Page 1

2" - 8"

(102 - 203 mm)

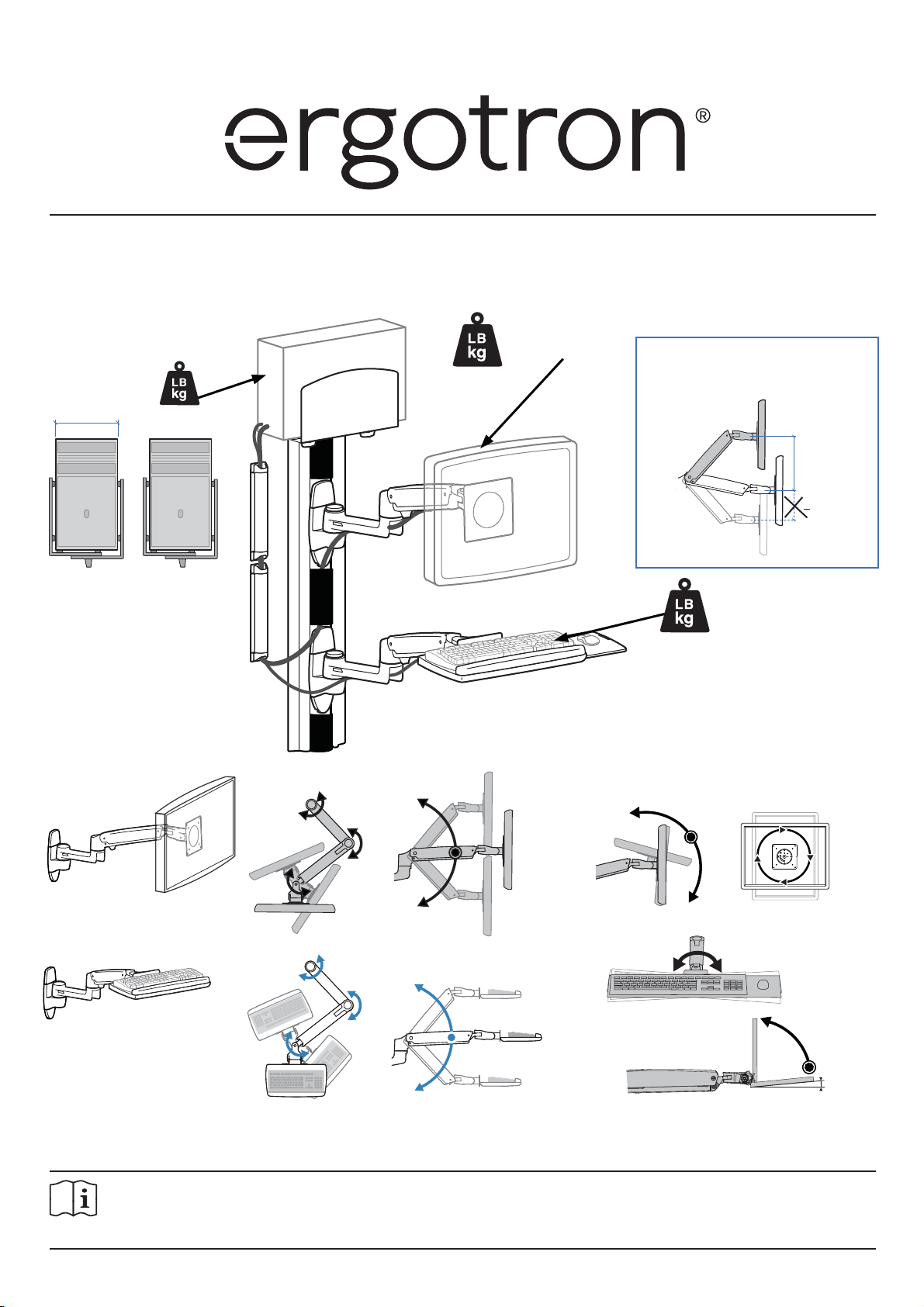

LX Wallmount System

7 - 25 lbs*

(2.3 - 11.3 kg)

40 lbs (18 kg)

User's Guide

* The lower most range of motion for vertical lift is

decreased up to 4.5” (114 mm) when arm is adjusted to

hold over 20lbs (9 kgs).

