Aristo®

Mig4004iPulse

Instruction manual

0463 380 031 US 20150929 Valid for: serial no. 419-xxx-xxxx, 528-xxx-xxxx

TABLE OF CONTENTS

1 SAFETY PRECAUTIONS ..................................................................................... 3

2 INTRODUCTION...................................................................................................9

2.1 Equipment............................................................................................................. 9

3 TECHNICAL DATA ............................................................................................ 10

4 INSTALLATION................................................................................................... 12

4.1 Location .............................................................................................................. 12

4.2 Lifting instruction............................................................................................... 12

4.3 Electrical supply................................................................................................. 12

5 OPERATION ....................................................................................................... 16

5.1 Connections and control devices..................................................................... 16

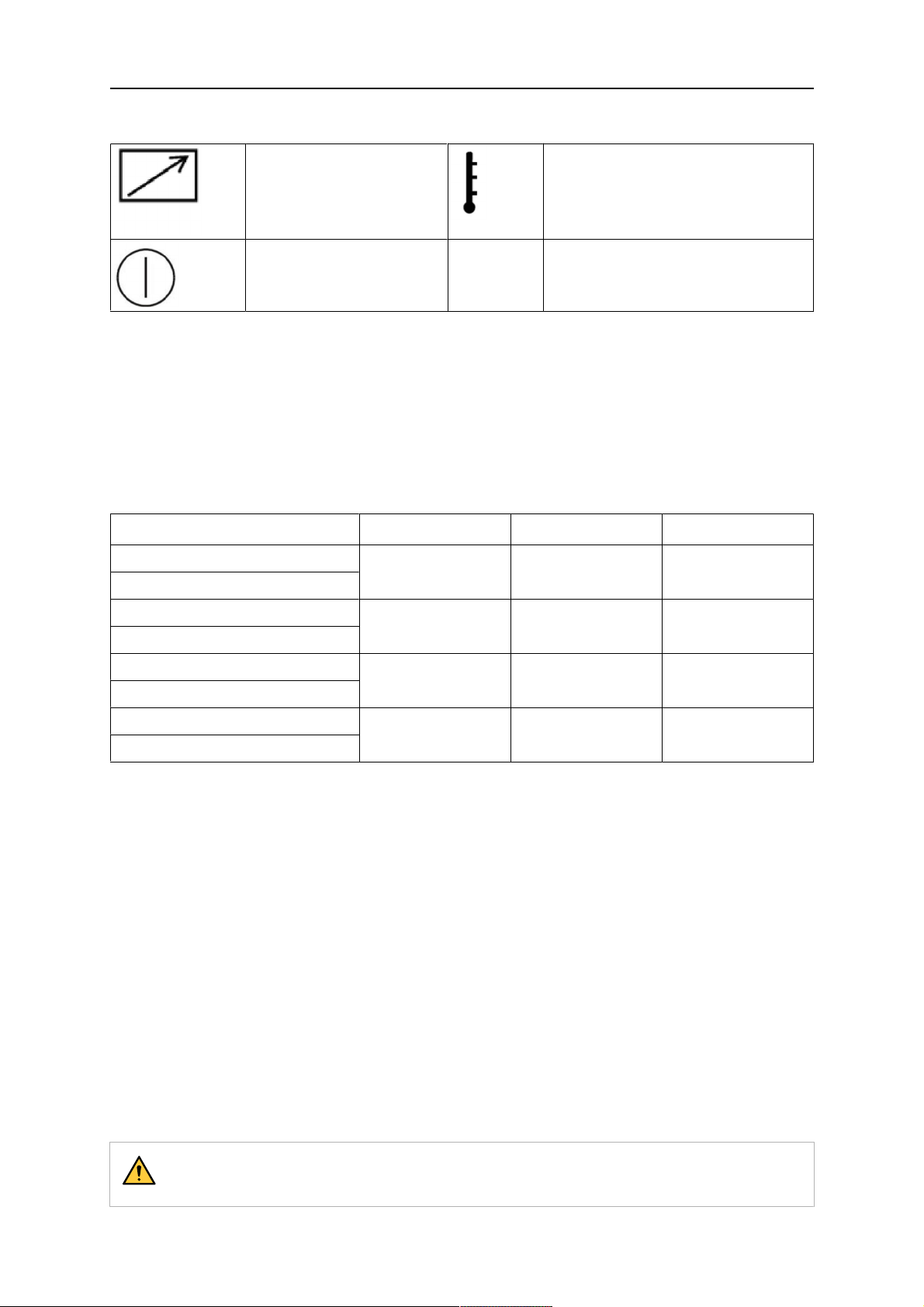

5.2 Symbols .............................................................................................................. 17

