Ericsson EDACS MTL Maintenance Manual

LBI-38632A

MAINTENANCE MANUAL

EDACS MTL 800 MHz

SERVICE SECTION

TABLE OF CONTENTS

Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TEST EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FRONT COVER TEST ACCESSORY KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FUNCTIONAL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DISASSEMBLY /REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ALIGNMENT PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SET-UP PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TRANSMITTER ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RECEIVER ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TRACKING AND CHANNEL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

REAR COVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FRONT COVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

COMPONENT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SURFACE MOUNTED COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SURF ACE MOUNTED COMPONENT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SURFACE MOUNTED COMPONENT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 24

SURFACE MOUNTED IC REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MODULE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

INTERNAL LITHIUM BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

WEATHERPROOF INTEGRITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

BATTERY PACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHARGING THE BATTERY PACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

REDUCED CAPACI TY CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

RECHARGEABLE BATTERY PACK DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CONTROL KNOB STOP PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

STOP PLATE REPOSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MODULE AND INTEGRATED CIRCUIT DAT A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

INTRODUCTION

This manual outlines service procedures for the EDACS

MTL 800 MHz portable radio. Information includes radio

disassembly and reassembly procedures, RF alignment and

component-level troubleshooting steps. Information is also

included for tracking and channel data, surface mounted

component replacement, weatherproofing procedures, and

service data on the batteries. Module and integrated circuit

data sheets are listed at the end of this manual.

In order to perform many of the following alignments,

tests and troubleshooting checks, it will be necessary to

(re)program the radio. Further programming information can

be found in the EDACS Programming Manual and software

TQ-3364.

It is suggested that an improperly operating radio be first

bench tested thoroughly in conventional mode. This allows

the technician, using standard test equipment, to verify the

majority of the radio’s circuitry is functional. Any necessary

repairs can be completed and the radio can then be tested in

1

LBI-38632

trunked mode using an available site and/or a second

EDACS portable or mobile radio.

Conventional mode testing can (and will) verify proper

operation of all of the radio’s circuitry w ith the following

exceptions:

• modem IC operation

• data modulation and demodulation circuity

• trunked mode associated areas of the radio’s memory

TEST EQUIPMENT

The following is a list of test equipment which may be

required to troubleshoot and/or align the portable radio.

GENERAL

• RF Signal Generator

• RF Wattmeter with 5-Watt capability

• Audio Distortion Analyzer with V u Meter

• Oscilloscope with x1 and x10 Probes

• Audio Oscillator

• Frequency Counter

• Modulation Analyzer

• SINAD Meter

• SPK9010 Front Cover Test Accessory Kit:

19D902562P5 Front Cover Test Cable

19D902562P1 LCD Extender Plate & Clamp

19D902562P2 LCD Test Cable

19D902562P6 Test Program Diskette

• SPK9011 Front Cover Test Accessory Kit:

19D902562P3 Adapter Board

19D902562P4 Control Board Extender

• ST3559P2 RF Antenna Adapter (top jack to

BNC female)

• TQ-0609 Test Box (simulates all external

UDC options)

• 19B219079P1 Alignment Tool, 0.1" slotted

(metal) tips

• 19B801640P1 Alignment Tool, 0.1" slotted tips

In addition to the above listed equipmen t, access to a

local trunked site and a second EDACS portable or mobile

radio will be necessary to test trunked mode operation.

PROGRAMMING

• IBM PC Compatible Computer

• TQ-3364 Programming Manual and Software (in-

cludes 5 1/4" and 3 1/2" disks)

• TQ-3310 PC Programming Adapter (Serial Adapter

Box and PC-to-Adapter Box Interface Cable)

• TQ-3311 Radio Programming Cable (Adapter Box-

to-Radio Cable)

• Regulated DC Power Supply, 5 - 9 V dc adjustable, 5

amperes maximum

• Digital Multimeter

SPECIALIZED

• K19/A4WX01542 RF Test Cable (UDC mount)

• K19/A4WX01543 Battery Eliminator ("Dummy

Battery")

• K19/A4WX01544 RF/Logic Extender Cable

• K19/A4WX01604 Discharge Analyzer (checks bat-

tery pack capacity and battery

chargers)

• LBI-38518 Front Cover Test Accessory Kit

Manual

Copyright March 1991, Ericsson GE Mobile Communications Inc.

2

FRONT COVER TEST

ACCESSORY KIT

A Front Cover Test Accessory Kit is available for exercising and troubleshooting the circuits in the front cover.

Connection to an IBM PC or compatible computer (parallel

printer port) allows all of the circuits in the front cover, less

Control Board, to be exercised via the PC computer.

An adapter and extender board in the kit allows the

Control Board to be extended out of the case for troubleshooting access. See the "TEST EQUIPMENT" section

of this manual for a breakdown of the kit.

The Keypad Flex can be exercised without the Control

Board while still in the radio’s case. All of the switches and

the logic circuitry can be tested via the PC conn ection. Status

of the switches is displayed on the PC.

CAUTION

LBI-38632

Test points are provided for the volume control and

microphone audio. A resistor network on the Front Cover

T est Cable provides a dc bias to the mic in the absence of the

Control Board’s bias.

FUNCTIONAL TEST

The following test procedure outlines a functional bench

test of the radio. It may be necessary to (re)program the radio

before proceeding with this test.

1. Power the radio up.

2. Connect a wattmeter and frequency counter to the radio

and select a conventional (test) channel. Press the PTT

Button to key the transmitter and measure RF power and

frequency. See Table 4 for transmitter power specs. See

Table 3 for transmitter frequency error specs.

3. Select a channel that has been programmed f or receive

only. Press the PTT Button. The radio should beep.

4. Select a conventional channel that has been programmed

for Channel Guard decode operation. Press the Monitor

Button to unsquelch the radio. Receiver noise should be

heard from the internal speaker and the noise level

should follow the rotation of the Volume Control. Hold-

ing the Monitor Button for more than approximately two

(2) seconds will toggle CG operation off. Release the

button and press it again. CG operation should toggle

back on after approximately two seconds.

5. Remove t he wattmeter and connect the radio to an RF

signal generator. Test several conventional channels.

Verify receiver specifications.

6. Disconnect the signal generator an d install an antenna.

Select a local trunked system and group. From a second

EDACS portable or mobile radio set to the same system

and group, transmit a group call to the unit under test.

Verify t he unit under t est u nsquelches a nd recei ves the

call.

7. Transmit a group call from the unit under test. V e rify the

call is heard in the second mobile or portable radio.

TOOLS REQUIRED

• TORX

T6 Driver

• M1.5 Hex Driver or Wrench

• Needle-Nose Pliers

• Small Flat-Blade Screwdriver

• Spanner Wrench (top antenna jack)

• Spanner Wrench (UDC antenna jack)

• Spanner Wrench (volume control and group/channel

switch)

Always remove the battery pack before disassembling the unit to avoid blowing the fuse or causing

other component damage.

This radio contains CMOS ICs that can be damaged

by static electricity. Observe static handling precautions.