8.5” (216 mm)

< 4.5” (114 mm)

Includes

Constant Force™

Technology

180°

180°

180°

180°

360°

360°

13" (330 mm)

13"

(330 mm)

0 - 5 lbs

(0 - 2.3 kg)

80°

3°

5°

5°

3°

90°

For the latest User Installation Guide please visit: www.ergotron.com

English, Español, Français, Deutsch, Nederlands, Italiano, Svenska, 日本語, 汉语

www.ergotron.com |

888-45-184-W-05 rev.T • 01/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

|

China: 400-120-3051

|

English

Japan: japansupport@ergotron.com

1 of 17

Page 2

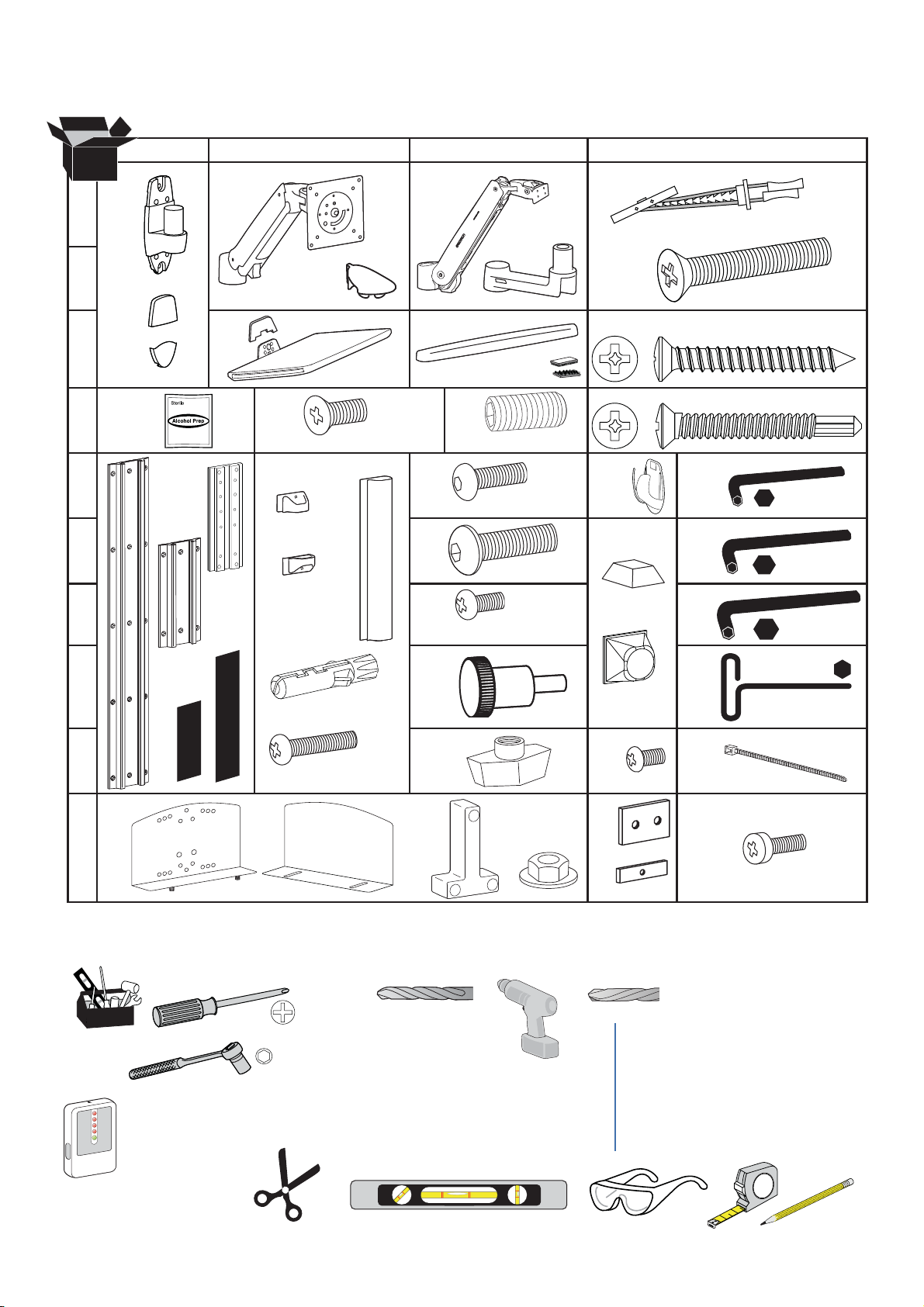

Components

AB CD

1

1x

1x

14x

2x

2x

2

2x

14x

1/4-20 x 2"