5.3 Connection of welding and return cable.......................................................... 17

5.4 Turning the power source on/off ......................................................................17

5.5 Fan control.......................................................................................................... 17

5.6 Overheating protection...................................................................................... 18

5.7 VRD (Voltage Reducing Device) .......................................................................18

5.8 Remote control unit ........................................................................................... 18

5.9 MIG/MAG and self-shielded cored wire welding .............................................18

6 MAINTENANCE..................................................................................................19

6.1 Inspection and cleaning .................................................................................... 19

6.2 Welding torch ..................................................................................................... 19

7 FAULT TRACING................................................................................................ 20

8 ORDERING SPARE PARTS ............................................................................... 21

DIAGRAM ..................................................................................................................22

ORDERING NUMBERS.............................................................................................23

SPARE PARTS LIST.................................................................................................. 24

ACCESSORIES .........................................................................................................25

Rights reserved to alter specifications without notice.

0463 380 031 © ESAB AB 2015

1 SAFETY PRECAUTIONS

1 SAFETY PRECAUTIONS

NOTE!

Be sure this information reaches the operator. You can obtain extra copies via

your supplier.

CAUTION!

These INSTRUCTIONS are for experienced operators. If you are not fully familiar

with the principles of operation and safe practices for arc welding equipment, we

urge you to read our booklet, "Precautions and Safe Practices for Arc, Cutting

and Gouging", Form 52-529 . Do NOT permit untrained persons to install,

operate, or maintain this equipment. Do NOT attempt to install or operate this

equipment until you have read and fully understand these instructions. If you do

not fully understand these instructions, contact your supplier for further

information. Be sure to read the Safety Precautions before installing or operating

this equipment.

This equipment will perform in conformity with the description thereof contained in this

manual and accompanying labels and/or insert when installed, operated, maintained and

repaired in accordance with the instruction provided. This equipment must be checked

periodically. Malfunctioning or poorly maintained equipment should not be used. Parts that

are broken, missing, worn, distorted or contaminated should be replaced immediately. Should

such repair or replacement become necessary, the manufacturer recommends that a

telephone or written request for service advice be made to the Authorised Distributor from

whom it was purchased.

This equipment or any of its parts should not be altered without the prior written approval of

the manufacturer. The user of this equipment shall have the sole responsibility for any

malfunction which results from improper use, faulty maintenance, damage, improper repair or

alteration by anyone other than the manufacturer or a service facility designated by the

manufacturer.

CAUTION!

Read and understand the instruction manual before

installing or operating.

WARNING!

These Safety Precautions are for your protection. They summarise precautionary

information from the references listed in the Additional Safety Information section.

Before performing any installation or operating procedures, be sure to read and

follow the safety precautions listed below as well as all other manuals, material

safety data sheets, labels, etc. Failure to observe the Safety Precautions could

result in injury or death.

PROTECT YOURSELF AND OTHERS

Some welding, cutting and gouging processes are noisy and require

hearing protection. The arc, like the sun, emits ultraviolet (UV) and

other radiation and can injure the skin and eyes. Hot metal can cause

burns. Training in the proper use of the processes and equipment is

essential to prevent accidents. Therefore:

0463 380 031

- 3 -

© ESAB AB 2015

1 SAFETY PRECAUTIONS

1. Always wear safety glasses with side shields in any work area, even if welding helmets,

face shields and goggles are also required.

2. Use a face shield fitted with the correct filter and cover plates to protect your eyes, face,

neck and ears from sparks and rays of the arc when operating or observing operations.

Warn bystanders not to look at the arc and not to expose themselves to the rays of the

electric-arc or hot metal.

3. Wear flameproof gauntlet type gloves, heavy long-sleeve shirt, cuffless trousers,

high-topped shoes and a welding helmet or cap for protection, to protect against arc rays

and hot sparks or hot metal. A flameproof apron may also be desirable as protection

against radiated heat and sparks.

4. Hot sparks or metal can lodge in rolled up sleeves, trouser cuffs, or pockets. Sleeves and

collars should be kept buttoned and open pockets eliminated from the front of the

clothing.

5. Protect other personnel from arc rays and hot sparks using a suitable nonflammable

partition or curtains.

6. Use goggles over safety glasses when chipping slag or grinding. Chipped slag may be

hot and can fly for long distances. Bystanders should also wear goggles over safety

glasses.

FIRES AND EXPLOSIONS

The heat from flames and arcs can start fires. Hot slag or sparks can

also cause fires and explosions. Therefore:

1. Remove all combustible materials well away from the work area or cover the materials

with a protective nonflammable covering. Combustible materials include wood, cloth,

sawdust, liquid and gas fuels, solvents, paints and coating paper, etc.

