Page 1

70.5"

1791 mm

44"

1118 mm

21" *

533 mm

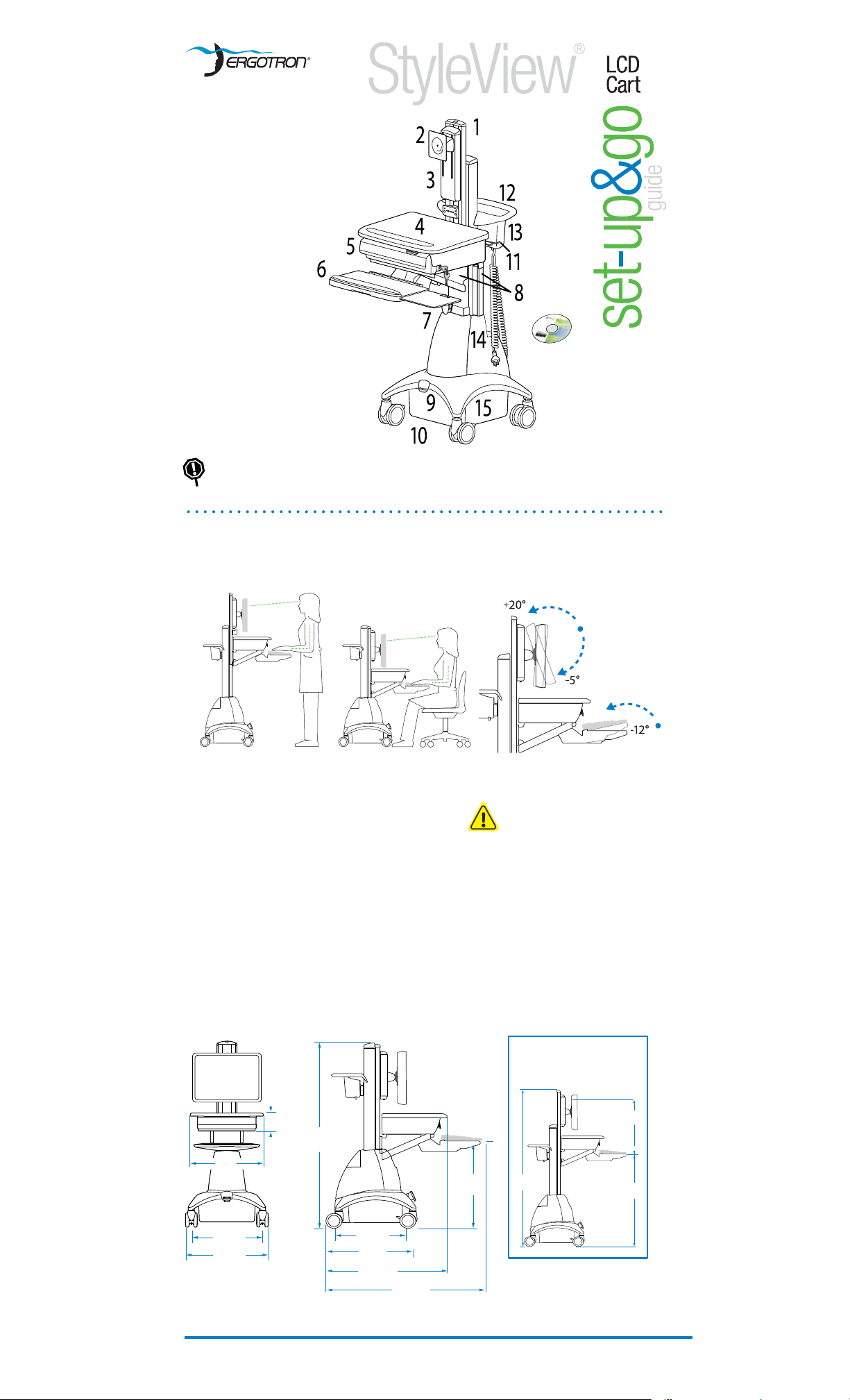

Features - SV22-92023

1

Riser

2

LCD Pivot

3

5" Lift

4

Worksurface

5

Electronic Autolock Drawer

6

Tilting Keyboard Tray and Wrist Rest

7

Right/Left Mouse Tray and Holder

8

Cable Management

9

Riser Lift Brake

10

Locking Front Casters

11

Scanner Holder Bracket

12

Ergonomic Rear Handle

13

Storage Basket

14

CPU Holder

15

Power System - 120VAC/60 HZ

a

55 Ah Battery

b

4 AC Outlets (300 Watts total)

c

Remote User Interface (RUI)

d

StyleLink Software CD & Cable

e

Coiled Power Cord

Please read all parts of this guide. When set-up is complete, do not discard

this guide. The guide should be led in a secure place for future reference.

c

b

e

a

d

StyleView powered

carts provide

electrical AC power for

mobile point of care

computing equipment

in a healthcare

environment.

Cart Speci cations - For Power System Speci cations see page 12.

Range of motion

Vertical Adjustment Range: 20" (508 mm)

STAND SIT

Weight capacities

Display* 6-18 lbs 2.72-8.26 kg

Drawer 4 lbs 1.8 kg

Worksurface 2.5 lbs 1.1 kg

CPU Holder 25 lbs 11 kg

Keyboard Tray 2.5 lbs 1.1 kg

Mouse Holder .5 lb .23 kg

Scanner Holder .5 lb .23 kg

Basket 5 lbs 2.3 kg

If display is greater than 18 lbs

contact customer care for xed pivot.

*

LCD Tilt: ± 25° Viewing Angle

Based on a 17" VESA Compliant LCD

Keyboard Tray Tilt: -12°

CAUTION: The lift brake locks

vertical lift of riser during

normal use but it DOES NOT increase

load capacity. DO NOT load riser with

equipment totalling more than the

maximum weight capacity speci ed by

Ergotron. Ensure optimum lift function

by testing and if necessary, re-adjusting

tension whenever the weight mounted

to the riser changes (i.e., equipment is

removed or added). See "Set Riser Lift

Tension" adjustment instructions in

step 9 on page 5.

Dimensions

Riser in Lowest Position

v

136 mm

50.8"

1290 mm

v

533 mm

18"

457 mm

21"

533 mm

21" (508mm) is the recommended distance between

top of keyboard tray and top of monitor screen.

