StyleView® SV42 Electronic Medical Records (EMR) Cart

StyleView powered carts provide electrical AC power for

mobile point of care computing equipment in a healthcare

environment. The carts are not intended to power medical

products or devices. Outlets are provided to power

information technology equipment only such as computer

equipment and computer peripherals.

User Guide

with LCD Arm and LiFe Power System

Features & Speci cations .................................................... 3

Set-up ............................................................................ 4 - 12

Adjustment .................................................................... 11

Battery Charge/Discharge .............................................12

Change Fuse (5 Amp) ..........................................................13

Change Power System Batteries ................................ 14 - 15

Cart Storage .......................................................................15

Ergonomics .........................................................................16

Maintenance & Safety ................................................ 16 - 19

Dimensions .........................................................................20

For Warranty visit: www.ergotron.com/warranty

For Service visit: www.ergotron.com

ENGLISH

For local customer care phone numbers visit: http://contact.ergotron.com

For the latest User Installation Guide and StyleLink Software Download please visit: www.ergotron.com

User's Guide - English

Guía del usuario - Español

Manuel de l’utilisateur - Français

Gebruikersgids - Deutsch

Benutzerhandbuch - Nederlands

Guida per l’utente - Italiano

Användarhandbok - svenska

ユーザーガイド:日本語

用户指南 : 汉语

888-24-181-G-02 rev. L • 02/16

1/20

WARNING

AVERTISSEMENT

14mm (9/16”)

10 °C

50 °F

29 °C

86 °F

-20 °C

- 4 °F

50 °C

122 °F

IMPACT HAZARD!

MOVING PARTS CAN CRUSH AND CUT.

Failure to heed this warning may result in serious personal

injury or property damage!

Minimize Lift Tension BEFORE:

Removing Mounted Equipment, Shipping Cart, Storing Cart.

DANGER D’IMPACT!

LES PARTIES EN MOUVEMENT PEUVENT ÉCRASER ET COUPER.

Il existe un risque de blessure corporelle ou d’endommagement

matériel en cas de non respect de cet avertissement.

Minimisez la tension d’élévation AVANT:

de retirer l’équipement xé, d’expédier le chariot, de stocker le chariot

www.ergotron.com

IMPORTANT! This product will need tension adjustments once installation is complete. Make sure all equipment is properly installed on the product before

attempting range of motion or tension adjustments. Any time equipment is added or changed on this product resulting in a di erent mounted weight, you

should repeat the adjustment steps to ensure safe and optimum operation. This product should move smoothly and easily through the full range of motion and

stay where you set it. If movement is di cult or the product does not stay where you set it, follow the adjustment instructions to loosen or tighten the tension

to create a smooth, easy motion. Depending on your product and the adjustment, it may take many turns to notice a di erence.

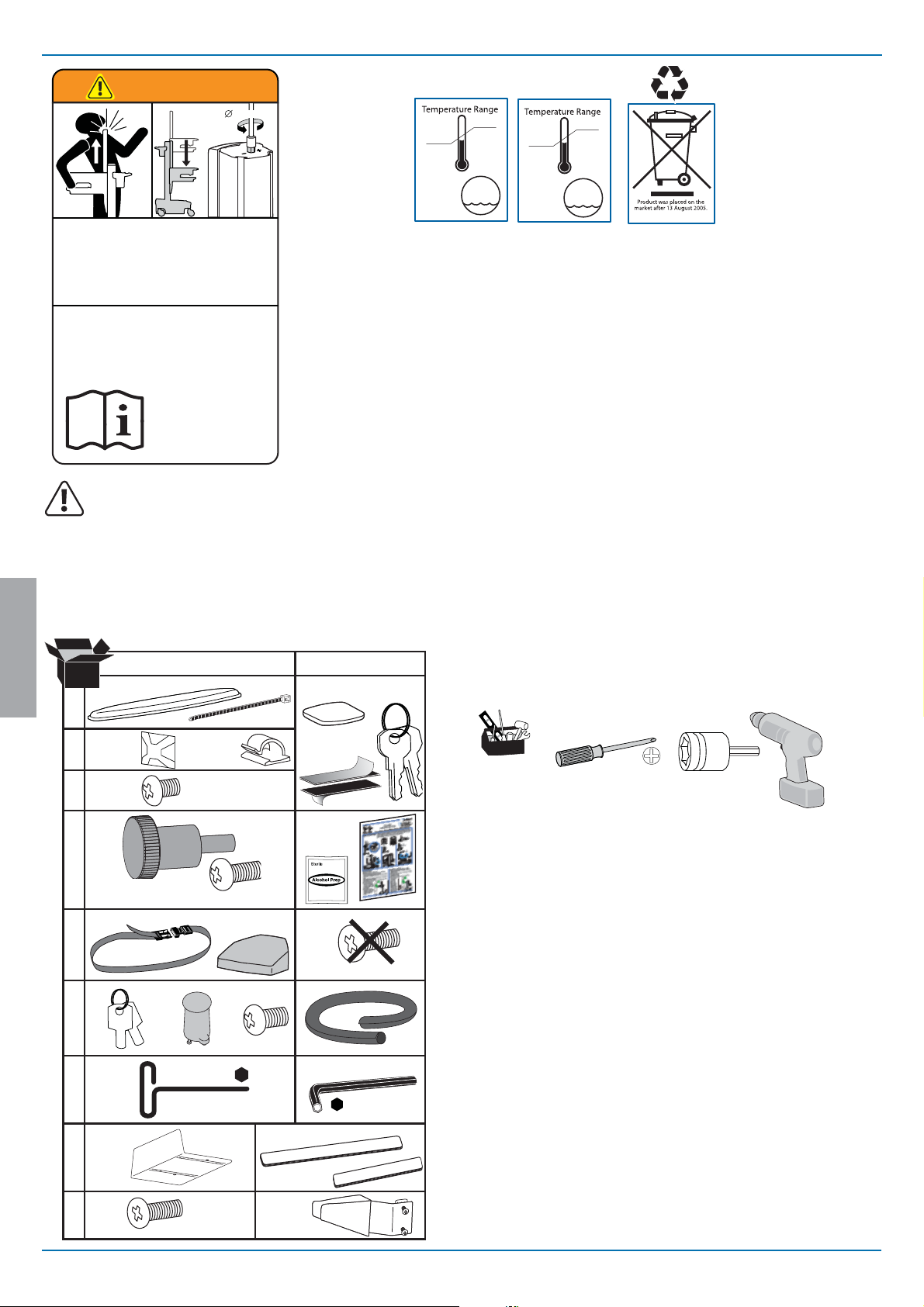

Components

826-501

Relative

5-95% rH

Humidity

Range

Operational Storage

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

FCC Compliance Statement

The cart has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Changes or modi cations not expressly approved by Ergotron, Inc. could void the user’s authority to operate the

equipment.

Please contact Ergotron for complete EMC compatibility information.

Relative

Humidity

Range

5-95% rH

ENGLISH

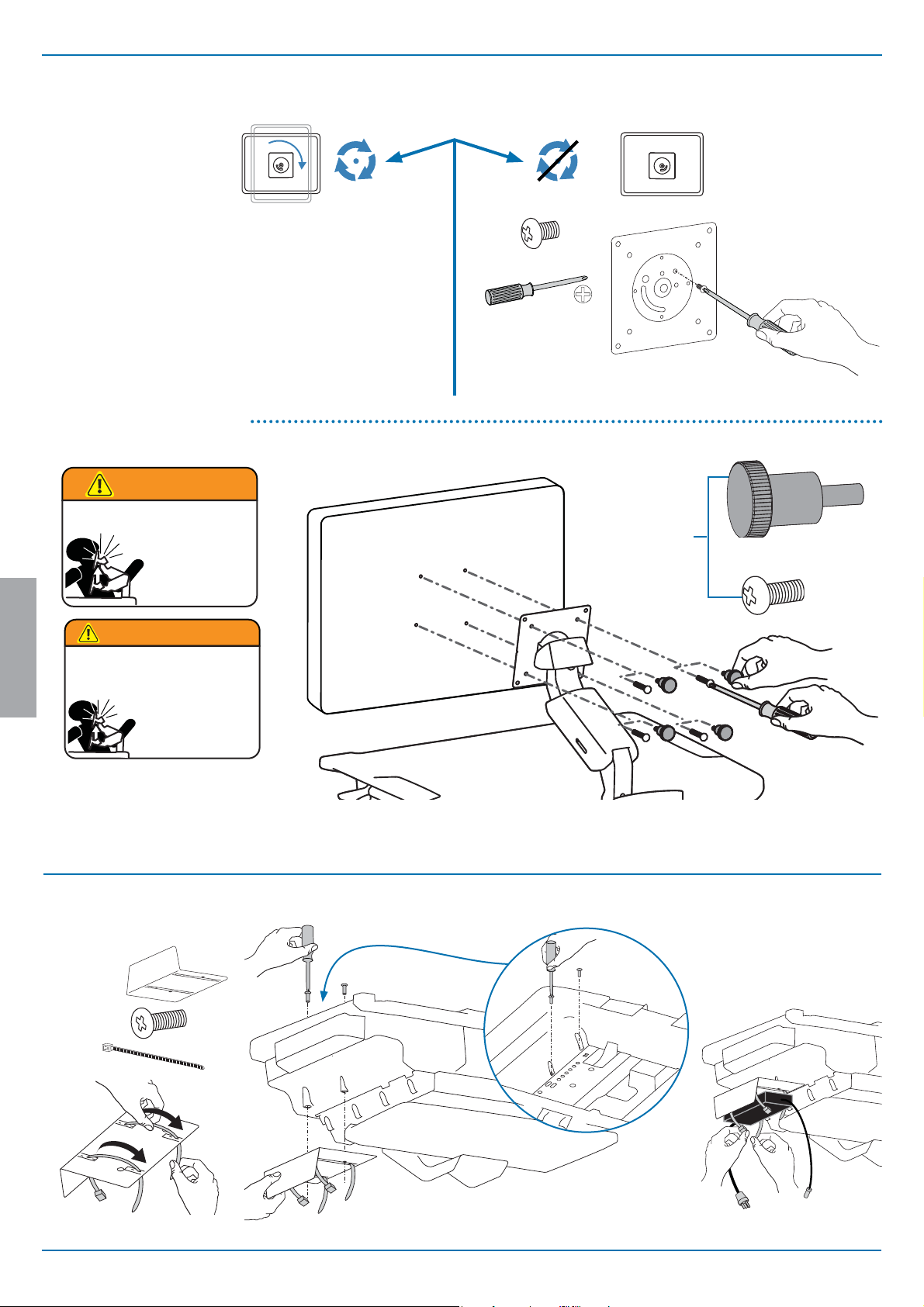

1

2

3

4x

4

5

6

1x

7

1x

1x

1x

1x

1x

AB

4x

2x

12x

1x

M4 x 5mm

M4 x 10mm

2x

1x

2x

8x

M4 x 10mm

1x

1x

M4 x 8mm

4x

1x

1x

M4 x 8mm

5mm

1x

3mm

Tools Needed

14mm (9/16")

2/20

1x

8

1x

1x

2x

9

M4 x 12mm

1x

888-24-181-G-02 rev. L • 02/16

Features & Speci cations

Part Number Power System

SV42-6202-1

SV42-6202-2

SV42-6202-3

SV42-6202-B

SV42-6202-C

Input: 120VAC/60 Hz, 5.0A;

Output: 120VAC/60 Hz, 150VA, 150W.

