Page 1

PF768, Standard Electrical Repairs

Approved according to 2/FEA 209 544

Trouble-shooting

instruction

PF 768

Service Manual by Toko

4/00021-2/FEA 209 544/11.C

Page 2

PF768, Standard Electrical Repairs

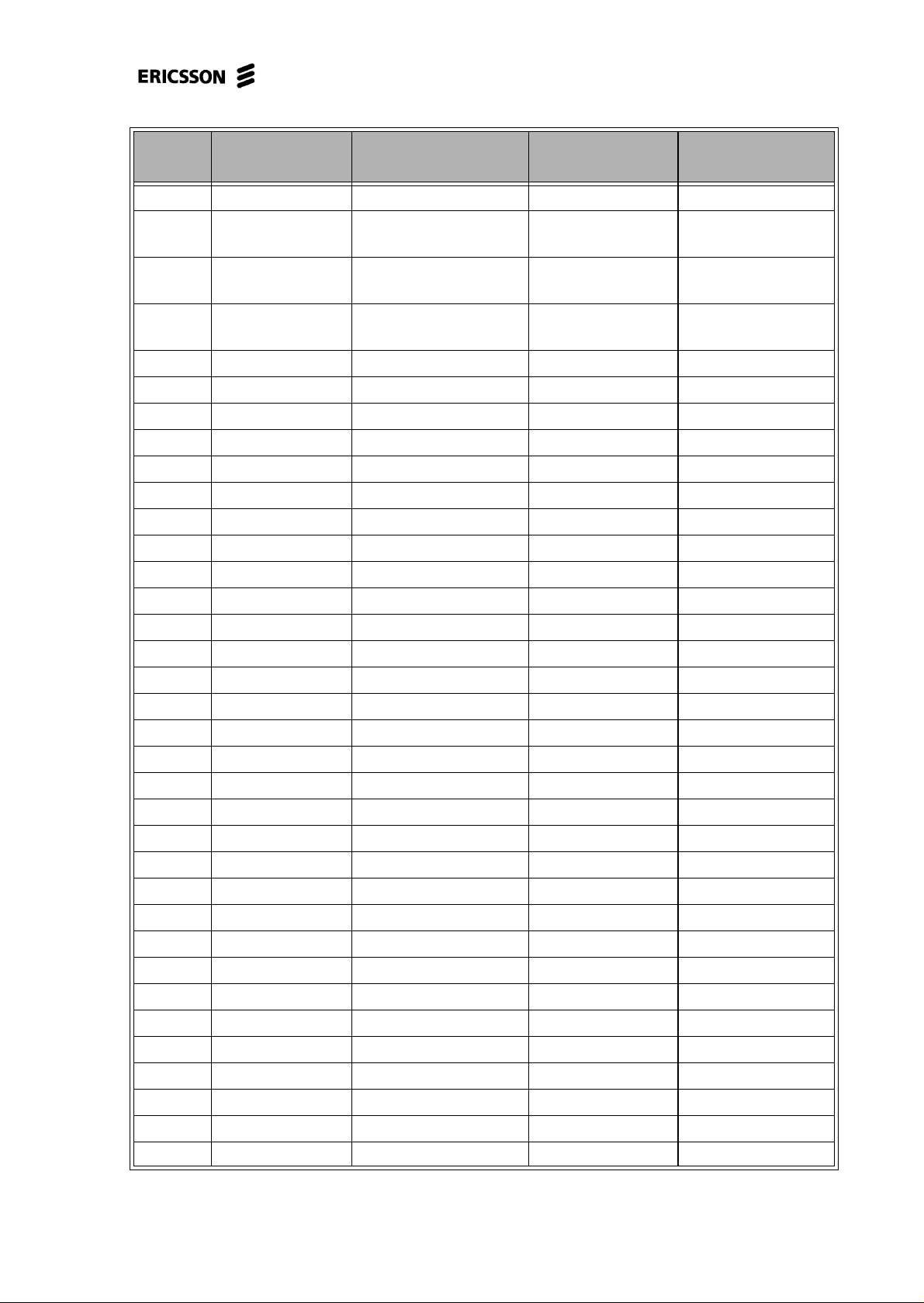

Table of contents

1 Conditions .......................................................................................... 3

1.1 Component classes. ......................................................................... 3

1.2 Abbreviations. ................................................................................. 4

1.3 Pin placements ................................................................................ 6

2 No serv/not able to connect calls. ..................................................... 8

3 Doesn’t start. ................................................................................... 11

4 Audio. ............................................................................................... 21

5 Display. ............................................................................................ 29

6 SIM (“Insert card”). ....................................................................... 33

7 Keyboard ......................................................................................... 37

8 Illumination and buzzer. ................................................................ 42

9 RTC .................................................................................................. 50

10 Component lists ............................................................................... 52

10.1 Explanations .................................................................................. 52

10.2 Component list 2/ROA 117 3235/2 ............................................. 53

10.3 Mounting drawing table .............................................................. 67

10.4 Revision change table ................................................................... 67

4/00021-2/FEA 209 544/11.C 2 (68)

Page 3

PF768, Standard Electrical Repairs

1 Conditions

1.1 Component classes.

All the components in thephone are divided into classes and after every component

in the troubleshooting guide you have a class written. The components are divided

into four classes: A, B, C and D.The class of the component depends on how much

of the phone’s performance is affected when replacing it.

Class A and B:A test call towards the “real” net (not only towards a GSM test

Class C: Since the tolerances of the component are so great it can substantially

instrument) and run it through the normal tests is enough to verify the

functionality since the performance of the phone is only slightly

affected.

affect the performance of the phone you need to calibrate it at station

level after replacing the component.

Class D: Class D components need to be calibrated at board level using very

advanced equipment and may therefore not be replaced.

4/00021-2/FEA 209 544/11.C 3 (68)

Page 4

PF768, Standard Electrical Repairs

1.2 Abbreviations.

A: The power module at some phones.

B: Crystal.

C: Capacitor.

D: Digital circuit.

F: Over voltage protection.

G: VCO.

H: Buzzer, LED, pads for display.

J: Connector.

L: Coil.

N: Analogue circuit.

R: Resistor.

S: Keyboard pads.

U: BALUN. A circuit that converts a signal from balanced to unbalanced or the

opposite.

V: Transistor or diode.

X: Contact surface at the circuit board.

Z: Filter.

AGND: Ground for analogue signals.

DCIO: DC voltage used for charging the battery through the system connector.

DCON: Logical signal from the processor that keeps the phone running after

you’ve released the On/Off key.

EXTAUD: Input signal at the system connector that the processor uses to deter-

mine if there’s any external audio equipment attached.

EXTAUDI: The same signal as the EXTAUD signal but at the processor side.

GND: Ground.

LED3K: Logical signal used to activate the background illumination.

ONSRQ: Voltage from the On/Off key that starts the phone.

PORTHF: Input signal at the system connector that the processor uses to deter-

mine if there’s any handsfree equipment attached.

PHF1: The same signal as PORTHF but at the processor side.

REGON: Logical signal that activates the voltage regulators.

RTC: Real time clock. The clock that keeps track of time and date.

4/00021-2/FEA 209 544/11.C 4 (68)

Page 5

PF768, Standard Electrical Repairs

SIMCLK: Clock signal from the processor used for communications with the

SIM.

SIMDAT: Data signal from the processor used for communications with the SIM.

SIMRST: Reset signal from the processor used for communications with the

SIM.

SIMVCC: Feed voltage for the SIM.

SWDC: Switched VBATT.

VANA: DC voltage for the analogue part of the logic (N800).

VBATT: Battery voltage.

VDIG: DC voltage for the processor and memory.

VDSP: DC voltage for the DSP (Digital Signal Processor).

VLCD: DC voltage for the display that controls the contrast.

VRAD: DC voltage for the radio part except the synthesizer.

VRPAD: DC voltage for the radio part in D600 (also used for the top diode and

the buzzer).

VRTC: DC voltage for the real time clock.

VSIMPAD: VDIG voltage that has been switched up to 5V used for SIM.

VVCO: DC voltage for the synthesizer.

2

C: Two line serial communications standard using one clock and one data

I

line.

LO: Local oscillator.

PWM: Pulse width modulation.

4/00021-2/FEA 209 544/11.C 5 (68)

Page 6

PF768, Standard Electrical Repairs

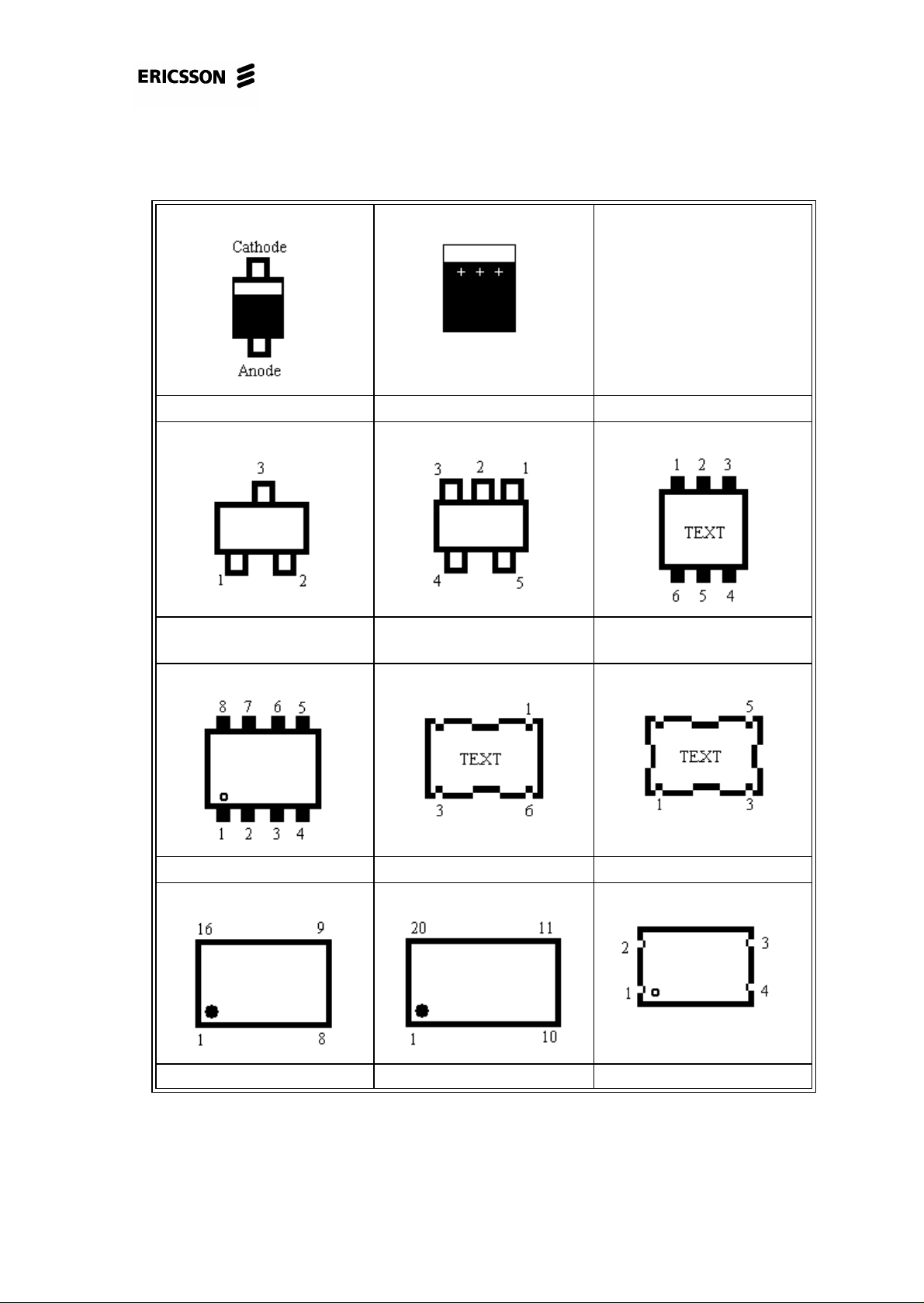

1.3 Pin placements

Single diode (PIN diode). Electrolytic capacitor.

Double diode or single trans-

stor.

