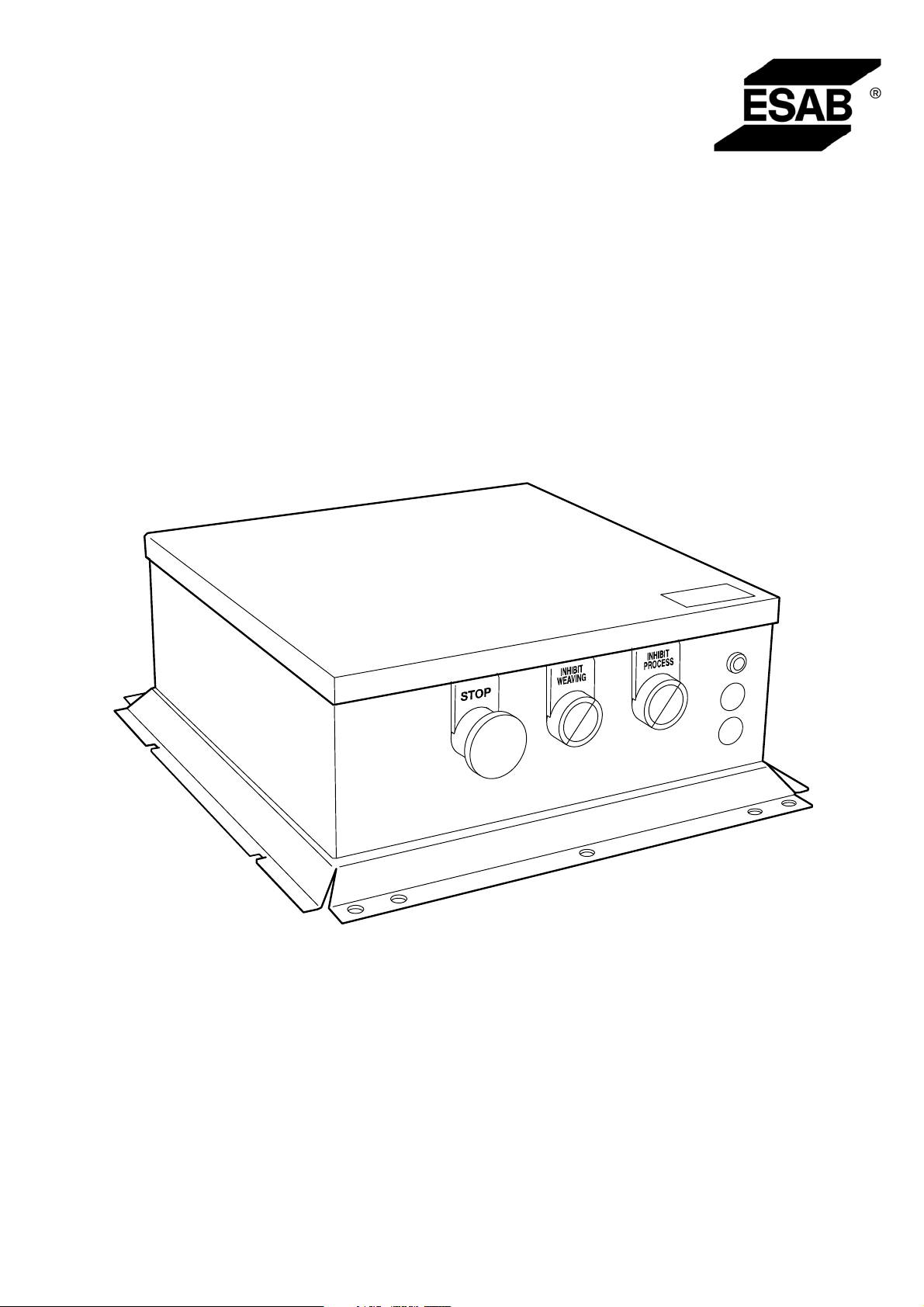

Applied Interface

Robot S4- A360

AH 0736

Instruction manual

Installation manual

0460 278 074 20110524

Valid for serial no.

541-636-6813,541-636-6814,541-636-6816 and 0541-838-6819

ENGLISH 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rights reserved to alter specifications without notice.