2. Hot sparks or hot metal can fall through cracks or crevices in floors or wall openings and

cause a hidden smoldering fire or fires on the floor below. Make certain that such

openings are protected from hot sparks and metal.

3. Do not weld, cut or perform other hot work until the workpiece has been completely

cleaned, to ensure there are no substances on the workpiece which might produce

flammable or toxic vapors. Do not perform hot work on closed containers. They may

explode.

4. Have fire extinguishing equipment handy for instant use, such as a garden hose, water

pail, sand bucket, or portable fire extinguisher. Be sure you are trained in its use.

5. Do not use equipment beyond its ratings. For example, overloaded welding cable can

overheat and create a fire hazard.

6. After completing work, inspect the work area to make sure there are no hot sparks or hot

metal that could cause a fire later. Use fire watchers when necessary.

7. For additional information refer to NFPA Standard 51B, "“Fire Prevention in Use of

Cutting and Welding Processes", available from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

ELECTRICAL SHOCK

Contact between live electrical parts and earth can cause severe injury

or death. DO NOT use AC welding current in damp areas, if movement

is confined, or if there is danger of falling. Therefore:

1. Be sure the power source frame (chassis) is connected to the earth system of the input

power.

2. Connect the workpiece to a good electrical earth.

0463 380 031

- 4 -

© ESAB AB 2015

1 SAFETY PRECAUTIONS

3. Connect the work cable to the workpiece. A poor or missing connection can expose you

or others to a fatal shock.

4. Use well-maintained equipment. Replace worn or damaged cables.

5. Keep everything dry, including clothing, work area, cables, torch/electrode holder and

power source.

6. Make sure that all parts of your body are insulated from the workpiece and from earth.

7. Do not stand directly on metal or the ground while working in tight quarters or a damp

area; stand on dry boards or an insulating platform and wear rubber-soled shoes.

8. Put on dry, hole-free gloves before turning on the power.

9. Turn off the power, before removing your gloves.

10. Refer to ANSI/ASC Standard Z49.1 (listed on next page) for specific earthing

recommendations. Do not mistake the work lead for a earth cable.

ELECTRIC AND MAGNETIC FIELDS

May be dangerous. Electric current flowing through any conductor

causes localised Electric and Magnetic Fields (EMF). Welding and

cutting current creates EMF around welding cables and welding

machines. Therefore:

1. Welders with pacemakers fitted should consult their doctor before welding. EMF may

interfere with some pacemakers.

2. Exposure to EMF may have other health effects which are unknown.

3. Welders should use the following procedures to minimise exposure to EMF:

a) Route the electrode and work cables together. Secure them with tape when possible.

b) Never coil the torch or work cable around your body.

c) Do not place your body between the torch and work cables. Route cables on the

same side of your body.

d) Connect the work cable to the workpiece as close as possible to the area being

welded.

e) Keep the welding power source and cables as far away from your body as possible.

FUMES AND GASES

Fumes and gases, can cause discomfort or harm, particularly in

confined spaces. Do not breathe fumes and gases. Shielding gases

can cause asphyxiation. Therefore:

1. Always provide adequate ventilation in the work area by natural or mechanical means.

Do not weld, cut or gouge on materials such as galvanised steel, stainless steel, copper,

zinc, lead beryllium or cadmium unless positive mechanical ventilation is provided. Do

not breathe in the fumes from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc can react with

chlorinated hydrocarbon vapours to form phosgene, a highly toxic gas and other irritant

gases.

3. If you develop momentary eye, nose or throat irritation while operating, this is an

indication that the ventilation is not adequate. Stop work and take the necessary steps to

improve ventilation in the work area. Do not continue to operate if physical discomfort

persists.

0463 380 031

- 5 -

© ESAB AB 2015

1 SAFETY PRECAUTIONS

4. Refer to ANSI/ASC Standard Z49.1 (see listing below) for specific ventilation

recommendations.

5. WARNING: This product when used for welding or cutting, produces fumes or gases that

contain chemicals known to the State of California to cause birth defects and in some

cases cancer (California Health & Safety Code §25249.5 et seq.)

CYLINDER HANDLING

Cylinders, if mishandled, can rupture and violently release gas.

Sudden rupture of cylinder valve or relief device can injure or kill.

Therefore:

1. Use the proper gas for the process and use the proper pressure reducing regulator

designed to operate from the compressed gas cylinder. Do not use adaptors. Maintain

hoses and fittings in good condition. Follow the manufacturer's operating instructions for

mounting a regulator to a compressed gas cylinder.

