Page 1

SmartEdge 1200 Router Hardware Guide

Release 6.1.3

Part Number 220-0716-05

Corporate Headquarters

Redback Networks Inc.

100 Headquarters Drive

San Jose, CA 95134-1362

USA

http://www.redback.com

Tel: +1 408 750 5000

Page 2

© 1996 to 2008, Redback Networks Inc. All rights reserved.

Redback Networks

Redback and SmartEdge are trademarks registered at the U.S. Patent & Trademark Office and in other countries. AOS, NetOp, SMS, and User Intelligent Networks are

trademarks or service marks of Redback Networks Inc. All other products or services mentioned are the trademarks, service marks, registered trademarks or registered service

marks of their respective owners. All rights in copyright are reserved to the copyright owner. Company and product names are trademarks or registered trademarks of their

respective owners. Neither the name of any third party software developer nor the names of its contributors may be used to endorse or promote products derived from this

software without specific prior written permission of such third party.

Rights and Restrictions

All statements, specifications, recommendations, and technical information contained are current or planned as of the date of publication of this document. They are reliable as of

the time of this writing and are presented without warranty of any kind, expressed or implied. In an effort to continuously improve the product and add features, Redback

Networks Inc. ("Redback") reserves the right to change any specifications contained in this document without prior notice of any kind.

Redback shall not be liable for technical or editorial errors or omissions which may occur in this document. Redback shall not be liable for any indirect, special, incidental or

consequential damages resulting from the furnishing, performance, or use of this document.

Third Party Software

The following third party software may be included with this Software and is subject to the following terms and conditions:

The OpenLDAP Version 2.0.1 © 1999 The OpenLDAP Foundation; OpenSymphony Software License, Version 1.1 2001-2004 © The OpenSymphony Group; libpng library ©

1995-2004; FreeType library © 1996-2000; NuSOAP Web Services Toolkit for PHP © 2002 NuSphere Corporation; The PHP License, versions 2.02 and 3.0 © 1999 - 2002 The

PHP Group; The OpenSSL toolkit Copyright © 1998-2003 The OpenSSL Project; Apache HTTP © 2000 The Apache Software Foundation; Java © 2003 Sun Microsystems,

Inc.; ISC Dhcpd 3.0pl2 © 1995, 1996, 1997, 1998, 1999 Internet Software Consortium - DHCP; IpFilter © 2003 Darren Reed; Perl Kit © 1989-1999 Larry Wall; SNMP

Monolithic Agent © 2002 SNMP Research International, Inc.; VxWorks © 1984-2000, Wind River Systems, Inc.; Point-to-Point Protocol (PPP) © 1989, Carnegie-Mellon

University; Dynamic Host Configuration Protocol (DHCP) © 1997, 1998 The Internet Software Consortium; portions of the Redback SmartEdge Operating System use

cryptographic software written by Eric Young (eay@cryptsoft.com);Redback adaptation and implementation of the UDP and TCP protocols developed by the University of

California, Berkeley (UCB) as part of UCB’s public domain version of the UNIX operating system. © 1982, 1986, 1988, 1990, 1993, 1995 The Regents of the University of

California. All advertising materials mentioning features or use of this Software must display the following acknowledgment: “This product includes software developed by the

University of California, Berkeley and its contributors.”

This Software includes software developed by Sun Microsystems, Inc., Internet Software Consortium, Larry Wall, the Apache Software Foundation (http://www.apache.org/) and

their contributors. Such software is provided “AS IS,” without a warranty of any kind. ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND

WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT, ARE

HEREBY EXCLUDED. LICENSORS AND ITS CONTRIBUTORS SHALL NOT BE LIABLE FOR ANY DAMAGES SUFFERED BY LICENSEE AS A RESULT OF

USING, MODIFYING OR DISTRIBUTING THIS SOFTWARE OR ITS DERIVATIVES. IN NO EVENT WILL LICENSOR OR ITS CONTRIBUTORS BE LIABLE FOR

ANY LOST REVENUE, PROFIT OR DATA, OR FOR DIRECT, INDIRECT, SPECIAL, CONSEQUENTIAL, INCIDENTAL OR PUNITIVE DAMAGES, HOWEVER

CAUSED AND REGARDLESS OF THE THEORY OF LIABILITY, ARISING OUT OF THE USE OF OR INABILITY TO USE THIS SOFTWARE, EVEN IF THE

LICENSOR HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. This software consists of voluntary contributions made by many individuals on behalf of

the Apache Software Foundation. For more information on the Apache Software Foundation, please see http://www.apache.org/. Portions of this software are based upon public

domain software originally written at the National Center for Supercomputing Applications, University of Illinois, Urbana-Champaign. The portions of this Software developed

by Larry Wall may be distributed and are subject to the GNU General Public License as published by the Free Software Foundation.

FCC Notice

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required to correct the interference

at their own expense:

1. MODIFICATIONS—The FCC requires the user to be notified that any changes or modifications made to this device that are not expressly approved by Redback could void

the user’s authority to operate the equipment.

2. CABLES—Connection to this device must be made with shielded cables with metallic RFI/EMI connector hoods to maintain compliance with FCC Rules and Regulations.

(This statement only applies to copper cables, Ethernet, DS-3, E1, T1, and so forth. It does not apply to fiber cables.)

3. POWER CORD SET REQUIREMENTS—The power cord set used with the System must meet the requirements of the country, whether it is 100-120 or 220-264 VAC. For

the U.S. and Canada, the cord set must be UL Listed and CSA Certified and suitable for the input current of the system. For DC-powered systems, the installation

instructions need to be followed.

Page 3

VCCI Class A Statement

European Community Mark

The following marking on this product signifies that it meets all relevant European Union directives.