- 2 -

- 3 -

ENGLISH

1 SAFETY 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 INTRODUCTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Equipment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 TECHNICAL DATA 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Location 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Connection instructions 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 OPERATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Connections and control devices 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Function description 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 MAINTENANCE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Inspection and cleaning 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Fault-tracing 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 ORDERING SPARE PARTS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 FUNCTION DESCRIPTION OF I/O SIGNALS 13. . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Configuration of the I/O-version (Aristot U8 I/O) 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Input data I/O signal from control equipment (robot) to the welding equipment 13. . . . .

8.3 Output I/O signal from welding equipment to control equipment 15. . . . . . . . . . . . . . . . . .

8.4 Others 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

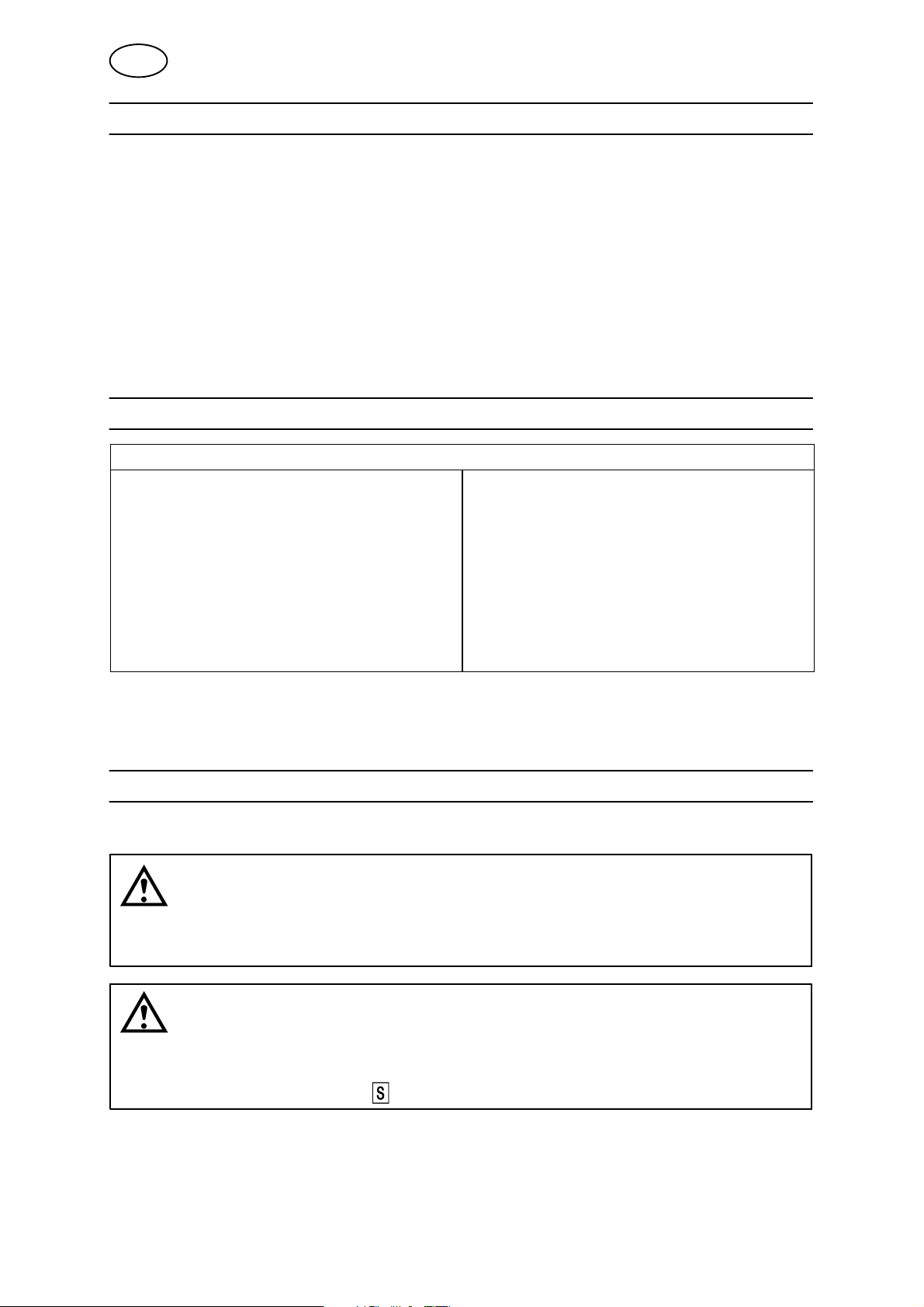

DIAGRAM 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING NUMBER 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPARE PARTS LIST 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOCe

- 4 -

GB

1 SAFETY

Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or

near the equipment observes all the relevant safety precautions. Safety precautions must meet the

requirements that apply to this type of equipment. The following recommendations should be ob

served in addition to the standard regulations that apply to the workplace.

