Page 1

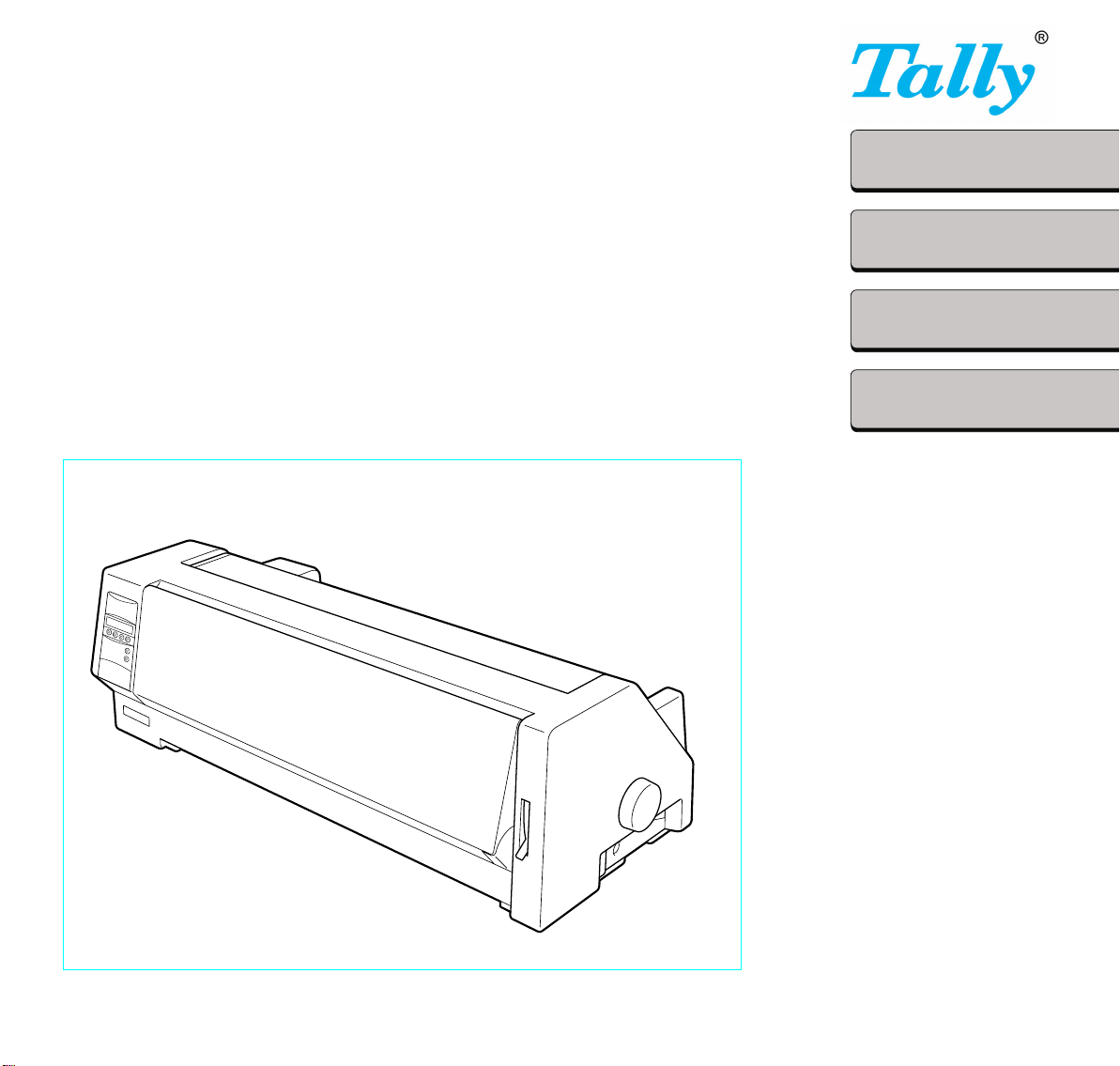

T2240/9

Operator’s Manual Matrix Printer

Bedienungsanleitung Matrixdrucker

Manuel d’utilisation Imprimante matricielle

Istruzioni per l’uso Stampante a Matrice

Instrucciones de servicio Impresora matricial

T2240/24

T2340/9

T2340/24

Page 2

Important Information

This equipment generates and uses radio frequency energy and if not

installed and used properly, that is, in accordance with the manufacturer’s

instructions, may cause interference in radio and television reception. It

has been type tested and found to comply with the limits for class B

computing devices in accordance with the specification in subpart J of part

15 of FCC rules, which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no

guarantee that interference will not occur in a partial installation. If this

equipment does cause interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Reorient the receiving antenna,

Relocate the peripheral away from the receiver,

Move the peripheral away from the receiver

Plug the peripheral into a different outlet, so that the peripheral and

receiver are on different branch circuits

If necessary, the user should consult the dealer or an experienced

radio/television technician for additional suggestions. The user may find

the following booklet, prepared by the Federal Communications Commission, helpful: “How to Identify and Resolve Radio-TV Interference

Problems”.

This booklet is available from the U.S. Government Printing Office, Washington DC 20402 Stock No. 004.000.00345.4.

WARNING: To comply with FCC regulations on electromagnetic interference for a class B computing device, the printer cable must be shielded.

To assure compliance with FCC regulations for a computing device, use

a shielded interface cable with a metal shell connector. The use of cables

not properly shielded may result in violating FCC regulations.

This digital apparatus does not exceed the class B limits for radio noise

emissions from digital apparatus as set out in the radio interference

regulations of the Canadian department of communications.

This unit complies with DOC standard C108.8-M 1983

ATTENTION: Le présent appareil numérique n’ement pas de bruits

radioélectriques déspassant les limites applicables aux appareils

numériques de la classe B prescrites dans le règlement sur le brouillage

radio- électrique édicté par le minstère des communications du Canada.

The paper used is made of raw materials treated with a chlorine-free

bleaching process.

Das verwendete Papier ist aus chlorfrei gebleichten Rohstoffen

hergestellt.

Le papier utilisé est fabriqué à partir de matières premières blanchis sans

chlore.

La carta utilizzata è prodotta con materiali sbiancati senza cloro.

El papel utilizado ha sido fabricado con un proceso de blanqueo libre de

cloro.

This device fulfils the European standards requirements by complying with the Directive of the Commission

dated May 3, 1989 (89/336/EEC) relating to electromagnetic compatibility and the Directive dated February 19,

is indicated by the CE symbol attached to the device.

1973 (73/23/EEC) relating to low-voltage electrical equipment. Conformity with the above mentioned Directives

Note: Conformity may be affected by:

using interface cables not complying with the specifications

non-observance of important instructions in the operator’s manual

installing components not approved for this device by the manufacturer

unauthorized manipulation

Dieses Gerät erfüllt die Anforderungen der Europäischen Normen durch Einhaltung der Richtlinie des Rates

vom 3. Mai 1989 (89/336/EWG) bezüglich der Elektromagnetischen Verträglichkeit sowie die Richtlinie vom 19.

den oben angeführten Richtlinien ist durch das am Gerät angebrachte CE-Zeichen gekennzeichnet.

Februar 1973 (73/23/EWG) bezüglich Elektrischer Betriebsmittel mit Niederspannungen. Die Konformität zu

Hinweis: Die Konformität kann beeinflußt werden durch:

Benutzung von nicht spezifizierten Schnittstellenkabeln

Nichtbeachtung wichtiger Hinweise der Bedienungsanleitung

Ersetzen von Bauteilen, die nicht vom Hersteller für dieses Gerät freigegeben wurden

Eingriffe durch Unbefugte

Cet appareil remplit aux exigences des normes européennes en respectant la directive du Conseil du 3 mai

1989 (89/336/CE) relative à la compatibilité électromagnétique et la directive du 19février 1973 (73/23/CE) en

marque de conformité de la Communauté Européenne (CE).

matière du matériel à basse tension. La conformité aux directives mentionnées ci-dessus est repérée par la

Remarque: La conformité peut être influencée par:

l’utilisation de câbles d’interface non spécifiés

le non-respect de consignes importantes du manuel d’utilisation

le remplacement de composants qui n’ont pas été homologués pour cet appareil par le constructeur

l’intervention de personnes non autorisées

Questo apparecchio soddisfa le richieste delle norme europee rispettando la direttiva del consiglio del 3 Maggio

1989 (89/336/CEE) relativa alla compatibilità elettromagnetica nonché la direttiva del 19 Febbraio 1973

è contrassegnata con il simbolo CE applicato sull’apparecchio.