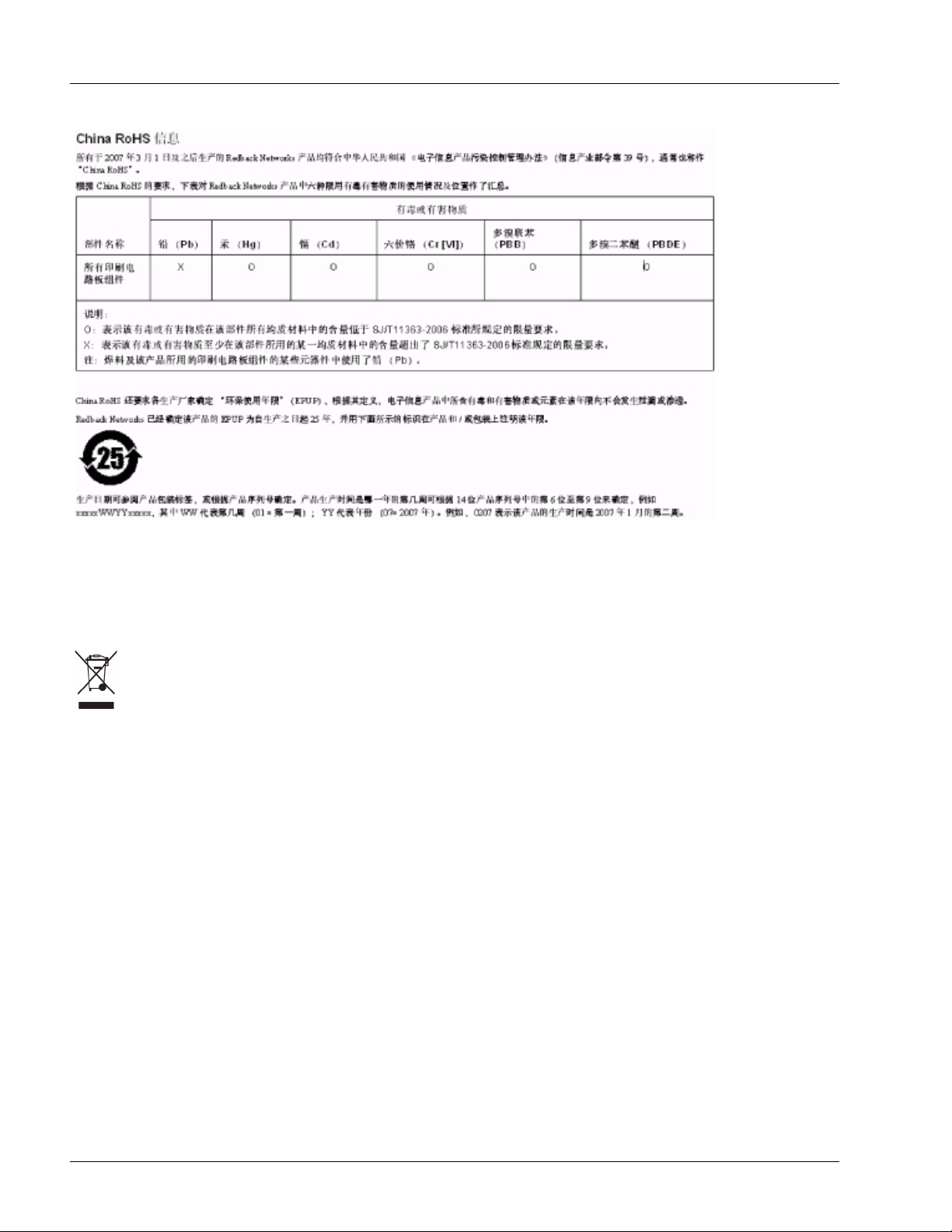

China RoHS Information

All Redback Networks products built on or after March 1, 2007 conform to the People’s Republic of China’s Management Methods for Controlling Pollution by Electronic

Information Products (Ministry of Information Industry Order #39), also known as “China RoHS.”

As required by China RoHS, the following tables summarize which of the 6 regulated substances are found in Redback Networks products and their location.

China RoHS also requires that manufacturers determine an “Environmental Protection Use Period” (EPUP), which has been defined as the term during which toxic and hazardous

substances or elements contained in electronic information products will not leak out or mutate.

Redback Networks has determined that the EPUP for this product is 25 years from the date of manufacture and indicates this period on the product and/or packaging with the logo

shown below.

The date of manufacture can be found on the product packaging label, or determined from the product serial number. The week and year of manufacture can be determined from

the 6th though 9th digits of the 14 digit product serial number, xxxxxWWYYxxxxx, where WW represents the week of the year (01 = first week of year) and YY represents the

year (07= 2007). For example, 0207 means that the unit was manufactured in the 2nd week of January 2007.

Page 4

WEEE Policy

Redback Networks products are fully compliant with Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE) for all applicable geographies in the European

Union. In accordance with the requirements of the WEEE Directive, Redback Networks has since August 13, 2005 labeled products placed on the market with the WEEE symbol,

a crossed-out “wheelie bin” symbol with a black rectangle underneath, as shown below.

The presence of the WEEE symbol on a product or on its packaging indicates that you must not dispose of that item in the normal unsorted municipal waste stream. Instead, it is

your responsibility to dispose of that product by returning it to a collection point that is designated for the recycling of electrical and electronic equipment waste.

Contact the reseller where the product was originally purchased and provide details of the product in question. The reseller will confirm whether the product is within the scope

of the recycling program and then arrange for shipment of the product to the designated recycling location for proper recycling/disposal.

If you are unable to locate the original reseller or need additional information, please contact Redback Networks at weee-info@redback.com. Additional information on the

Redback Networks WEEE policy is available at http://www.redback.com.

Safety Notices

Redback equipment has the following safety notices.

Laser Equipment

Class 1 Laser Product—Product is certified by the manufacturer to comply with DHHS Rule 21 Subchapter J.

Caution! Use of controls or adjustments of performance or procedures other than those specified herein may result in hazardous radiation exposure.

Caution! Invisible laser radiation when an optical interface is open.

Lithium Battery Warnings

It is recommended that, when required, Redback replace the lithium battery.

Warning! Do not mutilate, puncture, or dispose of batteries in fire. The batteries can burst or explode, releasing hazardous chemicals. Discard used batteries according to the

manufacturer’s instructions and in accordance with your local regulations.

War ning Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type as recommended by the manufacturer’s instructions.

Page 5

Var n in g Eksplosionsfara vid felaktigt batteribyte. Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren. Kassera använt batteri enligt

fabrikantens instruktion.

Advarsel! Lithiumbatteri—Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri af samme fabrikat og type. Levér det brugte batteri tilbage

tilleverandøren.

Variotus Paristo voi räjähtää, jos se on virheellisesti asennettu. Vaihda paristo ainoastaan valmistajan suosittelemaan tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mikaisesti.

Advarsel Eksplosjonsfare ved feilaktig skifte av batteri. Benytt samme batteritype eller en tilsvarende type anbefait av apparatfabrikanten. Brukte batterier kasseres i henhold til

fabrikantens instruksjoner.

Waarschwing! Bij dit produkt zijn batterijen geleverd. Wanneer deze leeg zijn, moet u ze niet weggooien maar inleveren als KCA.

Page 6

Page 7

Contents

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Navigation Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Ordering Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Order Additional Copies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Complete the Online Redback Networks Documentation Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Provide Direct Feedback on Specific Product Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1: System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Router Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Specification Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Traffic Card Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Packet Mesh Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

SmartEdge 1200 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chassis Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chassis Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Chassis Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Controller Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Controller Card Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Controller Card Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Traffic Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Chapter 2: Traffic Card Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

ATM OC-12c/STM-4c Intermediate Reach Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

ATM OC-3c/STM-1c Intermediate Reach Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

10/100 Ethernet and Fast Ethernet-Gigabit Ethernet Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Transceiver-Based Gigabit Ethernet Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Gigabit Ethernet and Advanced Gigabit Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Gigabit Ethernet 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Gigabit Ethernet 1020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

10 Gigabit Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Contents vii

Page 8

OC-192c/STM-64c Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Chapter 3: Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Planning the Site and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Select the Installation Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Agency Compliance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Electrical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Select the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Select the Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Equipment and Personal Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

DC Power Source Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Selecting the Type of Management Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Access During the Initial Startup and Reload Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Access During Normal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Management Access Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Gathering Cables and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Chapter 4: Installing the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preinstallation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Safety and ESD Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Site and Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Electrical Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Reducing the Risk of ESD Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Mounting the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Select the Chassis Position in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Select the Chassis Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Install the Chassis Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Install the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Mounting the Removable Air Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Install the Air Ramp Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Install the Removable Air Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Connecting the Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Connect the Chassis Ground Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Connect the Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Installing the Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Select the Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Install the Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Install Blank Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Install the Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Install a CF Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Connecting and Routing the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Cable Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Connections for Management Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Management Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Local or Remote Console Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Connections for External Timing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Connections for Traffic Card Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

viii SmartEdge 1200 Router Hardware Guide

Page 9

Connect and Route the Cables at the Front of the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Connect and Route the External Timing and Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-34

Connect the Equipment and Network Ends of the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Connect the Cables from the Front of the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Connect the Cables from the Rear of the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Chapter 5: Determining Operating Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Powering On and Powering Off the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Determining Hardware Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Determine System Status with LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Determine Card Status with LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Controller Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