Eight pin circuit. Tx VCO circuit (G300) LO VCO circuit (G350)

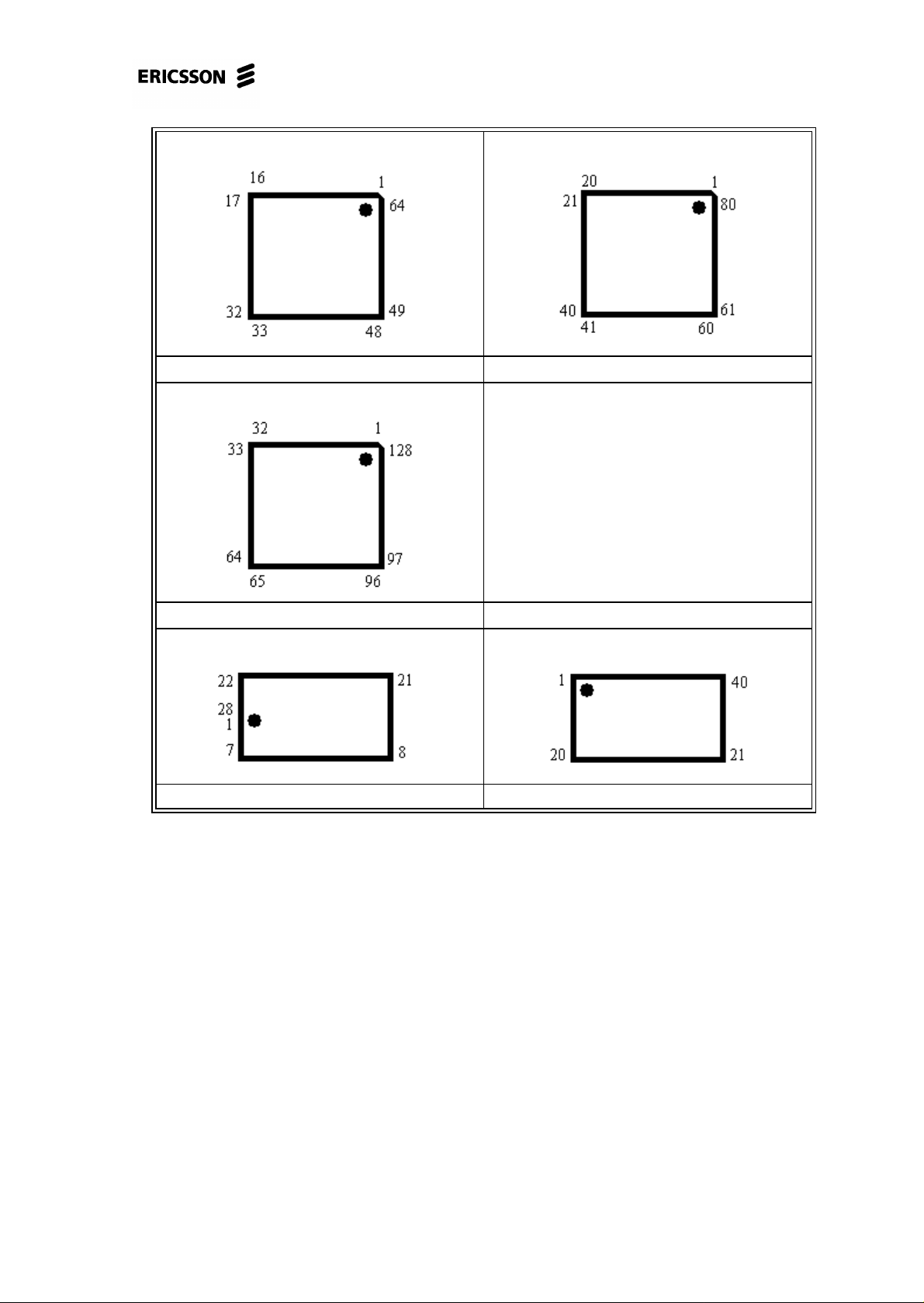

Sixteen pin circuit Twenty pin circuit Crystal

Five pin circuit (usually volt-

age regulator).

Double transistor.

4/00021-2/FEA 209 544/11.C 6 (68)

Page 7

PF768, Standard Electrical Repairs

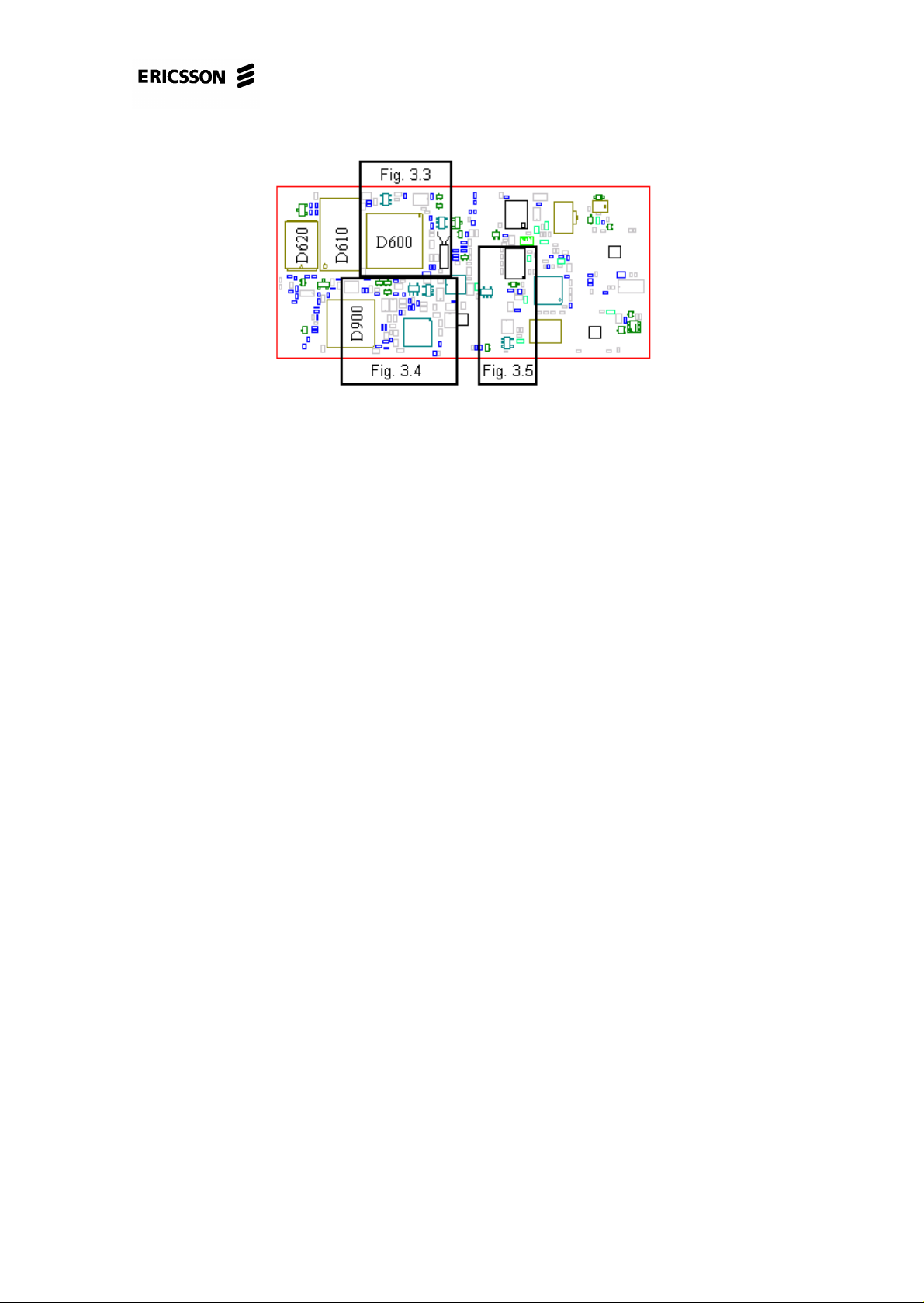

N800 D900

D600

D620 D610

4/00021-2/FEA 209 544/11.C 7 (68)

Page 8

PF768, Standard Electrical Repairs

2 No serv/not able to connect calls.

2.1 Finding out if the fault is Rx- or Tx-related.

Connect the phone (with signalling program) to a GSM test instrument and try to

get serv at –68.5dBm signal strength.

• If the phone doesn’t get serv, proceed to section 2.2.

• If the phone gets serv, proceed to section 2.3.

2.2 The phone doesn’t get serv.

Open the phone and check for liquid damages.

Make sure the back cover is intact and that it’sof the right model since there are two

models available. Fig. 2.1 shows which back cover model to use.

Fig. 2.1

Replace the antenna connector and try again. Note that there are several models of

the antenna connector and it’s important not to mount the wrong model. Fig. 2.2

shows which antenna connector model is to be used.

Fig. 2.2

4/00021-2/FEA 209 544/11.C 8 (68)

Page 9

PF768, Standard Electrical Repairs

• If the phone gets serv, proceed to section 2.3.

• If the phone doesn’t get serv there is probably a LO-part fault or the losses in the

signal path are too great. It’s also possible it could be a feed voltage fault.

If the fault remains, send the phone to the next level.

2.3 Connect a call towards the GSM test instru-

ment at power level 0 and –68.5dBm input

signal strength.

If you’re able to connect a call, proceed to section 2.4.

If you’re not able to connect a call, open the phone and check for liquid damages.

Make sure the back cover is intact and of the correct model since there are 2 models

(fig. 2.1).

Replace the antenna connector (if you haven’t replaced it already) and try again.

Note that there are several different models of the antenna connector too and it’s

important to mount the correct one.

• If you where able to connect a call, proceed to section 2.4.

The fault is probably Tx related or it’s a feed voltage fault if you still aren’t able to

connect calls.

If the fault remains, send the phone to the next level.

2.4 Read the Rx-level value from the instru-

ment while the call still is connected.

If the Rx-level value is at 42 2 steps, make sure the output power is 28-32dBm.

• The phone probably isn’t faulty if that’s correct.

Lower the signal from the instrument to –102.5dBm and make sure the Rx-level

value is 4-12 steps and that the Rx-quality value is 0-2 steps.

Try running the phone through the test again.

• If the phone passes the test but isn’t able to connect a call towards the “real” net,

make sure the phone hasn’t been locked out of the system due to theft. If it

hasn’t, replace D600 (class B, fig. 2.3).

4/00021-2/FEA 209 544/11.C 9 (68)

Page 10

PF768, Standard Electrical Repairs

Fig. 2.3

If the output power is too low or if the Rx-quality value or the RX-level vaule is too

high, send the phone to the next level.

If the Rx-level value is below 39 steps at –68.5dBm input signal strength or below 4

steps at –102.5dBm input signal strength, then the fault is Rx-related.

Open the phone and check for liquid damages.

Make sure the back cover is intact and that it’sof the right model since there are two

models available. Fig. 2.1 shows which back cover model to use.

Replace the antenna connector and try again. Note that there are several models of

the antenna connector and you must mount the correct model. Fig. 2.2 shows which

antenna connector model is to be used.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 10 (68)

Page 11

PF768, Standard Electrical Repairs

3 Doesn’t start.

3.1 Find out if the phone starts by pressing the

On/Off key.

Insert a fully charged battery and press the On/Off key.

• If the phone doesn’t start, proceed to section 3.2.

• If the phone starts, turn off the phone and check the charging function by con-

necting a charger into the system connector.

* If the phone doesn’t start or doesn’t charge, send the phone to the next level.

* If the phone starts (lights the background illumination, asks for SIM or PIN,

seeks net…) and the charging function is ok then there’s probably nothing

wrong with the phone or the fault is intermittent.

Open the phone and make a visual check of the circuit board.

Check for eventual liquid damages at the circuit board and dirt or oxide at the sys-

tem and battery connector pads.

Fig. 3.1 shows typical dirt at the battery connector pads.

Fig. 3.1

Make sure the dome switches isn’t damaged, especially at the On/Off key.

Make sure D600, D610 and D620 are soldered correctly (fig. 3.2).

4/00021-2/FEA 209 544/11.C 11 (68)

Page 12

PF768, Standard Electrical Repairs

Fig. 3.2

Send the phone through the normal flow as soon as you’ve fixed the fault.

3.2 Visual check.

Make an outer visual check:

• Make sure the battery connector is intact and that there aren’t any dirt or oxide at

the connector pins.

• Make sure there’s no dirt or oxide at the battery connector pads.

• Make sure the system connector isn’t damaged or dirty.

Continue at 3.3.

3.3 Current consumption with the On/Off key

pressed.

Insert a dummy battery into the phone.

• If the phone consumes current immediately, proceed to section 3.4.1.

Start the phone by pressing the On/Off key and check the current consumption.

• If the phone doesn’t consume any current when you keep the On/Off key pressed

it most probably is due to faulty dome switches.

Open the phone and remove the dome switches.

Make sure the board isn’t liquid damaged or dirty, especially around the On/Offkey.

Dirt is washed away by using alcohol and a brush.

Mount a new dome switches (note that the board must be dry before mounting the

dome switches).

4/00021-2/FEA 209 544/11.C 12 (68)

Page 13

PF768, Standard Electrical Repairs

Give the board power and start it up by pressing the On/Off key (in the fixture or in

the back cover with a dummy battery inserted, mount system connector to make the

board lie steady in the back cover).

* If the phone still doesn’t consume any current when the On/Off key is

pressed, proceed to section 3.4.2.

• If the phone consumes more than 200mA, remove the display and try again.

* If the consumption decreased it was the display that was faulty.

* If the consumption still is high, proceed to section 3.4.3.

• If the phone consumes 1-200mA, starts (asks for SIM, seeks net…) and runs as

long as you keep the On/Off key pressed but dies when you release the key, proceed to section 3.4.4.

• If the phone doesn’t start, try to program it in the flash programmer.

* If the phone doesn’t start in the flash programmer, proceed to section 3.4.5.

* If you can program the phone but it doesn’t start afterwards or if the phone

is troublesome in the flash programmer, proceed to section 3.4.6

* If the phone starts once it’s programmed in the flash programmer it proba-

bly isn’t a faulty phone. To eliminate intermittent faults, check the board for

liquid damages and check if the D600, D610 and D620 (fig. 3.2) chips are

correctly soldered.

3.4 Measuring a powered board.

3.4.1 Consumes power immediately when battery is

inserted.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t liquid damaged, dirty or

oxidised.