2. Always secure cylinders in an upright position, by chain or strap, to suitable hand trucks,

undercarriages, benches, wall, post or racks. Never secure cylinders to work tables or

fixtures where they may become part of an electrical circuit.

3. When not in use, keep cylinder valves closed. Have valve protection cap in place if

regulator is not connected. Secure and move cylinders by using suitable hand trucks.

4. Locate cylinders away from heat, sparks and flames. Never strike an arc on a cylinder.

5. For additional information, refer to CGA Standard P-1, "Precautions for Safe Handling of

Compressed Gases in Cylinders", which is available from Compressed Gas Association,

1235 Jefferson Davis Highway, Arlington, VA 22202.

WARNING!

EQUIPMENT MAINTENANCE

Faulty or improperly maintained equipment can cause injury or death.

Therefore:

1. Always have qualified personnel perform the installation, troubleshooting and

maintenance work. Do not perform any electrical work unless you are

qualified to perform such work.

2. Before performing any maintenance work inside a power source, disconnect

the power source from the incoming electrical power.

3. Maintain cables, earthing wire, connections, power cord and power supply in

safe working order. Do not operate any equipment in faulty condition.

4. Do not abuse any equipment or accessories. Keep equipment away from

heat sources such as furnaces, wet conditions such as water puddles, oil or

grease, corrosive atmospheres and inclement weather.

5. Keep all safety devices and cabinet covers in position and in good repair.

6. Use equipment only for its intended purpose. Do not modify it in any manner.

0463 380 031

- 6 -

© ESAB AB 2015

1 SAFETY PRECAUTIONS

CAUTION!

ADDITIONAL SAFETY INFORMATION

For more information on safe practices for electric arc welding and cutting

equipment, ask your supplier for a copy of "Precautions and Safe Practices

for Arc Welding, Cutting and Gouging", Form 52-529.

The following publications, which are available from the American Welding

Society, 550 N.W. LeJuene Road, Miami, FL 33126, are recommended to you:

1. ANSI/ASC Z49.1 - "Safety in Welding and Cutting"

2. AWS C5.1 . "Recommended Practices for Plasma Arc Welding"

3. AWS C5.2 - "Recommended Practices for Plasma Arc Cutting"

4. AWS C5.3 - "Recommended Practices for Air Carbon, Arc Gouging and

Cutting"

5. AWS C5.5 - "Recommended Practices for Gas Tungsten Arc Welding"

6. AWS C5.6 - "Recommended Practices for Gas Metal Arc welding"

7. AWS SP - "Safe practices" - Reprint, Welding Handbook

8. ANSI/AWS F4.1 - "Recommended Safe Practices for Welding and Cutting of

Containers That Have Held Hazardous Substances"

MEANING OF SYMBOLS

As used throughout this manual: Means Attention! Be Alert!

DANGER!

Means immediate hazards that, if not avoided, will result in immediate,

serious personal injury or loss of life.

WARNING!

Means potential hazards which could result in personal injury or loss of

life.

CAUTION!

Means hazards which could result in minor personal injury.

CAUTION!

This product is solely intended for arc welding.

WARNING!

Secure the equipment particularly if the ground is

uneven or sloping.

0463 380 031

- 7 -

© ESAB AB 2015

1 SAFETY PRECAUTIONS

WARNING!

The product must be lifted using a

fork lift truck or as shown in the

figure.

Disassembly and disposal

The welding torch system is mainly made from copper, nylon and other polymers, and must

be disposed of in accordance with local environmental regulations.

NOTE!

Dispose of electronic equipment at a recycling

facility!

To conform with the European Directive 2012/19/EC on

Waste Electrical and Electronic Equipment and its

implementation in accordance with national law, electrical

and/or electronic equipment that has reached the end of

its life must be disposed of at a recycling facility.

As the person responsible for the equipment, it is your

responsibility to obtain information on approved collection

stations.

For further information contact the nearest ESAB dealer.

0463 380 031

- 8 -

© ESAB AB 2015

2 INTRODUCTION

2 INTRODUCTION

The Mig 4004i Pulse combined with U6 or U82offers a complete multi-process package

supporting MMA, TIG, MIG/MAG and pulse MIG.

The power source is intended for use with the wire feed unit Feed 3004 or YardFeed 2000

and the cooling unit COOL 1. Feed 3004 is available with two operational solutions, the U6

panel and the U82pendant. YardFeed 2000 is available with the U6 panel.

ESAB's accessories for the product can be found in the "ACCESSORIES" chapter of

this manual.

