Ericsson LBI-38701 Maintenance Manual

LBI-38701

MAINTENANCE MANUAL

SERVICE SECTION

800 MHZ TRUNKED MOBILE RADIO

TABLE OF CONTENTS

Page

Description............................................................................................................................................ 3

Initial Ad justment................................................................................................................................. 3

Tra nsmitter Adj ustment .. .............................................................................................................. 3

Rec eiver Adjustmen t..................................................................................................................... 3

Re-installation ................................................................................................................................ 3

Preventative Maintenance.................................................................................................................... 3

Connections ................................................................................................................................... 3

Electrical System........................................................................................................................... 3

Mechanical Inspection .................................................................................................................. 3

Antenna .......................................................................................................................................... 3

Alignment....................................................................................................................................... 3

Fre q uency Check........................................................................................................................... 3

Dis assembly Procedures.......... ............................................................................................................. 3

To Remove Top Cover.................................................................................................................. 4

To Remove Bottom Cover............................................................................................................ 4

To Remove The Duplexer Assembly........................................................................................... 4

To Remove The RF Board............................................................................................................ 4

To Remove The Audio Board ...................................................................................................... 5

To Remove The Front Cap Assembly ......................................................................................... 5

To Remove The Logic Board....................................................................................................... 5

To Remove The Duplexer/Interface Board................................................................................. 7

To Remove The System Board .................................................................................................... 7

To Remove The Handset Interface Board........ .. ......................................................................... 7

Chip Component Replacement............................................................................................................ 7

To Remove Chip Components ..................................................................................................... 7

To Replace Chip Components...................................................................................................... 7

Troublesho oting Procedures ................................................................................................................ 8

Self Diagnostics/Error Messages................................................................................................. 8

Test Preparation.................................................................................................................................... 11

Test Mode Commands.......................................................................................................................... 11

Default Conditions ........................................................................................................................ 11

Channel Frequen cy S elect ............................................................................................................ 11

Test Mode Commands and Functions................................................................................................. 11

Single Key Tests............................................................................................................................ 12

Three Key Function Tests............................................................................................................. 14

1

LBI-387 01

TABLE OF CONTENTS

(CONTINUED)

Rad io Alignment Procedure.. ............................................................................................................... 17

Test Equipment And Service Aids............................................................................................... 17

Transmitter Alignmen t.................................................................................................................. 17

Rec eiver Alignment....................................................................................................................... 18

Transm itter Verification................................................................................................................ 19

Rec eiver Verification .................................................................................................................... 20

Diagrams

Audio Signal Flow Diagram......................................................................................................... 21

Control Signal Flow Diagram....................................................................................................... 22

Power Distribution Diagram......................................................................................................... 23

Page

Copyright© March 1992, Ericsson GE Mobile Communications, Inc.

2

LBI-38701

DESCRIPTION

The Service Section contains the information neces-

sary for aligning and troubleshooting the MDR Series

mobile radio. In addition, info rmation is pro v ided for dis assembli ng the radio and replacing c hip c o mpo ne nts.

INITIAL ADJUSTMENT

After the radio has been installe d as described i n the

Installation Manual, the following adjustments should be

made by a certified electronics technician.

TRANSMITTER ADJUSTMENT

The transmitter has been adjusted at the factory and

should require no readjustment. However, the antenna

length should be adjusted for optimum VSWR, and the

freque ncy a nd modul atio n meas ured and recorded for future reference. For the complete transmitter alignment,

refer to the Transmitter Alignment Procedure.

RECEIVER ADJUSTMENT

No initial adjustments to the receiver are required.

Refer to the Receiver Alignmen t Procedure.

ELECTRICAL SYSTEM

Check the vo ltage regulato r and alt ernator or generator per io dically to kee p th e e lectrica l system within safe

and economical operating limits. Overvoltage is indicated

when the battery loses water rapidly. Use of 1 or 2 ounces

of wate r per cell per week is acceptab le for batterie s in

continuous operation. A weak battery will often cause

excessive noise or faulty operation.