ATM Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Ethernet and Gigabit Ethernet Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

SONET/SDH Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Display Results from Power-On Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Managing Hardware with CLI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Hardware Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Hardware Configuration, Control, and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Hardware Configuration and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Hardware Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Values for CLI Input Arguments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Values for CLI Output Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Output Fields for the show chassis Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Output Fields for the show disk Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Output Fields for the show hardware Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Output Fields for the show port Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Troubleshooting Hardware Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Troubleshoot System and Card LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Troubleshoot with System Power and Alarm LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Troubleshoot with Card Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Troubleshoot with On-Demand Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Overview of On-Demand Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Initiate an ODD Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Return a Traffic Card to the In-Service State from the ODD State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Administer Results from an ODD Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Clear Results from ODD Sessions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

ODD Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Obtaining Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Chapter 6: Servicing the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Inserting and Extracting a Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Insert a Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Extract a Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Inserting and Removing a Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Insert a Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Remove a Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Adding, Replacing, or Upgrading a Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Add a Second Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Replace a Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Upgrade a Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Upgrade an XCRP3 Controller Card to More Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Installing and Removing a CF Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Adding and Replacing a Traffic Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Contents ix

Page 10

Add a Traffic Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Replace a Traffic Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Replacing a Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Replacing the Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Replacing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Cleaning Optical Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Appendix A: Cables and Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Management Access Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Craft Console Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Ethernet Crossover Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Ethernet Straight Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

External Timing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Traffic Card Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

ATM Traffic Card Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

10/100 Ethernet and Fast Ethernet-Gigabit Ethernet Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Transceiver-Based Gigabit Ethernet Traffic Card Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

SONET/SDH Traffic Card Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Appendix B: Alarms and Probable Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Chassis Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Traffic Card Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Controller Card Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Optical Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Ethernet Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Gigabit Ethernet Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

x SmartEdge 1200 Router Hardware Guide

Page 11

This preface contains the following sections:

• Objectives

• Related Publications

• Intended Audience

• Organization

• Conventions

• Navigation Aids

• Ordering Documentation

Objectives

About This Guide

This guide contains all the information you need to prepare the site for, install, and service the hardware for

the Redback

®

SmartEdge®1200 router.

Related Publications

To ensure a complete and correct installation of a SmartEdge 1200 router, we recommend that you read and

use the documentation set in the following order:

• SmartEdge 1200 System Unpacking Instructions

Provides information about unpacking the system and its components.

• Release Notes for the SmartEdge OS

Provides the most current information about the product, including any information that is critical to the

installation and any document errata. Read this document before proceeding with the installation.

• SmartEdge 1200 Router Hardware Guide

Provides information about site preparation, hardware installation, and maintenance.

About This Guide i

Page 12

Intended Audience

• Transceivers for SmartEdge Traffic Cards

• Ports, Circuits, and Tunnels Configuration Guide for the SmartEdge OS

• Ports, Circuits, and Tunnels Operations Guide for the SmartEdge OS

• NetOp EMS Operations Guide

• Redback Glossary

Describes the transceiver types and their specifications, including cable data, for all traffic cards, and

how to install them.

Describes the tasks and commands that you use to configure traffic cards, their ports, channels, and

circuits, including link groups, bridged and cross-connected circuits, and tunnels.

Describes the operations tasks and commands that you use to monitor, administer, and troubleshoot

traffic cards, their ports, channels, and circuits, including link groups, bridged and cross-connected

circuits, and tunnels.

Provides detailed instructions on configuring, managing, and troubleshooting a network of SmartEdge

routers using the NetOp™ Element Management System (EMS) software.

Provides a list of industry standard terms and terms found in the SmartEdge hardware and software

documentation.

Intended Audience

This guide is intended for network engineers who are responsible for the planning and configuration of the

SmartEdge 1200 router and qualified (trained) service personnel who install and service SmartEdge 1200

equipment. This guide assumes that readers are familiar with hardware installation and service procedures

in general, but might not have previously installed or serviced a SmartEdge 1200 router.

Organization

This guide is organized as follows:

• Chapter 1, “System Description”

Provides a functional overview of the SmartEdge 1200 router that includes the interfaces, system

components, features, and typical applications for the system.

• Chapter 2, “Traffic Card Descriptions”

Describes each of the packet traffic cards that are currently available for the SmartEdge 1200 router.

• Chapter 3, “Preparing for Installation”

Describes planning for the hardware installation, including site and management access requirements

for the SmartEdge 1200 router.

• Chapter 4, “Installing the Hardware”

Describes how to install the SmartEdge 1200 hardware.

ii SmartEdge 1200 Router Hardware Guide

Page 13

• Chapter 5, “Determining Operating Status”

Describes the SmartEdge 1200 chassis and card LEDs used to determine the status of the system. It also

describes how to troubleshoot hardware problems and use the on-demand diagnostics to isolate faults

to the card level.

• Chapter 6, “Servicing the Hardware”

Describes how to install additional cards and how to replace existing cards and other units in a

SmartEdge 1200 chassis.

• Appendix A, “Cables and Pin Assignments”

Provides cable and connector specifications for all SmartEdge 1200 cables and connectors.

• Appendix B, “Alarms and Probable Causes”

Provides tables of alarm conditions and probable causes for the SmartEdge 1200 chassis and cards.

Conventions

The conventions used for notes, cautions, and warnings provide special information in this guide:

Conventions

Note Provides related information for the topic described in the previous paragraph.

Caution Describes a general warning, caution, or risk that could cause loss of data or damage to the

system or one of its components and how to reduce that risk.

Caution Describes a risk that could cause loss of data or damage to the system or one of its components

because of electrostatic discharge (ESD) and how to reduce that risk.

Warning Describes a risk to you, the installation or service engineer, such as electric shock, that could

cause bodily harm and how to reduce that risk.

Laser Describes a risk to you, the installation or service engineer, from lasers which could cause

severe damage to your eyes and how to reduce that risk.

Navigation Aids

To aid in accessing information in this guide, the following types of cross-references have been hot linked

to provide navigation aids in the online formats of the guide:

• Cross-references to chapters, sections, tables, and figures in the text

• Lists of topic or subsection titles at the beginning of each section and subsection

About This Guide iii

Page 14

Ordering Documentation

• Entries in the table of context

• Entries in any of the indexes

Ordering Documentation

Redback documentation is available on a CD-ROM that ships with the following Redback products:

• SMS™ products

• SmartEdge router products

• NetOp EMS and NetOp Policy Management (PM) products

The following sections describe how to order additional copies and provide feedback:

• Order Additional Copies

• Complete the Online Redback Networks Documentation Survey

• Provide Direct Feedback on Specific Product Documentation

We appreciate your comments.

Order Additional Copies

To order additional copies of the documentation CD-ROM or printed and bound books, perform the

following steps:

1. Log on to the Redback Networks Support web site at http://support.redback.com, enter a username and

password, and click Login.

If you do not have a username and password, consult your Redback Networks support representative,

or send an e-mail to supportlogin@redback.com with a copy of the show hardware command output,

your contact name, company name, address, and telephone number.

2. Click one of the Redback products at the bottom of the web page, click Documentation on the

navigation bar, then click To Order Books on the navigation bar.