*

1

1

18"

457 mm

22.3"

566 mm

28"

711 mm

38"

965 mm

EN

24"

610 mm

Riser at Full Height

For more information on this

or other Ergotron products,

visit our website:

www.ergotron.com

888-SV-22DL-00 rev C

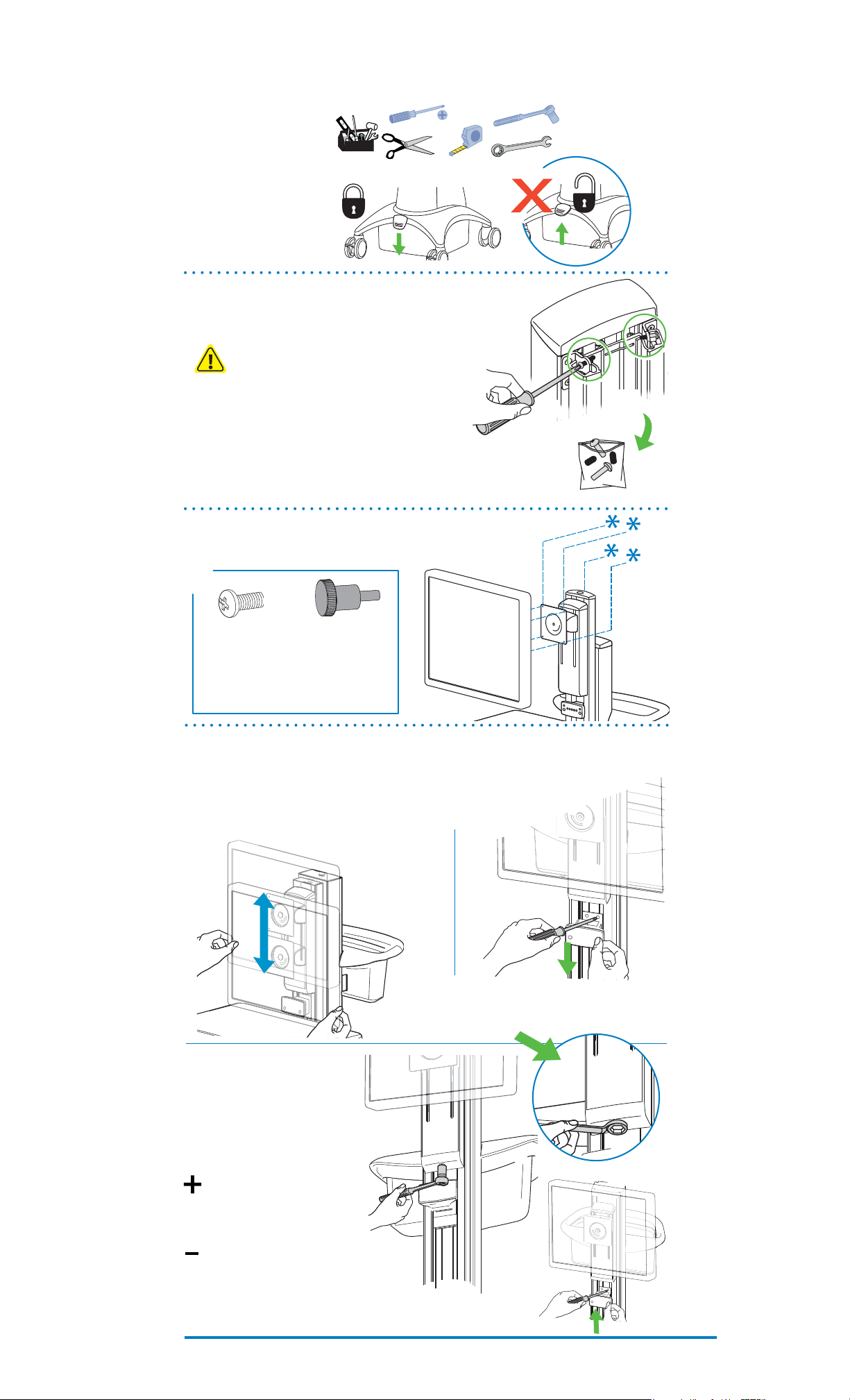

Page 2

8

Mounting Equipment

Prepare for cart set-up.

1

a

a

Gather tools for cart

set-up.

b To prevent the riser

from moving during

set-up, lock riser by

pushing the lift brake

down.

Remove anchor screws connecting riser to tower.

2

b

a Make sure riser is locked (lift brake down), then remove the two

capped screws anchoring the riser to the tower.

WARNING: The riser can move up on its own very

Therefore, always lock the riser down with the lift brake

when adding or removing equipment and when removing

or inserting the anchor screws which secure the riser to

the tower during shipping. Failure to lock the riser at

such times can result in serious personal injury and

possible damage to cart and/or equipment.

quickly when a counter-balancing force is removed!

2

1

a

• 9/16"

• 3/8" (10mm)

• 3/8" (10mm)

tower

riser

b

b Save the screws and caps in the provided bag to be used if the

riser needs to be anchored to the tower at a later time.

3

Attach the pivot to your display.

a Attach LCD to pivot with provided M4 x 10mm screws or knobs.*

*

Screw attachment deters theft while

Knob attachment allows fast removal

of the LCD without the use of tools.

Products o ering additional security are

available for purchase -

Adjust LCD lift for smooth up and down motion.

4

a Hold LCD on both sides and lift up and down - if you feel excessive resistance, or if the LCD doesn't

stay in the desired position when released, adjust for equal lift in both directions.

b Lower the RUI display by loosening the bracket screws with a screwdriver

for better access to the lift adjustment nut which is located at the

bottom of the 5" lift.

a

visit our website:

www.ergotron.com

b

The RUI does not need to be lowered if you prefer

to make the lift tension adjustment with a box wrench

*

instead of a socket wrench, as illustrated below.

c To adjust lift tension, turn nut

at bottom of lift. After several

revolutions of nut, test tension by

moving LCD up and down. Continue adjustment procedure until

LCD can be moved easily up or

down with equal force, but stays in

desired position when released.

To Increase Lift:

Turn adjustment nut clockwise

several turns - test again and

repeat if necessary.

To Decrease Lift:

Turn adjustment nut counter

clockwise several turns - test

again and repeat if necessary.

3/8"

c

(10mm)

d

3/8"

(10mm)

d When adjustment is complete, move RUI back into place.