Remove the dome switches. Clean the keypads using alcohol and a brush.

Put the board in the fixture without starting it up.

Measure the VDIG, VANA, VDSP, VRAD, VVCO and VRPAD feed voltages

(~0V).

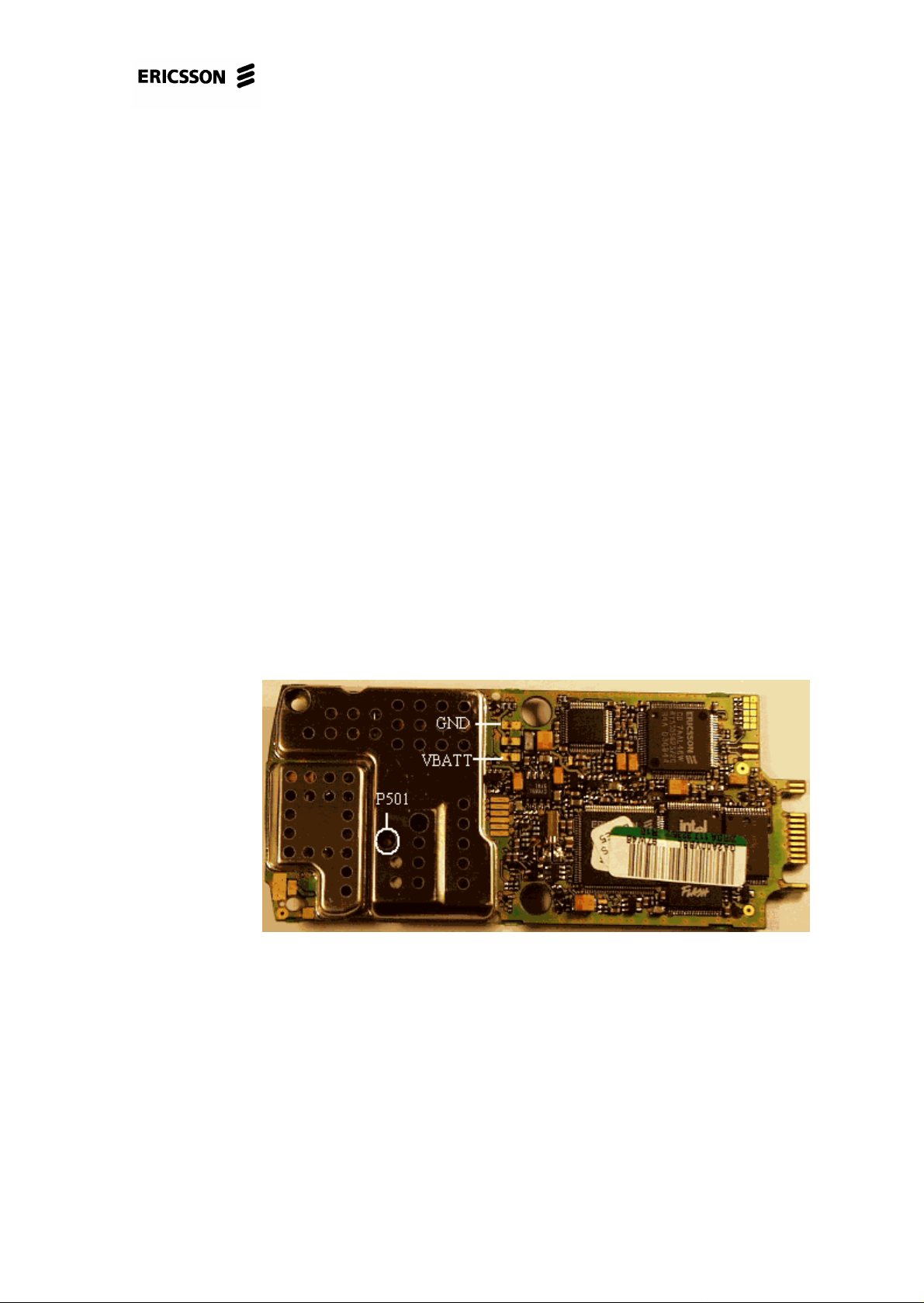

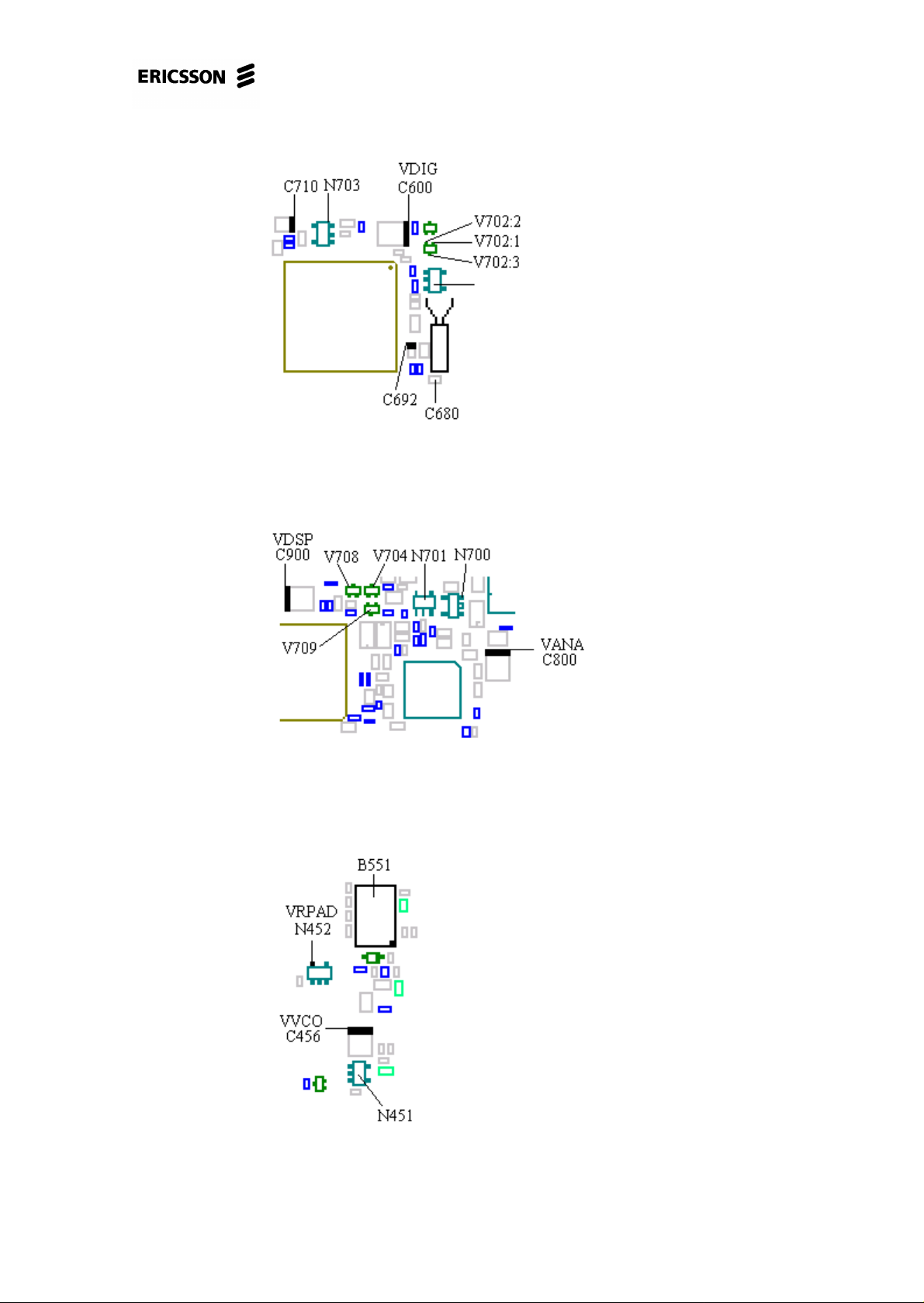

Fig. 3.1 shows the measuring point for VRAD (P501) and fig. 3.3 show the measuring point for VDIG.

4/00021-2/FEA 209 544/11.C 13 (68)

Page 14

PF768, Standard Electrical Repairs

Fig. 3.3

Fig. 3.4 shows the measuring point for VANA and VDSP.

Fig. 3.4

Fig. 3.5 shows the measuring point for VRPAD and VVCO.

Fig. 3.5

4/00021-2/FEA 209 544/11.C 14 (68)

Page 15

PF768, Standard Electrical Repairs

Since the measuring point for VVCO is under the big radio shielding (E202) you

have to measure the voltage carefully through one of the holes with a thin and preferably isolated probe as in fig. 3.6.

Fig. 3.6

• If there is voltage at any of the voltages but not all, replace the corresponding

regulator (VDIG – N702, VANA – N700, VDSP – N701, VRAD – N453, VVCO

– N451, VRPAD – N452, all of them class A). Note that the N453 and N451

regulators are under the radio shieldings and can therefore not be replaced

at this level.

• If there is voltage at all of the regulators, measure REGON at V702 pins 2 and 3

(fig. 3.3, ~0V).

* The REGON signal probably comes from one of the regulators or from

V704, V708 or V709 (fig. 3.4) if there’s no voltage at V702 pins 2 and 3.

Replace a component at a time and check after every component replaced.

* If there’s voltage at both pin 2 and pin 3 or V702 there’s probably a short

circuit at the pads for the On/Off key. It’s almost always crumbs from the

dome switches that causes this short circuit. Wash it away using alcohol and a

brush.

If the fault remains, send the phone to the next level.

3.4.2 Consumes no current when On/Off key is being

pressed.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t dirty, liquid damaged or

oxidised.

Give the board power and start it up by pressing the On/Off key (in the fixture or in

the back cover with a dummy battery inserted, mount system connector to make the

board lie steady in the back cover).

Check the current consumption.

4/00021-2/FEA 209 544/11.C 15 (68)

Page 16

PF768, Standard Electrical Repairs

• If the phone still doesn’t consume any current, measure the resistances from the

unmarked side of the “No” keypad (fig. 3.7) to pin 2 of V702 (~0 ohms, fig. 3.3)

and from pin 3 of V702 to pin 3 if N702 (~0 ohms, fig. 3.3).

Fig. 3.7

* If one or both of the resistances are too high there’s a foil damage and the

phone is to be discarded.

* If the resistances are correct, replace V702 (class A).

If the fault remains, send the phone to the next level.

3.4.3 Consumes more than 200mA.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t dirty, liquid damaged or

oxidised.

Place the board in the fixture. Keep it running by keeping DCIO high.

Check the VDIG, VANA and VDSP voltages (~3.2V, fig. 3.3 and 3.4).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG>500 ohms, VANA>25 kohms, VDSP>25kohms).

* If the resistance is correct, replace the corresponding regulator (VDIG –

N702, VANA – N700, VDSP – N701, all of class A).

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If any of the voltages are too high, replace the corresponding regulator.

Check the VRAD (fig. 3.1, P501 measuring point), VVCO (fig. 3.5) and VRPAD

(fig. 3.5) voltages (all of them ~3.8V).

Note that P501 is a calibration point. It is VRAD you measure but after 2 resistors.

The calibration point has the right voltage as long as the transmitter isn’t activated.

4/00021-2/FEA 209 544/11.C 16 (68)

Page 17

PF768, Standard Electrical Repairs

Also note that the measuring point for VVCO is under the big radio shielding

(E202) and therefore you have to measure the voltage carefully through one of the

holes with a thin and preferably isolated probe as in fig. 3.6.

• If the VRAD or VVCO voltage is incorrect, send the phone to the next level.

• If the VRPAD voltage is too low, measure the resistance from it to ground (>25

kohms).

* If the resistance is correct, replace N452 (class A)..

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If the VRPAD voltage is too high, replace N452.

Measure the resistance from VBATT to ground (>200 kohms, fig. 3.1).

• If the resistance is too low there’s a short circuit in one of the circuits fed by

VBATT. Send the phone to the next level.

If the fault remains, send the phone to the next level.

3.4.4 The phone runs as long as the On/Off key is

pressed.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t dirty, liquid damaged or

oxidised.

Place the board in the fixture. Keep the board running by keeping the On/Off key

pressed.

Measure the voltage at C692 (~3.1V, fig. 3.3).

• If there is voltage, make sure pin 119 of D600 is correctly soldered.

* If the soldering is correct, replace D600 (class B, fig. 3.2).

• If there is no voltage at C692, measure the resistance of C692 (class A, >200

kohms).

* If the resistance is too low, replace C692 and check the voltage again.

