ESAB Mig 4002cw, Mig 5002cw, Mig 4002c, Mig 5002c, Mig 6502cw Service Manual

...

0349 300 080 Valid for serial no.

740,743,741,744,742,745,801,802,803,804,806,805--xxx--xxxx

101229

Mig 4002cw, Mig 4002c

Mig 5002cw, Mig 5002c

Mig 6502cw, Mig 6502c

Origo

Servicemanual

-- 2 --

TOCe

READ THIS FIRST 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TECHNICAL DATA 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component description 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OrigoTM Mig 4002c / 5002c / 6502c block diagram 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

? 230V / 400--415V / 440--460V / 500V ? 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burndy 23 <--> Amphenol 19 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION OF OPERATION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0 Control circuit board 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:1 Circuit board identity 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:2 Power supply 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:3 The CAN bus 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminating resistors 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:4 Temperature monitoring 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:5 Current sensor 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:5.1 Calibrating the current sensor signal 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:6 Arc voltage input Mig/Mag 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:6.1 Calibration of the arc voltage feedback 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0:7 Arc voltage input in MMA process 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CB0 Components positions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10 Driver/relays board 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:1 Circuit diagram 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:2 Power supply 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:3 PWM driver 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:4 Pre charging voltage sense 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:5 Mains contactor circuit, energy saving 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:6 Cooling fan 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:7 Cooling liquid pump 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10:8 Flow guard 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACH10 Components positions 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PF20 Suppression circuit board 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PF20:1 Circuit diagram 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PF20:2 Components positions 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE CONTROLS 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAULT CODES 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault log 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault code description, power source 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE INSTRUCTIONS 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is ESD? 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service aid 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESAB Administration Tool (ESAT) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN supply service kit 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Antistatic service kit 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking PWM signal 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking thermal cutout 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Flow guard

(only machines with Flow Guard sensor) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking pre charging circuit 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Fan Circuit 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking liquid pump circuit 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the LED Indicators on board CB0 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking chopper block V0 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview test 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectifier test 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking of output stage 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing of damaged transistors 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High current aluminum leads maintenance 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-- 3 --

TOCe

INSTRUCTIONS 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Placing 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly of components 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains power supply 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections and control devices 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overheating protection 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water connection 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water flow guard 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and cleaning 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Topping up the coolant 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAULT TRACING 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING OF SPARE PARTS 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTES 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-- 4 --

1sxx02cw

READ THIS FIRST

Maintenance and repair work should be performed by an experienced person, and

electrical work only by a trained electrician. Use only recommended replacement parts.

This service manual is intended for use by technicians with electrical/electronic training for

help in connection with fault--tracing and repair.

Use the wiring diagram as a form of index for the description of operation. The circuit

board is divided into numbered blocks, which are described individually in more detail in

the description of operation. All component names in the wiring diagram are listed in the

component description.

This manual contains details of all design changes that have been made up to and

including December 2010.

The OrigoTMMig 4002cw, Mig 4002c, Mig 5002cw, Mig 5002c, Mig 6502cw, Mig 6502c

are designed and tested in accordance with European standard EN 60974--1 and EN

60974--10.

On completion of service or repair work, it is the responsibility of the person(s) etc.

performing the work to ensure that the product does not depart from the requirements

of the above standard.

WARNING

Many parts of the power unit are at mains voltage.

INTRODUCTION

The OrigoTMMig 4002cw, Mig 5002cw, Mig 6502cw are MIG/MAG welding power

sources, which can also be used for MMA welding.

There are two variants of the power sources:

S OrigoTMMig xx02c without cooling unit

S OrigoTMMig xx02cw with cooling unit

The power sources are intended for use with the AristoTMFeed 3004 or Aristo

TM

Feed 4804 wire feed units.

All the settings are made from the wire feed unit.