All work must be carried out by trained personnel well-acquainted with the operation of the equip

ment. Incorrect operation of the equipment may lead to hazardous situations which can result in in

jury to the operator and damage to the equipment.

1. Anyone who uses the equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding and cutting

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment when it is

started up.

S no-one is unprotected when the arc is struck

3. The workplace must:

S be suitable for the purpose

S be free from drafts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame-proof

clothing, safety gloves.

S Do not wear loose-fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment may only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

CAUTION

Read and understand the instruction manual before

installing or operating.

CAUTION

This product is solely intended for arc welding.

br06d1ea

- 5 -

© ESAB AB 2007

GB

WARNING

Arc welding and cutting can be injurious to yourself and others. Take precausions when welding and

cutting. Ask for your employer's safety practices which should be based on manufacturers' hazard

data.

ELECTRIC SHOCK - Can kill

S Install and earth the unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES - Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS - Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE - Excessive noise can damage hearing

S Protect your ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION - Call for expert assistance in the event of malfunction.

Read and understand the instruction manual before installing or operating.

PROTECT YOURSELF AND OTHERS!

ESAB can provide you with all necessary welding protection and accessories.

Dispose of electronic equipment at the recycling facility!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment and its implementation in accordance with national law, electrical and/or

electronic equipment that has reached the end of its life must be disposed of at a

recycling facility.

As the person responsible for the equipment, it is your responsibility to obtain

information on approved collection stations.

For further information contact the nearest ESAB dealer.

br06d1ea

- 6 -

© ESAB AB 2007

GB

2 INTRODUCTION

Applied Interface Robot S4 A360 checks and converts the CAN bus signals from

the power source to the welding robot and is used for CAN bus controlled power

sources, such as AristoMig 400/500 with Aristot U8 I/O.

Applied Interface Robot S4 A360 converts analog and digital signals to field bus

communication (CAN) and from field bus signals to digital and analog signals.

2.1 Equipment

Applied Interface Robot S4 A360 is supplied with an instruction manual.

3 TECHNICAL DATA

Applied Interface Robot S4 A360

Mains voltage 42 V 50 - 60 Hz

Mains voltage 2 (from robot) 24 V DC

Fuse 1 A

External power source robot +/- 15V to robot

Robot connection 48 pin connection socket

Weight 6.1 kg

Dimensions (l x w x h) 365 x 351 x 110 mm

Protection class IP23

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP23 is designed for indoor and outdoor use.

4 INSTALLATION

The installation must be executed by a professional.

CAUTION

This product is intended for industrial use. In a domestic environment this product may

cause radio interference. It is the user's responsibility to take adequate precautions.

WARNING

When welding in an environment with increased electrical danger, only power

sources intended for this environment may be used. These power sources are

marked with the symbol

br06d1ea

- 7 -

© ESAB AB 2007

GB

4.1 Location

Applied Interface Robot S4 A360 is installed above the power source. Remove the

rubber mat (C) on the power source and then slide the flange of the interface box (A)

into the side profiles (B) of the power source, see the illustration below.

IMPORTANT! Screw the 3 screws into place on the front of the interface box,

sufficiently hard in the screw threads that electrical connection is made. Check that

electrical connection has been established.

4.2 Connection instructions

AH 0738

Complete descriptions of the power source / wire feed unit are available in separate instruction

manuals.

br06d1ea

- 8 -

© ESAB AB 2007

GB

5 OPERATION

General safety regulations for the handling of the equipment can be found on

page 5. Read through before you start using the equipment!