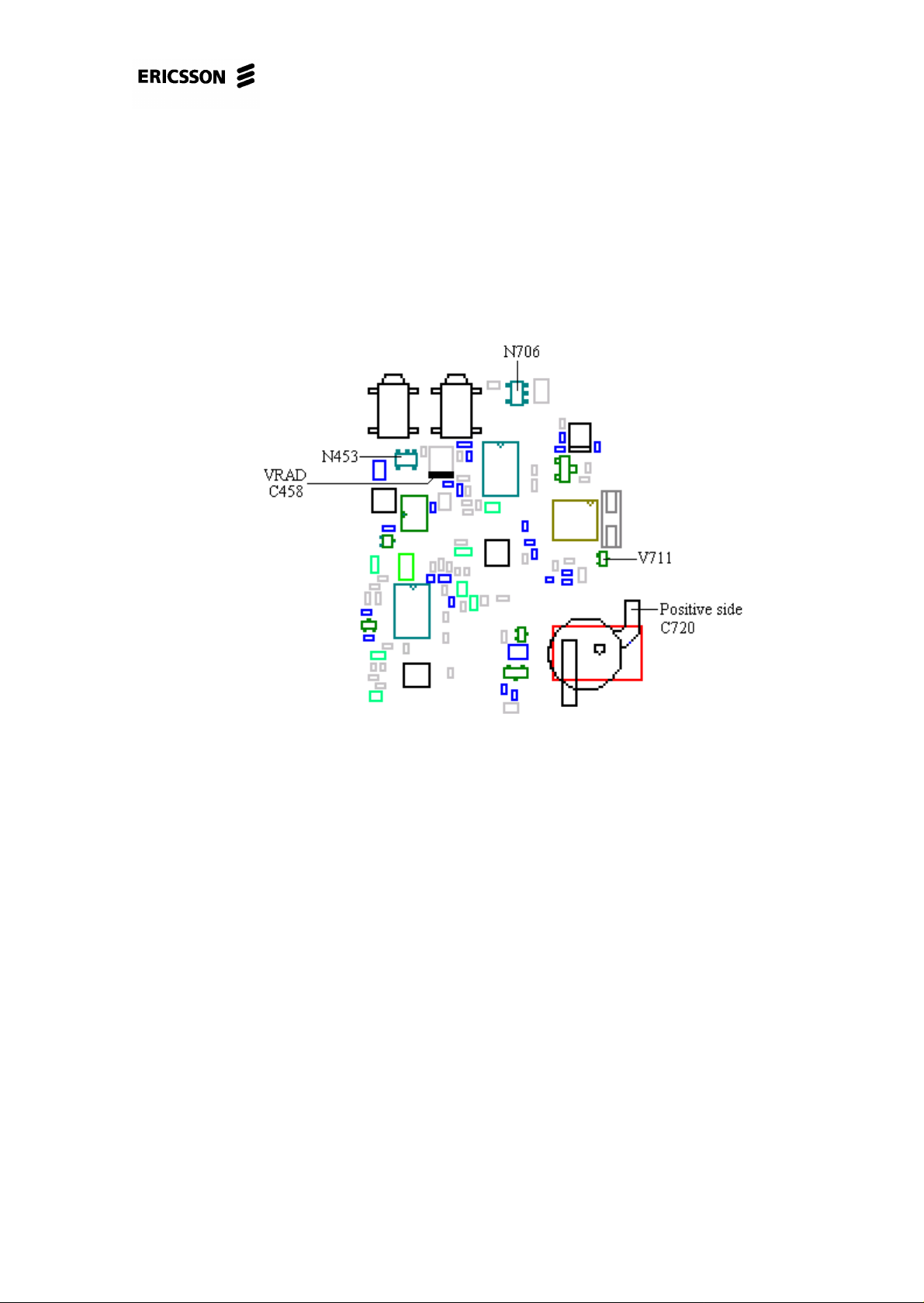

* If the resistance is correct, check the voltages at N706 (fig. 3.8). VBATT at

pin 2, ground at pin 1 and the output voltage (~3.5V) at pin 3.

* If VBATT or ground is missing there’s a foil damage and the phone is to

be discarded.

* If VBATT and ground are correct but not the output voltage, replace

N706.

4/00021-2/FEA 209 544/11.C 17 (68)

Page 18

PF768, Standard Electrical Repairs

* If all the voltages are correct, measure the VRTC voltage between the

positive side of C720 (class A, ~3.1V, fig. 3.8) and ground.

* If there’s no VRTC voltage, replace V711 (class A, fig. 3.8).

* If there’s VRTC voltage, measure the resistance from the positive

side of C720 (fig. 3.8) to the marked side of C692 (fig. 3.3, ~0 ohms).

* If the resistance is too high there’s a foil damage and the phone is

to be discarded.

Fig. 3.8

If the fault remains, send the phone to the next level.

3.4.5 Doesn’t start in the flash programmer.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t dirty, liquid damaged or

oxidised.

Place the board in the fixture. Keep the board running by keeping DCIO high.

Check the VANA and VDIG voltages (~3.2V, fig. 3.4 and 3.3).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG>500 ohms, VANA>25 kohms).

* If the resistance is correct, replace the corresponding regulator(VDIG –

N702, VANA – N700, both of class A).

4/00021-2/FEA 209 544/11.C 18 (68)

Page 19

PF768, Standard Electrical Repairs

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If any of the voltages are too high, replace the corresponding regulator.

Check the power reset voltage at C710 (fig. 3.3, >3V).

• If it’s too low, replace C710 (class A) and measure again.

* If that doesn’t help, replace N703 (class A, fig. 3.3).

Check the VRAD (fig. 3.1, P501 measuring point), VVCO (fig. 3.5) and VRPAD

(fig. 3.5) voltages (all of them ~3.8V).

Note that P501 is a calibration point. It is VRAD you measure but after 2 resistors.

The calibration point has the right voltage as long as the transmitter isn’t activated.

Also note that the measuring point for VVCO is under the big radio shielding

(E202) and therefore you have to measure the voltage carefully through one of the

holes with a thin and preferably isolated probe as in fig. 3.6.

• If the VRAD or the VVCO voltage is incorrect, send the phone to the next level.

• If the VRPAD voltage is too low, measure the resistance from it to ground (>25

kohms).

* If the resistance is correct, replace N452 (class A).

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If the VRPAD voltage is too high, replace N452.

• If all the feed voltages are correct, check the amplitude of the clock frequency at

C680 (class A, >0.6V t-t, fig. 3.3). To check the amplitude you can use an oscilloscope, spectrum analyser, frequency counter, diode probe or similar. The D900

circuit usually gets warm when the system clock frequency is missing.

* If the amplitude is too low, send the phone to the next level.

Make sure there aren’t any faulty solderings at D600, D610 or D620 (fig. 3.2).

• If they look ok, replace D610 (class A). Do not replace any component if you

haven’t established the fact that the amplitude at C680 is correct.

* If that doesn’t help, replace D600 (class B) first and then D620 (class A) if

that doesn’t help. Try programming the phone in the flash programmer after

every circuit replaced.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 19 (68)

Page 20

PF768, Standard Electrical Repairs

3.4.6 Able to program the phone but it doesn’t start

afterwards or it is troublesome in the flash programmer.

Open the phone and check for liquid damages.

Make sure the battery and system connector pads aren’t dirty, liquid damaged or

oxidised.

Place the board in the fixture. Keep the board running by keeping DCIO high.

Check the VANA and VDIG voltages (~3.2V, fig. 3.4 and 3.3).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG>500 ohms, VANA>25 kohms).

* If the resistance is correct, replace the corresponding regulator (VDIG –

N702, VANA – N700, both of class A).

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If any of the voltages are too high, replace the corresponding regulator.

Check the VRAD (fig. 3.1, P501 measuring point), VVCO (fig. 3.5) and VRPAD

(fig. 3.5) voltages (all of them ~3.8V).

Note that P501 is a calibration point. It is VRAD you measure but after 2 resistors.

The calibration point has the right voltage as long as the transmitter isn’t activated.

Also note that the measuring point for VVCO is under the big radio shielding

(E202) and therefore you have to measure the voltage carefully through one of the

holes with a thin and preferably isolated probe as in fig. 3.6.

• If the VRAD or the VVCO voltage is incorrect, send the phone to the next level.

• If the VRPAD voltage is too low, measure the resistance from it to ground (>25

kohms).

* If the resistance is correct, replace N452 (class A).

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• f the VRPAD voltage is too high, replace N452.

Make sure there aren’t any faulty solderings at D600, D610 or D620 (fig. 3.2).

• If they look ok, replace D610 (class A).

* If that doesn’t help, replace D600 (class B) first and then D620 (class A) if

that doesn’t help. Try programming the phone in the flash programmer after

every circuit replaced.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 20 (68)

Page 21

4 Audio.

PF768, Standard Electrical Repairs

4.1 Type of fault.

Make a call from the phone that is to be tested (later called the phone) to a phone

that is working correctly (later called the reference phone).

Check the function of the microphone and the earphone.

Connect a handsfree unit to the system connector of the phone.

Check the function of the phone’s external connections by listening to the external

speaker/earphone when talking in the reference phone and by listening to the earphone of the reference phone when talking in the external mic of the phone.

• If there is low or no sound in the earphone of the phone, proceed to section 4.2.

• If both the earphone and the handsfree speaker don’t work, send the phone to the

next level.

• If the sensitivity of the microphone is low (low or no sound in the reference

phone), proceed to section 4.3.

• If both the microphone in the phone and the microphone of the handsfree don’t

work, send the phone to the next level.

• If both the microphone and the earphone don’t work, proceed to section 4.4.

• If the microphone, the earphone and the handsfree don’t work, send the phone to

the next level.

• If the microphone of the handsfree doesn’t work, proceed to section 4.5.

• If the speaker of the handsfree doesn’t work, proceed to section 4.6.

• If both the microphone and the speaker of the handsfree don’t work, proceed to

section 4.7.

• If the phone sounds strange (the sound is distorted, scrambled, full of static or

“chopped”), proceed to section 4.8.

4.2 Earphone out of order.

Open the phone and check for liquid damages.

Most of the earphone faults are mechanical. Therefore you should start with replac-

ing the front (with the earphone) to one you know works and try again.

• If the fault remains, make sure the earphone connector (X810, fig. 4.1) isn’t

faulty or incorrectly soldered.

4/00021-2/FEA 209 544/11.C 21 (68)

Page 22

PF768, Standard Electrical Repairs

Fig. 4.1

Check the solderings of N800 (fig. 4.3).

Fig. 4.2

Fig. 4.3

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 22 (68)

Page 23

PF768, Standard Electrical Repairs

4.3 Microphone out of order.

Open the phone and check for liquid damages.

Wash the system and microphone connector pads if needed.

Make sure the sound channel gasket is properly mounted and free from dust.

Replace the system connector and microphone with a pair you know work. Test the

phone again.

• If the fault remains, measure the resistance of C850 and C851 (both >100

kohms, class A, fig. 4.3). Measure the resistance of R816 (~470 ohms, fig. 4.4,

class A), R817 and R819 (~1 kohms, class A, fig. 4.3). Check the solderings of

N800 (fig. 4.3).

Fig. 4.4

If the fault remains, send the phone to the next level.

4.4 Both the earphone and the microphone of

the phone out of order.

Open the phone and check for liquid damages.

Make especially sure there’s no dirt or oxide between the components below the

dome switches (fig. 4.5) and at the system connector pads.

Fig. 4.5

4/00021-2/FEA 209 544/11.C 23 (68)

Page 24

PF768, Standard Electrical Repairs

Wash the circuit board if needed using alcohol and a brush.

Assemble the phone and test it as in 4.1.

If the fault remains, open the phone. Give the board power and start it up by pressing the On/Off key without the system cable connected.

Measure the VDSP (~3.2V, fig. 4.3) feed voltage.

• If the VDSP voltage is too low, replace N701 (class A, fig. 4.3).

• If the VDSP voltage still is too low after replacing the N701 circuit there is prob-

ably a short circuit in one of the components fed by the VDSP voltage regulator.

If that’s the case, send the phone to the next level.

Measure the voltage at both sides of R601 and at D600 pin 70 (~5V, fig. 4.3 and 4.2,

you follow the PHFI signal).

Measure the voltage at both sides of R605 and at D600 pin 67 (~5V, fig. 4.5 and 4.2,

you follow the EXTAUDI signal).

• If the voltage at only one side of R601 or R605 is too low, replace the corre-

sponding resistor (fig. 4.3 and 4.5, both of class A).

• If the voltage is too low at both sides of R601 or R605, check the VSIMPAD

voltage at marked sides of R635 and R636 (~5V, fig. 4.4 and 4.5).

* If there’s no voltage there, check the resistance from the marked side of

R635 or R636 to N705 pin 3 (~0 ohms, fig. 4.5/4.4, 4.2).

* If the resistance is too high there’s a foil damage and the phone is to be

discarded.

* If the resistance is correct, proceed to section 6.3.

* If the VSIMPAD voltage is correct, measure the resistances of R635 and

R636 (~22 kohms, fig. 4.4 or 4.5).

* If any of the resistances are incorrect, replace the corresponding resistor.

Measure the resistance from X602 pad 5 to ground (>100 kohms, fig. 4.6). Make

sure there’s no dirt or oxide between the components below the dome switches (the

components in fig. 4.5).

4/00021-2/FEA 209 544/11.C 24 (68)

Page 25

PF768, Standard Electrical Repairs

Fig. 4.6

• If the resistance is too low, wash carefully and measure again.

* If the resistance still is too low,remove R601 (class A, fig. 4.3) and measure

again.

* If the resistance increased, replace D600 (class B, fig. 4.2).

* If the resistance didn’t increase when removing the R601 resistor or if it

didn’t help to replace D600, send the phone to the next level.

Measure the resistance from X602 pad 3 to ground (>100 kohms). Make sure there’s

no dirt or oxide between the components at the marked area (fig. 4.8).

• If the resistance is too low, wash carefully and measure again.

* If the resistance still is too low,remove R605 (class A, fig. 4.5) and measure

again.

* If the resistance increased, replace D600 (class B, fig. 4.2).