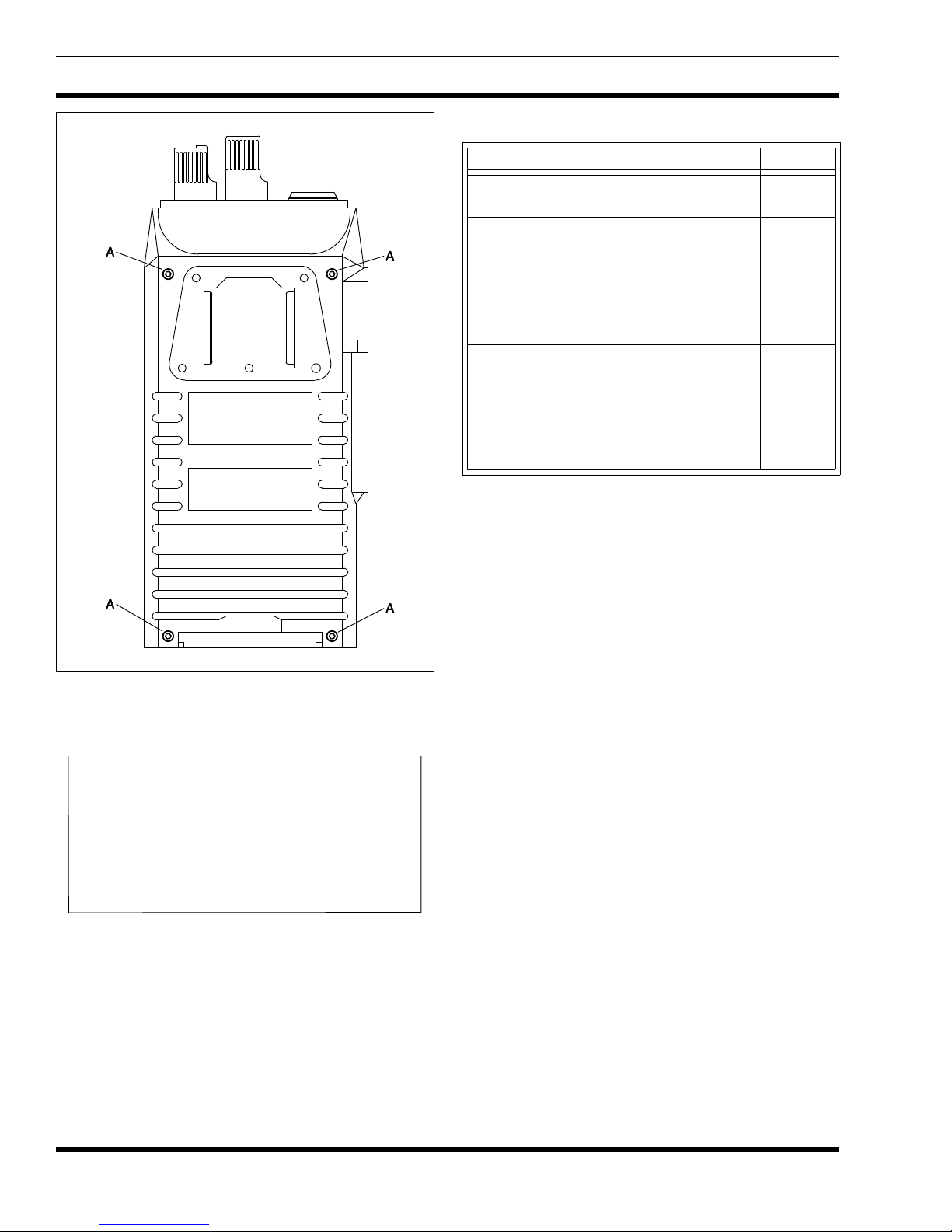

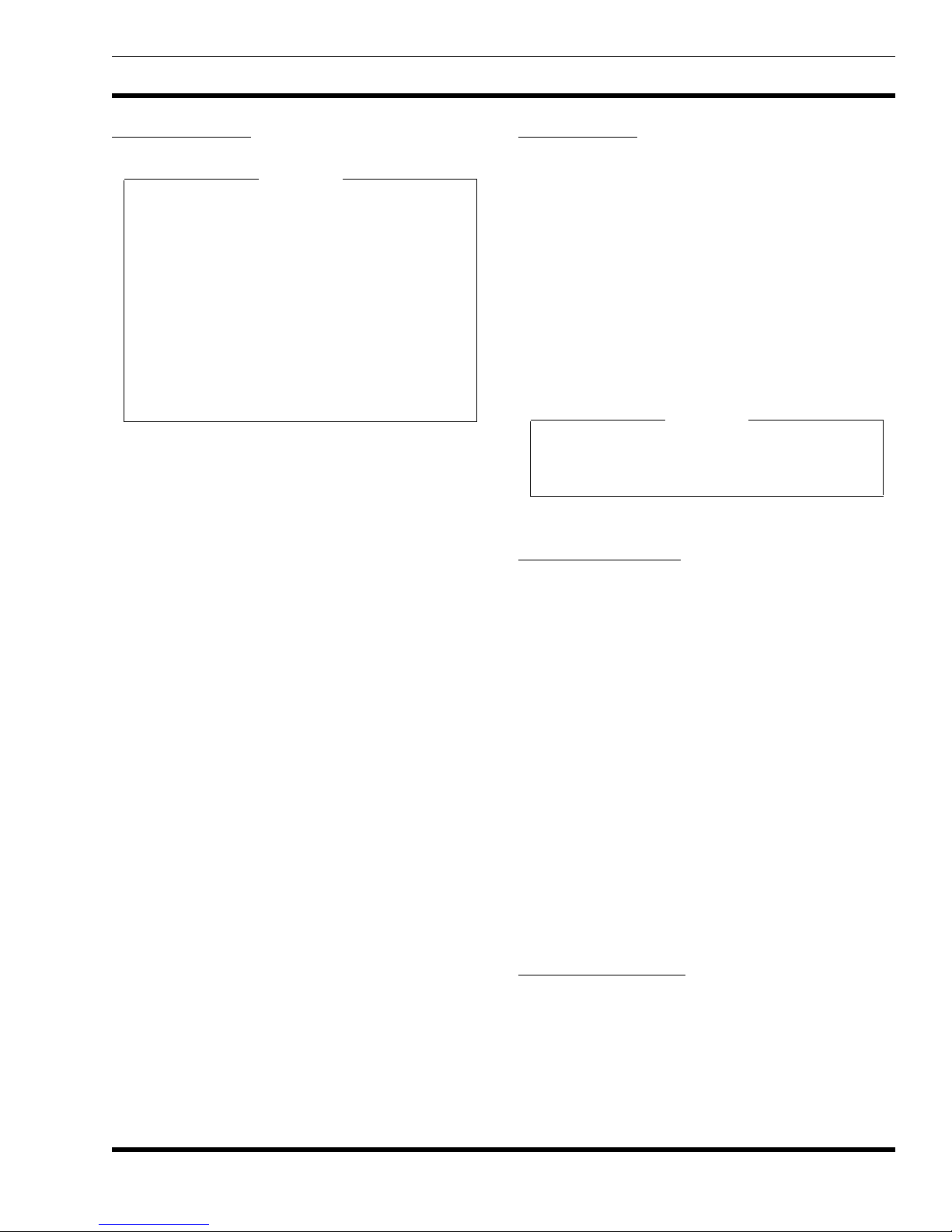

FRONT AND REAR COVER SEPARATION

Lay the radio face down and loosen the four (4) Torx

screws (A) on the back of the radio; complete screw removal

is not necessary. See F ig ure 1. Separate the covers by carefully lifting the Rear Cover Assembly straight-up to avoid

bending the connector pins between the RF and Control

Boards.

When reassembling the unit, verify the rubber gasket

surrounding the perimeter of the cover is in good condition

and it is in the groove. Also verify the connector pins align

properly. For proper operation, the screws should be tightened so there is no gap between the covers. It is recommended that the top screws be tightened first while squeezing

the radio together to ensure the gap is completely closed. The

bottom screws can then be tightened.

DISASSEMBLY / REASSEMBLY

In the event internal service is required, disassemble the

radio in accordance with the following outlined steps. See

Figures 1 - 5.

Reassemble the unit by following the steps in reverse

order. Observe screw lengths and do not over tighten the

screws when reassembling the unit. T orque specifications are

listed in Ta ble 1.

