Coldline

MAINTENANCE HANDBOOK

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ И УХОДУ

Via Enrico Mattei, 38

35038 Torreglia

Padova (PD) - Italy

coldline@pec.it

MAINTENANCE HANDBOOK Page 5

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ И УХОДУ Стр 23

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

Надлежащая утилизация данного изделия (Отработавшее электрическое и электронное оборудование)

(Applicable in the European Union and other European countries with separate collection system)

This marking shown on the product or its literature, indicates that it should not be disposed with other household wastes at the end of

its working life. To prevent possible harm to the environment or human health from uncontrolled waste disposal, please separate this

from other types of wastes and recycle it responsibly to promote the sustainable reuse of materiale sources.

Household users should contact either the retailer where they purchased this product, or their local government office, for details of

where and how they can take this item for environmentally safe recycling.

Business users should contact their supplier and check the terms and conditions of the purchase contract. This product should not be mixed with other

commercial wastes for disposal.

(Применимо в Европейском Союзе и других странах Европы с внедренной системой раздельного сбора мусора)

Такая маркировка, нанесенная на изделие или приведенная в соответствующей документации, указывает на то, что по окончании срока

службы продукт не должен утилизироваться вместе с прочими бытовыми отходами. Для предотвращения возможного вреда окружающей

среде или здоровью людей в результате бесконтрольной утилизации отходов, пожалуйста, отделите данный продукт от прочих бытовых

отходов и подойдите к

использования источников материалов.

Бытовые пользователи должны обратиться к розничному продавцу, у которого был приобретен данный товар, или в местные органы власти за получением

информации о том, как они могут направить данный продукт на экологически безопасную переработку.

Промышленные пользователи должны обратиться к своему поставщику и выяснить у него условия договора закупки изделия. При переработке данный

продукт не должен смешиваться с другими коммерческими отходами.

его утилизации ответственно, поддержав тем самым инициативу по обеспечению устойчивости повторного

English

Русский

CONTENTS

1.0 OPERATING CONDITIONS 6

1.1 General information

1.2 Operating conditions

2.0 SPECIFICATIONS 6

3.0 INSTALLATION 7

3.1 Introduction

3.2 Damage check

3.3 Cleaning

3.4 Working conditions

3.5 Levelling

3.6 Putting into operation

4.0 CONTROL PANEL 8

5.0 DESCRIPTION OF CYCLES 9

5.1 Notions on blast chilling/blast freezing cycles

5.2 Blast chilling/blast freezing modes

5.3 Holding

6.0 OPERATION 10

6.1 Switching on/off

6.2 Blast chilling/blast freezing

6.3 Opening the door while a cycle is running

6.4 Pump-down

6.5 Temperature sensor and needle probe readings

6.6 Heated needle probe (optional extra)

6.7 Automatic defrosting

6.8 Manual defrosting

7.0 TEMPERATURE-BASED BLAST CHILLING/BLAST FREEZING 11

7.1 Temperature-based soft blast chilling

7.2 Temperature -based hard blast chilling

7.3 Temperature -based blast freezing

8.0 TIME-BASED BLAST CHILLING/BLAST FREEZING 13

8.1 Time-based soft blast chilling

8.2 Time-based hard blast chilling

8.3 Time-based blast freezing

9.0 PROGRAMS 16

9.1 Creating a new program

9.2 Calling up an existing program

10.0 HACCP ELECTRONIC RECORDER (OPTIONAL) 17

11.0 OPERATING TIPS AND WARNING 17

12.0 ALARMS 19

13.0 CONNECTION DIAGRAM 20

14.0 MAINTENANCE AND CLEANING 21

14.1 Cleaning the appliance

14.2 Cleaning the condenser

14.3 Emptying condensation

5

English

Русский

Do not store pressurised spray botles bearing the wording “flammable”. Risk of explosion!

certificate of EC

conformity.

Model

Voltage

Total

Power

Total current

demand

Yield (Kg)

+65°/+3°C

Yield (Kg)

+65°/-18°C

Yield (Kg/h)

-10°C/-18°C

BCC 5T

14

10

10

BCC 6T

18

14

15

BCC 7T

25

18

20

BCC 10T

40

28

35

BCC 14T

55

35

50

BCC 20T

80

55

-

115

75

-

BCC 20K

80

55

-

115

75

-

BCC 40K

120

80

-

200

140

-

1.0 OPERATING CONDITIONS

1.1 GENERAL INFORMATIONS

Our appliances are disigned and optimised in order to obtain high performance. This appliance must not be

used by people with limited physical, mental or sensory abilities or without experience and knowledge of it,

unless instructed in its use by those responsible for thir safety.