* If the resistance didn’t increase or if it didn’t help to replace D600, send

the phone to the next level.

If all of the above measured resistances are correct but anyone of the voltages at

R601 or R605 are too low anyway, it usually is because of a short circuit caused by

dirt between the components in fig. 4.5.

If the voltages at R601 and R605 are correct, connect a handsfree to the system connector.

Measure the voltage at both sides of R601 (~0V, fig. 4.3) and at D600 pin 70 (~0V,

fig. 4.2).

• If the voltage isn’t correct, check the soldering at D600 pin 70 (fig. 4.2).

* If the soldering is correct, measure the resistance of R601 (~1 kohms, class

A).

4/00021-2/FEA 209 544/11.C 25 (68)

Page 26

PF768, Standard Electrical Repairs

* If the resistance is correct, replace D600 (class B).

• If the voltage is correct, check the solderings of N800 and D600 (fig. 4.3 and

4.2).

If the fault remains, send the phone to the next level.

4.5 Handsfree microphone out of order.

The fault occurs when there’s an interrupt in the audiopath between the handsfree

microphone (connected through the system connector) and the N800. The audio

path is shown in fig. 4.7.

Fig. 4.7

Open the phone and check for liquid damages, especially around the system connector pads (X602) 1, 2 and 4 (fig. 4.6).

Measure the resistance of C850 and C851 (both >100 kohms, fig. 4.3, class A).

Make sure all the components in fig. 4.7 (R830, R825, R802, R805, C835, C810

and C812) are mounted on the circuit board (fig. 4.3).

Check the solderings of N800 (fig. 4.3).

Give the board power and start it up by pressing the On/Off key without the system

cable connected.

Measure the voltage at the marked side of R825 (~3.1V, fig. 4.3).

• If there isn’t any voltage or if it is incorrect, check the VANA voltage at the

marked side of R830 (fig. 4.4).

* If the VANA voltage is incorrect, proceed to chapter 3 (“Doesn´t start”fault).

* If VANA is correct, check the resistances of R830 (~470 ohms), R825 (3.3

kohms) and C835 (>1 kohms, all of class A and in fig. 4.3).

4/00021-2/FEA 209 544/11.C 26 (68)

Page 27

PF768, Standard Electrical Repairs

• If there’s correct voltage at R825, check the resistance of C810 (>10 kohms),

C812 (>100 kohms), R802 (~3.9 kohms) and R805 (~15 kohms, all of class A

and in fig. 4.3).

If the fault remains, send the phone to the next level.

4.6 Handsfree speaker out of order.

The fault occurs when there’s an interrupt in the audio path from the N800 to the

handsfree speaker (connected through the system connector). The audio path is

shown in fig. 4.8.

Fig. 4.8

Open the phone and check for liquid damages, especially around the system connector pads (X602, fig. 4.6) 1, 2 and 4.

Measure the resistance of C850 and C851 (both >100 kohms, both of class A and in

fig. 4.3).

Make sure all the components in fig. 4.8 (R803, R804 and C813) are mounted at the

circuit board (fig. 4.4).

Check the solderings of N800 (fig. 4.3).

Measure the resistances of R803 (~100 ohms), R804 (~100 kohms) and C813 (>100

kohms, all of class A and in fig. 4.4).

Measure the resistance from the marked side of R803 to pad 1 of X602 (~0 ohms,

fig. 4.4 and 4.6).

• If the resistance is too high there’s a foil damage and the phone is to be dis-

carded.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 27 (68)

Page 28

PF768, Standard Electrical Repairs

4.7 Both the microphone and the speaker of

the handsfree out of order.

Open the phone and check for liquid damages, especially at the components in fig.

4.5.

Wash the above mentioned components using alcohol and a brush.

Measure the resistance from X602 pad 3 to the unmarked side of R635 (~0 ohms,

fig. 4.6 and 4.5).

Measure the resistance from X602 pad 2 to the unmarked side of R636 (~0 ohms,

fig. 4.6 and 4.4).

• If any of the resistances are incorrect there’s a foil damage and the phone is to be

discarded.

Measure the resistances of R601 and R605 (~1 kohms, class A, fig. 4.3 and 4.5).

If all the resistances are correct, check the solderings of N800 and D600 (fig. 4.3

and 4.2).

If the fault remains, send the phone to the next level.

4.8 The phone sounds strange (the sound is

distorted, scrambled, full of static or

“chopped”).

Open the phone and check for liquid damages.

Give the board power and start it up by pressing the On/Off key.

Measure the VDSP feed voltage (~3.2V, fig. 4.3).

• If the VDSP voltage is too low, replace N701 (class A, fig. 4.3).

* If the VDSP voltage still is too low after replacing the N701 circuit there is

probably a short circuit in one of the components fed by the VDSP voltage

regulator. If that’s the case, send the phone to the next level.

• If the voltage is correct, check the solderings of N800 and D600 (fig. 4.3 and

4.2).

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 28 (68)

Page 29

PF768, Standard Electrical Repairs

5 Display.

5.1 Kind of fault.

Insert a charged battery into the phone and start it up by pressing the On/Off key.

• If it doesn’t start, proceed to chapter 3 (“Doesn´t start”-fault).

• If the display is missing one or more segments, proceed to section 5.2.

• If there’s nothing being displayed in the display or if the contrast is low, proceed

• If the display is black (all the segments are “lit” and you can sometimes make

5.2 Segments are missing.

Open the phone and check for liquid damages. Replace the display.

to section 5.3

out what it’s displaying), proceed to section 5.4.

5.3 There’s nothing showing in the display or

the contrast is low.

Insert a dummy battery into the phone, start it up and check the current consumption. You could also disassemble the phone, place the board in the fixture, give the

board power, start it up by pressing the On/Off key or by pulling DCIO high and

check the current consumption.

• If the phone consumes more than 200mA, make sure the display isn’t mechani-

cally damaged.

* If the display is ok, replace the elastomer and try again.

* If that doesn’t help, replace the display and try again.

* If the current consumption still is too high, proceed to chapter 3

(“Doesn´t start”-fault).

• If the phone consumes less than 200mA, open the phone and check for liquid

damages.

Give the board power and start it up without the display mounted.

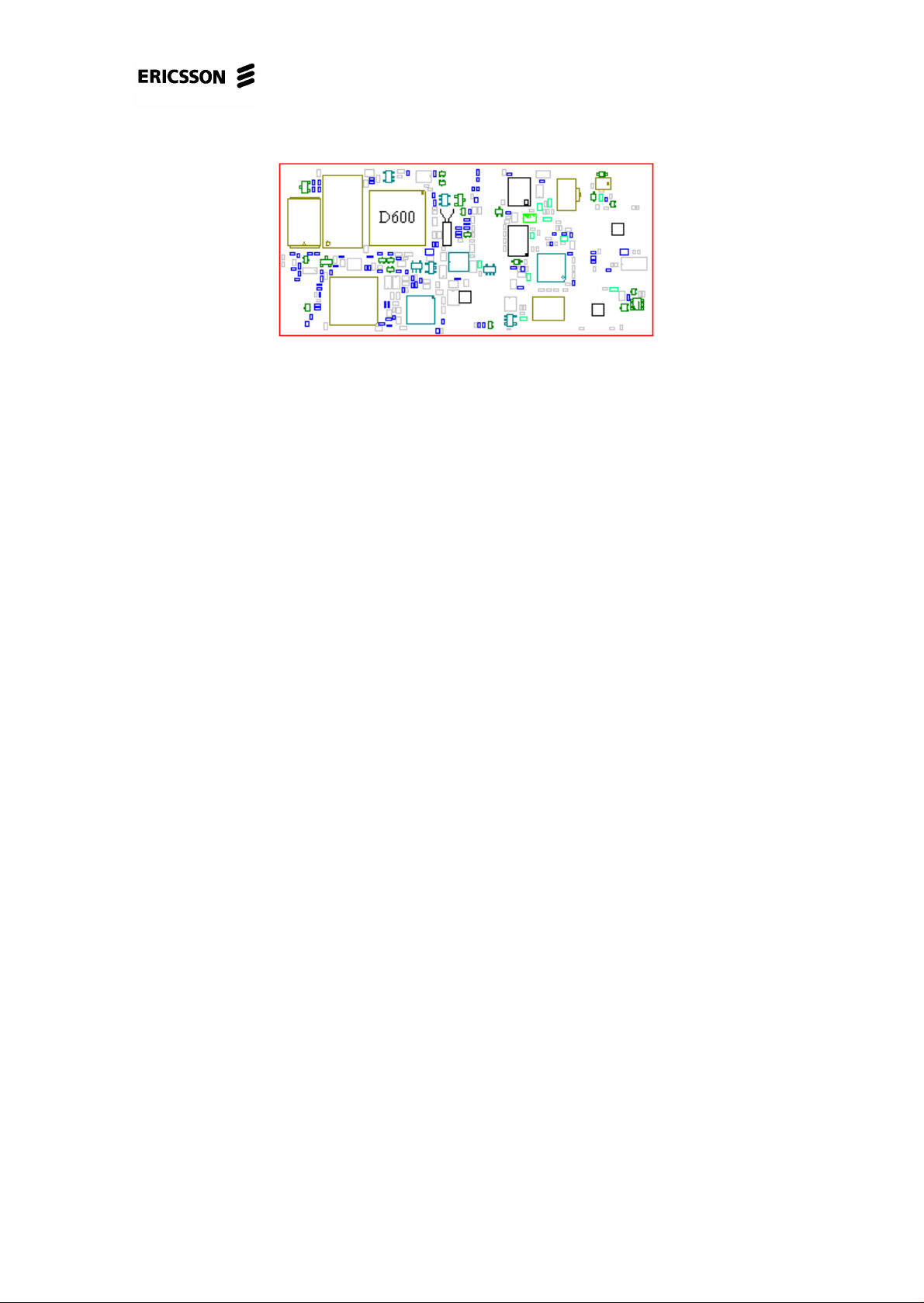

The component side of the circuit board is shown in fig. 5.1.

4/00021-2/FEA 209 544/11.C 29 (68)

Page 30

PF768, Standard Electrical Repairs

Fig. 5.1

Measure the voltages at the V608 diode (class A). Compare the results to the values

at fig. 5.2.

Fig. 5.2

All values are approximately 0.2V.

• If any of the voltages differ from the ones in fig. 5.2, measure the resistances of

C633 (class A, >100 kohms, fig. 5.2) and C824 (class A, >25 kohms, fig. 5.2).

* If any of the resistances are too low, replace the corresponding capacitor.

4/00021-2/FEA 209 544/11.C 30 (68)

Page 31

PF768, Standard Electrical Repairs

* If the resistances and the VRPAD voltage are correct, replace the V608

diode.

* If the voltages at the diode (except VRPAD) still are incorrect after

replacing it, make sure pin 96 of D600 is correctly soldered.

* If the soldering is correct, replace C632 (class A, fig. 5.2) and meas-

ure the voltages again.

* If that doesn’t help, replace D600 (class B).

• If the VRPAD voltage is incorrect, proceed to chapter 3 (“Doesn´t start”-fault).

Fig. 5.3

Fig. 5.4

• If the voltages at V608 are correct but there still isn’t anything showing in the

display, measure the voltages at the display pads (H622, fig. 5.4).

Pad 1 – (I

Pad 2 – (I

2

C-CLOCK): ~3.2V

2

C-DATA): ~3.2V

Pad 3 – (VDIG): ~3.2V

Pad 4 – (VDIG): ~3.2V

Pad 5 – (GND)

Pad 6 – (VLCD): ~4.6V

Make sure there’s VLCD voltage (~4.6V) at pad 5.

4/00021-2/FEA 209 544/11.C 31 (68)

Page 32

PF768, Standard Electrical Repairs

• If there isn’t, check the resistances from H622 pad 6 to V608 (the VLCD marked

pin in fig. 5.2, ~0 ohms) and from pad 5 of H622 to ground (~0 ohms).

* If any of the resistances are too high there’s a foil damage and the phone is

to be discarded.

2

• If the I

at C600 (~3.2V, fig. 5.2)

C-DATA or the I2C-CLOCK voltage is missing, check the VDIG voltage

* If the VDIG voltage is incorrect, proceed to chapter 3 (“Doesn´tstart”fault).

* If the VDIG voltage is correct, measure the resistances of R619 (~2.2

kohms, fig. 5.2), R620 (~2.2 kohms, fig. 5.2), R615 (~10 kohms, fig. 5.5) and

R616 (~10 kohms, fig. 5.5, all of class A). Check the solderings of D600 pins

3 and 4 (fig. 5.1).

* If all the resistances and the solderings are correct, replace D600 (class

B).

5.4 The display is black (all the segments are

“lit” and you can sometimes make out

what it’s displaying).

Open the phone and check for liquid damages.

Give the board power and start it up by pressing the On/Off key. If the phone shuts

itself down after a few minutes, keep it running by keeping DCIO high.

Check the VDIG and VANA voltages (~3.2V, fig. 5.2).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG>500 ohms, VANA>25 kohms).

* If the resistance is correct, replace the corresponding circuit (VDIG – N702,

VANA – N700, both of class A).

* If the resistance is too low there’sa short circuit in one of the circuits fed by

the regulator. Send the phone to the next level.

• If any of the voltages are too high, replace the corresponding regulator.