(73/23/CEE) relativa a mezzi di produzione elettrici a bassa tensione. La conformità alle direttive sopra citate

Nota: La conformità può essere influenzata tramite:

Utilizzo di cavi interfaccia non specificati

Inosservanza di importanti indicazioni delle istruzioni per l’uso

Sostituzione di componenti per i quali non è stato dato il benestare dal produttore per questo apparecchio

Interventi tramite persone non autorizzate

Este equipo corresponde a lo exigido en las normas europeas a base del cumplimiento de la directriz del Consejo

del 3 de mayo de 1989 (89/336/CEE) en lo que se refiere a la compatibilidad electromagnética así como de la

tensiones. Para señalizar la conformidad con las directrices antes mencionadas, el equipo está dotado de la marca CE.

Indicación:

directriz del 19 de febrero de 1973 (73/23/CEE) en lo que se refiere a los materiales eléctricos con bajas

La conformidad puede estar influida por:

la utilización de cables de interface no especificados

la inobservancia de indicaciones importantes contenidas en el manual de servicio

la sustitución por componentes, que no han sido homologados por el fabricante para el equipo en cuestión

intervenciones de personas no autorizadas

WARNING Only trained and qualified personnel may open covers or remove parts that are not explicitly shown and described in the User Guide as being accessible to

the operator.

WARNUNG Das Entfernen oder Öffnen von Abdeckungen und Teilen darf nur durch geschultes Fachpersonal vorgenommen werden. Ausgenommen hiervon sind nur

solche Abdeckungen und Teile, deren Entfernen bzw. Öffnen in der Bedienungsanleitung ausdrücklich gekennzeichnet und beschrieben sind.

ATTENTION Seul un personnel qualifié et formé est habilité à démonter les sous-ensembles de la machine qui ne sont pas formellement indiqués dans le Manuel

d’utilisation meme s’ils sont accessibles par l’opérateur.

ATTENZIONE Solo personale qualificato puo’accedere a parti che non siano esplicitamente descritte nelle Istruzioni per l’operatore come accessibill all’operatore.

ADVERTENCIA Las cubiertas y piezas sólo deberán ser quitadas o abiertas por personal especializado. Se exceptúan de esta regla sólo las cubiertas y piezas cuya

retirada y apertura estén indicadas y descritas expresamente en las Instrucciones de uso.

Page 3

Quick start-up

Table of contents

Operator’s Manual

QUICK START-UP

Introduction 2

Symbols used in this manual 2

Important safety instructions 2

Using the online documentation 2

Troubleshooting 2

The printer at a glance 3

Installation 5

Unpacking the printer 5

Positioning your printer 5

Connecting the printer 6

Switching the printer on and off 6

Control panel 7

Online mode 7

Offline mode 7

Setup mode 7

Installing the ribbon cassette 8

Loading paper 10

Cut Sheet paper 10

Printer in fanfold paper mode 12

Changing the paper type 14

Paper path quick selection 14

Paper transport 15

Using 15

Moving paper to the tear position 15

Settings (I) 16

Setting the tear position 16

Setting the first printing line (TOF) 16

Settings (II) 18

Setting the print head gap 18

Changing paper in Setup mode 19

From fanfold paper to single sheet mode 19

From single sheet to fanfold paper mode 20

Selecting a font 21

Setting the character pitch 22

Specifications 23

Printer specifications 23

Paper specifications 23

Accessories 24

ENGLISH

1

Page 4

Introduction Quickstart-up

Introduction ThisOperator’sManualisintendedasaquickintroductionintoworkingwiththeprinterandis

Ah ha!

➤Symbolsusedinthis

manual

STOP

➤Importantsafety

instructions

STOP

toenablealsounexperienceduserstohandlethedeviceproperly.Itdescribesthemostimportant

functionsoftheprinterandcontainstheessentialinformationforyoureverydayworkwiththe

printer.Amoredetaileddescriptionoftheprinter,itscharacteristicfeaturesandfurtherinformationiscontainedinthereference manual ontheonline CD-ROMwhichisincludedattheback

of thismanual.

Importantinformationishighlightedinthismanualbytwosymbols.

CAUTIONmarksinformationwhichmustbeobservedinordertopreventinjuriestotheuser

anddamagetotheprinter.

NOTEmarksgeneraloradditionalinformationaboutaspecifictopic

Readthefollowinginstructionscarefullybeforeputtingtheprinterintooperationinorderto

protectyourselffrominjuryandavoiddamagetotheprinter.

KeepthisOperator’sManualalwaysreadilyaccessible.

Placetheprinteronastablesurfacesothatitcannotfalldowntotheground.

Avoidexposingtheprintertohightemperatureordirectsunlight.

Keepallliquidsawayfromtheprinter.

Donotexposetheprintertoshock,impactorvibration.

Neverswitchontheprinterwhenitisnotsettothecorrectvoltage.

Nevertrytocarryoutmaintenanceandrepairworkyourself;alwayscallaqualifiedservice

technician.

STOP

➤Usingtheonline

documentation

Whenyouwanttodisconnecttheprinterfromthemainspowersupply,alwayspulloutthe

mainsplugfromthewalloutlet.

Youwillfindadditionalsafetyinformationatspecificplacesinthetext.

FirstinstalltheAdobeAcrobatReaderonyourharddiskunlesstheprogramhasalreadybeen

installed.Toinstallit,followthestepsdescribedintheREADMEfileintheREADERdirectory.

Tostarttheonlinedocumentation,calltheFileManager(Windows3.1)orExplorer(Windows95/Windows98/WindowsNT)anddoubleclickontheSTART.PDFfile.Thenfollowthe

instructionsandmenusonthescreen.

IfyourCD-ROMshouldbedefectiveormissing,pleaseconsultyourdealer.

Theonlinedocumentationisalsoavailableasaprintedmanual(forasmallfee)andviathe

internet.

Minimumhardwarerequirements:PCAT486,4xCD-ROM,15"monitor,mouse.

➤Troubleshooting TheonlinedocumentationsuppliedontheCD-ROMcontainsdetailedinformationontrouble-

shooting.

