ERL F-PRO 5100 User Manual

F-PRO

Feeder Protection Relay

Model 5100

User Manual

Version 4.0 Rev 0

Preface

Information in this document is subject to change without notice.

© 2016 ERLPhase Power Technologies Ltd. All rights reserved.

Reproduction in any manner whatsoever without the written permission of

ERLPhase Power Technologies Ltd. is strictly forbidden.

This manual is part of a complete set of product documentation that includes

detailed drawings and operation. Users should evaluate the information in the

context of the complete set of product documentation and their particular

applications. ERLPhase assumes no liability for any incidental, indirect or

consequential damages arising from the use of this documentation.

While all information presented is believed to be reliable and in accordance

with accepted engineering practices, ERLPhase makes no warranties as to the

completeness of the information.

All trademarks used in association with B-PRO, F-PRO, iTMU, L-PRO,

ProLogic, S-PRO, T-PRO, TESLA, TESLA Control Panel, Relay Control

Panel, RecordGraph and RecordBase are trademarks of ERLPhase Power

Technologies Ltd.

Windows® is a registered trademark of the Microsoft Corporation.

HyperTerminal® is a registered trademark of Hilgraeve.

Modbus® is a registered trademark of Modicon.

Contact Information

ERLPhase Power Technologies Ltd

Website: www.erlphase.com

Email: info@erlphase.com

Technical Support

Email: support@erlphase.com

Tel: 1-204-477-0591

D02416R04.00 F-PRO 5100 User Manual i

Table of Contents

Preface ......................................................................................i

Contact Information ...................................................................i

Table of Contents ....................................................................iii

Using This Guide ......................................................................v

Version Compatibility.............................................................. vii

1 Overview ................................................................. 1-1

Front View........................................................................ 1-3

Back View ........................................................................ 1-3

Model Options/Ordering................................................... 1-4

2 Setup and Communications.................................. 2-1

Power Supply................................................................... 2-1

IRIG-B Time Input ............................................................ 2-1

Communicating with the Relay (IED) ............................... 2-2

Using HyperTerminal to Access the Relay’s User

Interface........................................................................... 2-5

Setting the Baud Rate...................................................... 2-7

Accessing the Relay’s SCADA Services.......................... 2-8

Communication Port Details ............................................ 2-9

Maintenance Menu ........................................................ 2-12

Firmware Update ........................................................... 2-13

3 Using the IED (Getting Started) ............................ 3-1

Start-up Sequence........................................................... 3-1

Front Panel Display.......................................................... 3-2

Terminal Mode ................................................................. 3-5

View, Change or Service Login........................................ 3-9

Breaker Login................................................................. 3-13

Metering Data ................................................................ 3-14

4 Protection Functions and Specifications ............ 4-1

Protection and Recording Functions................................ 4-1

Demand Metering .......................................................... 4-17

Accumulated Energy (kWh, kVARh metering)............... 4-20

Recording Functions...................................................... 4-26

Logging Functions.......................................................... 4-28

5 Offliner Settings Software..................................... 5-1

Introduction ...................................................................... 5-1

Installing PC Software...................................................... 5-2

D02416R04.00 F-PRO 5100 User Manual iii

Table of Contents

Offliner Features .............................................................. 5-2

Handling Backward Compatibility .................................... 5-4

RecordBase View Software ............................................. 5-5

Main Branches from the Tree View.................................. 5-6

Settings From a Record ................................................. 5-19

6 Testing the F-PRO Functions................................ 6-1

7 Installation .............................................................. 7-1

Physical Mounting............................................................ 7-1

AC and DC Wiring............................................................ 7-1

Communication Wiring..................................................... 7-1

Appendix A IED Specifications .............................................A-1

Distance Element Operating Time Curves at Nominal

Frequency ........................................................................A-4

Frequency Element Operating Time Curves....................A-5

Appendix B IED Settings and Ranges..................................B-1

Appendix C Hardware Description .......................................C-1

Appendix D Event Messages ...............................................D-1

Appendix E Modbus RTU Communication Protocol.............E-1

Appendix F DNP3 Communication Protocol......................... F-1

Appendix G Mechanical Drawings........................................G-1

Appendix H Rear Panel Drawings ........................................H-1

Appendix I AC Schematic Drawing........................................ I-1

Appendix J DC Schematic Drawing.......................................J-1

Appendix K Function Logic Diagram ....................................K-1

Appendix L F-PRO Setting Example .................................... L-1

Setting Examples ............................................................. L-2

Switching Setting Groups................................................. L-5

Index..........................................................................................I

iv F-PRO 5100 User Manual D02416R04.00

Using This Guide

This User Manual describes the installation and operation of the F-PRO feeder

protection relay. It is intended to support the first time user and clarify the details of the equipment.

The manual uses a number of conventions to denote special information:

Example Describes

Start>Settings>Control Panel Choose the Control Panel submenu in the Set-

Right-click Click the right mouse button.

Recordings Menu items and tabs are shown in italics.

tings submenu on the Start menu.

service User input or keystrokes are shown

Text boxes similar to this one Relate important notes and information.

.. Indicates more screens.

Indicates further drop-down menu, click to display list.

Indicates a warning.

in bold.

D02416R04.00 F-PRO 5100 User Manual v

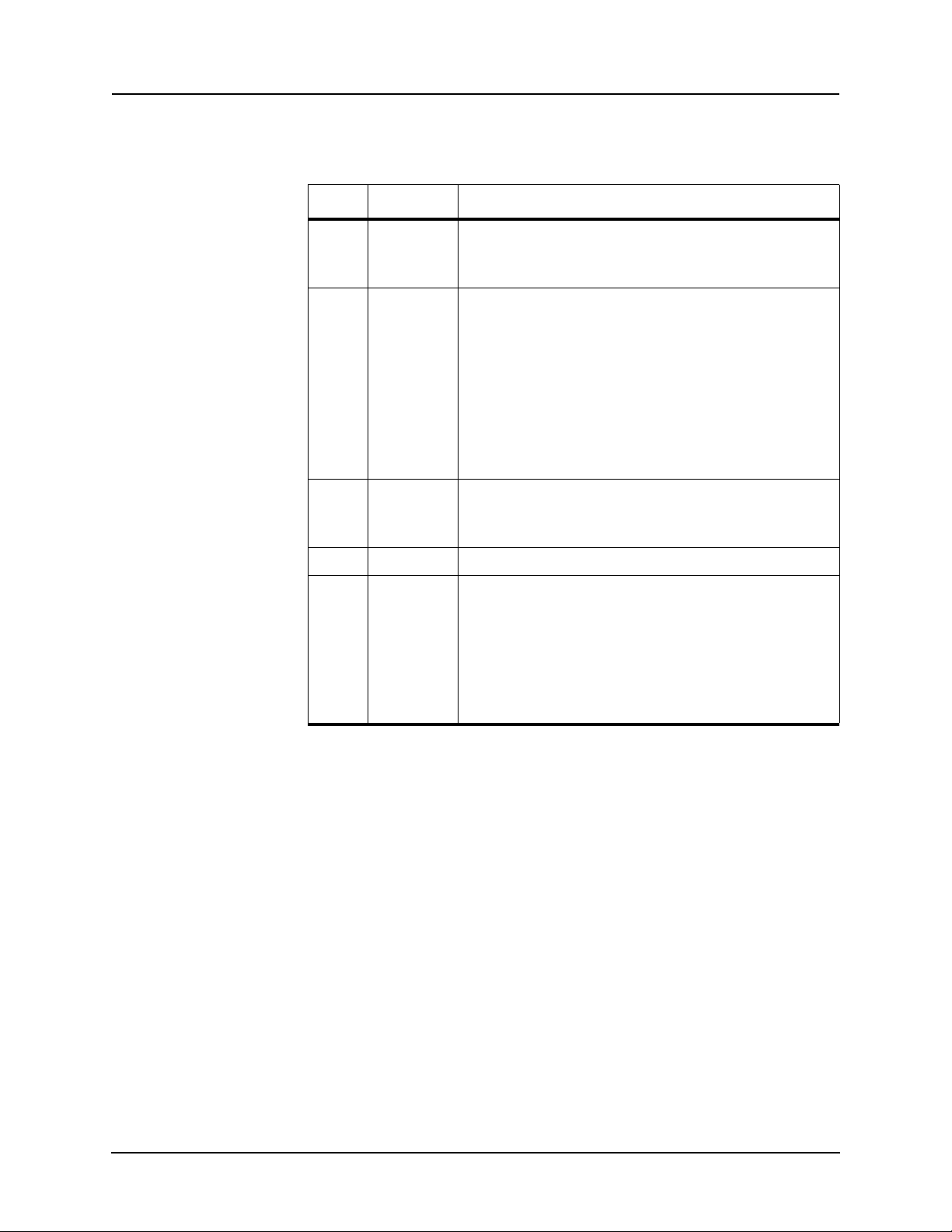

Version Compatibility

This chart indicates the versions of Offliner Settings, RecordBase View and

the User Manual which are compatible with different versions of F-PRO firmware.

RecordBase View and Of

lier versions of records and setting files. You can use RecordBase View to view

records

create and edit older setting file versions.

