Page 1

EDN612, ESN212, EPN210 Installation

Guide

EDA 1200

Page 2

EDN612, ESN212, EPN210 Installation

Guide

EDA 1200

.

ii

3/1531-HSD 101 41 Uen E 2007-08-13

Copyright

© Ericsson AB 2006-2007. All Rights Reserved

Disclaimer

No part of this document may be reproduced in any form without the written

permission of the copyright owner.

The contents of this document are subject to revision without notice due to

continued progress in methodology, design and manufacturing. Ericsson shall

have no liability for any error or damage of any kind resulting from the use of

this document.

Page 3

.

3/1531-HSD 101 41 Uen E 2007-08-13

iii

Contents

1

Introduction 1

1.1

Revision History 1

1.1.1

This Revision 1

1.1.2

Version D 1

1.1.3

Version C 2

1.1.4

Version B 2

1.1.5

Version A 2

2

Tools 3

3

Overview of the EDN612, ESN212, EPN210 4

4

Power Requirements and Distribution 7

5

Environmental and Space Requirements 9

6

Installation 11

6.1

Preparation for Installation 11

6.2

Mounting the EDN612, ESN212 and EPN210 Nodes 11

6.2.1

Setting the Switch ID in ESN212 12

6.2.2

Mounting the Hardware 15

6.2.3

Cabling of Ethernet Connections (No.1) 15

6.2.4

Cabling the Power Connections (No.2 and No.4) 16

6.2.5

Cabling the Subscriber Line (No.3) 16

6.2.6

SFP Cages for ESN212 18

6.3

Mounting the Front Cover for the Cable Tray 19

7

Initial Configuration and Commissioning 20

7.1

Embedded Nodes 20

7.2

Stand Alone ESN212 20

Page 4

Contents

iv

3/1531-HSD 101 41 Uen E 2007-08-13

8

Installing and Upgrading the Software 22

9

Verification of the Installation 23

Page 5

Introduction

3/1531-HSD 101 41 Uen E 2007-08-13

1

1 Introduction

This document describes the installation of the EDN612 IP DSLAM,

ESN212 Switch and Ethernet Power Node EPN210. It is intended for

planning and installation personnel.

The guide can be read separately, but for a full understanding of the EDA

system the reader is referred to the System Description and EDN612,

ESN212, EPN210 User Guide.

The guide can be printed on a monochrome printer, but the illustrations are

easier to understand if a color printer is used.

1.1 Revision History

The guide is valid for EDA 1200 4.0 R3A and later. Please refer to the

Release Notes for valid versions of the nodes. Other product versions, with

functions not described in this guide, may be available.

1.1.1 This Revision

Other than editorial changes, this document has been changed as follows:

• Environmental and Space Requirements section added (section 5 on

page 9).

1.1.2 Version D

Other than editorial changes, this document has been changed as follows:

• Warning in section 6.2.1 on page 12 about not to use other SID than

zero removed.

• The description of the subscriber cable used for connection to the

EDN612 has been revised.

• Tools needed section added (section 2 on page 3)

• Procedure for inserting subscriber line connector revised (section 6.2.5

on page 16).

Page 6

Introduction

2

3/1531-HSD 101 41 Uen E 2007-08-13

1.1.3 Version C

Other than editorial changes, this document has been changed as follows:

• Initial configuration for stand alone ESN212 added

1.1.4 Version B

Other than editorial changes, this document has been changed as follows:

• Hardware mounting instructions added

• Switch ID setting instructions added

1.1.5 Version A

This is the first version.

Page 7

Tools

3/1531-HSD 101 41 Uen E 2007-08-13

3

2 Tools

Before starting the installation the following tools should be at hand:

Table 1 Tools and Recommended Torque

Item Shape Used for Recommended

Torque

1.

Torque-driver

with TORX T08

bit

Power and

subscriber

connectors screws

0.3 Nm

2. Small flat head

screw driver

Opening cover for

and setting the DIP

switch of the

ESN212

-

3. Torque-driver

with TORX T30

bit

Screws (M6x16 mm)

for fastening units

and subracks to the

cabinet

10 Nm

4. Side-cutting

pliers

Cutting cable ties

-

5. Band tensioner

Tensioning cable ties

-

Apart from the tools some cable ties for fastening of the cables are needed.

