Page 1

Service Instructions

Ericsson Mobile Phone EF738

Page 2

Service Instructions

2

Page 3

Service Instructions

g

Contents

System Connector Signals ____________________________ 5

Disassembly________________________________________ 6

Reassembly ________________________________________ 7

Flip Mount Inspection______________________________________ 8

Warranty Seal ____________________________________________ 8

Exchanging the Circuit Board_________________________ 9

Fault Findin

Sequence of Adjustments __________________________________ 11

Item 1: VCTCXO ____________________________________________ 11

Item 2: RSSI Calibration ______________________________________ 12

Item 3: RF Output Power ______________________________________ 13

Item 4: Maximum Deviation ___________________________________ 14

Item 5: Nominal Deviation_____________________________________ 15

Item 6: SAT Deviation ________________________________________ 16

Item 7: TX Data Deviation_____________________________________ 17

Item 8: AFMS and Harmonic Distortion __________________________ 18

Item 9: Receiver Sensitivity ____________________________________ 19

and Alignment ________________________ 10

3

Page 4

Service Instructions

4

Page 5

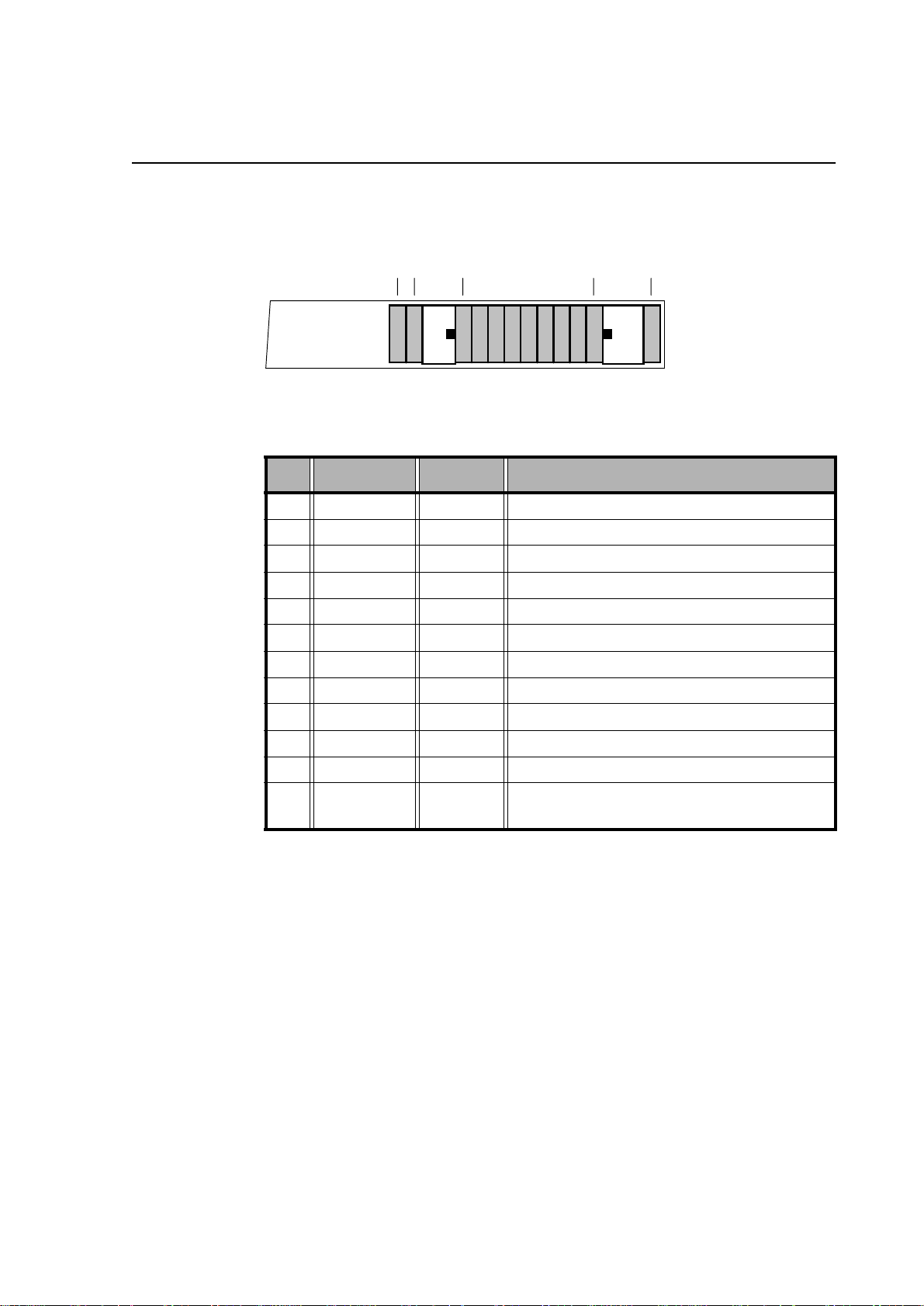

System Connector Signals

External units are connected to the Transceiver Board via the 12-pin System Connector.