Minor releases (designated with a letter suffix

compatibility as their base version. For example. F-PRO firmware v3.1c and

Offliner Settings v3.1a are compatible.

produced by any version of F-PRO firmware and Offliner Settings can

F-PRO Firmware/Software Compatibility Guide

fliner Settings are backward compatible with all ear-

- e.g. v3.1a) maintain the same

F-PRO

Firmware

v4.0 2 4000 v1.0 or greater

v3.0 2 4000 v1.0 and greater

v3.0 2 v3.0 or greater

v2.0a 2 v2.0 or greater

v2.0 2 v2.0 or greater

v1.0d 1 v1.0b or greater

v1.0c 1 v1.0a or greater

v1.0b 1 v1.0a or greater

v1.0a 1 v1.0a or greater

v1.0 1 v1.0 or greater

Setting File

Ver sio n

Compatible Of

fliner Settings

Please contact ERLPhase Customer Service for complete Revision History.

D02416R04.00 F-PRO 5100 User Manual vii

1 Overview

F-PRO Feeder Protection Relay

Offline Mode - Settings Software

Online Mode - Terminal Mode

F-PRO

Feeder Protection

Model 5100

Port 1

Date &

Time

View

Readings

View

Logs

Prev

Next

Targ et

Clear

Targ et

1999 JUN 07

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

The F-PRO (model 5100) is a microprocessor-based relay providing comprehensive directional overcurrent protection, reclosing, mete

ring, breaker moni-

toring and recording functions suitable for medium and low voltage lines.

F-PRO has two working modes—online and off

line. In the online mode you

can use any communication software package (e.g. Procomm or HyperTerminal) to connect to the F-PRO using VT100 terminal emulation. In online mode

y

ou can:

• change and review relay

settings

• view event and metering information

• initiate and retrieve recordings, and retrieve setti

In offline mode you can use Offliner Se

ttings and RecordBase View software

ngs

to:

• create and review relay settings

• analyze fault waveforms

• store records

D02416R04.00 F-PRO 5100 User Manual 1-1

In addition to the protection functions F-PRO provides fault recording (96

sample/cycle) to facilitate analysis of the power system after a disturbance has

taken place. The triggers for fault recording are established by programming

the output matrix and allowing any internal relay function or any external input

to initiate recording.

The primary protection provided is overcurrent based. A library for these

overcurrent f

unctions provides commonly used IEEE and IEC inverse curves.

Because the curves are equation-driven, you can choose to enter an equation

parameter directly, creating other overcurrent shapes as needed. All

overcurrent functions are provided with directional control, if required, using

the ERLPhase method of positive sequence control.

1 Overview

To provide a complete package of protection and control, F-PRO provides other functions such as:

• ring bus capability to protect and monitor

lines connected to ring schemes

Current inputs are labelled Main and Aux inputs to denote the breaker ring

current inputs. Use F-PRO with straight single breaker line schemes by using the main current inputs

• breaker failure detection and monitoring

• 2 completely dedicated four shot reclosers devices 79 Main and 79 Aux to

control line re

closing needs along with device 25C Sync Check/Dead Bus/

Dead Line supervision

• low set overcurrent functions for e

ach breaker as well as for the summated

line currents that include phase, neutral and negative sequence functions

• Watt, VAR flow detectors as well a

s undervoltage, overvoltage and over/

under frequency functions (Freq ROC) to provide protection for issues

such as inter-tie protection needs

• ProLogic provide a flexible way to addres

s special protection needs. Ten

ProLogic statements are provided

• Breaker Logic, Group Logic, Demand Metering

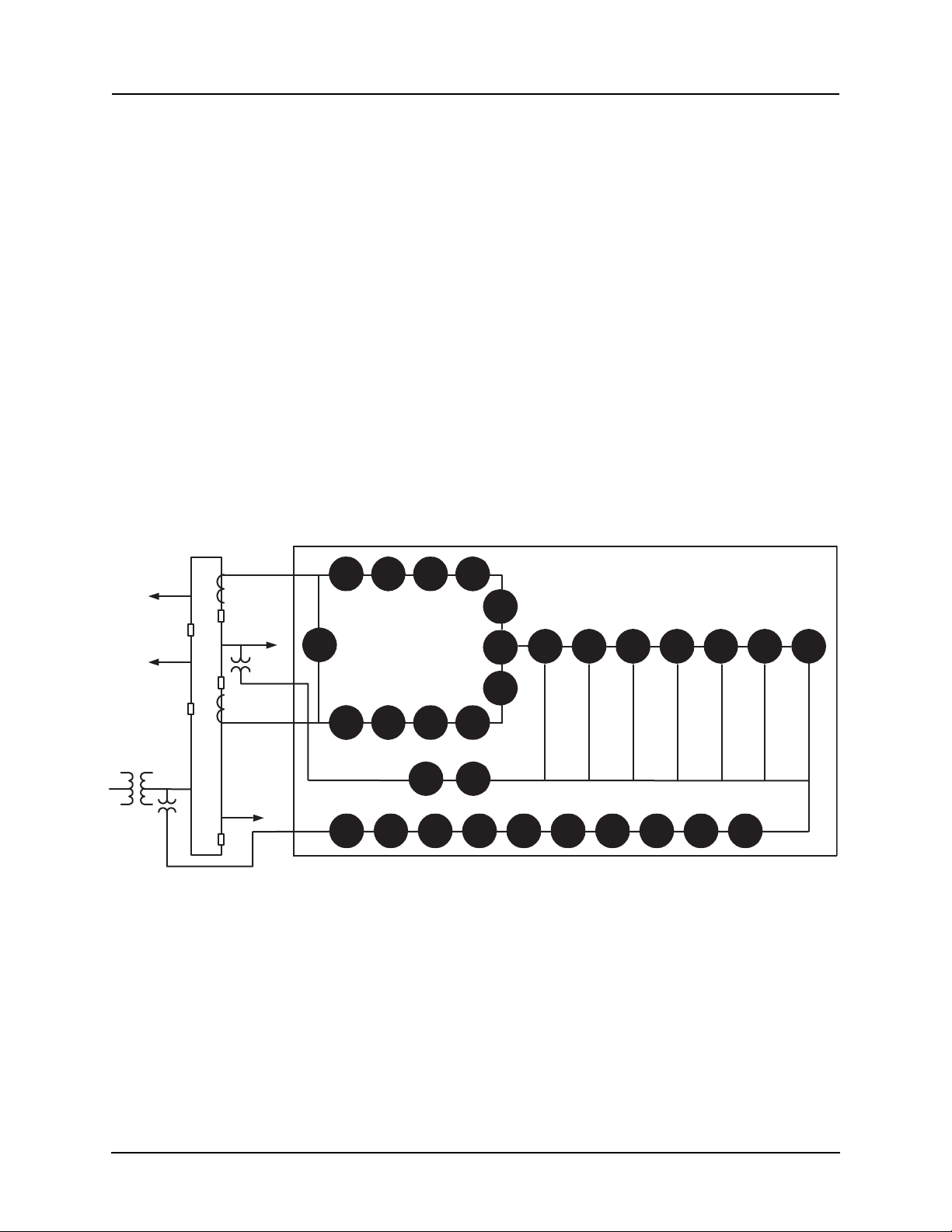

Source

Feeder

Feeder

PT (3 ph)

Analog Inputs

4 Analog Voltages

1 Three-phase Input

1 Single-phase Input

6 Analog Currents

2 Three-phase Inputs

Ring Bus

CT 2

CT 1

Aux.

PT (1 ph)

Main

Protected

Feeder

50LS-2

50LS-1

THD

50LS-1

50LS-2

Feeder

Outputs

12 Output Contacts

1 Relay Inoperative

Alarm Contact

Inputs

9 External Inputs

59-1 59-2 27-1 27-2

Trend Recording (Primary)

Real Power (MW In and Out)

Reactive Power (MVAR In and Out)

3 Phase Voltages (Va, Vb, Vc)

3 Phase Currents (Ia, Ib, Ic)

Real Energy (MWh In and Out)

Reactive Energy (MVARh In and Out)

THD Level (%)

System Frequency

Figure 1.1: F-PRO Line Diagram

50BF

50BF

Rec

79Aux

79

Main

25C

Rec

Σ

Rec

50/51/

67

60 81-1

Fault Recording

4 Voltages

6 Currents

97 Unique Events

50N/51N

67

46/

50/51/

67

81-2 81-3

21P

Metering

81-4

Metering (Front Display)

Primary Pos. Sequence Volts, Amps,

Primary Watts and VARs

Frequency

THD (Total Harmonic Distortion)

PF (Power Factor)

Primary Phase Voltage, Current, Phase

Angle (A, B, C)

Peak Demand MW, MVAR In and

Out Phase Currents

Energy Values MWh In and Out

MVARh In and Out

3I0

32P 32Q

Rec

1-2 F-PRO 5100 User Manual D02416R04.00

Front View

1. Front display of time, alarms, relay target and metering

2. Relay target LED (red)

3. LEDs indicating status of relay

4. Communications serial Port 1 for laptop computer

5. Clear target push button

6. Push buttons to manipulate information on LCD display

F-PRO

Feeder Protection Relay

Model 5100

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

Port 1

NextView

Readings

View

Logs

Previous

456

Target

Clear

Target

2000 Jan 07 11:49:54

Date &

Time

1 2

3

VA VB VC N

Main AC Line Currents

Main AC Volts

Power Supply

300 301 302 303 305 306 307 308 309 310 312311 313 314 315 316 317 318 319 320 321 322 323 324 326 327 328 329 330 331 332 333325