2x

1x

3

2x

1x

4

3x

1x

5

2x

4x

2x

M4 x 8mm

2x

1x

8x

9x

1/4-20 x 1/2"

10-24 x 1/2"

4x

1x

7x

7x

1x

2.5mm

1x

6

7

2x

2x

M10 x 16mm

4x

M4 x 10mm

12x

4x

1x

1x

1/8”

6mm

1x

8

9

1x 1x

10

2x

1x

Tools Needed

4x

4x

M4.2 x 25mm

7mm

7/16"

4x

2x

Ø 1/2” (12.7 mm)

Hollow Wall

Pared

Mur

Wand

Muur

Parete

壁

墙壁

M4 x 10mm

1x

M3 x 6mm

1x

2x

1x

Ø 3/16" (5 mm)

Wood

Madera

Bois

Solide Holzbalkenträger

Massief Houten Pilaren

Due montanti in legno massiccio

木

木质

나무

1x

4mm

4x

2x

M4 x 14mm

Studs ≥ 25 gauge steel

Pernos de acero de calibre ≥ 25

Goujons ≥ calibre25 en acier

Bolzen ≥ Blechlehre Nr. 25

Verbindingsbouten ≥ 25 gauge staal

Prigionieri in acciaio spessore ≥ gauge 25 (0,556 mm)