Complete the Online Redback Networks Documentation Survey

To complete the online Redback Networks Documentation Survey, perform the following steps:

1. On the Documentation web page, click Feedback on the navigation bar.

2. Complete and submit the feedback form.

Provide Direct Feedback on Specific Product Documentation

To provide feedback on a documentation issue related to the SmartEdge 1200 router, send e-mail to

seos-router-docs@redback.com.

iv SmartEdge 1200 Router Hardware Guide

Page 15

Chapter 1

System Description

This chapter provides a functional overview of the SmartEdge®1200 router that includes the interfaces,

system components, features, and typical applications for the system.

It includes the following topics:

• System Overview

• System Components

System Overview

The SmartEdge 1200 router is a carrier-class product with an architecture that supports packetized traffic.

The router can be used as an edge aggregation router and simultaneously as a broadband remote access

server (BRAS) to directly connect customers to the network. It supports a variety of interfaces and vital

services, such as routing protocols, quality of service (QoS), and inbound and outbound access control lists

(ACLs). New services can easily be added with software upgrades.

Because of the optimized packet-forwarding capabilities and support of high-bandwidth uplink interfaces,

the SmartEdge 1200 router can also be used in the metropolitan core to aggregate traffic from other routers

into the long-haul transit core.

This section includes the following topics:

• Router Versions

• Specification Summary

• Traffic Card Interfaces

• Packet Mesh Architecture

• Redundancy

•Alarms

• System Status

System Description 1-1

Page 16

System Overview

Note In the descriptions that follow, the term, controller card, refers to any version of the

Router Versions

The SmartEdge 1200 router has two versions: standard and NEBS-compliant (NEBS Level 3). These two

versions are distinguished by the type of air ramp that is integrated into the chassis.

Unlike SmartEdge 800 routers, which require separate air ramps installed above and below the chassis for

directing hot air away from the chassis, the air ramp integrated into a SmartEdge 1200 chassis replaces the

air ramp that would otherwise be installed above the chassis.

Both versions of the SmartEdge 1200 router use the same chassis, but each version has a different integrated

air ramp. The NEBS-compliant router uses a NEBS-compliant air ramp; the standard version uses a

standard integrated air ramp. In all other respects, the two versions of the SmartEdge 1200 router are

identical.

Because the integrated air ramp cannot be removed from the chassis, the chassis itself is referred to as being

a NEBS-compliant chassis or a standard chassis. However, to complete the installation, when a

SmartEdge 1200 router is installed at the bottom of a rack, a removable NEBS-compliant air ramp is

required for the NEBS-compliant version of the router; a standard removable air ramp is required for the

standard version of the SmartEdge 1200 router.

Cross-Connect Route Processor (XCRP) Controller card (XCRP, XCRP3, XCRP4), unless

otherwise noted.

The term, Gigabit Ethernet, applies to any Ethernet traffic card that supports a port speed of

1 Gbps or greater; unless explicitly stated, the speed of any Gigabit Ethernet port is 1 Gbps.

Note In the descriptions that follow, the term SmartEdge 1200 applies to either version of the router,

unless otherwise noted. The terms SmartEdge 1200n and SmartEdge 1200s refer to the

NEBS-compliant and the standard versions of the router, respectively. Throughout this guide,

figures for the SmartEdge 1200 router illustrate the SmartEdge 1200n router, unless otherwise

noted.

NEBS-compliance standards are listed in Table 3-1 in the “Agency Compliance Information”

section on page 3-2.

Table 1-1 lists the product codes for the two types of SmartEdge 1200 chassis. The product codes identify

the type of air ramp that is integrated into the chassis.

Table 1-1 SmartEdge 1200 Chassis Types

Chassis

SmartEdge 1200n D9 SmartEdge 1200 chassis with NEBS-compliant air ramp.

SmartEdge 1200s D7 SmartEdge 1200 chassis with standard (non-NEBS compliant) air ramp.

Product

Code Description

1-2 SmartEdge 1200 Router Hardware Guide

Page 17

Specification Summary

Table 1-2 summarizes the general specifications for the SmartEdge 1200 router.

Table 1-2 General Specifications

Specification Value

Synchronization • Line timing mode (various traffic cards)

• Internal timing mode

• External timing mode

Protection type • Power: independent dual-feed

• XCRP, XCRP3, XCRP4 Controllers: 1:1

• External timing: 1:1

System Overview

Operations

connections

• Management workstation (ENET): 10/100Base-T

• Console terminal (Craft): RS-232

• Alarms: audible and visual: critical, major, minor, ACO

Note Protection for cards and ports depends on the release of the SmartEdge OS.

Traffic Card Interfaces

The SmartEdge 1200 router supports a wide variety of interfaces, such as:

• Synchronous Optical Network/Synchronous Digital Hierarchy (SONET/SDH) OC-192c/STM-64c

• Asynchronous Transfer Mode (ATM) using SONET/SDH OC-3c/STM-1c, OC-12c/STM-4c

• 10Base-T, 100Base-TX, 1000Base-LX, 1000Base-SX, 1000Base-T, and 1000Base-ZX; and

10000Base-ER, 10000Base-LR, and 10000Base-SR

Note Neither SmartEdge 1200 chassis provides support for traffic cards that require BNC

connections. For a list of traffic cards, see Table 1-5.

Packet Mesh Architecture

The SmartEdge 1200 router implements a grid of cross connections in its backplane that allows any traffic

card to communicate directly to any other traffic card in the chassis. The feature allows incoming packets

to be directly routed from the receiving traffic card to the traffic card that will transmit them to the network.

Each traffic card uses a combination of a Packet Mesh ASIC (PMA) and Packet Processing ASICs (PPAs)

to perform this function.

Redundancy

The architecture of the system is fully redundant for all traffic-affecting components. Redundancy features

include:

• Dual power connections, each with separate A-side and B-side power connections

• 1+1 Automatic Protection Switching (APS) protection for ATM second-generation traffic cards: 4-port

ATM OC-3c/STM-1c and Enhanced ATM OC-12c/STM-4c

System Description 1-3

Page 18

System Components

Note Protection for cards and ports is configurable on a per-port basis; a mix of protected and

• Redundant controller cards and redundant file systems

• Redundant external timing sources, such as building integrated timing supply (BITS) or

Alarms

The SmartEdge 1200 router supports three levels of alarms—critical, major, and minor:

• A critical alarm alerts the operator to a severe, service-affecting condition. It requires immediate

• A major alarm alerts the operator to a service-affecting hardware or software condition, such as a

• A minor alarm alerts the operator to a condition that does not have a serious affect on service or on

unprotected ports is supported. Protection features and the types of ports that support APS

depend on the release of the software.

synchronization supply unit (SSU), with internal timing if both sources should fail

corrective action, regardless of time; for example, a fire.

serious disruption of service, or the malfunction or failure of important circuits. It requires immediate

corrective attention and the response of a service engineer; for example, a link failure.

circuits that are not essential to network operation; for example, a carrier line problem for which

transmission has been switched to another line.

System Status

The system LEDs are located on the fan tray. These LEDs include status indicators for each of the chassis

power sources (A1, A2, B1, and B2), alarms (critical, major, and minor), fan status and ACO status, and an

alarm cutoff (ACO) button. The ACO button provides one means of silencing an audible alarm; pressing

the ACO button silences an audible alarm and lights the ACO LED; pressing the button again turns off the

ACO LED and, if the alarm condition has not been corrected, sounds the alarm.

Note Support for the ACO button depends on the release of the SmartEdge OS.