1.2 OPERATING CONDITIONS

The appliance must only be used within the temperature range specified by the manufacturer.

2.0 SPECIFICATIONS

The appliance conforms to European directives as

given in detail on the attached

The data are featured on the CE plate inside the

appliance.

6

230V/50 Hz 886W 4.9A

230V/50 Hz 1088W 6.0A

230V/50 Hz 1096W 6.1A

400V 3N/50 Hz 3345W 6.2A

400V 3N/50 Hz 3440W 6.6A

400V 3N/50 Hz 5590W 16.4A

400V 3N/50 Hz 6480W 19.0A

400V 3N/50 Hz 5590W 16.4A

400V 3N/50 Hz 6480W 19.0A

400V 3N/50 Hz 6480W 19.0A

400V 3N/50 Hz 8310W 24.4A

English

Русский

The Manufacturer declines all responsibility in the event of improper use of the appliance.

Installation must be carried out by specialized technical personnel only.

The manufacturer cannot be held responsible for damage or injury resulting from failure to earth

the appliance or inefficient earthing thereof, incorrect installation, tampering, poor maintenance

and incompetent use, or resulting from failure to comply with electrical safety standards in force in the

country where the appliance is used.

3.0 INSTALLATION

3.1 INTRODUCTION

The appliance must be used solely for the purpose it was specifically designed for, i.e. for storing food within

the temperature range stated by the manufacturer. Understand that any other use shall be considered

improper.

3.2 DAMAGE CHECK

Check all parts of the appliance for damage and that the standard-issue accessories inside are as expected.

3.3 CLEANING

Remove the PVC film covering the inside and outside of the appliance. Clean the compartment inside using a

sponge damp with lukewarm water.

3.4 WORKING CONDITIONS

Make sure the room in which the appliance is installed meets the following conditions:

• Room temperature in the range +5°C to +43°C.

• Positioning away from sources of heat and in a well ventilated area.

3.5 LEVELLING

Move the appliance into its final position and adjust the screw-type feet until you have the unit perfectly level.

Keep the unit at least 10 cm from the wall for a proper ventilation of the technical compartment

.

3.6 PUTTING INTO OPERATION

Before connecting to the power mains, make sure:

• Voltage and frequency are in conformity with the working conditions featured on the CE plate inside the

appliance: maximum tolerance is ±10% of the rated value.

• The power supply circuit meets regulations in force.

• The electrical system is fitted with a residual current circuit breaker (automatic cutout).

• Earthing is compulsory.

If the appliance is going to be switched off for a length of time, it is best to disconnect its power cord.

7

English

Русский

4.0 CONTROL PANEL

On/Off. To switch the instrument off.

Start/Stop

View needle temperature

Switch to time-based cycle

Decrease

Increase

Select hard blast chilling cycle

Select soft blast chilling cycle

Select blast freezing cycle

Select sterilization (optional)