Reglar ≥ 25-gauge stål

25ゲージのスチールよりも強力なスタッド

板墙筋为不小于 25 标号的钢材

Stud Finder

2 of 17

2

1

888-45-184-W-05 rev.T • 01/19

Page 3

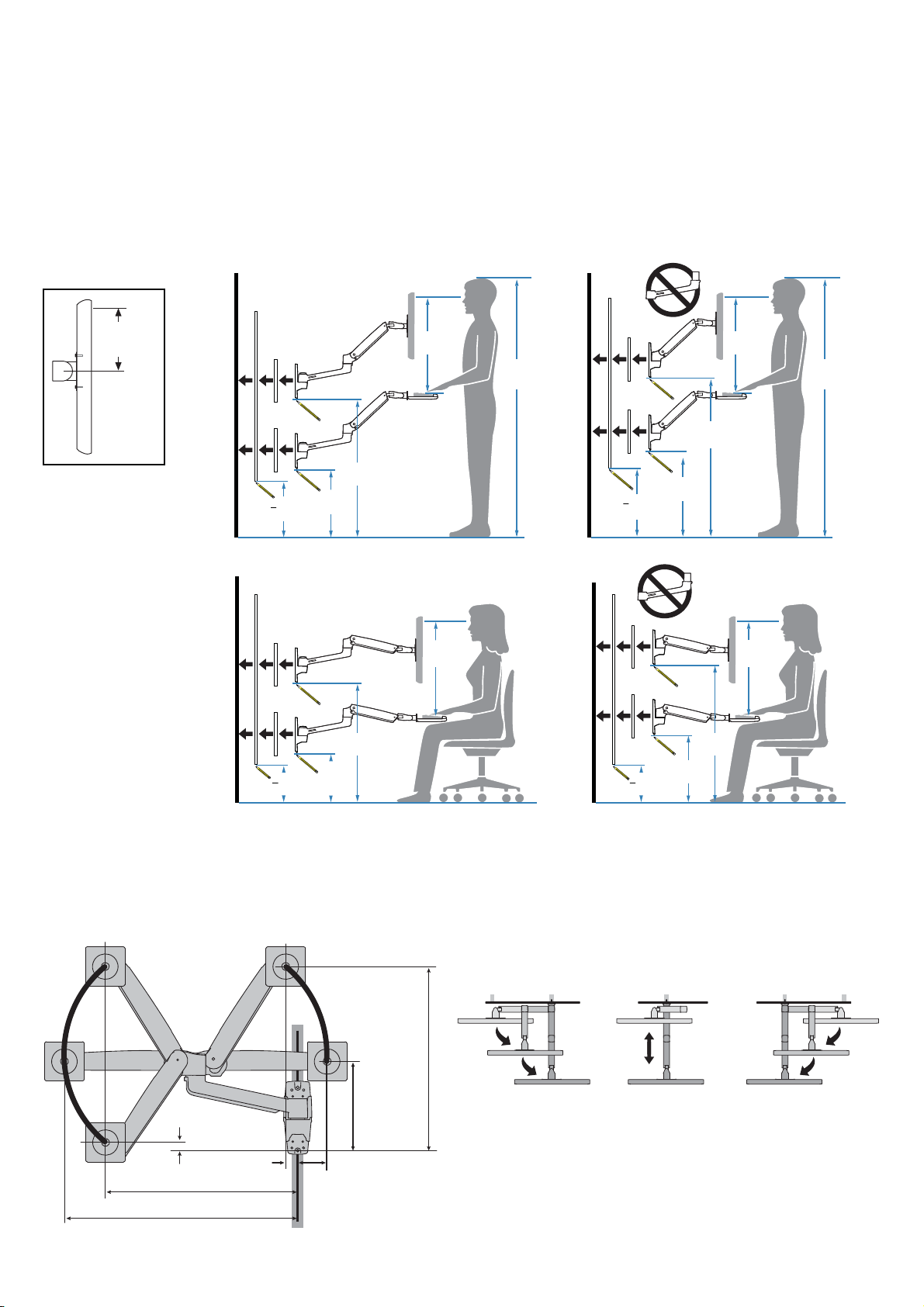

Mounting Height for Ergonomic Workstation

1

This mounting height is a recommendation for an ergonomic workstation that accommodates user heights of 5'0"-6'1"

(152-185cm) when set up for standing and user heights of 5’0”-6’4” (152-193cm) when set up for sitting.

If user heights are di erent than this, you should change mounting height to accommodate user heights. (Change mounting height one inch for every one inch di erence in user heights).

6”

(152 mm)

Mounting height assumes

there is a 6” (152 mm) distance between the center

of your monitor mounting

holes and the top of the

screen. If your distance is

smaller, you should increase

mounting height accordingly, if your distance is

larger, you should decrease

your mounting height accordingly.

< 30.5”

(775mm)

< 21.5”

(546mm)

(1194mm)

31.5”

(800mm)

22.5”

(571mm)

47”

31.5”

(800mm)

21”

(533 mm)

21”

(533 mm)

5’0” - 6’1”

(152-185cm)

5’0” - 6’4”

(152-193cm)

< 34.4”

(874mm)

< 25.4”

(645mm)

(1283mm)

35.4”

(899mm)

26.4

(670mm)

50.5”

35”

(889mm)

21”

(533 mm)

21”

(533 mm)

5’0” - 6’1”

(152-185cm)

5’0” - 6’4”

(152-193cm)

Determine mounting location:

Front view with arm pushed back against the wall.

2”

(50mm)

0.6”

17.7”

(449mm)

888-45-184-W-05 rev.T • 01/19

(14mm)

20.7”

(526mm)

Top view showing range of motion when pulled out from the wall.

14.7”

(373mm)

8.2”

(207mm)

2.5”

(63mm)

