Page 1

™

WorkFit

B, HD

User's Guide

For the latest User Installation Guide please visit: www.ergotron.com

English, Español, Français, Deutsch, Nederlands, Italiano, Svenska, 日本語, 汉语

www.ergotron.com |

888-24-227-G-01 rev. E • 12/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

|

China: 400-120-3051

|

English

Japan: japansupport@ergotron.com

1 of 19

Page 2

Hazard Symbols Review

These symbols alert users of a safety condition that

demands attention. All users should be able to

recognize and understand the signi cance of the following Safety Hazards if encountered on the product

or within the documentation. Children who are not

e to recognize and respond appropriately to Safety

abl

Alerts should not use this product without adult

supervision!

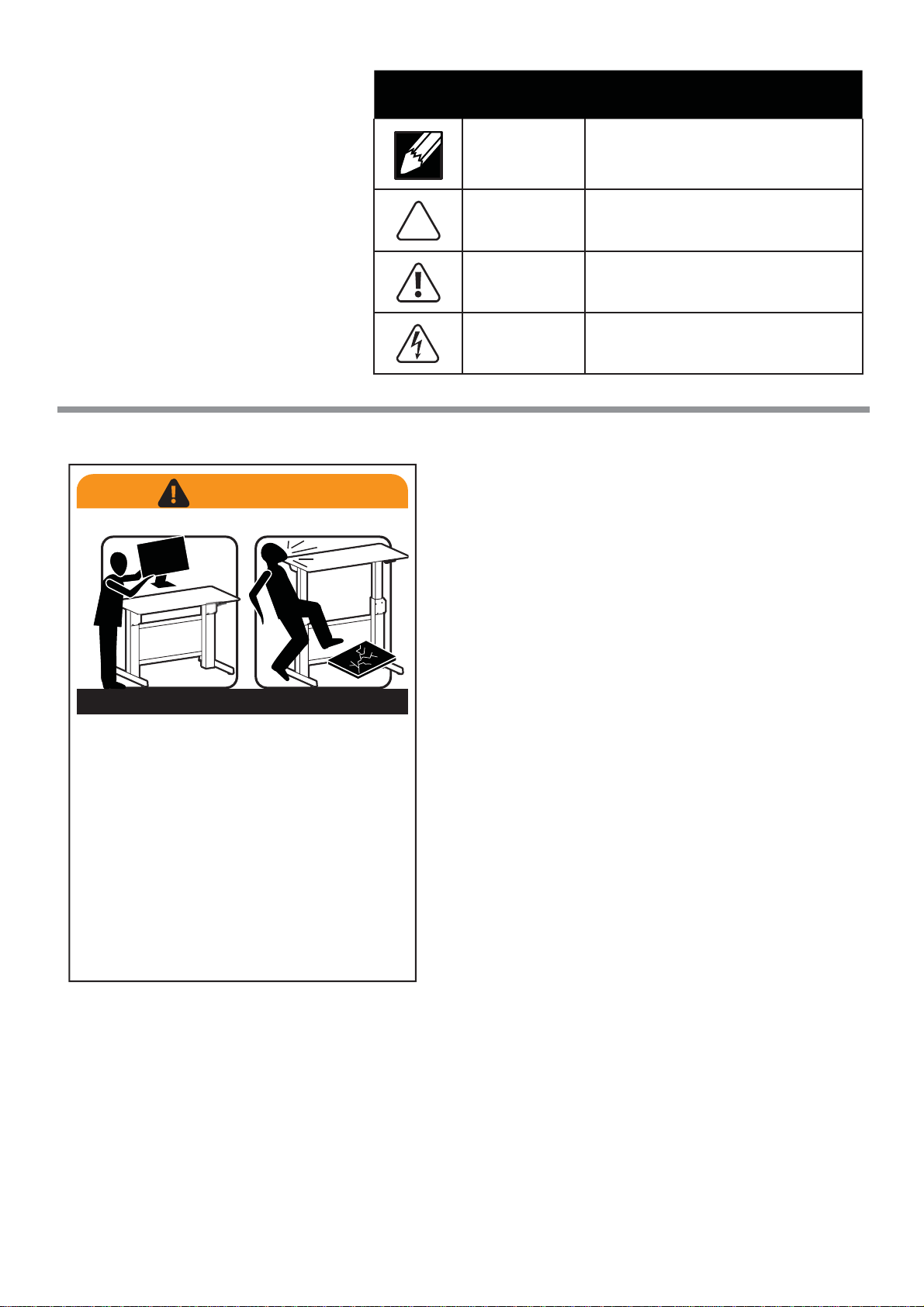

Safety

WARNING

IMPACT HAZARD

Symbol Signal Word Level of Hazard

NOTE

CAUTION

WARNING

ELECTRICAL

A NOTE indicates important information that helps you

make better use of this product.