2

888-SV-22DL-00 rev C

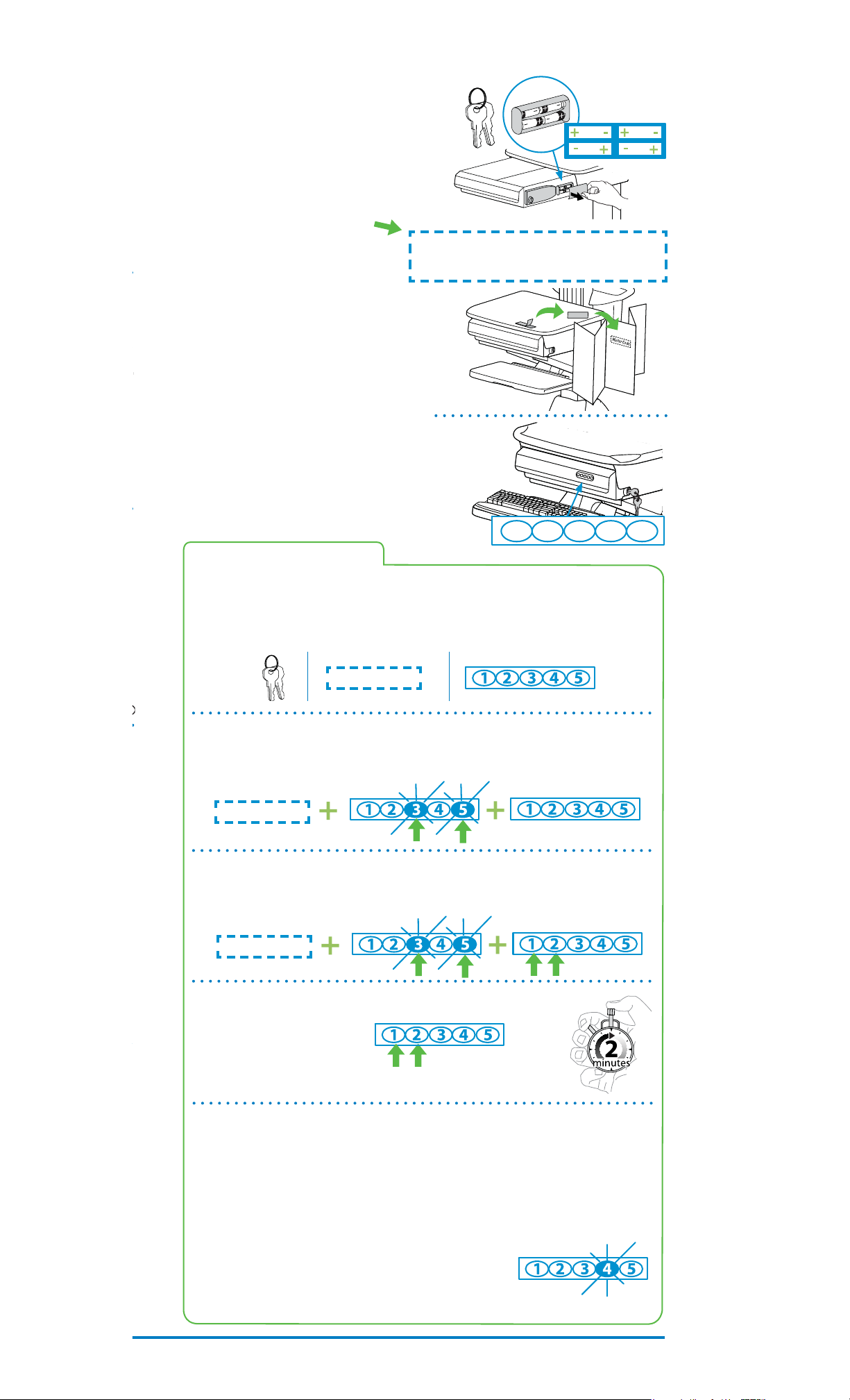

Page 3

Mounting Equipment

Personalize autolock drawer code.

5

a Unlock drawer with master key (identical dupli-

cate keys are provided). Pull drawer open to access

battery box; remove box cover; insert the four provided AA batteries. Replace cover and close drawer.

b Remove the Master Code sticker located near

the number pad and place it in the box at right for

safe keeping and future reference.

c Program Personal Code:

1 Enter Master Code

2 Press 3 and 5 at the same time

3 Enter a new personal code - any

series of five numbers

The drawer is now programmed to unlock

when either the personal code or the

master code is entered. The drawer remains

unlocked for 2 minutes and the number 5

remains lighted. At the end of two minutes, the

drawer automatically locks. You can manually

lock the drawer at any time by pressing 1 and 2

on the number pad simultaneously.

Store this guide along with the master keys

in a secure place to prevent unauthorized ac-

*

cess to autolock drawer.

a

b

c

Four AA

Master Code

Basic Drawer Functions

To Unlock Drawer - 3 methods

• Key - turn counter clockwise 1/8 turn

• Enter Master Code

• Enter Personal Code

Master Code

To Program Personal Code

1 Enter Master Code

2 Press 3 and 5 simultaneously (while blinking)

3 Enter new code - any series of five numbers

Master Code

To Erase Personal Code

1 Enter Master Code

2 Press 3 and 5 simultaneously (while blinking)

3 Press 1 and 2 on number pad at the same time

1 2 3 4 5

Personal Code

New Code

Master Code

To Lock Drawer - 2 methods

• Press 1 and 2 on number

pad simultaneously

or

• Wait two minutes for

drawer to lock automatically

Manual Auto

Drawer Troubleshooting

• Number pad numbers are dark

-Touch anywhere on number pad to activate back-light, (drawer remains locked until you

enter valid code)

-If touching number pad does not activate back-light, batteries may need to be replaced,

see instructions 5a above.

•

Number 4 on number pad is blinking = Low Voltage Warning

-Batteries may need to be replaced, see instructions 5a above.

• Drawer won’t open when Personal Code is entered

-Test system by entering Master Code. If drawer doesn’t unlock,

replace batteries as instructed 5a above.