2.1 Equipment

The power source is supplied with:

• 16.4 ft (5 m) return cable with ground clamp

• instruction manual for the welding power source

0463 380 031

- 9 -

© ESAB AB 2015

3 TECHNICAL DATA

3 TECHNICAL DATA

Mig 4004i Pulse

Mains voltage 380–460 V, ±10%, 3~ 50/60 Hz

Mains supply S

Primary current I

scmin

max

2.5 MVA

23 A

No-load power 160 W

Setting range (DC)

MIG/MAG 16 A/15 V–400 A/34 V

MMA 16 A/21 V–400 A/36 V

TIG 4 A/10 V–400 A/26 V

Permissible load at MIG/MAG

60% duty cycle 400 A/34.0 V

100% duty cycle 300 A/29.0 V

Permissible load at MMA

60% duty cycle 400 A/36.0 V

100% duty cycle 300 A/32.0 V

Permissible load at TIG

60% duty cycle 400 A/26.0 V

100% duty cycle 300 A/22.0 V

Power factor at maximum current 0.94

Efficiency at maximum current 88%

Open circuit voltage 55 V

Operating temperature 50 to 104°F (10 to 40°C)

Transportation temperature 68 to 131°F (20 to 55°C)

Constant sound pressure when idling <70 db (A)

Dimensions l×w×h 24.0 × 9.8 × 17.5"

(610 × 250 × 445 mm)

Weight 96 lb

(43.5 kg)

Insulation class H

Enclosure class IP 23

Application classification

Mains supply, S

sc min

Minimum short circuit power on the network in accordance with IEC 61000-3-12.

Duty cycle

The duty cycle refers to the time as a percentage of a ten-minute period that you can weld or

cut at a certain load without overloading. The duty cycle is valid for 104°F (40°C).

Enclosure class

The IP code indicates the enclosure class, i.e. the degree of protection against penetration

by solid objects or water.

Equipment marked IP23 is intended for indoor and outdoor use.

0463 380 031

- 10 -

© ESAB AB 2015

3 TECHNICAL DATA

Application class

The symbol indicates that the power source is designed for use in areas with increased

electrical hazard.

0463 380 031

- 11 -

© ESAB AB 2015

4 INSTALLATION

4 INSTALLATION

The installation must be carried out by a professional.

CAUTION!

This product is intended for industrial use. In a domestic environment, this

product may cause radio interference. It is the user's responsibility to take

adequate precautions.

4.1 Location

Position the welding power source such that its cooling air inlets and outlets are not

obstructed.

4.2 Lifting instruction

4.3 Electrical supply

NOTE!

Mains supply requirements

This equipment complies with IEC 61000-3-12 provided that the short-circuit

power is greater than or equal to S

supply and the public system. It is the responsibility of the installer or user of the

equipment to ensure, by consultation with the distribution network operator if

necessary, that the equipment is connected only to a supply with a short-circuit

power greater than or equal to S

TECHNICAL DATA chapter.

0463 380 031

at the interface point between the user's

scmin

. Refer to the technical data in the

scmin

- 12 -

© ESAB AB 2015

4 INSTALLATION

NOTE!

The power source can be connected for generator power. For more information,

contact authorised ESAB service personnel.

Check that the unit is connected to the correct power supply voltage, and that it is protected

by the correct fuse size. A protective ground connection must be made, in accordance with

regulations.

A. Rating plate with supply connection data

Recommended fuse sizes and minimum cable areas

Mig 4004i Pulse

Electrical voltage 380-460 V, +/- 10%, 3~50/60 Hz

Electrical cable area

Phase current I

Uin 380 V 22 A

eff

4C 10Awg (4G 4 mm2)

Fuse anti-surge 25 A

Fuse CMCB-surge 32 A

Phase current I

Uin 400 V 19 A

eff

Fuse anti-surge 20 A

Fuse CMCB-surge 32 A

Phase current I

Uin 440 V 18 A

eff

Fuse anti-surge 20 A

Fuse CMCB-surge 32 A

Phase current I

Uin 460 V 17 A

eff

Fuse anti-surge 20 A

Fuse CMCB-surge 25 A

0463 380 031

NOTE!

The mains cable areas and fuse sizes as shown above are in accordance with

Swedish regulations. Use the power source in accordance with the relevant

national regulations.

- 13 -

© ESAB AB 2015

4 INSTALLATION

Installation of electrical cable

If the electrical cable needs to be changed, the ground connection to the bottom plate must

be made correctly. Refer to the pictures above on how to remove the side panel and install

the electrical cable.

0463 380 031

- 14 -

© ESAB AB 2015

4 INSTALLATION

Connection instruction

The power source is connected to 460 V from factory. If another voltage is required, the cable

on the printed circuit board has to be moved and placed on the correct pin. See picture

above. This operation must be performed by someone who has the appropriate knowledge of

electrical systems.