A CAUTION indicates either potential damage to

hardware or loss of data and tells you how to avoid the

problem.

A WARNING indicates either potential for property damage, personal injury, or death.

An Electrical indicates an impending electrical hazard

which, if not avoided, may result in personal injury, re

and/or death.

Moving Parts Can Crush And Cut

Minimize Lift Strength BEFORE:

- Removing Mounted Equipment

and

Insert 4 Stop Screws BEFORE:

- Shipping or Storing (i.e. when Desk is not upright).

To Minimize Lift Strength

Refer to installation manual for instructions on

how to minimize lift strength.

To Insert 4 Stop Screws

Refer to installation manual for instructions on

Failure to heed this warning may result in

serious personal injury or property damage!

For More information and instructions visit www.ergotron.com

or contact Ergotron Customer Care at 1-800-888-8458.

Refer to Appendix A at the end of this manual

Refer to Appendix B at the end of this manual

installing stop screws.

826-901-00

2 of 19

888-24-227-G-01 rev. E • 12/19

Page 3

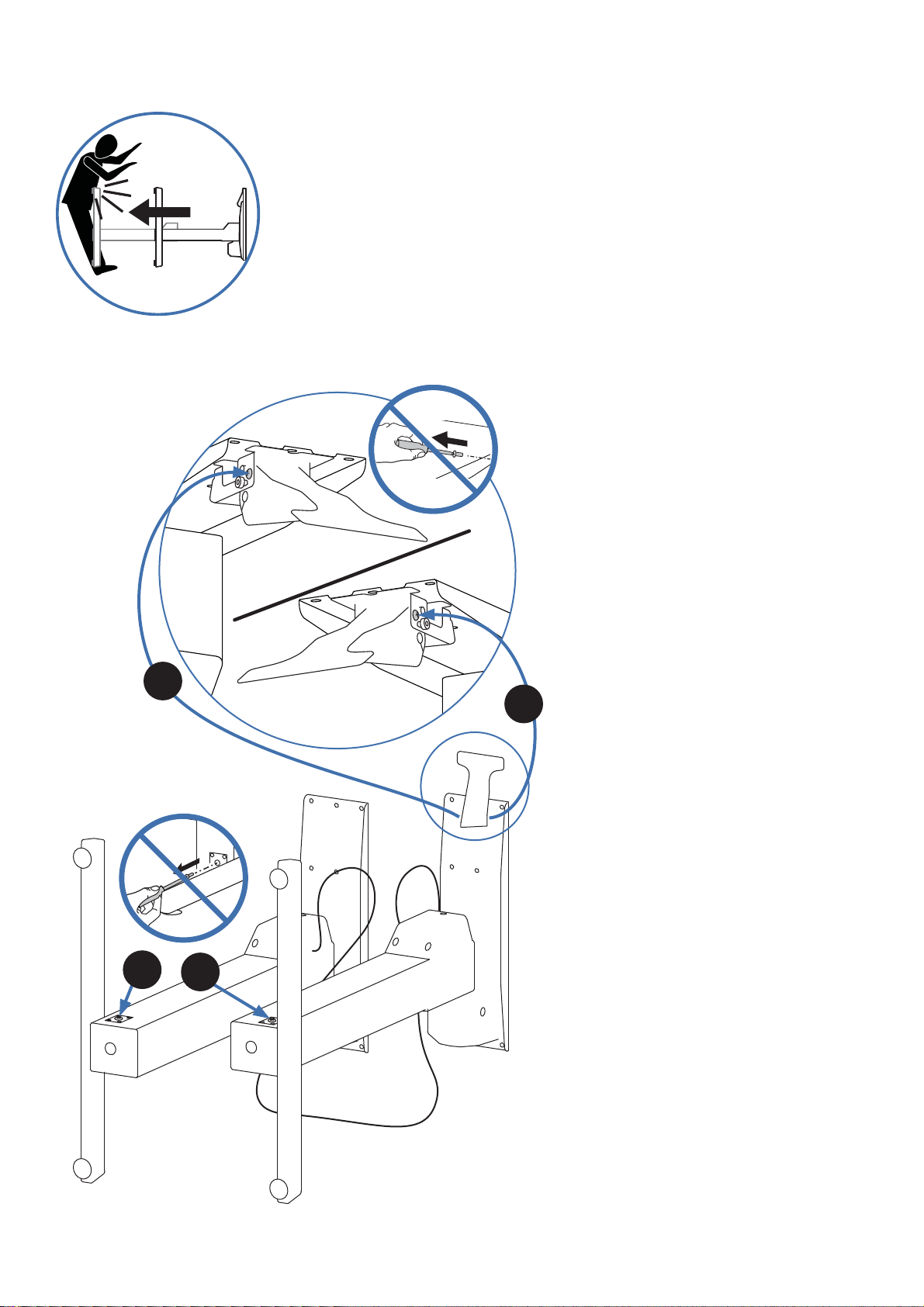

Safety

WARNING! Stop screws are pre-installed in this product to secure it in the compressed position

during shipping and installation. DO NOT REMOVE THESE SCREWS UNTIL INSTRUCTED TO DO SO

IN THESE INSTRUCTIONS. Make sure these screws are in place before starting installation. Failure

to follow these instructions may cause lift engine to expand rapidly and may result in equipment

damage and or personal injury. If any of the 4 stop screws are not installed in these locations,

contact customer care before continuing with installation.