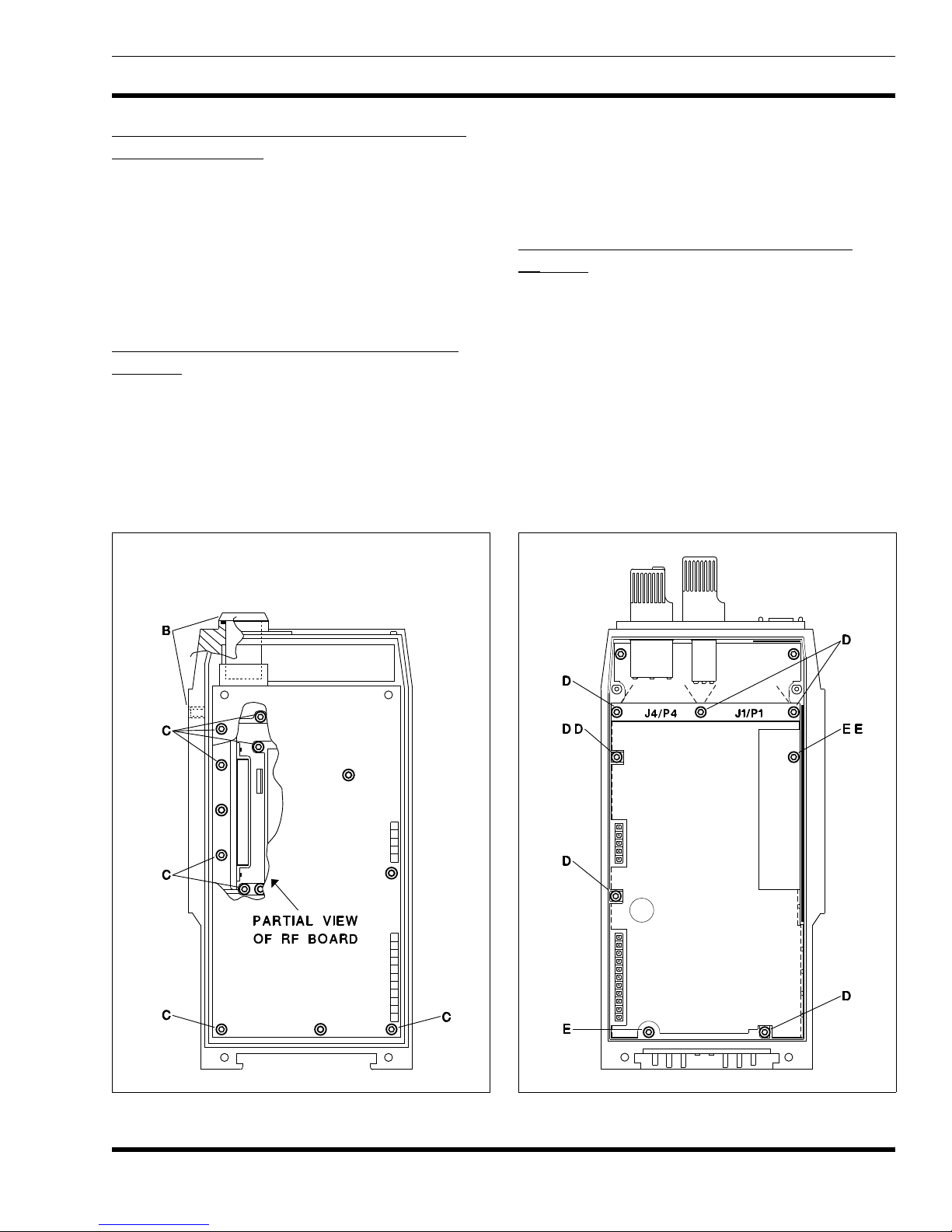

RF BOARD ACCESS

If removal of the RF Board from the case is necessary,

first remove the UDC anten na jack and t he top R F antenna

jack (B). Next, remove the eight (8) Torx screws (C) that

secure the RF Board to the Rear Cover. See Figure 2. The RF

Board and the eggcrate casting can now be lifted from the

rear cover. Two (2) PA mounting Torx screws and five ( 5)

Torx screws on the under-side secure the board to the

eggcrate casting.

3

LBI-38632

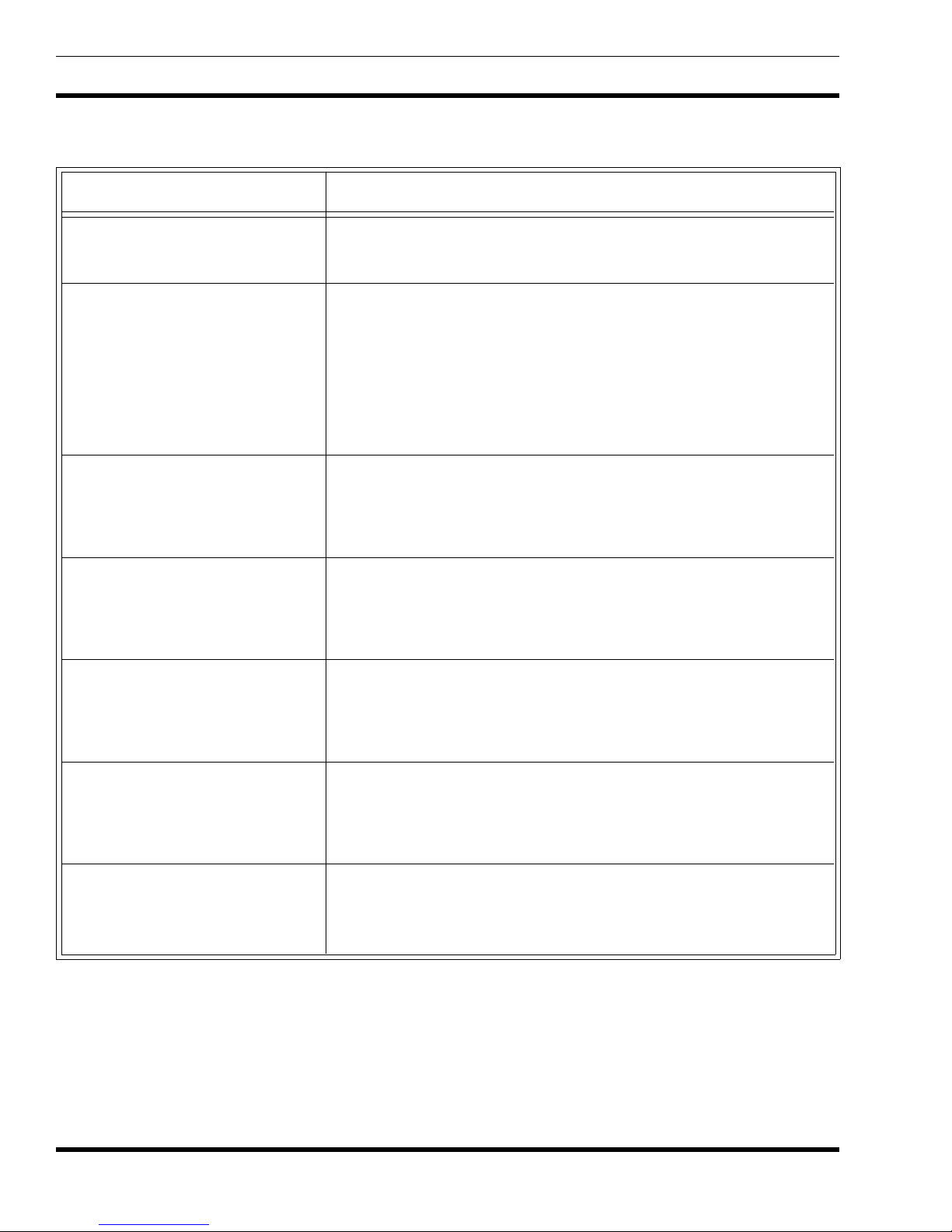

Table 1 - Torque Specifications

LOCATION LB-IN.

Rear/Front Cover Assem bly Screws 5.0

Rear Cover Assembly

Antenna Insert 10.0

UDC RF Connector 10.0

RF Board/Eggcrate Screws 4.0

PA Support Screws 10.0

Antenna Switch (SW1) Screw 1.5

Front Cover Assembly

Knob Set Screws (earlier) 3.0

Knob Set Screws (later) 5.0

Group/Channel and Volume Nuts 8.0

UDC Ground Screw 4.0

All M1.6 and M2 Screws 3.0

Many of the test points on the Control Board are accessible at this point; however, the Front Cover Assembly

should not be powered-up without first reinstalling the screw

into the lower right-hand hole to ground the board. Also, the

three (3) screws securing the top flex connectors need to be

reinstalled for good flex connections. USE CAUTION: Installation of screws that are longer than the o riginals may

damage the flex circuits or the threads.

Figure 1 - Front and Rear Cover Separation

NOTE

The RF shield used in the EDACS M-PA 800 MHz

radio is a press-fit metallized elastomer design. This

shield is not held in place with screws and it remains

in the radio’s Front Cover Assembly when the covers are separated. When reassembling the radio,

make sure the metallized surface of the shield faces

the RF assembly.

CONTROL BOARD ACCESS

To gain partial access to the Control Board, remove the

five (5) screws (D) securing the shield and board. An earlier

Front Cover Assembly has an additional screw located just

below connectors J4/P4 (DD). See Figure 3. Remove the

shield.

To remove the Control Board, remove t he Torx screw

(E) in the lower left-hand corner that supplies battery power

to the board. An earlier Front Cover Assembly has an additional screw located just below connectors J1/P1 (EE). Lift

the board and carefully unplug Speaker Flex plug P3 from

J3 on the Control Board. A void bending this or any other flex

circuits at sharp angles. The Control Board can now be

removed. Note the battery power and ground connections at

the bottom of the board where the screws have been removed.