The cable ties are not delivered with the equipment.

Page 8

Overview of the EDN612, ESN212, EPN210

4

3/1531-HSD 101 41 Uen E 2007-08-13

3 Overview of the EDN612, ESN212,

EPN210

The subrack is available in various configurations that can be adapted to

specific solutions.

The 19” subrack and the ETSI (21”) subrack can both be equipped with up

to 96 End-user lines. The subracks have a built-in cable tray and air guide

and it is possible to mount EDN612 IP DSLAMs, ESN212 switches,

external splitters, and an optional EPN210 Power Distribution Node in

different combinations. Table 2 and Table 3 on page 4 show examples on

various configurations.

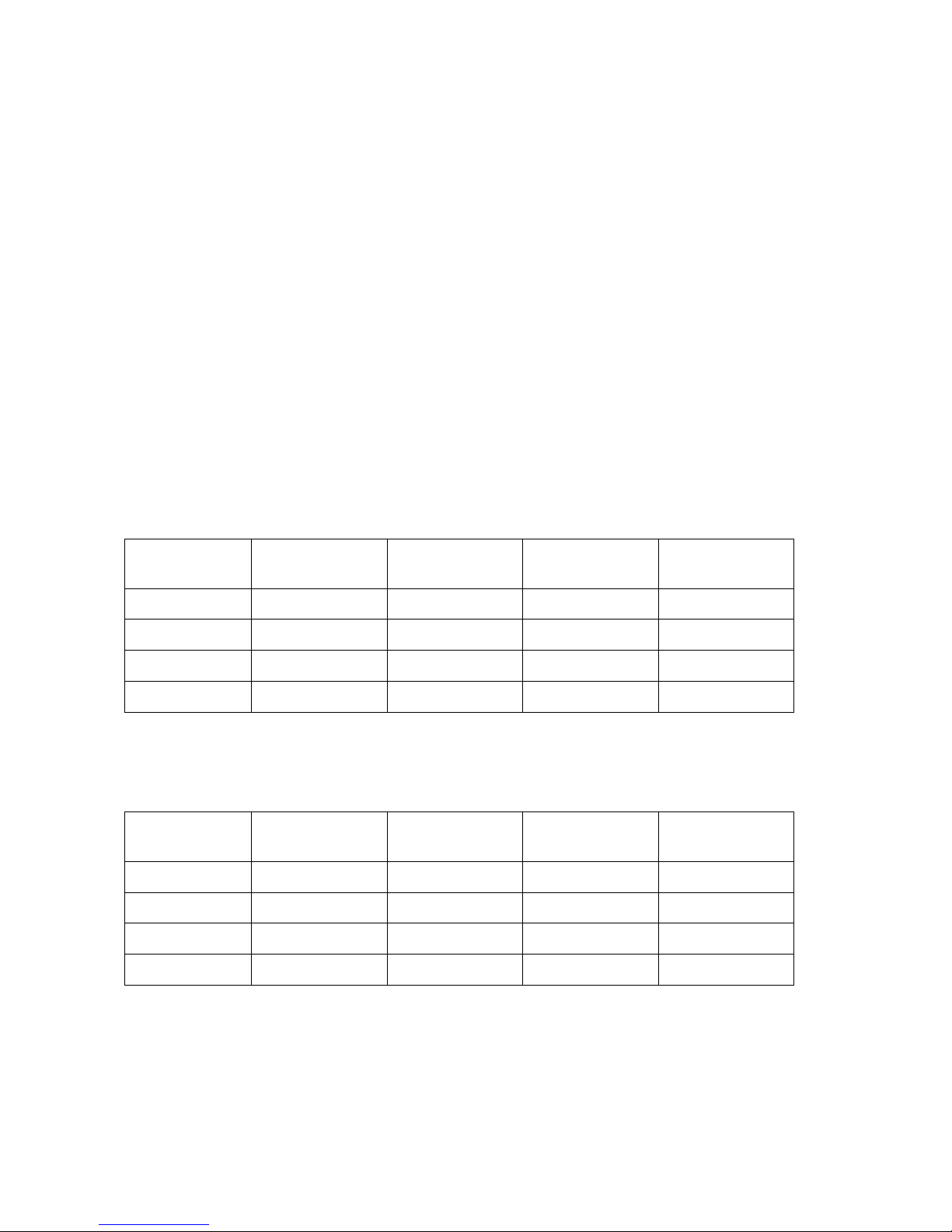

Table 2 Examples of Possible Configurations in an ETSI Subrack

Number of

lines

Splitter EDN612 ESN212 EPN210

96 0 8 1 1

96 0 8 1 0

72 6 6 1 0

60 5 5 1 1

Table 3 Examples of Possible Configurations in a 19” Subrack

Number of

lines

Splitter EDN612 ESN212 EPN210

96 0 8 1 0

84 0 7 1 1

60 5 5 1 0

48 4 4 1 1

Page 9

Overview of the EDN612, ESN212, EPN210

3/1531-HSD 101 41 Uen E 2007-08-13

5

Table 4 on page 5 shows the dimensions for the nodes in the subrack

solutions.

Table 4 Size Dimensions for Subrack Solutions

Nodes Size

ETSI (inside) 481 mm

19” (inside) 431 mm

EDN612, ESN212 or EPN210 47 mm

Splitter 23 mm

Figure 1 on page 5 shows a fully equipped 96-line ETSI subrack solution

without splitters with eight EDN612 IP DSLAMs, one ESN212 switch, and

one EPN210 Power Distribution Node.

Figure 1 96-line ETSI Subrack with EDN612, ESN212 and EPN210

Page 10

Overview of the EDN612, ESN212, EPN210

6

3/1531-HSD 101 41 Uen E 2007-08-13