DO NOT REMOVE SCREWS!

IMPORTANT!

Save these stop screws and instructions. Install stop screws

when shipping or storing this product. Failure to follow

these instructions may cause lift engine to expand rapidly

and may result in equipment damage and or personal

injury.

3

DO NOT REMOVE SCREWS!

1

2

4

888-24-227-G-01 rev. E • 12/19

3 of 19

Page 4

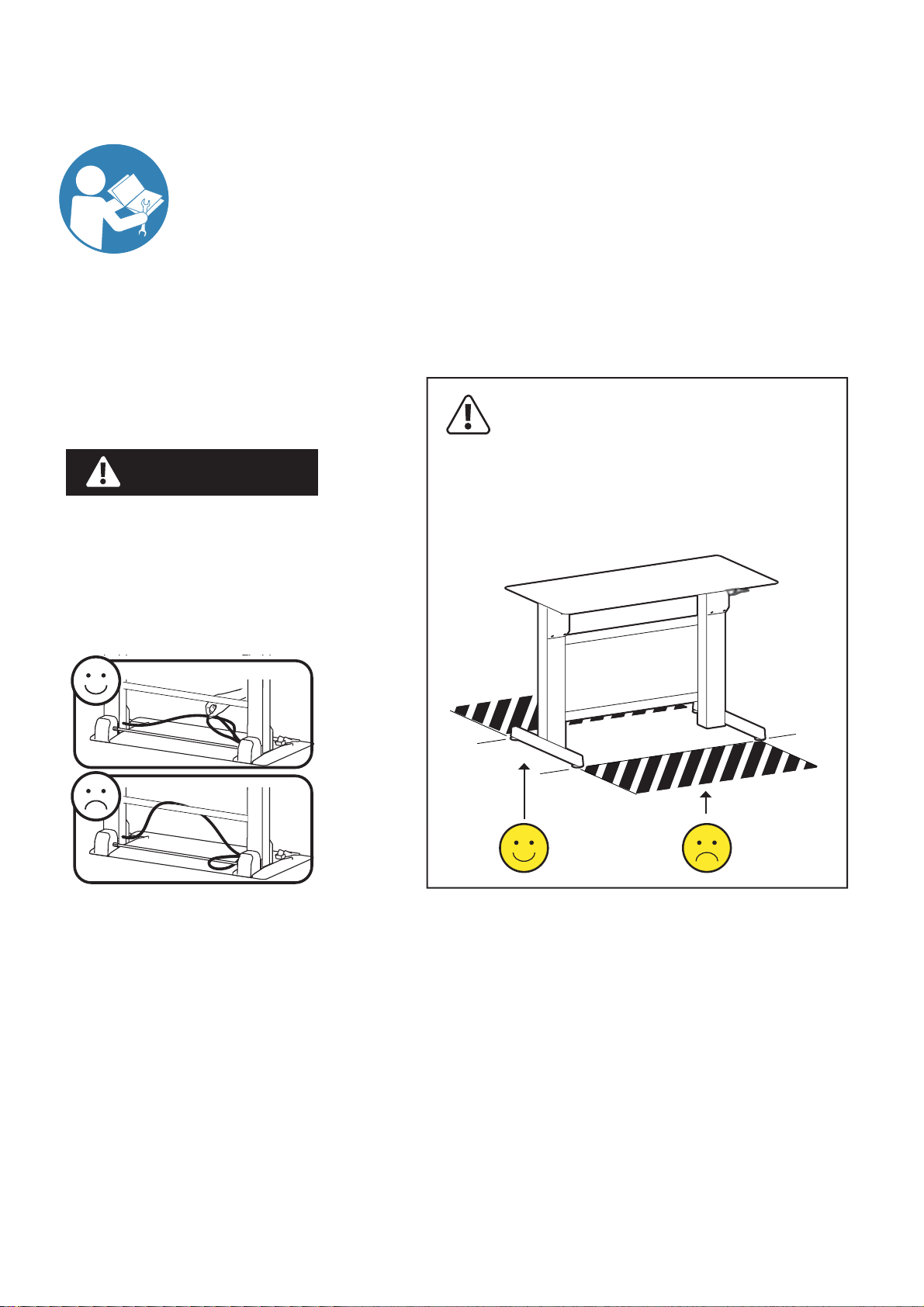

Safety

Important! You will need to adjust this product after installation is complete. Make sure all your equipment is properly

installed on the product before attempting adjustments. This product should move smoothly and easily through

the full range of motion and stay where you set it. If movements are too easy or di cult or if product does not stay

in desired positions, follow the adjustment instructions to create smooth and easy movements. Depending on your

product and the adjustment, it may take many turns to notice a di erence. Any time equipment is added or removed

from this product, resulting in a change in the weight of the mounted load, you should repeat these adjustment steps

to ensure safe and optimum operation.