Low Voltage Alert

888-SV-22DL-00 rev C

3

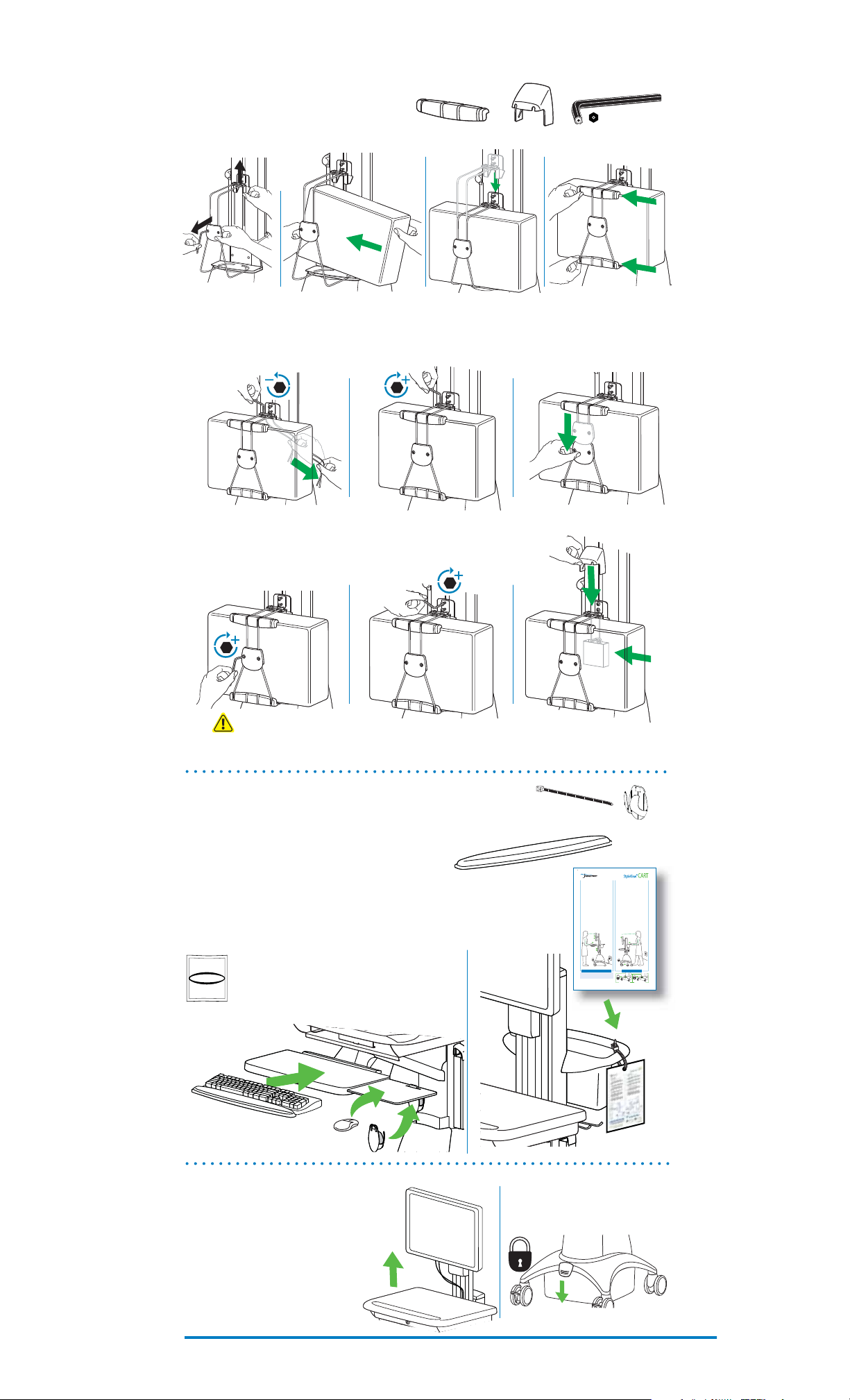

Page 4

8

Mounting Equipment

Mount CPU.

6

2x

1x

5/32"

a Position CPU on holder. b Slide bracket down channel c Place corners at top and bottom of CPU.

a

b c

d Loosen tamper-proof fasteners with provided tool then pull cables tightly around CPU.

e Re-tighten the tamper-proof screws.

f Pull the cable regulator down to create tension around CPU.

d e f

g Tighten the tamper-proof fasteners on the cable regulator to hold CPU in place.

h Tighten the tamper-proof fasteners on the channel bracket around CPU.

i Place cover over channel bracket.

g h i

Overtightening may cause damage to your equipment.

CAUTION: Do not overtighten fasteners.

Mount keyboard accessories & reference card

7

receptacle behind CPU.

*

a Apply double-sided tape to bottom of wrist rest and place on tray.

b Use hook & loop tape to x keyboard on tray.

c Snap mouse pouch on right or left side of tray.

d Attach reference card to handle with cable tie.

Sterile

Alcohol Prep

For optimum bonding, clean all surfaces

with alcohol wipe and allow to dry for one

*

minute before applying tape.

Store excess cable in

Moving

Working

stow - before you go

customize - to your size

1

Look where you’re going: unlock

1

Set monitor screen about one

lift brake and lower riser for an unob-

inch above eye level - unlock brake

structed view.

to allow riser to lift or lower as shown

below.

2

Tuck away open trays and return

2

Tilt screen for comfortable view-

mouse, scanner and other accessories

ing and to reduce eye and neck strain.

to their places.

3

Lock lift brake to keep riser down

3

Pullkeyboard tray forwardand

and equipment secure while cart is in

position mouse tray and mouse pouch

motion.

on right or left, as needed.

4

Unlock both front casters.

4

Work withelbows bent at about

90° to minimize muscle strain.

5

Push cart from rear with elbows

bent at about 90° to maximize control

5

If the riser moves up and down

and minimize muscle strain.

with diffi culty, or if it drifts out of set

position, consult the product manual

6

Don’t run out!

for adjustment information.

Before moving, make sure cord is

unplugged from outlet and hooked

6

Stay in charge!

to basket for safe travel. Remember,

Powered carts should be plugged into

charge battery fully100% every day!

outlet as often as possible to keep battery charged and computerrunning.*

1

2

5

3

2

4

5

6

6

1

3

4

“A charged battery is a happy battery!”

Riser Lift Brake Operation

Power Cart Users: refer to the other side of this

*

card to learn how to respond to RUI messages about

the status of your battery charge!

For more information on this or other

Up = Unlocked Down = Locked

Ergotron products, visit our website:

www.ergotron.com

*

888-24-039-00revA

b

a

c

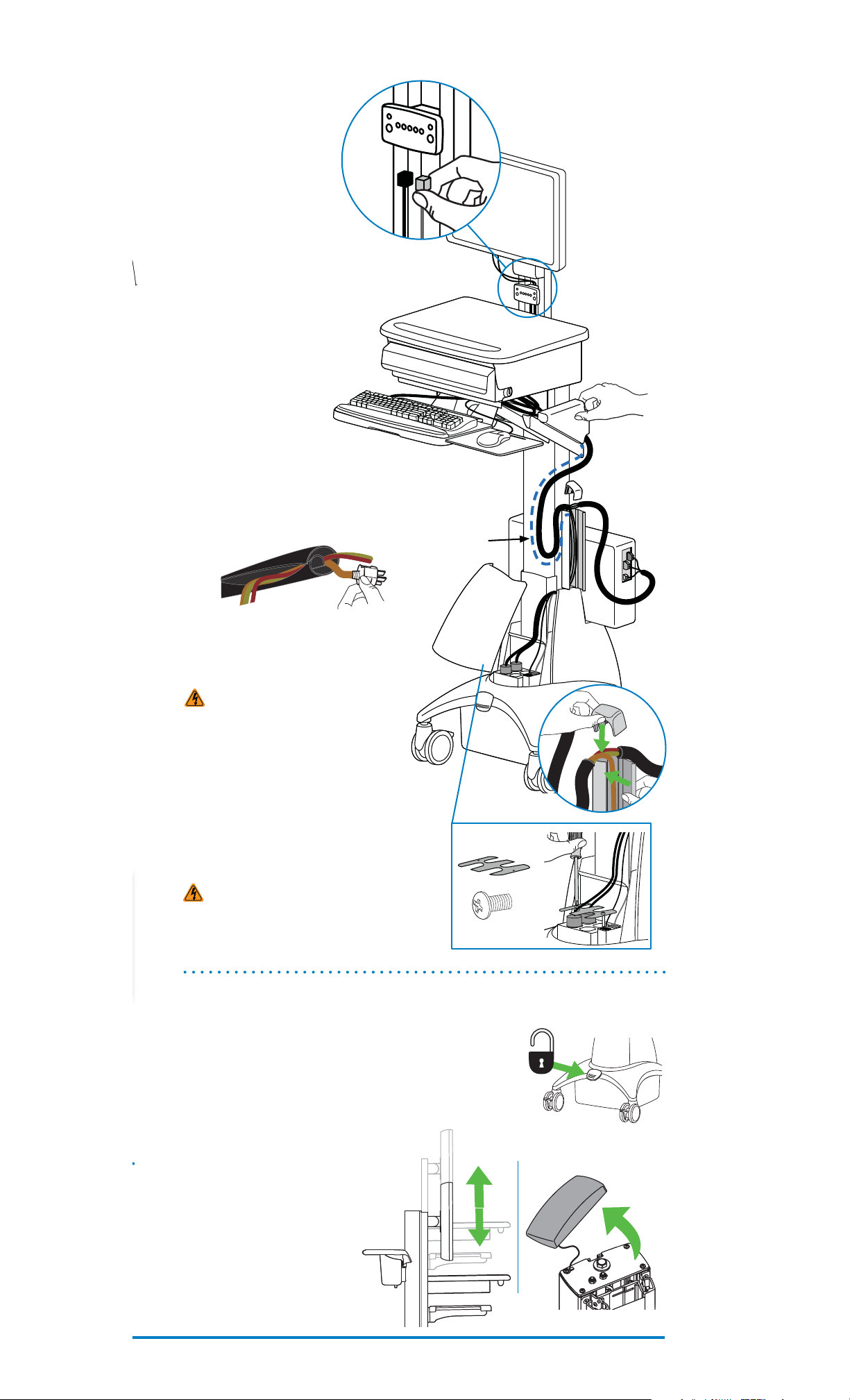

Cable Routing.

8

a

Lift riser to highest position and pull the

keyboard/mouse tray out as far as it will go.

b

Lock down lift brake.

Routing cables with the cart components

fully extended helps ensure su cient slack for

*

unrestricted movement during use.

4

a b

888-SV-22DL-00 rev C

Page 5

Cable Routing

Cable Routing.

8

c

Connect one end of the RUI

cables to the RUI that is mounted

to the riser. Connect grey cable to

grey jack and black cable to black

jack.

d

Remove side covers of cable

box mounted under the drawer.

Route the RUI and computer

cables down riser and into the

cable box. Route keyboard and

mouse cables into the cable box.

Use cable box to store excess

cable and power bricks.

e

Route cables out of cable box,

through cable channel to CPU.

Bundle the length of cables from

cable box to cable channel inside

one 20" (508 mm) length of the

provided exible tubing.

Leave about 20" (508 mm) of slack in

cables between the cable box and the cable channel.

*

c

d

f

Wrap any equipment cables and cords that need

to connect to the CPU at the rear of the cart inside a

second length of the provided exible tubing.

f

g

Route the RUI cables along with the equipment

power cords, down the channel to the outlets

under the front cover. Connect the RUI cables and

plug-in the power cords.

CAUTION:

(right) side of Cart only.

inside base covers. Storing power brick inside base

covers may damage electrical wires and interfere

with riser operation, resulting in damage to both

Cart and mounted equipment or injury from electrical shock.

h

Close cable channel around wrapped cables

and replace cable box side covers. Move riser up

and down to ensure cables are routed properly and

movement of the riser is not restricted. Adjust if

necessary.

CAUTION: Observe maximum watt ratings, do

not connect equipment that will draw beyond the 300

watt capacity of the power system in your StyleView

Cart. Failure to comply with this safety hazard may

result in equipment damage.

Route cables on Cable Channel

Do not store power brick

20"

(508 mm)

g

g

8-32 x 1/4"

2x

e

h

h

Riser Lift Adjustment

Set riser lift tension.

9

a Unlock riser (lift brake up).

b Move the riser up and down.

If you feel excessive resistance

within the range of motion, or

if the riser does not stay in the

desired position, the lift tension

should be adjusted.

c Remove tower cover.

888-SV-22DL-00 rev C

b

a

c

5

Page 6

8

Riser Lift Adjustment

d Lift riser to highest position on tower.

e Turn tension nut up or down as needed.

f After adjustment, check lift tension by moving riser up and down (as described in step 9b). If

more adjustment is necessary, continue turning nut until the riser lift is satisfactory.

d

e

Lift riser to highest position before making

any adjustments to the tension nut!

9/16"

Increase Lift

turn toward PLUS sign

LCD Tilt Adjustment

LCD Tilt Adjustment

10

a Move the LCD back and forth. If you feel excessive resistance

within the range of motion, or if the LCD does not stay in the

desired position, the titlt tension should be adjusted, (b).

b

To Increase Tension:

Turn adjustment nut clockwise

several turns - test again and

repeat if necessary.

IMPORTANT

Decrease Lift

turn toward MINUS sign

a

To Decrease Tension:

Turn adjustment nut counter

clockwise several turns - test

again and repeat if necessary.

11

Attach covers.

dcab

a Cover cables on riser.

b Attach tower cover.

c Attach top of riser cover.

d Lock riser cover.

Battery Charging Cycle

Charge Battery

12

a Plug power cord into appropriate wall outlet and verify that the green "100" light is ashing

to indicate battery is charging. Continue to charge until light stops ashing and stays lit.

FIRST TIME BATTERY CHARGE

To charge the battery for rst time and/or

to charge the battery after a period of storage

Do Not stretch coiled cord

further than 10 feet (3 meters),

*

damage to the cord may occur.

b Turn power system on by holding down the AC Outlet Power ON"

located on the RUI for 1 - 3 seconds. The Power light, the battery charge

indicator lights and the alarm enabled light will come on.

6

888-SV-22DL-00 rev C

Page 7

Battery Charging Cycle

13

Tracking battery power - the Remote User Interface (RUI)

The RUI will alert you to the percentage of charge remaining in the cart battery with a series of steady

or ashing red, yellow or green lights, and an alarm that can be set to beep or remain mute. Refer to

chart for common RUI messages and how to respond to each. Remember, the battery needs to be

charged to 100% every day, and you can use the cart while charging, so plug-in cord as often as pos-

sible to avoid running out of power!

NOTE: Put monitor in power save mode to optimize battery run time.

Power

Light

Power

Button

Battery charge cycle

understand and respond to RUI alerts

RUI Display

100% Light Flashes Green

Alert

Visual Audio

All Lights Steady Green

30% – 50% Lights Yellow

Alarm Beeps *

Alarm

Light*

Alarm

Button

Light On

Activated

- Beep

Light O

Disabled

- Mute

Charge Status Response

Allow battery to

Charging

Power Cord is

plugged-in

100%

Full

continue charging

until the 100% light

stops ashing.