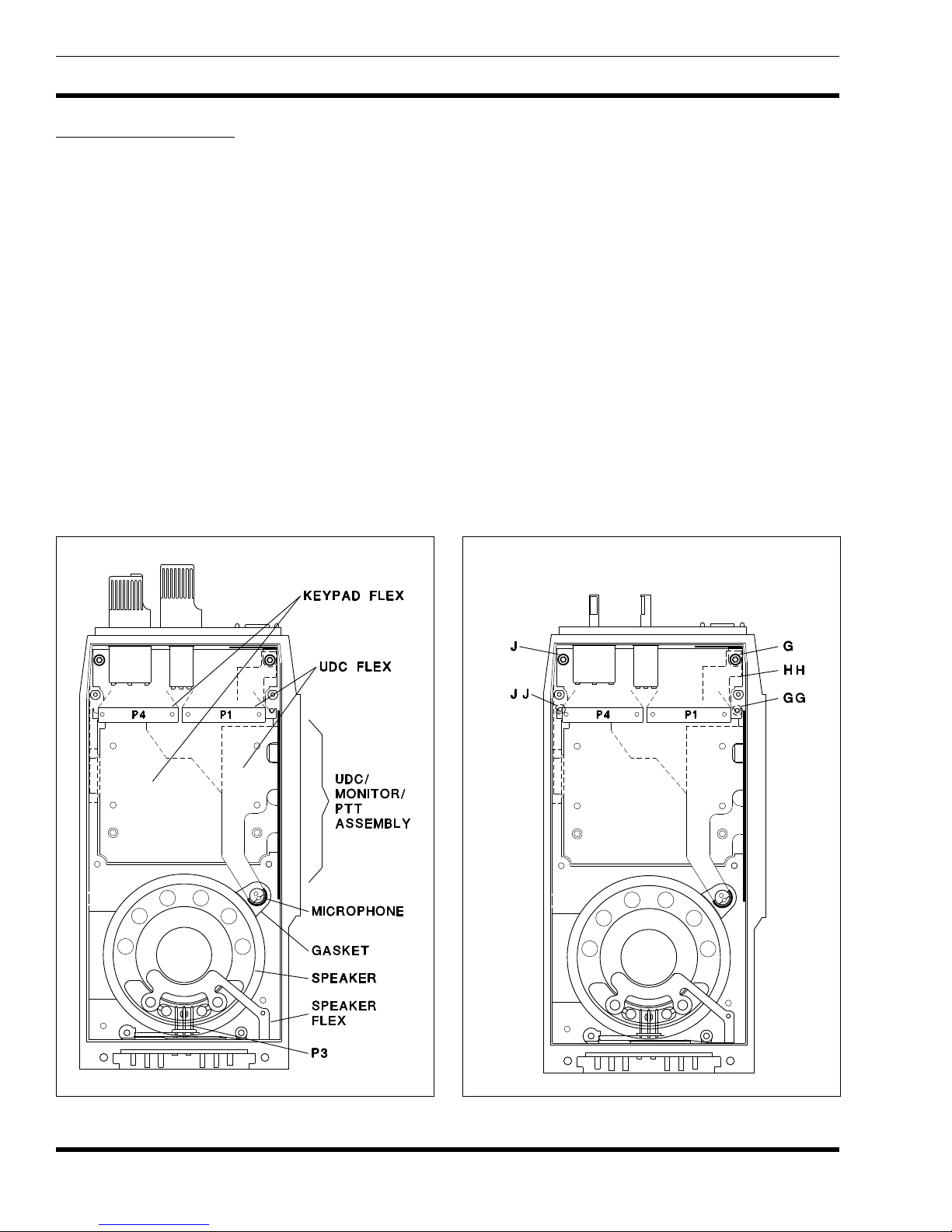

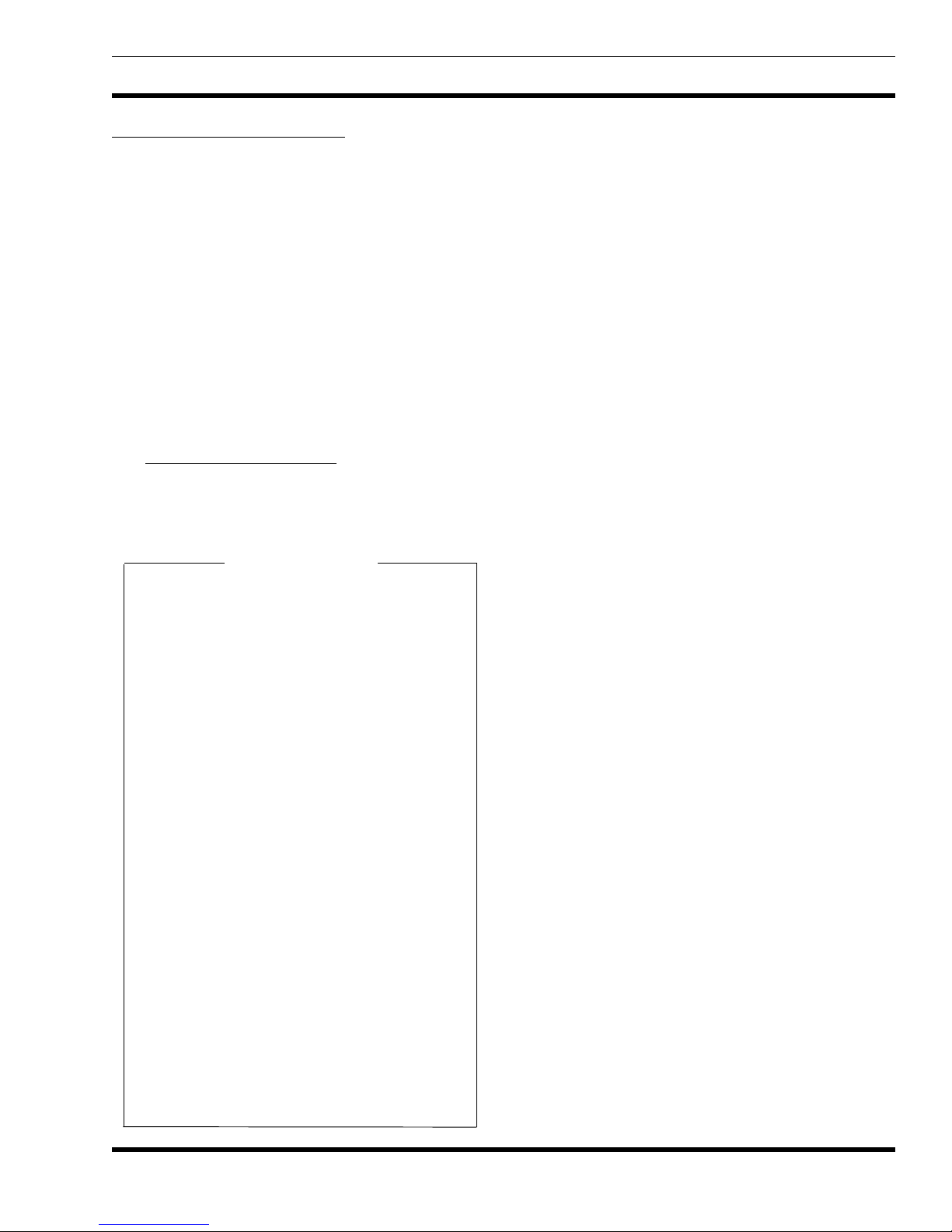

SPEAKER, MICROPHONE AND

FLEX CIRCUIT ACCESS

Remove the Control Board as previously stated and then

remove the six (6) Torx screws that secure the die-cast shield.

Remove the die-cast shield by lifting the top end first and

sliding it towards the top of the radio. The internal speaker,

microphone, Keypad and UDC Flex circuits are now partially accessible. See Figure 4.

4

LBI-38632

UDC Flex/UDC/Monitor Button/PTT Switch

Assembly Removal

If UDC Flex/UDC/Monitor Button/PTT Switch assembly removal is necessary, first un-solder the microphone.

With a spanner wrench, remove the UDC securing screw (the

UDC ground pin). Remove t he insulator (foam or plastic

type) on the inside side-rail of the case. Lift the UDC/Monitor Button/PTT Switch assembly from the side of the case

and slide the flex through the slot.

Earlier Front Cover Assembly Keypad Flex

Removal

To remove the Keypad Flex, first remove the UDC

Flex/UDC/Monitor Button/PTT Switch assembly as previously stated. Next remove the knobs using the hex driver.

Unscrew the two (2) screws securing the top panel and lift

and remove the panel. Lift the Emergency Button Board by

carefully unplugging J6 from P6. With a spanner wrench,

remove the nuts securing the volume and channel controls

and carefully slide the controls inside the radio. Unscrew the

two (2) screws (G and GG) and remove the J10/P10 Zebra

strip securing plate (HH). See Figure 5. The Keypad Flex is

now free for removal. Additional screws (J an d JJ) secure

the LCD Board used with the M-PA series radios.

Later Front Cover Assembly Keypad Flex

Removal

To remove the Keypad Flex, first remove the UDC

Flex/UDC/Monitor Button/PTT Switch assembly as previously stated. Next remove the s crew securing the emergency switch support (G) then remove the support. Remove

the knobs using the hex driver. With a spanner wrench,

remove the nuts securing the volume and channel controls

and carefully slide the controls inside the radio. Unscrew the

two (2) screws that secure the J10/P10 connection. Remove

the screws, the plate and the rubber pad. The Keypad Flex is

now free for removal.