WARNING

Keep Brake Cables Away from

Sync Rod and Crossbars

During Installation!

Failure to keep the brake cables away from

sync rod and crossbars may restrict lift

motion and may cause equipment damage

or personal injury! Refer to instruction

manual for more information.

WARNING! TIPPING HAZARD!

When mounting accessories to the

WorkFit-D, they must stay within the foot

print. Do not mount accessories past the

front and rear worksurface! Failure to follow this warning may result in equipment

damage and or personal

injury.

4 of 19

888-24-227-G-01 rev. E • 12/19

Page 5

Features & Specifi cations

0.80”-1.75”*

(20-44 mm)

23.5”-30.5”*

(597-775 mm)

22.5-88 lbs (10.2-40 kg)*

41"-72" *

(1041-1829 mm)

Important! You will need to adjust this product after installation is

complete. Make sure all your equipment is properly installed on the

product before attempting adjustments. This product should move

smoothly and easily through the full range of motion and stay where

you set it. If movements are too easy or di cult or if product does

not stay in desired positions, follow the adjustment instructions to

create smooth and easy movements. Depending on your product

and the adjustment, it may take many turns to notice a di erence.

Any time equipment is added or removed from this product,

resulting in a change in the weight of the mounted load, you

should repeat these adjustment steps to ensure safe and optimum

operation.

Wood Worksurface Weight Estimator

Worksurface

Thickness

Estimated Weight

per square foot

0.80” (20 mm) 2.9 lbs (1.32 kg)

1.25” (32 mm) 4.5 lbs (2.04 kg)

1.75” (44 mm) 6.3 lbs (2.86 kg)

*Total weight of worksurface and mounted equipment must

be < 88 lbs (40 kg).

Worksurface must meet ALL dimensional and weight range

speci cation requirements.

WARNING! The addition of accessories can negatively impact the

tip performance.

888-24-227-G-01 rev. E • 12/19

5 of 19

Page 6

1/4”