0463 380 031

- 15 -

© ESAB AB 2015

5 OPERATION

5 OPERATION

General safety regulations for handling the equipment can be found in the "SAFETY"

chapter of this manual. Read it through before you start using the equipment!

WARNING!

Secure the equipment particularly if the ground is

uneven or sloping.

NOTE!

To achieve the best possible result at Mig short pulsing, the welding and return

cables must not exceed 33 ft (10 m).

5.1 Connections and control devices

1. Electrical power supply switch, 0 / 1 5. Connection (+): Welding cable

2. Connection for wire feed unit or remote

control unit

3. Indicating lamp, overheating 7. Fuse (10 A) for supply voltage (42 V) for

4. Indicating lamp, power supply ON 8. Cable gland for connection of electrical

0463 380 031

6. Connection (-): Return cable

feeder unit

cable

- 16 -

© ESAB AB 2015

5 OPERATION

5.2 Symbols

Remote control unit (2) Overheating (3)

Power supply ON (4)

5.3 Connection of welding and return cable

The power source has two outputs, a positive terminal (+) and a negative terminal (-), for

connecting welding and return cables.

Connect the return cable to the negative terminal on the power source. Secure the return

cable's contact clamp to the work piece and ensure that there is good contact between the

work piece and the output for the return cable on the power source.

Recommended maximum current values for connection set cables

I

max

450 A (60% duty cycle)

350 A (100% duty cycle)

550 A (60% duty cycle)

430 A (100% duty cycle)

450 A (60% duty cycle)

350 A (100% duty cycle)

550 A (60% duty cycle)

430 A (100% duty cycle)

Cable area Cable length Note

70 mm

95 mm

70 mm

95 mm

2

2

2

2

6.6 ft - 114.8 ft

(2 - 35 m)

6.6 ft - 114.8 ft

(2 - 35 m)

6.6 ft - 114.8 ft

(2 - 35 m)

6.6 ft - 114.8 ft

(2 - 35 m)

19 pole

19 pole

19 pole, water

19 pole, water

Duty cycle

The duty cycle refers to the time, expressed as a percentage of a ten-minute period, during

which you can weld or cut at a certain load without overloading. The duty cycle is valid for

104°F (40°C).

5.4 Turning the power source on/off

Turn the power source on by turning switch (1) to the ”1” position. Turn the power source off

by turning the switch (1) to the ”0” position. Welding data will be stored regardless of whether

the electrical supply is interrupted abnormally or the power source is switched off in the

normal manner, which allows it to be available the next time the unit is turned on.

5.5 Fan control

The power source has a time circuit, which keeps the fans running for 6.5 minutes after

welding has stopped, then the unit switches to energy-saving mode. The fans start again

when welding begins. The fans run at reduced speed for welding currents up to 150 A, and at

full speed for higher currents.

CAUTION!

The fans may start at any time to protect the power source from overheating.

0463 380 031

- 17 -

© ESAB AB 2015

5 OPERATION

5.6 Overheating protection

The welding power source has overheating protection circuit that operates if the internal

temperature becomes too high. When this occurs, the welding current is blocked and a fault

code is displayed on the control panel. The overheating protection resets automatically when

the temperature has fallen.

5.7 VRD (Voltage Reducing Device)

The VRD function ensures that the open-circuit voltage does not exceed 35 V when welding

is not being carried out. This is indicated by an illuminated VRD LED on the control panel of

the wire feed unit. The VRD function must be activated with ESAT by an qualified service

technician.

The VRD function is blocked when the system senses that welding has started.

5.8 Remote control unit

For more information about the operation of the remote control unit, see the instruction

manual for the control panel.

5.9 MIG/MAG and self-shielded cored wire welding

An arc melts a continuously supplied wire. The weld pool is protected by shielding gas. For

MIG/MAG and self-shielded cored wire welding, the power source is supplemented with:

• wire feed unit

• welding torch

• connection cable between the power source and wire feed unit

• shielding gas bottle

0463 380 031

- 18 -

© ESAB AB 2015

6 MAINTENANCE

6 MAINTENANCE

NOTE!

Regular maintenance is important for safe, reliable operation.

Only persons with the appropriate electrical knowledge (authorized personnel) may remove

the safety plates to connect or carry out service, maintenance or repair work on the welding

equipment.

For information about the cooling unit see the instruction manual for the cooling unit.

CAUTION!

All warranty undertakings from the supplier cease to apply if the customer

attempts any work to rectify any faults in the product during the warranty period.

6.1 Inspection and cleaning

Check regularly that the power source is free from dirt.

The power source should be regularly blown clean using dry compressed air at reduced

pressure. More frequently in dirty environments.