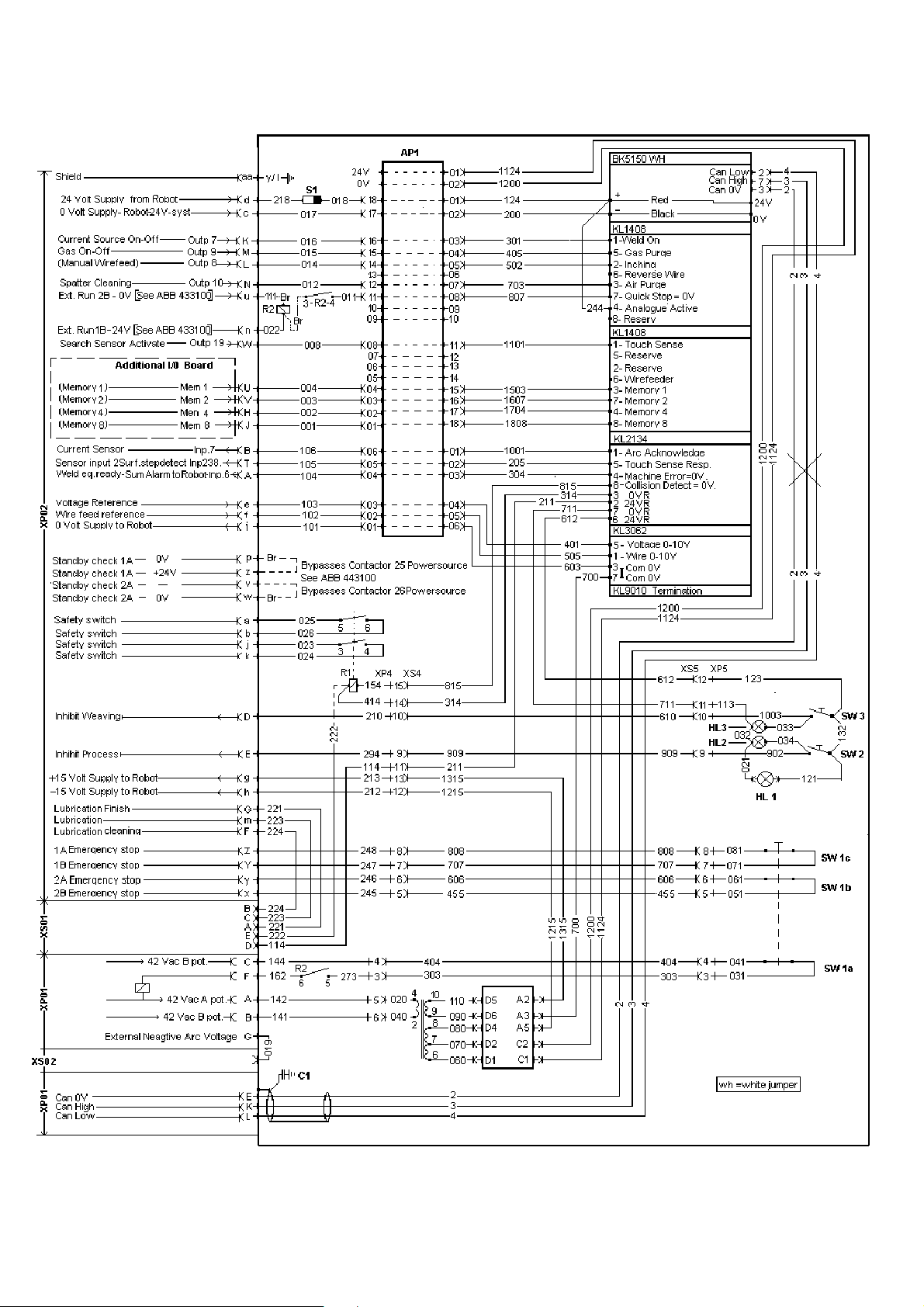

5.1 Connections and control devices

1 Stop, pushbutton YELLOW 6 Fuse / 1A 24 VDC from robot

2 Inhibit weaving, YELLOW push button 7 Connecting extra equipment (lubricating/

cleaning) socket 8 pin.

3 Inhibit process, YELLOW pushbutton 8 Connection for operating cable from power

source (12-pin CAN bus)

4 Indicator lamp (WHITE), power supply

from robot.

5 Connection for signals to/from the robot's

welding gun (48-pin socket connector)

5.2 Function description

9 Connection (negative) for arc voltage

detection (1 pin socket plug)

Applied Interface Robot S4 A360 is connected to the robot cabinet and the power

source.

When the Interface box is connected to AristoMig 400 or AristoMig 500 with

AristoPendant U8 with part number 0456 290 991 or higher.

The type plate is located on the

rear side of the Interface box.

br06d1ea

- 9 -

© ESAB AB 2007

GB

AH 0736

Button A - Stop

The button stops the robot and the welding process.

Button B – Runs the robot program without weaving

The INHIBIT WEAVING button prevents weaving in the robot program when pressed

(lights yellow). The robot program can be run with and without weaving.