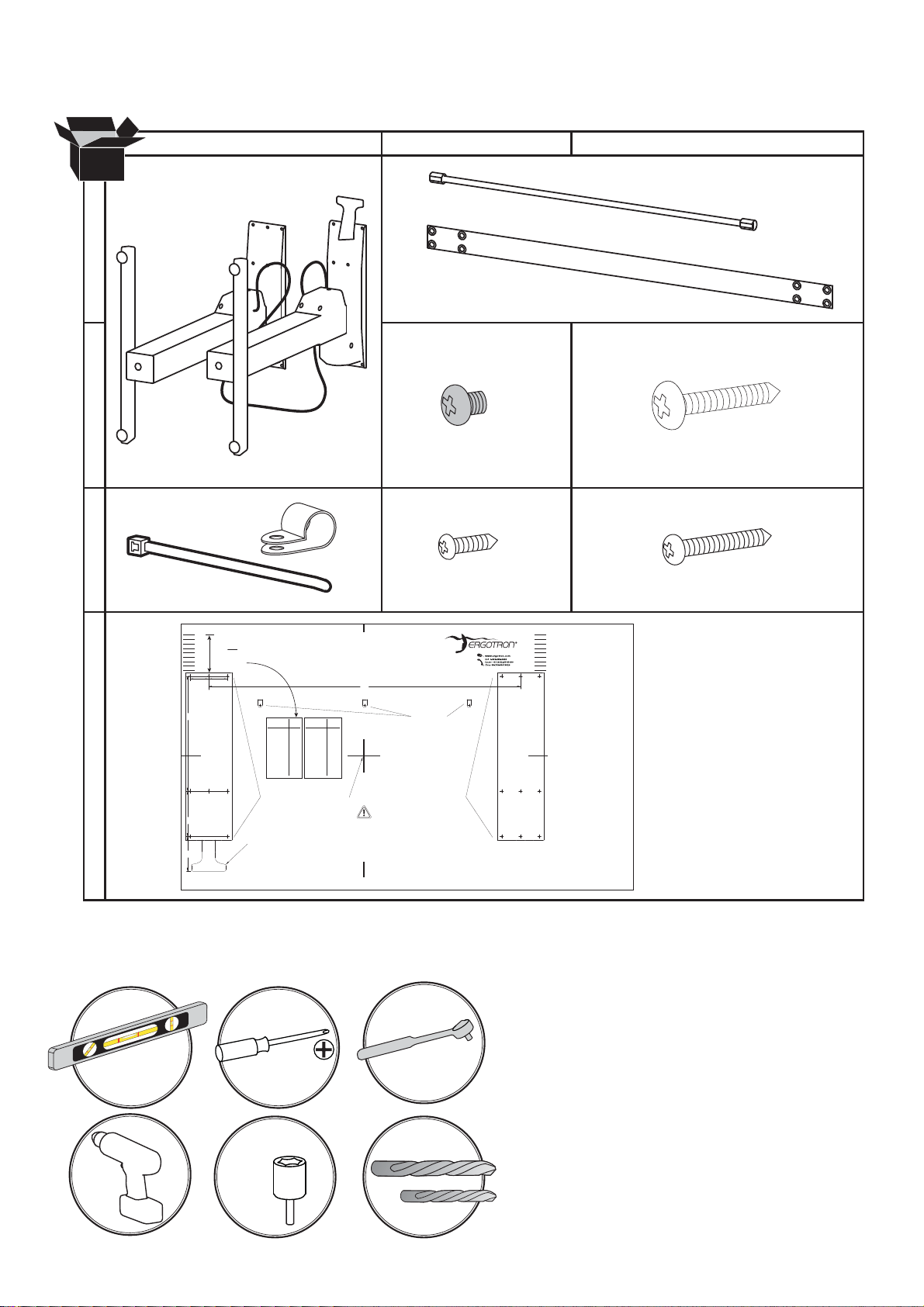

Components

AB C

1x

1x

1x

1

2x

2

16x

M5 x 6mm

17x

#12-14 x 5/8”

3x

3

3x

M2.9 x 8mm

4x

ST3.9 x 16mm

2x

1x

4.25” (108 mm)

3.75” (95 mm)

3.25” (83 mm)

2.75” (70 mm)

2.25” (57 mm)

1.75” (44 mm)

1.25” (32 mm)

0.75” (19 mm)

0.25” (6 mm)

Align

REAR

Edge of Worksurface X distance

from the back of the Base Brackets.

X

See table for value of

your worksurface.

Back of Base Bracket

2.1262.126

WORKSURFACE TEMPLATE FOR WORKFIT-B, HD

X

based on the depth of

Lay this template on the bottom of your worksurface

to drill the holes to attach the WorkFit-D, Base.

35.197

4.25” (108 mm)

3.75” (95 mm)

3.25” (83 mm)

2.75” (70 mm)

2.25” (57 mm)

1.75” (44 mm)

1.25” (32 mm)

0.75” (19 mm)

0.25” (6 mm)

12.992

4

5.118

3.900

Tools Needed

Depth of

Worksurface

23.50 - 24.25”----0.25”

24.25 - 25.00”----0.75”

25.00 - 25.75”----1.25”

25.75 - 26.50”----1.75”

26.50 - 27.25”----2.25”

27.25 - 28.00”----2.75”

28.00 - 28.75”----3.25”

28.75 - 29.50”----3.75”

29.50 - 30.25”----4.25”

Use Drill Bit #21,

Ø 0.19” (4.8 mm)

to drill these 8 holes

0.375” (9.5 mm) deep.

Brake Release

DIMENSIONS ARE IN INCHES

14mm

Depth of

X

X

Worksurface

597 - 616 mm---6 mm

616 - 635 mm---19 mm

635 - 654 mm---32 mm

654 - 673 mm---44 mm

673 - 692 mm---57 mm

692 - 711 mm---70 mm

711 - 730 mm---83 mm

730 - 749 mm---95 mm

749 - 768 mm---108 mm

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Base Brackets.

Failure to follow these instructions may make this product unstable

and may result in equipment damage and/or personal injury.

Use Drill Bit #46,

Ø 0.081” (2mm)

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

Ø 0.19” (4.8 mm)

to drill these 9 holes

0.375” (9.5 mm) deep.

823-558-00 rev.A 05/13

6 of 19

#12, Ø 0.19” (4.8mm)

#46, Ø 0.081” (2mm)

888-24-227-G-01 rev. E • 12/19

Page 7

Set-up Steps

Place the worksurface on a clean oor with the top side facing down.

1

Center Template

Side-to-Side on

worksurface.

Align REAR Edge of Worksurface X distance from the back of the Base Brackets.

See table for value of X based on the

Use Drill Bit #46,

0.081” (2mm)

Ø

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 8 holes

3/8” (9.5 mm) deep.

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Base Brackets.

Failure to follow these instructions may

and may result in equipment damage and/or personal injury.

