LHF

250/400/630/800

101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Val i d fo r serial no. 550 XXX -- XXXX0455 675 001 GB 990215

SVENSKA 3..............................................

DANSK 8................................................

NORSK 13................................................

SUOMI 18................................................

ENGLISH 23..............................................

DEUTSCH 28.............................................

FRANÇAIS 33.............................................

NEDERLANDS 38.........................................

ESPAÑOL 43..............................................

ITALIANO 48..............................................

PORTUGUÊS 53..........................................

ЕЛЛЗНЙКБ 58.............................................

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

-- 2 --

ENGLISH

1 DIRECTIVE 24........................................................

2SAFETY 24...........................................................

3 INTRODUCTION 25...................................................

3.1 TECHNICAL DATA 25........................................................

4 INSTALLATION 26....................................................

Connecting to mains 26.............................................................

5 OPERATION 27.......................................................

6 MAINTENANCE 27....................................................

6.1 General 27..................................................................

7 ORDERING OF SPARE PARTS 27......................................

ASSEMBLY INSTRUCTIONS 63...........................................

DIAGRAM 64............................................................

SPARE PARTS LIST 69...................................................

TOCe

-- 2 3 --

GB

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guarantee that welding power source LHF 250/400/630/800 from serial number 550 complies with standard EN 60974--1, in accordance with the requirements of directive

(73/23/EEC) and addendum (93/68/EEC) and with standard EN 50199 in accordance with the requirements of directive (89/336/EEC) and addendum (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -------Laxå 1995--04--10

Paul Karlsson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 12336

2SAFETY

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

bh10d12e

-- 2 4 --

GB

3 INTRODUCTION

LHF 250/400/630/800 are thyristor controlled welding rectifiers designed for welding

with coated electrodes, TIG welding and arc air gouging.

The welding rectifiers can be used with the following remote control devices:

PHA 1, PHA 2, PHA 5, PHB 1, PHB 2, och PHC 2.

An auxiliar y control unit is required for TIG welding with high frequency arc ignition.

LHF 400/630, versions with meters and timed cooling fan.

These welding rectifiers are equipped with a volmeter, ammeter and a circuit that

reduces the idle speed of the cooling fan.

The meters allow current and voltage settings to be read from the front of the

rectifier.

To minimise the amount of dust and dirt that is drawn into the rectifier the fan runs at

a reduced idle speed of 300 rpm. When welding with currents greater than 30 A the

fan speed increases to its working speed of around 1350 rpm. A timer relay

maintains the higher speed setting for 6 1/2 minutes after welding has stopped to

ensure adequate cooling of the rectifier.

3.1 TECHNICAL DATA

LHF 250 LHF 400 LHF 630 LHF 800

Maximum load

35 % duty cycle 250 A/30 V 400 A/36 V 630 A/44 V 800 A/44 V

60 % duty cycle 200 A/28 V 315 A/33 V 500 A/40 V 630 A/44 V

100 % duty cycle 160 A/26 V 250 A/30 V 400 A/36 V 500 A/40 V

Setting range 8A/20V--250A/

30(33)V

Open circuit volt. 78--84 V 80 --87 V 65--72 V 65--72 V

Open circuit output

at 400 V

Power factor

(max current)

Efficiency

(max current)

Enclosure class IP 23 IP 23 IP 23 IP 23

Application class

Weight 160 kg 195 kg 260 kg 295 kg

Dimens. lxwxh 1310/765/705 1310/765/705 1310/765/705 1310/765/705

300 W 340 W 615 W 640 W

0,88 0,90 0,87 0,82

68 % 74 % 77 % 78 %

8A/20V--400A/

36V

8A/20V--630A/

44(49)V

8A/20V--800A/

44(50)V

These welding power sources comply with the requirements of IEC 974--1 och

EN 60974--1.

The symbol indicates that the power source is designed for use in areas with an

increased electrical hazard. Equipment marked IP 23 is designed for indoor and

outdoor use.