2

Page 5

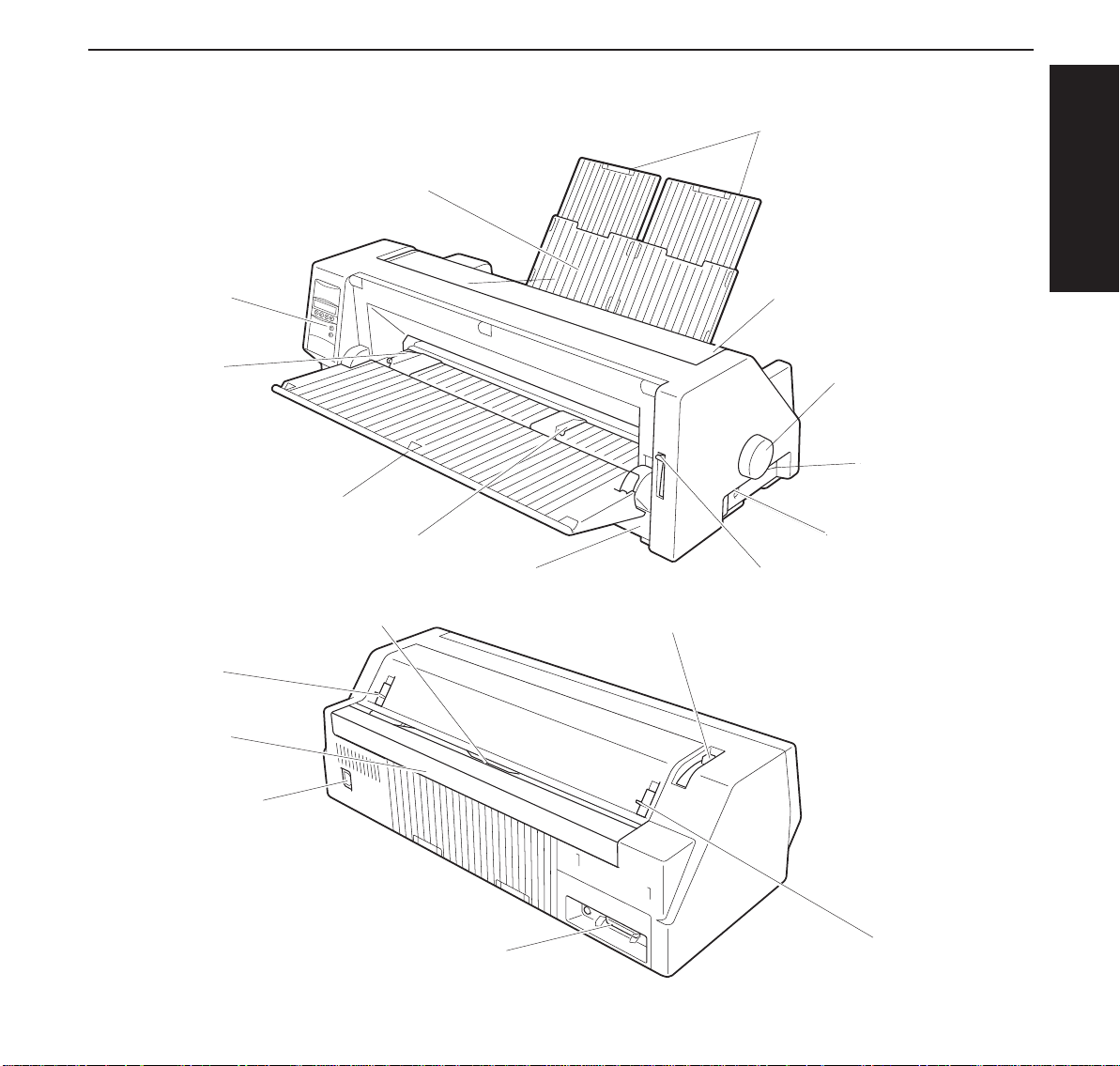

Quick start-up The printer at a glance

The printer at a

glance

Operation Panel

Left Paper Guide

Cut Sheet Paper Insert Guide

Perforated Line Cutter

The following figures show the name of each printer part, and the table on the following page

shows the functions of each part.

Paper Tray

Right Paper Guide

Front Cover

Paper Thickness Adjustment Lever

Paper Extension Trays

Access Cover

Paper Feed Knob

Power Switch

Option Connectors

Paper Type Selection Lever

ENGLISH

Latch Lever

Rear Covere

Power Inlet

Interface Connector

Latch Lever

3

Page 6

The printer at a glance Quick start-up

Name Functions

Operation Panel It indicates the printer status, and is used to change various settings.

Paper Tray It is used as a paper support for cut sheetpaper already printed when the

Paper Extension Trays They are used for extendingof the Paper Tray.

Access Cover When the Ink-ribbon Cartridgeis to be replaced or paper jams are to be

Paper Feed Knob It is used to manually feed paper forwardorbackward.

Power Switch It is used to turn ON or OFF the power of the printer.

Option Connector It is used to connect an Auto Sheet Feeder(ASF)or the Optional 2nd

Paper Type Selection

Lever

Front Cover It is opened when Continuous Form Feed Paperis to be set. This cover is

Right Paper Guide By aligning the right edge of the Cut SheetPaperto this guide, an uneven

Cut Sheet Paper Insert

Guide

Left Paper Guide It is used to adjust the left margin of the Cut SheetPaper.

Latch Lever By pulling this lever to the front, the latch is released and the Access

Perforated Line Cutter ContinuousForm Feed Paper will be cut at this position. By pressing the

Paper ThicknessAdjustment Lever

Interface Connector It is used to connect the I/O cable to the system unit.

Power Inlet It connectsto the power cord.

Rear Cover It is used to reduce noise. It must be removedwhenthe paper tray is in

option “F-Eject” is setto OFF in the Initial Setting.

removed, this cover is detached to allow access to the related parts. It also

serves to protect operators fromthe m echanical movements of the printer.

Tractor.

It is used to select the appropriate type of paper to be used in the printer:

Cut Sheet Paper (upper position)

Continuous Form Feed Paper (lowerposition)

detached when an Auto Sheet Feeder (ASF)or the Optional 2nd Tractor is

to be attached.

feed can be prevented.

It is opened for inserting Cut Sheet Paperand is used as a paper support.

It is also used as a support for post-printCut Sheet Paper when the option

“F-Eject” is set to ASF,Single or ALL in the Initial Setting.

Cover can be opened.

Tear key after printing,paper feeds up to this position.

It is used to adjust the paper-pinching strength of the printer in accordance

with the thickness of the paperto be used. As for the adjustment ranges,

see

Paper Thickness Adjustment

upright position.

, page 18.