• The cart and power system are certi ed to UL 60601 and CAN/CSA-C22.2 601.1-M90

Input: 230V~/ 50/60 Hz, 2.5A;

Output: 230V~/ 50/60 Hz, 150VA, 150W.

• The cart and power system are compliant with EN 60601-1.

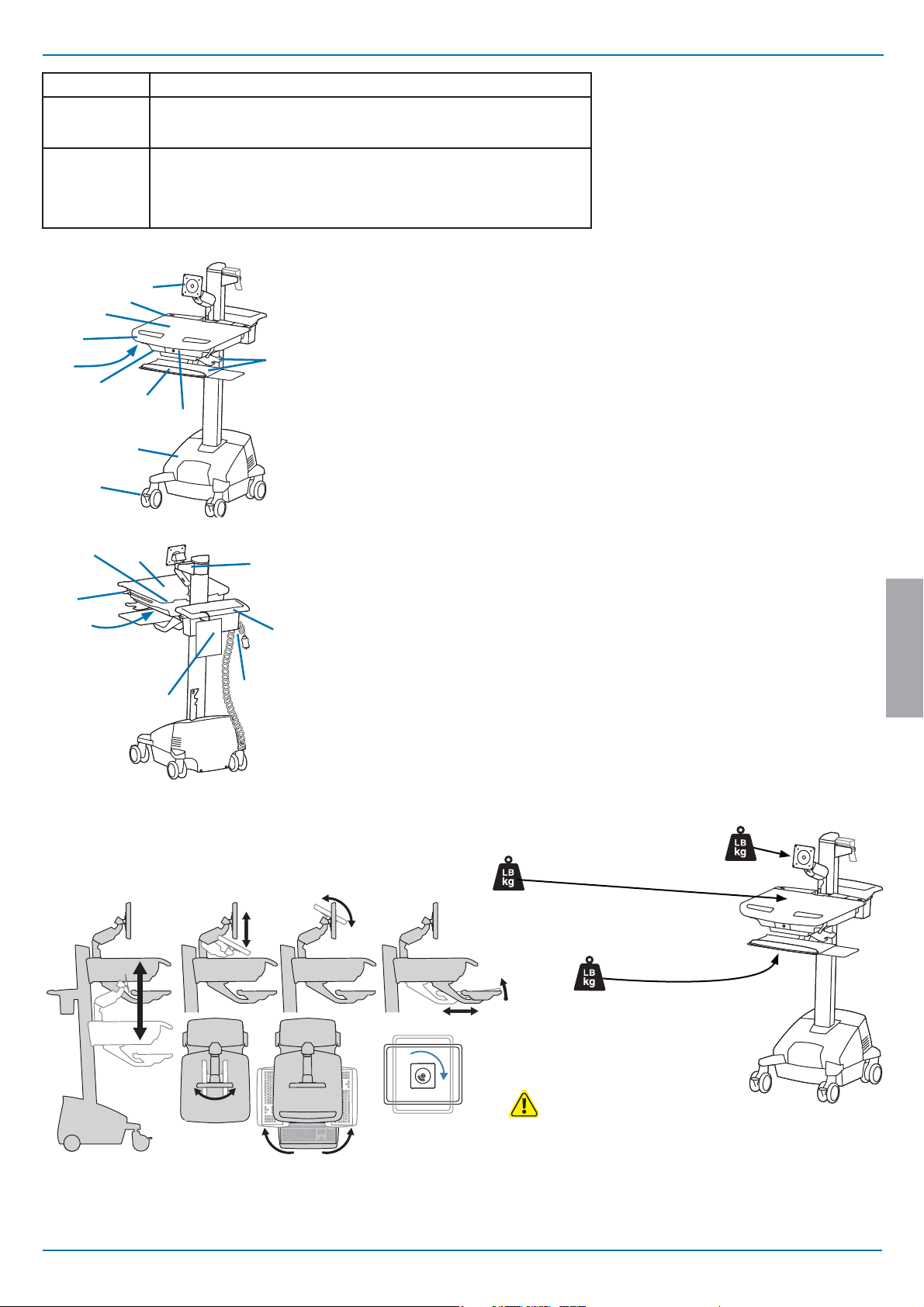

1

3

2

5

9

4/11

17

2a

18

13

10

17

6

7

14

16

15

8

12

1.

Height Adjustable LCD Mount attaches LCDs or tablet PC's with 75x75 or 100x100mm mounting

interface

2.

Worksurface 2a. Worksurface Lock and Release

3.

User Interface

4.

Secure Storage for Laptop, Thin Client or CPU

5.

Front Handle

6.

Height Adjustment Brake Handle

7.

USB Hub connects keyboard and mouse USB cables

8.

Keyboard tray slides out, tilts and allows for right or left mousing with attached mouse holder

9.

Keyboard Light under Front Handle

10.

Keyboard Light Switch

11.

Cable Management and Storage for excess cables and power supplies

12.

Storage Basket and Rear Handle

13.

Front Locking Casters

14.

Quick Reference Card

15.

Power Cord Hooks

16.

Scanner Holder

17.

Antimicrobial coating on worksurface and wrist rest

18.

Power System

The StyleView AC Power System allows your power supply to travel with the cart. The Power System is

integrated in the base of the cart and comes standard with battery, power module, User Interface (UI), outlet

box and power cord.

• User Interface (UI): Allows power system output to be turned on or turned o , monitors battery charge

remaining, and provides low battery charge audible alarm.

• Battery: One 40-Ah Lithium battery.

• The minimum operational temperature is 10°C (50°F) and the maximum operational temperature is 29°C (86°F). The

recommended humidity range for operation is 5-95% rH.

• The recommended cart storage temperature is 25°C (77°F). At this temperature, the battery’s age-related

capacity loss is minimized. The minimum storage temperature is -20°C (-4°F) and the maximum storage

temperature is 50°C (122°F). The recommended humidity range for storage is 5-95% rH.

ENGLISH

20"

(508 mm)

888-24-181-G-02 rev. L • 02/16

180˚

7"

(178 mm)

60˚

5˚

90˚90˚

0 lbs (0 kg)

<3 lbs (1.4 kg)

<12 lbs (5.4 kg)

12˚

If the combined LCD and CPU weight is greater than 27 lbs (12.2 kg) then the CPU must be

mounted to the rear of the cart using the Universal CPU Holder accessory (ordered separately).

Weight Capacity

Open Worksurface

Closed Worksurface

CPU Compartment

<2 lbs (0.9 kg)

CAUTION:

6-11 lbs (2.7-5 kg)

3/20

1

Release Brake to move riser.

CAUTION! Completely release brake

engagement before raising or lowering

the cart. Raising or lowering the cart with

the brake partially engaged may cause

product damage.