-- 2 5 --bh10d12e

GB

4 INSTALLATION

WARNING

This product is intended for industrial use. In a domestic environment this

product may cause radio interference. It is the user’s responsibility to take

adequate precautions.

S Installation must be carried out by a qualified electrician.

S Check that the welding rectifier is configured for the available mains supply be-

fore connecting it to the mains.

S See Connecting to mains for cable rating and fuse rating.

S Connect the mains cable to the rectifier according to the relevant regulations and

install a suitable fuse in the main fuse box.

S Make sure the welding rectifier is not covered or positioned so that cooling is ob-

structed.

Connecting to mains

Mains supply LHF 250 LHF 400 LHF 630 LHF 800

Frequency 50 Hz 50 Hz 50 Hz 50 Hz

Voltage 230/400/

415/500 V

Current at 100%

duty cycle

Current at 60%

duty cycle

Current at 35%

duty cycle

Fuse, slow 25/16/16/16 A 63/25/25/20 A 80/50/50/35 A 100/63/63/50A

Cable area

(4xmm2)

Frequency 60 Hz 60 Hz 60 Hz 60 Hz

Voltage 230/440/550V 230/440/550V 230/440/550V 230/440/550V

Current at 100%

duty cycle

Current at 60%

duty cycle

Current at 35%

duty cycle

Fuse, slow 25/16/16 A 63/25/20 A 80/50/35 A 100/63/50 A

Cable area

(4xmm2)

20/11/11/9A 34/19/19/16 A 65/38/38/30 A 86/49/49/40 A

25/14/14/11 A 42/24/24/20 A 81/47/47/38 A 107/62/60/50A

31/18/18/14 A 53/31/31/25 A 102/59/59/47A 136/79/79/63A

4/1,5/1,5/1,5 10/4/4/2,5 25/10/10/6 35/10/10/10

20/11/9 A 34/19/16 A 65/38/30 A 86/49/40 A

25/14/11 A 42/24/20 A 81/47/38 A 107/62/50 A

31/18/14 A 53/31/25 A 102/59/47 A 136/79/63 A

4/1,5/1,5 10/4/2,5 25/10/6 35/10/10

230/400/

415/500 V

230/400/

415/500 V

230/400/

415/500 V

Cable areas comply with Swedish regulations.