Case

Ground

231 232 233

Relay

Inoperative

Output Relay Contracts

200 201 202 203 204 205 206 207 208 209 210 212211 213 214 215 216 217 218 219 220 221 222 223 224 226 227 228 229 230225

External

Inputs

100 101 102 103 104 105 106 107 108 109 110 112111 113 114 115 116 117

+ - + - + - + - + - + - + - + - + -

234 235

Port 4

Unused

Port 3

SCADA

IRIG-B

1 2 3456 987

Out 1 Out 2 Out 3

Out 4 Out 5 Out 6 Out 7 Out 8 Out 9 Out 10

Out 11

Out 12

I1 A I1 B I1 C I2 A I2 B

I2 C

I3 A I3 B I3 C I4 A I4 B

+ -

VA VB

I4 C

VC

7. Port 5 - 10BaseT Ethernet Port/Internal Modem (optional)

8. External clock, IRIG-B modulated or unmodulated

9. Port 2 - Direct/Modem RS-232 Port

10. Port 3 - SCADA

11. Port 4 - unused

12. Case ground

13. 9 programmable external inputs (1 to 9)

14. This row contains 2 distinct areas from left to right:

12 programmable output relay contacts and relay inoperative contact

15. This row contains 3 distinct areas from left to right:

6 ac current inputs

4 ac voltage inputs

Power supply

13

14

15

Output

Contacts

In. Freq.

Aux.AC Line Currents AC Currents Inputs

Nominal

48-250 Vdc

120 Vac

Aux. AC Volts

Unused

N

Sync AC

Volts

125Vdc125Vdc 125Vdc 125Vdc 125Vdc 125Vdc 125Vdc 125Vdc 125Vdc

Port 2

Direct/Modem

Port 5

VN

Unused

7 8 9 10 11 12

1 Overview

Figure 1.2: F-PRO Front View

Back View

Figure 1.3: F-PRO Back View

D02416R04.00 F-PRO 5100 User Manual 1-3

1 Overview

AC Current and Voltage Inputs

F-PRO is provided with terminal blocks for up to 6 ac currents and 4 phase-toneutral voltages.

Each of the current input circuits has polarity (•) marks.

A complete schematic of current and voltage circuits is shown, for details see

“AC Schematic Drawing” in Appendix I and “DC Schematic Drawing”

in Appendix J.

External Inputs The F-PRO relay contains 9 programmable external inputs. External dc voltage

of either 48/125 volts or 125/250 volts nominal are possible depending on the

range provided.

Output Relay Contacts

The F-PRO relay has 12 output relay contacts. Each contact is programmable

and has breaker tripping capability. All output contacts are isolated from each

other. The output contacts are closed for a minimum of 100 ms after operation.

Relay Inoperative Alarm Output

If the relay becomes inoperative, then the Relay Inoperative Alarm output contact closes and all tripping functions are blocked.

Model Options/Ordering

F-PRO is available as a horizontal mount, for details see “Mechanical Drawings” in Appendix G.

F-PRO is available with an internal modem card or internal network card.

The CT inputs are 1 A nominal or 5 A nominal. The external inputs are 48/125

Vdc or 125/250 Vdc. The system base frequency is either 50 Hz or 60 Hz.

All of the above options must be specified at the time of ordering.

1-4 F-PRO 5100 User Manual D02416R04.00

2 Setup and Communications

Power Supply

A wide range power supply is standard. The nominal operating range is 48–250

Vdc, 120 Vac, 50/60 Hz. To protect against possible short circuit in the supply

use an inline fuse or circuit breaker with a 5 A rating. Make the chassis ground

connection to ensure proper operation and safety.

There are no power switches on the relay. When the

ed, the relay starts its initialization process and takes about

plete showing the green Relay Functional LED.

Case Grounding You must ground the relay to station ground using the case-grounding terminal

at the back of the

View on page 1-3.

WARNING!

To ensure safety and proper operation you must connect the relay to

station ground using the rear grounding terminal on the relay.

the

relay, for details see for details see Figure 1.3: F-PRO Back

power supply is connect-

40 seconds to com-

IRIG-B Time Input

The relay is equipped to handle modulated or unmodulated GPS satellite time

IRIG-B signals. The IRIG-B time signal is connected to the BNC connection

on the back of the relay. When the IRIG-B signal is provided to the relay and

is enabled in the settings through the user interface, the IRIG-B functional LED

comes on and the relay clock is referenced to this signal. No settings are required to differentiate between modulated or unmodulated signals; this is automatically detected by the relay.

You enable or disable the IEEE 1344 extension in

Utilities>Setup>Time, for details see “Utilities” on page 3-14. The enabled

mode allows the year to be received from the IRIG-B signal. If the available

IRIG-B signal

Ground the relay even when testing.

Do not rely on the rack mounting screws to provide case grounding.

the terminal mode settings

has no year extension, this setting should be disabled.

D02416R04.00 F-PRO 5100 User Manual 2-1

2 Setup and Communications

Communicating with the Relay (IED)

You can connect to the relay to access its user interface and SCADA services:

• direct serial link (user interface and SCADA)

• external or internal modem link (user interface only)

• ethernet network link (user interface and SCADA)

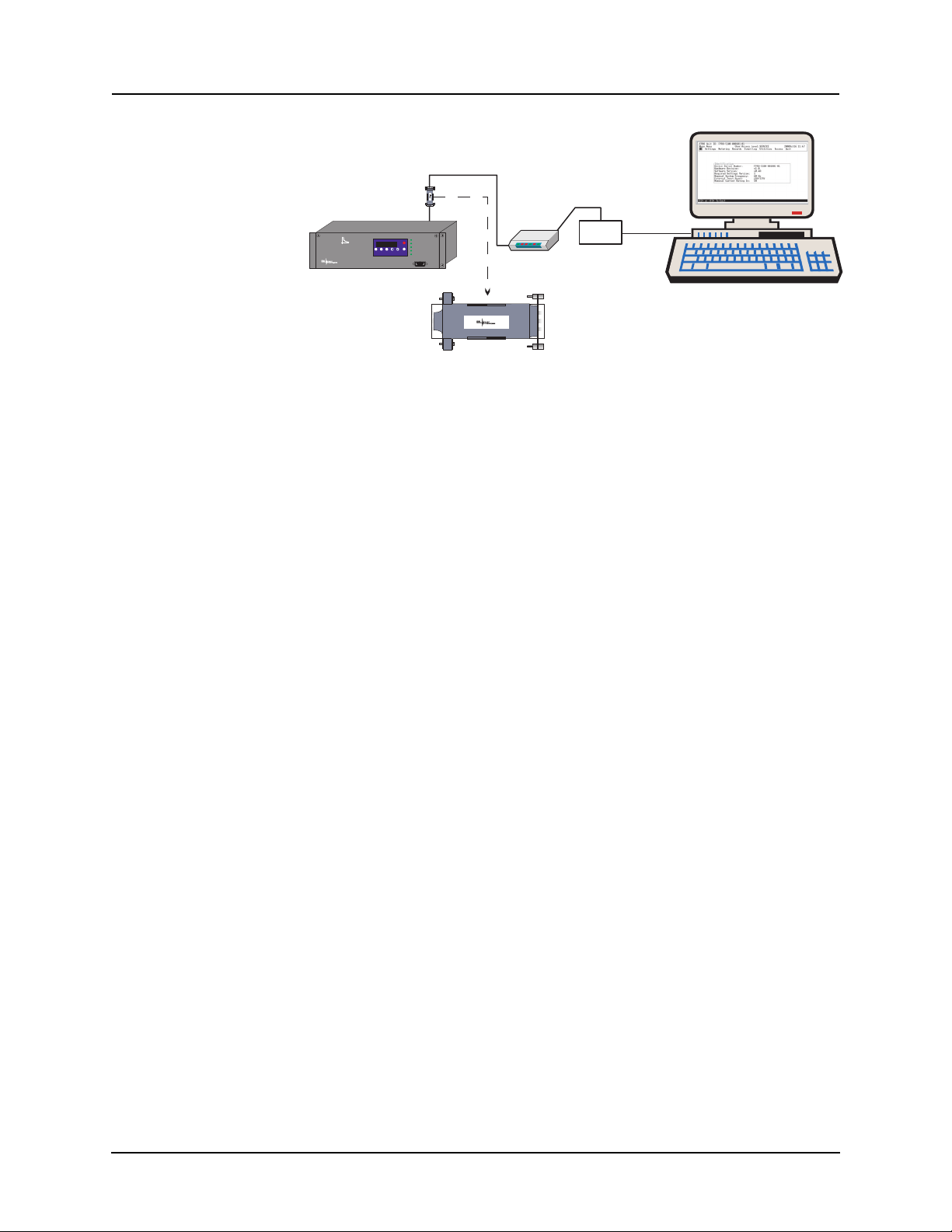

Direct Serial Link

Port 2 - direct/modem

F-PRO

Feeder Protection

Model 5100

Date &

Readings

Time

1999 JUN 07

View

View

Prev

Logs

Port 1

Relay Functional

IRIG-B Functional

Target

Service Required

Test Mode

Next

Clear

Target

Alarm

Port 1

Serial Extension Cable

Relay Port 1 or rear Port 2

to PC Serial Port

Laptop PC

Figure 2.1: Direct Serial Link

The relay has three serial ports that provide direct access to its user interface

and SCADA services.