Manual defrosting

Select programs

8

English

Русский

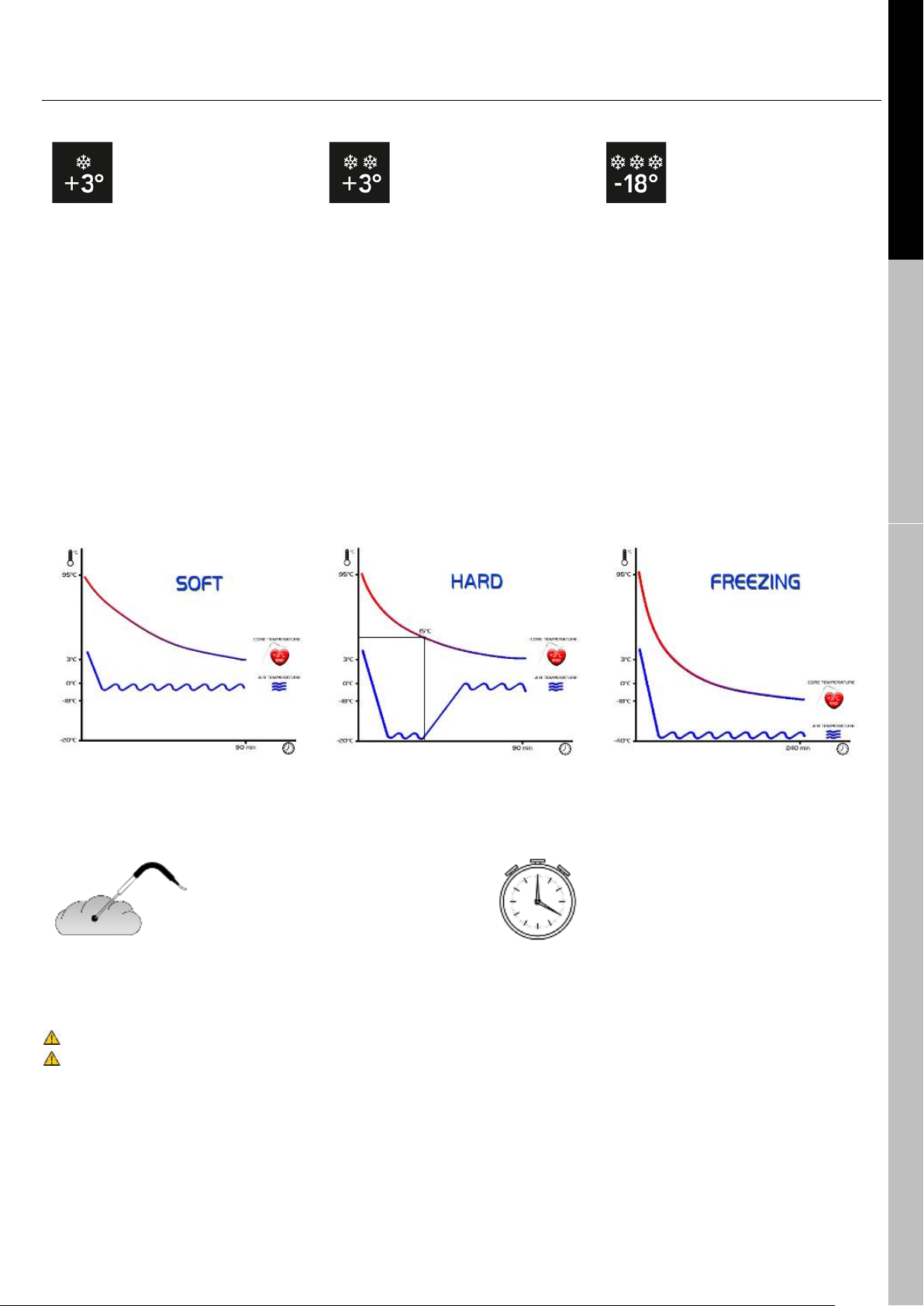

Soft

Hard

Freezing

Soft blast chilling is employed to

with a constant

air tempera-ture of -2°C

blast chill-ing time from +65°C to

+3°C must not exceed 90 minutes

Hard blast chilling is employed to

C with negative

air temperature during the first

stage (-35°C) and positive

temperature during the second

stage (0°C)

blast chill-ing time from +65°C to

+3°C must not exceed 90 minutes

Blast freezing is employed to freeze

with an air

temperature of -38°C

blast chilling time from +65°C to 18°C must not exceed 240

minutes.

Temperature

Time

Holding temperature at end of cycle

5.0 DESCRIPTION OF CYCLES

5.1 NOTIONS ON BLAST CHILLING/BLAST FREEZING CYCLES

cool the product quickly to a core

temperature of +3°C

Ideal for delicate, lightweight and

thin products: food tem-perature is

lowered quickly but without

damaging the outside. The food can

be stored for 5/6 days.

Whether dealing with products that

are cold or at room tem-perature, or

products that have just been cooked,

.

cool the product quickly to a core

temperature of +3°

. Ideal for products that

are dense, have a high fat con-tent,

come in large portions or are hard to

The food can be stored for 5/6

cool.

days.

Whether dealing with products that

are cold or at room tem-perature, or

products that have just been cooked,

.

the product quickly to a core

temperature of -18°

Ideal for increasing storage life of

food (weeks or a few months), quick

blast freezing preserves the product's

original visual, aromatic and flavour

properties, and stops macro crystals

forming, keeping quality and texture

intact.

Whether dealing with products that

are cold or at room temperature, or

products that have just been cooked,

5.2 BLAST CHILLING/BLAST FREEZING MODES

One of two modes can be selected for the blast chilling/blast freezing cycle:

needle probe

-based using the

-based using the timer

5.3 HOLDING

At the end of the blast chilling/blast freezing cycle, the appliance automatically switches to holding mode,

which continues indefinitely and is only stopped using the manual stop command.

Do not use the blast chiller/blast freezer as a normal storage unit.

The chilled/frozen product should be kept in a suitable appliance (refrigerator/freezer).

Soft: +3°C Hard: +3°C Blast Freezing: -20°C

9

English

Русский

3.0

OFF"

Switching on

standby

DY1

DY2

---

Switching off

OFF

DY1

OFF

DY2

7.0

8.0

]-[

DY2

The blast chilling/blast freezing cycle cannot be started with the door open. If the door stays

open for longer than 30 seconds during the blast chilling/blast freezing cycle, the blast chilling

cycle is stopped.