12 3 11 12

Pin Signal In/Out Function

1 AFMS Out Audio From Mobile Station

Service Instructions

2 ATMS In Audio To Mobile Station

3 EXTAUD In External Analog Audio Accessory Sense

4 AGND Audio Signal Ground, 0V reference

5 PORTHF In Portable Handsfree

6 MUTE Out Music Mute

7 VPPFLASH In Flash Memory Voltage and Service Voltage

8 VDD Out Logic Reference, Status ON

9 DFMS Out Data From Mobile Station

10 GND Digital Ground and DC Return

11 DTMS In Data To Mobile Station

12 DCIO In/Out DC positive pole for phone battery charging

and external accesso ry powering

5

Page 6

Service Instructions

y

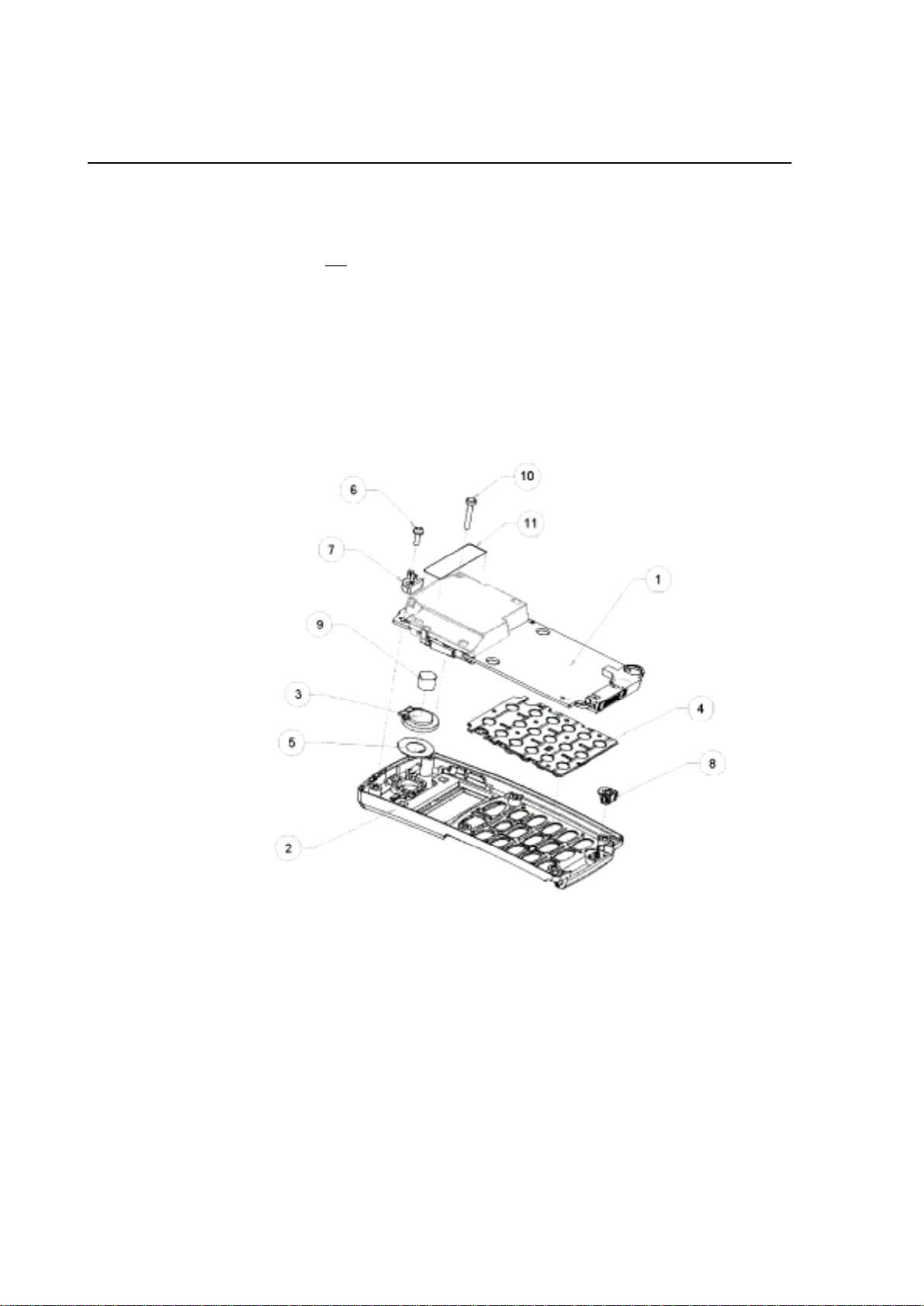

Disassembl

1. Remove the battery and the antenna

Before opening the unit for further disassembly, make sure that the parts can be

placed on a

NOTE!

2. Place the phone on its front and remove four screws with the appropriate torx

screwdrivers.

3. Remove the back cover carefully from underneath.

4. Loosen the remaining screws (6, 10).

Be careful not to damage the antenna connector (7).

5. Careful ly remove the board (1) from the front cover (2) by lifting it upwards.

6. Remove the keypad (4).

dust-free ESD-protected surface

Do not

touch the display with your fingers!

.

6

Page 7

Reassembl

y

1. Place a front cover (2) on the workbench

2. Carefully place the board (1) into the front cover with the shield can upwards.

3. Drop a screw (10) into the upper right corner hole in the board.

4. Drop an antenna connector (7) into the placement cavity of the antenna connec-

5. Drop a screw (6) into the screw hole in the antenna connector.

6. Mount the back cover (13) on the front cover (12).

7. Drop the four screws (14) into the holes on the back cover.

8. Mount the antenna by screwing it clockwise i nto the thread.

9. Insert the battery pack into the phone and push until a click is heard.

Service Instructions

Assemble the keypad (4).

NOTE! Do not touch the display with your fingers

Tighten the screw with a screwdriver (0.15Nm).

tor placement guide.

Ensure that the locat ing posts of the antenna connector are positioned in the mating holes of the board.

Tighten the screw with a scredriver (0.15Nm).

Hold down the lower part of t h e ba ck c over against the front co ver and press the