bh10d12e

-- 2 6 --

GB

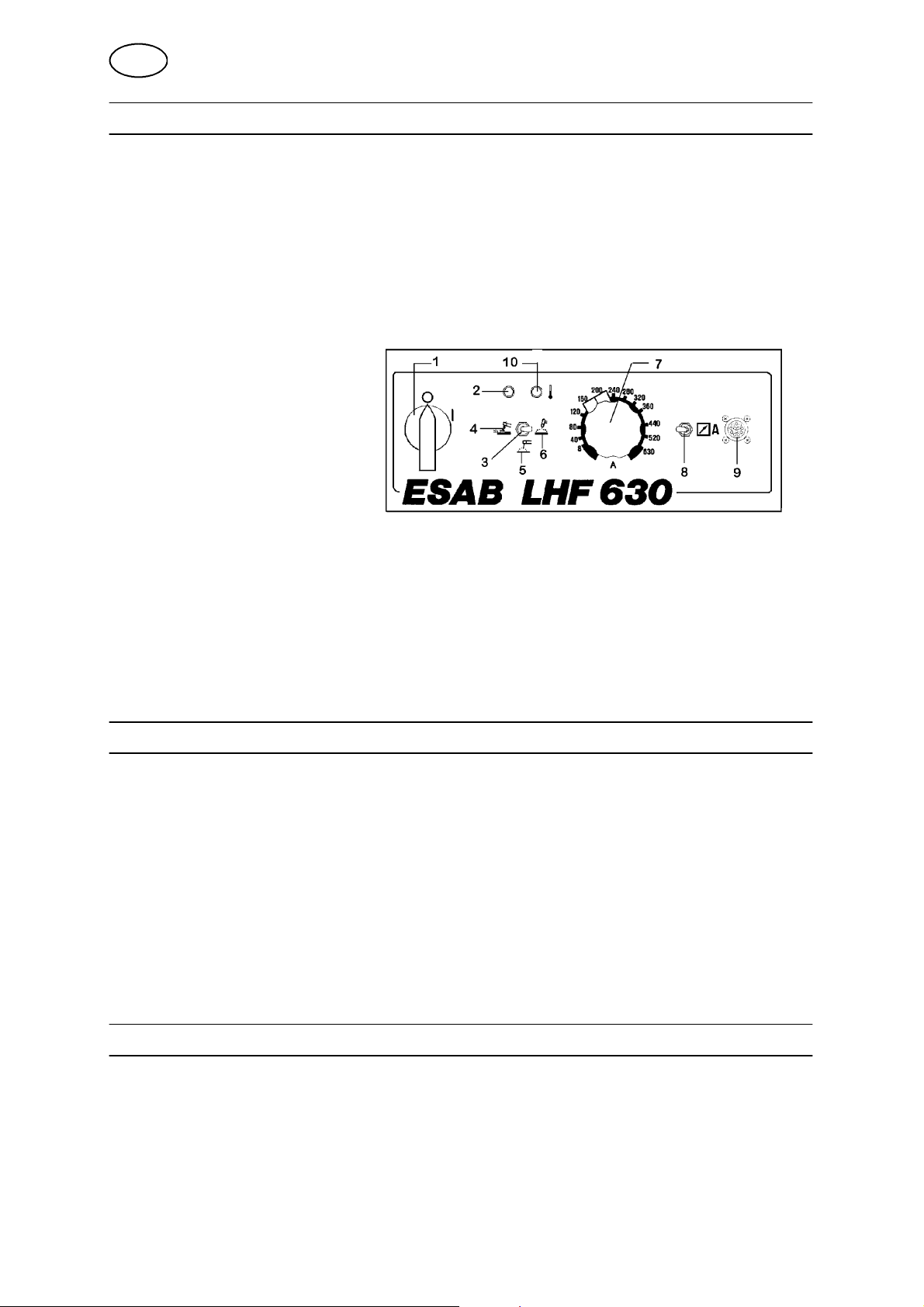

5OPERATION

S Set switch (1) to position ”I”. The white lamp (2) will light and the fan will start.

S Select the welding method using the toggle switch (3).

S Adjust the welding current using the knob (7) on the front, and set the toggle

switch (8) to the position nearest the socket.

S Select suitable earth and return cables and connect them to the terminals

marked + and -- on the front of the rectifier. Connect the return cable to the work

piece.

S The rectifier is now ready for welding.

1. On/Off

2. White lamp (power on)

3. Method selector switch

4. Arc air gouging

5. MMA

6. TIG

7. Current setting

8. Remote switch

9. Remote socket

10. Yellow lamp (thermal cut--out)

bh10d001

The yellow lamp comes on when the thermal cut--out trips.

When the rectifier has cooled down the thermal cut -- out is automatically reset.

6 MAINTENANCE

LHF 250/400/630/800 normally do not require any maintenance.

Once a year blow the inside of the welding rectifier clean using dry compressed air at

reduced pressure.

Repeat more often if the rectifier is used in a very dusty or dirty environment.

6.1 General

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

7 ORDERING OF SPARE PARTS

A service manual and list of spare parts can be ordered through your nearest ESAB

representative, see the last page of this booklet.

When ordering spare parts please specify the machine model, serial number and the

designation and order numbers of parts as shown in the list of spare parts. This

simplifies dispatch and ensures correct delivery.

-- 2 7 --bh10d12e

Loading...

Loading...