Pump-down

Stopping the compressor

5

DY1

the value

DY1

DY1

the value

DY1

6.0 OPERATIONS

6.1 SWITCHING ON/OFF

Once you have turned on the appliance's power, the control panel (

LEDs and displays come on for a few seconds, after which the display switches

still powered).

) automatically runs a lamp test. The

"

(control panel is off but

Hold button down for a few seconds: the appliance goes into

stands by to receive a command.

Display

Display

Hold button down for a few seconds: the appliance switches "

Display

Display

gives the temperature inside the appliance.

reads "

reads "

stays off.

".

".

. During this phase, the machine

".

6.2 BLAST CHILLING/BLAST FREEZING

See points

and

for details.

6.3 OPENING THE DOOR WHILE A CYCLE IS RUNNING

If the door is opened while a blast chilling/blast freezing cycle is running, the "

intermittently on display

and only restart once the door is closed.

and, at the same time, a buzzer will sound. The compressor and fans inside stop

6.4 PUMP DOWN

pressures during start-up.

is a system designed to protect the compressor and its job is to avoid excessive working

" code will flash up

When button is pressed to stop a blast chilling, blast freezing or holding cycle manually, the compressor

keeps working for

more seconds.

6.5 TEMPERATURE SENSOR AND NEEDLE PROBE READINGS

While a temperature-based cycle is running,

view compartment sensor temperature by pressing the button relating to the cycle selected:

The value is put up on

While a time-based cycle is running,

view needle probe temperature by pressing button

for 5 seconds.

indicates

indicates

. The value is put up on

measured by the compartment sensor. You can

measured by the needle probe. You can

for 5 seconds.

, or .

6.6 HEATED NEEDLE PROBE (Optional extra)

The heated needle probe (optional extra) has a device that heats its tip, making it easier to pull out of frozen

products. Holding button down for 5 seconds at the end of a blast freezing cycle turns on heating so that

the probe can be easily removed from the frozen product. Heating only comes on if the door is open.

6.7 AUTOMATIC DEFROSTING

During operation, frost forms on the surface of the evaporator: this is normal but it reduces evaporator

efficiency. The purpose of defrosting is to restore full efficiency. Defrosting is performed automatically:

10

English

Русский

Shortcut commands while in standby mode

6.1

soft

Shortcut commands while in standby mode

Detailed commands sequence:

standby

6.1

10.0

soft

.

DY1

-2°C).

DY2

---”.

soft

6.4

DY1

DY2

+3°C

6.4

- At the end of each blast chilling/blast freezing cycle.

- At 6-hour intervals during holding.

The purpose of the evaporator sensor is to produce the utmost efficiency and shorten defrosting times by

measuring the end-of-defrosting temperature.

6.8 MANUAL DEFROSTING

This mode should be used only when further defrosting is required in addition to that performed

automatically by the appliance.

Make sure the appliance is working (

Hold button down for 5 seconds.

The led by the button comes on, and goes off when cycle ends.

The defrosting cycle stops automatically. How long it takes depends on how much frost there is on the

evaporator coil.

Once defrosting has finished, the appliance resumes normal operation.

).

7.0 TEMPERATURE-BASED BLAST CHILLING/BLAST FREEZING

7.1 TEMPERATURE-BASED SOFT BLAST CHILLING

The temperature-based

blast chilling cycle is controlled by the needle probe.

1

1. Make sure the appliance is in

2. Insert the needle probe in the product to be chilled (

3. Press button to select the

• The led button comes on.

• Display

• Display

4. Press button to start the

• The led button

•

The compressor only starts working 5 seconds after key is pressed (pump-down

•

minutes

• If you press button

5. A buzzer sounds to advise that the blast chilling cycle has finished.

6. At the end of the cycle, holding mode starts and continues indefinitely at a holding temperature of

Soft blast chilling

gives the setpoint of the air in the compartment (

reads “

gives needle probe temperature, and

.

comes on.

while the cycle is running, you can view the time elapsed since it started.

2

mode (

blast chilling cycle

blast chilling cycle.

Start

).

).

the cycle time remaining, counting down from 90

).

.

• The led button flashes.

• If you press button

how long it took.

•

The holding stage must last only as long as strictly necessary.

7. To exit holding mode, press button

• The led button

•

The compressor stops 5 seconds after button is pressed (pump-down

during holding time, you can view the time of the cycle just completed to see

goes off.

.

).

11

English

Русский

Important

soft

-2°C

+3°C.