upper part of the phone together.

Tighten the screws with a screwdriver (0.15Nm).

7

Page 8

Service Instructions

Flip Mount Inspection

After mountin g the flip;

Hold the telephone upside down and check that the flip is not open.

The flip must be closed as shown in

fig. 1

; not open as shown in

fig. 2

.

Fig. 1: Flip Closed

Fig. 2: Flip Open

Warranty Seal

Place the warranty seal over the right hand torx screw at the bottom.

8

Page 9

Exchanging the Circuit Board

1. Transfer t he EEPROM con ten ts of the phone to the PC a s d esc ribed in section 3,

Test/Service Programs

2. Disassemble as previously described in this section.

3. Exchange the board.

4. Reload the EEPROM customer data into the phone.

5. Check the function of the phone and, if necessary, align as described next in

Fault Finding and Alignment

.

.

Service Instructions

9

Page 10

Service Instructions

Fault Finding and Alignment

The table below shows information about test points and test data of the radio and

logic/audio parts of the board. Th is info rmation wi ll beco me an aid in tes ting as well

as fault finding. In general, the following procedure can be used:

1. Align the boards in the sequence stated below.

2. If a specific value cannot be obt ained, use th e tools mentioned in step 3 below to

trace the reason.

3. The built-in

investigated, and any signal data that may be required is found in the section

Connectors and Signals

nector pins is found.

The telephone is tested, unless otherwise explicitly stated, with DC-power 6.2V

supplied via a dummy battery.

Channel 1 TP-1:1 (RX = 935.0125MHz, TX = 890.0125MHz)

RF Power Off TP-2:8

AFC Active TP-15:2

T e st Pr ogr am

, where the distribution of signals at the respective con-

will provide acces s to the functi on or si gnal to b ecome

Audio Switches On TP-20:3 (TX & RX audio paths unmuted)

SAT Tone Off TP-22:3

Manchester Out Off TP-23:0

Volume 4 TP-25:4 (mid range)

TX Source ATMS TP-27:0

Earpiece External TP-28:2

Compandor Disabled TP-29:0 (disabled)

Softlimiter Off TP-32:0

Green LED Off TP-41:MENU+4:0

Red LED Off TP-41:MENU+5:0

ICTRL Off TP-41:MENU+2:0

Illumination Off TP-41:MENU+6:0

TP = Test Program

The above settings are automatically executed when entering the test program.