Otherwise the air inlet/outlet may become blocked and cause overheating. To avoid this, the

air filter should be cleaned regularly.

Replacing and cleaning the dust filter:

1. Release the dust filter according to the figure.

2. Blow the filter clean with compressed air (reduced pressure).

3. Ensure that the filter with the finest mesh is placed toward the grill.

4. Reinstall the filter.

6.2 Welding torch

Wear parts should be cleaned and replaced at regular intervals in order to avoid problems

while welding.

0463 380 031

- 19 -

© ESAB AB 2015

7 FAULT TRACING

7 FAULT TRACING

Try these recommended checks and inspections before requesting a visit from an authorized

service technician.

Type of fault Actions

No arc. • Check that the electrical power supply

switch is turned on.

• Check that the electrical, welding current,

and return cables are connected correctly.

• Check that the correct current value is

set.

• Check the electrical power supply fuses.

Welding current is interrupted during welding • Check whether the thermal overload trip

has operated (indicated by the orange

lamp on the front)

• Check the main power supply fuses.

• Check that the return cable is correctly

fastened.

The thermal overload trips frequently • Check to see whether the air filters are

clogged.

• Make sure that you are not exceeding the

rated data for the power source (i.e. that

the unit is not being overloaded).

Poor welding performance. • Check that the welding current and return

cables are connected correctly.

• Check that the correct current value is

set.

• Check that the correct welding wires are

being used.

• Check the electrical power supply fuses.

Nothing happens when the trigger on the

welding torch is pushed.

• Check the fuse on the rear part of the

power source.

• Check if the welding and return cables

are damaged.

• Check that the wire feeder works

correctly. See the wire feeder instruction

manual.

0463 380 031

- 20 -

© ESAB AB 2015

8 ORDERING SPARE PARTS

8 ORDERING SPARE PARTS

CAUTION!

Repair and electrical work should be performed by an authorised ESAB service

technician. Use only ESAB original spare and wear parts.

The Mig 4004i Pulse 460 V is designed and tested in accordance with the international

standards IEC 60974-1 and US standards ANSI/IEC 60974-1:2008. It is the obligation

of the service unit that carried out the service or repair work to make sure that the

product still conforms to said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the back cover of this

document. When ordering, please state product type, serial number, designation and spare

part number in accordance with the spare parts list. This facilitates dispatch and ensures

correct delivery.

0463 380 031

- 21 -

© ESAB AB 2015

DIAGRAM

DIAGRAM

0463 380 031

- 22 -

© ESAB AB 2015

ORDERING NUMBERS

ORDERING NUMBERS

Ordering

Denomination Type Note

number

0465 152 882 Welding power source Aristo® Mig 4004i Pulse 460V version

0463 396 001 Spare parts list Aristo® Mig 4004i Pulse

Technical documentation is available on the Internet at: www.esab.com

0463 380 031

- 23 -

© ESAB AB 2015

SPARE PARTS LIST

SPARE PARTS LIST

Item Ordering no. Denomination

1 0462 197 001 Dust filter

2 0463 396 001 Warning label

0463 380 031

- 24 -

© ESAB AB 2015

ACCESSORIES

ACCESSORIES

Trolleys

0462 151 880

0459 839 039

Trolley 11, 4-wheels

Spare parts list for trolley

0463 125 880 Trolley bracket for Trolley 11

Option when no cooling unit is assembled

0460 564 880

0460 815 880

Trolley 8, 2-wheels

Shelf for YardFeed and MobileFeed

0460 565 880 Trolley 9, 4-wheel

For counterbalance device.