Brake Release

depth of your worksurface.

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 9 holes

3/8” (9.5 mm) deep.

make this product unsta

ble

Depth of

Your Worksurface

4.25” (108 mm)

3.75” (95 mm)

3.25” (83 mm)

2.75” (70 mm)

2.25” (57 mm)

1.75” (44 mm)

1.25” (32 mm)

0.75” (19 mm)

0.25” (6 mm)

Align

REAR

Edge of Worksurface X distance

from the back of the Base Brackets.

X

See table for value of

your worksurface.

Back of Base Bracket

2.1262.126

Tape Template in place.

X

based on the depth of

Use Drill Bit #46,

0.081” (2mm)

Ø

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 8 holes

3/8” (9.5 mm) deep.

Brake Release

Depth of

Worksurface

X

23.50 - 24.25”----0.25”

24.25 - 25.00”----0.75”

25.00 - 25.75”----1.25”

25.75 - 26.50”----1.75”

26.50 - 27.25”----2.25”

27.25 - 28.00”----2.75”

28.00 - 28.75”----3.25”

28.75 - 29.50”----3.75”

29.50 - 30.25”----4.25”

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 9 holes

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Base Brackets.

Failure to follow these instructions may make this product u

and may result in equipment damage and/or personal injury.

3/8” (9.5 mm) deep.

Depth of

Worksurface

597 - 616 mm ---6 mm

616 - 635 mm ---19 mm

635 - 654 mm ---32 mm

654 - 673 mm ---44 mm

673 - 692 mm ---57 mm

692 - 711 mm ---70 mm

711 - 730 mm ---83 mm

730 - 749 mm ---95 mm

749 - 768 mm ---108 mm

nstable

X

888-24-227-G-01 rev. E • 12/19

Use Drill Bit #46,

0.081” (2mm)

Ø

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 8 holes

3/8” (9.5 mm) deep.

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Base Brackets.

Failure to follow these instructions may make this product u

and may result in equipment damage and/or personal injury.

Brake Release

Use Drill Bit #21,

0.19” (4.8 mm)

Ø

to drill these 9 holes

3/8” (9.5 mm) deep.

nstable

7 of 19

Page 8

Set-up Steps

Using the speci ed drill bit, drill the 17 holes for base.

#12, Ø 0.19” (4.8mm)

Drill holes 0.375" (9.5 mm) deep.

TIP: To ensure proper depth, place a

piece of tape on the drill bit 0.375” (9.5

mm) from the tip.

Use Drill Bit #46,

Ø 0.081” (2mm)

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

0.375"

(9.5 mm)

Ø 0.19” (4.8 mm)

to drill these 8 holes

3/8” (9.5 mm) deep.

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Base Brackets.

Failure to follow these instructions may make this product u

and may result in equipment damage and/or personal inju

Brake Release

Use Drill Bit #21,

Ø 0.19” (4.8 mm)

to drill these 9 holes

3/8” (9.5 mm) deep.

nstable

ry.

Using the speci ed drill bit, drill the 3 holes for cable clips.

#46, Ø 0.081” (2mm)

Drill holes 0.24" (6 mm) deep.

TIP: To ensure proper depth, place a piece of tape on the drill bit

0.24" (6 mm) from the tip.

Use Drill Bit #46,

Ø 0.081” (2mm)

to drill these 3 holes

0.24” (6 mm) deep.

Use Drill Bit #21,

Ø 0.19” (4.8 mm)

to drill these 8 holes

3/8” (9.5 mm) deep.

0.24"

(6 mm)

Center Point of Base Brackets

TIPPING HAZARD!

Center Worksurface from Side-to-Side Across Bas

Failure to follow these instructions may make this product unstable

and may result in equipment damage and/or personal injury.

Brake Release

Use Drill Bit #21,

Ø 0.19” (4.8 mm)

to drill these 9 holes

3/8” (9.5 mm) deep.

e Brackets.

Remove Template.

8 of 19

WORKSURFACE TEMPLATE FOR WORKFIT-D, BASE O

DIMENSIONS ARE IN INCHES

NLY

888-24-227-G-01 rev. E • 12/19

Page 9

Set-up Steps

Place the worksurface on a clean oor with

2

3

the top side facing down.

Carefully position the leg with the hand

brake on the right end of the worksurface.

Place the other leg on the left end.

NOTE: The brake cable is attached to both legs. Take care when removing the legs from the packaging to avoid damaging or pulling the

brake cable from the legs.

Set the right leg (with hand brake) upright on the

worksurface.

Partially insert 3 of the provided #12-14 wood

screws at the rear of the leg, 3 near the middle of

the leg and 2 at the front of the leg.

Front Edge of Worksurface

Rear Edge of Worksurface

8x

4

#12-14 x 5/8”

NOTE: Do not fully

insert the screws

into the worksurface

at this time. Leave

approximately 1/8”

space.