3 of 17

Page 4

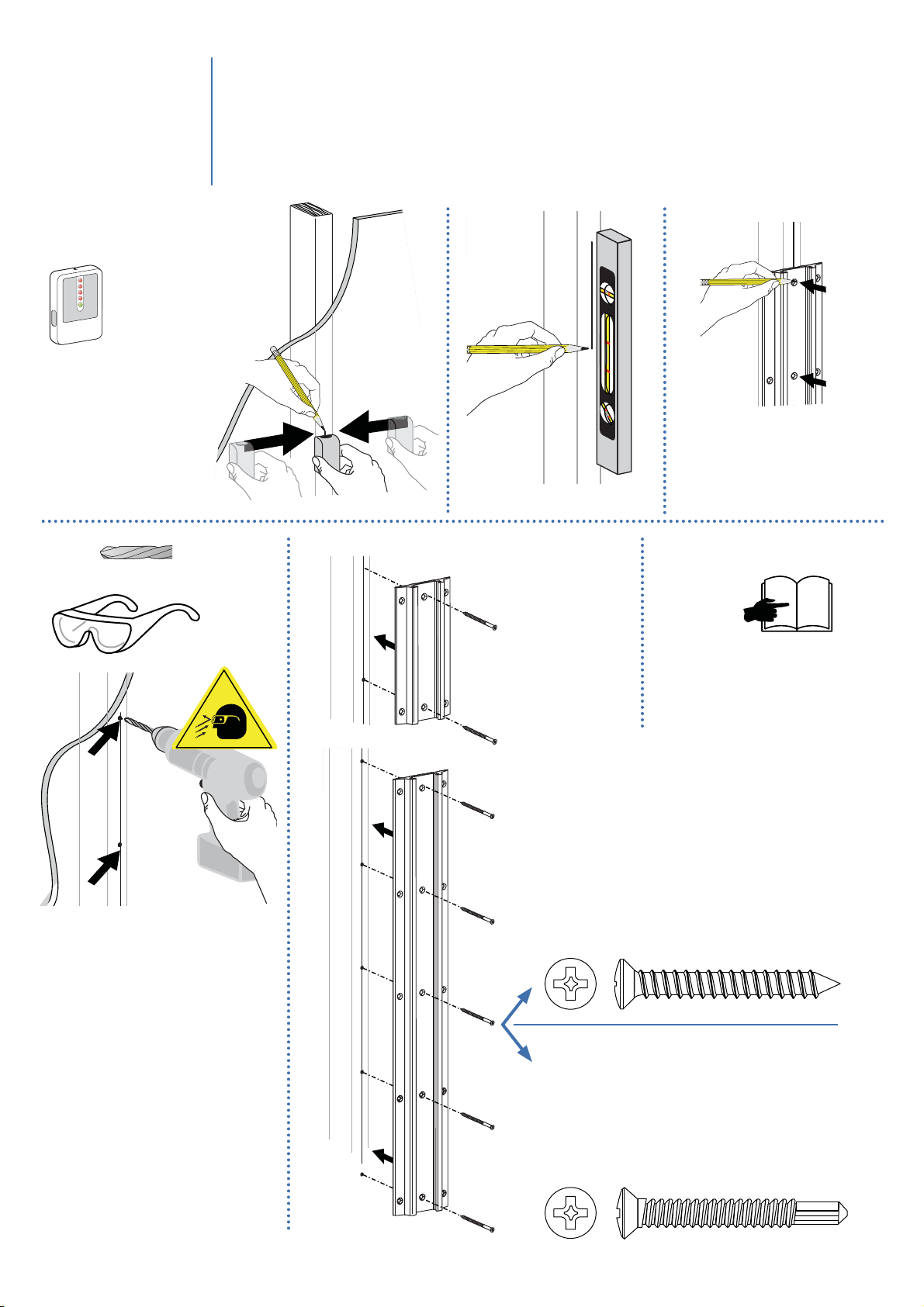

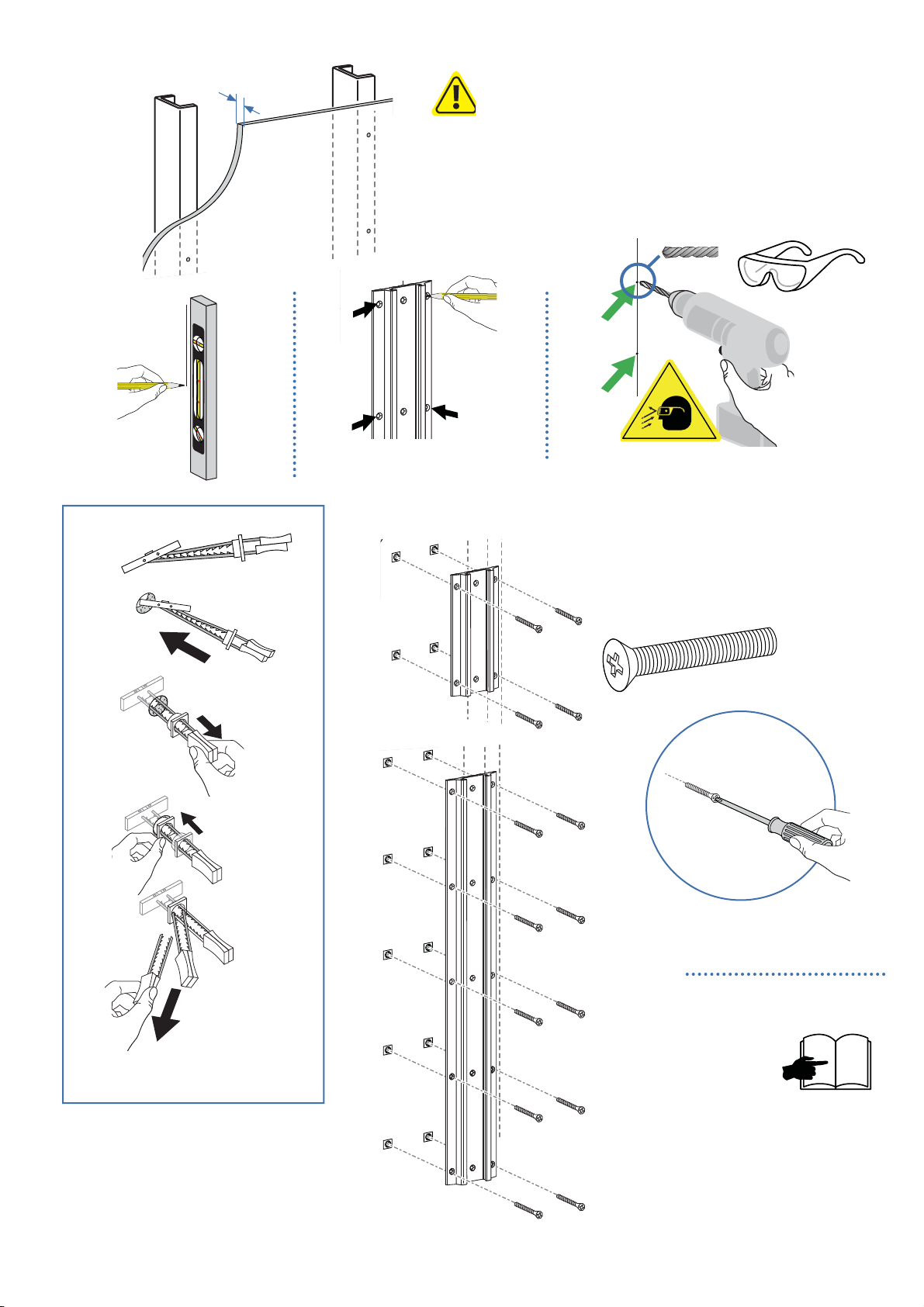

2

WARNING: Ensure that the wall structure is capable

of supporting four times the total weight of mounted

equipment. Mounting to wall surfaces that do not meet

this criteria may result in an unstable, unsafe condition

which could lead to personal injury and/or property

damage. Consult a construction professional if you

have any doubt about what this means in regard to

your particular application.

CAUTION: Make sure the wall mount bracket is level,

ush and snug to the wall surface. DO NOT OVERTIGHT-

EN THE BOLTS.

Wood

Madera

Bois

Solide Holzbalkenträger

Massief Houten Pilaren

Due montanti in legno massiccio

木

木质

나무

4 of 17

Studs ≥ 25 gauge steel

Pernos de acero de calibre ≥ 25

Goujons ≥ calibre25 en acier

Bolzen ≥ Blechlehre Nr. 25

Verbindingsbouten ≥ 25 gauge staal

Prigionieri in acciaio spessore ≥ gauge 25 (0,556 mm)

Reglar ≥ 25-gauge stål

25ゲージのスチールよりも強力なスタッド

板墙筋为不小于 25 标号的钢材

5

Hollow Wall

Pared

Mur

Wand

Muur

Parete

壁

墙壁

≥ 5/8”

Sheetrock

Sheetrock

Plaque de plâtre

Rigipsplatte

Sheetrock

Cartongesso

Gipsskiva

シートロック

石膏板

Requires minimum material thickness of 5/8” (16 mm).