Figure 2 60-line ETSI Subrack with EDN612, ESN212, EPN210 and

Splitters

Page 11

Power Requirements and Distribution

3/1531-HSD 101 41 Uen E 2007-08-13

7

4 Power Requirements and Distribution

EDN612 and ESN212 use -48 volt power supply. Either High Ohmic

distribution system, or independent power distribution (Standard -48V

telecom supply) according to ETSI EN 300 132-2 v2.1.2 (2003 09) can be

used. 15A fuse is required. It is recommended to use EPN210 for the

power distribution as illustrated in the following figure:

Figure 3 Recommended Power Distribution

If another power distribution unit is used instead of the EPN210, it is

possible to use the TSR 263 65/xxx cables (EDA Power Cable Open End).

A solution to omit the EPN210, and use the 5:1 power distribution cable as

illustrated in the following figure:

Figure 4 Power Distribution

Note: The fuse is not part of any cable, and is purchased separately.

-48 VDC

Fuse

10 – 15A

EDN612

EDN612

ESN212

Cable: TSR 263 72/xxx

(EDA Power cable 5:1 open ended)

-48 VDC

Fuse

15A

EDN612

EDN612

ESN212

Cable: TSR 263 69/3000

(EDA D-Sub Power cable open

ended

)

Cable: TSR 263 70/600

(EDA Power cable standard)

EPN210

Page 12

Power Requirements and Distribution

8

3/1531-HSD 101 41 Uen E 2007-08-13

Open ended cables use the following coloring scheme:

Gray: 0 V (the 0 V is connected internally to the chassis in all devices)

Black: -48 V

When using EPN210 to distribute power to EDN312x it is recommended to

use the following configuration:

Figure 5 EPN210 Distributing Power to EDN312x

Note that when EDN312x is powered from an EPN210, there can be no

traffic uplink redundancy.