Attach one end of the sync rod to the

right leg as illustrated. Make sure the

brake cables don’t loop around the sync

rod. See Warning, right.

Front =2 screws

Middle = 3 screws

Rear = 3 screws

WARNING

Keep Brake Cables Away from

Sync Rod and Crossbars

During Installation!

Failure to keep the brake cables away from

sync rod and crossbars may restrict lift

motion and may cause equipment damage

or personal injury! Refer to instruction

manual for more information.

888-24-227-G-01 rev. E • 12/19

9 of 19

Page 10

Set-up Steps

Set the left leg (without

5

hand brake) upright on the

worksurface.

Attach the left end of the

sync rod to the left leg.

Make sure the brake

don’t loop around the sync

rod. See Warning, right.

cables

WARNING

Keep Brake Cables Away from

Sync Rod and Crossbars

During Installation!

Failure to keep the brake cables away from

sync rod and crossbars may restrict lift

motion and may cause equipment damage

or personal injury! Refer to instruction

manual for more information.

6

7

Partially insert 9 of the provided #12-14 wood screws

in the left leg and worksurface.

Front =2 screws

Middle = 3 screws

Rear = 3 screws

Use a Phillips screwdriver to insert the provided M5x6

mm screws into the two crossbars connecting the left

and right legs. Make sure the brake cables don’t

loop around the crossbars.

9x

#12-14 x 5/8”

NOTE: Do not

fully insert

the screws

into the worksurface at this

time. Leave

approximate-

ly 1/8” space.

16x

M5 x 6mm

8

Tighten the screws slightly one at a time

and repeat to ensure that

on every screw is equal.

NOTE: Do not overtighten screws.

overtightening screws may result in stripping

the holes and may cause the installation to be

unsafe.

Use a Phillips screwdriver to tighten

down the screws attaching the legs to

the worksurface.

NOTE: Do not overtighten screws. overtightening

screws may result in stripping the holes and may

cause the installation to be unsafe.

the tension

10 of 19

888-24-227-G-01 rev. E • 12/19

Page 11

Set-up Steps

If your brake release handle is not aligned with the front edge of your worksurface and you

9

would like it to be, follow these instructions to relocate the brake release handle.

a

Relocate brake release handle along front edge

b

the leg only. DO NOT attach brake release handle in front of or to the outside of the leg.

Make sure cable has enough slack to allow worksurface to fully extend up and down.

c d

#46, Ø 0.081” (2mm)

of worksurface and next to the inside of

4x

ST3.9 x 16mm

888-24-227-G-01 rev. E • 12/19

11 of 19

Page 12

Set-up Steps

10

Capture the brake cable in the cable clip as

illustrated, then use a Phillips screwdriver

to attach the cable clips to bottom of work

surface with the provided M2.9 x 8 mm screws.

3x

3x

M2.9 x 8mm

11

Using the 2 provided cable ties, attach brake cable

to the l

between the cable tie and the leg to allow desk top to

raise up unrestricted.

egs leaving as much slack in cable as possible

NOTE: Leave as much

slack in cable as possible

between the cable tie and

the leg to allow desk top

to raise up unrestricted.

Failure to follow this

may result in equipment

damage.

2x

12 of 19

888-24-227-G-01 rev. E • 12/19

Page 13

Set-up Steps

Set the desk upright onto its legs.

12

CAUTION!

LIFT HAZARD!

Two persons are required for

this step. Failure to follow

this warning may result in

equipment damage and or

personal injury.

13

Adjust the riser on each leg and check with a level to

make sure the work surface is even.

Spin Right to Lower.Spin Left to R aise.

888-24-227-G-01 rev. E • 12/19

13 of 19

Page 14

Set-up Steps

Remove the 4 brake stop screws before installing equipment.

14

Remove the 2 stop screws from the legs then the 2 stop screws from

the brake to allow the worksurface to raise and lower.

IMPORTANT!

Save these stop screws and instructions. Install stop

screws when shipping or storing this product. Failure

to follow these instructions may cause lift engine to

expand rapidly and may result in equipment damage

and or personal injury.

1

2

14 of 19

After you remove the 4 brake stop

screws, release the hand brake

(on the

worksurface up to highest level.

right leg) and move the

888-24-227-G-01 rev. E • 12/19

Page 15

Set-up Steps

Install all equipment.

15

CAUTION! Make sure you leave 20” (508mm)

of slack in all equipment cables to allow the

worksurface to raise up it’s full 20” (508mm).

Failure to allow enough slack in equipment

cables may cause cables to get pulled,

equipment to fall o desk and may result in

product damage and or personal injury.