MECHANICAL INSPECTION

Since mobile units a re subject to consta nt shock and

vibration, check for loose plugs, nuts, screws a nd other

parts to make s ure that no thing is working loose.

ANTENNA

The antenna, antenna base and all contacts may become coated or poorly grounded; loss of radiation and a

weak signal will result.

ALIGNMENT

The transmitter and receiver meter readings should be

checked periodically, and the alignment "touched up"

when necessa ry . Ref er to the Alignment Procedure in this

manual.

RE-INSTALLATION

The ra dio is des igned to op erate i n 12 volt, negative

ground vehicles only. If the mobile radio is moved to a

different vehic le, alway s che ck t he batt ery po larity of the

new vehicle system.

PREVENTATIVE MAINTENANCE

To ensure high operating efficiency and to prevent

mechanical and electrical failu res from inter rupting system operatio ns, routine check s shoul d be mad e of all mechanical and electric al parts at regula r intervals. Preventive mainten a nce shoul d inclu de t he followi ng che cks.

CONNECTIONS

Ground connections to the voltage source should be

periodically checked for tightness. Loose or poor connections to the power source will cause excessive voltage

drops and faulty operatio n. When ground connections are

not made direct ly to the batte ry, the co nnection from the

battery to vehicle chassis must be checked for low impedance. A high impedance may cause excessive voltage

drops and alternator noise probl ems.

FREQUENCY CHECK

Check transmitter frequency and deviation. Normally,

these checks are made when the unit is first put into

operation, after the first six m onths, and once a year thereafter.