ENGLISH

2

a

1x

b

1x

1x

4/20

1x

888-24-181-G-02 rev. L • 02/16

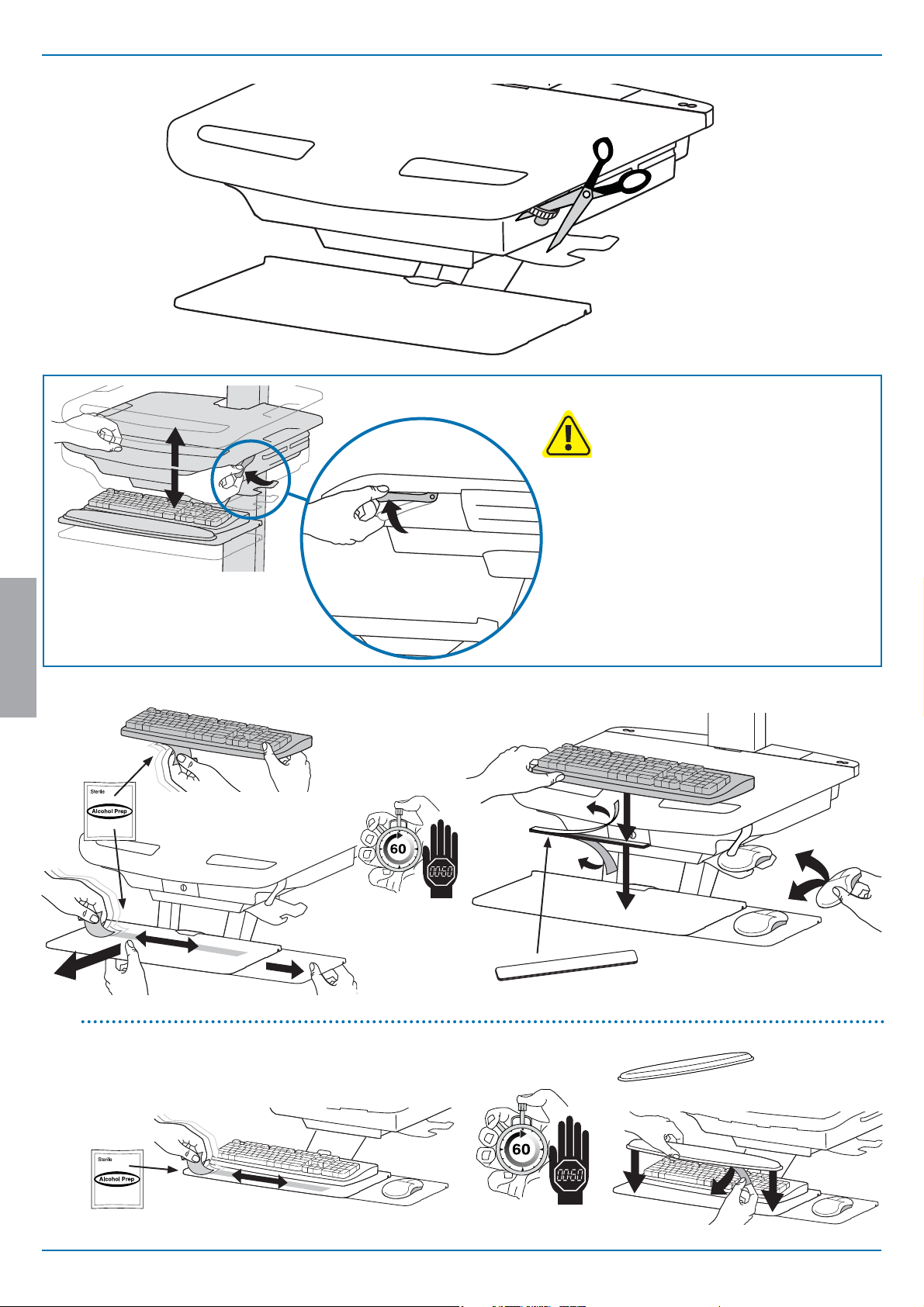

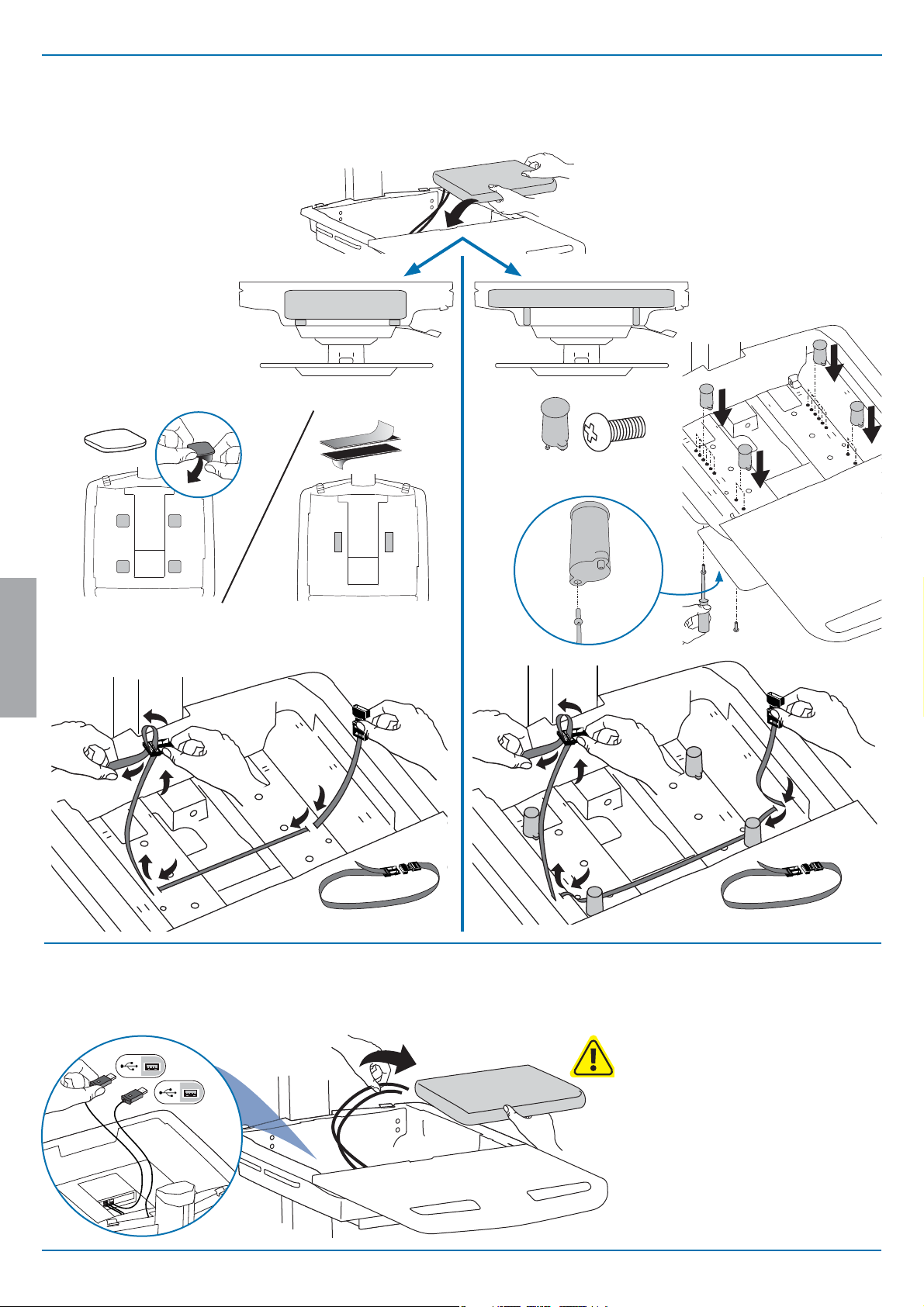

Set-up

c

1x

ENGLISH

ab

3

Connect Keyboard and Mouse to USB Hub

c

USB (Type A)

NOTE: Bar Code Scanner should be connected directly to

computer USB port.

DO NOT connect Bar Code Scanner to the USB Hub.

USB (Type A)

888-24-181-G-02 rev. L • 02/16

5/20

Set-up

75x75mm / 100x100mm

b

WARNING

Impact Hazard!

Moving Parts can Crush and Cut.

Raise monitor to top of vertical

adjustment BEFORE removing.

Failure to heed this warning

may result in serious personal

injury or property damage!

826-504

4

a

1x

M4 x 5mm

0˚

4x

0˚

M4 x 10mm

AVERTISSEMENT

Danger d’impact!

Les parties en mouvement peuvent

écraser et couper. Élevez l’écran au plus haut de

ENGLISH

l’ajustement vertical AVANT de le retirer.

To increase space and improve air ow, power brick may be stored under the storage area.

Il existe un risque de blessure

corporelle ou d’endommagement matériel en cas de non

respect de cet avertissement.

827-404

1x

2x

M4 x 12mm

b

2x

c

6/20

a

888-24-181-G-02 rev. L • 02/16

Set-up

Plug in power cables.

5

If you do not have power outlets located here,

then follow steps 'a' - 'd' to route power cables.

WARNING! Connecting electrical equipment to the outlet

e ectively leads to creating a medical system and the

result can be a reduced level of safety.

Route power cable down along tower.

a

1x

1x

6' (1.8 m)

Power cables need to be 6'

(1.8 m) long.

ENGLISH

b

WARNING

DO NOT OPERATE

WITHOUT

GUARD

IN PLACE

WARNING! DO NOT OPERATE WITHOUT GUARD IN PLACE. Only

remove guard when routing a cable with a large connector through

the bottom of the compartment. Replace guard imediately after

routing cable. Failure to replace guard my result in equipment

damage and or personal injury.

822-447-00

cd

1x

1x

888-24-181-G-02 rev. L • 02/16

WARNING! Connecting electrical equipment to the outlet e ectively leads to creating a medical system

and the result can be a reduced level of safety.

7/20

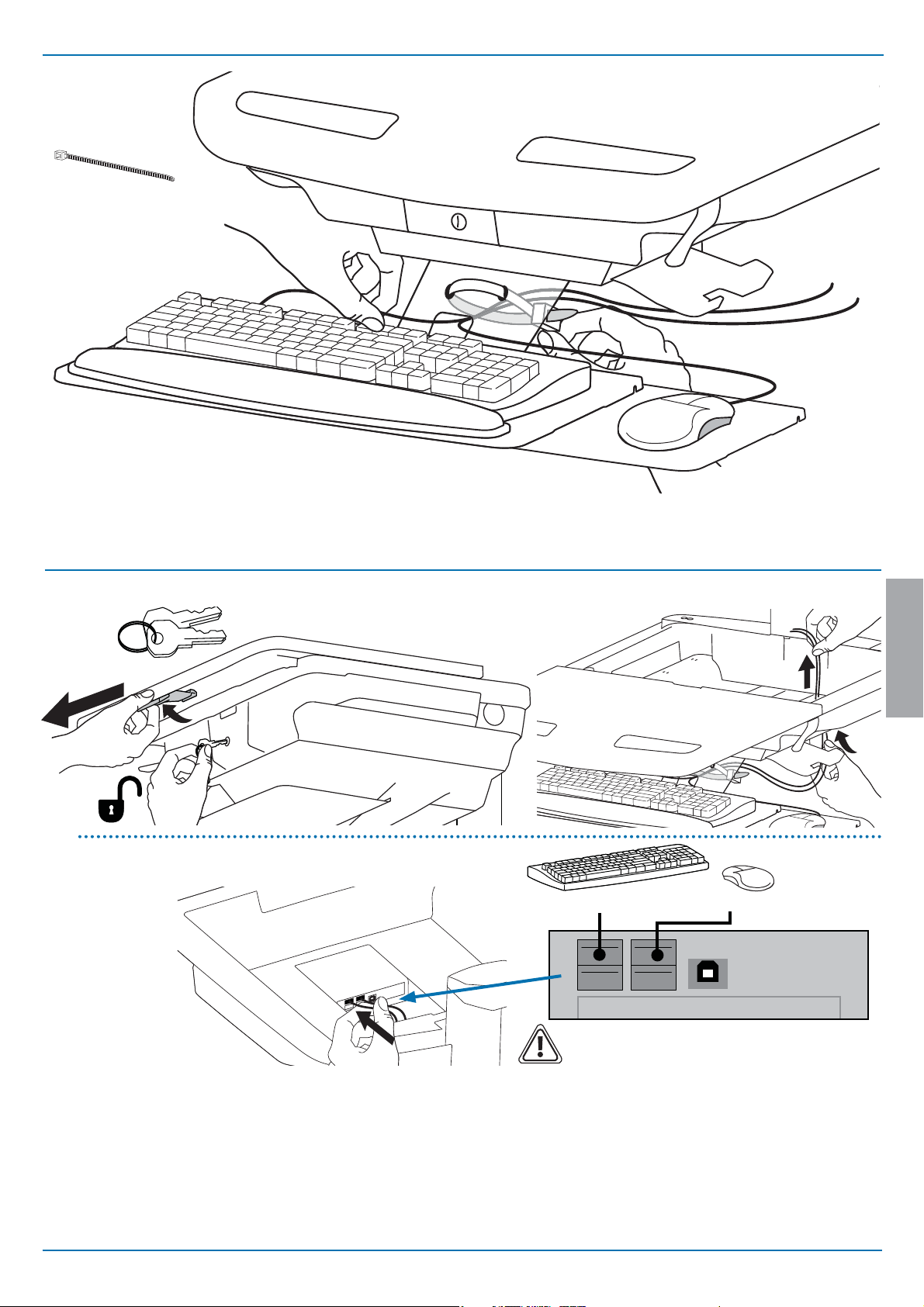

Set-up

Place computer and AC power adaptors in compartment. Do not place power bricks near

aa

4x

2x

computer or compartment air vents.