Requiere un grosor mínimo de 16 mm.

Epaisseur minimum de 16 mm.

Requer uma espessura mínima de 5/8” (16 mm).

Mit einer Materialdicke von mindestens 16 mm.

Vereist een minimale materiaaldikte van 1.6 cm.

Richiede uno spessore del materiale non inferiore a 16 mm.

厚さが最低5/8”(16mm)の資材が必要。

需要最低材料厚度为 5/8”(16 mm).

888-45-184-W-05 rev.T • 01/19

6

Page 5

Wood

Madera

Bois

Solide Holzbalkenträger

Massief Houten Pilaren

Due montanti in legno massiccio

木

木质

나무

Studs ≥ 25 gauge steel

Pernos de acero de calibre ≥ 25

Goujons ≥ calibre25 en acier

Bolzen ≥ Blechlehre Nr. 25

Verbindingsbouten ≥ 25 gauge staal

Prigionieri in acciaio spessore ≥ gauge 25 (0,556 mm)

Reglar ≥ 25-gauge stål

25ゲージのスチールよりも強力なスタッド

板墙筋为不小于 25 标号的钢材

a

Stud Finder

d

Ø 3/16" (5 mm)

cb

ef

3

7

x 5

Wood Stud Mounting

7x

Studs ≥ 25 gauge steel

Pernos de acero de calibre ≥ 25

Goujons ≥ calibre25 en acier

Bolzen ≥ Blechlehre Nr. 25

Verbindingsbouten ≥ 25 gauge staal

Prigionieri in acciaio spessore ≥ gauge 25 (0,556 mm)

Reglar ≥ 25-gauge stål

25ゲージのスチールよりも強力なスタッド

板墙筋为不小于 25 标号的钢材

7x

888-45-184-W-05 rev.T • 01/19

5 of 17

Page 6

Hollow Wall

Pared

Mur

Wand

Muur

Parete

壁

墙壁

≥ 5/8”

Sheetrock

Sheetrock

Plaque de plâtre

Rigipsplatte

Sheetrock

Cartongesso

Gipsskiva

シートロック

石膏板

Requires minimum material thickness of 5/8” (16 mm).

Requiere un grosor mínimo de 16 mm.

Epaisseur minimum de 16 mm.

Requer uma espessura mínima de 5/8” (16 mm).

Mit einer Materialdicke von mindestens 16 mm.

Vereist een minimale materiaaldikte van 1.6 cm.

Richiede uno spessore del materiale non inferiore a 16 mm.

厚さが最低5/8”(16mm)の資材が必要。

需要最低材料厚度为 5/8”(16 mm).

Ø 1/2"

(12.7 mm)

d

a

14x

1

2

bc

e

14x

1/4-20 x 2"

3

4

f

3

7

6 of 17

888-45-184-W-05 rev.T • 01/19

Page 7

4x

10-24 x 1/2"

4x

10-24 x 1/2"

3

a

bc

8x

1/4-20 x 1/2"

8x

10-24 x 1/2"

NOTE: Fasteners may unwind due to vibration caused by movement of mounting solution over

time. Inspect mounting solution for loose fasteners on a routine basis. If desired, apply a light duty

thread locking adhesive to fasteners before installation to prevent back-out.

d

888-45-184-W-05 rev.T • 01/19

7 of 17

Page 8

4

a

1x

1/8"

cbd

2x

M10 x 16mm

6mm

ef g

12x

2x

2" - 4"

(51 - 102 mm)

1x

4" - 8"

(102 - 203 mm)

Security Feature

Función de seguridad

Fonction de sécurité

Sicherheitsmerkmal

Beveiligingsfunctie

Dispositivo antifurto

セキュリティ機能

安全特性

8 of 17

2x

7/16"

888-45-184-W-05 rev.T • 01/19

Page 9

5

4x

M4 x 10mm

4x

M4 x 10mm

6

M3 x 6mm

0°

a

b

888-45-184-W-05 rev.T • 01/19

9 of 17

Page 10

7

8

a

d

1x

4x

M4 x 8mm

bc

efg

4x

10 of 17

hi

jk

888-45-184-W-05 rev.T • 01/19

Page 11

9

4x

888-45-184-W-05 rev.T • 01/19

11 of 17

Page 12

10

NOTE: Leave enough slack in cable to allow full range of motion.