All of the relay’s serial ports (Ports 1, 2 and 3) are configured as EIA

RS-232

Data Communications Equipment (DCE) devices with female DB9 connectors. This allows them

dard straight-through male-to-female serial cable, for pin-out,

to be connected directly to a PC serial port with a stan-

for details see

“Communication Port Details” on page 2-9.

The relay’s user interface is accessed through a

ulation program running on a PC. To create a direc

lay and your computer, connect the seri

al cable (provided) between your

standard VT-100 terminal em-

t serial link between the re-

computer's serial port and Port 1 on the relay’s front panel. Port 2 on the relay’s

back panel can also be used for direct serial access, provided the port is not

configured for modem use. When connected, run the terminal emulation software on your computer to establish the communication link, for details see

“Using HyperTerminal to Access the Relay’s User Interface” on page 2-5.

The relay’s Modbus and DNP3 SCADA services can be accessed via a direct

serial

link to Port 3 on the relay's back panel, for details see “Accessing the Re-

lay’s SCADA Services” on page 2-8.

2-2 F-PRO 5100 User Manual D02416R04.00

Modem Link -

External

Modem

Telephone

System

Analog

Telephone

Line

Modem Adapter

Supplied by ERLPhase

DB-9-Male-Male

Modem Cable

(as supplied with modem)

Modem Adapter

Port 2 - Direct/Modem

Analog

Telephone

Line

F-PRO

Feeder Protection

Model 5100

Port 1

Date &

Time

View

Readings

View

Logs

Prev

Next

Target

Clear

Target

1999 JUN 07

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

External

2 Setup and Communications

Modem Cable

(as supplied with modem)

Modem Adapter

Port 2 - Direct/Modem

F-PRO

Feeder Protection

Model 5100

1999 JUN 07

Target

Next

View

View

Prev

Date &

Clear

Readings

Logs

Time

Target

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

Port 1

External

Analog

Telephone

Line

Telephone

System

Analog

Telephone

Line

Modem

Modem Adapter

Supplied by ERLPhase

DB-9-Male-Male

Figure 2.2: External Modem Link

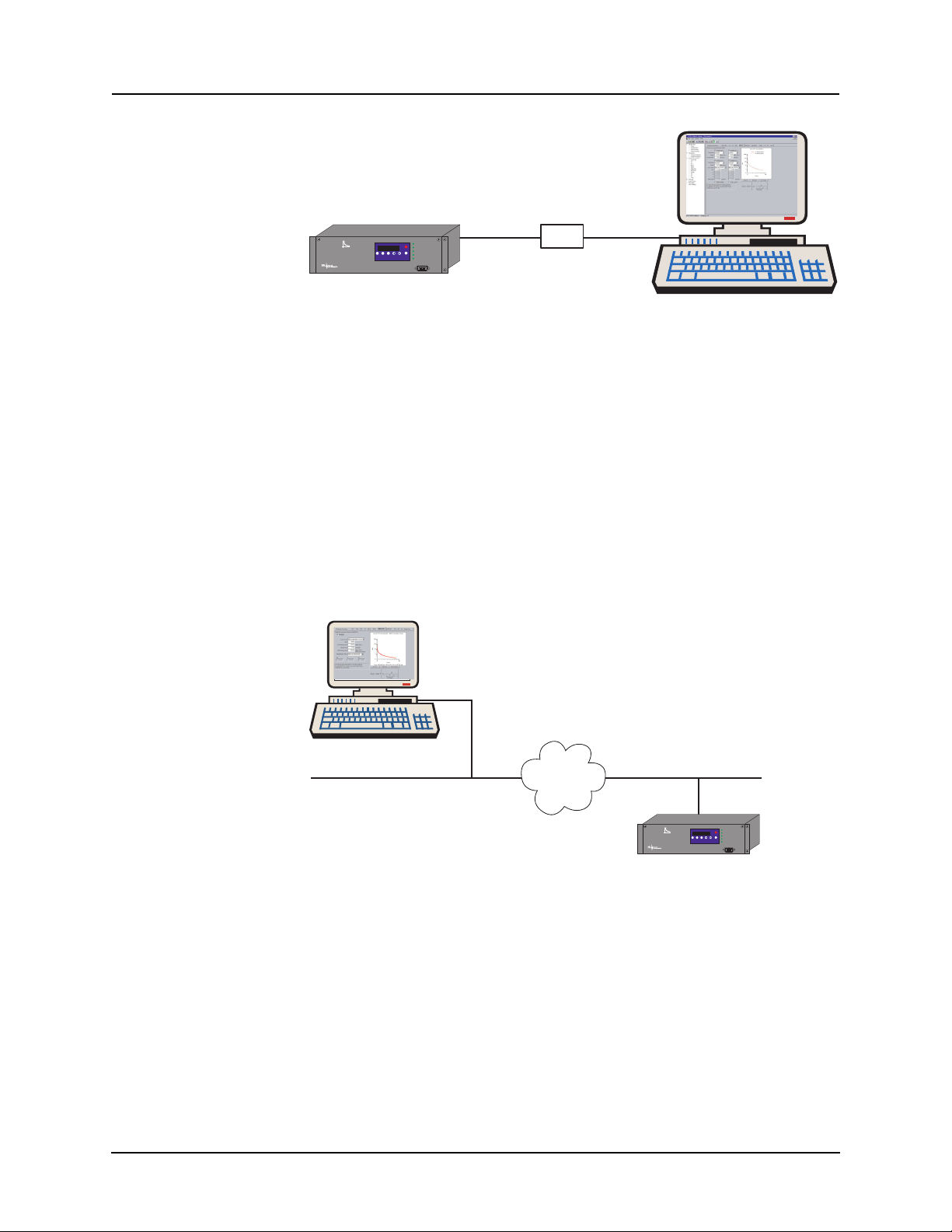

The relay’s user interface can also be accessed through a telephone link between the relay and your computer, using an external modem.

Connect the serial port on the external modem to

the Port 2 on the relay's back

panel. Both devices are configured as RS-232 DCE devices with female connectors, so the cable between the relay a

nd the modem requires a crossover and

a gender change. Alternatively, you can use the ERLPhase modem port adapter

provided with the relay to make Port 2 appear the same as a PC’s serial port. A

standard modem-to-PC serial cable can then be used to connect the modem and

the relay, for pin-out details see “Communication Port Details” on page 2-9.

Connect the modem to an analog telephone line or switc

h using a standard RJ-

11 connector.

To work with a modem, the relay’s Port 2 must be appropriately configured.

Log into the rel

ay through a direct serial link, go to the Utilities>Setup>Ports

screen, and set the Port 2 Modem option to Yes. The Baud Rate should be set

as high as possible - most modems will handle 57,600 bps. The Initialize setting lets you set the control

nection session. The factory defaults are: “M0S0=0&B1” for

codes sent to the modem at the start of each con-

an external

modem and “M0S0=0” for an internal modem.

D02416R04.00 F-PRO 5100 User Manual 2-3

2 Setup and Communications

Modem Link Internal

Network Link

Port 5 - RJ-11 modem

F-PRO

Feeder Protection

Model 5100

1999 JUN 07

Next

View

View

Prev

Date &

Readings

Logs

Time

Analog

Telephone

Line

Relay Functional

IRIG-B Functional

Target

Service Required

Test Mode

Clear

Target

Alarm

Port 1

Telephone

System

Analog

Telephone

Line

Desktop Computer

Figure 2.3: Internal Modem Link

The relay’s user interface can also be accessed through a telephone link between the relay and your computer using an opti

onal internal modem. If the

modem has been installed, Port 5 on the rear panel will be labelled “INTERNAL MODEM.”

Connect the relay’s Port 5 to an analog telephone

line or switch using a stan-

dard RJ-11 connector.

When an internal modem is installed, the relay’

s Port 2 is used to interface to

the modem internally. Appropriate Port 2 settings are configured at the factory

when the internal modem is installed. The factory defaults are: “M0S0=0&B1”

for an external modem and “M0S0=0” for an internal modem.

PC with TCP/IP

TCP/IP

Network

10BaseT

Port 5 - RJ-45

Network

F-PRO

Feeder Protection

Model 5100

Relay Functional

IRIG-B Functional

1999 JUN 07

Target

Service Required

Test Mode

Next

View

View

Prev

Date &

Clear

Readings

Logs

Time

Target

Alarm

Port 1

Figure 2.4: Network Link

You can access both the relay’s user interface and DNP3 SCADA services simultaneously through the same network port with an

optional Ethernet TCP/IP

LAN link. If the Ethernet option has been installed, Port 5 on the rear panel will

be labelled “NETWORK.”