Button C – Runs the robot program without the welding process

The INHIBIT PROCESS button blocks the welding process when pressed (lights

yellow). One can run the robot program and test the movement pattern without

welding.

6 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

CAUTION

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any faults.

6.1 Inspection and cleaning

Regularly check that the interface box has electrical connection with the power

source and that the connections are correctly connected and not faulty.

6.2 Fault-tracing

S Has the indicator lamp (white) on the front gone out?

Check that the fuse is intact.

S Ensure that the wiring is correctly located in its connectors.

Complete descriptions of the power source, wire feed unit and control panel are available in separate

instruction manuals.

br06d1ea

- 10 -

© ESAB AB 2007

GB

7 ORDERING SPARE PARTS

Applied Interface Robot S4- A360 is designed and tested in accordance with the inter

national and European standards 60974-1 and 60974-10 . It is the obligation of the

service unit which has carried out the service or repair work to make sure that the pro

duct still conforms to the said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the last page of

this publication.

* * *

NOTE! 8. FUNCTION DESCRIPTION OF I/O SIGNALS is only in English and is

primarily meant for the integrator and installation of the Interface box on page 13.

br06d1ea

- 11 -

© ESAB AB 2007

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

notes

- 12 -

8 FUNCTION DESCRIPTION OF I/O SIGNALS

The Aristot Retrofit I/O is the interface between the welding robot and the welding

equipment. The Aristot Retrofit I/O converts the robot's I/O signals to field bus

signals to the welding equipment. The Aristot Retrofit I/O also converts the field bus

signals from the welding equipment to I/O signals to the welding robot.

8.1 Configuration of the I/O-version (Aristot U8 I/O)

With the service function 38 in the Aristot U8 I/O unit you can activate or deactivate

the different blocks of I/O's.

For more information, please read the Service manual for AristoPendant U8.

8.2 Input data I/O signal from control equipment (robot) to the

welding equipment

Welding start

The signal starts the welding process but before the welding process starts the quick

stop and stop signals are checked to ensure that they are not active.

Stop

The signal shuts off the robot and the welding process.

Quick stop

The signal stops the equipment if it is active in the welding process, it carries out a

normal stop without crater filling. The function is used when a quick stop is required

but it gives a normal burnback time to prevent the wire sticking in the weld pool. The

signal also blocks the start command.

Wire inching

Used when one wants to feed wire without welding voltage.

The signal starts the wire feed without the welding voltage being activated. The wire

feed unit feeds wire at the set speed. If the signal is active during the welding

process, the command is ignored.

If both welding and wire inching are activated at the same time the equipment will

ignore the wire inching command and start the welding process.

Gas flushing

Gas flushing is used when measuring the gas flow or to flush any air or moisture

from the gas hoses before welding starts. Gas flushing is carried out without voltage

or wire feed occurring.

Welding start always activates the gas valve even if the manual gas command is

given. In the same way the gas valve for gas post flow is always closed if it is not

closed already.

Gas flushing operates parallel to the functions gas pre-flow and gas post-flow. To

control the welding gas from the robot, set the gas pre-flow to minimum and the gas

post-flow to maximum, and then control the welding gas using the gas flushing

functions.

br04d2e

- 13 -

© ESAB AB 2007

Spatter cleaning

The signal controls the valve for air cleaning welding spatter.

Touch Sense Response

This command is used by the robot to sense where the wire is.

When the function is active, the power source will give out current limited idle voltage

to see if the wire is in contact with the workpiece. On contact, the output signal

”Touch Sense Response” is activated.

Active analog

The signal is used to switch between the analog and digital remote modes.

Analogue active allows analog control of the welding parameters, voltage, arc

voltage and the wire feed speed.

NOTE! On AristotRetrofit I/O the function is always activated.

If the welding method Aristot SuperPulse is to be used, the ”analog active” signal

must be deactivated.

When the analogue method is activated the power source will not use the preset

values for wire feed speed and voltage when new welding data is selected. When

”analog active” is activated the robot controls arc voltage and wire feed speed using

analog signals.

With the analog active signal deactivated, welding data is exchanged with preset

welding data such as voltage, wire feed speed to fixed set welding parameters.

The pre-programmed welding data (schedules) is requested from the

Aristot U8 I/O welding data memory.

Welding data

With the signals memory 1, 2, 4, 8, one accesses saved welding data (schedules) in

Aristot U8 I/O.