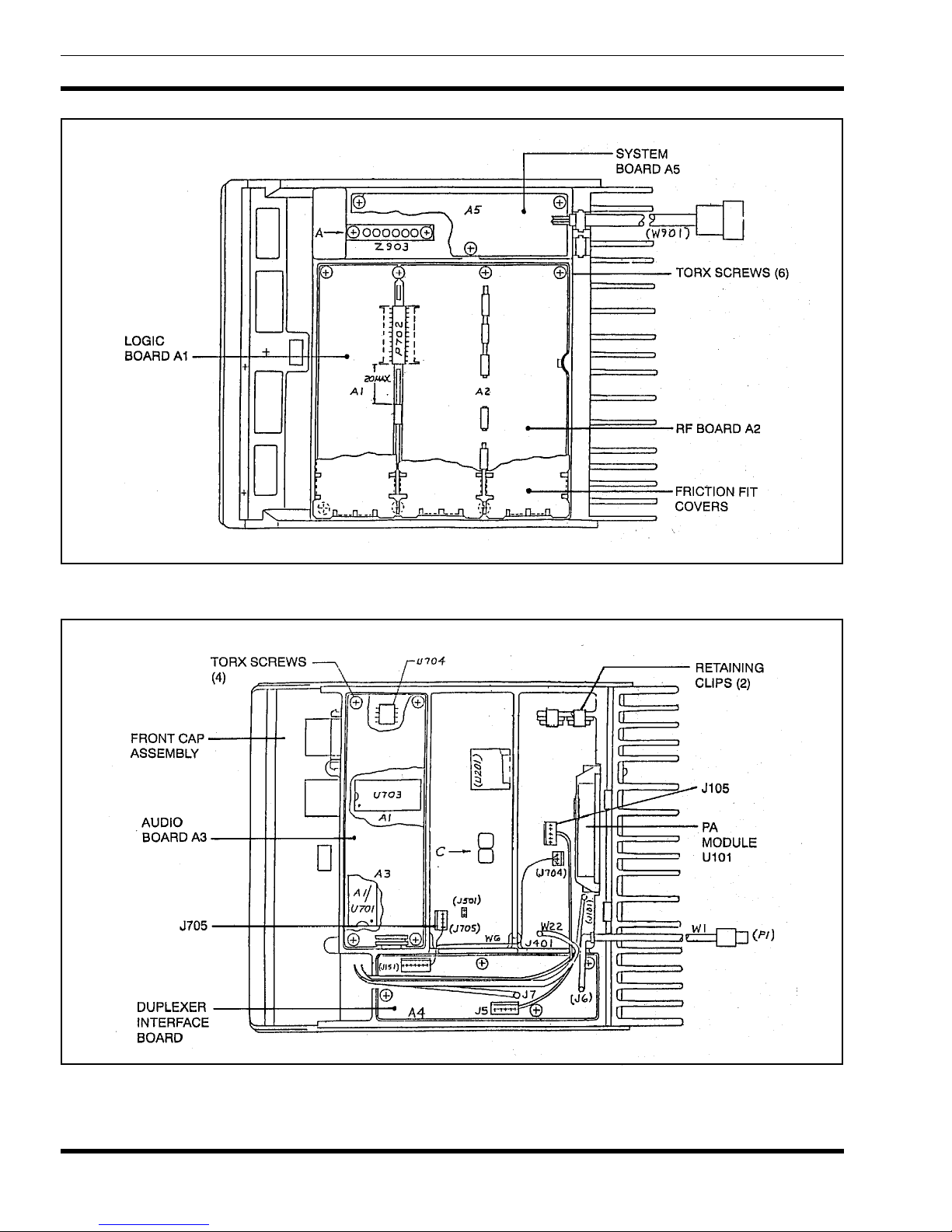

DISASSEMBLY PROCEDURES

Disassembly procedures are provided to completely

disassemble the radio. In general, reassembly is in the

revers e orde r. Inc luded are p roced ures to remo ve t he top

and bottom covers, duplexer, RF board, Audio Board,

Logic Board, Duplexer/Interface Board, System Board,

and Front Cap Assembly inc luding the Hands et/Inte rface

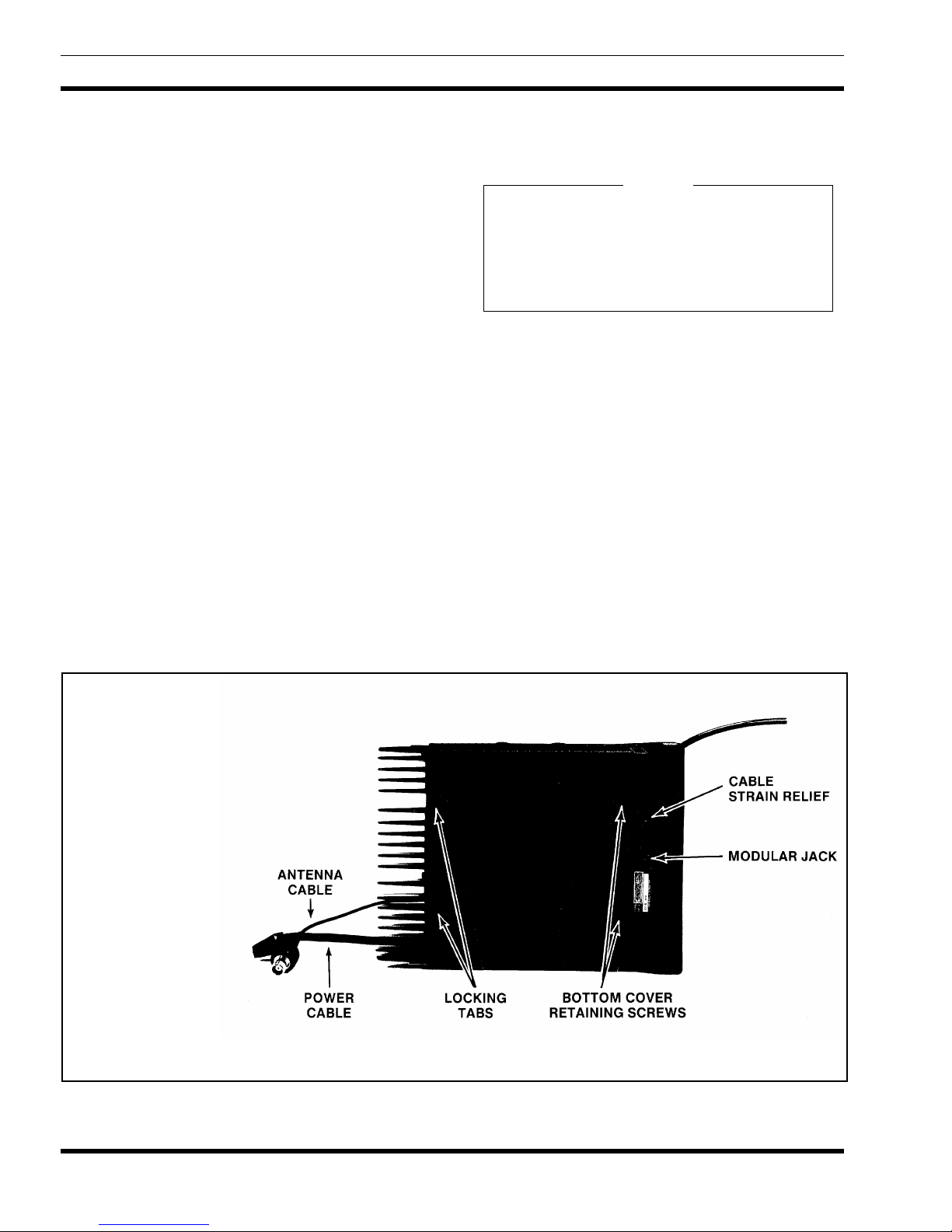

board. Refer to Figure 1, Radio Disassembly.

NOTE

Remove power from the radio before servicing.

3

LBI-387 01

TO REMOVE THE TOP COVER

l. Insert a small standa rd s crewdriver under one side o f the

top cover and gently pry t he side of the c over away from

the frame releasing the locking ta b.

2. Using the screwdri v er, press in on t he ta bs on the r ear of

the radio and release the tw o l ocking tabs.

3. Insert the screwdriver under the other side of the radio

top cover, releasing the remaining locking tab, and remove the cover from the rad io.

TO REMOVE THE BOTTOM COVER

1. Remove the two screws securing the bottom cover to the

radio. (Refer to Figure 1.) The bottom cover can then be

removed from the radio.

