Page 1

EPSON COLOR INKJET PRINTER

Stylus-500

SERVICE MANUAL

EPSON

4006359

Page 2

PREFACE

This document provides supplementary information to describe the EPSON Stylus COLOR 500, which is a

follow-on version of the EPSON Stylus COLOR II. Therefore, you must refer to this information in conjunction

with the EPSON Stylus COLOR II Service Manual for details on any subjects common to both printers.

-i-

Page 3

EPSON Stylus COLOR 500 Service Manual Product Description

1.1 FEATURES

The EPSON Stylus COLOR 500 is a small-footprint, personal-use color ink jet printer. The major new

features of this printer are:

❏ Newly developed black and color inks

High-quality black printing

Deep color printing

❏ Simple control panel operation

3 No lock switches

4 LED lamps

❏ A new design for the left guide edge locking mechanism in the ASF (auto sheet feeder)

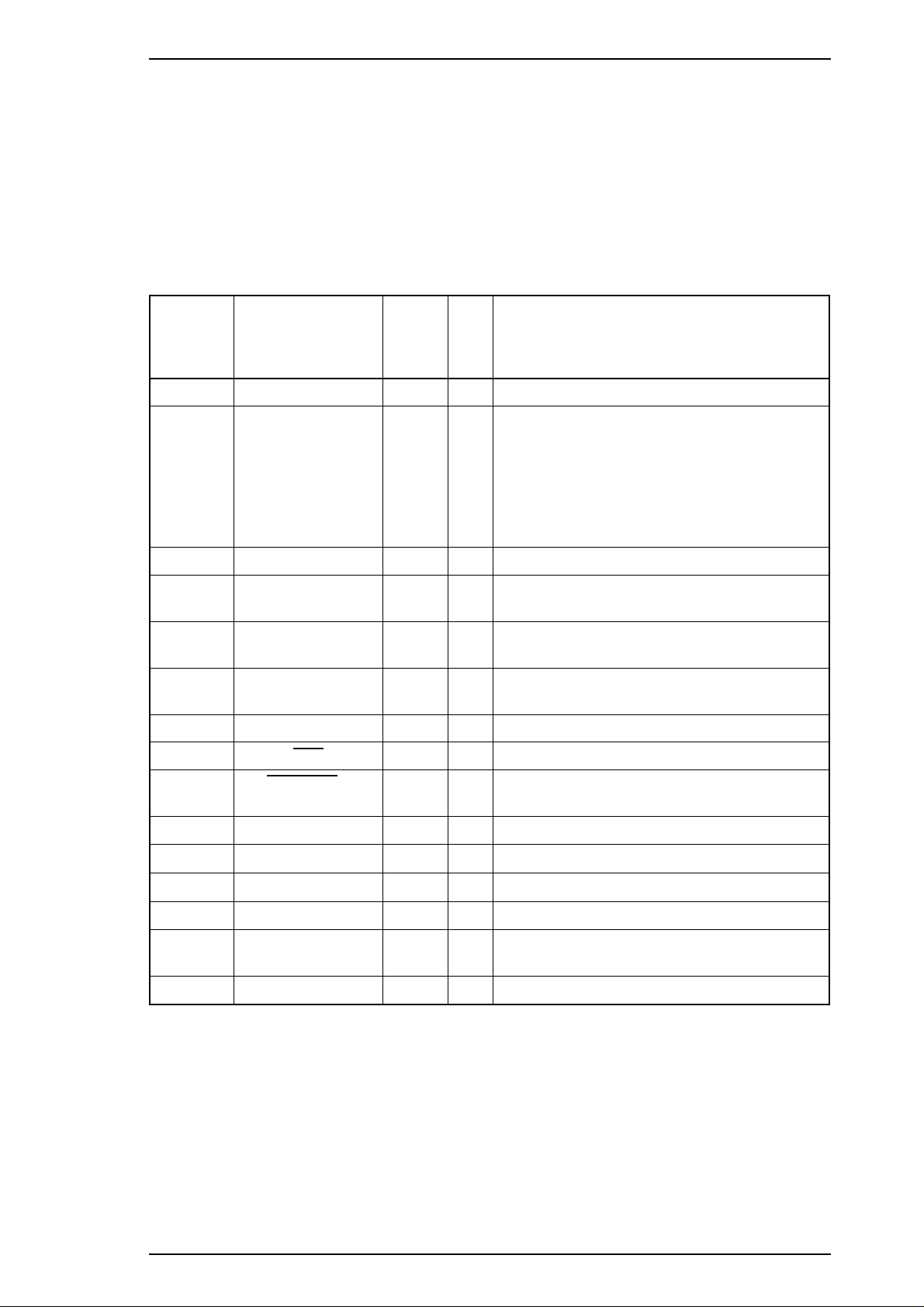

Table 1-1. Consumables

Model Description

S020093

S020097 Color ink cartridge

S041059

S041025

S041060

S041061 EPSON premium paper for 720 dpi printing (A4)

S041026

S041062 EPSON premium paper for 360 dpi printing (Letter)

S041067

S041048

S041071

S041072 High-quality glossy paper (Letter)

S041063

S041064

S041054

Monochrome ink cartridge

EPSON premium paper for 360 dpi printing (A4)

EPSON premium paper for 360 dpi printing (A4)

EPSON premium paper for 360 dpi printing (Letter)

EPSON premium paper for 720 dpi printing (A4)

EPSON premium paper for 360 dpi printing (Legal)

EPSON premium paper for 360 dpi printing (Legal)

High-quality glossy paper (A4)

Transparency film (A4)

Transparency film (Letter)

EPSON premium card stock for 720 dpi printing (A6)

Rev.A 1-1

Page 4

Product Description EPSON Stylus COLOR 500 Service Manual

1.2 SPECIFICATIONS

This section provides detailed information about the EPSON Stylus COLOR 500.

1.2.1 Printing Specification Table 1-2. Character Tables and Typefaces

Bitmap fonts Scalable fonts

EPSON

Roman

EPSON

Character Tables

Sans Serif

EPSON

Courier

EPSON

Prestige

EPSON

Script

EPSON

Roman

EPSON

Sans Serif

EPSON

Roman T

EPSON

Sans Serif H

Standard

version

NLSP

version

Italic

PC437 (U.S., Standard Europe)

PC850 (Multilingual)

PC860 (Portuguese)

PC861 (Icelandic)

PC863 (Canadian-French)

PC865 (Nordic)

BRASCII

Abicomp

Italic

PC437 (U.S., Standard Europe)

PC850 (Multilingual)

PC437 Greek

PC852 (East Europe)

PC853 (Turkish)

PC855 (Cyrillic)

PC857 (Turkish)

PC866 (Russian)

PC869 (Greek)

MAZOWIA (Poland)

Code MJK (CSFR)

ISO 8859-7(Latin/Greek)

ISO Latin 1T (Turkish)

Bulgaria (Bulgaria)

Supported Supported Supported

Supported

Supported Supported

Not

supported

1.2.2 Electric Specification

Power consumption 120v Approx.18W (ISO10561 Letter pattern)

220-240V Approx. 18W (ISO10561 Letter pattern)

Energy Star compliant

1-2 Rev.B

Page 5

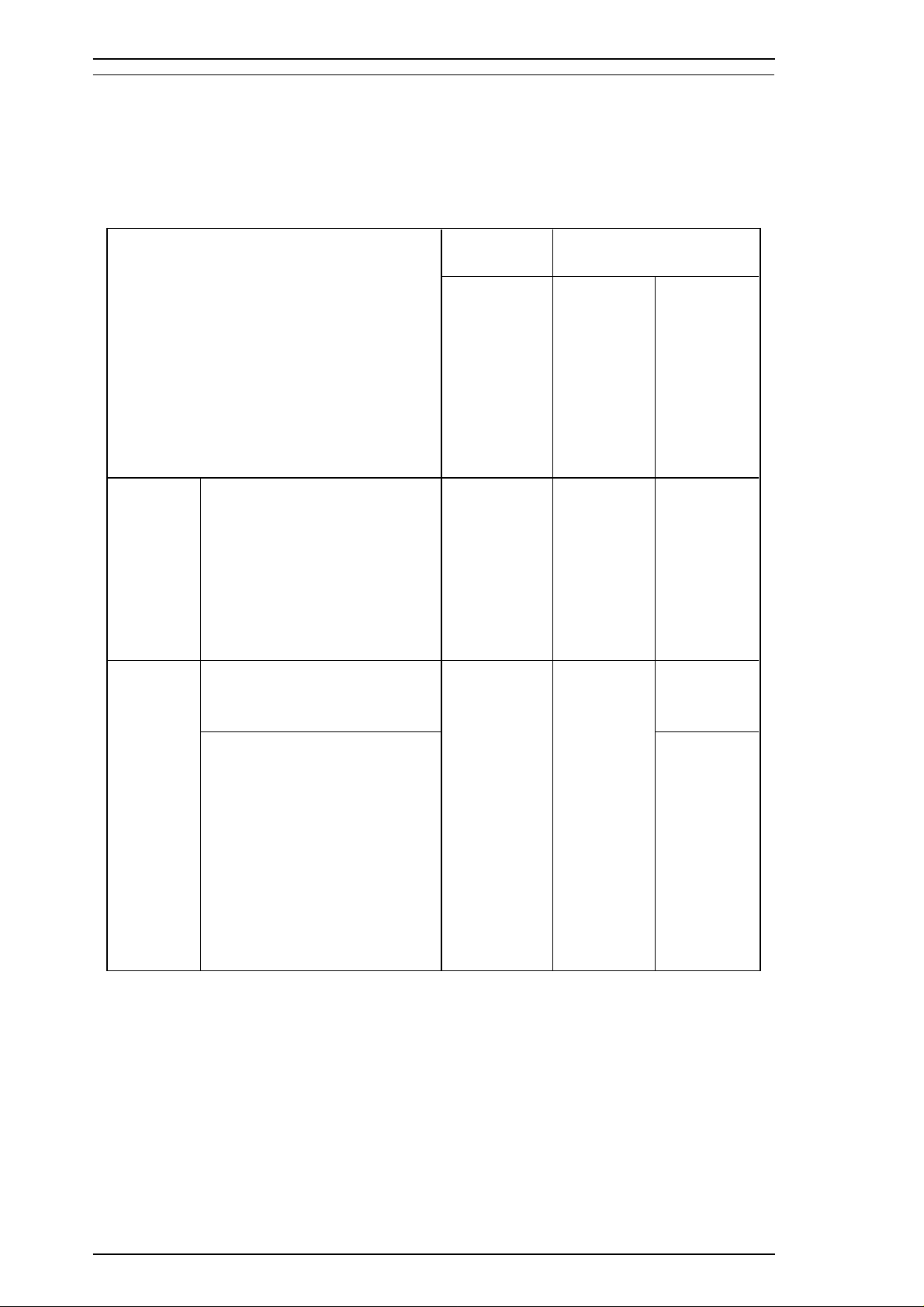

DATA (n)

DATA

-STROBE

BUSY

-ACKNLG

500 ns (min.)