Figur e 2 - RF B o a rd A c ce ss Figure 3 - Control Board Access

5

LBI-38632

Speaker Flex Removal

In order to replace the Speaker Flex, it must be un-sol-

dered from the speaker and the Battery Plate.

ALIGNMENT PROCEDURES

This section outlines alignment procedures for the 800

MHz RF Board located in the Rear Cover Assembly. Alignment procedures must be performed in the order presented

to insure proper radio operation. Several test procedures are

presented which will help isolate a problem if it exists. The

circuits in the Front Cover Assembly contain no adjustments

and therefore no alignment is necessary.

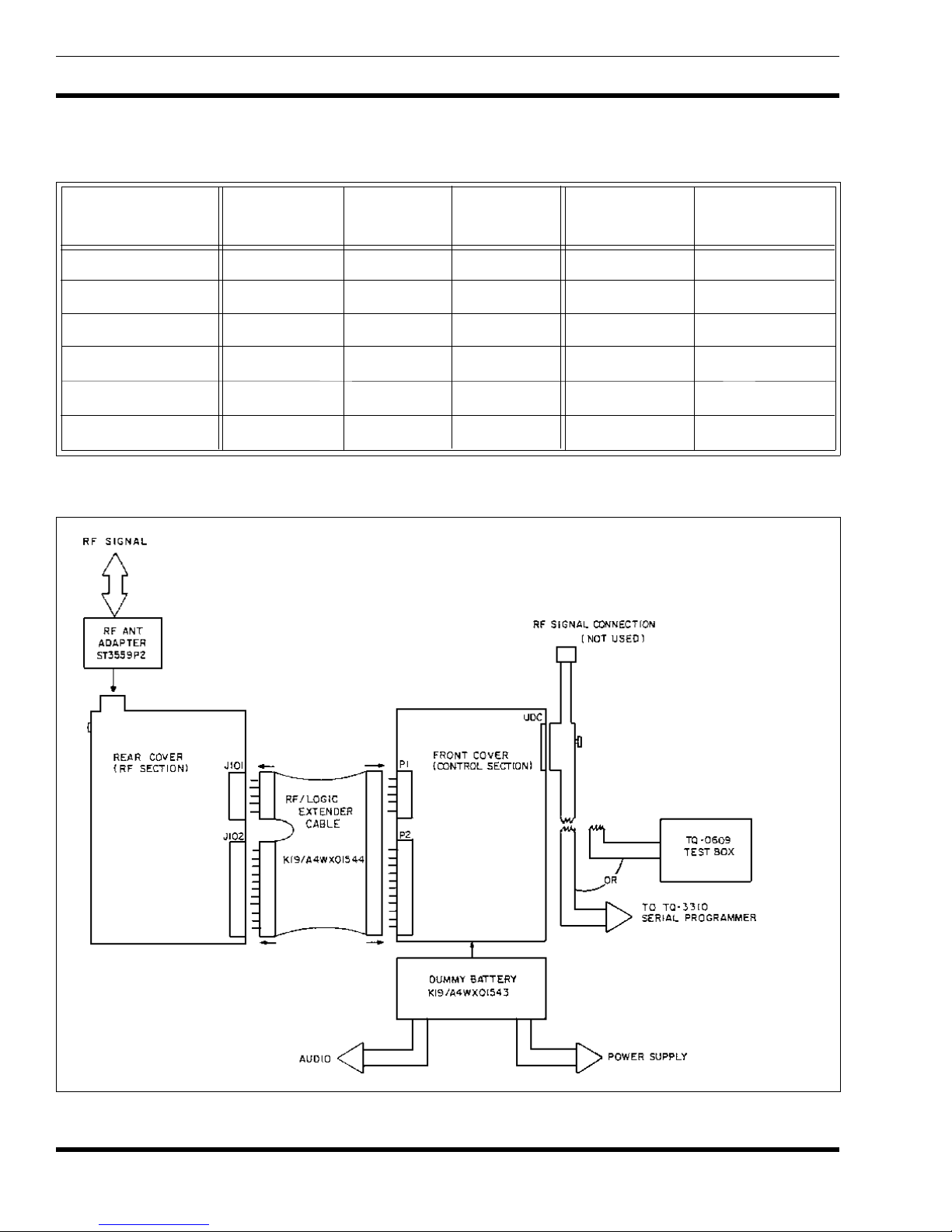

SET-UP PROCEDURE

1. Separate the Front and Rear Cover Assemblies and con-

nect the RF/Logic Extender cable between the RF Board

and the Control Board. See Figure 6.

2. Slide the Dummy Battery onto the Front Cover Assem-

bly and connect the audio output leads to the distortion

analyzer. Place the Dummy Battery’s on/off switch in

the OFF position to direct the speaker audio to its speakers leads and to the distortion analyzer. Connect the PC

Programmer to the UDC.

3.

Set the power supply to 7.5 ±0.1 Vdc and connect the

Dummy Battery supply leads to the power supply.

4. Program the radio with the LO W, MIDDLE and HIGH-

side test channels listed in Table 2. To fully test the

transmitter, program a channel pair for each frequency,

one at high-power and one at low-power. It may be

desirable to program more test channels into the unit.

Figure 4 - Speaker, Microphone And Flex Circuit Access Figure 5 - Keypad Flex Access

6

LBI-38632

5. Remove power f rom the radio and r eplace t he PC pro-

gramming cable with the TQ-0609 Test Box.

6. Connect the radio to the wattmeter using the RF Antenna

Adapter. C o uple a small amount of the RF signal to the

frequency counter.

SERVICE NOTES

Throughout the service procedures presented in this

manual, the following information should be observed:

• The bench power supply s hould be set for 7.5

±0.1 Vdc (unless otherwise noted) during trou-

bleshooting procedures presented in this manual. If a battery pack is used, it should be fully

charged. Typical battery pack voltage will be

7.5 Vdc ±20% over its full discharge cycle.

• Logic Levels:

Logic 1 = high = greater than 4.5 Vdc

Logic 0 = low = less than 0.5 Vdc

• The modules are not field repairable. Schemat-

ics and outline diagrams for the modules are

presented in this manual as a troubleshooting

reference only.

• The Front Cover Test Accessory Kit allows the

Control Board to be extended out of the case for

troubleshooting access. The Keypad circuits

can be tested in the case via a PC computer

connection.

TRANSMITTER ALIGNMENT

The following infomation can be used to test and align

the transmitter’s output and its modulation characteristics.

Completion of these tests/alignments will verify a near 100%

operating synthesizer and transmitter stages.

Reference Oscillator

NOTE

Reference Oscillator U4 is factory adjusted and

should not normally n eed readjustment. U se a re-

cently calibrated and stable frequency counter t o

determine if oscillator alignment is needed. This

test/alignment should be done at a room tempera-

ture of 25°C ±5°C.

1. On the TQ-0609 Test Box, select UDC switch position

6 and apply power to the radio. This enables the radio’s

control circuits for an external microphone and its inter-

nal speaker amplifier.

2. Channel the unit to 860.5125 MHz (low-power) and key

the transmitter using the TQ-0609. DO NOT apply any

modulation at this time.

NOTE

• The personality information stored in the radio

should be backed-up on the PC computer before

any service procedure is performed.

Table 2 - RF Test Cha nn els

TEST FREQUENCY (MHz)

RF BAND LOW MIDDLE HIGH

806-824 MHz* 806.0125 815.5125 824.0000

851-869 MHz 851.0125 860.5125 869.0000

* Transmit only (RX channels are 45 MHz higher)

LBI-38203 contains detailed information on the

TQ-0609 Test Box.

3. Monitor the t ransmitter’s frequency an d adjust Refer-

ence Oscillator U4 to a frequency reading of 860.5125

MHz ±100 Hz (a small trimmer hole is located on top of

module). If the ±100 Hz maximum error (at room tem-

perature) cannot be secured, Reference Oscillator re-

placement may be necessary. Table 3 list maximum

transmitter errors for the specified temperature range.

4.

Check all TX test channels for an error of less than ±100

Hz.

7

LBI-38632

Table 3 - Maximum Tr an s mitter Fr equency Errors*

And Typical VCO (TP 2 ) TX Tu ning V olt ag es

CHANNEL TOLERANCE* LOWEST HIGHEST VCO TUNING BAND SWITCH

(MHz) (Hz) (MHz) (MHz) VOLTAGE (J102 pin 3)

806.012500 ±1209 806.011291 806.013709 1.5 Vdc low

815.512500 ±1223 815.511277 815.513723 2.9 Vdc low

824.000000 ±1236 823.998764 824.001236 4.2 Vdc low

851.012500 ±1277 851.011223 851.013777 1.9 Vdc high

860.512500 ±1291 860.511209 860.513791 3.1 Vdc high

869.000000 ±1304 868.998696 869.001304 4.2 Vdc high

* Based on specified ±1.5 ppm over the entire operating temperature range.