You can use cart

while charging.

When 100% light

stops ashing the

battery is fully

charged and the cart

can be unplugged.

Plug-in power

Between

50%

cord and charge

and

to 100%!

30%

You can use cart

while charging.

30%

or less

30% Light Flashes Red

Alarm Beeps *

0%

No Lights

No Alarm

* If the alarm is activated (green light is on), it will start beeping when the battery charge level drops to 50% and

below. Beeping will stop only when the charge empties to 0% or when the power cord is plugged-in for recharging.

NOTE: If the alarm light is o , the beeping has been disabled and the alarm is mute. For details on enabling and

disabling alarm contact Ergotron Customer Care.

StyleLink

14

a

a Install StyleLink soft-

ware (after computer has

been connected to power):

place CD in computer and

follow set-up instructions that

appear on display.

No power

available until

power cord is

plugged-in.

StyleLink software for more

*

detailed information.

See help le in the

Frequent

operation of

*

the cart while

battery charge

levels are

below 30% will

signi cantly

reduce the life

of your battery.

b

b After software installation is

complete, connect one end of USB

cable to USB port on Cart-mounted

computer.

c Route USB cable down channel at

side of tower.

d Connect oposite end of USB cable

to USB port located on Cart base in

front of power outlets.

NOTE: When StyleLink software is

downloaded and used, your battery

warranty period is 1 year.

Set-up is complete - your Cart is ready to go!

The following pages contain important guidelines for safe operation and maintenance

Refer to our website for more information about the StyleView Cart and

other Ergotron products.

888-SV-22DL-00 rev C

d

c

of the SV Cart and the power system.

www.ergotron.com

7

Page 8

8

Battery Replacement

2

Replacing Battery

WARNING: Only Ergotron-speci ed batteries may be used in the StyleView Power System.

Please call customer care for details.

Do not replace the batteries while cart is located in an oxygen rich or hazardous environment.

Follow LONG TERM Storage Steps (a) - (i) to remove existing battery then continue

*

with steps (k) - (p) below, to connect the replacement battery.

k After removing battery from cart, lift out of tray. Recycle battery or contact Ergotron for proper

battery disposal guidelines.

l Place new battery in tray; insert battery into cart.

m Remove boot to expose Red (+) connector. Connect Red (+) lead to battery with terminal bolt and

wrench. Connect Red lead BEFORE Black lead! Be careful not to contact tools between terminals on

battery and metal chassis. Place boot on Red terminal.

n Remove boot to expose Black (-) connector. Connect Black (-) lead to battery with terminal bolt and

wrench. Connect Black lead AFTER Red lead! Be careful not to contact tools between terminals on

battery and metal chassis. Place boot on Black terminal.

Sparking may occur.

lk

LEAD

BATTERY

Black

Red

10mm

nm

o Plug-in cord reel cable.

p Attach cover to cart and tighten screws.

po

Power System Storage

Power System Storage

- SHORT TERM

If the Power System will be idle for up

to three months, the battery should be fully

*

charged before storage and recharged during

storage.

a

Black

Red

10mm

1/8"

If the Power System will be idle for 3 months

or more, the battery should be removed from

the cart and stored, follow LONG TERM Storage

instructions!

b

a Turn o all mounted equipment.

b Plug power cord into appropriate wall

outlet to fully charge battery to 100% (all RUI

indicator lights will be illuminated). Power

system must be fully charged before storing!

c

c Once battery has been charged to 100%,

turn power system o by holding down the

AC Outlet Power

seconds. Power light will shut o .

on the RUI for 1 - 3

d Leave power cord plugged into appro-

priate wall outlet if possible. If wall outlet is

not available for cart storage, remove front

cover, disconnect RUI cables from jacks

located on side of outlet box, and replace

cover. If cart is not plugged into a wall outlet

while stored, recharge battery once a month.

8

NOTICE: Warranty on fully charged bat-

teries left in an unused state for more than three

(3) consecutive months is automatically void.

Warranty on fully discharged batteries left in an

unused state for more than three (3) consecutive

days is automatically void.

888-SV-22DL-00 rev C

Page 9

Power System Storage

- LONG TERM

removed from the cart and stored, follow steps below. If the Power System will

be idle for less than 3 months, follow SHORT TERM storage instructions!

1

Remove batteries from Autolock drawer.

2

Remove power system battery.

If the Power System will be idle for 3 months or more, the battery should be

*

Four AA

b

a Turn o all mounted equipment.

a

b Disconnect Power System from

power source.

c Turn power system o by holding

on

c

d

down the AC Outlet Power

the RUI. Power light will shut o .

d Remove front cover and discon-

nect RUI cables from jacks located

on side of outlet box.

e Remove battery cover.

e

1/8"

f Unplug cord reel for better access.

g Remove protective boot from

Black (-) lead. Be careful not to

contact tools between terminals

on battery and metal chassis. Use

wrench to remove terminal bolt

from Black (-) lead. Slide boot over

exposed connector.

h Repeat step (g) for Red (+) lead.

Be careful not to contact tools

between terminals on battery and

metal chassis.

f

i Remove battery and store in cool,

dry area while Cart is out of use.

Optimal storage temperature is

15°C/59°F. Battery votage should

be checked every three (3) months. If voltage drops below 12.5VAC, fully recharge battery. Contact

Ergotron Customer Care for information about how storage might impact the battery warranty.

j Gently push boot-covered leads back into the cavity left by the removed battery and replace bat-

tery cover to base.

g

Black

WARNING

Disconnect power before entry.

Only authorized personnel may

service this equipment. Read

and understand operating instructions before opening unit

or replacing battery.

Red

10mm

Black

Red

h

10mm

ij

1/8"

888-SV-22DL-00 rev C

9

Page 10

8

Cart Safety Guidelines

Equipment Changes and Cart Transfers

Always anchor the riser to the tower BEFORE making changes to cart such as:

• removing or adding equipment

• preparing the cart for transit to another site

See step 2 on page 2 for more information.

Cleaning and Maintenance

The following procedures are not guaranteed to control infection. The hospital infection control administrator or epidemiologist should be consulted regarding cleaning procedures and processes.

To avoid risk of electric shock, do not expose electrical components to water, cleaning

solutions or other potentially corrosive liquids or substances.

Do not immerse Cart or Cart components in liquid or allow liquids to ow into the Cart.

Wipe all cleaners o surface immediately using a damp cloth. Thoroughly dry surface after

cleaning.

Do not use ammable cleaners on Cart surfaces due to close proximity of electrical

power and equipment.

All paints and plastic Cart components will withstand cleaning by most commonly used, diluted, nonabrasive solutions such as quaternary ammonia compounds, ammonia enzyme cleaners, bleach or

alcohol solutions.