If the fault remains, proceed to section 5.3 (nothing shows in the display or the display has low contrast).

4/00021-2/FEA 209 544/11.C 32 (68)

Page 33

PF768, Standard Electrical Repairs

6 SIM (“Insert card”).

6.1 What is SIM fault?

Insert a charged battery and a functional SIM card into the phone. Start it up by

pressing the On/Off key.

• If the phone displays “Wrong card” or “Insert correct card” in the display it

means that the phone is SIM-locked and it can’t be repaired at this level.

• If the phone displays “Phone lock” it means that the customer has locked the

phone with a personal code. The phone is unlocked in the reset part of the test

flow.

• If the phone displays “PIN:” or “Enter PIN” it means that the SIM card is

locked with a personal code.

• Only if the phone displays “Insert card” there’s a SIM fault.

6.2 Measuring VSIMPAD.

Measure the voltage between pin 8 and 10 of the system connector (~4.9V, fig. 6.1).

• If the voltage is too low or missing, proceed to section 6.3.

• If the voltage is correct, proceed to section 6.4.

Fig. 6.1

6.3 VSIMPAD voltage too low or missing.

Open the phone and check for liquid damages, especially around the system connector pads.

Measure the resistance of R724 (class A, ~47 ohms, fig. 6.2).

4/00021-2/FEA 209 544/11.C 33 (68)

Page 34

PF768, Standard Electrical Repairs

Fig. 6.2

Give the board power and start it up. Measure the input voltage at N705 pin 2

(~3.1V, fig. 6.4).

Fig. 6.3 shows the component side of the board.

Fig. 6.3

4/00021-2/FEA 209 544/11.C 34 (68)

Page 35

PF768, Standard Electrical Repairs

Fig. 6.4

• If the input voltage is too low or missing, check the VDIG (~3.2V) feed voltage

at C600 (fig. 6.4).

* If the VDIG voltage is too low, measure the resistance from it to ground.

* If the resistance is more than 500 ohms, replace N702 (class A, fig. 6.4).

* If it’s less, send the phone to the next level.

* If the VDIG voltage is correct, measure the resistance of R706 (class A,

~4.7 ohms, fig. 6.4).

* If the resistance is correct, check the resistance from the marked side of

R706 to the marked side of C600 (~0 ohms) and from the unmarked side

of R706 to pin 2 of N705 (~0 ohms).

* If any of the resistances are too high there’s a foil damage and the

phone is to be discarded.

• If the input voltage is correct, measure the output voltage (VSIMPAD, ~5V) at

N705 pin 3 (class A, fig. 6.4).

* If it’s incorrect, replace N705.

* If the output voltage is correct there can be a foil damage somewhere

between N705 pin 3 and R724 or between N705 pin 3 and V700 pin 2 (fig.

6.2 and 6.4). If there’s a foil damaged the phone is to be discarded.

6.4 VSIMPAD voltage is correct.

Open the phone and check for liquid damages.

Clean the SIM pads using alcohol and a brush.

4/00021-2/FEA 209 544/11.C 35 (68)

Page 36

PF768, Standard Electrical Repairs

Assemble the phone with a new SIM card holder and try again.

If the fault remains, disassemble the phone again.

Measure the resistance of R704 (class A, ~100 kohms, fig. 6.4).

Make sure pins 64 and 72-75 (fig. 6.3) are correctly soldered.

Measure the resistances of R600 (~33 ohms), R627 (~0 ohms) and R628 (~100

ohms, allof class A and in fig. 6.4).

Check the resistances from the marked side of R600 to X600 pad 2, from the

marked side of R627 to X600 pad 3 and from the marked side of R628 to X600 pad

7 (all ~0 ohms and in fig. 6.3/6.4).

• If any of these resistances are too high there’s a foil damage and the phone is to

be discarded.

• If the resistances are correct, replace D600 (class B, fig. 6.3).

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 36 (68)

Page 37

PF768, Standard Electrical Repairs

7 Keyboard

7.1 Kind of keyboard fault.

Insert a SIM card and a fully charged battery into the phone. Start the phone by

pressing the On/Off key.

• If it doesn’t start at all, proceed to chapter 3 (“Doesn´tstart”-fault).

Press all the keys (including the volume keys at the side) and verify which are func-

tional. Verification is most easily done like this:

1. Go to “key sound” in the menu. Choose “click”.

2. Press the 1, 2, 3…*, 0, # keys. A clicking sound should be heard at every key

pressed and the corresponding symbol should appear in the display.

3. Press the “Yes”, “No”, “clr”, “<” and “>” keys. When pressing “Yes” the phone

should attempt to place a call and when pressing “No” it should terminate it. The

“clr” key erases the symbols in the display one by one and the “<” and “>” keys

make you skim through the menu.

4. Press the volume keys on the side of the phone. A clicking sound should be

heard for every press of the keys.

• If only the volume keys aren’t functional, proceed to section 7.2.

• If one or more keys of the keyboard aren’t functional, proceed to section 7.3.

• If one or both of the volume keys and one or more keys of the keyboard aren’t

functional, proceed to section 7.2 and then to section 7.3.

7.2 Volume keys aren’t functional.

Open the phone and check for liquid damages, especially around the S820 and S821

switches (fig. 7.1).

Fig. 7.1

4/00021-2/FEA 209 544/11.C 37 (68)

Page 38

PF768, Standard Electrical Repairs

Make sure the S820 and S821 (both of class A) switches are intact and correctly soldered.

Measure the resistance of the switch that isn’t functional. You measure between pin

1/3 and 2/4 (fig. 7.2). The resistance should be >100 kohms when not pressed and

~0 ohms when pressed.

Fig. 7.2

• If the resistance is high all the time, replace the corresponding switch.

• If the resistance is low all the time, replace the corresponding switch first.

* If that doesn’t help, check the solderings at D600 pins 1, 123, 124 and 128.

* If the solderings are correct, replace D600 (class B, fig. 7.3).

Fig. 7.3

• If the switches work as they should, replace the volume keys and try again.

* If that doesn’t help, check the solderings at D600 pins 1, 123, 124 and 128.

* If the solderings are correct, replace D600 (class B, fig. 7.3).

7.3 One or more keys of the keyboard aren’t

functional.

Open the phone and check for liquid damages.

Remove the dome switches and check for liquid or mechanical damages, especially

around the keys that aren’t functional.

Clean the keypads thoroughly. Mount a new dome switches and make sure the key-

board isn’t damaged. Assemble the phone and check the function of the keys as in

7.1.

4/00021-2/FEA 209 544/11.C 38 (68)

Page 39

PF768, Standard Electrical Repairs

If that doesn’t help, open the phone. Give the board power and start it up (by pressing the On/Off key or setting DCIO high).

Schematic of the keyboard functions is shown in fig. 7.4.

Fig. 7.4

Measure the VDIG voltage (fig. 7.5, ~3.2V).

• If it’s incorrect, proceed to chapter 3 (“Doesn´t start”-fault).

• If the VDIG voltage is correct, check if there’s voltage (~3.2V) at the marked

sides of R630-R634 (fig. 7.5).

Fig. 7.5

* If the voltage is missing at one or more of the resistors, measure the resistance from the marked side of C600 to the marked side of the resistor in question (~0 ohms).

* If the resistance is too high there’s a foil damage and the phone is to be

discarded.

4/00021-2/FEA 209 544/11.C 39 (68)

Page 40

PF768, Standard Electrical Repairs

Measure the voltage at the unmarked side of the R630-R634 resistors (~3.2V).

• If the voltage is too low at one or more of the resistor, measure the resistance of

the corresponding resistor (all are of class A and ~100 kohms).

* If all the resistances are correct, check the solderings at D600 1, 120 and

122-128.

* If the solderings are correct, replace D600 (class B, fig. 7.3).

• If the voltages at both sides of all the resistors are correct, but the keyboard isn’t

functional, check the solderings at D600 pin 1, 120 and 122-128.

* If the solderings are correct, replace D600 (class B, fig. 7.3).

* If it doesn’t help replacing D600 remove the dome switches again.

Check if there’s VDIG (~3.2V) voltage at the marked sides of all the keypads in the row that isn’t functional (fig. 7.6). Note that there’s VBATT

(~4.8V) voltage at the marked side of the “No” keypad.

* If VBATT voltage is missing at the “No” keypad there’s a foil damage and the phone is to be discarded.

Fig. 7.6

* If the VDIG voltage is missing at a part of a row (as described in fig.

7.4) there’s a foil damage and the phone is to be discarded. This can

easily be verified by measuring the resistance from the marked side of

a functional keypad to the marked side of a non-functional keypad (~0

4/00021-2/FEA 209 544/11.C 40 (68)

Page 41

PF768, Standard Electrical Repairs

ohms). The foil damage is most usually caused by liquid damages. If

there, for instance, is voltage at the 4 and 5 keypads but not at the 6 and

“volume up” keypads there’s a foil damage somewhere between keypads 5 and 6 and the phone is to be discarded.

If a column or part of it isn’t functional, check the solderings at D600 pins 1 and

120-128.

• If all the solderings are correct, replace D600 (class B).

4/00021-2/FEA 209 544/11.C 41 (68)

Page 42

PF768, Standard Electrical Repairs

8 Illumination and buzzer.

8.1 Type of fault.

Insert a dummy battery and a SIM card into the phone, press the On/Off key and

wait for the phone to get serv (towards the net or a GSM test instrument).

• If the phone doesn’t beep at start, go to “menu/ring level” and try to increase the

ring level to full (not from full to step since that won’t generate any sound). If the

sound is faint or if you can’t hear it at all, proceed to section 8.2

• If one or more of the LEDs at the display illumination isn’t lit at start, proceed to

section 8.3.

• If one or more of the LEDs at the keyboard illumination isn’t lit at start, proceed

to section 8.3.

• If the top indicator doesn’t blink green when the phone has got serv, proceed to

section 8.4.

• If the top indicator blinks green when the phone has got serv, lower the battery

voltage to 4.2V. The top indicator should then start to blink red, the battery indicator should show an empty battery and the phone should warn with a beep.

* If the battery indicator doesn’t show an empty battery, the top indicator

doesn’t blink red and the phone doesn’t warn with a beep the phone needs a

voltage calibration.

* If the top indicator doesn’t blink red but the other things work, proceed to

section 8.6.

* If both the top indicators colours are faintly glowing and the buzzer sounds

faintly, proceed to section 8.7.

8.2 Buzzer faint or dead.

Open the phone and check for liquid damages.

The front side of the circuit board is shown in fig. 8.1.

Fig. 8.1

4/00021-2/FEA 209 544/11.C 42 (68)

Page 43

PF768, Standard Electrical Repairs

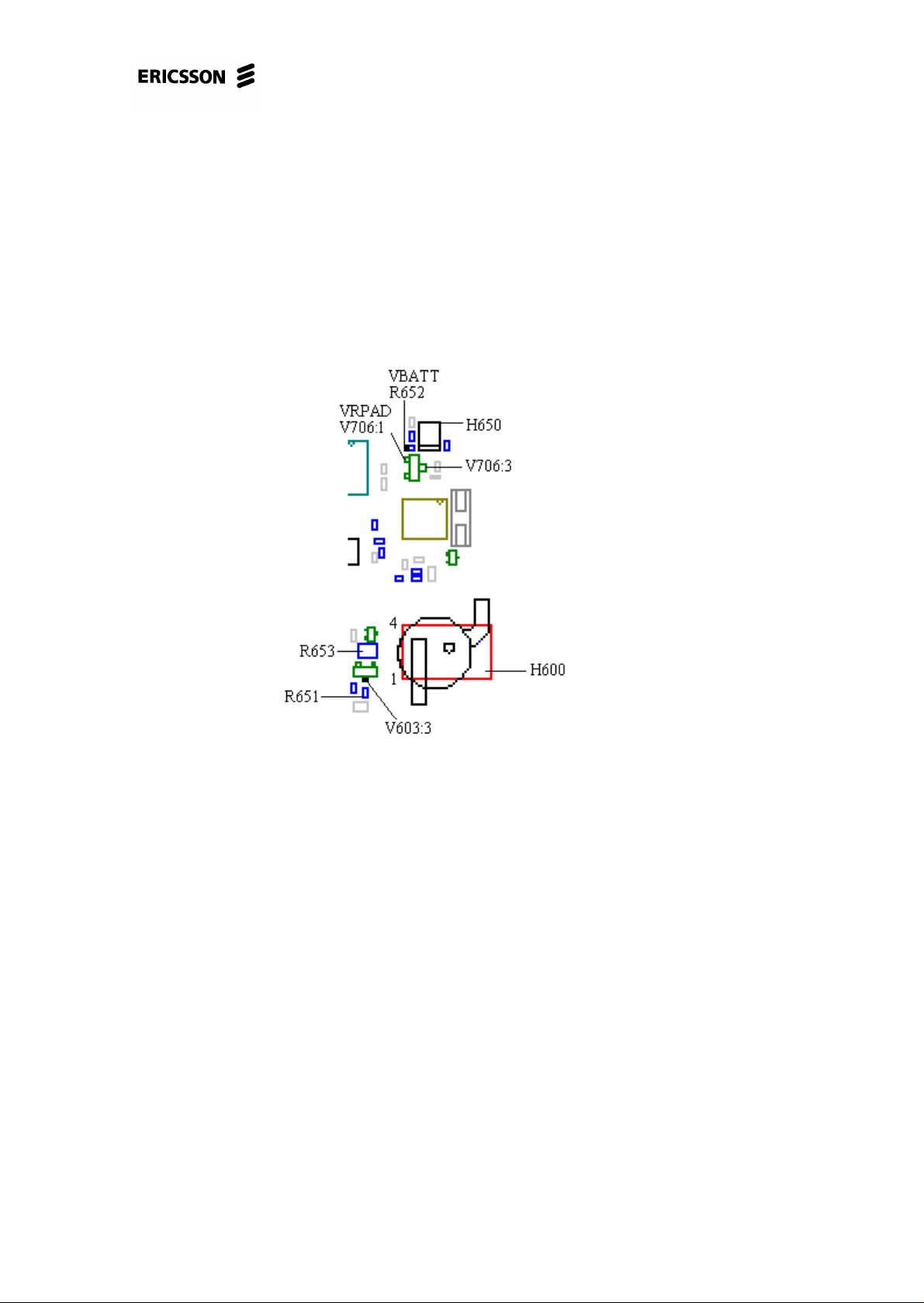

Make sure the buzzer (H600, class A, fig. 8.2) is correctly soldered.