System Components

This section describes the following system components:

• SmartEdge 1200 Chassis

• Controller Cards

•Traffic Cards

1-4 SmartEdge 1200 Router Hardware Guide

Page 19

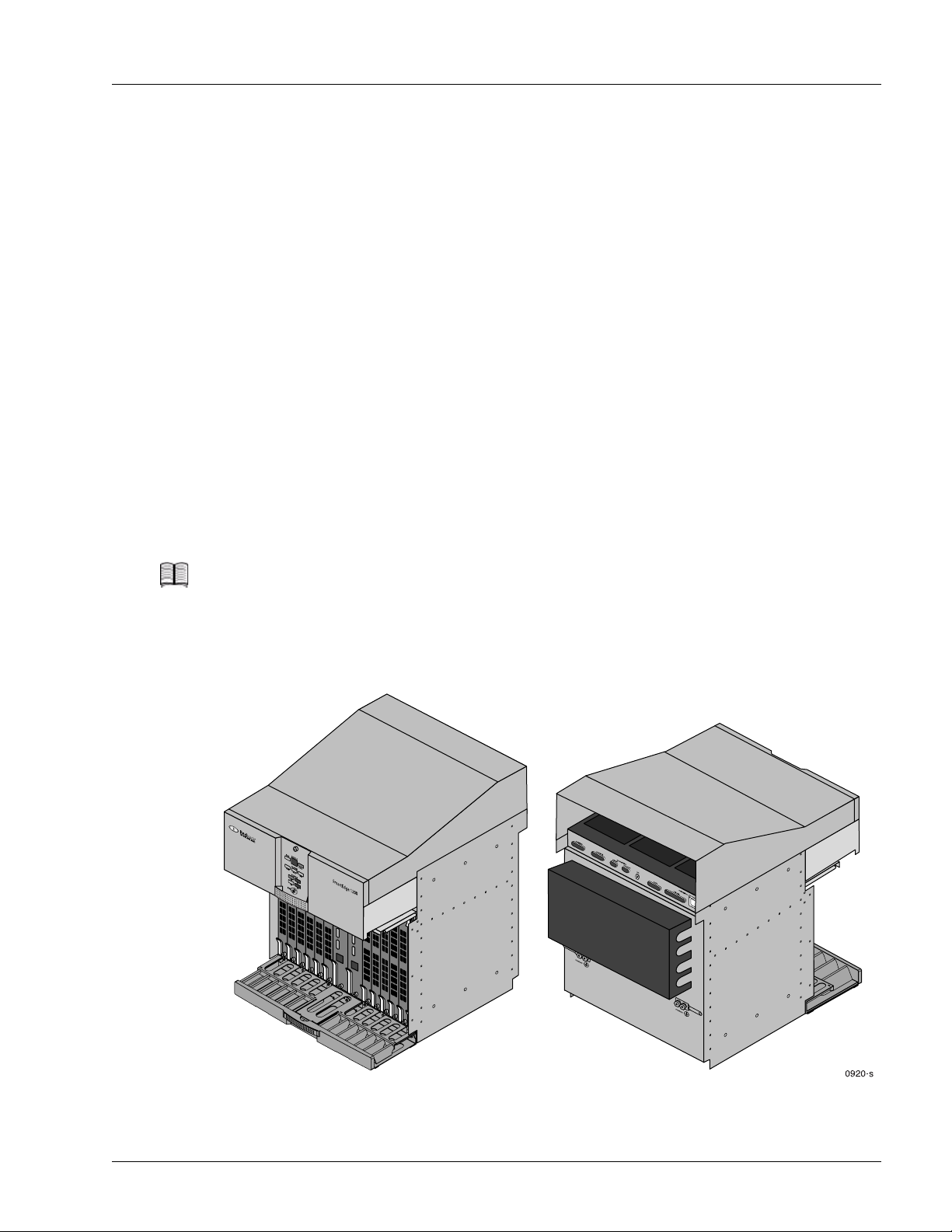

SmartEdge 1200 Chassis

The SmartEdge 1200 chassis is designed for mounting in a standard 19- or 23-inch rack. Figure 1-1 shows

the standard SmartEdge 1200 chassis; Figure 1-2 shows the SmartEdge 1200n chassis. Main features of the

chassis include:

• Chassis Card Cage

• Chassis Cooling

• Chassis Power

Chassis Card Cage

The SmartEdge 1200 chassis has a card cage with 14 slots. Two slots are dedicated to the controller cards

and 12 slots are available for a flexible combination of traffic cards.

All cards are installed at the front of the chassis. A cable tray provides the means to route the cables from

the front of the chassis to the external equipment. The cable tray requires no adjustments regardless of the

number and types of installed cables.

The rear of the chassis has connectors for alarm outputs, status inputs, dual external timing inputs for

synchronization, and dual RS-232 ports for local connections. Cable brackets at the rear of the chassis

provide the means for routing system cables and keeping them orderly.

System Components

Note The SmartEdge OS does not support the alarm, status, and RS-232 dial-up modem ports.

Electrostatic discharge (ESD) jacks are conveniently located on both the front and the rear of the chassis.