4x

4x

M4 x 10mm

6

ENGLISH

b

Plug the following factory connected cables into your computer.

c

USB: This cable runs from the USB Hub to your computer and uses your computer to power the USB Hub, Keyboard Lights and Fan. (NOTE: Your computer must be turned

on for the USB Hub, Keyboard Lights and Fan to function).

Optional StyleLink: This USB cable runs from the power system to your computer for StyleLink Software. For more info on StyleLink visit: http://4support.ergotron.com .

b

1x 1x

WARNING: Fan must always be running when

computer is on. Operating computer without fan

may lead to overheating, resulting in reduced

equipment performance.

8/20

888-24-181-G-02 rev. L • 02/16

Set-up

d

DO NOT OBSTRUCT AIR VENTS!

Obstructing air vents may cause overheating and result in

equipment damage.

e

If computer with cables is too wide, then

follow these instructions.

1

2

Placement of CPU's in Secure Storage Area:

USFF (Ultra Small Form Factor)

Center CPU in storage area.

To increase space and improve air ow,

power brick may be stored under the

storage area.

Thin Client

f

ENGLISH

1x

7

888-24-181-G-02 rev. L • 02/16

9/20

Set-up

8

9

ENGLISH

1x1x

10/20

888-24-181-G-02 rev. L • 02/16

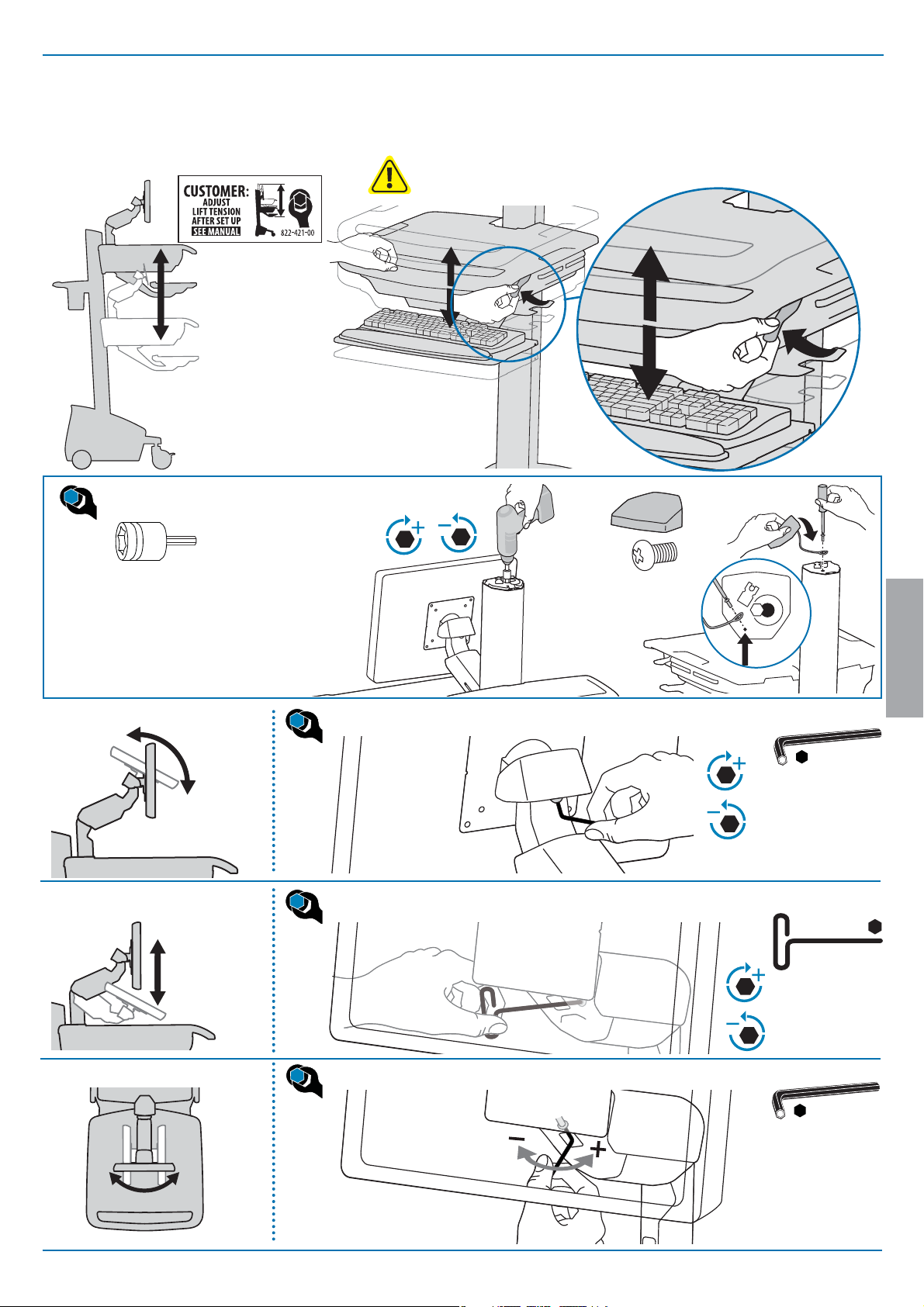

Adjustment

10

Lift – Up and down

a

It is important that you adjust this product according to the weight of the mounted equipment as described in the following steps. Any time equipment is added or removed from this

product, resulting in a change in the weight of the mounted load, you should repeat these adjustment steps to ensure safe and optimum operation.

Adjustments should move smoothly and easily through the full range of motion and stay where you set it. If adjustments are di cult and do not stay in the desired position, follow

the instructions to loosen or tighten the tension to create a smooth, easy adjustment motion. Depending on your product and the adjustment, it may take several turns to notice a

di erence.

Release Brake to move riser.

Follow these instructions to tighten or loosen tension.

14mm (9/16")

Tilt – Forward and Backward

b

Lift – Up and down

c

NOTE: Adjustment

may require 40 - 60

revolutions.

1x

M4 x 8mm

ENGLISH

Follow these instructions to tighten or loosen tension.

3mm

Follow these instructions to tighten or loosen tension.

5mm

Pan – Side-to-side

d

888-24-181-G-02 rev. L • 02/16

Follow these instructions to tighten or loosen tension.

3mm

11/20

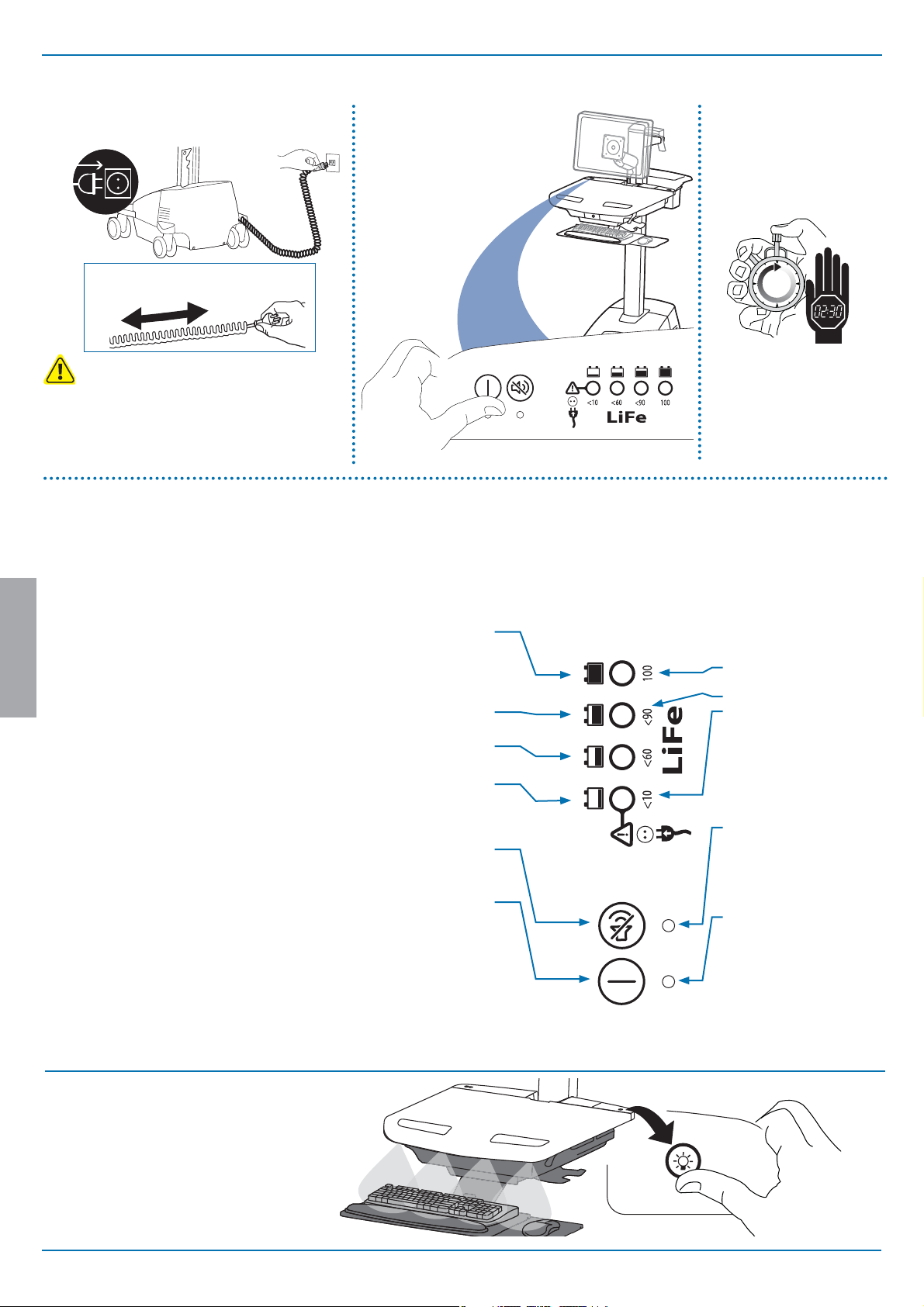

Battery Charge/Discharge

Initial Power on/Charge Battery (takes aproximately 2.5 hours to charge)

11

Plug Cart's Power Cord into wall outlet.

ab c

Turn on power system by holding

power button down for 1 - 3

seconds.