500 ns (min.) 500 ns (min.)

0 (min.)

0 (min.)

500 ns ~10 µs

0 (min.) 500 ns (max.)

DATA (n+1)

* : The rise and fall time of every output signal must be less than 120 ns.

The rise and fall time of every input signal must be less than 200 ns.

EPSON Stylus COLOR 500 Service Manual Product Description

1.3 INTERFACES

1.3.1 Hardware Interfaces

This section fully describes the EPSON Stylus COLOR 500 interfaces. The printer offers both a parallel and

serial interface, standard.

1.3.1.1 Parallel Interface

Forward Channel

Transmission mode: 8 bit parallel, IEEE-1284 compatibility mode

Synchronization:

Handshaking: BUSY and

Signal level: TTL compatible level (IEEE-1284 level 1 device)

Connector type: 57-30360 (Amphenol or equivalent)

STROBE pulse

ACKNLG signal

The BUSY signal is set to HIGH before either

ERROR is set LOW or PE is set HIGH, and BUSY is held

HIGH until all these signals return to the inactive state. The BUSY signal goes HIGH in the following cases:

• During data entry (See data transmission timing).

• When the input data buffer is full.

• When the

• During a printer error condition (see

INIT signal is at a LOW level, or during hardware initialization.

ERROR signal).

• During self-test printing.

• In default setting mode.

• When the parallel interface is not selected.

The

ERROR signal is LOW when the printer is in one of the following conditions:

• Printer hardware error (fatal error condition).

• Paper-out error.

• Release lever operation error.

The PE signal is HIGH during a paper-out error.

Rev.A 1-3

Figure 1-1. Data Transmission Timing

Page 6

Product Description EPSON Stylus COLOR 500 Service Manual

Table 1-4 shows the connector pin assignments and signals for the 8-bit parallel interface.

Table 1-3. Connector Pin Assignments and Signals (Forward Channel)

Pin No. Signal Name

1

2 ~ 9 DATA 0 ~ 7 20 ~ 27

10 ACKNLG 28

11 BUSY 29

12 PE 28 O

13 SLCT 28 O

14

15 NC — — Not connected.

31

STROBE 19 I

AFXT 30 I

INIT 30 I

Return

GND Pin

I/O Description

This is strobe pulse. Reading of data is

performed at the falling edge of this pulse.

Signals DATA0 ~ DATA7 represent data bits 0

to 7, respectively. When a DATA signal is

I

HIGH, the data is logical 1 and when LOW,

data is logical 0.

This signal is a negative pulse indicating that

O

the printer can accept more data.

When this signal is HIGH, the printer cannot

O

receive data.

When this signal is HIGH, the printer detects a

paper-out error.

This signal is always HIGH when the printer is

powered on.

The falling edge of a negative pulse or a LOW

signal on this line causes the printer to

initialize. A 50 µs pulse, minimum, is

necessary.

32

36

18 Logic H —

35 +5 V —

17 Chassis GND —

16, 33

19 - 30

15, 34 NC —

ERROR 29

SLIN 30

GND —

When this signal is LOW, the printer detects an

O

error.

I

Not used.

O

Pulled up to +5 V via 3.9 KΩ resistor.

O

Pulled up to +5 V via 3.3 KΩ resistor.

—

Chassis ground.

—

Signal ground.

—

Not used.

1-4 Rev.B

Page 7

EPSON Stylus COLOR 500 Service Manual Product Description

Reverse Channel

Transmission mode: IEEE-1284 nibble mode.

Connector: See forward channel.

Synchronization: Refer to the IEEE-1284 specification.

Handshaking: Refer to the IEEE-1284 specification.

Data transmission timing: Refer to the IEEE-1284 specification.

Signal level: Refer to the IEEE-1284 specification.

Table 1-4. Connector Pin Assignments and Signals (Reverse Channel)

Return

Pin No. Signal Name

1 Host Clk 19 I Host clock signal.

2 ~ 9 DATA0 ~ 7 20 - 27 I

GND

Pin

I/O Description

DATA0 ~ DATA7 signals represent data bits 0

to 7, respectively. Each signal is at a HIGH

level when data is logical 1 and at a LOW

level when data is logical 0.

These signals are used to transfer the

extensibility request values (described in

IEEE-P1284) to the printer.

10 PtrClk 28 O Printer clock signal.

11

12

13

14 Host Busy 30 I Host busy signal.

31

32

36 1284-Active 30 I Active signal for IEEE-P1284 mode.

18 Logic-H

35 +5 V — O

17 Chassis GND —

16, 33

19 - 30

15, 34 NC — — Not connected.

Ptr Busy /

Data Bits 3, 7

Ack Data Req /

Data Bits 2, 6

Xflag / Data Bits 1,

5

INIT 30 I Not used.

Data Avail /

Data Bits 0, 4

GND — — Signal ground.

29 O

28 O

28 O

29 O

—

Printer busy signal and reverse channel

transfer data 3 or 7.

Acknowledge data request signal and reverse

channel transfer data bit 2 or 6.

X-flag signal and reverse channel transfer

data bits 1 or 5.

Data available and reverse channel data bits

0 or 4.

O

Pulled up to +5 V via 3.9K Ω resistor.

Pulled up to +5 V via 3.3K Ω resistor.

—

Chassis ground.

Note: I / O refers to direction of the signal flow from the view of the printer.

Rev.A 1-5

Page 8

Product Description EPSON Stylus COLOR 500 Service Manual

Extensibility

Request

Device ID The printer sends following device ID string when it is requested:

The printer responds affirmatively when the extensibility request values are 00H or 04H.

That means:

00H: Request Nibble Mode Reverse Channel Transfer

04H: Request Device ID;

Return Data Using Nibble Mode Channel Transfer.

ESC/P2 mode X24E mode

00H 3AH 00H 3BH

MFG: EPSON; MFG: EPSON;

CMD:ESCPL2-00 CMD: PRPXL24-00

MDL: Stylus COLOR 500; MDL: Stylus COLOR 500;

CLS: PRINTER; CLS: PRINTER;

Note: 00H denotes a hexadecimal value of zero.

1-6 Rev.B

Page 9

EPSON Stylus COLOR 500 Service Manual Product Description

1.4 POWER AND CONTROL PANEL OPERATIONS

This section describes the controls used to operate the EPSON Stylus COLOR 500.

1.4.1 Power Switch

The Power switch is in the right rear corner of the printer.

CAUTION

This switch is for the primary power supply circuit. Therefore, you must put the printer in the

waiting condition to make it cap the head before power off.

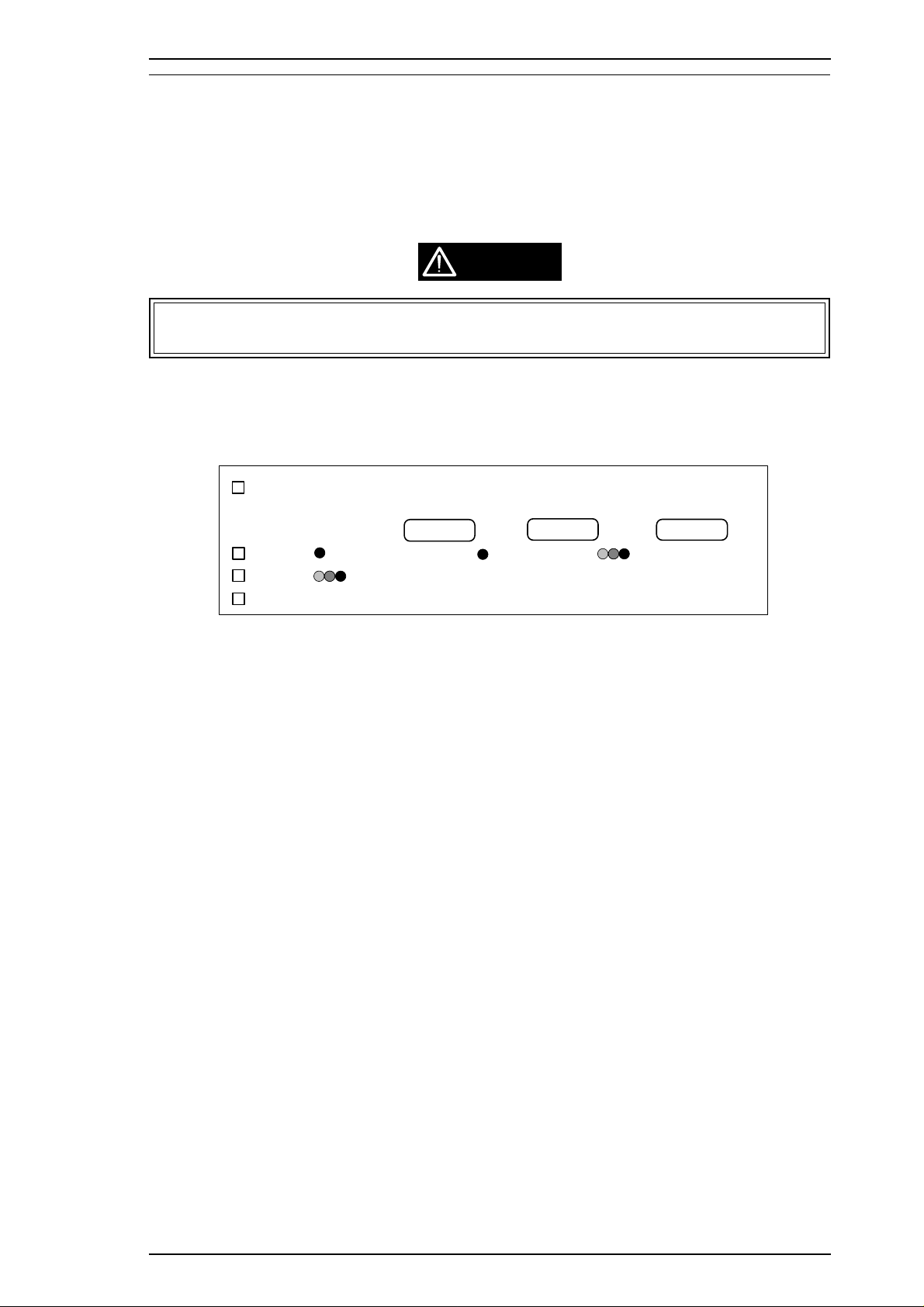

1.4.2 CONTROL PANEL

The control panel for this printer is in the center of the upper case. The panel has 3 non-lock type pushbuttons

and 4 LEDs.

Power

Ink Out

Ink Out

Paper Ou t

Cleaning

Figure 1-2. Panel Appearance

1.4.2.1 Buttons and Indicators

Cleaning (Black)

This button makes the printer perform the black head cleaning.

Cleaning (Color)

This button makes the printer perform the color head cleaning.

Load / Eject

This button loads and ejects paper.

❏ After you hold down Load / Eject for 3 seconds, the printer carriage moves to the ink cartridge

installation position. When Load / Eject is pressed again, the CR returns to the home position.

Cleaning Load / Eject

Rev.A 1-7

Page 10

Product Description EPSON Stylus COLOR 500 Service Manual

Indicators

Power

Lights when the printer’s Power switch is On, and AC power is supplied.