-- 5 --

1sxx02cw

TECHNICAL DATA

OrigoTMMig 4002cw

Mains voltage 230/400--415/500 V 3∼ 50 Hz

230/440--460 V 3∼ 60 Hz

Permissible load at

60 % duty cycle

100% duty cycle

Mig/Mag: 400 A / 34 V; MMA: 400 A / 36 V

Mig/Mag: 310 A / 30 V; MMA: 310 A / 33 V

Setting range (DC)

MIG/MAG

MMA

Mig/Mag: 16A / 8V--400 A / 34 V

MMA: 16A / 8V--400 A / 36 V

Open circuit voltage Mig/Mag: 62V; MMA: 68V

Open circuit power

with cooling unit

in energy saving mode

(15 min after last welding)

500 W

700 W

60W

Power factor at maximum current 0,88

Efficiency at maximum current 70 %

Control voltage 42 V, 50/60 Hz

Dimensions lxwxh 830 x 640 x 835 mm

Weight

with cooling unit

149 kg

163 kg

Operating temperature --10 to +40˚C

Enclosure class IP 23

Application classification

OrigoTMMig 5002cw

Mains voltage 230/400--415/500 V 3∼ 50 Hz

230/440--460 V 3∼ 60 Hz

Permissible load at

60 % duty cycle

100% duty cycle

Mig/Mag: 500 A / 39 V; MMA: 500 A / 40 V

Mig/Mag: 400 A / 34 V; MMA: 400 A / 36 V

Setting range (DC)

MIG/MAG

MMA

Mig/Mag: 16A / 8V--500 A / 39 V

MMA: 16A / 8V--500 A / 40 V

Open circuit voltage Mig/Mag: 62V; MMA: 68V

Open circuit power

with cooling unit

in energy saving mode

(15 min after last welding)

550 W

750 W

60W

Power factor at maximum current 0,90

Efficiency at maximum current 72 %

Control voltage 42 V, 50/60 Hz

Dimensions lxwxh 830 x 640 x 835 mm

Weight

with cooling unit

185 kg

199 kg

Operating temperature --10 to +40˚C

-- 6 --

1sxx02cw

Enclosure class IP 23

Application classification

OrigoTMMig 6502cw

Mains voltage 230/400--415/500 V 3∼ 50 Hz

230/440--460 V 3∼ 60 Hz

Permissible load at

60 % duty cycle

100% duty cycle

Mig/Mag: 650 A / 44 V; MMA: 650 A / 44 V

Mig/Mag: 500 A / 39 V; MMA: 500 A / 40 V

Setting range (DC)

MIG/MAG

MMA

Mig/Mag: 16A / 8V--650 A / 44 V

MMA: 16A / 8V--650 A / 44 V

Open circuit voltage Mig/Mag: 62V; MMA: 68V

Open circuit power

with cooling unit

in energy saving mode

(15 min after last welding)

670 W

870 W

60W

Power factor at maximum current 0,90

Efficiency at maximum current 76 %

Control voltage 42 V, 50/60 Hz

Dimensions lxwxh 830 x 640 x 835 mm

Weight

with cooling unit

222 kg

236 kg

Operating temperature --10 to +40˚C

Enclosure class IP 23

Application classification

Cooling unit

Cooling power 2500 W at40˚C temp. difference and flow

1,5l/min

Coolant 50 % water / 50% glycol

Coolant quantity 5,5 l

Maximum water flow 2,0 l/min

Duty cycle

The duty cycle refers to the time as a percentage of a ten--minute period that you can weld at a certain load without overloading.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP 23 is designed for indoor and outdoor use.

Application class

The symbol indicates that the power source is designed for use in areas with increased

electrical hazard.

-- 7 --

1sxx02cw

This page is left blank intentionally.