• Pen and permanent and dry erase markers can be removed with 91% isopropyl alcohol and a soft

cloth.

• Iodine stains can be removed with commonly used cleaners and a soft cloth.

• Never use steel wool or other abrasive materials that will damage the surface nish.

It is recommended that any cleaning solution be tested on a small, inconspicuous area to ensure

surface is not harmed.

Adjustment, Service, Replacement - DO NOT attempt to adjust, service or re-

place any part of the StyleView Cart unless directed to do so through Ergotron-approved documentation (i.e. installation instructions). Only Ergotron, Inc. or an Ergotron-certi ed entity may adjust, service

or replace StyleView Cart components. If any component on the Cart is missing or damaged, the Cart

must not be used, contact Ergotron Customer Care immediately to request a replacement part.

Cables

your cart for this purpose). Excess cables should be routed away from moving components with cable

clips. Review Cable Routing section of this guide, or contact Ergotron Customer Care for more information.

Casters

prevent smooth travel. Avoid moving Cart across uneven, dirty or damaged surfaces.

Cart Stability

brake MUST be locked to protect against possible tipping. Failure to lock the riser in the lowest position

with the lift brake may result in personal injury or equipment damage.

- Keep cables neatly organized on the Cart (a variety of solutions are provided with

- Check casters periodically to make sure they are clean and free of debris that would

Customer Equipment

curely to Cart. Do not reposition Cart components on riser or tower unless instructed to do

so in the installation instructions. Moving Cart components too high or too low on the Riser

may create an unstable condition, leading to equipment damage or even personal injury.

Contact Ergotron Customer Care for information about moving Cart components.

- When moving cart, the riser MUST be in the lowest position and the lift

- Make sure equipment is balanced and mounted se-

Safety Alerts Associated with this Product

The following Warnings/Cautions appear in this reference guide or on the cart:

NOTE: Failure to adhere to these guidelines may result in equipment damage or personal injury.

CAUTION: The lift brake helps stablilize the worksurface and keyboard tray during normal

use but it DOES NOT increase load capacity. DO NOT load riser with equipment totalling more

than the maximum weight capacity speci ed by Ergotron. Ensure optimum lift function by testing and if necessary, re-adjusting tension whenever the weight mounted to the riser changes

(i.e., equipment is removed or added). See "Set Riser Lift Tension" adjustment instructions in step

9 on pgae 5.

CAUTION: Do not operate StyleView Cart with missing or damaged components! Do not

remove, modify or substitute Cart components without consulting Ergotron. If you encounter

problems with Cart installation or operation, contact Ergotron Customer Care.

CAUTION: DO NOT overtighten fasteners. Overtightening may cause damage to your

equipment.

CAUTION: Riser is under spring tension. Rapid rise or fall of riser can occur prior to

counterbalancing. Lock riser down with Brake before removing Riser Anchor Screws or loading/

unloading equipment. Do Not put yourself in path of movable riser or mounted components until

riser is properly counterbalanced. Failure to comply with this caution may result in equipment

damage or personal injury.

CAUTION: DO NOT loosen, tighten or remove any other nuts or bolts on the riser or top of

tower. Tampering with nuts or bolts may result in an unstable Cart, leading to equipment damage

and/or personal injury.

WARNING: Unlock Lift Brake before moving work surface! Moving work surface while Lift

Brake is locked may cause serious damage to Lift Engine.

WARNING: In the event that repair of the StyleView Cart is needed, contact Ergotron Customer Care immediately. Cart repair can only be performed by Ergotron, Inc. or by an Ergotron

authorized agent.

CAUTION:

inside base covers. Storing power brick inside base covers may damage electrical wires and interfere with

riser operation, resulting in damage to both Cart and mounted equipment or injury from electrical shock.

Route cables on Cable Channel (right) side of Cart only.

Do not store power brick

10

888-SV-22DL-00 rev C

Page 11

Cart Ergonomics

Working

customize - to your size

1

Set monitor screen about one

inch above eye level - unlock brake

to allow riser to lift or lower as

shown below.

2

Tilt screen for comfortable

viewing and to reduce eye and neck

strain.

2

3

Pull keyboard tray forward and

position mouse tray and mouse

pouch on right or left, as needed.

4

Work with elbows bent at

about 90° to minimize muscle strain.

5

If the riser moves up and down

with di culty, or if it drifts out of

set position, consult the product

manual for adjustment information.

6

Stay in charge!

Powered carts should be plugged

into outlet as often as possible to

keep battery charged and computer

running.

4

3

5

6

1

Moving

stow - before you go

1

Look where you’re going: unlock

lift brake and lower riser for an unobstructed view.

1

2

Tuck away open trays and return

mouse, scanner and other accessories to their places.

3

Lock lift brake to keep riser down

and equipment secure while cart is in

motion.

4

Unlock both front casters.

5

Push cart from rear with elbows

bent at about 90° to maximize control and minimize muscle strain.

6

Don’t run out!

Before moving, make sure cord is

unplugged from outlet and hooked

to basket for safe travel. Remember,

charge battery fully 100% every day!

5

2

6

3

4

888-SV-22DL-00 rev C

11

Page 12

8

Cart Safety Guidelines

ELECTRICAL CORDS CAN BE HAZARDOUS

$!.'%2

-ISUSE#AN2ESULTIN&)2%OR$%!4(BY%,%#42)#!,3(/#+

0LEASE2EADAND&OLLOW0RODUCT-ANUAL)NSTRUCTIONS

4()3)3!0/,!2):%$#/2$(/30)4!,'2!$%/.,9

./4%'ROUNDING2ELIABILITY#AN/NLY"E!CHIEVED7HEN

THE%QUIPMENT)S#ONNECTED4O!N%QUIVALENT2ECEPTACLE-ARKED

h(/30)4!,/.,9v/Rh(/30)4!,'2!$%v

Hazard Symbols Review

The Meaning of Symbols appearing in this Guide, on the Cart or on the Power System

These symbols alert you to a safety condition that demands your attention. You should be able to

recognize and understand the significance of the following Safety Hazards if you encounter them on

the Cart or within Cart documentation such as this Set-up Guide.