Ink Out (Black)

Lights when there is no ink in the black ink cartridge, and blinks when the black ink cartridge is low.

Ink Out (Color)

Lights when there is no ink in the color ink cartridge, and blinks when the color ink cartridge is low.

Paper Out

Lights during a paper out, and blinks during a paper jam.

1-8 Rev.B

Page 11

EPSON Stylus COLOR 500 Service Manual Product Description

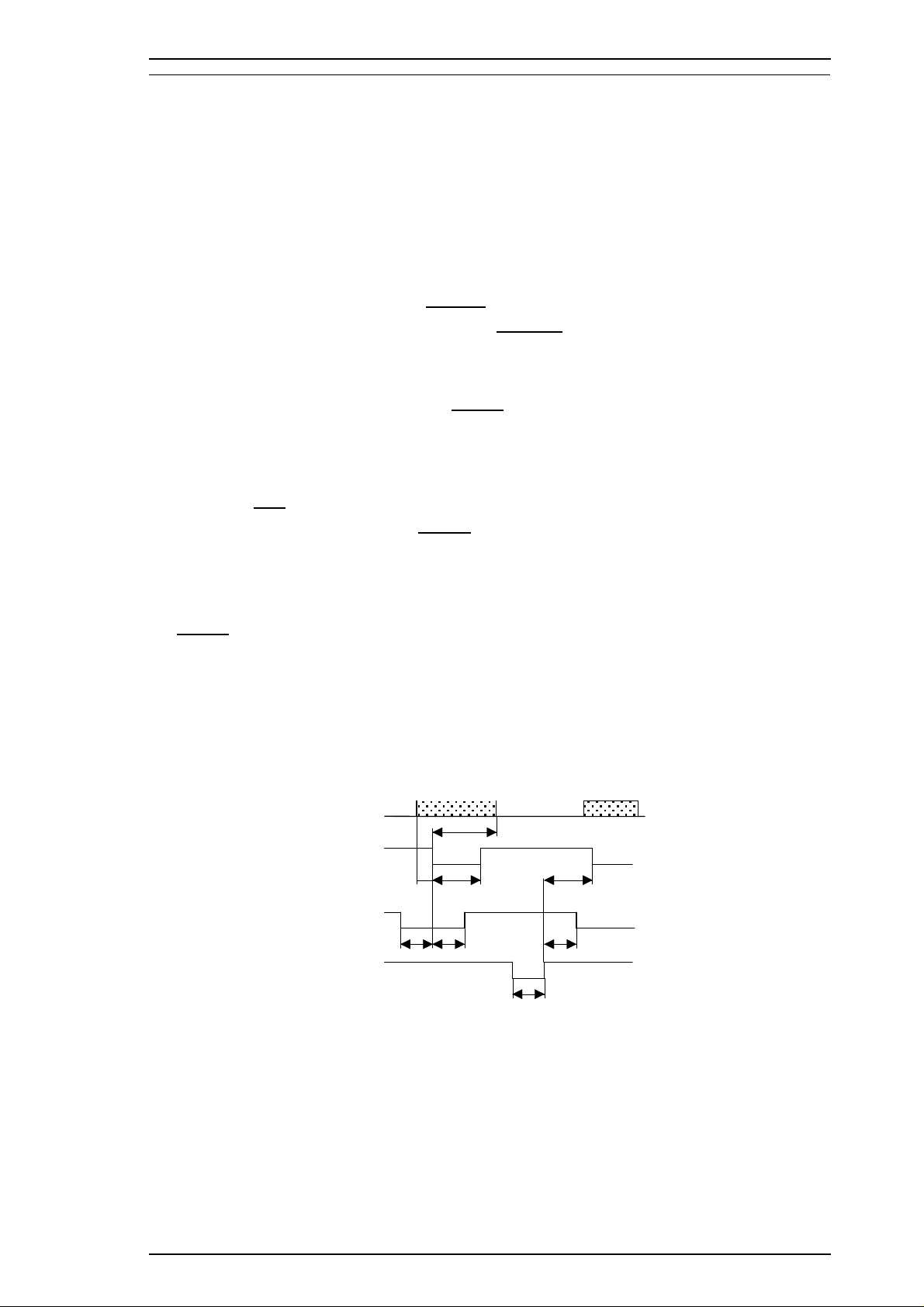

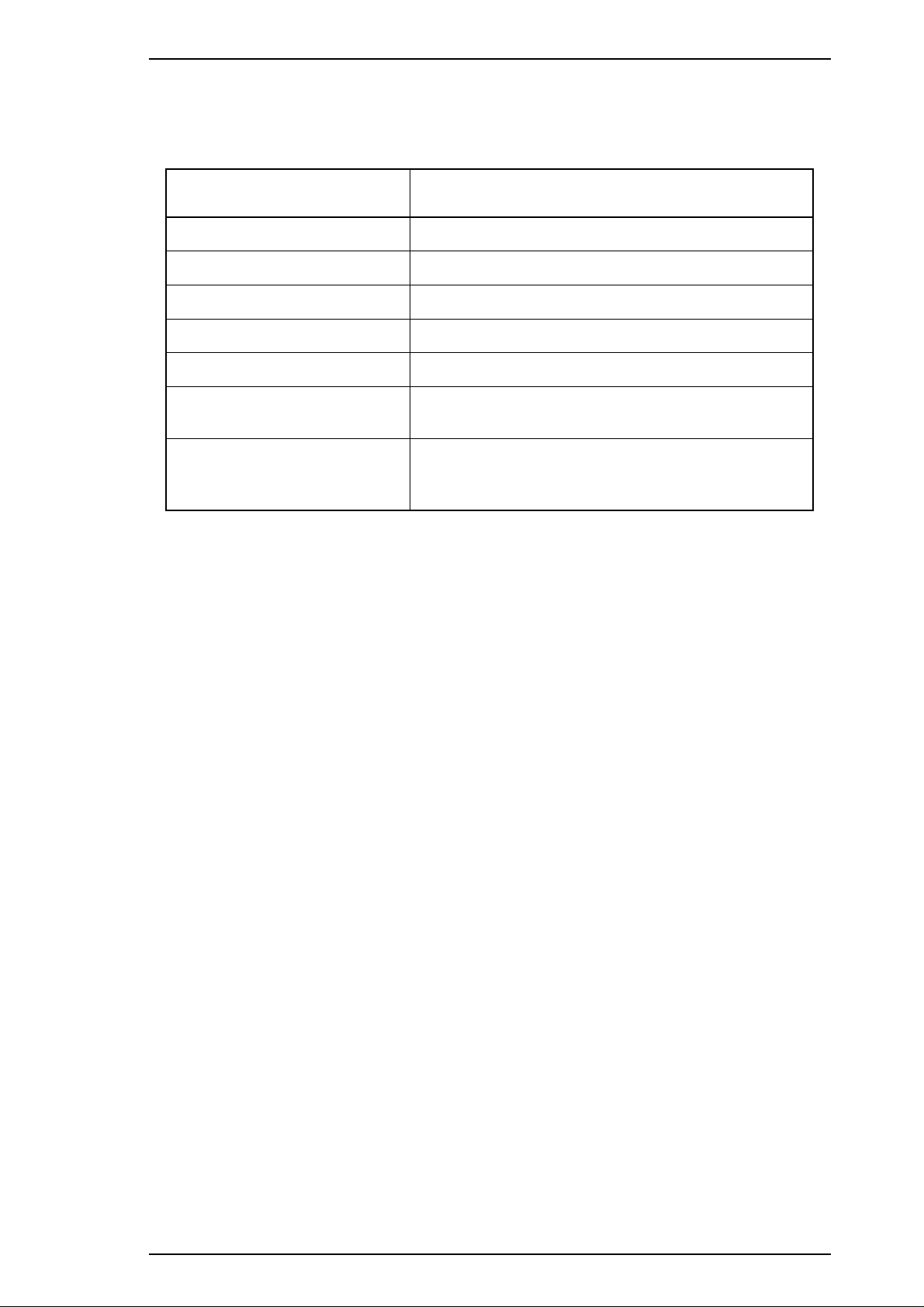

1.4.3 Panel Functions at Power On

The table below gives functions for different button combinations at power on.

Table 1-5. Panel Functions at Power On

Button Pressed along with Power On

Cleaning (Black) Starts demonstration print.

Load / Eject Enters the default setting mode.

Load / Eject + Cleaning (Black) Enters the printer adjustment mode.

Cleaning (Color) Starts LQ self-test printing.

Load / Eject + Cleaning (Color) Enters the ink smudge prevention mode.

Cleaning (Black) + Cleaning

(Color)

Load / Eject + Cleaning (Black)

+ Cleaning (Color),

Load / Eject less than 3 seconds

Note : 1. “+” indicates pressing one button while holding the other button(s) down.

2. EEPROM and Timer IC resets are for use by authorized servicers only.

Enters hex dump mode.

Enters reset mode for the EEPROM and Timer IC.

(Factory and service use only.)