4

Page 7

Quick start-up Installation

Installation

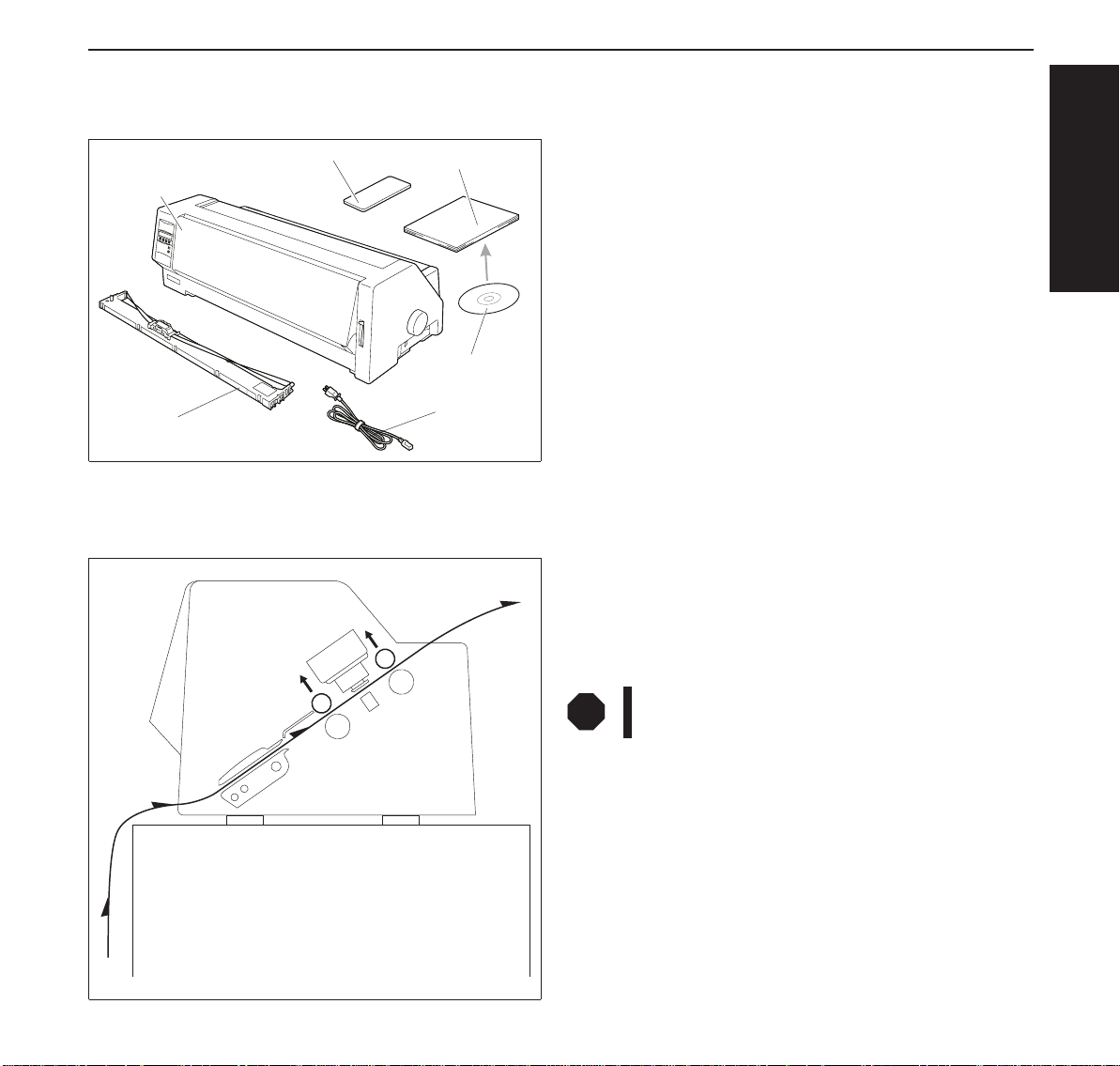

➤Unpacking the printer Please open the printer package and check that all the following items are included.

Unpacking Instructions

Printer

Ink-ribbon

➤Positioning your

printer

Operator’s Manual

CD-ROM

Power Cord

Place the printer on a stable, flat and non-slip surface in such a way that it cannot fall down.

Ensure easy access to the control panel and the paper feeders and leave sufficient space for the

paper ejected.

Ifany itemis missingor damaged,pleasecontactthestore where

the product was purchased.

Remove the transport protection elements as described in the

unpacking instructions.

The carton and the packing materials will be necessary for

moving or transporting the printer. Please store them in a safe

place.

If frequent forward and return feed movements will be performed with fanfold paper, you should position the printer as

illustrated in the figure.

Whenchoosinga suitableplace foryour printer,you should also

observe the following:

ENGLISH

STOP

■ Avoid exposing the printer to direct sunlight. If you cannot

avoid placing the unit near a window, protect it from sunlight

with a curtain.

■ Position the printer near the computer to which it will be

connected. The distance must not exceed 2 m.

■ Ensure sufficient distance from radiators.

■ Ensure that the printer is not exposed to extreme variations

in temperature or air humidity. Avoid exposure to dust.

Never place the printer near sources of easily inflammable gas or explosive substances.

5

Page 8

Installation Quick start-up

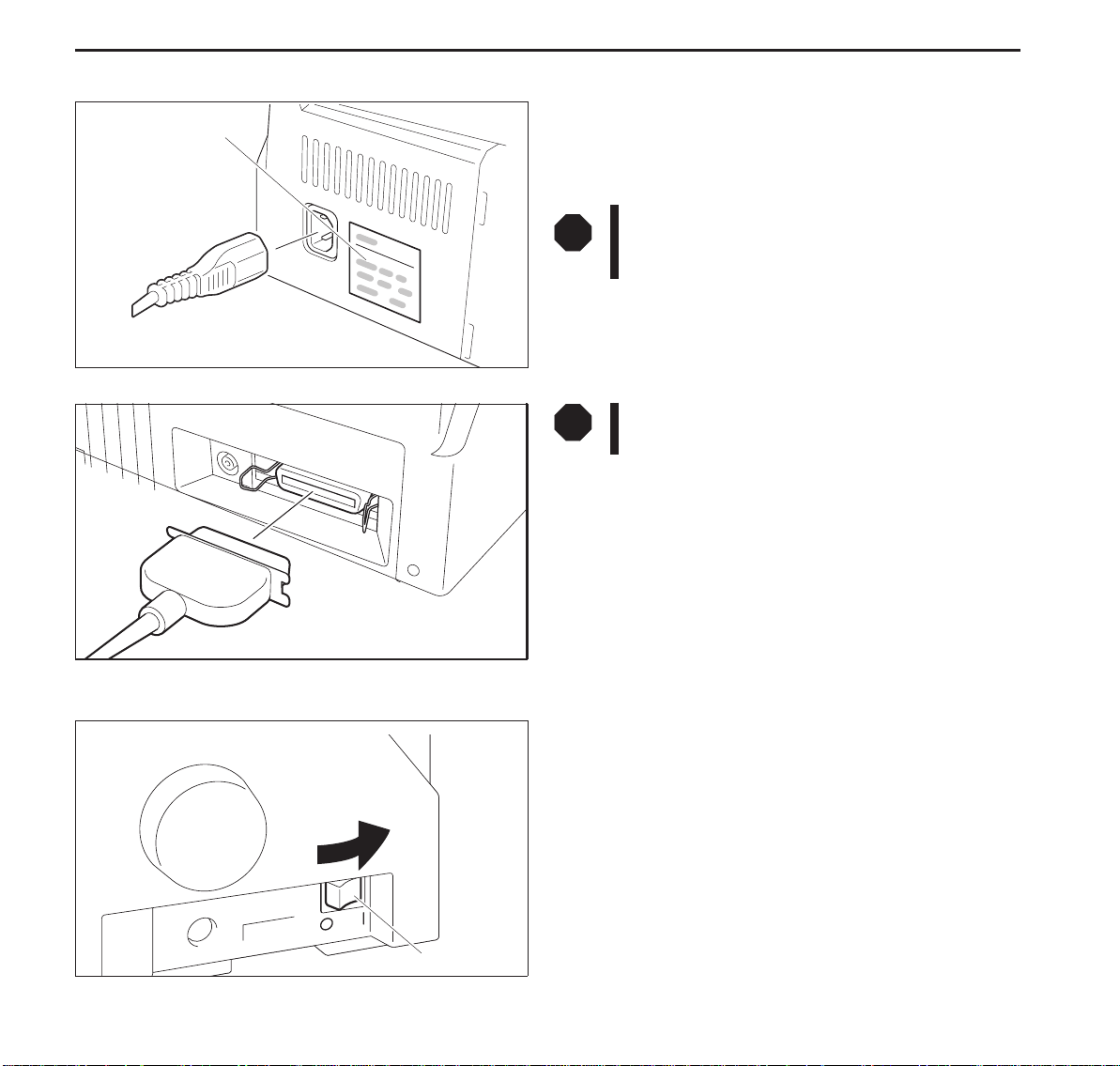

➤ Connecting the printer

Make sure that the unit is set to the correct voltage (i.e. 230 V

Type Plate

for Europe, 120 V for the USA). Refer to the type plate beside

the power inlet on the rear side of the printer.

If this is not the case, contact your dealer.

➤ Switching the printer on and off

STOP

Never switch on the printer when it is not set to the

correct voltage since this could cause severe damage.

Connect the power cable to the printer’s power

inlet as shown in the figure.

Connect the power cable plug to a wall outlet.

STOP

Make sure that the printer and the computer are

switched off.

Connect the printer-end connector of the data

cable to the female interface connector and secure it with the

spring clips.

Connect the other end of the cable to the computer.

The power switch, which is used for switching the printer on

and off, is located at the right side of the printer.