90 minutes

hard

Shortcut commands while in standby mode

Detailed commands sequence:

standby

6.1

10.0

DY1

-35°C).

DY2

---”.

6.4

DY1

DY2

+3°C

6.4

Important

hard

-35°C

-2°C

+3°C.

90 minutes

• Countdown starts when core temperature measured by the needle probe drops below +65°C.

When a

•

compartment reaches

prevent frost from forming.

The blast chilling cycle ends when the product's core temperature measured by the needle probe reaches

•

blast chilling cycle is started, the compressor works non-stop until air temperature in the

. After this, it can cycle on and off to keep this temperature constant and

The cycle cannot last more than

.

7.2 TEMPERATURE -BASED HARD BLAST CHILLING

The temperature-based

blast chilling cycle is controlled by the needle probe.

1

Hard blast chilling

2

Start

1. Make sure the appliance is in

2. Insert the needle probe in the product to be chilled (

3. Press button to select the hard blast chilling cycle.

• The led button comes on.

• Display

• Display

4. Press button to start the hard blast chilling cycle.

• The led button

•

•

minutes.

• If you press button while the cycle is running, you can view the time elapsed since it started.

5. A buzzer sounds to advise that the blast chilling cycle has finished.

At the end of the cycle, holding mode starts and continues indefinitely at a holding temperature of

6.

• The led button

gives the setpoint of the air in the compartment (

reads “

The compressor only starts working 5 seconds after key is pressed (pump-down

gives needle probe temperature, and

comes on.

flashes.

mode (

).

).

the cycle time remaining, counting down from 90

).

.

• If you press button

how long it took.

•

The holding stage must last only as long as strictly necessary.

7. To exit holding mode, press button

• The led button

•

The compressor stops 5 seconds after button is pressed (pump-down

• Countdown starts when core temperature measured by the needle probe drops below +65°C.

•

When a

compartment reaches

preventing the formation of frost

•

The blast chilling cycle ends when the product's core temperature measured by the needle probe reaches

blast chilling cycle is started, the compressor works non-stop until air temperature in the

The cycle cannot last more than

during holding time, you can view the time of the cycle just completed to see

.

goes off.

).

. After this, it can cycle on and off to keep a constant temperature of

.

.

7.3 TEMPERATURE -BASED BLAST FREEZING

The temperature-based blast freezing cycle is controlled by the needle probe.

,

12

English

Русский

Shortcut commands while in standby mode

Detailed commands sequence:

standby

6.1

10.0

DY1

-38°C).

DY2

---”.

working 5

6.4

DY1

DY2

240

-20°C

6.4

Important

-38°C

-18°C.

240 minutes

soft

Shortcut commands while in standby mode

Detailed commands sequence:

standby

6.1

soft

DY1

-2°C).

1

1. Make sure the appliance is in

2. Insert the needle probe in the product to be chilled (

3. Press button to select the blast freezing cycle.

• The led button comes on.

• Display

• Display

4. Press button to start the blast freezing cycle.

• The led button

•

The compressor only starts

•

minutes.

• If you press button while the cycle is running, you can view the time elapsed since it started.

5. A buzzer sounds to advise that the blast chilling cycle has finished.

At the end of the cycle, holding mode starts and continues indefinitely at a holding temperature of

6.

• The led button

Blast freezing

gives the setpoint of the air in the compartment (

reads “

gives needle probe temperature, and

comes on.

flashes.

2

mode (

Start

).

).

seconds after key is pressed (pump-down

the cycle time remaining, counting down from

)

.

• If you press button

how long it took.

•

The holding stage must last only as long as strictly necessary.

7. To exit holding mode, press button

• The led button

•

The compressor stops 5 seconds after button is pressed (pump-down

• Countdown starts when core temperature measured by the needle probe drops below +65°C.

When a blast freezing cycle is started, the compressor works non-stop until air temperature in the

•

compartment reaches

•

The blast freezing cycle ends when the product's core temperature measured by the needle probe reaches

The cycle cannot last more than

during holding time, you can view the time of the cycle just completed to see

.

goes off.

).

. After this, it can cycle on and off to keep this temperature constant.

.

8.0 TIME-BASED BLAST CHILLING/BLAST FREEZING

8.1 TIME-BASED SOFT BLAST CHILLING

The time-based

blast chilling cycle is controlled by the timer.

1

1. Make sure the appliance is in

2. Press button to select the

• The led button comes on.

• Display

Soft blast chilling

gives the setpoint of the air in the compartment (

2

mode (

blast chilling cycle.

Time-based cycle

).

3

Start

13

Loading...

Loading...