The binary coded combinations of these signals can be used to recall the memories

1-15 in the Aristot U8 I/O memory bank.

A complete set of welding data includes all settings that can be made in

Aristot U8 I/O, see the instruction manual for AristoPendant U8.

Voltage reference

This signal is used by the robot for analog control of the welding voltage if analog

active is selected. It stretches from 0-10V and corresponds to welding voltage socket

as follows.

0V reference gives a deviation on the selected arc voltage of -10V

10V reference gives a deviation on the selected arc voltage of +10V

If the machine is in non-synergy mode, the equipment will use the appreciated value.

0V reference gives arc voltage 8V

10V reference gives arc voltage 60V

br04d2e

- 14 -

© ESAB AB 2007

Wire feed speed reference signal

The signal is used by the robot to make analog adjustments to the wire feed speed.

The internal solution is 0.1 m/min.

Input voltage

0 V Mini. value for wire feed (normally 0.8 m/min) (RoboFeed)

10 V Max. value for wire feed (normally 25 m /min)

8.3 Output I/O signal from welding equipment to control

equipment

Arc Acknowledge

The signal is activated after established welding start if the voltage and current

strength lie within weldable limits. The signal disappears if welding cannot be

established.

The criterion for establishing a welding arc is that the process control has passed the

start- procedure, which means that there it not sufficient with only a short circuit to

meet the criteria. Normal delay from the first contact, which is acknowledged by the

welding arc (wire feed time for this that the first contact is established ) is in the

interval 2 to 20 ms. If there is a poor start to the welding arc the ”Arc acknowledge” is

further delayed.

Touch Sense Response

This signal indicates contact in the welding circuit, i.e. that the wire is in contact with

the workpiece. To obtain ”touch sense response” the ”touch sense” input signal must

be activated.

Collision robot (AntiCollisionDetect)

The signal comes via the internal CAN bus from the feeding mechanism

(RoboFeed). The signal indicates that the robot's breaker has activated. The

interface activates a relay which breaks two safety loops from the robot, at which the

robot orders a quick stop of both robot and the welding equipment.

The output is high when the welding gun breaker is tripped (the signal is sent to the

robot).

Machine faults

The signal is low when an error has been detected in the welding equipment.

8.4 Others

0-cable 4 mm

2

S The 0-cable 4mm2 between the power source and the robot cabin is delivered in length of 15

m and is to be cut to the length required at installation.

Start up time

S The start up time of the Interface box when current/power is activated can be delayed up to

1 minute.

- 15 -

br04d2e

© ESAB AB 2007

Diagram

br06dia

- 16 Edition 20110524

Applied Interface Robot S4- A360

Ordering number

AH 0736

Ordering no. Denomination Type Notes

- Applied Interface Robot

S4 A360

br06order

- 17 Edition 20110524

Applied Interface Robot S4- A360

Spare parts list

Item Qty Ordering no. Denomination Notes

101 1 0461 095 001 Cover

102 1 0461 110 881 Gable back 48p 1x12p

103 2 0452 116 004 Relay 2VX 24VDC

104 2 0452 116 008 Socket

105 1 0368 544 002 Sleeve socket 8-pol.

106 1 0368 543 008 Panel plug 48-pol

107 1 0458 681 891 Cable D-sub compl.

108 1 0467 911 884 Capacitor

109 1 0456 686 880 Clamp

110 1 0368 543 003 Burndy plug M/C Mount 12 way

- 50 0323 945 004 Contact pins (W) Min. 50 pcs

111 1 0443 740 007 Sign bracket

112 1 0457 800 001 Insulation

113 1 0366 285 001 Protection cap 12-pol

114 1 0193701 001 Fuse holder knob

115 1 0567 900 132 Fuse 1A

116 1 0193 701 002 Fuse holder

117 1 0461 092 001 Chassi S3 A350

118 1 0461 098 001 Adapter plate S3 A350

119 1 0461 092 880 Gable front. S3 A350

122 1 0461 740 011 Stop buttom Baco

121 3 0443 740 007 Sign bracket

120 1 0443 740 010 Sign “STOP”

123 2 0443 740 002 Contact block 14A/230 VAC (Stop buttom)

124 2 0443 740 003 Push buttom switch

125 1 0443 740 008 Sign “Inhibit Process”

126 1 0443 740 009 Sign “Inhibit Weawing”