Figure 1-1 Standard SmartEdge 1200s Chassis

System Description 1-5

Page 20

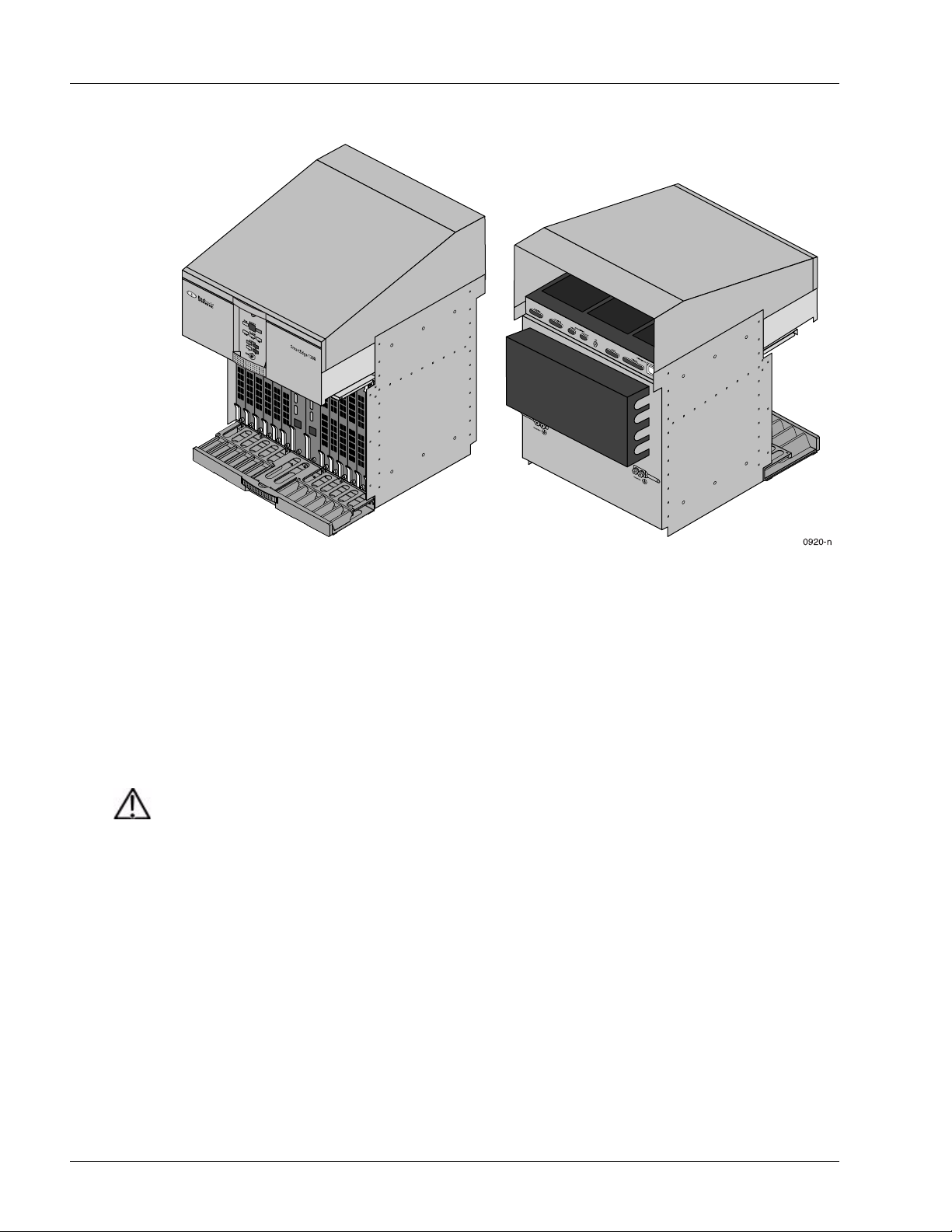

System Components

Figure 1-2 NEBS-Compliant SmartEdge 1200n Chassis

Chassis Cooling

Cooling for the chassis is provided by the fan tray, which is installed directly above the card slots. Six fans

provide the needed airflow from the bottom of the chassis to the top with exhaust at the rear of the chassis.

An air filter is installed below the card cage and filters incoming air before it reaches the cards.

A single fan failure does not impact the operation of the system; however, to prevent overheating, the unit

must be replaced as soon as possible. To maintain the airflow through the chassis, empty slots must have

blank cards installed.

Caution Risk of equipment damage. SmartEdge router cards can be damaged by lack of cooling when

Chassis Power

The SmartEdge 1200 router power architecture has two power zones, each with primary and backup

sources. Primary sources are referred to as A sources; backup sources are B sources. A1 refers to the

primary power source for zone 1; B1 refers to the backup power source for zone 1. Both zones 1 and 2 must

be connected for the chassis to be operational; the connections can be any combination of A and B sources.

For a fully redundant power configuration, all four sources must be connected.

Zone 1 sources provide power to slots 1 to 7 in the chassis; zone 2 sources provide power to slots 8 to 14.

The chassis fan tray is powered from either zone.

the chassis has empty slots. To reduce the risk, every slot must have a controller, traffic, or

blank card installed in it to ensure proper airflow through the chassis.

1-6 SmartEdge 1200 Router Hardware Guide

Page 21

Controller Cards

A controller card manages the system; it is responsible for the packet routing protocols, the SmartEdge OS

command-line interface (CLI), and communications with a network management system running the

NetOp™ Element Management System (EMS) software. The controller card also loads all configuration

information necessary for the traffic cards. Controller cards are installed in slots 7 and 8 in the

SmartEdge 1200 chassis. Controller cards are described in the following sections:

• Controller Card Versions

• Controller Card Features and Functions

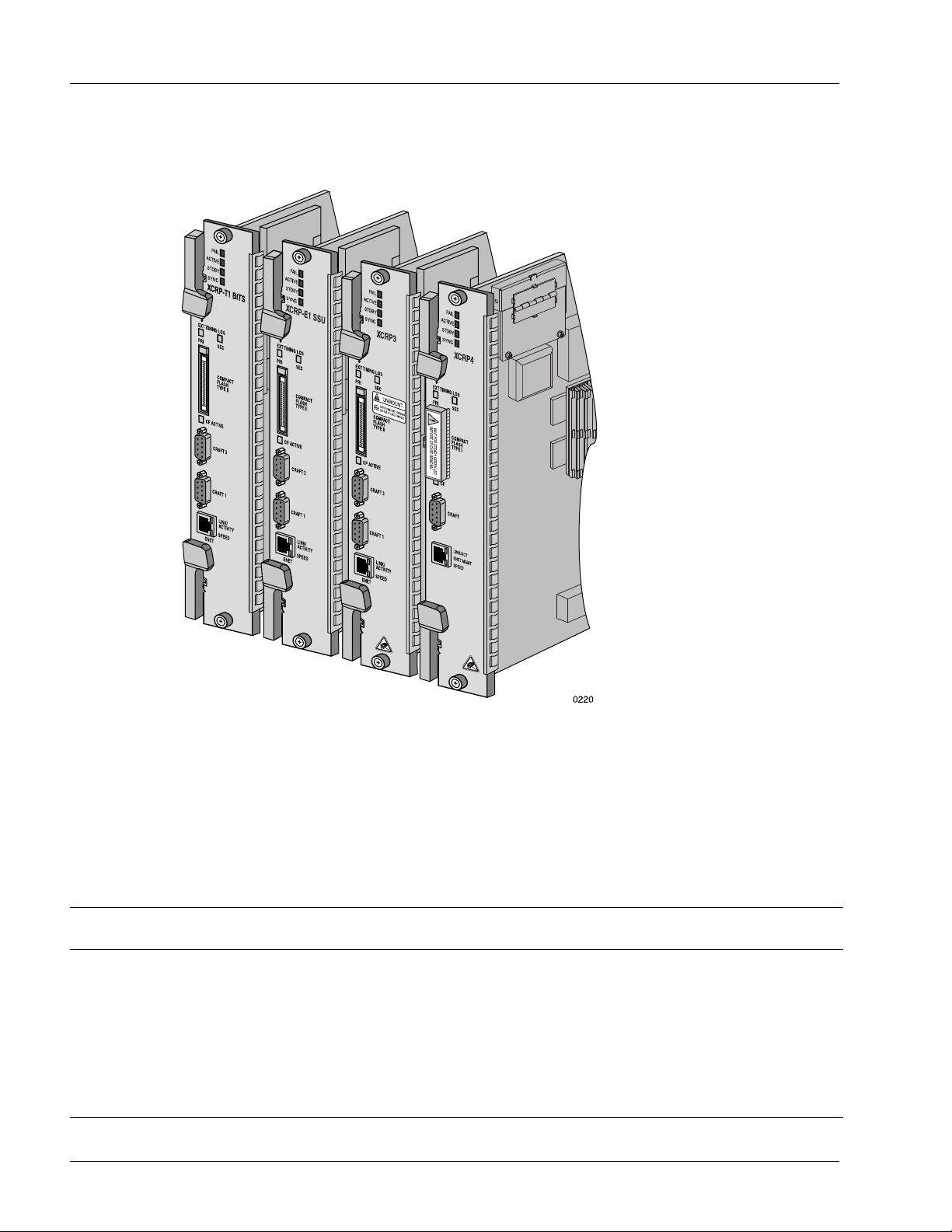

Controller Card Versions

The SmartEdge router supports three versions of the controller cards:

• XCRP Controller card

Two versions of this controller card support either a DS-1 interface for BITS equipment (labeled

“XCRP-T1 BITS”) or an E1 interface for SSU equipment (labeled “XCRP-E1 SSU”).

• XCRP3 Controller card

Two versions of this card differ only in the total size of main memory. The interface to BITS or SSU

equipment is software selectable.

System Components

• XCRP4 Controller card

This controller card supports applications that require high volumes of traffic; it also supports more

subscribers than the other controller cards. Unlike the XCRP3 Controller card, the interface to BITS or

SSU equipment does not support the transmission of timing data to the external equipment.