Color Symbol

Red

Orange

Yellow

Signal

Word

DANGER

WARNING

CAUTION

s)NSPECT#ORD4HOROUGHLY"EFORE%ACH5SE$/./453%)&$!-!'%$

s$O.OT0LUG-ORE4HAN30%#)&)%$.5-"%2/&7!443)NTO0OWER3YSTEM

s$O.OT2UN#ORD4HROUGH$OORWAYS(OLESIN#EILINGS7ALLSOR&LOORS

s&5,,9).3%240LUG)NTO/UTLET

s$O.OT2EMOVE"ENDOR-ODIFY!NY-ETAL0RONGSOR0INSOF#ORD

s$O.OT5SE%XCESSIVE&ORCETO-AKE#ONNECTIONS

s+EEP!WAY&ROM7ATER$/./453%7(%.7%4

s+EEP#HILDREN!WAY&ROM#ORD

s$O.OT0LUG#ORDINTO!N%XTENSION#ORD

s!6/)$/6%2(%!4).'5NCOIL#ORDAND$O.OT#OVER)T7ITH!NY-ATERIAL

s$O.OT$RIVE$RAGOR0LACE/BJECTS/VER#ORD$O.OT7ALK/N#ORD

s'2!300,5'TO2%-/6%&2/-/UTLET$O.OT5NPLUG"Y0ULLING/N#ORD

Level of Hazard

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates a poten-

None

CAUTION

tially hazardous situation which, if not avoided, may

result in property damage.

Red,

Orange

or

Electrical

Indicates an impending electrical hazard which, if not

avoided, may result in personal injury, re and/or death.

Yellow

Power System Speci cations - 120VAC/60 Hz power system

SV22-92023

Input: 120VAC/60 Hz, 5.1A

Output: 120VAC/60 Hz, 400VA 300W

The StyleView AC Power System (SPS) allows your power supply to travel with the cart. The Power System is

integrated in the base of the cart and comes standard with a battery, true sine wave inverter, ATS, RUI, charger,

isolation transformer, outlet box and power cord.

• True Sine Wave Inverter (TSW): designed to ensure satisfactory operation of Power Factor Corrected devices like

Flat Panel Monitors.

• Automatic Transfer Switch (ATS): allows connected computer equipment to switch to “house” power when

charging the battery.

• Remote User Interface (RUI): Located near worksurface, allows power system output to be turned on or turned

o , allows monitoring of battery charge left, and provides low battery charge audible alarm.

• 55Ah Sealed Lead Acid, Absorbed Glass Mat, Valve Regulated & Recombinant Gas Type, 12VDC battery.

• The recommended cart storage temperature is 15°C (59°F). At this temperature, the 55Ah battery’s age-related

capacity loss is minimized. The minimum storage temperature is -20°C (-4°F) and the

maximum storage temperature is 50°C (122°F). The recommended humidity range for

storage is 0-95% rH.

• The cart and power system are certi ed to UL 60601 and CAN/CSA-C22.2 601.1-M90

For more information on this or other Ergotron products,

visit our website:

www.ergotron.com

-20 °C

- 4 °F

Humidity

Relative

Range

50 °C

122 °F

0-95% rH

FCC Compliance Statement - Cart and Autolock Drawer

The autolock drawer has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Changes or modi cations not expressly approved by Ergotron, Inc.

could void the user’s authority to operate the equipment.

Please contact Ergotron for complete EMC compatibility information.

Product Marks

LEAD

BATTERY

12

888-SV-22DL-00 rev C

Page 13

Troubleshooting

Symptom Probable Cause Solution

Improper riser

Riser moves up or

down too easily or with

difficulty; or equipment

on riser does not stay

in desired position.

Monitor moves up or

down too easily or with

difficulty.

counterbalance.

Mounted equipment

exceeds weight capacity.

Improper monitor riser

counterbalance.

Monitor exceeds weight

capacity.

Symptom Solution

1) The lights on the

Remote User Interface

(RUI) will not illuminate.

2) The Cart Outlet

box will not power my

equipment.

3) My problem cannot

be solved with this

guide.

a) Press and hold the On/O switch located at the left side of the RUI. Verify

the small green light above the RUI On/O switch illuminates along with

one or more of the battery charge indicator lights. If multiple lights on the

RUI do not illuminate continue to the next step.

b) Verify the black and grey communications cables are not damaged

and are seated properly by lightly tugging on them at the base of the RUI.

Repeat step a).

c) Pull o the front panel and verify the black and grey communications

cables are not damaged and are seated properly (by lightly tugging on

them) in the correct jacks located at the side of the Cart Outlet box. Replace

cover and Repeat step a).

d) Contact Customer Service

a) Verify RUI is illuminated and that the equipment power cords are properly

connected to the Cart Outlet box. If the RUI is not illuminated try troubleshooting problem #1 before continuing on to step b).

b) Disconnect all equipment from the cart outlets. Use an outlet tester to

verify the outlets are able to correctly supply power. Keep the outlet tester

plugged into one of the outlets while troubleshooting.

c) Plug the cart into an external, appropriately rated powered outlet.

d) Attempt to turn on the RUI. Press and hold the On/O switch located

at the left side of the RUI. Verify the small green light above the RUI On/O

switch illuminates and that the outlet tester veri es the outlets are able to

correctly supply power. If the outlet tester does not verify the outlets are

able to correctly supply power continue to the next step.

e) Verify the Cart Outlet box cord is properly connected to the power

module. Then try step d).

f) Unplug the cart from the external powered outlet and remove the battery

cover to verify the cord is properly connected to the power module plug.

Plug the cart into an external, appropriately rated powered Outlet. and try

step d).

g) Contact Customer Service (

600)

for further troubleshooting instructions.

a) Contact Customer Service

Follow "Set Riser Lift Tension" Adjustment

procedure in step 9 on page 5.

Compare weight of mounted equipment to

recommended weight capacities in specifications

section.

Contact Ergotron Customer Care: North America

1-800-888-8458; Europe +31 (0)33-45 45 600

Follow "LCD Lift" Adjustment procedure in step 4

on page 2.

Compare weight of monitor to recommended

maximum capacities in specifications section.

Contact Ergotron Customer Care: North America

1-800-888-8458; Europe +31 (0)33-45 45 600

USA: 1-800-888-8458 or Europe +31 (0)33-45 45 600

USA: 1-800-888-8458 or Europe +31 (0)33-45 45

USA: 1-800-888-8458 or Europe +31 (0)33-45 45 600

visit our website:

www.ergotron.com

Recommended Periodic Inspection and Maintenance

Component Action How often By whom

Autolock Drawer

Batteries

Power System SLA

battery

Casters

RUI, USB,

computer cables

Coiled cord

Replace 4 ea AA

batteries

Replace lead acid

battery

1

1

Inspect for wear and

debris

Inspect for wear,

pinching, bad

connectors

Inspect for wear,

damage, or stretching.

Move attachment hook

to avoid dragging on

oor

Replace when

keypad #4

Any user

ashing

When instructed

by StyleLink or

when battery

runtime is ½ of

original runtime

Monthly Any user

Monthly Any user

Weekly Any user

IT personnel

Inspect to ensure

Maximum Load

that maximum

recommended loads are

not exceeded

1

Please dispose of all batteries in accordance with local law

888-SV-22DL-00 rev C

Daily Any user

13

Page 14

14

888-SV-22DL-00 rev C

Loading...

Loading...