Rev.A 1-9

Page 12

Product Description EPSON Stylus COLOR 500 Service Manual

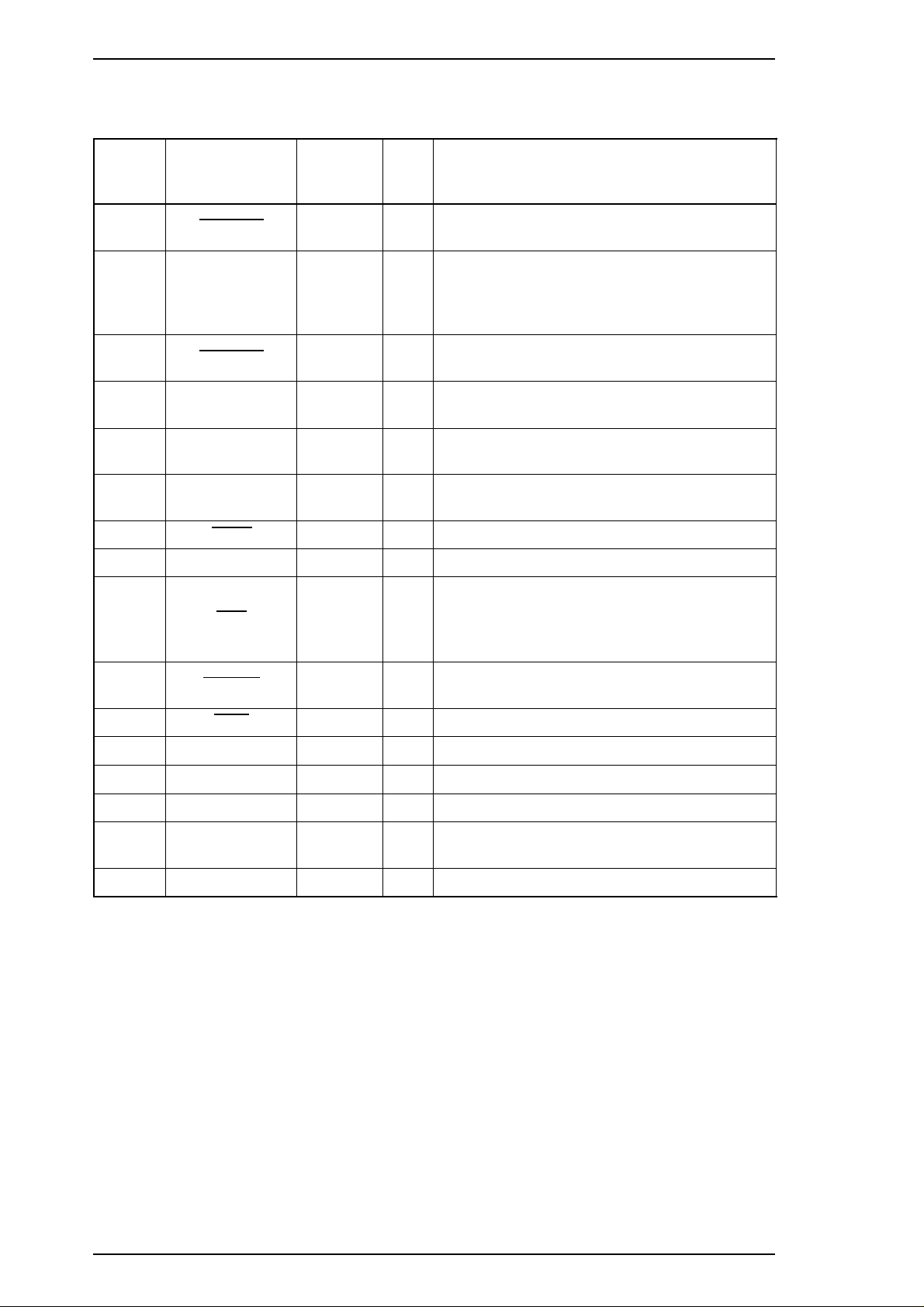

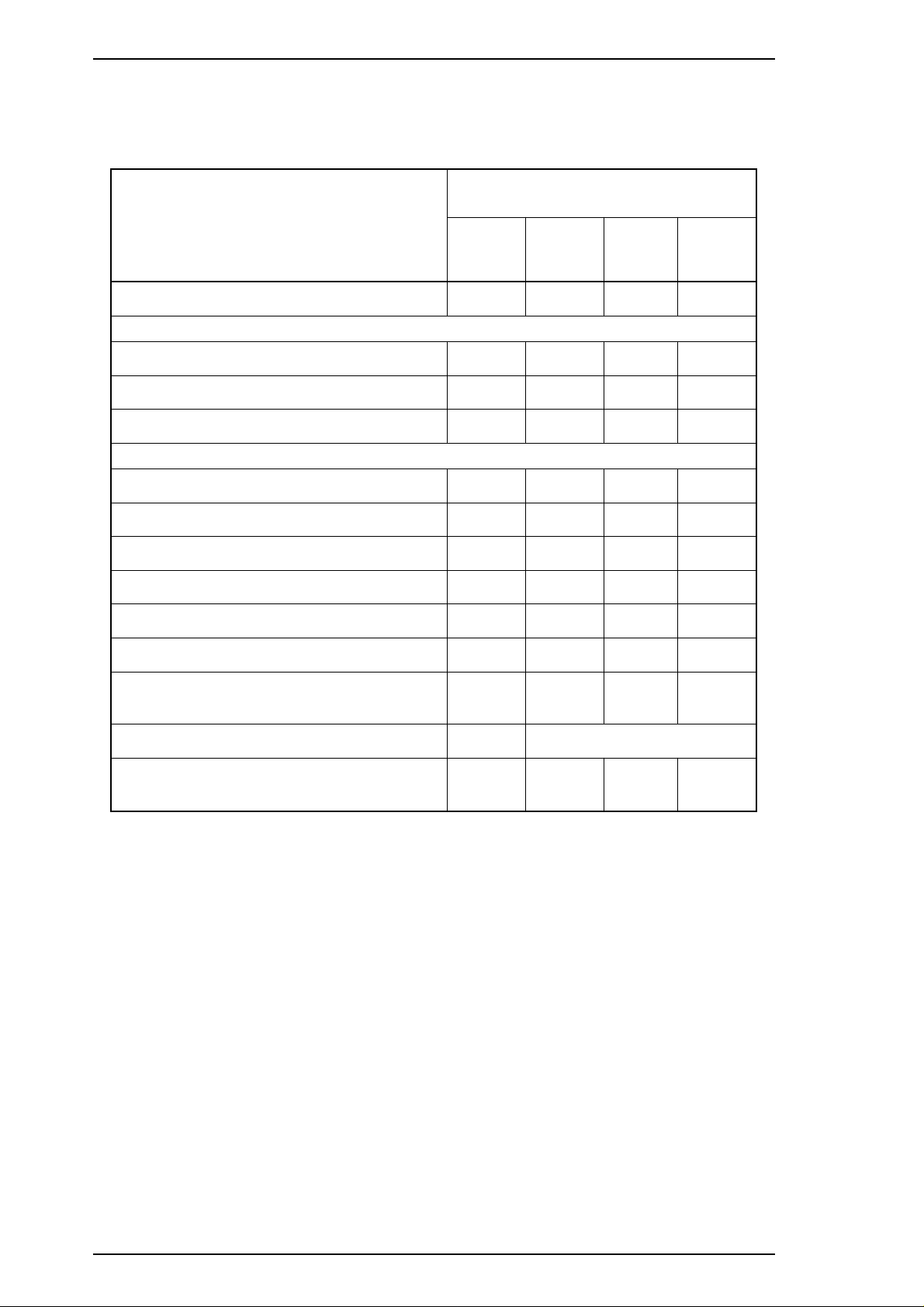

1.4.4 Printer Conditions and Status

This section describes how the printer indicates status and error conditions using LEDs.

Table 1-6. Indicator Status

LEDs

Printer Status

Power

Power on condition On — — —

Data exist Blinks — — —

Ink sequence Blinks — — —

Ink cartridge change mode Blinks — — —

Paper out — — — On

Ink Out

(Black)

Ink Out

(Color)

Paper

Out

Paper jam condition — — — Blinks

No ink cartridge or Ink end (black) — On — —

Ink level low (black) — Blinks — —

No ink cartridge or Ink end (color) — — On —

Ink level low (color) — — Blinks —

Maintenance request

EEPROM and timer reset — On for 1 second only

Fatal error

Blinks

Rapidly

Blinks

Rapidly

Blinks

Rapidly

On On On

Blinks

Rapidly

Notes: When transparency paper is selected, unidirectional printing is selected.

— Does not affect status listed in the left-hand column.

Blinks

Rapidly

1-10 Rev.B

Page 13

START

The printer pr ints out:

ROM Version No.

Protect Counter Value

Cleaning

(Black)

Print current settings.

Select the menu

for setting d efau lts?

Select the menu :

Cleaning (Black) button

Set the menu :

Cleaning (Color) button.

Power off the printer

END

Hold down the

Load / Eject

button with pow er on.

Use the language

setting mode.

Select language

for setting defaults?

Cleaning

(Color)

Cleaning

(Black)

Change the value :

C leaning (Blac k) button

Set the value :

Cl ean ing (Co lor ) bu tton .

Continue setting

defaults?

Yes

No

EPSON Stylus COLOR 500 Service Manual Product Description

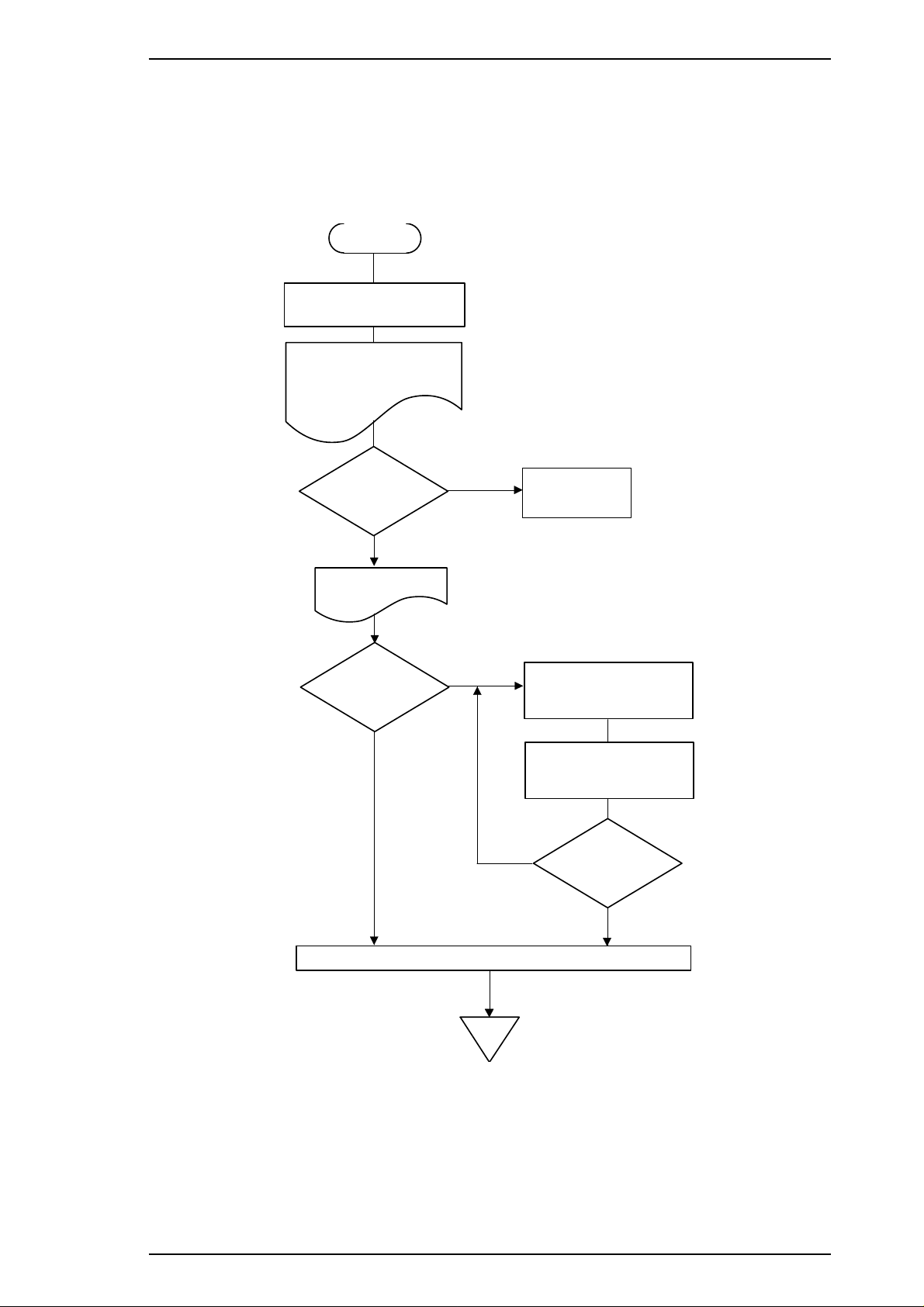

1.4.5 Default Settings

This printer has user-selectable default settings, which it refers to at initialization. The default (and factory)

settings are listed in the table on the next page.