Table 1-3 compares the XCRP and XCRP3 Controller cards.

Table 1-3 XCRP and XCRP3 Controller Card Comparison

Feature XCRP XCRP3

Processors Dual processors with shared memory that run

Control processor functions • SONET/SDH software

Main memory (total) 768 MB 768 or 1,280 MB

NVRAM No 512 KB DRAM with battery backup

Internal timing Stratum 3 oscillator

Real-time clock No Yes, synchronized with NTP server

External timing implementation

independently and perform different functions

• SmartEdge OS software

• NetOp EMS software

• External timing (synchronization) software

(±4.6 ppm with freerun, normal, and holdover

modes)

1

Separate hardware versions Software selectable

Dual processors with shared memory that run

independently and perform different functions

• SONET/SDH software

• SmartEdge OS software

• NetOp EMS software

• External timing (synchronization) software

Stratum 3 oscillator

(±4.6 ppm with freerun, normal, and holdover

modes)

Internal storage for system images

2

and files

384 or 512 MB 1 GB

System Description 1-7

Page 22

System Components

Table 1-3 XCRP and XCRP3 Controller Card Comparison (continued)

Feature XCRP XCRP3

External storage for core dumps

1 GB 1 GB (NEBS certified)

and system files

External ports 2 DB-9 (CRAFT 1, CRAFT 2)

3

1 10/100 Ethernet

1. Although either controller card can transmit data, the SmartEdge OS does not support the transmission of data to the external equipment.

2. Total storage on two internal storage devices.

3. The CRAFT 1 port is not supported.

2 DB-9 (CRAFT 1, CRAFT 2)3

1 10/100 Ethernet

Table 1-4 compares the XCRP3 Controller card with the XCRP4 Controller card.

Table 1-4 XCRP3 and XCRP4 Controller Card Comparison

Feature XCRP3 XCRP4

Processors Dual processors with shared memory that run

independently and perform different functions

Control processor functions • SONET/SDH software

• SmartEdge OS software

•NetOp EMS software

• External timing (synchronization) software

Main memory (total) 768 or 1,280 MB SDRAM 8 GB DDR-II SDRAM

NVRAM 512 KB DRAM with battery backup 512 KB DRAM with battery backup

Internal timing Stratum 3 oscillator

(±4.6 ppm with freerun, normal, and holdover

modes)

Four processors with shared memory that run

independently and perform different functions

• SONET/SDH software

• SmartEdge OS software

• NetOp EMS software

• External timing (synchronization) software

SONET minimum clock

(±20.0 ppm in freerun mode, normal mode only)

Real-time clock Yes, synchronized with NTP server Yes, synchronized with NTP server

External timing implementation

Internal storage for system

1

Software selectable

4

1 GB

2

Software selectable

3

2 GB

images and files

External storage for core dumps

1 GB (NEBS certified) 1 GB (NEBS certified)

and system files

External ports 2 DB-9 (CRAFT 1, CRAFT 2)

5

1 10/100 Ethernet

1. The SmartEdge OS does not support the transmission of data to the external equipment.

2. The XCRP3 can receive or transmit data.

3. The XCRP4 can receive data only.

4. Total storage on two internal storage devices.

5. The CRAFT 1 port is not supported.

6. Support for 1 Gbps depends on the release of the SmartEdge OS.

1 DB-9 (CRAFT)

1 10/100/1000 Ethernet

6

1-8 SmartEdge 1200 Router Hardware Guide

Page 23

Controller Card Features and Functions

A controller card has these features and functions:

• Processors

The XCRP and XCRP3 Controller cards have two processors. One processor runs low-level software,

including device drivers and equipment management software; the second processor runs the routing

and broadband remote access server (BRAS) software. The XCRP4 Controller card has four processors:

one processor runs the low-level software and the other three processors run the BRAS and routing

software.

Note Support for more than one processor to run the BRAS and routing software depends on the

release of the SmartEdge OS.

•Main memory

Synchronous dynamic RAM (SDRAM) is used by the SmartEdge OS shared databases that are

accessed by the traffic cards.

Note In a chassis with two controller cards, both cards must have the same memory configuration.

System Components

• NVRAM with battery

Each of the XCRP3 and XCRP4 Controller cards include 512 KB of non-volatile RAM (NVRAM),

which stores the current state of the system; because NVRAM is not affected by power failures or

system shutdown, the system can restore operations after such events. The NVRAM battery on the

XCRP4 Controller card is rechargeable; it is recharged from the power supplied to the SmartEdge router

during normal operations. The battery typically lasts more than two years when fully charged and

without benefit of being recharged by being powered on.

Note Support for NVRAM depends on the release of the SmartEdge OS.

• Internal, system, real-time, and time-of-day clocks

The internal clock onboard the XCRP and XCRP3 Controller cards is a Stratum 3 oscillator at ±4.6 ppm

that supports free-run, normal, and holdover modes; the internal clock on an XCRP4 Controller card is

a SONET minimum clock (SMC) at ±20.0 ppm in free-run and normal modes only.

The system clock refers to the clock that performs system hardware timing functions, regardless of the

source of its timing data. Using the SmartEdge OS, you can specify external equipment (external timing

mode), the received clock of a traffic card (line timing mode), or the internal clock on the controller card

(internal mode) as the source for the system clock.

The real-time clock (RTC) on the XCRP3 and XCRP4 Controller cards is initialized before the system

is shipped. It is not affected by power failures, system shutdown, or reload. The RTC uses the NVRAM

battery.

By default, the source for the transmit clock for the ports on a traffic card is its onboard clock.

Depending on the type of traffic card, the transmit clock for a port on a traffic card can use instead the

receive clock derived from an incoming signal to the port or the system clock. Because a port does not

interface to the source of the system clock directly, traffic card synchronization is independent of the

type of external timing equipment and the version of the controller card installed in the chassis.

System Description 1-9

Page 24

System Components

• Support for an external timing connection

Note The SmartEdge OS does not support transmission of data to external equipment.

• Internal storage for SmartEdge OS files

The time-of-day clock (TDC) for a SmartEdge router is implemented in software. When a system with

an XCRP3 or XCRP4 Controller card is powered on, the RTC sets the TDC; otherwise, the TDC is

undefined until it is configured and set using the SmartEdge OS. The TDC can be maintained by

synchronization with a Network Time Protocol (NTP) server. Periodically, the SmartEdge OS updates

the RTC based on the current value of the TDC.

All controller cards support a BITS (DS-1) or SSU (E1) interface as a source for the system clock. For

the XCRP Controller card, the type of interface is identified by the label suffix on the card: “T1 BITS”

for DS-1 and “E1 SSU” for E1; for the XCRP3 and XCRP4 Controller cards, the type of interface is

software selectable.

The external timing interfaces allow the system clock operation to be independent of the type of external

equipment and the framing of the external line.

A controller card has one or two CF cards (Type I), which store SmartEdge OS images and files.

SmartEdge OS storage is organized into three partitions: p0, p1, and /flash. The p0 and p1 partitions

each store a system image and its files; the memory on a controller card can be loaded from either

partition. The third partition, /flash, stores SmartEdge OS configuration files and other system- and

user-created data files.

Note The capacity of the CF cards can vary; the CF cards installed in the active and standby

controller cards need not have the same capacity.

• Optional CF card

A controller card has an external slot on the front panel in which you can install an optional Type I or

Type II CF card. The XCRP4 Controller card supports Type I CF cards only. When installed (the system

is shipped with the slot empty), the CF card captures crash dumps and provides an alternate source for

loading SmartEdge OS software, if it is not possible to download it over the network.