8

Figure 6 -Test Set-Up

LBI-38632

VCO Modulation

NOTE

VCO Modulation adjustment should only be necessary if changes in the Tracking Data values will not

compensate deviation levels to within specifications. Adjustment of R5 will obs olete all Tracking

and Channel Data modulation values. See the

"TRACKING AND CHANNEL DATA" section

in this manual for further details.

R5 "course aligns" the VCO modulation level. The

Audio Processor IC will perform "fin e le vel adj ustment" of TX deviation via the Tracking and Channel

Data.

1. To align R5 it will be necessary to modify the RF/Logic

Extender cable as follows:

• Add two 10K ohm resistors in series from 5.4 Vdc

(J102 pin 6) to ground (J102 pin 7).

• Break the connection at TX AUDIO, J102/P2 pin 1.

• Bias TX AUDIO into the RF Board to 2.7 Vdc by

connecting the junction of the 10K resistors to J102

pin 1.

Distortion Test

Measure transmitter audio distortion on the LOW, MIDDLE and HIGH-side test channels. Distortion readings

should be less than 3% at ±3 kHz deviation with a 1000 Hz

tone.

RECEIVER ALIGNMENT

The following information can be used to check and

align the receiver circuits. Successful completion of these

alignment procedures will verify a near 100% operating

synthesizer and receiver stages.

NOTE

There are no front-end filter, mixer or high-IF ad-

justments.

2nd Local Oscillator

1. Check the Reference Oscillator alignment a s outlined in

the "TRANSMITTER ALIGNMENT " section.

2. Channel the unit to 860.5125 MHz.

2.

Using a 100 µF (or greater) capacitor, couple a 1 kHz,

600 mV rms audio signal into TX AUDIO, J102 pin 1.

3. C onnect the radio to the modulation analyzer and key

the transmitter at 815.5125 MHz.

4.

Adjust the R5 for a deviation of ±4.3 kHz ±100 Hz.

Unkey the radio.

5. C heck low-frequency modulation as follows:

• Remove the 1 kHz signal and apply a 20 Hz, 1

Vp-p square wave. NOTE: The modulation

analyzer should have a low-frequency response

of less than 1 Hz for this test.

• Key the transmitter and monitor the demodu-

lated output from the modulation analyzer.

Check for a good square wave response at

860.5125 MHz. If the modulation peaks are not

flat, slightly readjust R5 for a good demodulated square wave. If this readjustment causes

the 1 kHz modulation set in step 4 to go outside

of the specified window, U4 may need to be

replaced.

3. Set the RF signal generator to 860.5125 MHz, -20 dBm

and no modulation. Apply this signal to the radio.

4. To measure the IF signal, connect the frequency counter

to TP1 on the RF Board or to the collector of Q1 on

Back-End Module U14. Use an appropriate high imped-

ance probe (or amp).

5. Adjust the signal generator level to achieve accurate

counting of the IF signal; the RF signal generator should

be set 10 dBm above the lowest level which gives

accurate counting.

6. Adjust the 2nd local oscillator via L13 for 455.000 kHz

±90 Hz.

Quadrature Detector

1.

Modulate the signal generator with a 1 kHz tone, ±3 kHz

deviation at 860.5125 MHz. Set the RF level to -50 dBm.

2. Adjust L14 for maximum audio level at J101/P1 pin 4.

9

LBI-38632

12 dB SINAD and Distortion Tests

1. Connect the distortion analyzer or SINAD meter to the

speaker load (in Dummy Battery).

2. With the RF signal generator and radio set to 860.5125

MHz, modulate the generator with a 1 kHz tone at ±3

kHz deviation. Measure the 12 dB SINAD sensitivity.

This reading should be equal to or better than -116 dBm

(0.35 µ V).

3. Return the signal level to -50 dBm.

4. Check audio distortion. Readings should be less than 5%

at rated audio output. Audio amplitude should be 100 150 mV rms (≈350 mVp-p) at J101/P1 pin 4.

5. Repeat the 12 dB SINAD sensitivity and distortion

check for the LOW and HIGH-side test channels. See

Table 2.

TRACKING AND CHANNEL DATA

The personality memory in the radio includes distinct

areas which are reserved for Tracking and Channel Data.

Tracking Data establishes individual radio parameters

and tailors the operation of the unit across the band. The

parameters are: high RF power, low RF power, mo dulation

level and receiver squelch opening. This data is programmed

into the RAM (U1) on the Control Board at the factory after

the front and rear covers are "married". The PC Programmer

allows alteration of this data if necessary.

Channel Data is the individual channel information such

as TX and RX frequencies, CG information, CCT information, and the four previously mentioned parameters. This

data is stored in the RAM on a per channel basis as each

channel is programmed. The PC Programmer allows alteration of this data (on a per channel basis) if necessar y .

Low, middle and high-side of the band values are programmed into the radio for each T racking parameter per band

(806-825 and 851-870). When a channel is added to the

radio, the Programmer reads the T racking Data stored in the

radio and calculates necessary values for each parameter

using a linear interpolation technique. The Programmer then

stores the newly calculated values in the Channel Data area

of memory along with the associated channel information.

Changing the Tracking Data in the radio will not alter Channel Data of previously programmed channels.

Tracking Data should not norma lly be altered; however,

it may be necessary to reprogram some of the values after

aligning circuitry, or replacing modules or other components

which obsolete the previously programmed values. Settings

for each parameter are listed in Table 4. If Tracking Data is

altered for the above reason, it will be necessary to reprogram

all channels to establish the new default data for each channel. See the Programming Manual for further information on

altering Tracking and Channel Data.

Digital values stored for the POWER SET analog voltage are one example of t racking information. As no two

transmitter stages are exactly matched, the POWER SET dc

voltage will be slightly different with any two radios to

produce the same power output. Tracking and Channe l Data

allows the microprocessor to tailor the POWER SET line for

RF stage gain differences from unit-to-unit and across the

band.