-48 VDC

Fuse

15A

EDN312x

EDN312x

Cable: TSR 263 69/xxx

(EDA D-Sub Power cable open

ended

)

Cable: TSR 263 71/xxx

(EDA Power cable RJ-45)

EPN210

Page 13

Environmental and Space Requirements

3/1531-HSD 101 41 Uen E 2007-08-13

9

5 Environmental and Space Requirements

The nodes complies with the following standards regarding storage,

transportation and operation. The operation category is also designated

stationary in-use at weather-protected locations.

• ETS 300 019-1-1: Storage, class 1.2

• ETS 300 019-1-2: Transportation, class 2.3

• ETS 300 019-1-3: Operation, class 3.3

• GR-3108-CORE class 3 operational temperature range (-40°C to 75°C)

The storage class 1.2 means tested for storage in weather-protected area,

not temperature-controlled.

The transportation class 2.3 means tested for public transportation.

The operation class 3.3 means tested for not partly temperature-controlled

location.

Caution!

The temperature within a rack assembly may be higher than the ambient

room temperature. Check that the rack environment temperature is within

the specified operating temperature range.

The nodes can be mounted in Ericsson subracks prepared for installation in

a 19” or ETSI rack. For detailed information, please see the Subracks

Installation Guide and Micro Outdoor Cabinet Installation Guide.

Mounting in the rack must be done in such a way that there is sufficient

space to allow airflow around the node as shown in Figure 6 on page 10.

Page 14

Environmental and Space Requirements

10

3/1531-HSD 101 41 Uen E 2007-08-13

Min.

50 mm

Min.

50 mm

Min.

70 mm

Mounting

rods

Min.

80 mm

Min. 300 mm

Min. 285 mm

(though only 250 mm

if installed in an EDA

1200 subrack with

Airguides)

Figure 6 Space Requirements when Mounting a Node

When the nodes are installed in the EDA subracks with air guides, the

subracks are mounted directly on to of one another. The following

requirements apply when using the EDA 1200 subracks:

Subrack

235 mm

15 mm

50 mm

Air guide

60 mm

Mounting

flange

Figure 7 Subrack Space Requirements

Page 15

Installation

3/1531-HSD 101 41 Uen E 2007-08-13

11

6 Installation

6.1 Preparation for Installation

The subrack is delivered in a cardboard box including assembly

instructions.

In Figure 8 on page 11 the assembled empty subrack is shown.

Figure 8 Assembled ETSI subrack

6.2 Mounting the EDN612, ESN212 and EPN210

Nodes

The EDN612, ESN212 and EPN210 nodes are mounted in the subrack

according to Figure 9 on page 12. The nodes can be mounted in different

ways see tables in section 3 on page 4.

Page 16

Installation

12

3/1531-HSD 101 41 Uen E 2007-08-13

Figure 9 Example of a mounted Subrack

6.2.1 Setting the Switch ID in ESN212

When the ESN212 SID value is different than zero, the Node controller in

the ECN will consider the ESN212 and the underlying nodes as a flexible

block with the SID value of the DIP switch. Note that value 255 is reserved

and cannot be used.

The Switch is located at the top of the ESN212, under the Fan assembly.

The DIP switch has eight on-off switches by which a binary value (0 – 255,

though 255 is reserved) is set.

Setting a switch to on, sets a bit to one, setting it to off, sets the bit to zero.

The following table shows some examples of switch settings and the

resulting SIDs:

EDN612 ESN212 EPN210

1

Ethernet connection

2

Power connection

3

Subscriber connection

4

External power connection

Page 17

Installation

3/1531-HSD 101 41 Uen E 2007-08-13

13

Table 5 SID Examples

DIP Switch Setting SID value

0

1

2

10

To set the SID do the following:

1. Remove the front cover of the fan assembly by inserting a flat

screwdriver in the bottom left side, turning it to open the cover and pool

the cover.