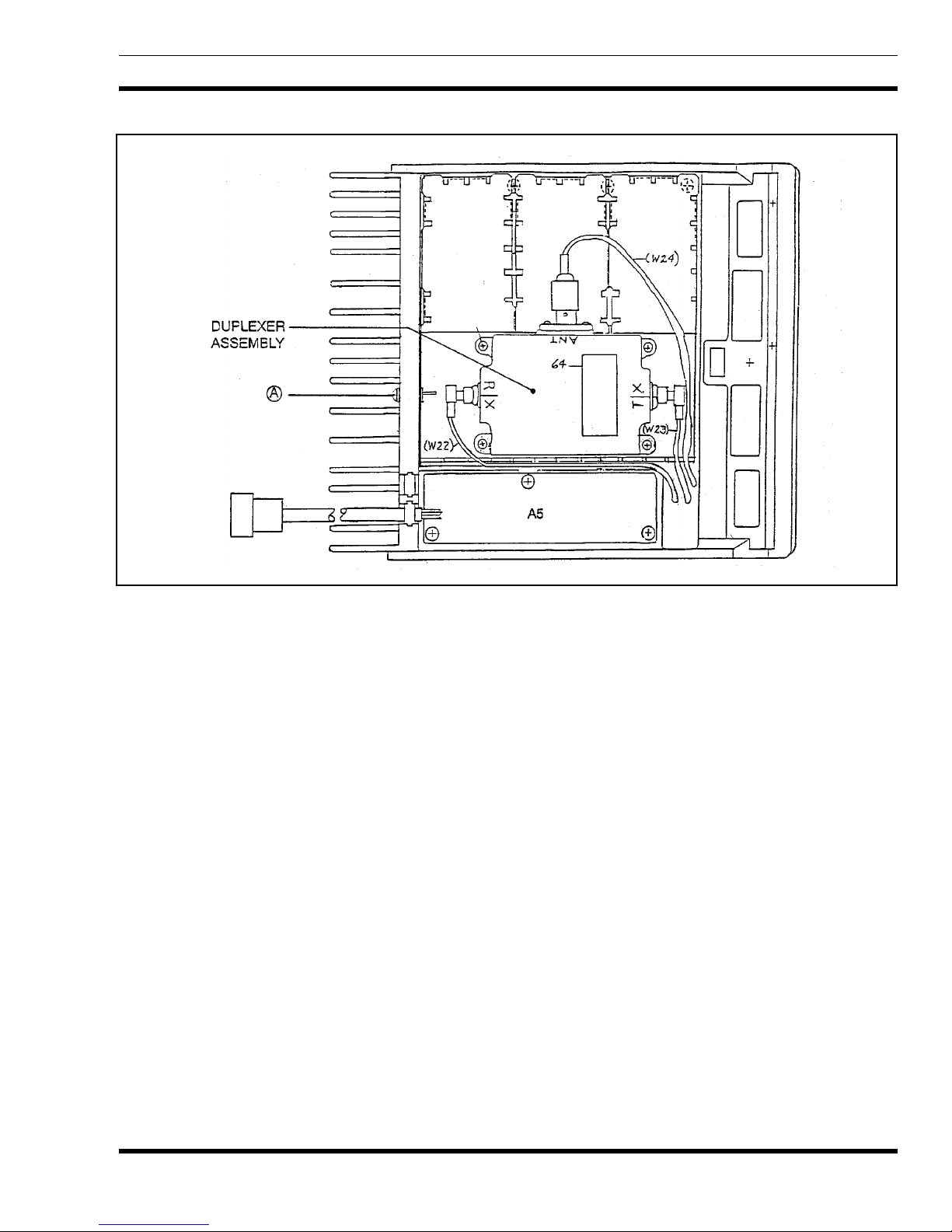

TO REMOVE THE DUPLEXER ASSEMBLY

1. Remove the bottom cover of the radio.

2. Refer to Figure 2. R emove the single M3. 0-0.8 X 20 (#1 0

drive) TORX screw "A", located on th e rear of the radio,

that secur es the dupl exer assembly to the casting.

3. The duplexer can now be removed by disconnecting the

SMB connectors from the TX and RX inputs of the

duplexer and disconnecting the TNC connector from the

ANT port of the duplexer.

NOTE

Servicin g the radio while the du plexer is not proper ly

secured may cause electrical shorts. Special care

must be taken to ensure that the duplexer does not

make contact with any circuitry while power is applied to the radio.

TO REMOVE THE RF BOARD A2

l. Remove the top and bottom covers and the duplexer

assembly from the radio (refer to the procedures above).

2. Refer to Fig ure 3. Pry off the friction fit covers covering

the RF Board.

3. Using a small standard screwdriver, gently pry the interconnect plug P702 from the Logic and RF Boards

4. Remove the two clips (Figure 4) securing Q101 and U102

to the frame (on top side of board).

5. Remove the t wo M3.5-0.6 x 20 TO RX screws (#15 drive )

securing PA module U101 t o the fra me.

4

Figure 1 Radio Cover Removal

LBI-38701

Figure 2 - Bottom View With Duplexer

6. Remove the six M3.5-0.6 x 8 TORX screws (#15 drive )

from the bottom side of the board.

7. Disconnect wires connected to J105, J704, J705 and the

cables going to the Duplexer Interface Board.

8. Remove the six spring clips protruding through the RF

Board from the bottom side.

9. Gently push the RF board out of the radio casting.

TO REMOVE THE AUDIO BOARD A3

l. Pull out the black clip protruding through the Audio

Board which holds the Logic Board 5-volt regulator

against th e ca sti n g.

2. Refer to Figure 4. Re mov e the four M3. 5-0.6 x 8 TO RX

screws (#15 drive) se curing the Audio Board to the radio.

Pry out the board using a screwdriver in the hole previously occupied by the clip.

TO REMOVE THE FRONT CAP

ASSEMBLY

2. Remove the two M3.5-06 x 8 TORX screws (#15 drive)

from both sides of the front cap and the TORX screw on

the bottom of the fr ont cap.