Caution Risk of data loss. You can corrupt the system if you attempt to install a CF card not obtained

from Redback

®

because these items have not been tested with the SmartEdge router. To

reduce the risk, use only the CF cards provided by Redback.

Note If a CF card is installed in the active controller card, the standby controller card, if installed,

must also have a CF card installed; however, for the XCRP and XCRP3 Controller cards, the

CF card types (Type I or Type II) need not match.

1-10 SmartEdge 1200 Router Hardware Guide

Page 25

System Components

• Two types of operations ports for system management access—Craft and Ethernet:

— The XCRP and XCRP3 Controller cards have two Craft ports, labeled “CRAFT 1” and “CRAFT 2”;

the XCRP4 Controller card has a single Craft port, labeled “CRAFT”. Each port has a DB-9

connector and provides an RS-232 connection to a local console terminal, a terminal server, or a

modem. The Craft port provides access to the SmartEdge OS CLI for configuring and monitoring

task; it is enabled on both the active and standby controller cards.

Note The CRAFT 2 port is the only enabled Craft port on the XCRP and XCRP3 Controller cards.

— All controller cards have a single Ethernet port with an RJ-45 connector that runs at 100 Mbps and

provides a connection to an Ethernet device such as a switch or hub. This port provides access to

the SmartEdge OS CLI from either a local or remote management workstation for configuring and

monitoring tasks. Using this port, the system can also communicate with a remote workstation that

is running the NetOp EMS software.

Note Support for 1-Gbps speed of the port on the XCRP4 Controller card depends on the release of

the SmartEdge OS.

Note The Ethernet management port on the standby controller card is disabled unless the card

becomes the active controller card.

• Temperature and voltage monitoring

Temperature is monitored at both air inlet and air outlet locations on a controller card;

an over-temperature interrupt signals the SmartEdge OS when the temperature rises above safe

operating conditions. Voltages are also monitored and reported to the SmartEdge OS. Administrators

can display both temperature and voltage data using commands in the SmartEdge OS CLI

• Fully redundant configuration:

— When two controller cards are installed in the SmartEdge 1200 chassis, one functions as the active

controller and the other card functions as the standby controller, providing full redundancy for

high-reliability networking requirements. In the event of a controller card failure, the redundant card

automatically becomes the active controller, thereby avoiding any unnecessary service disruption in

the network.

Note If you upgrade the active controller card with a new software release, the active controller

upgrades the standby controller.

— Redundancy extends to the console connections on the controller cards: the console ports can each

be connected to a terminal server, and the Ethernet management ports can be connected to the same

Ethernet hub, with individual cables.

— The software automatically switches to the external timing secondary source should the primary

source fail. If both sources fail, the active controller card uses an internal timing source.

System Description 1-11

Page 26

System Components

Figure 1-3 shows the front panels of the controller cards.

Figure 1-3 Controller Cards

Traffic Cards

Table 1-5 lists the traffic cards supported on the SmartEdge 1200 router; for more information about traffic

cards, see Chapter 2, “Traffic Card Descriptions.” In the table, the IR abbreviation specifies Intermediate

Reach.

Table 1-5 SmartEdge 1200 Traffic Cards

Type of Traffic Card/Description

ATM

4-port ATM OC-3c/STM-1c IR 12 4 Yes 2 None, 1+1 APS

Enhanced ATM OC-12c/STM-4c IR 12 1 No – None, 1+1 APS

Ethernet and Gigabit Ethernet

10/100 Ethernet 12 12 No – None

Fast Ethernet-Gigabit Ethernet 12 60, 2 No – None

Number

of Cards

Number

of Ports

Low-Density

1

Ver sio n

2

1-12 SmartEdge 1200 Router Hardware Guide

Low-Density

Ports

Protection

3

Ratios

Page 27

Table 1-5 SmartEdge 1200 Traffic Cards (continued)

System Components

Type of Traffic Card/Description

Number

of Cards

Number

of Ports

Low-Density

1

Ver sio n

2

Low-Density

Ports

Protection

3

Ratios

Gigabit Ethernet (first and second versions) 12 4 Yes 2 None

Gigabit Ethernet 3 12 4 No – None

Gigabit Ethernet 1020 (10-port) 12 10 No – None

Gigabit Ethernet 1020 (20-port) 6

4

20 No – None

10 Gigabit Ethernet 12 1 No – None

SONET/SDH

OC-192c/STM-64c 12 1 No – None, 1+1 APS

1. On optical cards, each port has separate connectors for the transmit (Tx) and receive (Rx) circuits.

2. The low-density version of a card provides a limited number of ports that are enabled through software entitlement.

3. Protection features for various types of cards and ports depend on the release of the SmartEdge OS; the system supports a mix of protected and unprotected

ports.

4. The 20-port GE1020 card requires two adjacent slots.

System Description 1-13

Page 28

System Components

1-14 SmartEdge 1200 Router Hardware Guide

Page 29

Chapter 2

Traffic Card Descriptions

This chapter describes each of the traffic cards that are currently available for the SmartEdge®1200 router.

Asynchronous Transfer Mode (ATM) cards include:

• ATM OC-12c/STM-4c Intermediate Reach Card

• ATM OC-3c/STM-1c Intermediate Reach Card

Fast Ethernet traffic cards include:

• 10/100 Ethernet and Fast Ethernet-Gigabit Ethernet Cards

Gigabit Ethernet traffic cards include:

• Gigabit Ethernet and Advanced Gigabit Ethernet

• Gigabit Ethernet 3

• Gigabit Ethernet 1020

• 10 Gigabit Ethernet

Packet over SONET/SDH traffic cards include:

• OC-192c/STM-64c Card

Note In the descriptions that follow, the term SmartEdge 1200 applies to any version of the chassis,

unless otherwise noted. The terms SmartEdge 1200s and SmartEdge 1200n refer to the

standard and NEBS-compliant versions of the chassis, respectively. Figures for the

SmartEdge 1200 chassis illustrate the SmartEdge 1200n chassis, unless otherwise noted.

In the descriptions that follow, the term controller card refers to any version of the

Cross-Connect Route Processor (XCRP) Controller card (XCRP, XCRP3, XCRP4), unless

otherwise noted.

The term Gigabit Ethernet applies to any Ethernet traffic card that supports a port speed of

1 Gbps or greater; unless explicitly stated, the speed of any Gigabit Ethernet port is 1 Gbps.

Traffic Card Descriptions 2-1

Page 30

A few traffic cards have a low-density version, on which a limited number of ports are enabled through

software entitlement. Table 2-1 lists the port data for traffic cards; in the table, IR, LR, and SR

abbreviations are used for Intermediate Reach, Long Reach, and Short Reach, respectively.

Table 2-1 Port Data for Traffic Cards

Type of Traffic Card/Description

ATM

ATM OC-12c/STM-4c IR

Enhanced ATM OC-12c/STM-4c IR

4-port ATM OC-3c/STM-1c IR

Ethernet and Gigabit Ethernet

10/100 Ethernet (12-port)

Fast Ethernet-Gigabit Ethernet

Gigabit Ethernet (first and second versions)

Gigabit Ethernet 3

Gigabit Ethernet 1020 (10-port)

Gigabit Ethernet 1020 (20-port)

10 Gigabit Ethernet

SONET/SDH

OC-192c/STM-64c 1 No –