Caution: To avoid the potential to pinch cables it is important to follow the cable routing

instructions in this manual. Failure to follow these instructions may result in equipment

damage or personal injury.

12 of 17

888-45-184-W-05 rev.T • 01/19

Page 13

Ø 7/32" (5.6 mm)

11

a

b

12 3

Flush with drywal

cbd

M4.2 x 25mm M4.2 x 25mm

ef

12

abd e

c

888-45-184-W-05 rev.T • 01/19

13 of 17

Page 14

13

Important! You will need to adjust this product after installation is complete. Make sure all your equipment is

properly installed on the product before attempting adjustments. This product should move smoothly and easily

through the full range of motion and stay where you set it. If movements are too easy or diffi cult or if product

does not stay in desired positions, follow the adjustment instructions to create smooth and easy movements.

Depending on your product and the adjustment, it may take many turns to notice a difference. Any time

equipment is added or removed from this product, resulting in a change in the weight of the mounted load, you

should repeat these adjustment steps to ensure safe and optimum operation.

Lift – Up and down

a

Adjustment Step

Increase Lift Strength

If the mounted weight is too heavy or

this product does not stay up when

raised, then you'll need to increase

Lift Strength:

Decrease Lift Strength

If the mounted weight is too light or

this product does not stay down when

lowered, then you'll need to decrease

Lift Strength:

4mm

CAUTION: DO NOT overtighten fasteners.

Overtightening may cause damage to your

equipment.

WARNING

WARNING

14 of 17

WARNING! Stored Energy Hazard: The arm mechanism is under tension and will move up rapidly, on its own, as

soon as attached equipment is removed. For this reason, DO NOT remove equipment unless the arm has been

moved to the highest position! Failure to follow this instruction may result in serious personal injury and/or

equipment damage!

888-45-184-W-05 rev.T • 01/19

Page 15

Tilt – Forward and Backward

b

4mm

Increase Friction

If this product moves too easily, then

you'll need to increase friction:

Decrease Friction

If this product is too diffi cult to move,

then you'll need to decrease friction:

CAUTION: DO NOT remove screw. Removing screw may

cause damage to equipment.

Arm Swing – Side-to-side

c

Rotate – Portrait/Landscape

d

2.5mm

Increase Friction

If this product moves too easily, then

you'll need to increase friction:

Decrease Friction

If this product is too diffi cult to move,

then you'll need to decrease friction:

888-45-184-W-05 rev.T • 01/19

M3 x 6mm

0°

15 of 17

Page 16

How to remove this tilting feature:

3°3°

Save these screws incase you want to add

this feature later.

2x

M4 x 14mm

16 of 17

888-45-184-W-05 rev.T • 01/19

Page 17

Set Your Workstation to Work For YOU!

Learn more about ergonomic computer use at:

www.computingcomfort.org

Height Position top of screen slightly below eye level.

Position keyboard at about elbow height with wrists at.

Distance Position screen an arm's length from face—at least 20” (508mm).

Position keyboard close enough to create a 90˚ angle in elbow.

Angle Tilt screen to eliminate glare.

Tilt the keyboard back 10° so that your wrists remain at.

To Reduce Fatigue

Breathe - Breathe deeply through your nose.

Blink - Blink often to avoid dry eyes.

Break • 2 to 3 minutes every 20 minutes

• 15 to 20 minutes every 2 hours.

For Warranty visit: www.ergotron.com/warranty

For Service visit: www.ergotron.com

For local customer care phone numbers visit: http://contact.ergotron.com

www.ergotron.com |

© 2014 Ergotron, Inc. All rights reserved.

888-45-184-W-05 rev.T • 01/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

™

|

China: 400-120-3051

|

Japan: japansupport@ergotron.com

17 of 17

Loading...

Loading...