3. Gently pull the front cap assembly away from the radio

exposing the ribbon cable on the rear of the assembly.

TO REMOVE THE LOGIC BOARD A1

l. Remove the top and bottom c overs, Front Ca p assembly

and the Audio Board from the radio. Refer to the disassembly for each, in this section.

2. Remove interconnect plug P702 from the RF and Logic

Boards on the bottom of the radio.

3. Remove the four M3.5- 0.6 x 8 TORX screws ( #15 drive)

securing the Logic Board to the radio frame.

4. Gently work the Logic Board out of the radio being

careful not to damage the plug going to the Front Cap

Assembly .

l. Remove the top and b ottom covers of the radio.

5

LBI-387 01

Figure 3 - Bottom View Without Duplexer

6

Figure 4 - Top View

CAUTION

LBI-38701

TO REMOVE THE DUPLEXER

INTERFACE BOARD A4

l. Remove the top c over of the radio. Refer to the procedure

above.

2. Disconnect the cables going back to the RF Board.

3. Disconnect the cables from the duplexer.

4. Remove the four M3.5-0.6 TORX screws (#15 drive)

securing the board to the frame. Care full y work the board

out of the radio, unplugging it from the feed through

assembly Z903.

TO REMOVE THE SYSTEM BOARD A5

1. Remove the bottom cover of the radio. Refer to the

procedure above.

2. Disconnect the ribbon cable from J902.

3. Disconnect the option cable if used.

4. Remove the three M3.5-0.6 x 8 TORX screws (#15

drive) securing the board to the frame.

5. Carefully work the b oard out of t he radio, unplugging it

from the feed through assembly Z90 3.

where the compone nt is used (PA module re placement is

located in the RF Board manual ).

Replacement of chip capacitors should always be done

with a temperature controlled soldering iron, operating at

700F (371C). However, DO NOT touch b lack met a l fi l m

of the resistors or the ceramic body of capacitors with the

soldering iron. NOTE: The metallized end terminations of

the parts may be tou ched with the solde ring iron without

causing damage.

The CMOS Integra ted Circuit devices us ed i n this equipment can

be destroyed by static disch arges.

Before symbol handling one of

these devices, the serviceman

should discharge himself by

touching the case of a bench in-

strument that has a 3-pron g power

cord connected to a n outlet with a kn own good earth

ground. When soldering or desoldering a CMOS

device, the soldering iron should also have a 3- prong

power cord connected to an outlet with a known

good earth ground. A battery-operated soldering

iron may be used in place of the regular soldering

iron.

6. Disconn ec t the ribbon cable from the rear of the assembly. The Front Cap Assembly can then be removed from

the radio.

TO REMOVE THE HANDSET

INTERFACE BOARD A9

The Front Cap Assembly contains the Handset Inter-

face Board. Remo ve the Handset Inte rface Board as instructed below.

1. Remove the clip securing the 3 watt PA (U801) to the

front cap casting.

2. Remove the fou r M3.5- 06 x 8 TO RX screws ( #15 dri ve)

securing the board to the front cap casting. Lift the b oard

out of the front cap.

CHIP COMPONENT

REPLACEMENT

The procedure for removing chip components is given

below. Replaceme nt procedures for other unique components ar e locate d in the re lated board instruc tion manual

To Remove Chip Components

l. Using two s old eri n g iro n s sim ultaneously hea t ea ch en d

of the chip until solder flows, and then remove and

discar d th e ch i p.

2. Remove excess solder wi th a vacuum solder extractor.

3. Carefully remove th e e poxy adhesive and excess flux to

preven t da ma ge t o th e pri n t ed board.

To Replace Chip Components

1. Using as little solder as possible, "tin" one end of the

component and one of the pads on the printed wiring

board.

2. Place th e "t inned" en d of the c omponen t on th e "ti nne d "

pad on th e b oar d and simult ane ously tou c h th e c omponent and th e pad with a wel l "tinned" s oldering iron w hile

pressing the component do wn on the board.

7

Loading...

Loading...