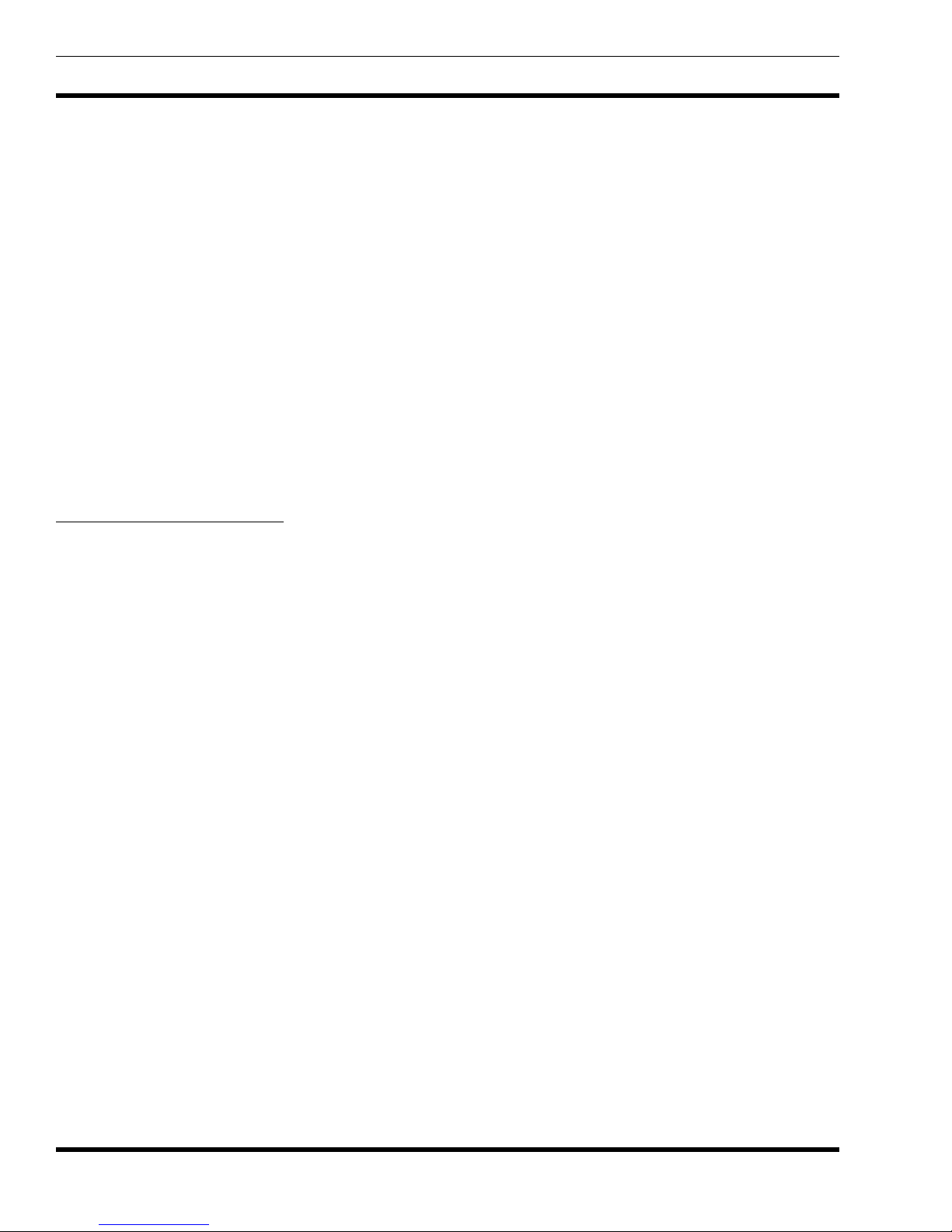

Table 4 - Tracking Data Parameters

PARAMETER FACTORY SETTINGHEX VALUE*

High-P o w er 3 .0 W a tts 85

Low-Po w er 1.0 Watt 50

Modulation ±4.3 kHz ** 0A

Squelc h Op e ni ng 8 dB SINAD A0

* Listed hex values are approximate; final pro-

grammed values will vary from unit-to-unit and

will need to be adjusted as such.

** EXT MIC HI = 1 kHz, 110 mV rms

TROUBLESHOOTING

The following procedures are designed to quickly lead

the service technician to the area of trouble. Rear and Front

Cover Assembly troubleshooting procedures are outlined.

Also see LBI-38834 for t roublshooting procedures that apply to later Front Cover Assembly 19D903620G1 (less Control Board).

The test set-up should be identical to the set-up used in

the "ALIGNMENT PROCEDURES" section in this manual. T able 5 lists common problems and most likely problem

areas.

REAR COVER ASSEMBLY

The troubleshooting procedures that follow primarily

assume a problem has been narrowed to a problem on the RF

Board. Transmitter, receiver and synthesizer symptoms/causes are outlined.

10

Transmitter Troubleshooting

Inoperative Or Low Power

Power sources and regulated power s upplies should be

one of the first areas to check before troubleshooting any

transmitter problem. The radio’s power source, whether it is

a battery or a bench power supply, is especially critical when

troubleshooting a portable radio. Current consumption is an

excellent troubleshooting tip when troubleshooting a dead or

weak transmitter. See Table 6 for complete radio current

consumption data.

If the synthesizer does not lock or stay locked at the start

of or during a transmission, I/O Microcontroller will not

enable or continue the transmission and the radio will beep

intermittantly or continously. Check LOCK detect at

J102/P2 pin 8 for a low or pulsi ng (not locked) condition.

See "

Synthesizer Troubleshooting" for further details.

1. C heck for batter y power on J102/P2 pin 2.

SERVIC E NOTES

Throughout the service procedures presented in this

manual, the following information should be ob-

served:

LBI-38632

2.

Check for 5.4 Vdc ±0.1 Vdc at J102/P2 pin 6 with the

transmitter enabled. Also check the operation of the TX

5.4V switch to insure 5.4 Vdc is being delivered to the

RF Board at J101/P1 pin 5 when the PTT button is

pressed.

3. Battery power should be present at the Power Amplifier

module pins 3 and 4. If current consumption appears

normal for both high and low-power modes, the probl em

may be Antenna T/R Switch module U2, the Low-pass

Filter module U5 or antenna switch SW1. If the Lowpass Filter module or the antenna switch have a problem,

generally the receiver will also be weak. A defective pin

diode inside the Antenna T/R Switch module m ay cause

transmitter and/or receiver problems.

4. I f low R F power i s a symptom, check the o peration of

Power Controller A2 and Q4. POWER SET on J101/P1

pin 1 should be approximately 1.8 Vdc in low-power

mode and 2.9 Vdc in high-power mode. If Q4 is saturated (collector voltage is approximately 7.5 Vdc), troubleshoot the PA U1 and Exciter U9 for a gain problem.

Also check the VCO and Q6 for low RF drive. Buffer

Q6 supplies approximately 0 dBm to U9. Exciter U9 has

an approximate gain of 23 dB and P A U1 has an approximate gain of 16 dB.

5. Check T racking a nd Channel Data. Reprogram if neces-

sary.

Excessive Power Output

• The bench power supply should be set for 7.5

±0.1 Vdc (unless otherwise noted) during trou-

bleshooting procedures presented in this manual. If a battery pack is used, it should be fully

charged. Typical battery pack voltage will be

7.5 Vdc ±20% over its full discharge cycle.

• Logic Levels:

Logic 1 = high = greater than 4.5 Vdc

Logic 0 = low = less than 0.5 Vdc

• The modules are not field repairable. Schemat-

ics and outline diagrams for the modules are

presented in this manual as a troubleshooting

reference only.

• The Front Cover T est Accessory Kit allows the

Control Board to be extended out of the case

for troubleshooting access. The Keypad circuits can be tested in the case via a PC computer

connection.

• The personality information stored in the radio

should be backed-up on the PC computer before any service procedure is performed.

Short battery life and possible damage to the PA module

may result if this problem occurs in the power controlling

circuitry.

1. C heck POWER SET from the Control Board. POWER

SET on J101/P1 pin 1 should be approximately 1.8 Vdc

in low-power (1 Watt) mode and 2.9 Vdc in high-power

(3 Watts) mode. If incorrect, troubleshoot the D/A con-

verter circuits (in Audio Processor U7) on the Control

Board. Check Tracking and Channel Data. Reprogram

if necessary.

2. The collector of Q4 should be approximately 3.5 Vdc in

low-power mode and 5.5 Vdc in high-power mode. If

Q4’s collector stays near 7.5 Vdc in receive mode, it is

most likely shorted. Temporarily short the emitter and

base while monitoring the collect or voltage. If t he col-

lector voltage falls, there is a problem in Power Control-

ler A2.

11

LBI-38632

Table 5 - General Troubleshooting

SYMPTOM POSSIBLE CAUSES

Completely inoperative (no audio 1. Dead Battery Pack.

and no LCD indication) 2. Fuse blown: Check radio fuse in Battery Plate.

3. Control Board problem.

At power-up, radio beeps:

a. twice (once in addition to 1a. Weak Battery P ack.

power-up beep)

b. continuously at an 1b. Unit is not programmed: Program ra dio - See TQ - 3364.

≈2 Hz rate 2b. Lithium battery on Control Board defective.

3b. Synthesizer is not locked: Check LOCK detect line, synthesizer

loading and VCO tun ing vo ltag e.

4b. RAM failure on Control Board.

5b. Interprocessor communication failure on Control Board.

Receiver inoperative or weak 1. Squelch levels programmed too high: Press Monitor Button to

disable squelch.

2. Channel Guard or T y p e 99 E nabled: See Operator’s M a nual.

3. Defective antenna.

4. RF Board problem: Troubleshoot Rear Cover Assembly.

Transmitter inoperative or low 1. Power levels programmed l ow: Check RF out put a nd r ep r og ram

range unit if necessary.

2. Weak battery.

3. Defective antenna.

4. RF Board problem: Troubleshoot Rear Cover Assembly.

TX and RX inoperative on some 1. Programming incorrect: Reprogram unit - See TQ-3364.

channels only 2. Synthesizer problem (VCO or prescaler):

Check LOCK de te c t (h igh = lo ck), VCO tuning voltag e a nd

modulas control line.

3. RAM problem: Troubleshoot Control Board.

TX and RX inoperative on all 1. Programming incorrect: Reprogram unit - See TQ-3364.

channels2. Synthesizer problem: Check LO CK dete ct (high = lock), VCO

tuning voltage and modulas control line.

3. Control Board problem.

4. Check SW1, U2 and U5 o n RF Board.

Trunk Mode Problems 1. Modem circuitry problem: Check U5, U6.1 and U17.3 and associated

circuitry on Control Board.

2. Low-speed data problem: T rouble sh oot the r elated e n code or

decode circuitry on Control Board.

Frequency Error

Modulation Problems

If transmit frequency error exists (greater than 1.5 ppm)

when the synthesizer is locked, Reference Oscillator U4

alignment or replacement is necessary . See " ALIGNMENT

PROCEDURES" for details. The I/O Microcontroller will

not enable a transmission if the synthesizer is not locked.