With cart's power cord

plugged into the wall

outlet, wait until cart is

at 100% charge. (takes

aproximately up to 2.5

hours to charge)

Do Not stretch coiled cord further than 8 feet

(2.5 meters), damage to the cord may occur.

CAUTION: There is no on/o switch on

this equipment; the AC power cord is the only

power disconnect. The socket outlet should be

easily accessible and should be installed near the

equipment.

This power system interface will alert you to the percentage of charge remaining in the cart battery with a series of steady or ashing

red, yellow or green lights, and an alarm that will beep when charge gets below 10%. Remember, the battery needs to be charged to

100% every day, and you can use the cart while charging, so plug-in cord as often as possible to avoid running out of power!

NOTE: Put monitor in power save mode to optimize battery run time.

Light ashes when charging (power cord plugged into wall outlet)

charging until light stops ashing. After light stops ashing, it is OK to unplug the

ENGLISH

Battery has less than 10% charge and alarm beeps. Light is orange and then turns red when

battery has less than 5% charge. Plug-in power cord and charge to 100%! You can use cart while

Alarm Mute button. Pressing this will temporarily mute alarm. When battery has less than 5%

Power button for internal power system outlets. Pressing this will provide or remove power to/

power cord from the wall.

charge, the alarm mute is only e ective for 1 min.

from components plugged into the internal outlets.

Battery has 100% charge.

Allow battery to continue

You can use cart while charging.

Battery has less than 90% charge.

Battery has less than 60% charge.

charging.

2.5hrs

If the battery is stored too long

without recharging, the electronics

in the battery may cause the

battery voltage to drop too low. If

this happens, the power system will

enter a low charge recovery mode

when plugged into power source.

During the low charge recovery

process this light will blink green.

This light will be green.

This light will be blinking red.

Once the process has nished the

power system will resume charging

as normal. if the low charge

recovery process takes longer than

45 min please contact Ergotron

Customer Care.

When lit, alarm is enabled and

will beep when battery charge

gets below 10%. For details on

enabling and disabling alarm

contact Ergotron Customer Care.

When lit, the power system is on.

When dark, power system is o .

If other lights are ashing red/green it could indicate a power system fault. If this occurs contact

NOTE: Frequent operation of the cart while battery charge levels are below 10% may reduce the

Ergotron Customer Care.

life of your battery.

Keyboard Light

12

12/20

1. Turn Computer on.

2. Test Keyboard Light.

Keyboard Light will automatically turn o

after 15 minutes if not manually turned o .

888-24-181-G-02 rev. L • 02/16

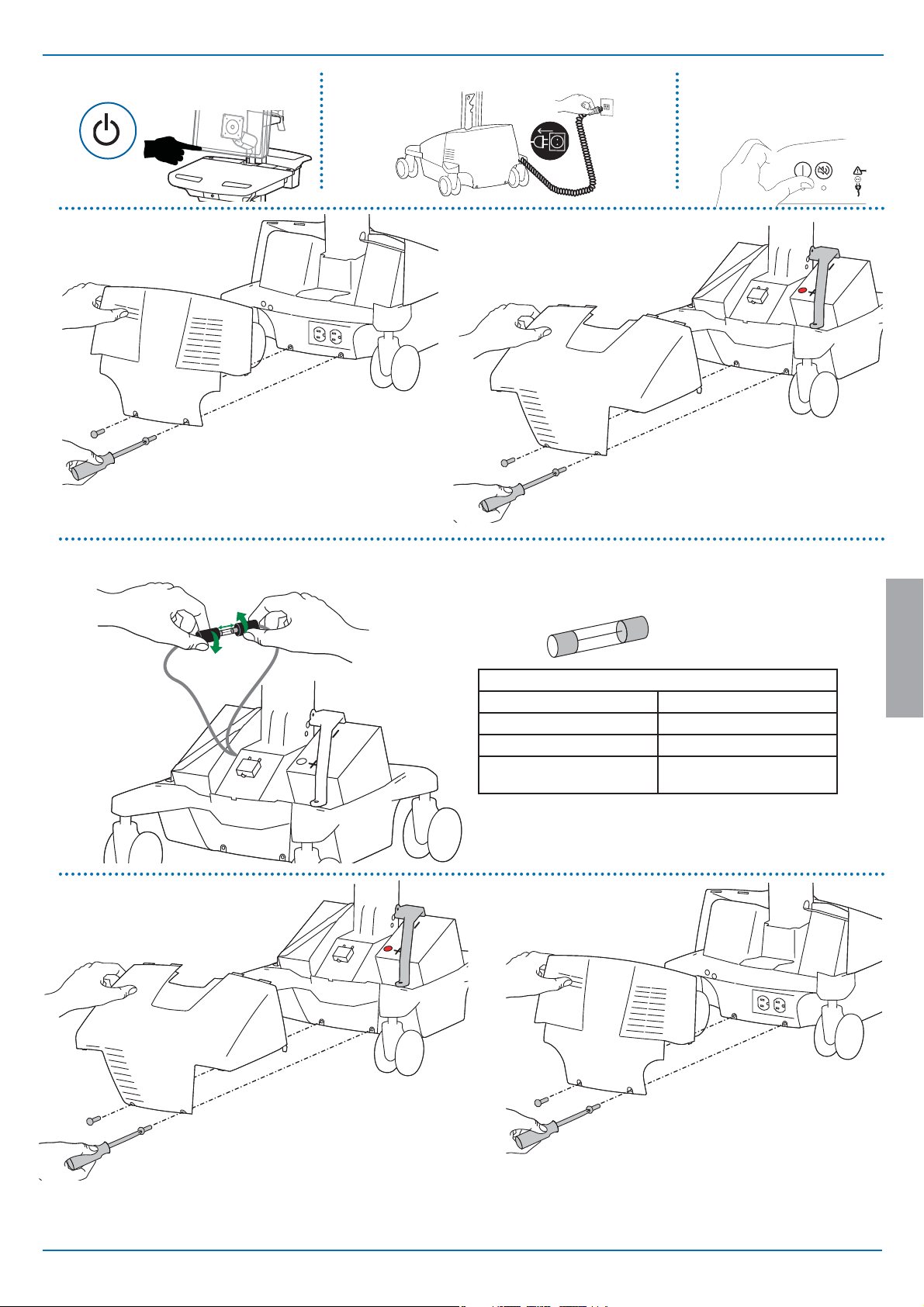

How to Change Fuse

Turn o all mounted equipment.

1 23

Disconnect Power System from power source.

Turn power system o by

holding down the AC Outlet

Power button for 1 - 3 seconds.

Power light will shut o .

4

5 Amp Fuse

5

6

Recommended:

Littelfuse 312005HXP

FUSE RATING

VOLTAGE 250V

CURRENT 5A

OPERATING SPEED FAST-ACTING

BREAKING CAPACITY 200A @ 250VAC

10000A @125VAC

ENGLISH

888-24-181-G-02 rev. L • 02/16

13/20

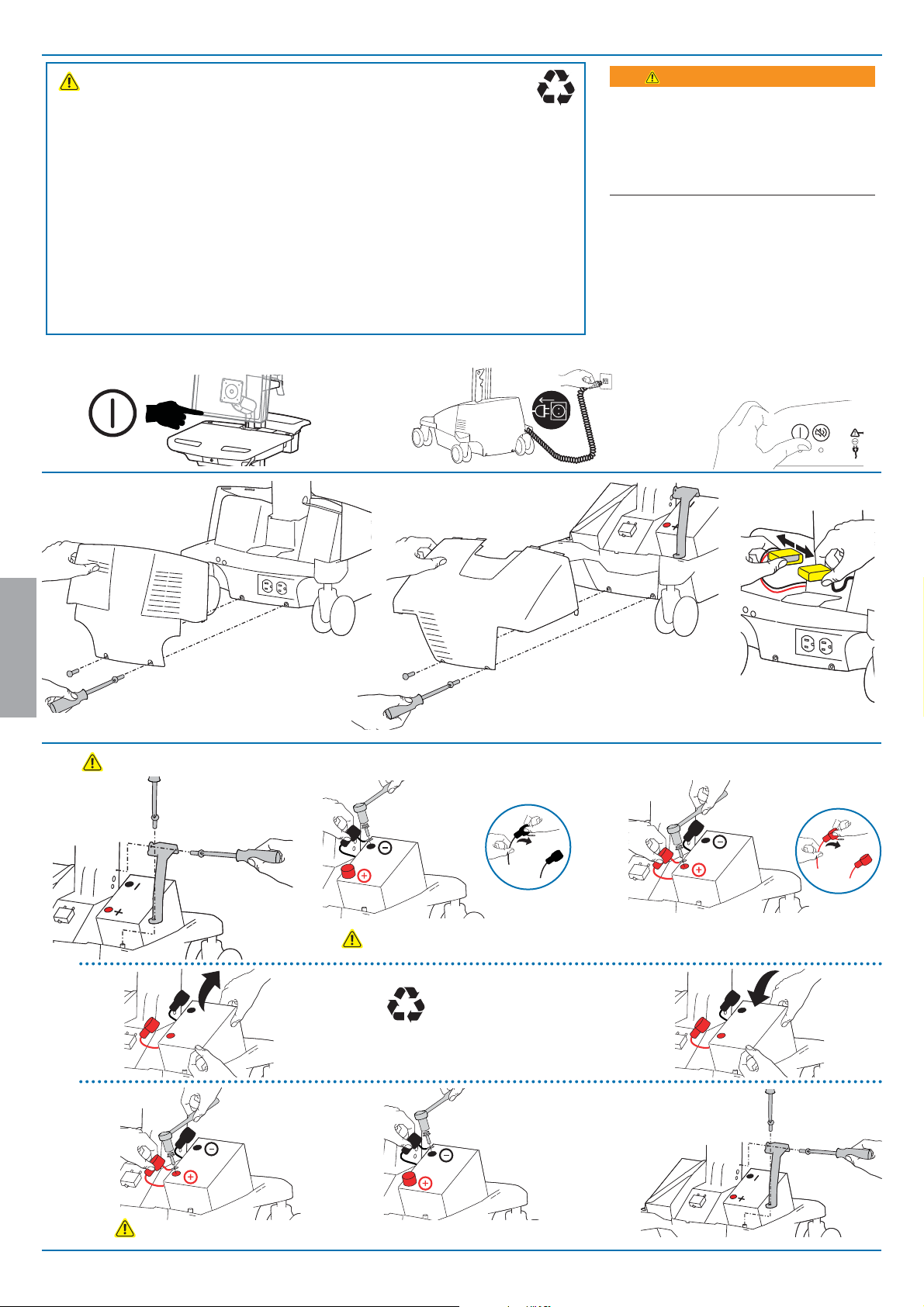

How to Change Power System Battery

WARNING: RISK OF ELECTRICAL DISCHARGE

• Do NOT swap battery cables, doing so will cause arcing and trip the circuit breaker.

• Do not remove or replace the batteries while cart is located in an oxygen rich or

hazardous environment, arcing may occur and cause combustion.

CAUTION: To avoid risk of electrical shock when replacing battery:

• Remove Black (-) cable from post before removing Red (+) cable from post.

• Connect Red (+) cable to post before connecting Black (-) cable to post.

NOTE

• Only Ergotron-speci ed batteries may be used in the StyleView Power System.

Contact Ergotron customer care for more details.

• Do not dispose of the Lithium battery in the trash.

Recycle the battery according to local regulations.

Please note, the EPA classi es spent lithium batteries as “Universal Waste”.

The shipping requirements for “Universal Waste” are available at the EPA website at www.epa.gov.

1 a bc

2

Turn o all mounted equipment.

a b c

Disconnect Power System from power source.

WARNING/AVERTISSEMENT

Only the following 40 -Ah lithium batteries are compatible with this system:

Installing batteries other than the Valence battery listed above will void the product warranty and

result in power system malfunction. Failure to heed this warning may result in severe damage to

batteries, power module and possible re hazard.

L’installation de toute batterie autre que la batterie Valence indiquée ci-dessus rendra nulle la

garantie du produit et entraînera le dysfonctionnement du système d’alimentation. Si vous ne vous

conformez pas à cette précaution d’utilisation, les batteries et le module d’alimentation risquent

d’être sérieusement endommagés, ce qui pourrait provoquer un incendie.

BATTERY REPLACEMENT

Valence Model Number: U1-12RT REV2

Ergotron Part Number: 910-434

Valence Model Number: U1-12RJ

Ergotron Part Number: 915-766

REMPLACEMENT DE LA BATTERIE

Seule la batterie suivante est compatible avec ce système:

Batterie au lithium de 40Ah.

Batterie Valence modèle numéro: U1-12RT REV2

Numéro de pièce Ergotron: 910-434

Batterie Valence modèle numéro: U1-12RJ

Numéro de pièce Ergotron: 915-766

Turn power system o by holding down

the AC Outlet Power button for 1 - 3

seconds. Power light will shut o .

826-505

ENGLISH

3

a

d

f

Caution: Do NOT swap battery cables, doing so will cause sparking and trip the circuit breaker.

b

Caution: Remove Black (-) before removing Red (+).

Recycle the battery according to

local regulations.

Red

g

c

Red

e

h

14/20

Caution: Connect Red (+) before connecting Black (-).

888-24-181-G-02 rev. L • 02/16

How to Change Power System Battery

a b c

4

5

Follow Battery Charge/Discharge Initial Power on steps a, b, c.

Cart Storage Instructions

Storage - The battery needs to be fully charged before storing and the battery must be recharged a minimum of every 90 days.

50 °C

• The recommended cart storage temperature is 25°C (77°F). At this temperature, the battery’s age-related

122 °F

capacity loss is minimized. The minimum storage temperature is -20°C (-4°F) and the maximum storage

temperature is 50°C (122°F). The recommended humidity range for storage is 5-95% rH.

Relative

5-95% rH

Range

Storage

Turn o all mounted equipment.

Plug power cord into appropriate wall outlet to fully charge battery to 100% (all indicator lights will be illuminated). Power system must be fully charged

before storing!

Humidity

1

2

-20 °C

- 4 °F

ENGLISH

Once battery has been charged to 100%, turn power system o .

Turn power system o by holding down the AC Outlet Power button for 1 - 3 seconds. Power light will shut o .

3

Recharge battery a minimum of every 90 days.

4

NOTICE:

Warranty on fully charged batteries left in an unused state for more than three (3) consecutive months is automatically void.

Warranty on fully discharged batteries left in an unused state for more than three (3) consecutive days is automatically void.

If the battery is stored too long without recharging, the electronics in the battery may cause the battery voltage to drop to an unsafe level. If this happens, the power system will

enter a low charge recovery mode when plugged into power source. Once the process has nished the power system will resume charging as normal. if the low charge recovery

process takes longer than 45 min please contact Ergotron Customer Care.

888-24-181-G-02 rev. L • 02/16

15/20

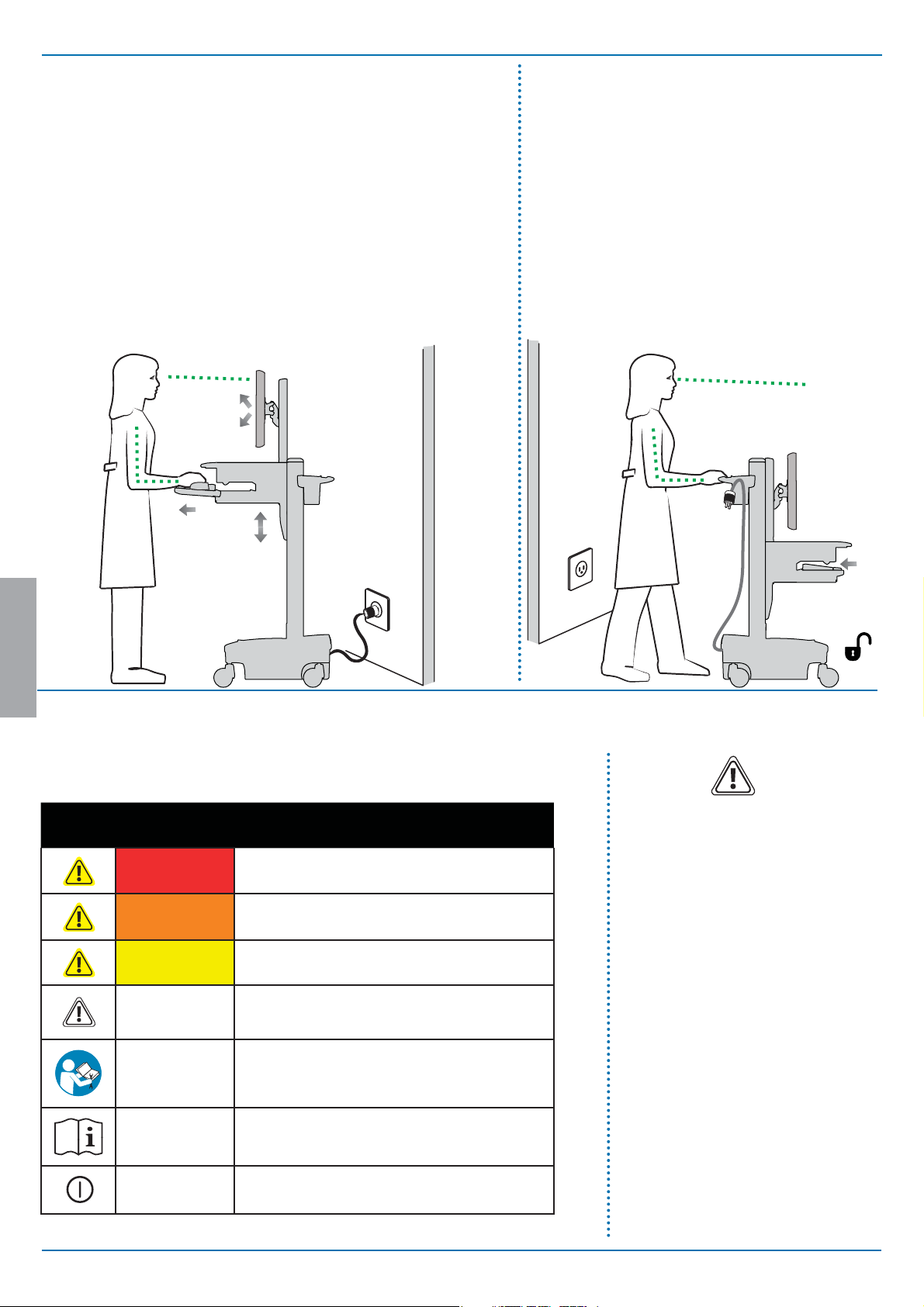

Ergonomics

Working

customize - to your size

Moving

stow - before you go

1 Set top of monitor screen about one inch below eye level - Release brake and lift or lower riser

as needed.