127 1 0443 740 005 Lamp 24 VDC Baco

128 2 0443 740 004 Bracket

129 2 0443 740 006 Contact block 14A/230 VAC

20 0194 179 327 Screw MRT Ground-cutter M5x12

2 0194 120 285 Screw MRT M4x6

4 - Screw RTS ST 3.5 x 9.5

2 - Nut M6M 4 M4x6

2 - Washer (VEC) D7.6/4.1

1 0458 950 001 Sign MEL30/MEL48

1 0192 576 003 Lamp 24V White

br04asp1

- 18 -

Edition 20110524

Applied Interface Robot S4- A360

br04asp1

- 19 -

Edition 20110524

Applied Interface Robot S4- A360

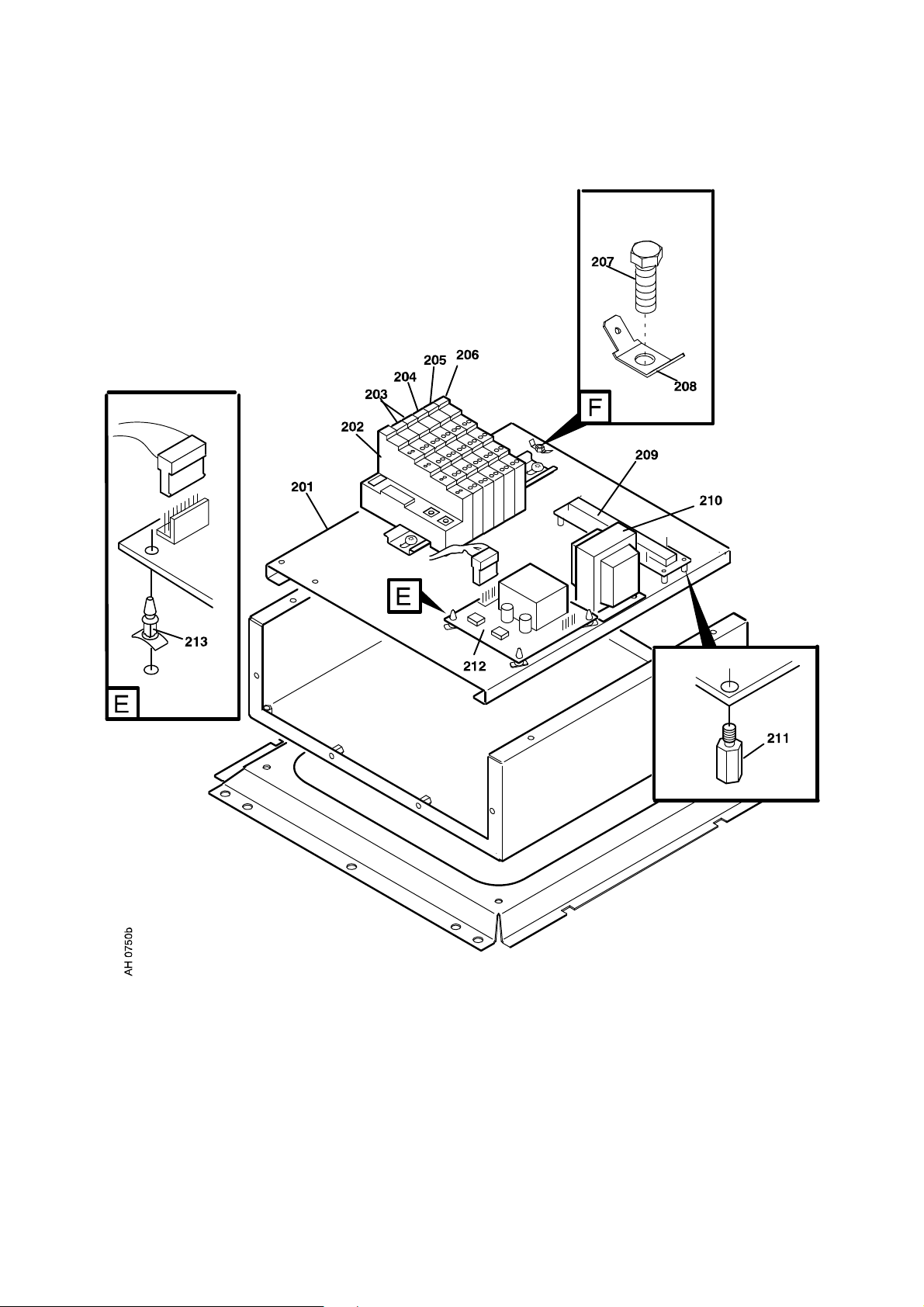

Item Qty Ordering no. Denomination Notes

MOUNTING PLATE

201 1 0461 097 001 Mounting plate

202 1 0194 204 001 Terminal Bud coupler BK5151

203 2 0194 205 001 Terminal Digital input KL1408

204 1 0194 205 002 Terminal Digitial output KL2134

205 1 0194 205 003 Terminal Analog input KL3062

206 1 0194 205 004 Terminal Bus End KL9010

207 1 0194 179 327 Screw, MRT Ground-cutter M5x12

208 1 0191 548 009 Flat pin 6.3 x 0.8 M6

209 1 0487 427 880 Printed Circuit Board

210 1 0319 828 003 Transformer WFU

211 1 0192 790 102 Circuit Card holder 6.3 mm

212 1 0740 545 001 Printed Circuit Board 24 V

212 1 0740 545 002 Printed Circuit Board 15 V

213 2 0192 547 002 Quick-Act lock nut B6

br04asp2

- 20 -

Edition 20110524

Applied Interface Robot S4- A360

br04asp2

- 21 -

Edition 20110524

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

notes

- 22 -

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

notes

- 23 -

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna-Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 745 11 28

BULGARIA

ESAB Kft Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Vamberk

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Herlev

Tel: +45 36 30 01 11

Fax: +45 36 30 40 03

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel: +33 1 30 75 55 00

Fax: +33 1 30 75 55 24

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 218

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel: +36 1 20 44 182

Fax: +36 1 20 44 186

ITALY

ESAB Saldatura S.p.A.

Bareggio (Mi)

Tel: +39 02 97 96 8.1

Fax: +39 02 97 96 87 01

NORWAY