-- 8 --

1sxx02cw

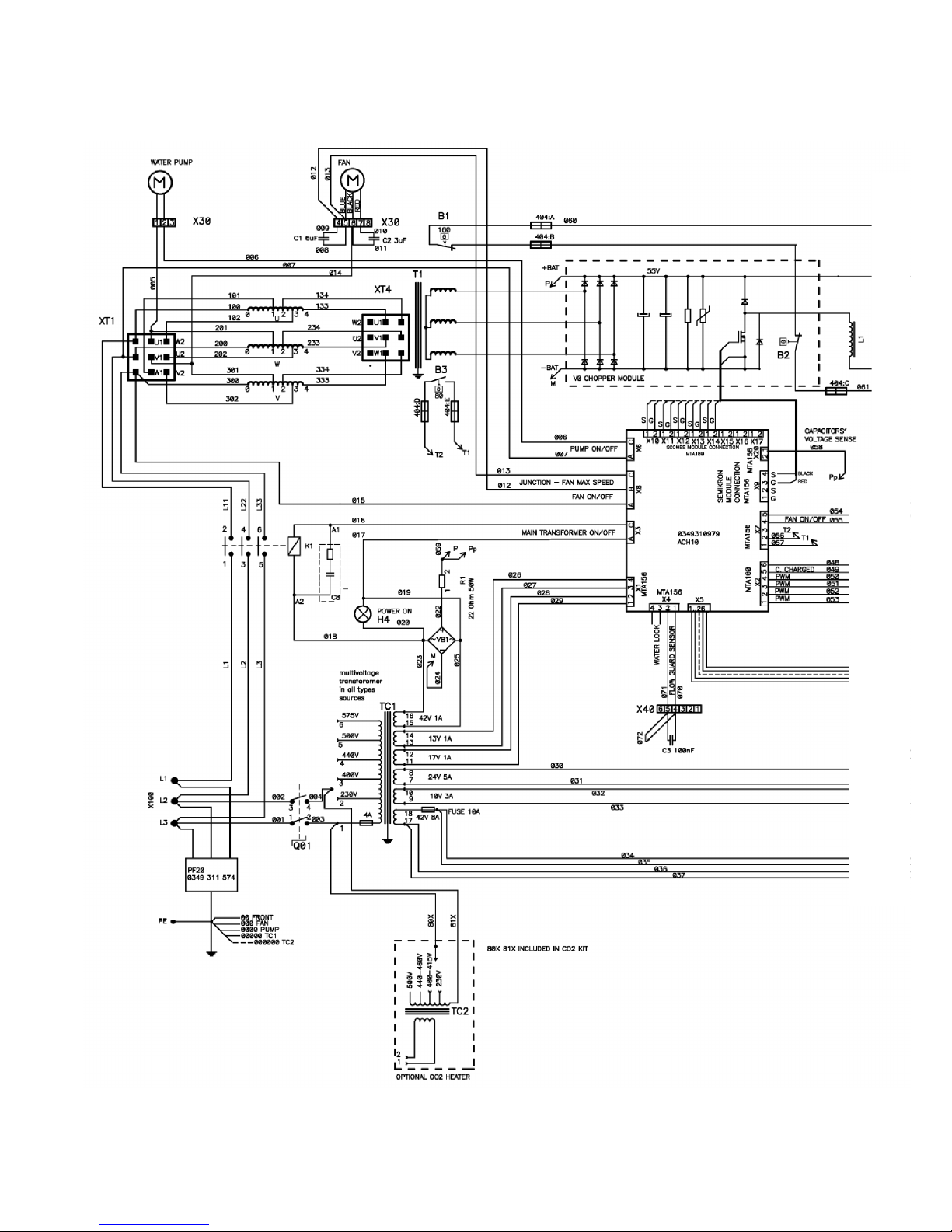

WIRING DIAGRAM

WARNING !

STATIC ELECTRICITY can damage circuit

boards and electronic components.

SSSS Observe precautions for handling electrostatic

sensitive devices.

SSSS Use proper static--proof bags and boxes.

ESD

Component description

XT1 9 pole terminal block

PF20 Suppression circuit board

Q01 Main ON/OFF switch

K1 Main contactor

M1 Fan 230V 50Hz

M2 Pump motor, 230V 50Hz 0.2kW. Only machines with water cooler

C1 Capacitor, 6uF 250V, for reducing the speed of fan motor M1

C2 Capacitor, 3uF 400V. Start and run capacitor for fan motor M1

C3 -- C7 Suppression capacitors, 0,1uF 250V

C8 Snubber for K1 coil

H2 Orange indicating lamp, Error,overheating

H4 White indicating lamp, power supply ON

T1 Main transformer

TC1 Control power transformer

TC2 Transformer for CO2 heater. (an accessory, see an accessories listed in

user manual)

VB1 Rectifier

B1 Thermal switch. Protects the main transformer against excessive

temperature

B2 Thermal switch. Protects the chopper block against excessive temperature

B3 Thermal switch. Controls the speed of fan motor M1

CS Current sensor

R1 Resistor (pre--charging)