Power Switch

6

Page 9

Quickstart-up Controlpanel

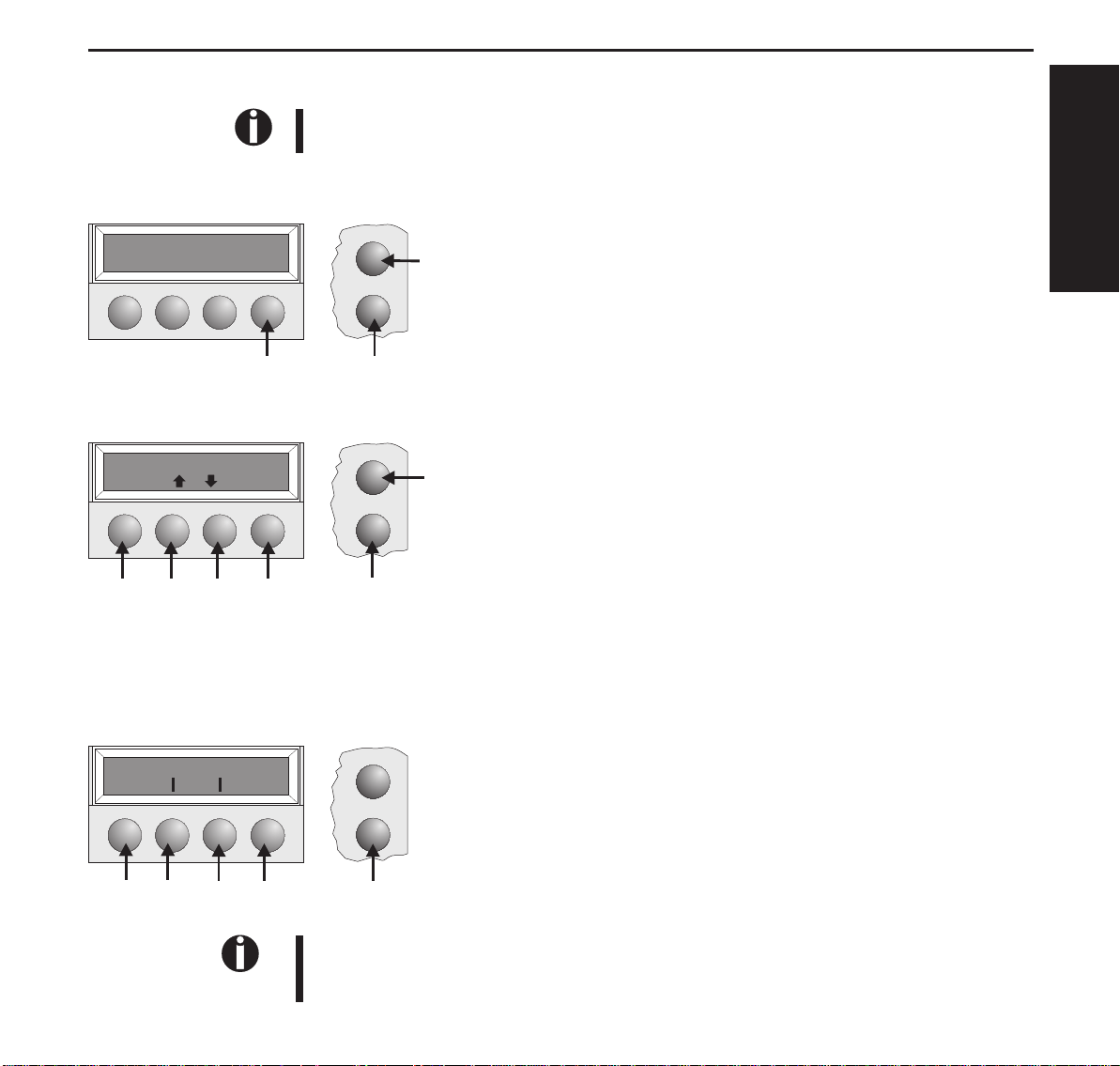

Controlpanel Youcancontrolprinteroperationusingthecontrolpanelandthekeys.

ThefirstlineofthedisplayinformsyouaboutwhethertheprinterisinOnlineorinOffline

modeandaboutthepaperpathselected(Trac.1orSingle).

➤Onlinemode Whenswitchingontheprinter,itautomaticallyselectsOnlinemode.Itcanreceivedatafromthe

computeronlyinthismode.

Online Trac.1

Tear

Online

Setup

➀SetstheprintertoOfflinemode.

➁SetstheprintertoSetupmode.

➀

➂Tearkey:Activatesthetearfunctionwhenfanfoldpaperisloaded

(seepage15).IfLoadisdisplayedabovethiskey,nopaperisloadedin

theprinter;pressthekeytofeedpapertotheprintingposition.

ENGLISH

➂

➁

➤Offlinemode Stepfeeds,linefeedsandformfeedscanbeperformedviathecontrolpanelonlyinthismode

(seepage15).

Offline Trac.1

Park LF/FF

Online

Setup

➀SetstheprintertoOfflinemode.

➁SetstheprintertoSetupmode.

➀

➂Ifnopaperisloaded:Loadkey(seeabove).Ifpaperisloaded:

Shortkeypress:Linefeed(LF)

Longkeypress:Formfeed(FF)

➃Shortkeypress:Micro-stepreturn

➄➅

➂➃

➁

Longkeypress:Constantpaperfeedreturn

➄Shortkeypress:Micro-stepforward

Longkeypress:Constantpaperfeedforward

➅Clearsthepaperpathwithpaperloadedandactivatespaperpathquick

selection(seepage14).

➤Setupmode

Adjust Paperway

Menu Char

➄

➃

➂

➁

Online

Setup

➀

➀SetstheprintertoSetupmode.Inthismode,thefollowingsettingsare

available:

➁Setsthefontandthenumberofcharactersperinch(Charmenu).

➂Paperpath(Paperwaymenu)

➃Tearpositionandfirstprintingline(Adjustmenu)

➄Othermenusettings(Menu)

Accesstotheothermenuoptionsisdisabledbythemanufacturer.Forinformationonhowto

enableaccesstotheseoptionsaswellasabouttheoptionsavailable,refertotheonlinedocumentationontheCD-ROM,chapter1, Operation (Unlock the menu mode).

7

Page 10

Installing the ribbon cassette Quick start-up

Installing the

ribboncassette

STOP

Latch Lever

Remove any paper loaded into the printer.

Before opening the cover, make sure that the printer is switched off.

Set the Paper Thickness Adjustment Lever to the “8” position.

Paper Thickness

Adjustment Lever

Access Cover

Latch Lever

Pull the Latch Levers near the right and left ends on the Access

Cover to the front, and detach the entire Access Cover.

Print head

Move the Print head to approximately the center.

STOP

The PrintHeadmay be hot. Soplease be careful not

to touch the metal part of the Print Head.

8

Page 11

Quick start-up Installing the ribbon cassette

Ribbon Feed Knob

Ink-ribbon

cartridge

Part “A” (left side)

Align the part “A” on the left side of the Ink-ribbon Cartridge

to the two hooks of the printer, push the cartridge all the way

until it clicks. If there is resistance, push it while turning the

Ribbon Feed Knob.

Hooks

ENGLISH

Detach the Ribbon Guide from the Ink-ribbon Cartridge.

Do not detachthe shield that hasbeenattached to the

Ribbon Guide; it is necessary to protect the ribbon.

Put the Ribbon Guide between the Print Head and the Platen

and push it all the way until it clicks.

Ribbon Feed

Knob

When attaching the RibbonGuide,be careful not to

fold the ribbon. Also, pay attention to the shield so

that it does not become damaged.

Turn the Ribbon Feed Knob in the direction indicated by the

arrow to remove any slack in the ribbon.

9

Page 12

Loadingpaper Quickstart-up

Access

Cover

WhentheInk-ribbonCartridgesettingiscomplete,attachthe

AccessCover.

SetthePaperThicknessAdjustmentLeverinaccordancewith

thethicknessofthepapertobeused.Refertopage18(Setting

theprintheadgap).

Loadingpaper

Onlyusepaperwhichissuitableforthisprinter.Formoreinformation,refertotheonline

documentationontheCD-ROM,AppendixC(Specification).

➤CutSheetpaper CutSheetPaperistobeinsertedfromthefrontoftheprinter.Thepost-printpapercanbefedout

fromtherearorthefront.PleaserefertotheonlinedocumentationontheCD-ROM,Chapter1,

Menu description table.

TurnthePowerSwitchoftheprinterON(“|”).

AdjustthePaperThicknessLeveraccordingtothetypeofpaper

tobeused.Refertopage18(Settingtheprintheadgap).

Paper Tray

10

Power Switch

Paper Extension Trays

StandthePaperTrayupinthedirectionindicatedbythearrow.

WhileholdingthePaperTray,pullupthePaperExtension

Trays.