2. Insert a finger into the hole in the front and pull the fan assembly out.

1 2 3 4 5 6 7 8ON

1 2 3 4 5 6 7 8ON

1 2 3 4 5 6 7 8ON

1 2

1 2 3 4 5 6 7 8ON

Page 18

Installation

14

3/1531-HSD 101 41 Uen E 2007-08-13

3. Take out the rubber cover with a flat screwdriver

4. Set the DIP switch to the desired position

5. Put the rubber cover back in place

6. Press the fan unit into the cover. Do not press on the fan rotor or

motor. Slide the fan assembly onto the node, while holding the fan unit

pressed in the cover. Press until the fan assembly front is aligned with

the front of the node.

Page 19

Installation

3/1531-HSD 101 41 Uen E 2007-08-13

15

7. Mount the front cover back in place, sliding the right side in first and

then pressing the left side of the front cover.

6.2.2 Mounting the Hardware

All nodes are mounted on the rods in the same way. Insert the node on the

top rod first and than the bottom. Push the node firmly onto both rods.

6.2.3 Cabling of Ethernet Connections (No.1)

The EDN612 IP DSLAM is connected to the network (ESN212 switch)

using TSR 432 120/700 cable (1000 Base-T Patch cable STP).

In Figure 9 on page 12 (No. 1) shows Ethernet connections between the

EDN612 Uplink ports and the ESN212 downlink ports.

1

2

Page 20

Installation

16

3/1531-HSD 101 41 Uen E 2007-08-13

6.2.4 Cabling the Power Connections (No.2 and No.4)

The EDN612 IP DSLAM and ESN212 switch are connected to the EPN210

Power Distribution using TSR 263 70/600 cable (EDA Power cable

standard).

The cable connectors are fastened to the nodes by using a Torque-driver

with TORX T08 bit (0.3 Nm recommended). Figure 9 on page 12 (No. 2)

shows power connections.

The EPN210 Power Distribution Node is connected to an external power

distribution using TSR 263 69/3000 (EDA D-Sub Power cable open ended)

see details about the power requirements and distribution in section 4 on

page 7. Figure 9 on page 12 (No. 4) shows the external power distribution

connectors.

6.2.5 Cabling the Subscriber Line (No.3)

The EDN612 IP DSLAM is connected to the splitter using EDA Subscriber

cable. The subscriber cable is produced in different lengths. The following

cables are available:

Table 6

Ericsson no. Description

TSR 432 126/3000 EDA Subscriber cable open ended

3m

TSR 432 126/10M EDA Subscriber cable open ended

10m

TSR 432 138/500 EDA Subscriber cable Edge

connector 500mm

TSR 432 138/800 EDA Subscriber cable Edge

connector 800mm

To connect the subscriber lines cable align the cable connector with the

connector on the EDN612, and insert the connector gently.

!

Page 21

Installation

3/1531-HSD 101 41 Uen E 2007-08-13

17

Fasten the connector to the EDN612 using a Torque-driver with TORX T08

bit (0.3 Nm torque recommended). Figure 9 on page 12 (No. 3) shows the

subscriber cable connectors.

Figure 10 on page 17 shows the splitter connections.

Figure 10 Edge Connector with Splitter Connections

If it is desired to make a cable instead of using the standard cable it is

possible to do so using TFL 301 5202/12 cable and RNV 247 096/1

connector (subscriber connector). Use the EDA Subscriber hand tool (LSY

901 54) to connect the cable to the connector.

Figure 11 on page 18 shows the subscriber cable (color code according to

IEC 189-2) between the EDN612 and the splitter.

Connection to EDN612

Connection to Exchange Connection to Line

Page 22

Installation

18

3/1531-HSD 101 41 Uen E 2007-08-13

Figure 11 Subscriber Cable

6.2.6 SFP Cages for ESN212

The SFP cages enable the use of different SFP modules for the ESN212

switch depending of the use. These ports may be used as uplinks or as

downlinks. The following modules are available:

Table 7

Module Ericsson no. Description

SFP SX 500M ROA 128 0839/1

Short-wavelength SFP transceiver with max

500 m reach

SFP LX 10KM ROA 128 0839/2

Long-Wavelength SFP Transceiver for reach

up to 10 km

SFP LX 35KM ROA 128 0839/3

2 Gigabit Long-Wavelength SFP Transceiver

with max 35 km reach

Page 23

Installation

3/1531-HSD 101 41 Uen E 2007-08-13

19

Module Ericsson no. Description

SFP LX 80KM ROA 128 0839/4

2 Gigabit Long-Wavelength SFP Transceiver

with max 80 km reach

SFP FCLF8520/8521-3

RYT 921 605/1

10/100/1000 BASE-T Electrical SFP

transceiver

Note: The above mentioned SFP modules may have a different operating

temperature range than the ESN212.