L1 Inductor

CB0 Control circuit board

-- 9 --

1sxx02cw

ACH10 Driver/relays circuit board

V0 Chopper module

X02 Connector, r Amphenol 10 pole or Burndy 12 pole (obsolete). For connection

to/from the wire feed unit

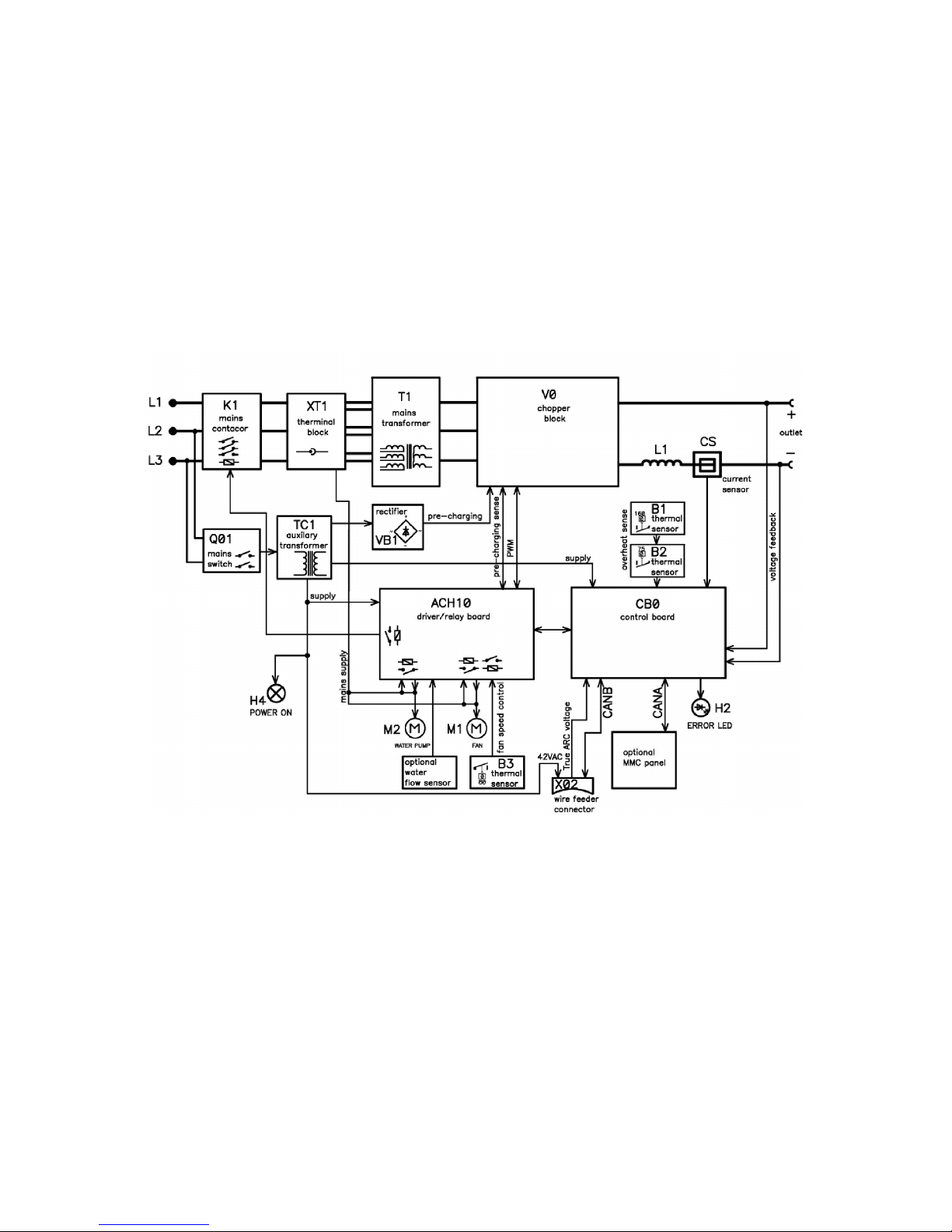

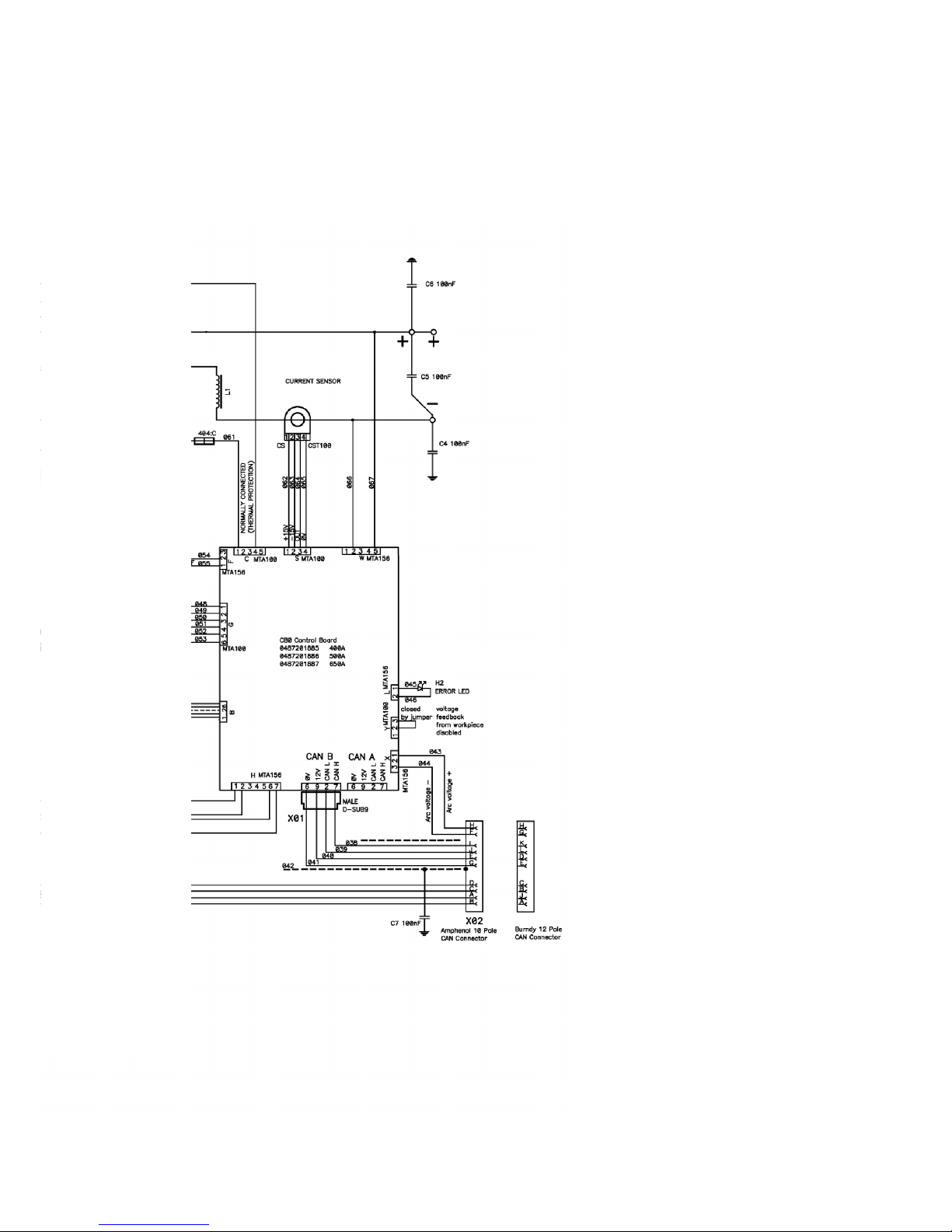

OrigoTMMig 4002c / 5002c / 6502c block diagram

-- 10 --

1sxx02cw

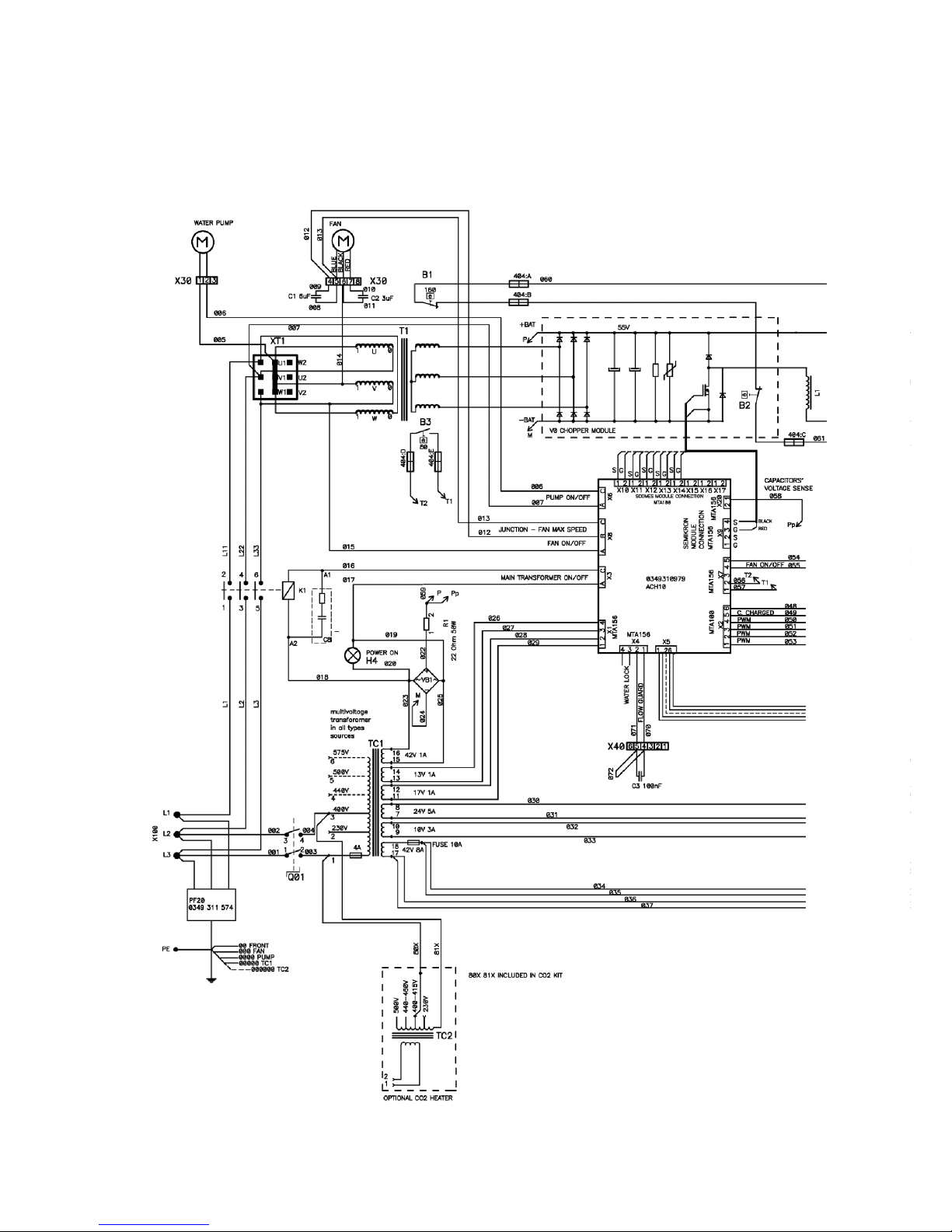

Mig 4002cw, 5002cw, 6502cw, 400 -- 415 V

-- 11 --

1sxx02cw