Page 13

Quick start-up Loading paper

Set the Paper Type Selection Lever to Cut Sheet Paper mode.

Make sure that the printer is in Single Sheet mode. For how to

select Single Sheet mode refer to page 14 (Paper path quick

selection).

Cut Sheet Insert

Guide

Paper Type

Selection Lever

Determine the left margin by moving the Left Paper Guide left

or right. (The “[A” mark indicates the standard print start

position.)

ENGLISH

Cut sheet paper

Paper guides

Placea sheetof paperaligned tothe LeftPaper Guide,and adjust

the Right Paper Guide to the right edge of the paper.

Insert the paper between the Left and Right Paper Guides. The

paper is automatically fed to the print start position and the

printer is ready to print.

The paper feed-out capacity is about 30 sheets in

case 55Kg-paper (ream) is used and the post-print

paper is set to feed out to the rear side. When the

post-print paper is set to feed out to the front, the

paper must be removed sheet by sheet.

11

Page 14

Loading paper Quick start-up

➤ Printer in fanfold paper mode

Paper Type

Selection Lever

Front Cover

SetthePaper ThicknessAdjustment Leveraccording to thetype

of paper to be used. Refer to page 18 (Setting the print head

gap).

Set the Paper Type Selection Lever to Continuous Form Feed

Paper mode.

Open the Front Cover to its upright position until it snaps in.

This prevents unexpected closing of the cover.

Stand the Left and Right Tractor Fixing Levers up (in the

direction indicated by the arrow), and release the locks.

12

Open the Flaps of the Left and Right Tractors.

Match the Left and Right Tractors to the paper width.

Locate the Paper Plate in the center between the Left and Right

Tractors.

Tractor

Paper Plate

Tractor

Page 15

Quick start-up Loading paper

With the printing side of the paper facing up, fit the feeding

holesonthe left edge ofthe paper over theLeft Tractor pinsand

close the Paper Flap.

Fitthe feedingholesontheright edgeof thepaper overthe Right

Tractor pins, and close the Paper Flap.

To avoid paper jams, ensure that the same left and

right feeding holes are used, and placed over tractor pins of the same level.

Paper Holes over

Tractor Pins

After the paper is set, adjust the left margin by moving the

Tractors left or right. The “[A” mark is the standard print start

position.

ENGLISH

Tractor

Fixing lever

Push down the Left Tractor Fixing Lever to lock the Left

Tractor.

Move the Right Tractor to remove any paper slack, and then

push down the Fixing Lever to lock it in place.

If the paperslackcannotbe removed by moving the

Right Tractor alone, adjust the position of the Left

Tractor.

Be careful not to stretch the paper so much that it

tears.

Switch on the printer.

The active feeder (Trac.1) is displayed.

Paper is automatically fed when the printer is in Online status

and receives data from the computer.

Press the Load key to load paper before printing.

13

Page 16

Changing the paper type Quick start-up

Changing the

papertype

➤ Paper path quick

selection

Offline Trac.1

Park Load

Single Trac.1

Offline Single

Park

Turn paperlever

You canchangethe paper type (thepaper path) either usingthepaper path quickselectionfeature

or via the Setup menu.

First cut the fed-out portion of a Continuous Form Feed Paper at the perforated line. To do this,

proceed as follows.

Online

Make sure that the printer is in Offline status; press the Onlinekey, if necessary.

Press the Park key.

Setup

If fanfold paper is in the printer, it is transported to the tear position. “Tear paper

off” appears on the display. Press any key.

If a single sheet is loaded in the printer, it is ejected.

Online

Setup

Online

Select the desired paper path bypressingoneofthe I keys, in our example Single.

If you do not make a selection within 5 seconds, the printerexits

the menu.

The printer returns to Offline mode.

The display toggles between…

Setup

and…

Online

SetthePaper Type SelectionLever to CutSheet Paper mode(see page 11Loading

paper).

Setup

Load paper from

Single

Offline Single

Park

14

Online

Setup

Online

Setup

The display toggles between…

and…

Stand the Paper Tray up in the direction indicated by the arrow. While holding

the Paper Tray, pull up the Paper Extension Trays.

Determine the left margin by moving the Left Paper Guide left or right.

Place a sheet of paper aligned to the Left Paper Guide, and adjust the Right Paper

Guide to the right edge of the paper. Insert the paper between the Left and Right

PaperGuides.The paperis automaticallyfed tothe printstart position(seepage11

Loading paper).

Page 17

Quick start-up Paper transport

Online Single

Online

Setup

Press the Online key to make the printer ready for operation.

Paper transport Loaded paper (fanfold paper/single sheets) can be transported in the printer in different ways.

Offline Trac.1

Park LF/FF

➂

➁

➀

Online

Setup

Make sure that the printer is in Offline status; press the Online key, if

necessary.

➀ Short keypress: Line feed (LF) is initiated

Long keypress: Form feed (FF) is initiated

➁ Short keypress: Paper is transported downwards step by step

Long keypress: Continuous transport down

➂ Short keypress: Paper is transported upwards step by step

Long keypress: Continuous transport up

Using

➤ Moving paper to the

tear position

Online Trac.1

Tear

Fanfold paper can be transported to the tear position by pressing the Tear key.

Online

Make sure that the printer is in Online status.

Press the Tear key. The printer moves the perforation edge of the fanfold paper

Setup

to the tear edge.

ENGLISH

Tear position

Tractor1

Online Tear

Exit

Online

Setup

Online

Setup

The display toggles between…

and…

Press the Exit key after having torn off the paper. The printer moves the paper

back to the first printing position.

15

Page 18

Settings (I) Quick start-up

Settings (I)

➤ Setting the tear

position

Offline Trac.1

Park LF/FF

Adjust Paperway

Menu Char

TOF

TearAdj=00/72" *

Set Exit

Tear

If the tear position of the paper is not aligned with the tear edge of the printer, you can adjust it.

Online

Setup

Online

Setup

Online

Setup

Online

Press the Setup key. The printer changes to Setup mode.

Press the Adjust key.

Press the Tear key.

Press the < or > key to move the perforation to the appropriate position.

Confirm thesettingby pressing theSetkey. The printer returns to itsinitialstatus.

Setup

➤ Setting the first

printing line (TOF)

Adjust Paperway

Menu Char

16

The correction made (a maximum of approx. 2.5 cm [1"] in both directions) will be retained

after printer power-off.

You can use the TOF function to set the position of the topmost printing line individually for

each paper source and each menu.

You should adjust the tear position (see above) before using the TOF function (when using fanfold paper).

Online

Setup

Press the Setup key. The printer changes to Setup mode.

Page 19

Quick start-up Settings (I)

Adjust Paperway

Menu Char

TOF

Tear

A

FormAdj=12/72" *

Set Exit

Online

Setup

Online

Setup

Online

Setup

Press the Adjust key.

Press the TOF key.

ENGLISH

The bottom edgeof the currently valid firstprintingline Aofthe

paper is transported to the tear edge B.

The factory setting for the first printing position is 12/72".

B

Press the < or > key to move the first printing line to the appropriate position.

You canset values from 0to 220/72" forfanfoldpaper, from0 to 72/72"forsingle

sheets.

Standard 1. print line 12/72"

Newly set 1. print line

The setting made will be retained after printer power-off. For more detailed information, refer to

the online documentation on the CD-ROM, chapter 3 (Mechanical adjustments to the printer).

Confirm the setting by pressing the Set key.

The printer returns to its initial status.

17

Page 20

Settings (II) Quick start-up

Settings (II)

➤ Setting the print

head gap

The printer has been provided with a Paper Thickness Adjustment Lever for adjusting the print

head gap

Toobtain optimumprintquality,thegapbetweenthePrintHead

and the Platen needs to be adjusted according to the thickness

Paper Thickness

Adjustment Lever

of the paper to be used.