6.3 Mounting the Front Cover for the Cable Tray

After all cables have been mounted the front cover for the cable tray has to

be mounted according to Figure 12 on page 19.

Figure 12 Mounting the Front Cover

Page 24

Initial Configuration and Commissioning

20

3/1531-HSD 101 41 Uen E 2007-08-13

7 Initial Configuration and Commissioning

7.1 Embedded Nodes

It is not needed to do any configuration for either ESN212 or EDN612. The

default settings for the ESN212 switch are following:

• IGMP Snooping Enabled

• DHCP Interception Enabled

• Management VLAN 247

• Untagged Management VLAN 1

• RSTP and MSTP Disabled

7.2 Stand Alone ESN212

When the ESN212 is not embedded it must be configured for static IP and

for the management VLAN. To make the initial configuration a terminal (or

a PC with a terminal emulation application such as HyperTerminal) and a

consol connection cable are needed. The consol cable is not delivered with

the ESN212.

Consol Connection Cable

Use a standard straight through LAN cable with a standard converter, or

make a cable with the following connections:

Page 25

Initial Configuration and Commissioning

3/1531-HSD 101 41 Uen E 2007-08-13

21

Figure 13 RJ-45 and D-SUB 9 Pin Numbering

Table 8 Console Cable RJ-45 to D-SUB 9 Pin Assignment

RJ-45 Pin Signal Name D-SUB 9

1 Not used -

2 Not used -

3 Not used -

4 ------- Ground ---------- 5

5 RXD -----<-------- TXD 3

6 TXD ------->------ RXD 2

7 Not used -

8 Not used -

1. Connect the cable to the Console terminal

2. Set the following setting in the terminal emulation application:

• Data rate to 9600 baud.

• Data format to 8 data bits, 1 stop bit, and no parity.

• Flow control to none, emulation mode to VT100

3. Logon to the ESN212 with the username admin and password admin.

4. Set the management VLAN to the VLAN used in the network (if this

VLAN is different from 247. For example 246:

5

1

6

9

RJ45

1

8

D-SUB 9 female

Page 26

Installing and Upgrading the Software

22

3/1531-HSD 101 41 Uen E 2007-08-13

ESN212# management vlan 246

5. Configure IP parameters. In the following example the following

parameters are set:

− IP address 172.30.10.100

− Subnet mask 255.255.255.0

− Trap receiver 172.30.10.10

− SNTP server 172.30.10.10

− Default gateway 172.30.10.1

Note that Trap receiver, SNTP server and default gateway must be

configured even though they might be overwritten by a management

system (PEM for example).

esn212# boot mode manual ip address 12.30.10.100

255.255.255.0 trap receiver 12.30.10.10 sntp server

12.30.10.10 def gateway 12.30.10.1

6. Restart the ESN212:

esn212# restart

Note that the settings are automatically saved. It is therefore not necessary

to save them manually before the restart.

8 Installing and Upgrading the Software

Both application and boot SW of the ESN212 and EDN612 is upgraded

from the ECN330 Ethernet Controller Node (CLI) or from a management

system. See the management system documentation or the ECN330 User

Guide for instructions.

Page 27

Verification of the Installation

3/1531-HSD 101 41 Uen E 2007-08-13

23

9 Verification of the Installation

Verification of the installation is done through the Ethernet Controller Node.

See the ECN330 Installation Guide for instructions.

Page 28

Ericsson AB

© Ericsson AB 2006-2007. All Rights Reserved

www.ericsson.com 3/1531-HSD 101 41 Uen E 2007-08-13

Loading...

Loading...