Mig 4002cw, 5002cw, 6502cw, 400 -- 415 V

-- 12 --

1sxx02cw

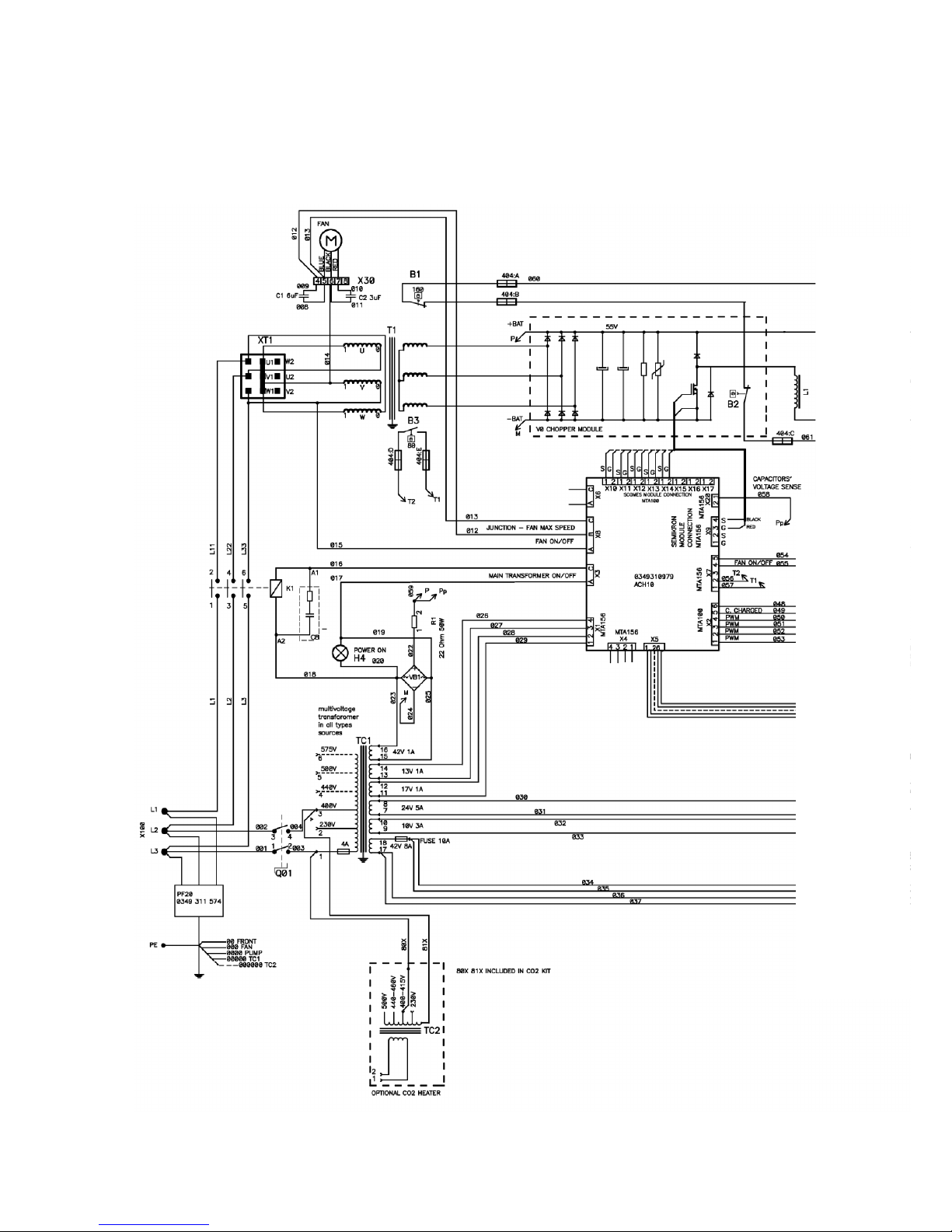

Mig 4002c, 5002c, 6502c, 400 -- 415 V

-- 13 --

1sxx02cw

Mig 4002c, 5002c, 6502c, 400 -- 415 V

-- 14 --

1sxx02cw

Mig 4002cw, 5002cw, 6502cw, 230 -- 500 V

-- 15 --

1sxx02cw

Mig 4002cw, 5002cw, 6502cw, 230 -- 500 V

-- 16 --

1sxx02cw

Mig 4002c, 5002c, 6502c, 230 -- 500 V

-- 17 --

1sxx02cw

Mig 4002c, 5002c, 6502c, 230 -- 500 V

-- 18 --

1sxx02cw

? 230V / 400--415V / 440--460V / 500V ?

-- 19 --

1sxx02cw

Burndy 23 <--> Amphenol 19

Burndy 23 Amphenol 19 Signals

A A 42V

B B 42V

C

D D 12V

E E 0V

F F Start contact

G G Artificial ground

H H Arc voltage

J J +15VB

K K Ref

L L 0VB

M

N

P

R

S

T T Data display

U U Clock display

V V Load display

W M Crater fill

X R Water connection monitoring

Y S Water connection monitoring

Z

-- 20 --

1sxx02cw

DESCRIPTION OF OPERATION

CB0 Control circuit board

The processor on the control board monitors and controls the various functions of the power

source. It obtains information on welding data and welding processes from the welding data

board in the MMC control panel.

CB0:1 Circuit board identity

The control board has a machine ID, a hardware ID and a unit type number. To

read this you need the ESAT service kit. The machine ID defines which type of

power source the board is intended for. The hardware ID shows design and type of

circuit board. The unit type is used for identification on the CAN bus.