The user interface accessed through the LAN is the same as that available

through

a direct serial connection or a modem link, but requires the use of a

Telnet client on your PC. The HyperTerminal program, which is included in

Windows XP and is also available separately as HyperTerminal PE, provides

Telnet services. To select Telnet, go to HyperTerminal’s Properties dialog box

and set the Connect Using field to TCP/IP (Winsock). If this option is not avail-

2-4 F-PRO 5100 User Manual D02416R04.00

2 Setup and Communications

able in the pick list, you require a newer version of HyperTerminal (v1.2 or

greater). Alternatively, you can use any Telnet program that fully supports VT100 terminal emulation and z-modem file transfer.

DNP3 SCADA services can also be accessed over the LAN, for details see

“Accessing the Relay’s SCADA Services” on page 2-8.

Connect Port 5 to the Ethernet LAN using an appropriate 10BaseT cable with

an RJ-45 connector. The relay supports 10 Mbit Ethernet, although a dual

speed 10/100 Ethernet hub or switch can be used.

By default, the relay is assigned an IP address of 192.168.1.100. If this address

is not suitable, it may be modified using the relay’s , for details see

“Using Hy-

perTerminal to Access the Relay’s User Interface” on page 2-5.

Using HyperTerminal to Access the Relay’s User Interface

Change settings, view measured values and retrieve data from the relay using

its user interface. This section describes how to configure a standard Windows

VT-100 terminal program on your PC for use with the relay.

The computer must be connected to the relay by one of its serial, modem or

Ethernet communication ports, for details see

(IED)” on page 2-2.

The relay user interface is accessed using a standard VT-100 terminal style

program on your computer eliminating the need for specialized user interface

software. Any terminal program that fully supports VT-100 emulation and pro

vides z-modem file transfer services can be used. The HyperTerminal program

is used here as an example.

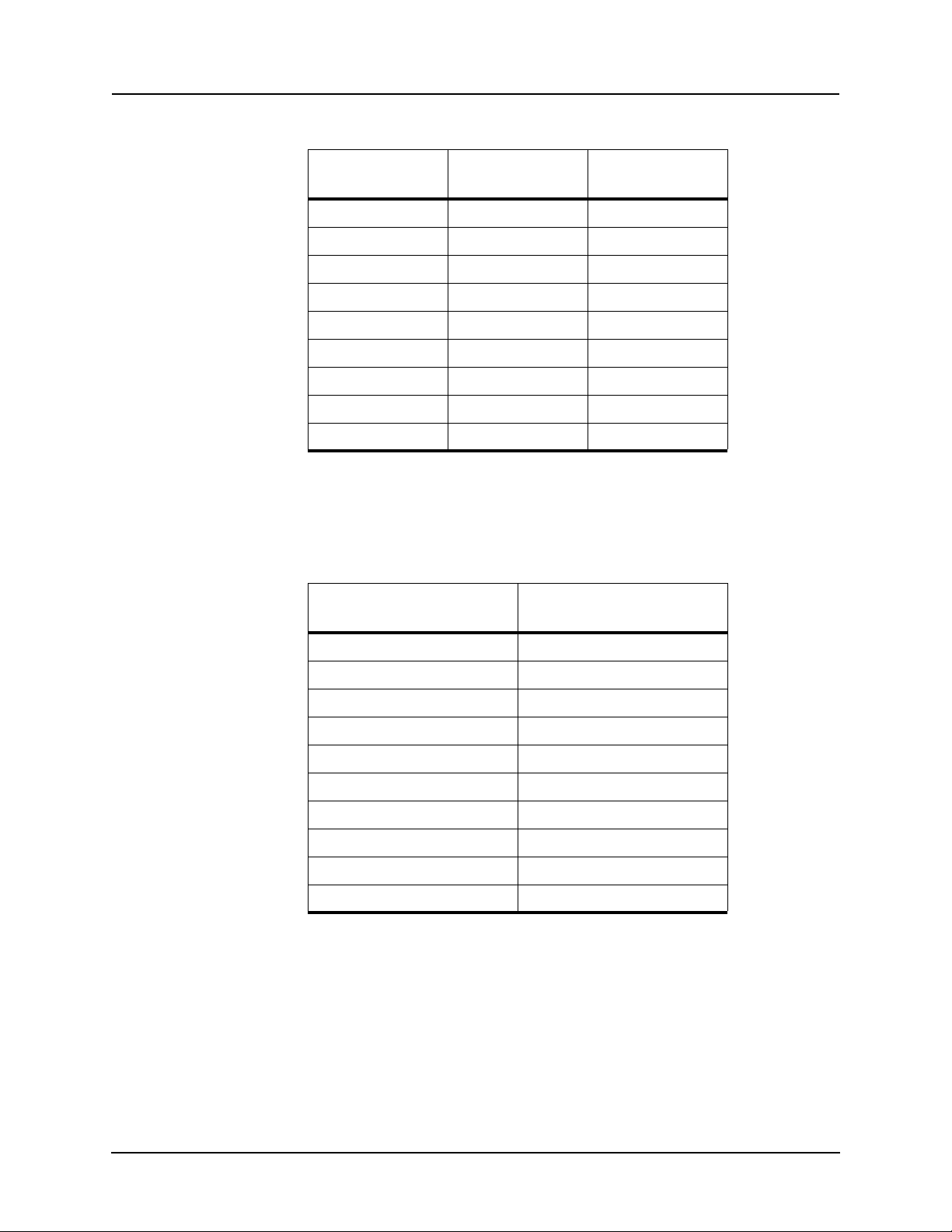

Configure your terminal program as described in the table below and link it to

the appropriate serial port, modem or TCP/IP socket on your computer.

“Communicating with the Relay

-

Terminal Program Setup

Baud rate

Data bits

Parity

Stop bits

Flow control

Function, arrow

and control keys

Emulation

D02416R04.00 F-PRO 5100 User Manual 2-5

For a direct serial link, the baud rate must match that of the relay serial

port.

For a modem link, the baud rate refers only to the link between your

computer and its own modem.

Refer to “Setting the Baud Rate” on page 2-7 for further information

8

None

1

Hardware or Software.

Hardware flow control is recommended. The relay automatically

supports both on all its serial ports.

Terminal keys

VT100

2 Setup and Communications

Terminal Program Setup

Font Use a font that supports line drawing (e.g. Terminal or MS Line Draw).

If the menu appears outlined in odd characters, the font you have

selected is

not supporting line drawing characters.

To initiate the connection with the relay, use HyperTerminal’s Call>Connect

function.

When the connection is established, press Enter in the

terminal window to

bring up the following login prompt:

Instructions on logging in and running the user interface are given in “Terminal

Mode” on page 3-5.

If you see incorrect characters on a direct

serial connection, it may mean there

is a mismatch between the relay’s baud rate and that of the PC.

Ending a User

Inte

rface Session

Use the Quit function in the relay’s user menu to end a session. This will close

the interface and require the next user to log in to the relay.

The relay automatically ends a session when it detec

ts the disconnecting of a

direct serial cable or a modem hang-up. For other types of connections (e.g. serial switches or Ethernet) you are advised to

use the Quit function to ensure the

interface is closed and login protection is activated.

2-6 F-PRO 5100 User Manual D02416R04.00

2 Setup and Communications

Setting the Baud Rate

The baud rate of the relay's serial ports can be shown on the relay’s

front panel display. From the main Date & Time display, press the

Next button.

Direct Serial Link For a direct serial connection, both the relay and your computer must be set to

the

same baud rate.

To change the baud rate of a relay serial port:

1 Access the relay’s user interface through any of the available ports

2 Log in to the user interface and go to the Utili

details see “Terminal Mode” on page 3-5.

3 Select the desired baud rate for the appropriate port by toggling through the

options using

the Space or Enter keys. Save the new setting with the F2 key.

The message “New communications settings loaded” will appear.

The new baud rate will be used on that

To change the baud rate on your computer’s serial port:

port the next time you log in to it.

1 From within HyperTerminal, bring up the Properties dialogue, press the

Configure button and set the baud rate field to the desired value.

2 Save the changes.

ties>Setup>Ports menu, for

Modem Link Unlike a direct serial link, the baud rates for a modem link do not have to be

the same on your computer and on the relay. The modems automatically negotiate an optimal baud rate for their communication.

The baud rate set on the relay only affe

nicates with the modem. Similarly, the

cts the rate at which the relay commu-

baud rate set in HyperTerminal only affects the rate at which your computer communicates with its modem. Details

on how to s

et these respective baud rates are described above, except that you

modify the Port 2 baud rate on the relay and the properties of the modem in HyperTerminal.

D02416R04.00 F-PRO 5100 User Manual 2-7

2 Setup and Communications

Accessing the Relay’s SCADA Services

The relay supports DNP3 (Level 2) and Modbus SCADA protocols as a standard feature on all relays. DNP3 is available through a

Ethernet LAN on top of either TCP or UDP protocols. The Modbus implementation supports both RTU (binary) or A

direct serial link.