1.4.5.1 Setting Method

The method of setting defaults is shown in the flowchart below.

Figure 1-3. Default Setting Flowchart

Rev.A 1-11

Page 14

Product Description EPSON Stylus COLOR 500 Service Manual

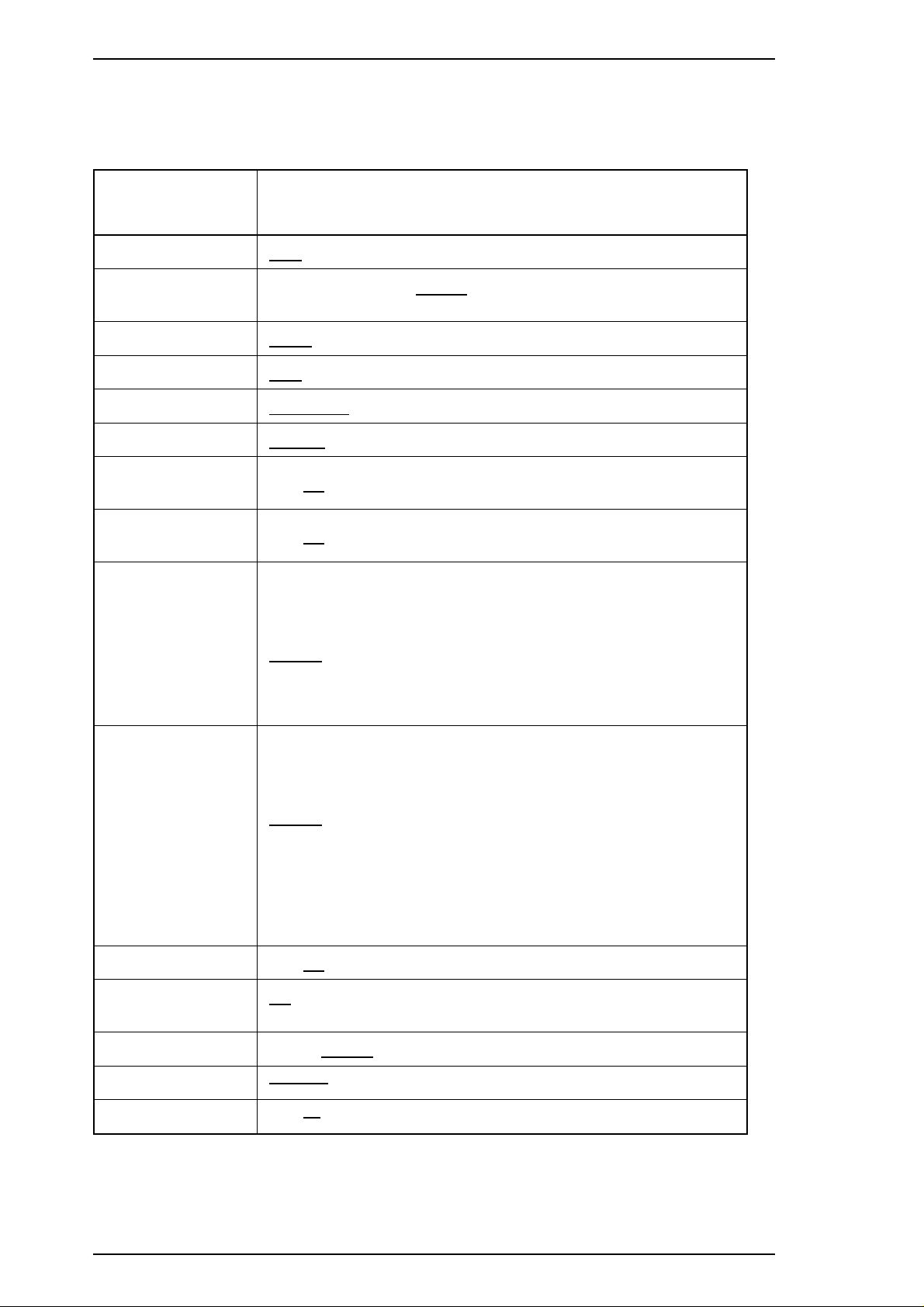

1.4.5.2 Setting Menus

The default setting menus are:

Table 1-7. Default Settings

Menus

Print direction

Font

Pitch

I/F mode

Auto I/F wait mode

Software

Auto CR

(IBM mode only)

AGM

(IBM mode only)

Character tables

(standard version)

Settings

(Underlines Indicate Factory Default Settings)

Auto / Bi-D / Uni-D

Roman / Sans Serif /

Courier / Prestige / Script / Roman T /

Sans Serif H

10 cpi / 12 cpi / 15 cpi / 17.1 cpi / 20 cpi / Proportional

Auto / Parallel / Serial

10 seconds / 30 seconds

ESC/P2 / IBM X24E

On /

Off

Off

On /

Italic U.S.A. Italic France

Italic Germany Italic U.K.

Italic Denmark Italic Sweden

Italic Italy Italic Spain 1

PC 437 PC 850

PC 860 PC 863

PC 865 PC 861

BRASCII Abicomp

Italic U.S.A. Italic France

Italic Germany Italic U.K.

Italic Denmark Italic Sweden

Italic Italy Italic Spain 1

Character tables

(NLSP version)

PC 437 PC 437 Greek

PC 850 PC 853

PC 855 PC 852

PC 857 PC 866

PC 869 MAZOWIA

Code MJK ISO 8859-7

ISO Latin 1T Bulgaria

Auto line feed On /

Network I/F mode

Loading position 3 mm /

Thick paper

Economy mode

Note *1. Other settings are set using special commands for the EEPROM.

Off

Off: Used in standalone environment

On: Used in network environment

8.5 mm / Others *

Envelopes / Index cards (portrait)

Off

On /

1

1-12 Rev.B

Page 15

EPSON Stylus COLOR 500 Service Manual Product Description

1.5 INK CARTRIDGE SPECIFICATIONS

Black

Type Exclusive cartridge

Model S020093

Color Black

Print capacity 620 pages/ A4 (LQ Roman EQMAtext)

Ink Life 2 years from production

Storage temperature 20 °C~40°C (–4° F ~ 104° F)

Storage, less than a month at 40 °C (104° F)

–30 °C~40°C (86° F ~ 104°F)

Packing storage, less than a month at 40 °C (104° F)

–30 °C~60°C (86° F ~ 140°F)

Transit, under 120 hours at 60° C(140°F)

and less than a month at 40° C (104° F )

Dimensions 19.8 mm (W) × 52.7 mm (D) × 38.5 mm (H)

0.8" (W) x 2.1" (D) x 1.5" (H)

Color

Type Exclusive cartridge

Model S020097

Color Magenta, cyan, yellow

Print capacity 320 pages /A4 (360 dpi, 5% duty, each color)

Ink Life 2 years from production

Storage temperatures –20°C~40°C(–4°F ~ 104°F)

Storage, less than a month at 40° C (104° F)

–30° C~40°C(86°F ~ 104° F)

Packing storage, less than a month at 40° C (104° F)

–30° C~60°C(86°F ~ 140° F)

Transit, less than 120 hours at 60 °C (140° F)

and less than a month at 40° C (104° F )

Dimensions 42.9 mm (W) × 56.8 mm (D) × 38.5 mm (H)

1.7" (W) x 2.2" (D) x 1.5" (D)

Rev.A 1-13

Page 16

Product Description EPSON Stylus COLOR 500 Service Manual

1.6 MAIN COMPONENTS

The main components of the EPSON Stylus COLOR 500 are designed for easy removal and repair. The main components are:

❏ Main Board (C161 MAIN)

❏ Power Supply Board (C160 PSB/PSE)

❏ Panel Board (C161 PNL)

❏ Mechanism

❏ Housing

1.6.1 Main Board (C161 MAIN)

This board consists of a CPU (TMP95C061F), a gate array (E05B12), ROM (CG), PROM, DRAM, EEPROM, motor driver ICs,

printhead driver circuits, etc.

1.6.2 Power Supply Board (C160 PSB/PSE)

This power supply board is the same as the one used for the Stylus Color IIs. This board consists of a transformer, a switching FET,

regulator IC, diode bridge, etc. This board has two ratings for input AC voltages.

1-14 Rev.B

Page 17

Normal

state

Ejecting

state

Vibration Plate

Vibration Plate

Cavity

Nozzle

Piezo

Piezo

Cavity

EPSON Stylus COLOR 500 Service Manual Operation Principles

2.1 OVERVIEW

This section describes operating principles of the EPSON Stylus COLOR 500 printer mechanism and

electrical circuits.

2.2 OPERATING PRINCIPLES OF THE PRINTER MECHANISM

2.2.1 Principles of the Printing Operation

The printhead operates in one of two modes to eject ink from each nozzle:

❏ Normal state

No electrical charge is applied to the piezoelectric element attached to the back of the cavity, and

pressure inside the cavity is kept at a constant level.

❏ Ejecting state

The head data signal is applied to the specific nozzle control line to select the active nozzle for printing,

and the piezoelectric element is gradually charged by the drive voltage. Charging the piezoelectric

element bends the vibration plate to compress the cavity. Then, ink is ejected from the nozzle.

Figure 2-1. Principles of the Printing Operation

When the ink charge or printhead cleaning operation is performed, ink in the cavity is vacuumed out with a

pump mechanism. During printing, on the other hand, ink is simultaneously supplied from the ink cartridge

and ejected from the nozzle, depending on changes in the volume of the cavity.

A thermistor is attached to the side of the color printhead driver board to monitor the temperature, because the

viscosity of the ink varies, depending on the temperature. The detected temperature level is fed back to the

printhead drive voltage control circuit to change the time of the Tc pulse.

Rev.A 2-1

Page 18

Operating Principles EPSON Stylus COLOR 500 Service Manual

2.3 OPERATING PRINCIPLES OF THE ELECTRICAL CIRCUITS

The EPSON Stylus COLOR 500 contains the following circuit board units:

❏ C161 MAIN / C198 MAIN Board (main control circuit board)

❏ C160 PSB/PSE Board (power supply circuit board). This board is the same as for the Stylus

COLOR.

❏ C161 PNL (control panel board)

In addition to the circuit boards above, part of the printhead driver circuit is built on a separate circuit board

installed in the carriage unit; the printhead is attached directly to this board. The figure below shows a block

diagram of the electrical circuitry.

2.3.1 Operating Principles of the Main Control Circuit

The main control circuit for this printer is the C161 MAIN Board. This circuit is controlled by a 16-bit

TMP96C061AF CPU (IC1), running at a 12.5 MHz internal clock (25 MHz external clock). A 4M DRAM

(CAS method) on this board is controlled by the CPU itself. The CPU manages the serial interface control

(RS-422 for Mac).

C198 MAIN board equips with the hybrid IC for monochrome head common driver circuit.