The ID numbers of the machines :

S OrigoTMMig 4002c/cw: 38

S OrigoTMMig 5002c/cw: 39

S OrigoTMMig 6502c/cw: 40

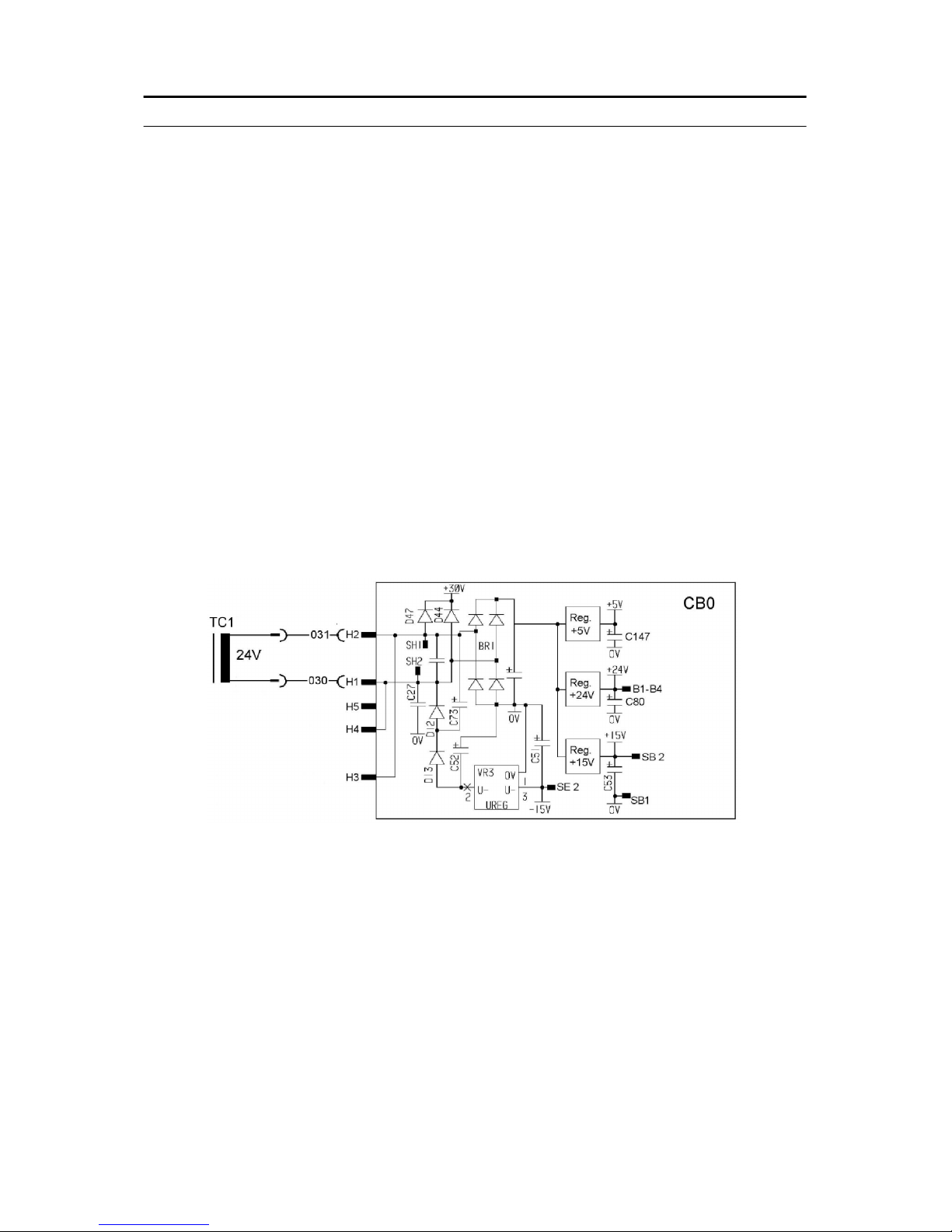

CB0:2 Power supply

+24 V Power supply to relay board CB0

+15 V Internal power supply on CB0

--15 V Internal power supply on CB0

+5 V Internal power supply on CB0

Loading...

Loading...