• If the solderings are correct, replace the buzzer.

Assemble the phone and try the buzzer as in 8.1 again.

• If the fault is repaired, send the phone through the normal flow.

• If the fault remains, open the phone. Give the board power and start it up.

Measure the voltage at H600 pad 4 (~3.4V, fig. 8.2).

Fig. 8.2

• If the voltage at H600 pad 4 is missing, measure the VRPAD voltage (~3.8V) at

V706 pin 1 (class A, fig. 8.2).

* If the voltage at V706 pin 1 is missing, check if there’s VRPAD voltage at

N452 pin 5 (fig. 8.3).

4/00021-2/FEA 209 544/11.C 43 (68)

Page 44

PF768, Standard Electrical Repairs

Fig. 8.3

* If the VRPAD voltage is faulty or missing, proceed to chapter 3

(“Doesn´t start”-fault).

* If it’s correct, check the resistance from pin 2 of N452 to pin 1 of V706

(~0 ohms).

* If the resistance is too high it’s probably the L450 (~0 ohms, class A,

fig. 8.3) that’s faulty.

* If L450 isn’t faulty or incorrectly soldered there’s a foil damage

and the phone is to be discarded.

* If the VRPAD voltage at V706 is correct, measure the resistance from

VBATT to V706 pin 3 (~4.7 ohms, fig. 8.3 and 8.2).

* If the resistance is too high it’s probably R652 (~4.7 ohms, class A, fig.

8.2) that’s faulty.

* If the resistor isn’t faulty or incorrectly soldered there’sa foil damage

and the phone is to be discarded.

* If the resistance from VBATT to V706 is correct, replace V706 (class

A).

• If the voltage at pad 4 of H600 is correct, measure the resistance from H600 pad

1 to V606 pin 3 (~0 ohms, fig. 8.2).

* If the resistance is too high it’s probably R653 (~0 ohms, class A, fig. 8.2)

that’s faulty.

* If R653 isn’t faulty or incorrectly soldered there’s a foil damage and the

phone is to be discarded.

* If the resistance is correct, make sure pin 91 of D600 (fig. 8.3) is correctly

soldered.

* If it is correctly soldered, replace R651 (class A, fig. 8.3) and V606

(class A, fig. 8.2).

* If that doesn’t help, replace D600 (class B, fig. 8.3).

4/00021-2/FEA 209 544/11.C 44 (68)

Page 45

PF768, Standard Electrical Repairs

If the fault remains, send the phone to the next level.

8.3 The background illumination for the display

is missing or faintly glowing.

Open the phone and check for liquid damages.

Make sure all the LEDs (H651-H654, all of class A, fig. 8.1) are mounted and cor-

rectly soldered.

Give the board power and start it up by pressing the On/Off key (in the fixture or in

the back cover with a dummy battery inserted, mount system connector to make the

board lie steady in the back cover).

• If a few but not all of the LEDs aren’t lit, replace them.

• If none of the LEDs are lit, measure the resistance of one of them.

* If the resistance is ~0 ohms there’s a short circuit in at least one of the

LEDs. Remove them one at a time and measure the resistance after every

LED removed. When the resistance increases the faulty LED has been

removed.

* If the resistance of the LEDs is high, make sure there’s VBATT voltage at

the marked side of the LEDs (fig. 8.1).

* If VBATT voltage is missing it’s likely due to liquid damage and the

phone is to be discarded.

* If the VBATT voltage is correct, check that R612 (~0 ohms, class A),

R610 (~33 ohms, class A) and R611 (~0 ohms, class A, all in fig. 8.4) are

mounted and of the correct resistance.

Fig. 8.4

4/00021-2/FEA 209 544/11.C 45 (68)

Page 46

PF768, Standard Electrical Repairs

Table 8.1 shows the symptoms when there’s incorrect resistance in any of the resistors.

Missingor

broken.

R609 Lit Not lit

R610 Not lit Lit

R611 Faintly

R612 Not lit Faintly

Table 8.1

• If none of the H651-H660 LEDs are lit, measure the voltage at the marked side

of R607 (~3.1V, fig. 8.4). Before measuring you have to press a key for the processor to set the LED3K signal high for about 10s.

* If the voltage is missing, make sure pin 92 of D600 (fig. 8.3) is correctly

soldered.

* If the soldering is correct, replace D600 (class B).

* If the voltage is correct, replace R607 (class A).

If the fault remains, send the phone to the next level.

H651-

H654

glowing

H655-

H660

Not lit

glowing

8.4 The background illumination for the key-

board is missing or is faintly glowing.

Open the phone and check for liquid damages.

Make sure all the LEDs (H655-H660, all of class A, fig. 8.1) are mounted and cor-

rectly soldered.

Give the board power and start it up by pressing the On/Off key (in the fixture or in

the back cover with a dummy battery inserted, mount system connector to make the

board lie steady in the back cover).

• If a few but not all of the LEDs aren’t lit, replace them.

• If none of the LEDs are lit, make sure there’s VBATT voltage at the marked side

of the LEDs.

* If VBATT is missing there’s a foil damage, probably due to liquid damage,

and the phone is to be discarded.

* If VBATT is correct, make sure R612 (~0 ohms, class A), R609 (~33 ohms,

class A) and R611 (~0 ohms, class A, all in Fig. 8.4) are mounted and of the

4/00021-2/FEA 209 544/11.C 46 (68)

Page 47

PF768, Standard Electrical Repairs

correct resistance. Table 8.1 shows the symptoms when there’s incorrect

resistance in any of the resistors.

• If none of the H651-H660 LEDs are lit, measure the voltage at the marked side

of R607 (~3.1V, fig. 8.4). Before measuring you have to press a key for the processor to set the LED3K signal high for about 10s.

* If the voltage is missing, make sure pin 92 of D600 (fig. 8.3) is correctly

soldered.

* If the soldering is correct, replace D600 (class B).

* If the voltage is correct, replace R607 (class A).

If the fault remains, send the phone to the next level.

8.5 Green top indicator doesn’t work.

Open the phone and check for liquid damages.

Make sure the double LED (H650, class A, fig. 8.2) is correctly soldered.

Give the board power and start it up by pressing the On/Off key.

Measure the voltage at pad 4 of H600 (~3.4V, fig. 8.2).

• If the voltage is missing, measure the VRPAD voltage (~3.8V) at pin 1 of V706

(class A, fig. 8.2).

* If there’s no voltage at pin 1 of V706, check if there’s VRPAD voltage at

pin 5 of N452 (fig. 8.3).

* If the VRPAD voltage at pin 5 of N452 is incorrect, proceed to chapter 3

(“Doesn´t start”-fault).

* If the voltage at N452 pin 5 is correct, measure the resistance from pin 5

of N452 to pin 1 of V706 (~0 ohms).

* If the resistance is too high it’s probably L450 (~0 ohms, class A, fig.

8.3) that’s broken.

* If L450 isn’t faulty or incorrectly soldered there’s a foil damage

and the phone is to be discarded.

* If the voltage at V706 pin 1 is correct, measure the resistance from VBATT

to V706 pin 3 (~4.7 ohms, fig. 8.3 and 8.2).

* If the resistance is too high it’s probably R652 (~4.7 ohms, class A, fig.

8.2) that’s faulty.

* If R652 isn’t faulty or incorrectly soldered there’s a foil damage and

the phone is to be discarded.

* If the resistance from VBATT to pin 3 of V706 is correct, replace V706

(class A).

• If the voltage at H600 pad 4 is correct, check the soldering at pin 94 of D600.

4/00021-2/FEA 209 544/11.C 47 (68)

Page 48

PF768, Standard Electrical Repairs

If the fault remains, send the phone to the next level.

8.6 Red top indicator doesn’t work.

Open the phone and check for liquid damages.

Make sure the double LED (H650, class A, fig. 8.2) is correctly soldered.

Give the board power and start it up by pressing the On/Off key.

Measure the voltage at pad 4 of H600 (~3.4V, fig. 8.2).

• If the voltage is missing, measure the VRPAD voltage (~3.8V) at pin 1 of V706

(class A, fig. 8.2).

* If there’s no voltage at pin 1 of V706, check if there’s VRPAD voltage at

pin 5 of N452 (fig. 8.3).

* If the VRPAD voltage at pin 5 of N452 is incorrect, proceed to chapter 3

(“Doesn´t start”-fault).

* If the voltage at N452 pin 5 is correct, measure the resistance from pin 5

of N452 to pin 1 of V706 (~0 ohms).

* If the resistance is too high it’s probably L450 (~0 ohms, class A, fig.

8.3) that’s broken.

* If L450 isn’t faulty or incorrectly soldered there’s a foil damage

and the phone is to be discarded.

* If the voltage at V706 pin 1 is correct, measure the resistance from VBATT

to V706 pin 3 (~4.7 ohms, fig. 8.3 and 8.2).

* If the resistance is too high it’s probably R652 (~4.7 ohms, class A, fig.

8.2) that’s faulty.

* If R652 isn’t faulty or incorrectly soldered there’s a foil damage and

the phone is to be discarded.

* If the resistance from VBATT to pin 3 of V706 is correct, replace V706

(class A).

• If the voltage at H600 pad 4 is correct, check the soldering at pin 93 of D600.

If the fault remains, send the phone to the next level.

8.7 Both top indicator colours faintly glowing

and buzzer sounds faintly.

Open the phone and check for liquid damages.

Give the board power and start it up.

4/00021-2/FEA 209 544/11.C 48 (68)

Page 49

PF768, Standard Electrical Repairs

Measure the VRPAD voltage (~3.8V) at V706 pin 1 (class A, fig. 8.2).

• If the VRPAD voltage is correct, replace V706 (class A).

• If the voltage is missing at V706, check if there’s VRPAD voltage at pin 5 of

N452 (fig. 8.3).

* If it’s incorrect or missing, proceed to chapter 3 (“Doesn´t start”-fault).

* If the voltage at pin 5 of N452 is correct, check the resistance from N452

pin 5 top V706 pin 1 (~0 ohms, fig. 8.3 and 8.2).

* If the resistance is too high it’s probably L450 (~0 ohms, class A, fig.

8.3) that’s broken.

* If L450 isn’t faulty or incorrectly soldered there’s a foil damage and

the phone is to be discarded.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/11.C 49 (68)

Page 50

9 RTC

PF768, Standard Electrical Repairs

9.1 Determine the fault.

Insert a SIM card and a fully charged battery into the phone and start it up.

Set the correct time. Remove the battery and reinsert it after a minute.

• If the time says 00:00, proceed to section 9.2.

Compare to the correct time.

• If the clock is speeding or if it is halted, proceed to section 9.3.

The component side of the circuit board is shown in fig. 9.1.

Fig. 9.1

9.2 The time says 00:00 after removing and

reinserting the battery.

Open the phone and make sure the backup capacitor, C720 (class A, fig.9.2), is correctly soldered.

Fig. 9.2

4/00021-2/FEA 209 544/11.C 50 (68)

Page 51

PF768, Standard Electrical Repairs

• If it is, replace it.

Assemble the phone, start it up and set the correct time. Wait a few minutes for the

backup capacitor to get charged. Remove the battery and reinsert it after a minute.

Check if the fault is fixed (the backup capacitor needs a few hours of charging to

reach full capacity).

Compare to the correct time.

• If the clock is speeding or if it is halted, proceed to section 9.3.

9.3 The clock is speeding or it is halted.

Open the phone and make sure the B600 crystal is correctly soldered.

• If it is, replace B600, C690 and C691 (all of class A and in fig. 9.3).

Assemble the phone and compare to the correct time.

Fig. 9.3

4/00021-2/FEA 209 544/11.C 51 (68)

Page 52

PF768, Standard Electrical Repairs

10 Component lists

10.1 Explanations

10.1.1 Component list

Position:

The Components position number at the board

Designation:

Description of the component.

Part No.:

The components part number (or reference to Revision Change table) is specifed

only if the component can be replaced with Standard Electrical Repair. Advanced

means that the component can be replaced with Advanced Electrical Repair.

Note:

Functions that are affected if the component is replaced. The specified verification

should be paid extra attention when testing the telephone.

Trouble shooting instruction: Means section in the Trouble shooting instruction.