Gate array E05B12 (IC2) manages printhead driver control, the external Centronics

panel, and the motor control. The main board also is equipped with a 93C46 EEPROM (IC11) to store certain

parameters, such as the printer mechanism control parameter, default setting parameters, as well as the special

counter value used for printhead (ink management) protection. The NJU6355E timer IC (IC10) counts each

time the printer is cleaned and keeps track of how long since the printer has been used, allowing the printer to

be cleaned only when necessary.

®

parallel I/F, the control

PROM(4M)

(IC3)

RS-422

Seria l I/ F

From A

From B

PROM

(IC4)

CPU

TMP95C061AF

(IC1)

Vx

Battery

C161/ C198 MAIN Board

Black/Color Head

Common D ri v er C ir c ui t

UDN2917EB (IC14, 15)

Carriage/Paper Feed

Motor Driver

DRAM

(IC5)

DMAREQ

CLK

SD I/O

(IC10)

NJU6355E

(Timer

Counter)

CG-ROM

(IC6)

E05B12

(IC2)

To B

Parallel I/ F

(Centronics)

Carriage/Paper Feed

Carriage

SED6100D0A/

SED6110D0A (U1)

SED5619D0A (U1)

Data Bus

Address Bus

To A

Drive Signal

Black/Color Head

Common and Nozzle

CG-ROM

(IC7)

(IC8)

PST592D

Panel

EEPROM

(IC11)

93C46

(IC9)

M51955B

Selector Drive Signal

Reset

(Logic)

Reset

(Power)

Black

64 Nozzles

Color

60 Nozzles

Figure 2-2. Main Control Circuit Block Diagram

2-2 Rev.B

Page 19

COM

GND

Pc

Head Drive Voltage

Pd

BHLAT

BHSO

BHCLK

#1

#64

EPSON Stylus COLOR 500 Service Manual Operation Principles

2.3.1.1 Printhead Driver Circuit

The printhead driver circuit for this printer is composed of the following two parts:

❑ Common driver circuit (trapezoidal drive pulse generation)

❑ Head driver circuit (nozzle control built on the printhead)

The SED6100D0A/SED6110D0A monochrome printhead driver circuit for the 64-dot head on the carriage

acts as a nozzle selector to drive the black printhead nozzles selectively. The SED5619D0A 60-dot (Y, M, C

× 20 ) thermal head driver in the color printhead’s driver circuit on the carriage also acts as a nozzle selector

to drive the color head nozzles selectively. Print data is converted to serial data by gate array E05B12 (IC2)

and is output from port BHSO to the black head driver circuit or output from port CHSO to the color head

driver circuit. Then, head driver SED6100D0A/ SED6110D0A or SED5619D0A latches the head data when

gate array E05B12 outputs the BHLAT or CHLAT signal, and the latched data becomes 64-bit parallel data

for the black head, or 60-bit parallel data for the color head. One bit corresponds to each nozzle.

When data transfer and nozzle selection are complete, gate array E05B12 outputs the common driver pulse Pc

(charge pulse) and Pd (discharge pulse) to the common driver circuit. The common driver circuit then

generates the trapezoidal pulse and applies it to the printhead as a common driver pulse. After this, the nozzle

selected by the head data is activated to eject ink.

E05B12 (IC2)

Pc

Pd

BHLAT

BHCLK

BHSO

Pc

Pd

CHLAT

CHCLK

CHSO

Figure 2-2. Print Data Transmission Timing

SED6100D0A

SED6110D0A (U1 )

Common Driver

Common Driv er

C161 MAIN

CN8

CN1

CN9

CN1

COM1-36

LAT

DOUT63 - 1

CLK

DOUT64 - 2

SI

SED5619D0A (U1)

COM1-3

LAT

DO64-61

CLK

DO60 - 1

SI

On Carriage (Head Driver Board)

Row A

Row B

Not Con nected

Magenta

Cyan

Yellow

Figure 2-3. Printhead Driver Circuit Block Diagram

Rev.A 2-3

Page 20

Operating Principles EPSON Stylus COLOR 500 Service Manual

2.4 INK SYSTEM MANAGEMENT

The ink system is controlled to protect the printhead and ink supply system and ensure high-quality output.

2.4.1 Counter

EEPROM 93C46 (IC11) on the main board stores certain counter and timer values used for controlling ink

system operation. The counters are stored in the EEPROM on the main board, and while the printer is on, this

data is stored into the RAM on the main board.

❏ Ink Consumption Counter This counter value is stored in the EEPROM on the main board,

and while the printer is on, the data is stored in RAM on the

main board. This counter is always reset when the ink cartridge

is removed.

2-4 Rev.B

Page 21

EPSON Stylus COLOR 500 Service Manual Disassembly and Assembly

3.1 OVERVIEW

This section describes procedures for disassembling the main components of the printer. Unless otherwise

specified, disassembled units or components can be reassembled by reversing disassembly procedures, so no

assembly procedures are included. Precautions for any disassembly or assembly procedure are described

under the heading “Disassembly/Assembly Points”. Adjustments required after assembly are described under

the heading “Required Adjustments”.

3.1.1 Precautions for Disassembling the Printer

WARNING

❑ Disconnect the power cable before disassembling or assembling the printer.

❑ Wear goggles to protect your eyes from ink. If ink gets in your eye, flush it with fresh water

and see a doctor immediately. If ink comes into contact with your skin, wash it off with

soap and water. If irritation occurs, contact a physician.

❑ A lithium battery is installed on the C161 MAIN/C198 MAIN board of this printer. Be sure to

observe the following instructions when servicing the battery:

1. Keep the battery away from any metal or other batteries so that electrodes of opposite

polarity do not come in contact with each other.

2. Do not heat the battery or place it near fire.

3. Do not solder on any part of the battery. (Doing so may result in leakage of electrolyte

from the battery, burning, or explosion. The leakage may affect other devices close to

the battery.)

4. Do not charge the battery. (An explosive gas may be generated inside the battery, and

cause burning or explosion.)

5. Do not dismantle the battery. (The gas inside the battery may hurt your throat.

Leakage, burning, or explosion may also result.)

6. Do not install the battery in the wrong direction. (This may cause burning or explosion.)

CAUTION

There is danger of explosion if the battery is incorrectly replaced. Replace only with the same or

equivalent type, recommended by the manufacturer. Dispose of used batteries according to the

government’s laws and regulations.

ATTENTION

Risque d’explosion si la pile est remplacée incorrectement. Ne remplacer que par une pile du

même type ou d’un type équivalent recommandé par le fabricant. Elminer les piles déchargées

selon les lois et les règles de sécurité en vigueur.

CAUTION

❑ Never remove the ink cartridge from the carriage unless specified to do so.

❑ When transporting the printer after installing the ink cartridge, be sure to pack the printer

for transportation without removing the ink cartridge.

❑ Use only recommended tools for disassembling, assembling, or adjusting the printer.

❑ Apply lubricants and adhesives as specified. (See Chapter 6.)

❑ Make specified adjustments when you disassemble the printer. (See Chapter 4.)

Rev.B 3-1

Page 22

Projections

Projections

CBS (3x8)

CBS (3x8)

Plain Washer

Spacer

Paper Guide

Disassembly and Assembly EPSON Stylus COLOR 500 Service Manual

3.2 DISASSEMBLY AND ASSEMBLY

CAUTION

Follow the precautions in Section 3.1.1 when disassembling the printer.

This section consists of the topics shown in the diagram below. See the exploded view of the printer in the

Appendix, if necessary.

3.2.1 ASF (Auto Sheet Feeder) Assembly Removal

1. Remove the upper housing assembly. (See EPSON Stylus COLOR II Service Manual, Section 3.2.1.)

2. Disconnect the PS sensor cable from connector CN11 on the C161 / C198 MAIN board.

3. Remove 2 CBS (3x8) screws, a plain washer, and a spacer securing the ASF assembly to the base frame.

4. Move the paper guide to the stopper on the ASF paper support, and bend the back of the left guide

toward the rear.

5. Remove the ASF assembly by lifting from the rear of the printer and pulling it back.

DISASSEMBLY/ASSEMBLY POINTS

❑ Do not install with the power supply cable under the ASF assembly.

❑ To attach the ASF assembly to the base frame, insert the projections from the ASF assembly

into corresponding holes in the base frame.

Figure 3-1. ASF Assembly Removal

3-2 Rev.B

Page 23

CB(O) (2.5x8)

Cartridge Holder H

Cartridge Sensor

Hooks

Black Head Cable

Black Printhead

CB(O) (2.5x8)

Cartridge Sensor

Cable

Cartridge Sensor

Connector

Carriage Unit

EPSON Stylus COLOR 500 Service Manual Disassembly and Assembly

3.2.2 Black Head Removal

CAUTION

Although the EPSON Stylus COLOR 500’s printhead is not compatible with the printhead for the

Stylus COLOR II, either printhead can fit in the other printer physically. So, take care not to

misassemble the printer with the wrong printhead.

1. Remove the upper housing assembly. (See EPSON Stylus COLOR II Service Manual, Section 3.2.1.)

2. Remove the cartridge sensor cable from the cartridge sensor connector.

3. Remove the black cartridge lever from black ink cartridge holder H.

4. Remove the CBS (2.5x8) screw securing cartridge holder H to the carriage unit. Disengage the hooks

for cartridge holder H that secure it to the carriage unit. Remove holder H by pulling it upward.

5. Remove the head fastening pin from the carriage unit.

6. Remove the black printhead.

7. Disconnect the black cartridge sensor harness from the printhead.

Figure 3-2. Black Head Removal

Rev.B 3-3

Page 24

Disassembly and Assembly EPSON Stylus COLOR 500 Service Manual

CAUTION

❑ After you remove the ink cartridge, always install a new cartridge immediately.

❑ The ink cartridge always must be installed in carriage unit so that the printhead does not

dry up.

❑ The carriage unit must be moved to carriage home position and fixed to the base frame

with the CR clamp so that it does not move during transport. (See EPSON Stylus COLOR II

Service Manual, Section 3.2.10.) Otherwise, the carriage may receive permanent damage.

DISASSEMBLY/ASSEMBLY POINT

❑ Fit the head fastening pin completely into the notch in the carriage unit. (Refer to EPSON

Stylus COLOR II Service Manual, Figure 3-21.)

❑ Install the cartridge sensor cable in the carriage unit as shown in the EPSON Stylus COLOR II

Service Manual, Figure 3-21.

Cartridge Sensor Conn ector

Black Printhead

Head Fastening Pin

Carriage Unit Notches

Figure 3-3. Inside the Carriage Unit

REQUIRED ADJUSTMENT

After removing or changing the black head, perform the following adjustments:

1. Black head angle adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.4)

2. Black-color head vertical adjustment (See EPSON stylus COLOR II, Service Manual, Section

4.1.5)

3. Head gap adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.3)

4. Bi-D alignment adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.2)

CAUTION

The following data is written on the printheads:

Black Head

Nozzles

The Rank of Holding Time 2

Head Drive Voltage (VH1)

Standard Head

Voltage (VH2)

Serial Number

R

L

Color Head

ID4

ID3

ID1

ID2

Color Head

Drive Voltage

Indication

Figure 3-4. Data Found on the Printhead

3-4 Rev.B

Page 25

EPSON Stylus COLOR 500 Service Manual Disassembly and Assembly

3.2.3 Color Head Removal

1. Remove the upper housing assembly. (See EPSON Stylus COLOR II Service Manual, Section 3.2.1.)

2. Push the head fastening lever back, and remove the color printhead with the color ink cartridge up.

3. Disconnect the color head cable from the color printhead.

DISASSEMBLY/ASSEMBLY POINT

❑ Attach the color printhead to the carriage by installing the color printhead so that the color

head can be seen projecting from the hole in the right side of the carriage window.