AS ESAB

Larvik

Tel: +47 33 12 10 00

Fax: +47 33 11 52 03

POLAND

ESAB Sp.zo.o.

Katowice

Tel: +48 32 351 11 00

Fax: +48 32 351 11 20

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 8 310 960

Fax: +351 1 859 1277

ROMANIA

ESAB Romania Trading SRL

Bucharest

Tel: +40 316 900 600

Fax: +40 316 900 601

RUSSIA

LLC ESAB

Moscow

Tel: +7 (495) 663 20 08

Fax: +7 (495) 663 20 09

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel: +421 7 44 88 24 26

Fax: +421 7 44 88 87 41

SPAIN

ESAB Ibérica S.A.

Alcalá de Henares (MADRID)

Tel: +34 91 878 3600

Fax: +34 91 802 3461

SWEDEN

ESAB Sverige AB

Gothenburg

Tel: +46 31 50 95 00

Fax: +46 31 50 92 22

ESAB international AB

Gothenburg

Tel: +46 31 50 90 00

Fax: +46 31 50 93 60

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

UKRAINE

ESAB Ukraine LLC

Kiev

Tel: +38 (044) 501 23 24

Fax: +38 (044) 575 21 88

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem-MG

Tel: +55 31 2191 4333

Fax: +55 31 2191 4440

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 57 48

Asia/Pacific

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 2326 3000

Fax: +86 21 6566 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. ESABindo Pratama

Jakarta

Tel: +62 21 460 0188

Fax: +62 21 461 2929

JAPAN

ESAB Japan

Tokyo

Tel: +81 45 670 7073

Fax: +81 45 670 7001

MALAYSIA

ESAB (Malaysia) Snd Bhd

USJ

Tel: +603 8023 7835

Fax: +603 8023 0225

SINGAPORE

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 6861 43 22

Fax: +65 6861 31 95

SOUTH KOREA

ESAB SeAH Corporation

Kyungnam

Tel: +82 55 269 8170

Fax: +82 55 289 8864

UNITED ARAB EMIRATES

ESAB Middle East FZE

Dubai

Tel: +971 4 887 21 11

Fax: +971 4 887 22 63

Africa

EGYPT

ESAB Egypt

Dokki-Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

SOUTH AFRICA

ESAB Africa Welding & Cutting Ltd

Durbanvill 7570 - Cape Town

Tel: +27 (0)21 975 8924

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

THE NETHERLANDS

ESAB Nederland B.V.

Amersfoort

Tel: +31 33 422 35 55

Fax: +31 33 422 35 44

www.esab.com

110426© ESAB AB

Loading...

Loading...