Not all components are mentioned in the Trouble shooting instruction.

10.1.2 Mounting drawing table

The Mounting drawings show the components placements (Pos) on the Printed

Board. The Mounting drawings are not included in this document.

10.1.3 Revision change table

If there are multiple partnumbers for a position, this table specifies which one to use

for different boards or board revisions.

4/00021-2/FEA 209 544/11.C 52 (68)

Page 53

PF768, Standard Electrical Repairs

10.2 Component list 2/ROA 117 3235/2

Positon Designation Part No. NOTE

Trouble shooting

instruction

DOME

SWITCHES

2 SHIELDINGPOT Advanced

3 SHIELDINGPOT Advanced

4 SHIELDINGPOT Advanced

B551 QUARTZ CRYS-

TAL UNIT

B600 QUARTZ CRYS-

TAL UNIT

C104 CAPACITOR Advanced

C105 CAPACITOR Advanced

C106 CAPACITOR Advanced

C107 CAPACITOR Advanced

C111 CAPACITOR Advanced

C119 CAPACITOR Advanced

C202 CAPACITOR Advanced

C203 CAPACITOR Advanced

C204 CAPACITOR Advanced

C211 CAPACITOR Advanced

C212 CAPACITOR Advanced

C213 CAPACITOR Advanced

SXA 120 9446 Doesn’t start, Key-

Advanced

RTM 501 661/01 Verify Real Time

board

RTC

Clock function

C214 CAPACITOR Advanced

C226 CAPACITOR Advanced

C227 CAPACITOR Advanced

C228 CAPACITOR Advanced

C230 CAPACITOR Advanced

C231 CAPACITOR Advanced

C235 CAPACITOR Advanced

C236 CAPACITOR Advanced

C242 CAPACITOR Advanced

C243 CAPACITOR Advanced

C250 CAPACITOR Advanced

C251 CAPACITOR Advanced

C252 CAPACITOR Advanced

C253 CAPACITOR Advanced

4/00021-2/FEA 209 544/11.C 53 (68)

Page 54

PF768, Standard Electrical Repairs

Positon Designation Part No. NOTE

C254 CAPACITOR Advanced

C255 CAPACITOR Advanced

C256 CAPACITOR Advanced

C257 CAPACITOR Advanced

C258 CAPACITOR Advanced

C264 CAPACITOR Advanced

C300 CAPACITOR Advanced

C301 CAPACITOR Advanced

C302 CAPACITOR Advanced

C310 CAPACITOR Advanced

C311 CAPACITOR Advanced

C312 CAPACITOR Advanced

C315 CAPACITOR Advanced

Trouble shooting

instruction

C324 CAPACITOR Advanced

C350 CAPACITOR Advanced

C351 CAPACITOR Advanced

C352 CAPACITOR Advanced

C353 CAPACITOR Advanced

C354 CAPACITOR Advanced

C355 CAPACITOR Advanced

C356 CAPACITOR Advanced

C357 CAPACITOR Advanced

C358 CAPACITOR Advanced

C359 CAPACITOR Advanced

C360 CAPACITOR Advanced

C361 CAPACITOR Advanced

C371 CAPACITOR Advanced

C400 CAPACITOR Advanced

C401 CAPACITOR Advanced

C402 CAPACITOR Advanced

C403 CAPACITOR Advanced

C404 CAPACITOR Advanced

C406 CAPACITOR Advanced

C407 CAPACITOR Advanced

C410 CAPACITOR Advanced

C420 CAPACITOR Advanced

C430 CAPACITOR Advanced

4/00021-2/FEA 209 544/11.C 54 (68)

Page 55

PF768, Standard Electrical Repairs

Positon Designation Part No. NOTE

C431 CAPACITOR Advanced

C432 CAPACITOR Advanced

C433 CAPACITOR Advanced

C450 CAPACITOR Advanced

C452 CAPACITOR Advanced

C453 CAPACITOR Advanced

C454 CAPACITOR Advanced

C455 CAPACITOR Advanced

C456 CAPACITOR Advanced

C457 CAPACITOR RJE 599 1107/47A

C458 CAPACITOR Advanced

C460 CAPACITOR Advanced

C461 CAPACITOR Advanced

Trouble shooting

instruction

C462 CAPACITOR RJC 464 3025/1

C463 CAPACITOR Advanced

C468 CAPACITOR Advanced

C470 CAPACITOR Advanced

C501 CAPACITOR Advanced

C502 CAPACITOR Advanced

C503 CAPACITOR Advanced

C505 CAPACITOR Advanced

C507 CAPACITOR Advanced

C512 CAPACITOR Advanced

C513 CAPACITOR Advanced

C515 CAPACITOR Not available

C516 CAPACITOR Not available

C518 CAPACITOR Advanced

C520 CAPACITOR Advanced

C521 CAPACITOR Advanced

C530 CAPACITOR Advanced

C531 CAPACITOR Advanced

C532 CAPACITOR Advanced

C540 CAPACITOR Advanced

C541 CAPACITOR Advanced

C542 CAPACITOR Advanced

C543 CAPACITOR Advanced

C544 CAPACITOR Advanced

4/00021-2/FEA 209 544/11.C 55 (68)

Page 56

PF768, Standard Electrical Repairs

Trouble shooting

Positon Designation Part No. NOTE

instruction

C545 CAPACITOR Advanced

C551 CAPACITOR Advanced

C553 CAPACITOR Advanced

C554 CAPACITOR Advanced

C556 CAPACITOR Advanced

C600 CAPACITOR RJE 599 1108/1W SIM, Keyboard, Dis-

play

C602 CAPACITOR RJC 464 3035/68

C603 CAPACITOR RJC 464 3035/68

C604 CAPACITOR RJC 464 3035/68

C605 CAPACITOR RJC 464 3035/68

C606 CAPACITOR RJC 464 3035/68

C608 CAPACITOR RJC 464 3035/68

C609 CAPACITOR RJC 464 3035/68

C610 CAPACITOR RJC 464 3035/68

C611 CAPACITOR RJC 464 3035/68

C614 CAPACITOR RJC 496 2047/1

C616 CAPACITOR RJC 464 3035/68

C626 CAPACITOR RJC 464 3035/68 Verify SIM func-

tion

C627 CAPACITOR RJC 463 3022/1 Verify SIM func-

tion

C628 CAPACITOR RJC 463 3022/1 Verify SIM func-

tion

C629 CAPACITOR RJC 463 3022/1 Verify SIM func-

tion

C630 CAPACITOR RJC 463 3022/22 Verify SIM func-

tion

C631 CAPACITOR RJC 463 3022/33

C632 CAPACITOR RJC 463 3022/56 Verify display

function

C633 CAPACITOR RJC 464 3035/68 Verify display

function

Display

Display

C635 CAPACITOR RJC 464 3035/68 Verify SIM func-

tion

C642 CAPACITOR RJC 464 3035/68

C643 CAPACITOR RJC 463 3022/1

C644 CAPACITOR RJC 463 3022/1

C650 CAPACITOR RJC 463 3022/1

C651 CAPACITOR RJC 463 3022/1

4/00021-2/FEA 209 544/11.C 56 (68)

Page 57

PF768, Standard Electrical Repairs

Positon Designation Part No. NOTE

C652 CAPACITOR RJC 463 3022/1

C656 CAPACITOR RJC 463 3022/1

C657 CAPACITOR RJC 463 3022/1

C660 CAPACITOR RJC 463 3022/1

C668 CAPACITOR RJC 464 3035/68

C669 CAPACITOR RJC 463 3022/82

C670 CAPACITOR See Rev.Change tab 1.

C672 CAPACITOR RJC 463 3022/82

C673 CAPACITOR RJC 463 3022/1

C675 CAPACITOR RJC 464 3035/68

C676 CAPACITOR RJC 464 3025/1

C677 CAPACITOR RJC 464 3025/1

C678 CAPACITOR RJC 464 3025/1

Trouble shooting

instruction

C679 CAPACITOR RJC 464 3024/1

C680 CAPACITOR RJC 464 3023/68 Doesn't start

C690 CAPACITOR See Rev.Change tab 1. Verify Real Time

RTC

Clock function

C691 CAPACITOR See Rev.Change tab 1. Verify Real Time

RTC

Clock function

C692 CAPACITOR RJC 464 3035/68 Verify Real Time

Doesn't start

Clock function

C700 CAPACITOR RJC 463 3022/1

C704 CAPACITOR RJC 463 3022/1

C705 CAPACITOR RJC 464 3035/68 Verify SIM func-

tion

C706 CAPACITOR RJC 464 3047/1 Verify SIM func-

tion

C707 CAPACITOR RJE 599 2107/47A Verify SIM func-

tion

C708 CAPACITOR RJC 464 3046/1 Verify SIM func-

tion

C709 CAPACITOR RJC 464 3046/1 Verify SIM func-

tion

C710 CAPACITOR RJC 464 3046/1 Doesn't start

C711 CAPACITOR RJC 464 3025/1

C719 CAPACITOR RJE 599 1167/1 Verify Real Time

Clock function

C720 CAPACITOR RJE 338 1256/6 Verify Real Time

RTC, Doesn't start

Clock function

4/00021-2/FEA 209 544/11.C 57 (68)

Page 58

PF768, Standard Electrical Repairs

Positon Designation Part No. NOTE

C721 CAPACITOR RJC 464 3035/68 Verify Real Time

Clock function

C730 CAPACITOR RJC 464 3047/1 Verify On/Off func-

tion

C731 CAPACITOR RJC 464 3024/1 Verify On/Off func-

tion

C760 CAPACITOR RJC 464 3035/68

C800 CAPACITOR RJE 599 1108/1W

C801 CAPACITOR RJC 463 3022/1

C802 CAPACITOR RJC 464 3035/68

C803 CAPACITOR RJC 464 3035/68

C804 CAPACITOR RJC 464 3035/68

C805 CAPACITOR RJC 464 3035/68

Trouble shooting

instruction

C806 CAPACITOR RJC 464 3035/68

C807 CAPACITOR RJC 464 3035/68

C810 CAPACITOR RJC 464 3035/33 Verify handsfree

mic function

C812 CAPACITOR RJC 464 3035/68 Verify handsfree

mic function

C813 CAPACITOR RJE 599 2107/15 Verify handsfree

earphone function

C814 CAPACITOR RJE 599 2107/47A Verify mic function

C815 CAPACITOR RJC 463 3022/1 Verify mic function

C816 CAPACITOR RJC 464 3024/1 Verify mic function

C817 CAPACITOR RJC 463 3022/1 Verify handsfree

mic function

C818 CAPACITOR RJC 464 3035/68 Verify mic function

C819 CAPACITOR RJC 464 3035/68 Verify mic function

C824 CAPACITOR RJC 464 3025/1 Verify display

function

C826 CAPACITOR RJA 532 4055/12

C829 CAPACITOR RJC 463 3022/1 Verify mic function

Audio

Audio

Audio

Display

C830 CAPACITOR RJC 463 3022/1 Verify mic function

C833 CAPACITOR RJC 464 3035/68

C835 CAPACITOR RJE 599 2107/47A Verify handsfree

Audio

mic function

C840 CAPACITOR RJC 463 3022/1

C841 CAPACITOR RJC 463 3022/1

C842 CAPACITOR RJC 463 3022/1

C850 CAPACITOR RJC 464 3035/68 Verify mic function Audio

4/00021-2/FEA 209 544/11.C 58 (68)

Page 59

PF768, Standard Electrical Repairs

Trouble shooting

Positon Designation Part No. NOTE

instruction

C851 CAPACITOR RJC 464 3035/68 Verify mic function Audio

C853 CAPACITOR RJC 464 3035/68

C900 CAPACITOR RJE 599 1108/1W

C902 CAPACITOR RJC 464 3035/68

C903 CAPACITOR RJC 464 3035/68

C904 CAPACITOR RJC 464 3035/68

C905 CAPACITOR RJC 464 3035/68

C906 CAPACITOR RJC 464 3035/68

D600 MICROCIRCUIT ROP 101 678/2C R2A SIM, Keyboard,

Doesn't start, No

serv, Display, Illumination and Buzzer,

Audio

D610 MICROCIRCUIT RYT 118 6061/1 Doesn't start

D620 MICROCIRCUIT RYT 119 6047/1 Doesn't start

D630 MICROCIRCUIT Not available

D900 FUNCTIONAL

RYS 105 625/2C R4A Doesn't start

CIRCUIT

F601 VARISTOR See Rev.Change tab 1.

G300 OSCILLATOR Advanced

G350 OSCILLATOR Advanced

H600 BUZZER KLJ 107 11/1 Verify buzzer func-

tion

H650 LIGHT EMIT-

TING DIODE

H651 LIGHT EMIT-

TING DIODE

H652 LIGHT EMIT-

TING DIODE

H653 LIGHT EMIT-

TING DIODE

H654 LIGHT EMIT-

TING DIODE

H655 LIGHT EMIT-

TING DIODE

H656 LIGHT EMIT-

TING DIODE

RKZ 433 613/1 Verify red/green

top LED

RKZ 433 643/1 Verify Illumination

function

RKZ 433 643/1 Verify Illumination

function

RKZ 433 643/1 Verify Illumination

function

RKZ 433 643/1 Verify Illumination

function

RKZ 433 634/4 Verify Illumination

function

RKZ 433 634/4 Verify Illumination

function