The following table shows the adjustable range:

Number of Copies/

Thickness of Paper

Original only Thin

Normal

Thick

Original + 1 34/34 40/40

Original + 2 34/34/34 40/40/40

Original + 3 34/34/34/34 40/40/40/40

Original + 4 34/34/34/34/34 40/40/40/40/40

Original + 5 34/34/34/34/34/34 40/40/40/40/40/40

Postal Card 110 130

Reserved — —

Ream (kg) g/m

45–55

55–77

77–110

2

50–65

65–90

90–130

Lever Position

1

1–2

2

2–3

2–4

3–4

4–5

5–6

3

7–8

18

1. “Ream” is a unit of paper thickness, indicating the weight in kg, of 1,000 cut sheets at 788

mm x 1091 mm.

2. When printing the original sheet only, Cut Sheet Paper of 45 kg and thicker or Continuous

Form Feed Paper of 50 kg and thicker can be used.

3. When the Paper Thickness Adjustment Lever is set higher than appropriate, the printout

will appear scratchy and the print head and ribbon lives will be shortened.

Page 21

Quick start-up Settings (II)

➤Changing paper in

Setup mode

➤From fanfold paper

to single sheet mode

Online Trac.1

Load

Adjust Paperway

Menu Char

Tractor 1 *

Set Exit

Single

Set Exit

When fanfold paper was in use and you want to change over to single sheet mode, proceed as

described below.

You do not need to remove the fanfold paper.

Online

Cut the fed-out portion of the Continuous Form Feed Paper at the perforated line.

To do this, proceed as follows.

Setup

Online

Setup

Online

Setup

Online

Press the Setup key. The printer changes to Setup mode.

Press the Paperway key. The printer changes to the paper path menu.

Press < or > to change to Single (sheet) operating mode.

The currently valid setting (Tractor 1) is marked by a “

*

”.

Confirm the setting by pressing the Set key.

The input is acknowledged by an acoustic signal and the fanfold paper is trans-

Setup

ported to the tear position. Cut the fed-out portion of the Continuous Form Feed

Paper at the perforated line.

In the display appears…

ENGLISH

Tear paper off

Press any key

Offline Single

Park Load

Online

Setup

Online

Setup

Press any key.

The printer returns to its initial status and the fanfold paper is transported to the

park position.

The display toggles between…

and…

19

Page 22

Settings (II) Quick start-up

Turn paperlever

Load paper from

Single

Online Single

➤ From single sheet to

fanfold paper mode

Online Single

Online

Setup

Set the Paper Type Selection Lever to Cut Sheet Paper mode.

In the display appears…

Online

Stand the Paper Tray up and pull up the Paper Extension Trays (see page 10).

Place a sheet of paper aligned to the Left Paper Guide, and adjust the Right Paper

Setup

Guide to the right edge of the paper.

Insert the paper between the Left and Right Paper Guides. The paper is automatically fed to the print start position (see page 11).

Online

Setup

Press the Online key to make the printer ready for operation.

When single sheets were in use and you want to change over to fanfold paper mode, proceed as

described below.

Make sure that fanfold paper is loaded. Refer to page 12 (Loading Fanfold Paper) for details.

Online

Pull down the Paper Extension Trays and fold the Paper tray down.

Press the Setup key. The printer changes to Setup mode.

Setup

Adjust Paperway

Menu Char

Single

Set Exit

20

Online

Setup

Online

*

Setup

Press the Paperway key. The printer changes to the paper path menu.

Press < or > to change to Trac.1 (fanfold paper) mode.

The currently valid setting (Single) is marked by a “

*

”.

Page 23

Quick start-up Settings (II)

Tractor1

Set Exit

Offline Trac.1

Online

Setup

Online

Confirm the settingbypressingtheSet key. An acoustic signal acknowledges the

input.

The display toggles between…

Park LF/FF

Setup

and…

Turn paperlever

Online

Setup

Shift the Paper Type Selection Lever to the position needed.

The printer is now ready for printing fanfold paper.

Press the Online key to make the printer ready for operation.

➤ Selecting a font You can use the Font key to select fonts in Setup mode.

Adjust Paperway

Menu Char

Online

Setup

Press the Setup key.

Press the Char key.

ENGLISH

Font CPI

DRAFT COPY *

Set Exit

Font CPI

Online

Setup

Online

Setup

Online

Setup

Press the Font key.

Press the < or > key to select the desired font.

Confirm your selection by pressing the Set key.

Press the Setup key. The printer returns to its initial status.

You can also press the Online key. The printer changes directly in Online mode.

21

Page 24

Settings(II) Quickstart-up

STOP

➤Settingthe

characterpitch

Adjust Paperway

Menu Char

Font CPI

10CPI *

Set Exit

Font CPI

Theselectionmadewillnotberetainedafterprinterpower-off.Forinformationonhowtoselectafontpermanently,refertoonlinedocumentationontheCD-ROM,chapter1(Menu

description table).

YoucanusetheCPIkeytosetthecharacterpitchinSetupmode.

Online

PresstheSetupkey.

PresstheCharkey.

Setup

Online

Setup

Online

PresstheCPIkey.

Pressthe<or>keytoselectthedesiredpitch.

ConfirmyourselectionbypressingtheSetkey.

Setup

Online

PresstheSetupkey.Theprinterreturnstoitsinitialstatus.

YoucanalsopresstheOnlinekey.TheprinterchangesdirectlyinOnlinemode.

Setup

22

STOP

Theselectionmadewillnotberetainedafterprin terpower-of f.Forinfo rmationonhowtose lecta

fontpermanently,refertoonlinedocumentationontheCD-ROM,chapter1(Menu description

table).

Page 25

Quick start-up Specifications

Specifications

➤Printer specifications

Printing method serial printing with 9-pin matrix print head serial printing with 24-pin matrix print head

Print width narrow printer 80 characters at 10 cpi

wide printer 136 characters at 10 cpi

Print speed (bidirectional) LN-Draft 413 cps at 10 cpi

Draft 310 cps at 10 cpi

NLQ 77 cps at 10 cpi

Character densities 5, 6, 7.5, 8.6, 10, 12, 15, 17.1, 20 cpi

(HS-Draft: 10, 12 cpi only)

Graphics print density horizontal 240 dpi / vertical 144 dpi horizontal 360 dpi / vertical 180 dpi

Ribbon life 4 million char. 4 million char.

Acoustic noise levell ca. 55 dB (A) ca. 55 dB (A)

Dimensions narrow printer 485 x 206 x 272 mm (W x H x D)

wide printer 625 x 206 x 272 mm (W x H x D)

Weight narrow printer 9 kg / wide printer 11 kg narrow printer 9 kg / wide printer 11 kg

Power supply USA/Canada AC 120 V 10% / 60 Hz 3%

Europe AC 230 V 10%/ 5 0Hz 3%

Power consumption at 100% throughput < 60 VA

in the Ready state < 10 VA

Operating environment Temperature 10ºC to 40ºC

Humidity 20% to 80%

Print head specifications Number of pins 9

Pin diameters 0,3 mm

Number of copies 1 original + 5 copies

Interface buffer max. 64 kB max. 64 kB

Regulations UL 1950, VDE-GS, CE, FCC Class B, UL/Ulc UL 1950, VDE-GS, CE, FCC Class B, UL/ULc

narrow printer 80 characters at 10 cpi

wide printer 136 characters at 10 cpi

Draft 409 cps at 10 cpi

Draft Copy 275 cps at 10 cpi

NLQ/LQ 92 cps at 10 cpi

5, 6, 7.5, 8.6, 10, 12, 15, 17.1, 20 cpi

narrow printer 485 x 206 x 272 mm (W x H x D)

wide printer 625 x 206 x 272 mm (W x H x D)

USA/Canada AC 120 V 10% / 60 Hz 3%

Europe AC 230 V 10% / 5 0 Hz 3%

at 100% throughput < 60 VA

in the Ready state < 10 VA

Temperature 10ºC to 40ºC

Humidity 20% to 80%

Number of pins 24

Pin diameters 0,22 mm

Number of copies 1 original + 3 copies

ENGLISH

➤ Paper specifications

Cut sheets Paper weight

Fanfold paper

Simple forms

Sets of forms

Width

Length

Paper weight

Width

Length

Paper weight

Width/Length

Form thickness

Number of copies

60 – 120 g/m

narrow printer: 76 – 220 mm / wide printer: 76 – 420 mm

76 – 559 mm

60 – 120 g/m

narrow printer: 76 – 254 mm / wide printer: 76 – 420 mm

76 – 559 mm

original: 45 – 65 g/m

see simple forms

max. 0,5 mm

1+5 (9 wire) / 1+3 (24 wire)

2

2

2

/ copy: 45 – 56 g/m2 / last page: 45 – 65 g/m

2

23

Page 26

Accessories Quick start-up

For more information on printer specifications and paper specifications, refer to the online

documentation on the CD-ROM.