2 Tilt screen for comfortable viewing and to reduce eye and neck strain.

3 Pull keyboard tray forward and position mouse tray on right or left, as needed.

4 Work with elbows bent at about 90° to minimize muscle strain.

5 If the riser moves up and down with di culty, or if it drifts out of set position, consult the product

manual for adjustment information.

6 Stay in charge!

Powered carts should be plugged into outlet as often as possible to keep battery charged and

computer running.

1

2

4

3

5

1 During normal movement, release brake and lower worksurface to

lowest position for optimal stability and unobstructed view.

2 Tuck away open trays and return mouse, scanner and other accessories

to their places.

3 Unlock both front casters.

4 Push cart from rear with elbows bent at about 90° to maximize control

and minimize muscle strain.

5 Don’t run out!

Before moving, make sure cord is unplugged from outlet and hooked to

basket for safe travel. Remember, charge battery fully 100% every day!

1

4

5

6

ENGLISH

Maintenance & Safety

Hazard Symbols Review

The Meaning of Symbols appearing in this Guide, on the Cart or on the Power System

These symbols alert you to a safety condition that demands your attention. You should be able to recognize and

understand the signi cance of the following Safety Hazards if you encounter them on the Cart or within Cart

documentation such as this Set-up Guide.

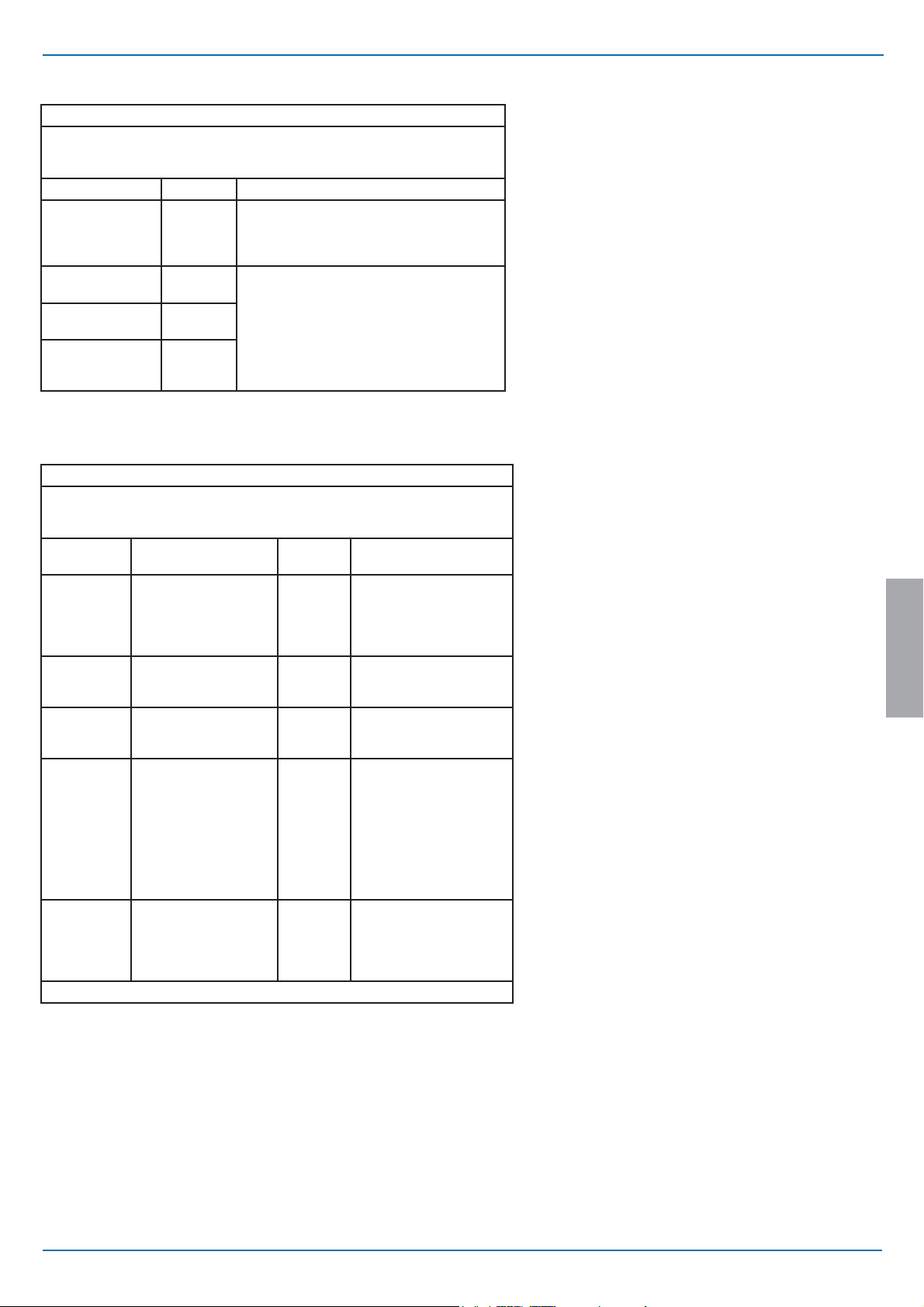

Symbol

Signal Word/

Color

DANGER

WARNING

CAUTION

CAUTION

Level of Hazard

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in

property damage.

2

3

EQUIPMENT & ACCESSORIES DISPOSAL

1. Please dispose of all batteries in accordance with

local law

2. All Electronics should be recycled through an

electronics recycler.

3. Remaining plastics and metals can be recycled

through a commercial recycler.

16/20

INSTRUCTIONS

INSTRUCTIONS

POWER

Follow operating instructions.

Follow operating instructions.

"ON" / "OFF" (push-push)

NOTE: Each position "ON" / "OFF" is a stable position.

888-24-181-G-02 rev. L • 02/16

Maintenance & Safety

Cleaning and Maintenance

The following procedures are not guaranteed to control infection. The hospital infection control administrator or epidemiologist should be consulted regarding cleaning procedures

and processes.

To avoid risk of electric shock, do not expose electrical components to water, cleaning solutions or other potentially corrosive liquids or substances.

Do not immerse Cart or Cart components in liquid or allow liquids to ow into the Cart. Wipe all cleaners o surface immediately using a damp cloth. Thoroughly dry surface

after cleaning.

Do not use ammable cleaners on Cart surfaces due to close proximity of electrical power and equipment.

All paints and plastic Cart components will withstand cleaning by most commonly used, diluted, non-abrasive solutions such as quaternary ammonia compounds, ammonia

enzyme cleaners, bleach or alcohol solutions.

• Pen and permanent and dry erase markers can be removed with 91% isopropyl alcohol and a soft cloth.

• Iodine stains can be removed with commonly used cleaners and a soft cloth.

• Never use steel wool or other abrasive materials that will damage the surface nish.

• Do not use strong solvents such as trichloroethylene and acetone. These solvents will damage the surface nish.

It is recommended that any cleaning solution be tested on a small, inconspicuous area to ensure surface is not harmed.

Adjustment, Service, Replacement - DO NOT attempt to adjust, service or replace any part of the StyleView Cart unless directed to do so through Ergotron-approved

documentation (i.e. installation instructions). Only Ergotron, Inc. or an Ergotron-certi ed entity may adjust, service or replace StyleView Cart components. If any component on the

Cart is missing or damaged, the Cart must not be used, contact Ergotron Customer Care immediately to request a replacement part.

Cables - Keep cables neatly organized on the Cart (a variety of solutions are provided with your cart for this purpose). Excess cables should be routed away from moving

components with cable clips. Review Cable Routing section of this guide, or contact Ergotron Customer Care for more information.

Casters - Check casters periodically to make sure they are clean and free of debris that would prevent smooth travel. Avoid moving Cart across uneven, dirty or damaged

surfaces.

Customer Equipment- Make sure equipment is balanced and mounted securely to Cart. Do not reposition Cart components on riser or tower unless instructed to do so in the

installation instructions. Moving Cart components too high or too low on the Riser may create an unstable condition, leading to equipment damage or even personal injury. Contact

Ergotron Customer Care for information about moving Cart components.

WARNING: In rare cases, if the power system and battery protection features fail, the battery may become overcharged and in some instances it may become extremely hot,

possibly melting the plastics and releasing smoke. If a battery begins to smoke or melt:

• Unplug the cart, or if possible disconnect the battery from the power system immediately.

• Move the cart to a well ventilated area.

• Use a Carbon Dioxide, Dry Chemical or appropriate foam re extinguisher to spray the hot battery.

If a re extinguisher is not available, use copious amounts of water, or cover the battery with sand.

If exposed to battery contents seek immediate medical attention and follow the below guidelines.

Exposure to vapor released from the battery is irritating to the eyes, skin, mucous membranes and respiratory tract. This may cause nausea, dizziness and headache.

In case of direct contact to the battery’s electrolyte:

• Immediately ush eyes with water for at least 15 minutes.

• Thoroughly rinse hands and other a ected areas with water.

• Promptly remove and wash any contaminated clothing.

In All Cases, Seek Immediate Medical Attention!

ENGLISH

Safety Alerts Associated with this Product

The following Warnings/Cautions appear in this reference guide or on the cart:

NOTE: Failure to adhere to these guidelines may result in equipment damage or personal injury.

CAUTION: The lift brake helps stablilize the worksurface and keyboard tray during normal use but it DOES NOT increase load capacity. DO NOT load riser with equipment

totaling more than the maximum weight capacity speci ed by Ergotron. Ensure optimum lift function by testing and if necessary, re-adjusting tension whenever the weight

mounted to the riser changes (i.e., equipment is removed or added). See "Set Riser Lift Tension" adjustment instructions.

CAUTION: Do not operate StyleView Cart with missing or damaged components! Do not remove, modify or substitute Cart components without consulting Ergotron. If you

encounter problems with Cart installation or operation, contact Ergotron Customer Care.

CAUTION: DO NOT overtighten fasteners. Overtightening may cause damage to your equipment.

WARNING: Stored Energy Hazard: The worksurface lift mechanism is under tension and will move up rapidly, on its own, as soon as attached equipment is removed. For this

reason, DO NOT remove equipment unless the worksurface has been moved to the highest position on the tower! Failure to follow this instruction may result in serious personal

injury and/or equipment damage! When Shipping the cart, set the worksurface lift mechanism to the lowest tension setting.