16

Adjustment Step

Important! You will need to adjust this product after installation is complete. Make sure all your equipment is properly

installed on the product before attempting adjustments. This product should move smoothly and easily through

the full range of motion and stay where you set it. If movements are too easy or di cult or if product does not stay

in desired positions, follow the adjustment instructions to create smooth and easy movements. Depending on your

product and the adjustment, it may take many turns to notice a di erence. Any time equipment is added or removed

from this product, resulting in a change in the weight of the mounted load, you should repeat these adjustment steps

to ensure safe and optimum operation.

WARNING

IMPACT HAZARD

Moving Parts Can Crush And Cut

Minimize Lift Strength BEFORE:

- Removing Mounted Equipment

Insert 4 Stop Screws BEFORE:

- Shipping or Storing (i.e. when Desk is not upright).

To Minimize Lift Strength

Refer to installation manual for instructions on

To Insert 4 Stop Screws

Refer to installation manual for instructions on

Failure to heed this warning may result in

serious personal injury or property damage!

For More information and instructions visit www.ergotron.com

or contact Ergotron Customer Care at 1-800-888-8458

and

how to minimize lift strength.

installing stop screws.

.

826-901-00

888-24-227-G-01 rev. E • 12/19

15 of 19

Page 16

17

Release the hand brake (on the right leg) and move

the worksurface up to highest level.

Push in the cover located behind each leg to access

the adjustment point.

Maintain equal amount of tension on both legs by

alternating the adjustment from one leg to the

using a 14mm socket drill.

Adjustment Step

NOTE: The covers on the legs will not open

unless the worksurface has been lifted to it’s full

height. The worksurface will not lower unless

the covers have been completely closed.

other

14mm

=

Increase Lift Strength

If the mounted weight is too heavy or this

product does not stay up when raised, then you'll

need to increase Lift Strength:

Decrease Lift Strength

If the mounted weight is too light or this product

does not stay down when lowered, then you'll

need to decrease Lift Strength:

Make sure

covers are fully

closed before

lowering the

worksurface.

16 of 19

WARNING! DO NOT tip desk over to adjust. Only perform adjustment while desk is upright.

Failure to follow these instructions may cause the lift engine to expand rapidly and may result in

equipment damage and or personal injury.

888-24-227-G-01 rev. E • 12/19

Page 17

APPENDIX A - Minimize Lift Tension

WARNING. Before removing mounted equipment (monitor, arm, stand CPU, etc.), from desk, or

to prepare for shipping or storing the desk it is extremely important to minimize the lift tension.

Failure to install these instructions may cause lift engine to expand rapidly and may result in

equipment damage and or personal injury.

1. Release the hand brake (on the right leg) and move the worksurface up to

highest level.

2. Push in the cover located behind each leg to access the adjustment point.

NOTE: The covers on the legs will not open unless

the worksurface has been lifted to it’s full height. The

worksurface will not lower unless the covers have been

completely closed.

3. To minimize tension, turn adjustment bolts left using a 14mm

socket drill. Maintain equal tension on both legs by alternating

adjustment from one leg to the other. Keep adjusting until the

wrench stops turning.

4. Once at minimum tension it is ok to remove mounted equipment.

Turn adjustment

bolts left to

minimize tension.

=

14mm

Make sure

covers are fully

closed before

lowering the

worksurface.

888-24-227-G-01 rev. E • 12/19

WARNING! DO NOT tip desk over to adjust. Only perform adjustment while desk is

upright. Failure to follow these instructions may cause the lift engine to expand rapidly

and may result in equipment damage and or personal injury.

17 of 19

Page 18

APPENDIX B - Inserting Stop Screws

WARNING. Before shipping or storing the desk, or in cases where the desk is placed on it’s back

or side*, it is extremely important that the 4 stop screws be re-inserted. Failure to follow these

instructions may cause lift engine to expand rapidly and may result in equipment damage and

or personal injury.

1. Follow instructions in Appendix A to minimize lift tension.

2. Push the desk down to its lowest position.

3. Insert 2 stop screws at the bottom of each leg.

4. Insert the other 2 stop screws on each side of the hand brake located on the right

side of the worksurface.

5. Once the 4 stop screws have been

installed the desk can be shipped

or stored.

* Placing the desk on its back or side is not

recommended.

1

2

18 of 19

888-24-227-G-01 rev. E • 12/19

Page 19

Learn more about ergonomic computer use at: www.ergotron.com/ergonomics

For Warranty visit: www.ergotron.com/warranty

For Service visit: www.ergotron.com

For local customer care phone numbers visit: http://contact.ergotron.com

www.ergotron.com |

© 2016 Ergotron, Inc. All rights reserved. WorkFit™ is a registered trademark of Ergotron, Inc.

888-24-227-G-01 rev. E • 12/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

|

China: 400-120-3051

|

Japan: japansupport@ergotron.com

19 of 19

Loading...

Loading...