For detailed information regarding the adjustments, re fer to subsection

gram

in this section.

Test Pro-

10

Page 11

Service Instructions

Sequence of Adjustments

Item 1: VCTCXO

Purpose:

Checking and, if nece ssary, calibrating the reference fre quency gene rator for the

synthesizers

Test method:

Radio test set in TX mode, measured with a frequency counter

Input signal:

None

Measurement point:

Transmitter frequency at antenna connector

Limit:

890.0125MHz ±200Hz

Procedure:

1. Turn on the transmitter (

2. Disable the AFC (

3. Check the frequency error

4. If the transmitter frequency is not within 890.0125MHz ±200Hz;

enter VCTCXO calibra tion (

5. Press M + # to enable the calibration

6. Use # and * buttons to change value and press M + S to store the new value

TP-2:2

TP-15:0

)

TP-18

)

:)

11

Page 12

Service Instructions

Item 2: RSSI Calibration

Purpose:

Calibration of the RSSI (received signal strength indicator)

Test method:

Radio test set in RX mode

Input signal:

Apply 935.0125MHz RF signal modulated with a 1kHz tone at 5.7k Hz devi ati on at

a level of -115dBm to the antenna connector

Measurement point:

None

Limit:

-115dBm 20 < value < 150

-107dBm 30 < value < 218

-87dBm 50 < value < 279

Procedure:

1. Apply 935.0125MHz RF signal modula ted with a 1kHz t one at 5.7kHz de viation

2. Turn the transm itter on (

3. Disable the AFC (

4. Enter RF sensitivity test (

5. Press M +

6. Press M + # to move to next adjustment

7. Set the signal generator to -107dBm

8. Press M + S to store the value

9. Press M + # to move to next adjustment

10.Set the signal generator to -87dBm

11.Press M + S to store the value

at a level of -115dBm to the antenna connector

TP-2:2

TP-15:0

S

)

TP-9

)

)

12

Page 13

Service Instructions

Item 3: RF Output Power

Purpose:

Checking and, if necessary, calibrating the RF output power

Test method:

Radio test set in TX mode

Input signal:

None

Measurement point:

Output power at the antenna connector measured with an RF power meter

Limit:

Power level Output power

2 +26.5dBm ±0.1dB

3 +22.5dBm ±0.5dB

4 +18.5dBm ±0.5dB

5 +14.5dBm ±0.5dB

6 +10.5dBm ±0.5dB

7 +6.5dBm ±1.0dB

Procedure:

1. Turn the transm itter on (

Check if the output power is within the above stated limits

Check the output power at low (1329), mid (1), and high channels (600)

2. If the output power is not within the above stated limits;

TP-5

use

3. Press M + # to start the calibration and display power level and calibrated value

4. Use # and * to increase/decrease the output power

Press M + S to store the value and step to next power level

5. Press C to turn off TX, restore channel number, and jump to menu 0 (test input)

to calibrate the output power

TP-2:2-7

)

13

Page 14

Service Instructions

Item 4: Maximum Deviation

Purpose:

Checking and, if necessary, calibrating the maximum deviation of the transmitter

Test method:

Radio test set in TX mode

Input signal:

1kHz sine wave signal at 320mV

Measurement point:

At the antenna connector measured with a deviation meter

Tolerance:

±7.2kHz -1dB (6.462 - 7.200 kHz)

Procedure:

1. Set TXSENS programmable gain stage to nominal value (

2. Enable the compandor (

3. Connect a 1kHz sine wave signal at 320mV

4. Turn the transm itter on (

5. Monitor RF peak deviation

6. If the deviation is outside the limits; adjust the deviation

7. Enter

8. Start the trimming by pressing M +

9. Trim audio deviation to 6.462 - 7.200 kHz by pressing # and * to increase/

10.Press M + S to store the value

TP-29:1

TP-2:2

TP-14

decrease the deviation

Allowed trim values are 2 to 13

Trim step size is 0.4dB per step

to ATMS (system connector)

RMS

)

to ATMS (system connector)

RMS

)

#

TP-7

, value 7)

14

Page 15

Service Instructions

Item 5: Nominal Deviation

Purpose:

Checking and, if necessary, calibrating the nominal deviation of the transmitter

Test method:

Radio test set in TX mode

Input signal:

1kHz sine wave signal at 190mV

Measurement point:

At the antenna connector measured with a deviation meter

Limit:

±5.7kHz ±0.5dB (5.38 - 6.02 kHz)

Procedure:

1. Enable the compandor (

2. Connect a 1kHz sine wave signal at 190mVRMS to ATMS (system connector)

3. Turn the transm itter on (

4. Monitor RF peak deviation

5. If the deviation is outside the limits; adjust the deviation

6. Enter

7. Start the trimming by pressing M +

8. Trim audi o d evi at ion to 5.38 - 6.02 k Hz b y p res si ng # and * to increase/decrea se

9. Press M + S to store the value

TP-27

the deviation

Allowed trim values are 2 to 29

Trim step size is 0.4dB per step

TP-29:1

TP-2:2

to ATMS (system connector)

RMS

)

)

#

15

Page 16

Service Instructions

Item 6: SAT Deviation

Purpose:

Checking and, if necessary, calibrating the SAT (Supervisor Audio Tone) deviation

of the transm itter

Test method:

Radio test set in TX mode

Input signal:

None

Measurement point:

At the antenna connector measured with a deviation meter

Limit:

±1.7kHz ±0.5dB (1.60 - 1.80 kHz)

Procedure:

1. Mute the TX audio path (

2. Activate the SAT-tone (

3. Unmute the TX SAT path (

4. Turn the transm itter on (

5. Monitor the SAT deviation

6. If the deviation is outside the limits; adjust the deviation

7. Enter

8. Start the trimming by pressing M + #

9. Trim SAT deviation to 1.60 - 1.80 kHz by pressing # and * to increase/decrease

10.Press M + S to store the value

TP-20:0

TP-22:1

TP-22:4

TP-2:2

TP-22

the deviation

Allowed trim values are 2 to 29

Trim step size is 0.3dB per step

)

)

)

)

16

Page 17

Service Instructions

Item 7: TX Data Deviation

Purpose:

Checking and, if necessary, calibrating the TX da ta deviation of the transmitter

Test method:

Radio test set in TX mode

Input signal:

None

Measurement point:

At the antenna connector measured with a deviation meter

Limit:

±6.4kHz ±0.5dB (6.021 - 6.780 kHz)

Procedure:

1. Mute the TX audio path (

2. Activate the TX Data (

3. Turn the transm itter on (

4. Monitor the TX data deviation

5. If the deviation is outside the limits; adjust the deviation

6. Enter

7. Start the trimming by pressing M +

8. Trim TX Data Deviation to 6.021 - 6.780 kHz by pressing # and * to increase/

9. Press M + S to store the value

TP-23

decrease the deviatio n

Allowed trim values are 2 to 13

Trim step size is 0.4dB per step

TP-20:0

TP-23:1

TP-2:2

)

)

)

#

17

Page 18

Service Instructions

Item 8: AFMS and Harmonic Distortion

Purpose:

Checking and, if necessary, calibrating the deviation of the receiver

Test method:

Radio test set in RX mode

Input signal:

Apply a -50dBm 935.0125MHz RF signal modulated with a 1kHz tone, ±2.3kHz

deviation to the antenna input

Measurement point:

At the AFMS output from the system connector measured with an AC volt meter

Limit:

25mV ±1.5dB (21.035 - 29.710 mV)

Procedure:

1. Enable the compandor (

2. Apply a -50dBm 935.0125MHz RF signal modulated with a 1kHz tone, ±2.3kHz

3. Monitor the AFMS output with a 100kΩ load

4. If AFMS is outside the limits; adjust the AFMS level

5. Enter

6. Start the trimming by pressing M +

7. Trim the AFMS level by pressing # and * to increase/decrease

8. Press M + S to store the value

9. Measure the receiver harmonic distortion

10.Should be less than 4.5% at AFMS using a CCITT filter

TP-29:1

deviation to the antenna input

TP-10

)

#

18

Page 19

Service Instructions

Item 9: Receiver Sensitivity

Purpose:

Checking the receiver sensitivity

Test method:

Radio test set in RX mode

Input signal:

Apply an RF signal at low, mid, and high channel modulated with a 1kHz tone at

5.7kHz deviation at a level of -113dBm to the antenna input

Measurement point:

At the AFMS output from the system connector measured with an AC volt meter

Limit:

Better than 20dB SINAD at low, mid, and high channel

Procedure:

1. Select channel (

2. Disable AFC (

3. Turn the transm itter on

4. Apply an RF signal at low, mid, and high channel modula ted wi th a 1kHz to ne at

5.7kHz deviation at a level of -113dBm to the antenna input

5. Measure better than 20dB SINAD on AFMS using a CCITT filter

TP-1:1329, 1, or 600

TP-15:0

)

(TP-2:2

)

)

19

Page 20

Service Instructions

20

Loading...

Loading...