connected and with maximum delivery pressure in the delivery line.

TO RELEASE PRESSURE:

If operations are to be stopped for a half-hour or more,

you should release all pressures from regulator. T o do

this, proceed as follows:

1.Close the cylinder valve.

2.Open all valves downstream of the regulator.

3.Wait until the pressure has dropped to zero, then

turn the pressure-adjusting screw counterclockwise

until it turns freely .

NOTE: If a regulator is to be out of use for a few days

or more, turn in the pressure-adjusting screw

enough to move the valve stem off its seat.

When the regulator is returned to use, be sure

to back off the pressure-adjusting screw until it

turns freely before pressure is admitted to the

regulator.

REPAIR SERVICE:

Regulators in need of repair should be returned to your

distributor, or to ESAB Welding & Cutting Products,

Remanufacturing Center, 411 S. Ebenezer Road, Florence, SC 29501.

If you have your own properly-equipped and staffed

repair facility , repair parts information for this regulator

is available on request to your distributor. Request

Form 15-455, which covers the regulators listed on this

sheet.

NOTE: Safety release device equipped on oxygen and

inert gas regulators is designed for regulator

protection; not for hose or equipment downstream. If gas escapes through the safety release device, immediately close cylinder valve,

and then remove regulator from service for repair.

F-15-454 10/2000 Printed in U.S.A.

Loading...

Loading...