12

Modulation problems can be caused by a failures in the

audio circuits in the front cover or the modulating circuitry

of the RF Board.

LBI-38632

1. Verify modulating audio is present on J102/P2 pin 1. A

1 kHz, 600 mV rms TX AUDIO signal at this point

should produce approximately ±5.0 kHz deviation. Im-

proper modulation from 300 - 3000 Hz points to a VCO

modulation problem. Check the VCO pin 2 for the TX

AUDIO signal. Suspect the VCO if the signal is present

and incorrect modulation exists.

2. I f improper l ow-frequency modulation exists (Channel

Guard and trunked mode low-speed data), first check

J102 pin 1 for the proper tone. Next check U4 pin 3 for

the tone; suspect C11 if the tone is not present. Replace

U4 if the tone is present on pin 3 and incorrect low-frequency modulation exists. See the "ALIGNMENT

PROCEDURES" for details.

3. Check T racking a nd Channel Data. Reprogram if neces-

sary.

4. See the troubleshooting information in the "FRONT

COVER AS SEMBLY" section relating to the Control

Board.

Distorted Modulation

Check TX AUDIO for an u ndistorted signal to the RF

Board. The audio signal on J102/P2 pin 1 should appear

undistorted at maximum deviation and it should be riding on

a 2.7 Vdc bias developed on the Control Board.

1. If TX AUDIO distortion is minimal and transmitter

distortion is excess ive, suspect the VCO or the Reference Oscillator on the RF Board.

2. C heck RX AUDIO on J1 01/P1 pin 4 f or signal and/or

noise. With an RF input modulated at 1 kHz, ±3 kHz

deviation, RX AUDIO should be 100 - 150 mV rms

(approximately 350 mV p-p). If the 1 kHz audio is

present, troubleshoot the audio circuits in the Front

Cover Assembly. Noise levels on RX AUDIO with no

RF input should be approximately 700 mV p-p.

3. C heck for 7.5 Vdc at RF Amp U10 pin 5 and IF Amp

U11 pin 1. Check U14 pin 7 for 5.8 Vdc (±0.2 Vdc) from

A1 pin 10. Verify TX 5.4V is low in receive mode.

4. Verify mixer injection through Q2 from the VCO is

present at TP7. Check the VCO output with a frequency

counter at TP7. The VCO should be running 45.0125

MHz below the RX frequency. VCO output power level

is typically +4 dBm at TP7 into 50 ohms (mixer impedance).

5. To test the back-end circuits, follow this procedure:

• Verify 5.8 Vdc (±0.2 Vdc) is present on U14

pins 1 and 7.

• Connect a frequency counter to TP1 to monitor

the IF. Use a high-impedance probe (or amp).

• Couple a 45.0125 MHz signal (no modulation)

from an HF signal generator to TP4. Adjust the

signal generator level to achieve accurate

counting of the IF; the signal generator should

be set 10 dBm above the lowest level which

provides stable counting of the 455 kHz I F. See

the "ALIGNMENT PROCEDURES" sec tion

if the 2nd IF is in error by more than 90 Hz.

2. I f TX AUDIO is distorted, su spect a defective microphone, mic amps, modulation limiting, or pre-emphasis

circuity.

If audio sensitivity is good, the microphone, amplifiers

and limiters are p robably OK. Regeneration from an open

decoupling capacitor may make the unit appear to be too

sensitive. See the troubleshooting information in the

"FRONT COVER ASSEMBLY" section relating to the

Control Board.

Receiver Troubleshooting

Inoperative

1. If the synthesizer is not locked the radio should be

beeping and flashing "NO LOCK" in the LCD. See

"

Synthesizer Troubleshooting".

• Modulate the HF signal generator and observe

the recovered audio on U14 pin 2 and J101 pin

4.

Low Sensitivity

Low receiver sensitivity and/or failure of a modulation

acceptance bandwidth test indicates a receiver gain or selectivity problem in the IF stages. An excessively wide bandwidth will cause unnecessary noise, detracting from the

receiver quieting. If the bandwidth is too narrow squelching

could occur at the modulation peaks. Suspect a defective IF

filter if one of the above symptoms occurs.

A 12 dB SINAD sensitivity of around -90 dBm indicates

a problem with H igh-IF Amp U 11. The module provides a

nominal gain of around 17 dB.

A 12 dB SINAD sensitivity of around -100 dBm could

be caused by a problem with RF Amp U10. This module

provides 10 dB of gain.

13

LBI-38632

Squelch Problem

A squelch circuit problem (assuming good signal and/or

noise is present at J101 pin 4) indicates a problem with the

Audio Processor chip on the Control Board. Troubleshooting

should begin at the discriminator output. Signal trace

through the discriminator amp to the Audio Processor. Check

the operation of the noise rectifier to verify the noise is being

converted into the proper dc voltage. See the troubleshooting

information in the "FRONT COVER ASSEMBLY" section

relating to the Control Board.

Excessive Distortion

If the measu red distortion exceed s the rated specification signal trace starting at the discriminator output and

through the audio stages until the fault i s isolated. Signal

tracing with an oscilloscope proves very useful in locating

the trouble areas.

Synthesizer Troubleshooting

Will Not Loc k O r S tay Lock ed

Each time the channel is changed, the PTT Button is

pressed or the PTT Button is released, Synthesizer IC U3 is

serially loaded with new TX or RX d ata. If the synthesizer

does not lock or stay locked, the following will be observed:

• the radio continuously or intermittently beeps

• LOCK detect (J102 pin 8) will be low or puls-

ing to flag the I/O Microcontroller of the unlocked condition

If this condition occurs, the I/O Microcontroller will

continue to try to reload U3 with channel data until the

synthesizer locks.

4. Using a frequency counter with a high impedance probe

or amp, check TP8 for the 13.2 MHz (±20 Hz at room

temperature) signal from Reference Oscillator U4. Replace U4 if this signal is not present and pin 1 is 5.4 Vdc.

Also verify the signal is present on U3 pin 2. See

"ALIGNMENT PROCEDURES" for oscillator align-

ment details.

5. Verify BAND SWITCH (J102 pin 3) is at the correct

logic level. It should be low for transmit frequencies of

806 - 825 MHz and high for transmit frequencies of 851

- 870 MHz. BAND SWITCH should remain low for all

receive frequencies. (The VCO operates 45.0125 MHz

below the 851 - 870 MHz receive frequencies.) Suspect

the I/O Microcontroller on the Control Board if there is

a problem with the BAND SWITCH line. Check Y3 pin

5 for an inversion of this logic level via Q5. If the correct

inverted level is present on both bands and the synthesizer will not lock on one band onl y , re pla ce the VCO.

6. If LOCK detect is low and not pulsing, temporarily pull

it high by connecting J102 pin 6 to J102 pin 8. I f the

radio now operates normally on all test TX and RX

channels, replace U3 - the output on pin 9 is defective.

7. Check the VCO output with a frequency count er at T P7

or by tuning a service monitor to the radio’s local osc illator (VCO) signal and loosely couplin g the VCO signal

into the service monitor. The VCO should be running

45.0125 MHz below the RX frequency. VCO output

power level is typically +4 dBm at TP7 into 50 o hms

(mixer impedance). VCO tuning voltage can be monitored at TP2 or the VCO pin 1. See Table 3 for details.

8. I f a synthesizer lock p roblem cannot be narrowed to a

problem in the Rear Cover Assembly, reprogram the

inoperative channels and test the unit again. Also see the

service information on the Control Board for further

details.

Excessive Switching Time

1.

V erify the 5.4 Vdc supply to the RF Board is within ±0.1

Vdc, 7.5V B ATT is present, and TX 5.4 V is low (receive

mode only).

2. Monitor CLOCK, DATA and ENABLE (on J102 pins

11, 10 and 9 respectively) for pulse activity when the

channel is changed. See Figure 8 for specific waveform

details. If these signals are not present, suspect a defec-

tive I/O Microcontroller on the Control Board.

3.

Check A1 pin 9 for 5.8 Vdc (±0.2 Vdc) to U3, U4, U8

and the VCO. If this power source is not present, check

A1 pin 7 f or 5.8 Vdc (±0.2 Vdc) from Q201 and check

A1 pin 11 for 7.5 Vdc. Replace A1 if the inputs are good

and the output is not.

14

The synthesizer should generally lock within 10 milli-

seconds after a frequency change.

1. Su spect leaky low-pass filter capacitors C57 or C58 if

slow switching time is a symptom. Replace these components with original equipment parts only. See the RF

Board parts list for part numbers.

2. Module A1 also influences switching time. Verify the

ENABLE pulse is present at A1 pin 4. See Figure 8.

Loading...

Loading...