❑ Place the color head cable so it is attached by the projection of head fastening lever.

Color Cartridge Lever

Color Head

Color Head

Head Fastening Lever

Carriage Unit

Projection on Color Head

Color Head Cable

Head Cable

Projection on Head Fastening Lever

Head Fastening Lever

Figure 3-5. Color Head Removal

Rev.B 3-5

Page 26

Disassembly and Assembly EPSON Stylus COLOR 500 Service Manual

CAUTION

❑ After removing an ink cartridge, always install a new cartridge immediately.

❑ The ink cartridge always must be installed in the carriage unit, so the printhead does not

dry up.

❑ The carriage unit must be moved to carriage home position and fixed to base frame with the

CR clamp so that it does not move during transport. (See EPSON Stylus COLOR II Service

Manual, Section 3.2.10.) Otherwise, the carriage may receive permanent damage.

REQUIRED ADJUSTMENT

After removing or changing the color head, perform the following adjustments:

1. Head data writing operation (See EPSON Stylus COLOR II Service Manual, Section 4.1.3.)

2. Color head angle adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.5.)

3. Bi-D alignment adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.6.)

4. Black-color head vertical adjustment (See EPSON stylus COLOR II Service Manual,

Section 4.1.7.)

5. Head gap adjustment (See EPSON Stylus COLOR II Service Manual, Section 4.1.8.)

CAUTION

The data shown in Figure 3-4 is written on the printheads:

❑ If the value of VH2 is the same as VH1, HV2 is abbreviated. So, input the value of HV1 as VH2.

3-6 Rev.B

Page 27

PF Drive Roller Assem bly

Grounding Spr ing

M/B Shield P late

EPSON Stylus COLOR 500 Service Manual Disassembly and Assembly

3.2.4 Printer Mechanism Removal

3.2.4.1 Drive Roller Removal

1. Remove the printer mechanism. (See EPSON Stylus COLOR II Service Manual, Section 3.2.4.)

2. Remove the pump unit. (See EPSON Stylus COLOR II Service Manual, Section 3.2.6.1.)

3. Remove the carriage unit. (See EPSON Stylus COLOR II Service Manual, Section 3.2.6.5.)

4. Remove the lower paper guide assembly. (See EPSON Stylus COLOR II Service Manual, Section

3.2.6.6.)

5. Remove the grounding spring connecting between the M/B shield plate and PF drive roller assembly on

the left side of the printer.

6. Disengage one end of the 46.3 torsion spring from the base frame. Then remove the upper paper guides

and the left upper paper guide from the base frame.

7. On the left and right frames on the each side of the printer, turn bushing 10 to disengage it from the

frame. Then remove the drive roller assembly pulling it upward.

CAUTION

For paper feed accuracy, be careful not to hurt or mar the teeth of spur gear 43.2.

Figure 3-6. Remove the Grounding Spring

Rev.B 3-7

Page 28

EPSON Stylus COLOR 500 Service Manual Adjustment

4.1 OVERVIEW

This section describes adjustments required when the printer is disassembled and assembled for repair. Since

this printer has both black and color heads, it needs new adjustments not required for previous printers.

Perform the appropriate adjustments by referring to the following table.

CAUTION

❑ Always perform adjustments in the order indicated.

❑ When printing adjustment patterns, use the exclusive 720 dpi paper.

❑ Always install a new ink cartridge immediately after removing the old one at returning to user.

Table 4-1. Required Adjustments

Work Performed Adjustment Required

1. Writing head data (See Section 4.1.2.)

2. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

After disassembling or

replacing parts in the

printer mechanism

manual, Section 4.1.6.)

3. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual, Section 4.1.7.)

4. Head gap adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.8.)

After replacing the

C161 / C198 MAIN

board or the printer

mechanism

After replacing or

disassembling the

black head (board)

After replacing or

disassembling the

color head (board)

1. Writing destination data (See Section 4.1.1.)

2. Writing head data (See Section 4.1.2.)

3. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.6.)

4. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual, Section 4.1.7.)

5. Head gap adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.8.)

1. Writing head data (See Section 4.1.2.)

2. Black head angle adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.4.)

3. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.6.)

4. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual, Section 4.1.7.)

5. Head gap adjustment (See EPSON Stylus COLOR II service

manual, Section 4.1.8.)

1. Writing head data (See Section 4.1.2.)

2. Color head angle adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.5.)

3. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.6.)

4. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual Section 4.1.7.)

5. Head gap adjustment (See EPSON Stylus COLOR II service manual

Section 4.1.8.)

Rev.B 4-1

Page 29

Adjustment EPSON Stylus COLOR 500 Service Manual

Table 4-1. Required Adjustments (continued)

Work Performed Adjustment Required

1. Writing head data (See Section 4.1.2.)

2. Black head angle adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.4.)

After replacing or

disassembling both

the

color and black heads

After replacing or

disassembling

the carriage unit

3. Color head angle adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.5.)

4. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.6.)

5. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual Section 4.1.7.)

6. Head gap adjustment (See EPSON Stylus COLOR II service manual

Section 4.1.8.)

1. Platen gap adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.1.)

2. Writing head data (See Section 4.1.2.)

3. Black head angle adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.4.)

4. Color head angle adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.5.)

5. Bi-D alignment adjustment (See EPSON Stylus COLOR II service

manual Section 4.1.6.)

6. Black - color head vertical adjustment (See EPSON Stylus COLOR II

service manual Section 4.1.7.)

7. Head gap adjustment (See EPSON Stylus COLOR II service manual

Section 4.1.8.)

4-2 Rev.B

Page 30

EPSON Stylus COLOR 500 Service Manual Adjustment

4.1.1 Writing the Destination Data

The setup value that specifies the printer destination is stored in an EEPROM on the C161 / C198 MAIN

board. Therefore, this setup value must be rewritten to the EEPROM when the printer mechanism, the main

board, or the EEPROM chip is replaced, or whenever the EEPROM is reset.

CAUTION

Before writing the destination, you must set the Interface Setting to the Parallel interface•or Auto

Select setting.

1. Connect a PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC, and run the program. Load 720 dpi paper into the printer. Then the main menu

appears as shown below:

EPSON STYLUS COLOR 500 Adjustment Program Customer data <> **/**/**

( Customer data input ) .... 1

( Adjustment/Print Inspection ) .... 2

( END ) .... E

Select Menu :? ■

3. Choose 1 first. The Destination setting menu appears on the display.

Factory Setting

(1st : Program Ver. 0 : Standard 1 : Japan )

(2nd : Market 0 : Standard 1 : NLSP )

(3rd : C.G. Table 0 : Italic U.S.A 1 : PC437 2 : PC866)

Memory-SW data (3 col data) :? ■

4. Refer to Table 4-3 to input a 3-digit number for the destination (For example, USA: 000). Then the

main menu appears again.

Table 4-2. Customer Data

Destination Code Destination Code Destination Code Destination Code

EAI 000 EDG 001 EIS 001 ETT 000

EAI

(Latin

America)

000 EFS 001 EIB 001 EHK 001

EAL 000 EUL 001

EUL

ESP 000

Thai 300

Rev.B 4-3

(Northern

Europe)

001

EDG

(NLSP)

EUL

(Middle

East )

011 Russia 012

001 Korea 200

Page 31

Adjustment EPSON Stylus COLOR 500 Service Manual

5. Choose 2 to enter the adjustment mode. The adjustment select menu appears as follows:

EPSON STYLUS COLOR 500 Adjustment Program Rev. x

Customer : Customer data <xxx>

0. Initial Ink Charge

1. Head Voltage Values

2. Angular Head Adjustment

3. Bi-D Adjustment

4. Head Liner Adjustment

5. Head-GAP Timing Adjustment

6. Head Data Indication

9. Customer data charge / END

Select Menu ? ■

Note: The ink consumption counter is always reset when the ink cartridge is removed.

6. After another adjustment, you type 9 and press Enter. The destination data is installed into the printer

and the main menu appears on the display. If you want end the program, press the E key.

CAUTION

The values you have set are not saved permanently in the EEPROM until the printer is turned off.

Turn off the printer at once after the adjustments are complete.

11. Turn off the printer.

4-4 Rev.B

Page 32

EPSON Stylus COLOR 500 Service Manual Adjustment

4.1.2 Writing the Head Data

4.1.2.1 Writing the Head Data

Head data settings for each printhead are stored in the EEPROM on the C161 MAIN/C198 MAIN board.

Therefore, these setup values must be rewritten to the EEPROM when the printer mechanism, the main board,

or the EEPROM chip is replaced, but the head data and destination settings are not reset whenever the

EEPROM is reset by panel operation.

CAUTION

Before writing the destination, you must set the Interface Setting to the Parallel interface•or Auto

Select setting.

1. Connect a PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC and run the program. Load 720 dpi paper into the printer. Then the main menu

appears, as shown below:

EPSON STYLUS COLOR 500 Adjustment Program Customer data <> **/**/**

( Customer data input ) .... 1

( Adjustment/Print Inspection ) .... 2

( END ) .... E

Select Menu :? ■

3. Choose 1 first. The Destination setting menu appears on the display.

Factory Setting

(1st : Program Ver. 0 : Standard 1 : Japan )

(2nd : Market 0 : Standard 1 : NLSP )

(3rd : C.G. Table 0 : Italic U.S.A 1 : PC437 2 : PC866)

Memory-SW data (3 col data) :? ■

4. Refer to Table 4-2 to input a 3-digit number for the destination. (For example, USA: 000). Then the

main menu appears again.

5. Choose 2 to enter the adjustment mode. The adjustment select menu appears as shown:

EPSON STYLUS COLOR 500 Adjustment Program Rev. x

Customer : Customer data <xxx>

0. Initial Ink Charge

1. Head Voltage Values

2. Angular Head Adjustment

3. Bi-D Adjustment

4. Head Liner Adjustment

5. Head-GAP Timing Adjustment

6. Head Data Indication

9. Customer data charge / END

Select Menu ? ■

Rev.B 4-5

Page 33

Adjustment EPSON Stylus COLOR 500 Service Manual

6. Press 1 to begin writing the printhead data (head voltage values). The display for entering the head

voltage values appears. Refer to the printhead circuit boards to enter the appropriate values. (See the

illustration below.)