CAUTION: DO NOT loosen, tighten or remove any other nuts or bolts on the riser or top of tower. Tampering with nuts or bolts may result in an unstable Cart, leading to

equipment damage and/or personal injury.

CAUTION: Release Lift Brake before moving work surface! Moving work surface while Lift Brake is engaged may cause serious damage to Lift Engine.

WARNING: In the event that repair of the StyleView Cart is needed, contact Ergotron Customer Care immediately. Cart repair can only be performed by Ergotron, Inc. or by an

Ergotron authorized agent.

WARNING: This cart is not intended for use in a ammable, anesthetic mixture or oxygen rich environment.

Con guration & Safety

Additional multiple socket-outlet or extension cord shall not be connected to the medical system.

When used in a Medical Electrical system, connect only equipment that complies with IEC, ISO, UL/ANSI, or CSA standards that are relevant to that equipment.

Risk of shock or personal injury when connecting non-medical equipment supplied as part of a system directly to the wall outlet when non-medical equipment is intended to

be supplied by the multiple socket outlet.

Risk of shock or personal injury when connecting any equipment that has not been supplied as part of the medical system to the multiple socket outlet.

888-24-181-G-02 rev. L • 02/16

17/20

Maintenance & Safety

Recommended Periodic Inspection and Maintenance

Component Action How often By whom

UI, Ethernet, USB

cables

Fan on side of CPU

compartment

Casters Inspect for wear and debris Monthly Any user

Maximum Load

Power System

batteries

Power Module

Battery harness

Coiled Cord

1. Please dispose of all batteries in accordance with local law.

2. Always replace battery with approved Valence battery.

ENGLISH

Misuse Can Result in FIRE or DEATH by ELECTRICAL SHOCK.

LES CORDONS ELECTRIQUES PEUVENT ETRE DANGEREUX

Une mauvaise utilisation peut provoquer un INCENDIE ou la MORT par CHOC

820-672

3OHDVH5HDGDQG)ROORZ3URGXFW0DQXDO,QVWUXFWLRQV

THIS IS A POLARIZED CORD - HOSPITAL GRADE ONLY

127(*URXQGLQJ5HOLDELOLW\&DQ2QO\%H$FKLHYHG:KHQ

WKH(TXLSPHQW,V&RQQHFWHG7R$Q(TXLYDOHQW5HFHSWDFOH0DUNHG

820-672

Inspect for wear, pinching, bad

connectors

Inspect for dust at intake, vacuum

as required using a vacuum cleaner

that DOES NOT generate ESD

(Electrostatic Discharge)

Inspect to ensure that maximum

recommended loads are not

exceeded

Replace lithium battery

1,2

Inspect for dust at intake, vacuum

as required using a vacuum cleaner

that DOES NOT generate ESD

(Electrostatic Discharge)

Inspect for wear, cracking, pinching,

or other damage

Inspect for wear, damage, or

stretching

DANGER!

ELECTRICAL CORDS CAN BE HAZARDOUS

ELECTRIQUE.

³+263,7$/21/<´2U³+263,7$/*5$'(´

Monthly Any user

Monthly Any user

Daily Any user

When battery

runtime is 60% of

original runtime

Monthly IT Personnel

Monthly IT Personnel

Weekly Any user

IT Personnel

Earth Bond Test: To ensure safety grounding between the

power cord ground connection and any accessible metal

parts on the cart, although not mandatory, the following test

is recommended to be performed every two years using a

calibrated medical device safety analyzer. The procedure is as

follows:

1. Disconnect the cart from mains power (unplug cart from the

wall).

2. Remove power from internal power system outlets by

pressing the power button on the Power System Interface.

3. Set up Earth Bond Test per the medical device safety analyzer

instructions.

4. Connect the Cart power cord to the medical device safety

analyzer.

5. Remove cover to access Lift Tension Adjustment point.

6. Attach second medical safety device analyzer probe to Lift

Tension Adjustment point on Cart.

7. Perform Test (25 amps).

8. Ensure Earth Bond is less than or equal to 0.2-ohms.

9. Remove medical device safety analyzer connections to Cart,

replace cover over Lift Tension Adjustment point, return the

Cart to service.

Insulation Resistance Test: To ensure mains power lines are

adequately insulated from earth ground, the following test,

although not mandatory, is recommended to be performed

annually using a calibrated medical device safety analyzer. The

procedure is as follows:

1. Disconnect the cart from mains power (unplug cart from the

wall).

2. Remove power from internal power system outlets by

pressing the power button on the Power System Interface.

3. Set up the Insulation Resistance Test per the medical device

safety analyzer instructions.

4. Connect the Cart power cord to the medical device safety

analyzer.

5. Perform test (500 V).

6. Ensure Insulation Resistance is greater than or equal to 1

Mohms.

7. Remove medical device safety analyzer connections to Cart

and return Cart to service.

,QVSHFW&RUG7KRURXJKO\%HIRUH(DFK8VH'212786(,)'$0$*('

'R1RW3OXJ0RUH7KDQ63(&,),('180%(52):$776,QWR3RZHU6\VWHP

'R1RW5XQ&RUG7KURXJK'RRUZD\V+ROHVLQ&HLOLQJV:DOOVRU)ORRUV

)8//<,16(573OXJ,QWR2XWOHW

'R1RW5HPRYH%HQGRU0RGLI\$Q\0HWDO3URQJVRU3LQVRI&RUG

'R1RW8VH([FHVVLYH)RUFHWR0DNH&RQQHFWLRQV

.HHS$ZD\)URP:DWHU'212786(:+(1:(7

.HHS&KLOGUHQ$ZD\)URP&RUG

'R1RW3OXJ&RUGLQWR$Q([WHQVLRQ&RUG

$92,'29(5+($7,1*8QFRLO&RUGDQG'R1RW&RYHU,W:LWK$Q\0DWHULDO

'R1RW'ULYH'UDJRU3ODFH2EMHFWV2YHU&RUG'R1RW:DON2Q&RUG

*5$633/8*WR5(029()5202XWOHW'R1RW8QSOXJ%\3XOOLQJ2Q&RUG

18/20

888-24-181-G-02 rev. L • 02/16

Ergotron Electromagnetic Guidance and Manufacturer’s Declaration

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions

The Powered Computer Cart is intended for use in the electromagnetic environment speci ed

below. The customer or the user of the Powered Computer Cart should assure that it is used in

such an environment.

Emissions Test Compliance Electromagnetic environment – guidance

RF Emissions

CISPR 11

Group 1 The Powered Computer Cart uses RF energy only for its

internal function. Therefore, its RF emissions are very

low and unlikely to cause any interference in nearby

electronic equipment.

RF Emissions

CISPR 11

Harmonic Emissions

IEC 61000-3-2

Voltage uctuations/

Class A The Powered Computer Cart is suitable for use in all

establishments other than domestic and those directly

Class A

connected to the public low-voltage power supply

network that supplies buildings used for domestic

purposes.

Complies

icker emissions

IEC 61000-3-3

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The Powered Computer Cart is intended for use in the electromagnetic environment speci ed

below. The customer or the user of the Powered Computer Cart should assure that it is used in such

an environment.

Immunity Test IEC 60601

Test Level

Electrostatic

Discharge (ESD)

±6 kV contact

±8 kV air

IEC 61000-4-2

Compliance

Level

Electromagnetic environment

- guidance

Complies Floors should be wood,

concrete, or ceramic tile. If oors

are covered with synthetic

material, the relative humidity

should be at least 30%

Electrical Fast

Transient/Burst

IEC 61000-4-3

Surge

IEC 61000-4-5

±2 kV for power supply lines

±1 kV for input/output lines

±1 kV di erential mode

±2 kV common mode

Complies Mains power quality should be

that of a typical commercial or

hospital environment.

Complies Mains power quality should be

that of a typical commercial or

hospital environment

Voltage

Dips, short

interruptions,

and voltage

variations on

power supply

input lines

IEC 61000-4-11

<5% U

T

(>95% dip in UT) for 0.5 cycle

40% U

T

(60% dip in UT) for 5 cycles

70% U

T

(30% dip in UT) for 25 cycles

<5% U

T

(>95% dip in UT) for 5

Complies Mains power quality should be

that of a typical commercial or

hospital environment.

seconds

Power

Frequency

(50/60 Hz)

Magnetic Field

IEC 61000-4-8

3 A/m Complies Power frequency magnetic

elds should be at levels

characteristic of a typical

location in a typical commercial

or hospital environment.

Note: UT is the AC mains voltage prior to application of the test level

ENGLISH

888-24-181-G-02 rev. L • 02/16

19/20

Dimensions

50.5"

(1283 mm)

40"

(1016 mm)

13"

(330 mm)

CPU Compartment

When guring dimensions,

include mounted accessories,

ENGLISH

protruding cables and

port replicators or docking

stations.

8.5"

(216 mm)

(584-1092 mm)

1.75" (44 mm)

17"

(432 mm)

4" - 11"

(102-279 mm)

2.5"

(64mm)

23" - 43"

4"

(102 mm)

Front View

Side View

(445 mm)

31" - 51"

(787-1295 mm)

(394 mm)

(465 mm)

*

< 4" (102 mm)

< 12.25"

(311 mm)

< 12.25"

(311 mm)

< 14.75" (375 mm)**

< 13"

(330 mm)

17.5"

15.5"

18.3"

< 1.38"

(35 mm)

7"- 8.5"

(178-216 mm)

< 2.3"

(58 mm)

3.4"

(86 mm)

19.75"

(502 mm)

(102 mm)

(203 mm)

**< 2.75"

(70 mm)

Top View

**< 4"

**< 8"

13.4"

(340 mm)

22.38"

(568 mm)

*< 17.63"

(448 mm)

< 2.75" (70 mm)

*< 21.75"

(552 mm)

*< 17.75"

(451 mm)

31"

(787 mm)

**< 2.75"

(70 mm)

**< 7.75"

(197 mm)

**< 4.25"

(108 mm)

© 2016 Ergotron, Inc. All rights reserved.

20/20

888-24-181-G-02 rev. L • 02/16

Loading...

Loading...