The relay’s Port 3 is dedicated for use with

Port 3 uses standard RS-232 signalling. An external RS-232<->RS-485 converter can also be used to connect to an RS-485 network.

For details on connecting to serial Port 3 see “Communicating with the Relay

(IED)” on page 2-2 and “Communication Port Details” on page 2-9.

The DNP3 protocol can also be run across the optional Ethernet LAN. Both

DNP o

to the Ethernet LAN see “Network Link” on page 2-4.

Complete details on the Modb

the Appendices, “Modbus RTU Communication Protocol” in Appendix E and

“DNP3 Communication Protocol” in Appendix F respectively.

ver TCP and DNP over UDP are supported. For details on connecting

us and DNP3 protocol services can be found in

direct serial link or the

SCII modes and is available through a

Modbus or DNP3 serial protocols.

Protocol Selection To select the desired SCADA protocol, login

access the Utilities>Setup>SCADA menu. Select the protocol and set the corresponding parameters.

The DNP3 LAN/WAN - TCP and UDP options are only available if the

ptional Ethernet LAN port installed.

rs are set using the Utilities>Setup>Ports

Communication Parameters

unit has an o

Port 3’s communication paramete

menu in relay’s user interface. Both the baud rate and the parity bit can be configured. The number of data bits and stop bits are

the selected SCADA protocol. Modbus ASCII uses 7 data bits. Modbus RTU

and DNP Serial use 8 data bits. All protocols use 1 stop bit except in the case

where either Modbus protocol is used with no parity; this uses 2 stop bits, as

defined in the Modbus standard.

Diagnostics Protocol monitor utilities are available

nication difficulties such as incompatible

to assist in resolving SCADA commu-

baud rate or addressing. The utilities

can be access through the Maintenance user interface, for details see “Maintenance Menu” on page 2-12.

to the relay’s user interface and

determined automatically by

2-8 F-PRO 5100 User Manual D02416R04.00

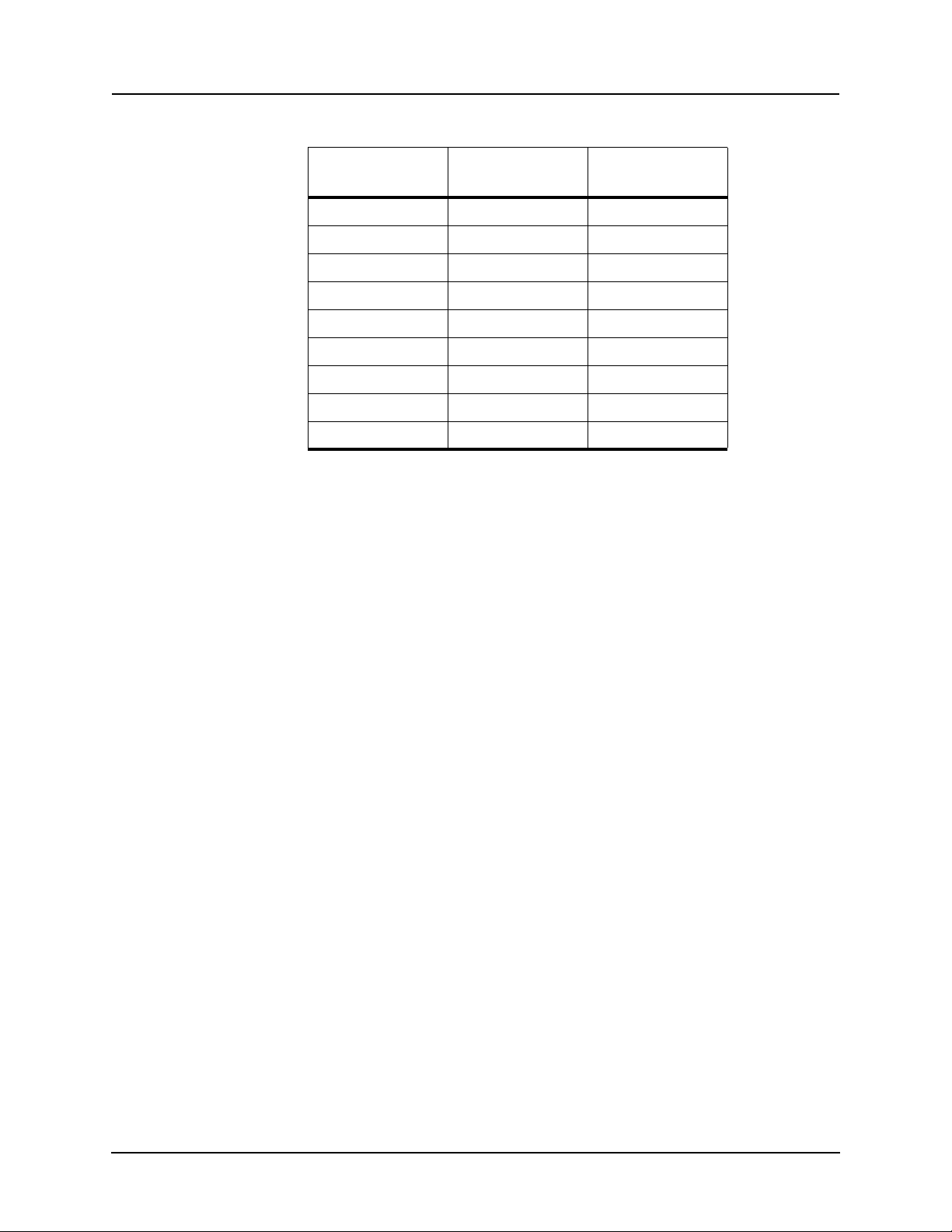

Communication Port Details

Port Location Function

1 Front Panel RS-232 Data Communication Equipment (DCE) female DB9.

2 Rear Panel RS-232 DCE female DB9.

3 Rear Panel RS-232 DCE female DB9.

2 Setup and Communications

Used for user interface access thro

Default Setting: 38,400 baud, 8 data bits, no parity, 1 stop bit.

Used for:

• User interface access thr

• User interface access through an external modem. The optional

ERLPhase Mode

nal Equipment (DTE) to simplify co

modem.

Default Setting: 9,600 baud, 8 data bits, no parity, 1 stop bit.

Port 2 is disabled if the relay is equipped with an internal modem

see Port 5).

(

Used for SCADA communication.

Default Setting: 9,600 baud, 8 data bits, no parity, 1 stop bit.

m Adapter converts this port to a Data Termi-

ugh a direct serial connection.

ough a direct serial connection.

nnection to an external

4 Rear Panel Not used

5 Rear Panel RJ-11/RJ-45 receptacle.

When equipped with optional internal modem:

• Used for user interface access through modem.

When equipped with optional internal Ethernet card:

• User interface access.

• DNP SCADA access.

Default Ethernet IP address: 192.168.1.100.

D02416R04.00 F-PRO 5100 User Manual 2-9

2 Setup and Communications

Signal Name

DCD 1

RxD 2

TxD 3

DTR 4

Common 5

DSR 6

RTS 7

CTS 8

No connection 9

Direction

PC<-> Relay

Pin # on the Relay

Port

Notes:

• Relay is DCE, PC is DTE

• Pins 1 and 6 are tied together internal to the relay

Male DB-9 Cable End for Relay

Port

Female DB-9 Cable End for

Computer Port

Pin # on Cable Pin # on Cable

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

2-10 F-PRO 5100 User Manual D02416R04.00

2 Setup and Communications

Signal Name

DCD 1

RxD 2

TxD 3

DTR 4

Common 5

DSR 6

RTS 7

CTS 8

No connection 9

Direction

Modem <-> Relay

Pin # on the Modem

Ad

apter

Notes:

• Relay (with modem adapter) is DTE,

modem is DCE

• Pins 1 and 6 are tied together internal to the relay

D02416R04.00 F-PRO 5100 User Manual 2-11

2 Setup and Communications

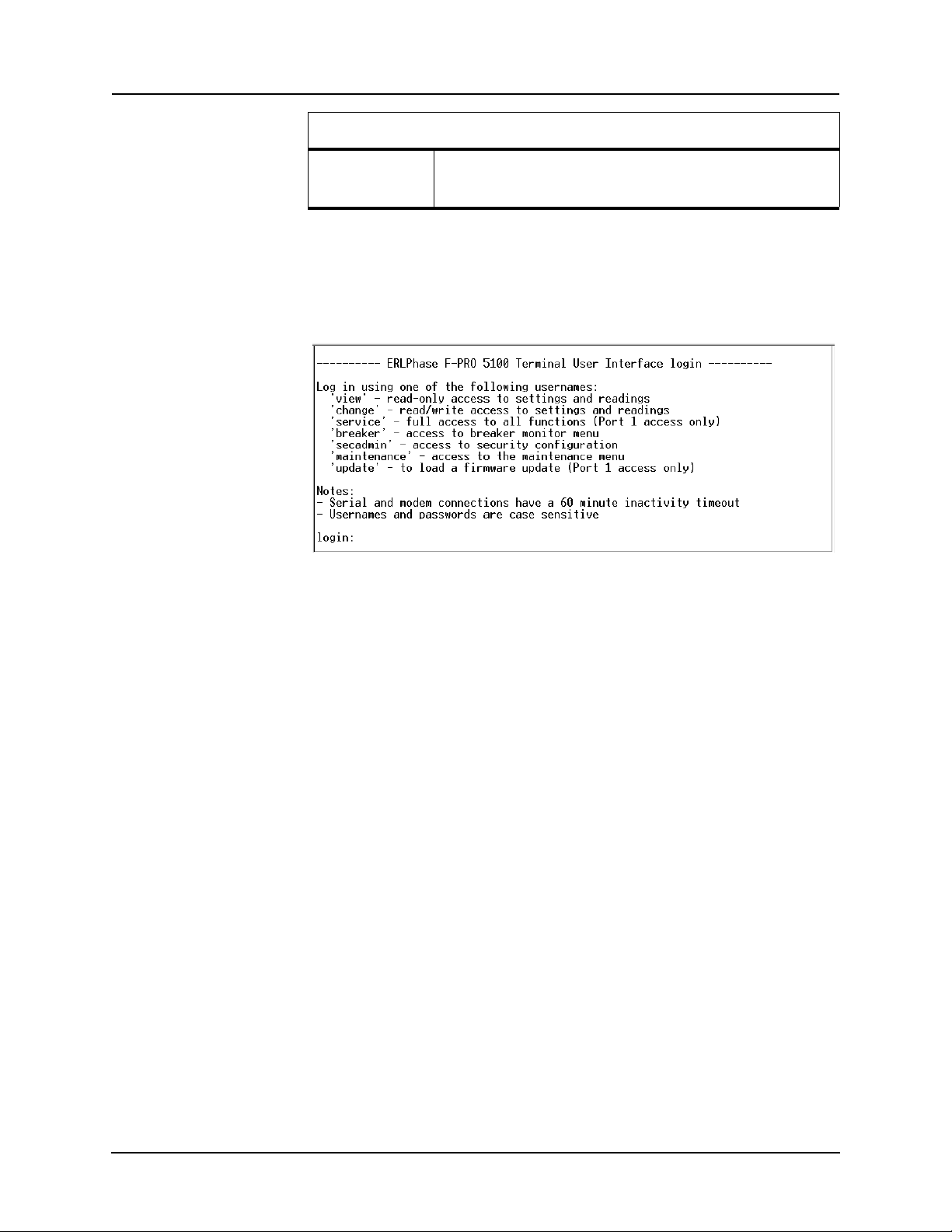

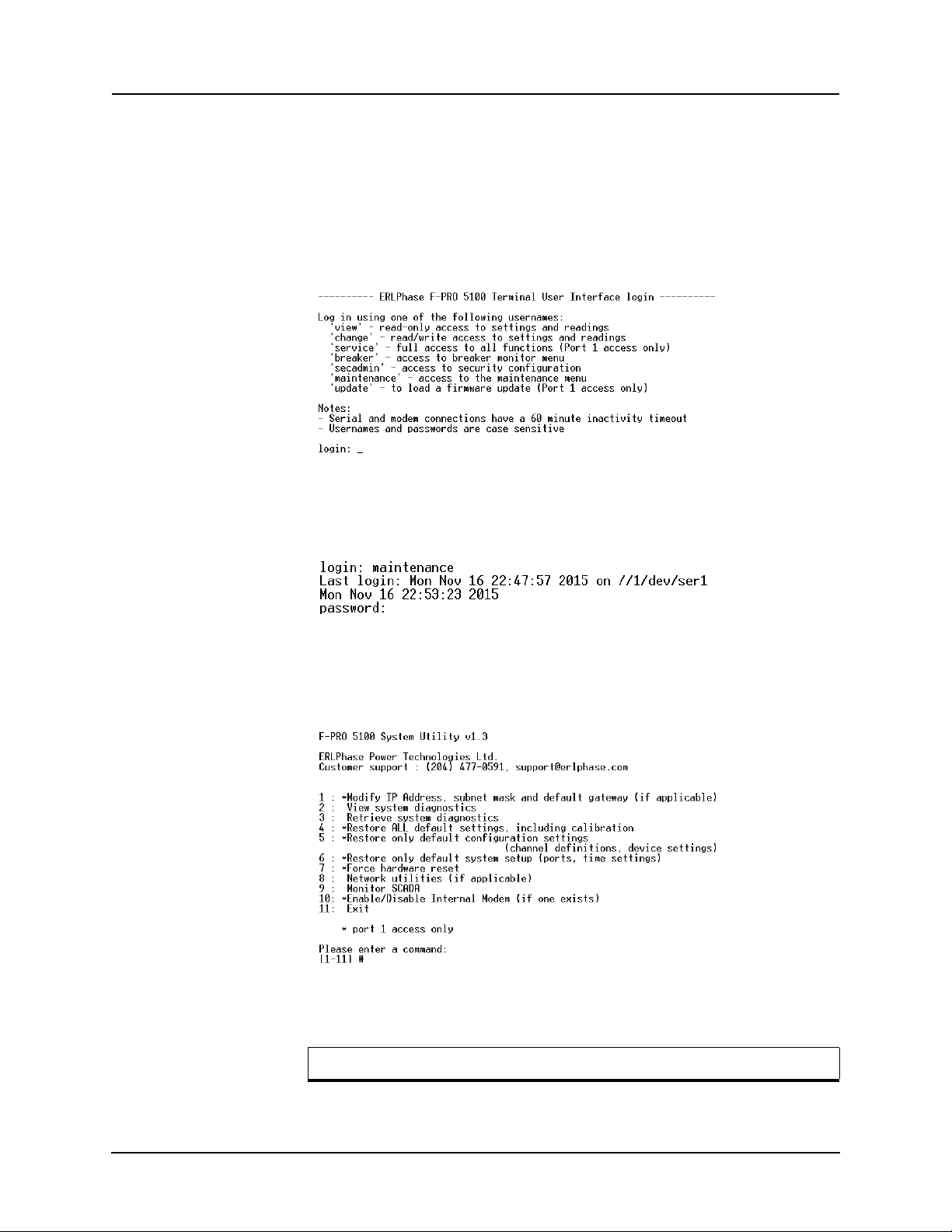

Maintenance Menu

The relay has a Maintenance Menu that can be accessed by connection through

a VT-100 terminal emulator (such as the HyperTerminal program). Using either direct serial or modem connection:

1 Use the terminal program to connect to

2 Select Ent

Figure 2.5: Login prompt

3 Login as “maintenance” in lower case.

4 Relay responds with "password" prompt.

the serial port, either through direct

serial link or modem.

er, the relay responds with a login prompt.

Figure 2.6: Maintenance password prompt

5 Enter password.

6 A menu appears as below.

Figure 2.7: Maintenance menu

Commands 1, 4, 5, 6, 7 and 10 are Port 1 access only.