Trolley accessories

0461 310 880 Bracket kit

To assembly 4004i/5004i to the 2/4-wheel

trolley 0460 564/565

0460 946 880 Stabilizer 4-wheel for counterbalance

0463 380 031

- 25 -

© ESAB AB 2015

ACCESSORIES

0458 705 880 Counterbalance device

Includes mast and counterbalance

Wire feeders

0460 526 486

0460 526 896

0460 526 481

0460 526 891

0459 906 896

Feed 3004 U6

Feed 3004 U6, water-cooled

Feed 3004 for U8

2

Feed 3004 for U82, water-cooled

YardFeed 2000 U6, water-cooled

Feeder accessories

0458 674 880 1 Bobbin cover, plastic

0459 431 880 1 Bobbin cover, metal

0463 380 031

- 26 -

© ESAB AB 2015

ACCESSORIES

0455 410 001 1 Adapter for 5 kg bobbin

0459 233 880 1 Adapter for 440 mm bobbin

0458 706 880 1 Lifting eye

F102 440 880

899F50

2 Quick connector Marathon Pac™

2 Quick connector Marathon Pac™ NA

0558 002 354 Connector Adapter Marathon Pac™ NA

0463 380 031

- 27 -

© ESAB AB 2015

ACCESSORIES

0458 707 880 1 Wheel kit for feeder, front wheels

turnable

0457 341 881 1 Strain relief for welding torch

0459 234 880 Strain relief for interconnection cables

Cooler

0462 300 880 Water cooling unit, COOL1

0456 855 881 Flow guard, COOL1

0463 380 031

- 28 -

© ESAB AB 2015

ACCESSORIES

Control panels

0460 820 880 Aristo®U82, complete including holder

0460 820 881 Aristo®U82, plus complete including

holder

0460 877 891 Control cable extension U82, 7.5 m

Connection set, 70 mm

0349 312 450

0349 312 451

0349 312 452

0349 312 453

0349 312 454

0349 312 455

5.6 ft (1.7 m)

16.0 ft (5 m)

32.8 ft (10 m)

49.2 ft (15 m)

82.0 ft (25 m)

114.8 ft (35 m)

Connection set water, 70 mm

0459 528 790

0459 528 791

0459 528 792

5.6 ft (1.7 m)

16.0 ft (5 m)

32.8 ft (10 m)

2

2

0459 528 793

0459 528 794

0459 528 795

0463 380 031

49.2 ft (15 m)

82.0 ft (25 m)

114.8 ft (35 m)

- 29 -

© ESAB AB 2015

ACCESSORIES

Remote controls

0459 491 880 Remote control unit MTA1 CAN

MIG/MAG: wire feed speed and voltage

MMA: current and arc force

TIG: current, pulse and background current

0459 491 882 Remote control M1 10 Prog. CAN

Remote control cable 10 pole - 4 pole

0459 960 880

0459 960 881

0459 960 882

0459 960 883

16 ft (5m)

32.8 ft (10 m)

82.0 ft (25 m)

10 in. (0.25 m)

Remote adapter kit

0459 681 880

0459 681 881

For Miggy-/Railtrac

For MXH PP and PSF RS3

Connection kit

0459 020 883 For MXH™ 300/400w PP connection kit

Information on PSF welding torches can be found in separate brochures.

0463 380 031

- 30 -

© ESAB AB 2015

ACCESSORIES

0463 380 031

- 31 -

© ESAB AB 2015

ESAB Welding & Cutting Products, Florence, SC Welding Equipment

COMMUNICATION GUIDE - CUSTOMER SERVICES

A CUSTOMER SERVICE QUESTIONS:

Telephone: (800) 362-7080 / Fax: (800) 634-7548 Hours: 8.00 AM to 7:00 PM EST

Order Entry Product Availability Pricing Order Information Returns

B ENGINEERING SERVICE:

Telephone: (834) 664-4416 / Fax: (800) 446-5693 Hours: 7.30 AM to 5:00 PM EST

Warranty Returns Authorized Repair Stations Welding Equipment Troubleshooting

C TECHNICAL SERVICE:

Telephone: (800) ESAB-123 / Fax: (843) 664-4452 Hours: 8.00 AM to 5:00 PM EST

Part Numbers Technical Applications Specifications Equipment Recommendations

D LITERATURE REQUESTS:

Telephone: (843) 664-5562 / Fax: (843) 664-5548 Hours: 7.30 AM to 4:00 PM EST

E WELDING EQUIPMENT REPAIRS:

Telephone: (843) 664-4487 / Fax: (843) 664-5557 Hours: 7.30 AM to 3:30 PM EST

Repair Estimates Repair Status

F WELDING EQUIPMENT TRAINING:

Telephone: (843) 664-4428 / Fax: (843) 679-5864 Hours: 7.30 AM to 4:00 PM EST

Training School Information and Registrations

G WELDING PROCESS ASSISTANCE:

Telephone: (800) ESAB-123 / Fax: Hours: 7.30 AM to 4:00 PM EST

H TECHNICAL ASST. CONSUMABLES:

Telephone: (800) 933-7070 / Fax: Hours: 7.30 AM to 5:00 PM EST

IF YOU DO NOT KNOW WHOM TO CALL

Telephone: (800) ESAB-123

Fax: (843) 664-4452

Hours: 7:30 AM to 5:00 PM EST

or

visit us on the web at http://www.esabna.com

The ESAB web site offers:

Comprehensive Product Information

Material Safety Data Sheets

Warranty Registration

Instruction Literature Download Library

Distributor Locator

Global Company Information

Press Releases

Customer Feedback & Support

ESAB Welding & Cutting Products

PO BOX 100545, Florence SC 29501-0545

© ESAB AB 2015

Loading...

Loading...