Accessories Ribbon cassettes

Narrow printer: Part No. 044 829

Wide printer: Part No. 044 830

Demo page The demo page contains information on the firmware version, serial number, needle check,

fonts, font attributes and bar codes/LCP.

Hold down button 4 while switching on the printer to print the demo page.

To terminate printing, switch off the printer.

24

Page 27

“All rights reserved. Translations, reprinting or copying by any means of this manual complete or in part or in any different form requires our explicit approval. We reserve the right to make changes to this manual

without notice. All care has been taken to ensure accuracy of information contained in this manual. However, we cannot accept responsibility for any errors or damages resulting from errors or inaccuracies of

information herein.”

,, Alle Rechte vorbehalten. Übersetzungen, Nachdruck und sonstige Vervielfältigungen dieses Handbuchs, auch in Teilen und gleichgültig in welcher Form, bedürfen unserer ausdrücklichen schriftlichen Erlaubnis.

Inhaltliche Änderungen dieses Handbuchs behalten wir uns ohne Ankündigung vor. Dieses Handbuch wurde mit Sorgfalt erstellt; wir können jedoch für etwaige Fehler und Mängel dieses Handbuchs sowie für

daraus sich ergebende Folgeschäden keine Haftung übernehmen.“

“Tous droits réservés. Toute reproduction ou traduction de ce manuel, qu’elle soit complète, partielle ou sous une forme différente est interdite sans notre accord formel. Nous nous réservons le droit de modifier

ce manuel sans préavis. Toutes les précautions ont été prises afin d’assurer l’exactitude des informations contenues dans ce manuel. Cependant, nous déclinons toute responsabilité pour les fautes ou dégats

provenant d’erreurs ou d’inexactitudes qui seraient restées dans ce manuel.”

,, Tutti i diritti sono riservati. Traduzione, ristampa o copia di contenuti in parte, totalmente o in qualsiasi differente forma richiede la nostra esplicita approvazione. Noi ci si riserviamo il diritto di variare questo

manuale senza preavviso. Tutte le precauzioni sono state prese per assicurare la precisione delle informazioni contenute in questo manuale. Comunque, noi non possiamo accettare reponsabilità per errori o

danni provocati da errori o inesattezze contenuti nel manuale.“

“Todos los derechos reservados. Para traducciones, la reimpresión y otras reproducciones de este manual, incluso parciales y en cualquier forma, será necesaria nuestra autorización expresa, por escrito. Nos

reservamos el derecho de modificar el contenido de este manual sin previo aviso. Este manual fue elaborado con cuidado, pero no podemos responsabilizarnos por eventuales errores e imperfecciones del

presente manual, ni por daños consiguientes que resulten de ellos.”

TRADEMARK ACKNOWLEDGEMENTS

“CENTRONICS” is a trademark of Centronics Data Computer

Corporation.

“EPSON” is a trademark of Epson America Incorporated.

“IBM” is a trademark of International Business Machines

Corporation.

“MS-DOS” is a trademark of Microsoft Corporation.

“Windows”, “Windows 95”, “Windows 98“ and “Windows NT” are

trademarks of Microsoft Corporation.

WARENZEICHEN

,,CENTRONICS“ ist ein Warenzeichen der Centronics Data

Computer Corporation.

,, EPSON“ ist ein Warenzeichen der Epson America Incorporated.

,,IBM“ ist ein Warenzeichen der International Business Machines

Corporation.

,,MS-DOS“ ist ein Warenzeichen der Microsoft Corporation.

,, Windows“, , , Windows 95“, , , Windows 98“ und , , Windows NT“ sind

Warenzeichen der Microsoft Corporation.

MARQUES DÉPOSÉES

“CENTRONICS” est une marque déposée Centronics Data

Computer Corporation.

“EPSON” est une marque déposée Epson America Incorporated.

“IBM” est une marque déposée International Business Machines

Corporation.

“MS-DOS” est une marque déposée Microsoft Corporation.

“Windows”, “Windows 95”, “Windows 98” et “Windows NT” sont

des marques déposéea Microsoft Corporation.

MARCHI REGISTRATI

”CENTRONICS” é un marchio registrato della Centronics Data

Computer Corporation.

”EPSON” é un marchio registrato della Epson America

Incorporated.

”IBM” è un marchio registrato della International Business

Machines Corporation.

”MS-DOS” é un marchio registrato della Microsoft Corporation.

”Windows”, ”Windows 95”, “Windows98” e “Windows NT” e sono

marchi registrati della Microsoft Corporation.

MARCAS REGISTRADAS

“CENTRONICS” es una marca registrada de la Centronics Data

Computer Corporation.

“EPSON” es una marca registrada de la Epson America

Incorporated

“IBM“ es una marca registrada de la International Business

Machines Corporation.

“MS-DOS” es una marca registrada de la Microsoft Corporation.

“Windows”/“Windows 95”/“Windows 95”/“Windows NT” son

marca registrada de la Microsoft Corporation.

Page 28

TALLY REPRESENTATIVES

GERMANY

Tally Computerdruck er GmbH

Postfach 2969

D-89019 Ulm

Deutschland

Tel.: +49 7308 80 0

Fax: +49 7308 5903

http://www.Tally.de

ITALY

Tally S.R.L.

Via Borsini 6

I-20094 Corsico (MI)

Italia

Tel.: +39 02 48608 1

Fax: +39 02 48601 141

http://www.Tally.it

SPAIN

Tally SRL

Joaquin Lorenzo 4, Local

28033 Madrid

España

Phone: +34 902 196 183

Fax: +34 913 739 943

http://www.Tally.es

SINGAPORE

Tally AMT Printers Pte. Ltd

63 Hillview Avenue

#08-22, Lam Soon Industrial Building

Singapore 669569

Phone: +65 6760 8833

Fax: +65 6760 1066

http://www.Tally.com.sg

U.S.A.

Tally Corp.

P.O.Box 97018

8301 South, 180th Street

Kent, WA 98032

U.S.A.

Phone: +1 425 25155 00

Fax: +1 425 25155 20

http://www.Tally.com

UNITED KINGDOM

Tally Limited

Rutherford Road

Basingstoke, Hampshire

RG24 8PD

England, U.K.

Phone: +44 870 872 2888

Fax: +44 870 872 2889

http://www.Tally.co.uk

CANADA

Tally Corp.

125 Traders Boulevard, 9

Missisauga, Ontario L4Z 2E5

Canada

Phone: +1 905 8904646

Fax: +1 905 8904567

http://www.Tally.com

FRANCE

Tally S.A.

19 avenue de L´lle Saint Martin

F-92237 Nanterre Cedex

France

Tél.: +33 1 41 30 11 00

Fax: +33 1 41 30 11 10

http://www.Tally.fr

AUSTRIA

Tally Ges.m.b.H.

Eduard-Kittenberger-Gasse 95 B

A-1232 Wien

Austria

Tel.: +43 1 863 40 0

Fax: +43 1 863 40 240

http://www.Tally.co.at

Russian Federation and C.I.S.

Tally Representative

Park Place Moscow

Office D-206

Leninsky Prospekt 113/1

117198 Moscow

Russian Federation

Phone: +7 095 956 56 40

Fax: +7 095 956 55 41

http://www.Tally.ru

© January 2003 Tally Computerdrucker GmbH 379 761a

Loading...

Loading...