2-12 F-PRO 5100 User Manual D02416R04.00

2 Setup and Communications

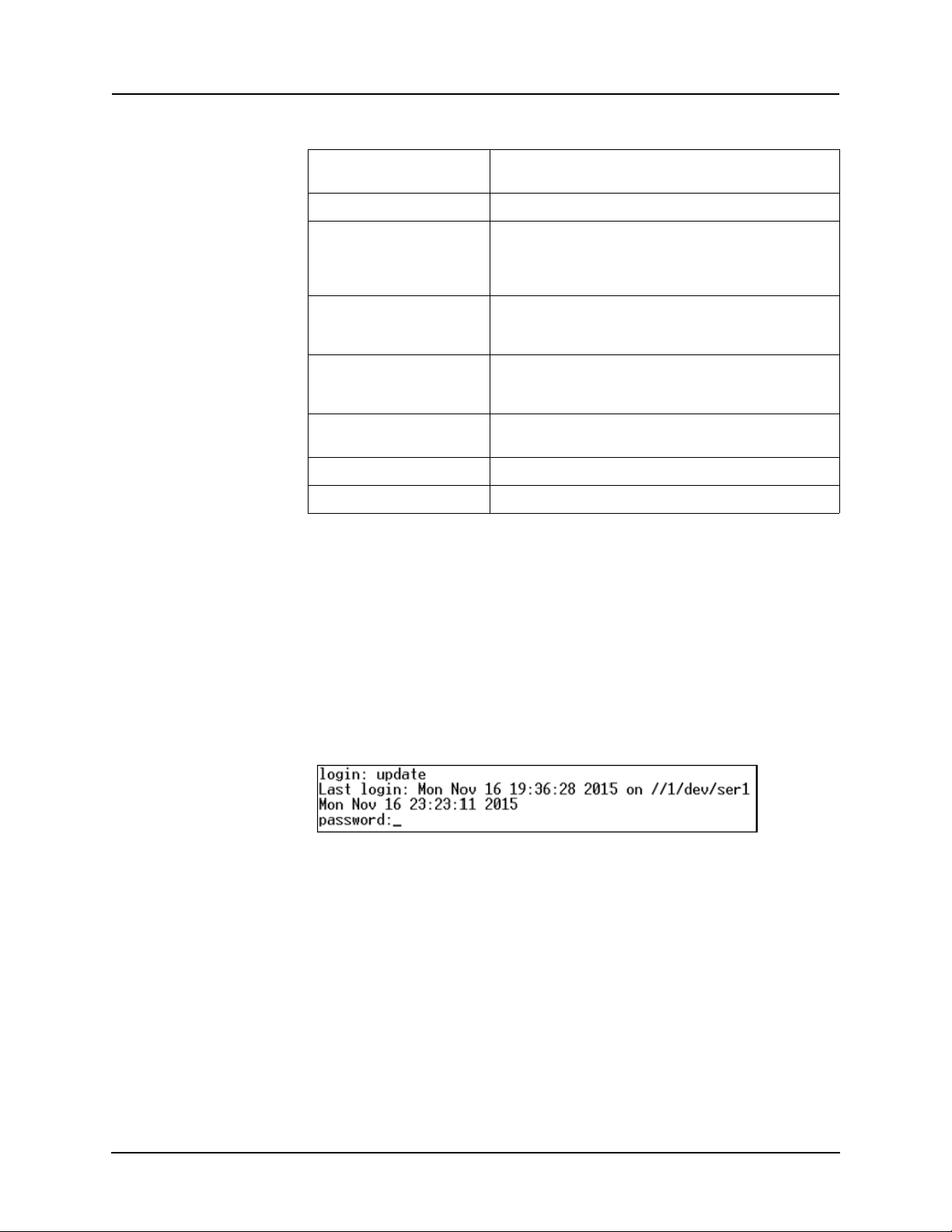

Firmware Update

Modify IP address Modifies the LAN IP address when equipped with an

View system diagnostic Displays the internal status log.

Retrieve system diagnostics Automatically packages up the inter

Restore settings Use this menu to force the system back to default values, if

Force hardware reset Manually initiates a hardware reset. Note that the communi-

View network statistics View IP, TCP and UDP statistics when equipped with inter-

Monitor SCADA Shows real time display of SCADA data.

Enable/disable Modem Enables or disables the internal modem.

optional internal 10BaseT Ethernet card.

nal status log plus set-

ting and setup information and downloads it in compressed

to your computer. This file can then be sent to our cus-

form

tomer support to help diagnose a problem.

spect a problem due to the unit’s settings, calibration

you su

and/or setup parameters.

cation link is immediately lost and cannot be re-established

e unit completes its start-up.

until th

nal 10BaseT Ethernet card.

The relay has an update login that can be accessed by a connection through a

VT100 terminal emulator (such as HyperTerminal). This login is available

only from Port 1.

1 Use the terminal program to connect to Port 1.

2 Select Ent

3 Login as update in

er, the terminal responds with a login prompt.

lower case.

4 Relay responds with "password" prompt.

Figure 2.8: Firmware Update password prompt

5 Enter password.

The firmware update is used to update

the relay’s software with maintenance

or enhancement releases. Please see the B-PRO Firmware Update Procedure

documentation that comes with the firmware update for instructions on how to

update the firmware.

D02416R04.00 F-PRO 5100 User Manual 2-13

3 Using the IED (Getting Started)

F-PRO Feeder Protection Relay

Offline Mode - Settings Software

Online Mode - Terminal Mode

F-PRO

Feeder Protection

Model 5100

Port 1

Date &

Time

View

Readings

View

Logs

Prev

Next

Targ et

Clear

Targ et

1999 JUN 07

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

Start-up Sequence

The following initialization sequence takes place:

Test Mode—red LED on 2 seconds after power applied

Relay Functional—green LED on 5 seconds after power applied

Front Display—on 30 seconds after power applied

Test Mode—red LED off 40 seconds after power applied

When the relay is powered up, the normal sequenc

e of LED operation is Test

Mode followed by Relay Functional and IRIG-B Functional (if available), display on, then Test Mode off. The

entire sequence takes about 40 seconds.

Ways to interface with F-PRO:

• Front panel display

• Terminal Mode

• Offliner Settings software

D02416R04.00 F-PRO 5100 User Manual 3-1

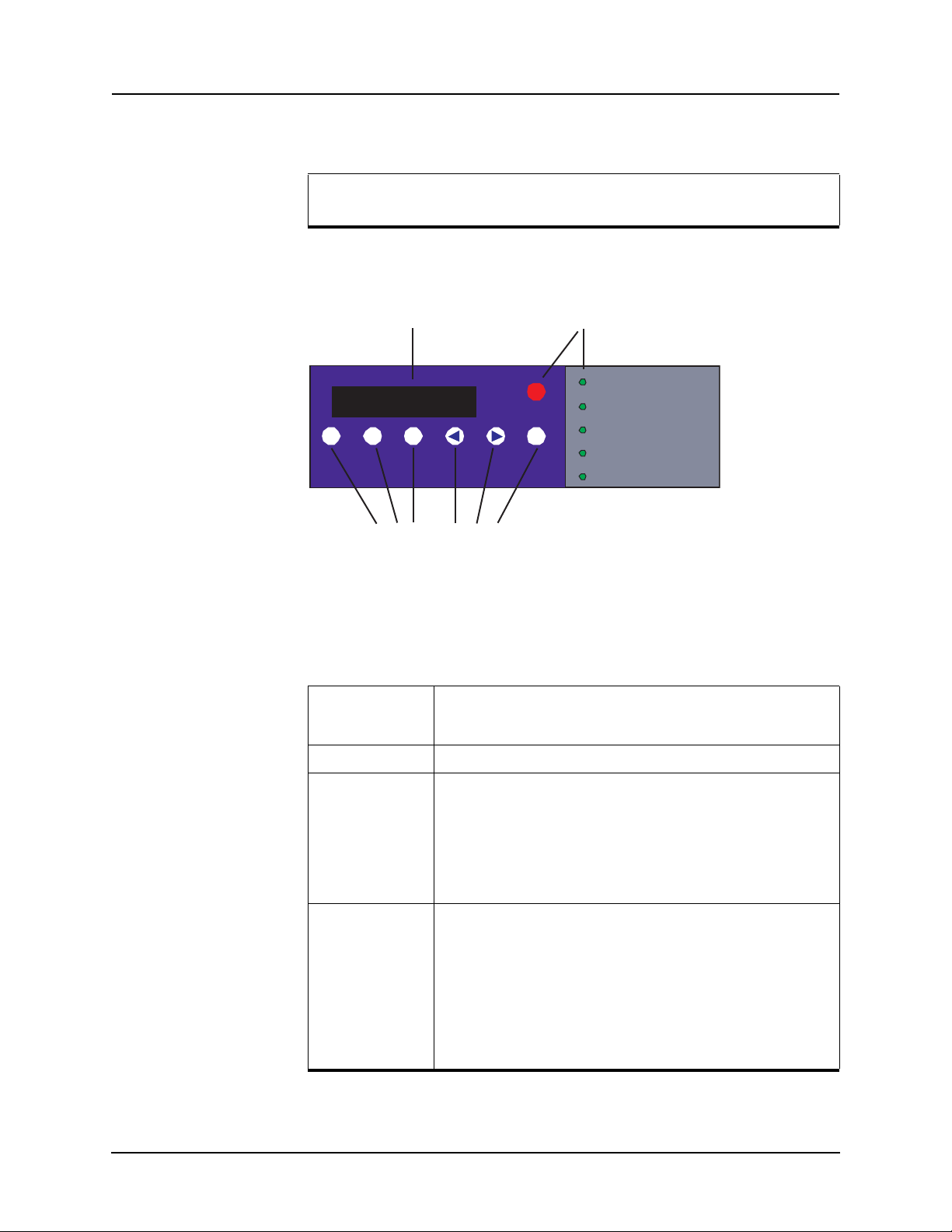

3 Using the IED (Getting Started)

Date &

Time

View

Readings

View

Logs

Previous Next

Target

Clear

Target

Pri V 0.0 kV ph - ph

I 0.0 A line

Display LED Lights

Push Buttons

Relay Functional

IRIG-B Functional

Service Required

Test Mode

Alarm

Front Panel Display

View or change settings using Terminal Mode or loading a setting file

from Offliner Setting.

LED Lights

The front panel display is the fastest a

nd easiest way of getting information

from the relay.

Figure 3.1: Front Panel Display

The line display, the six LED lights and the six push buttons provide selective

information about the relay.

Relay

Functional

Indicates when the relay is functional. When the Relay Functional

gre

en LED goes on, the rear Relay Inoperative contact changes to an

open and the protective functions become functional.

IRIG-B Functional Indicates the presence of a valid IRIG-B time signal.

Service Required Indicates the relay needs service. This LED can be the same state as

Test Mod e Occurs when the relay output contact

3-2 F-PRO 5100 User Manual D02416R04.00

Relay Functional LED or can be of the opposite state depending on

the

the nature of the problem.

The following items bring up this LED:

• DSP failure - protection difficulties within the relay.

• Communication failure within the relay.

• Internal relay problems.

s are intentionally blocked.

Possible reasons are:

• Relay initialization on start-up

• User interface processor has reset and is being tested.

You cannot communicate with the relay through the ports until the front

display becomes a

the red Target LED remains off after this start-up unless the relay had

unviewed target messages.

Output contacts are controlled from the Util

ctive and the Test Mode LED goes out. Normally,

ities menu.

Loading...

Loading...