Black Head

Nozzles

The Rank of Holding Time 2

Head Drive Voltage (VH1)

Standard Head

Voltage (VH2)

Serial Number

L

R

Color Head

ID4

ID3

Color Head

Drive Voltage

Indication

ID1

ID2

Figure 4-1. Printhead Voltage Values

CAUTION

❑ If the value of VH2 is the same as VH1, HV2 is abbreviated. So, input the value of HV1 as VH2.

❑ Color printhead data consists of 4 bits of binary data (for example, 0110) taken from the

dots labeled ID4 to ID1. Input the values from ID4 to ID1 continuously.

❑ The value of the ID is 1 when the dot corresponding to that ID is painted black; otherwise,

when the dot is not black, the value is 0.

<<<< Head Voltage Value Setting >>>>

Black Head VH value setting

Head Rank : ■

Black VH1 : ■

Black VH2 : ■

Color Head VH (4 bit data only!!)

7. Press Return to exit the setting mode, or press Space to continue with adjustments.

CAUTION

Because the values you have set are not stored in EEPROM until the printer is turned off, turn off

the printer immediately after completing the adjustments.

8. Turn off the printer.

4-6 Rev.B

Page 34

EPSON Stylus COLOR 500 Service Manual Adjustment

4.1.2.2 Head Data Indication

Selecting this function, this printer prints out the printhead data in EEPROM on the main board. When the

main board is alive, this function is useful to know the printhead data without removing the printheads. As

the printed data are descried by Hexa-decimal digits, get the printhead data referring to later translation tables.

1. Connect a PC to the target printer using a parallel interface cable and turn the printer on.

2. Load BASIC on the PC and run the program. Load 720 dpi paper into the printer. Then the main menu

appears, as shown below:

EPSON STYLUS COLOR 500 Adjustment Program Customer data <> **/**/**

( Customer data input ) .... 1

( Adjustment/Print Inspection ) .... 2

( END ) .... E

Select Menu :? ■

3. Choose 1 first. The Destination setting menu appears on the display.

Factory Setting

(1st : Program Ver. 0 : Standard 1 : Japan )

(2nd : Market 0 : Standard 1 : NLSP )

(3rd : C.G. Table 0 : Italic U.S.A 1 : PC437 2 : PC866)

Memory-SW data (3 col data) :? ■

4. Refer to Table 4-2 to input a 3-digit number for the destination. (For example, USA: 000). Then the

main menu appears again.

5. Choose 2 to enter the adjustment mode. The adjustment select menu appears as shown:

EPSON STYLUS COLOR 500 Adjustment Program Rev. x

Customer : Customer data <xxx>

0. Initial Ink Charge

1. Head Voltage Values

2. Angular Head Adjustment

3. Bi-D Adjustment

4. Head Liner Adjustment

5. Head-GAP Timing Adjustment

6. Head Data Indication

9. Customer data charge / END

Select Menu ? ■

Rev.B 4-7

Page 35

Adjustment EPSON Stylus COLOR 500 Service Manual

6. Press 6 to choose the head data indication function. The printer prints out head data as followings, and

the adjustment select menu appears again.

For example

Printed data is as followings;

Rev. X <***> VH:04232001

Referring to later translation tables,

Rev. X means the revision of the adjustment program.

<***> means the customer data. (Refer to Section 4.1.1.)

“04" means that the head rank is 2. (Refer to Table 4-3.)

”23" means that the head drive voltage (VH1) is 26.52 (V). (Refer to Table 4-4.)

“20" means that the standard head voltage (VH2) is 27.40 (V). (Refer to Table 4-4.)

”01" means that the color head drive voltage is “0001". (Refer to Table 4-5.)

Note If the main board is inactive, there is no way without removing the printhead once to know

head data.

Table 4-3. Head Rank

Indication Rank Indication Rank

00 0 20 32

01 1 21 33

02 2 22 34

03 3 23 35

04 4 24 36

05 5 25 37

06 6 26 38

07 7 27 39

08 8 28 40

09 9 29 41

0A 10 2A 42

0B 11 2B 43

0C 12 2C 44

0D 13 2D 45

0E 14 2E 46

4-8 Rev.B

Page 36

EPSON Stylus COLOR 500 Service Manual Adjustment

Table 4-4. Black VH1 / VH2

Indication Head Voltage Indication Head Voltage

3F 18.27 1F 27.70

3E 18.57 1E 27.99

3D 18.86 1D 28.28

3C 19.16 1C 28.58

3B 19.45 1B 28.87

3A 19.74 1A 29.17

39 20.04 19 29.46

38 20.33 18 29.76

37 20.63 17 30.05

36 20.92 16 30.35

35 21.22 15 30.64

34 21.51 14 30.94

33 21.81 13 31.23

32 22.10 12 31.52

31 22.40 11 31.82

30 22.69 10 32.11

2F 22.98 0F 32.41

2E 23.28 0E 32.70

2D 23.57 0D

2C 23.87 0C 33.29

2B 24.16 0B 33.59

2A 24.46 0A 33.88

29 24.75 09

28 25.05 08 34.47

27 25.34 07 34.76

26 25.63 06 35.06

33.00

34.17

25 26.93 05

24 26.22 04 35.65

23 26.52 03 35.94

22 26.81 02 36.24

21 27.11 01

20 27.40 00 36.83

Rev.B 4-9

35.35

36.53

Page 37

Adjustment EPSON Stylus COLOR 500 Service Manual

Table 4-5. Color Head Drive Voltage

Indication ID 4 ID 3 ID 2 ID 1

F9 1 0 0 0

FA 1 0 0 1

FB 1 0 1 0

FC 1 0 1 1

FD 1 1 0 0

FE 1 1 0 1

FF 1 1 1 0

00 0 0 0 0

01 0 0 0 1

02 0 0 1 0

03 0 0 1 1

04 0 1 0 0

05 0 1 0 1

06 0 1 1 0

07 0 1 1 1

4-10 Rev.B

Page 38

EPSON Stylus COLOR 500 Service Manual Maintenance

6.1 PREVENTIVE MAINTENANCE

Although this printer is designed so that no specific maintenance is required on a regular basis, it is

recommended that you clean the printer thoroughly whenever you get a chance to do so. You can clean:

❑ Outer case

Use a soft, clean cloth, dampened with mild detergent, if necessary.

❑ Auto sheet feeder

If the inside of the auto sheet feeder is dirty (dusty), carefully brush away all dust and dirt using a soft

brush. If the pickup roller of the sheet feeder is dirty, clean its surface with a soft, clean cloth.

❑ Inside the printer

If you notice any dust or dirt that has accumulated inside the printer when you open the outer case for

repair, remove all dust and dirt using a small vacuum cleaner designed for such purposes.

❑ Never use paint thinner, trichloroethylene, or ketone-based solvents for cleaning. These

chemicals can damage the components of the printer.

WARNING

CAUTION

❑ Do not use a hard or abrasive brush for cleaning.

❑ Be careful not to damage the components of the printer when using a vacuum cleaner.

❑ A lithium battery is installed on the C161 MAIN board of this printer. Be sure to observe

the following instructions when servicing the printer or storing the after-service parts:

1. Keep the battery away from any metal or other batteries so that electrodes of opposite

polarity do not come in contact with each other.

2. Do not heat the battery or place it near fire.

3. Do not solder on any part of the battery. (Doing so may result in leakage of electrolyte

from the battery, burning, or explosion. The leakage may damage devices close to the

battery.)

4. Do not charge the battery. (An explosive gas may be generated inside the battery, and

cause burning or explosion.)

5. Do not dismantle the battery. (The gas inside the battery may hurt your throat. Leakage,

burning, or explosion may also result.)

6. Do not install the battery in the wrong direction. (This may cause burning or explosion.)

Rev.A 6-1

Page 39

Maintenance EPSON Stylus COLOR 500 Service Manual

6.2 SERVICE MAINTENANCE

Certain maintenance is required when the printer detects an error or when you observe a decline in print

quality.

6.2.1 Printhead Cleaning

If print quality deteriorates, clean the printhead using the built-in printhead cleaning function. The printer also

has an automatic printhead cleaning cycle to ensure the proper nozzle operation for ink ejection as well as to

preserve its best condition. Therefore, to avoid wasting ink, perform this printhead cleaning operation only if

print quality declines.

1. Press the Cleaning ● button for black head cleaning and press the Cleaning ●●● button for color head

cleaning.

2. After printhead cleaning, the printer returns into previous condition automatically.

CAUTION

The printhead cleaning operation is usually performed in waiting condition. And this function is

able to performed in printing condition too. But we recommend to perform it in waiting condition

to prevent from the irregular paper feeding.

6-2 Rev.A

Page 40

EPSON Stylus COLOR 500 Service Manual Maintenance

6.3 LUBRICATION AND ADHESIVEs

The printer must be lubricated properly when the printer is disassembled for component replacement, or if the

mechanical noise exceeds a certain level. EPSON recommends only the lubricants listed in table below for

this printer, both of which have been tested extensively and found to comply with the requirements of this

printer mechanism. Figure 6-1 shows the lubrication points and adhesive points.

Table 6-1. Recommended Lubricants

Type Name Quality Part No. Availability

Oil O-8 40 cc 1019753 E

Grease

Adhesive NEJI LOCK #2 (G) 1000 g B730200200 E

Note: E = EPSON Exclusive product (Not commercially available)

Table 6-2. Lubrication and Adhesive Points

Ref. No. Lubrication/Adhesive Point Lubricant

G-20 40 gm B702000001 E

G-26 40 gm B702600001 E

1

2 The sliding surface of the gear guide shaft with spur gear 12.9

3 The surface of the spur gear guide shaft G-26 (3-5 mg)

4 The contact point of the right frame shaft with spur gear 80/40 G-26 (3-5 mg)

5

6

7

8 Carriage unit oil pad O-8 (0.3 ml)

9 The surface of the CR guide shaft O-8 (unify and thin)

10 The both sides of the CR guide shaft G-20 (3-5 mg)

11 The contact point of PG transmission lever with PG lever G-26 (1-3 mg)

12 The surface of PG lever where it contacts the base frame G-26 (3-5 mg)

13 The sliding surface of the base frame with carriage unit G-26 (3-5 mg)

14 The point of shaft #4 in the right frame G-26 (3-5 mg)

15 The surface of spur gear 22.4 where it contacts the release cam G-26 (3-5 mg)

16

(1) From the color head angle adjust lever to the cartridge unit

(2) From the black head angle adjust lever to the cartridge unit

The contact point of the right pulley assembly shaft with spur gear

28.5 and spur gear 15.

The contact point of the PF roller assembly compression spring

with the plain washer

The right and left surfaces of the PF drive roller assembly under

the lower paper guide assembly

The contact point of the eject roller ground plate with the lower

paper guide

The contact point of the PF roller assembly with the grounding

spring

G-26 (3-5 mg)

O - 8 (1/2 turn of

teeth surface)

G-26 (3-5 mg)

G-26 (3-5 mg)

G-26 (3-5 mg)

G-26 (3-5 mg)

NEJI LOCK #2

(1-3 mg)

NEJI LOCK #2

(1-3 mg)

CAUTION

❑ Do not apply too much lubricant, as it may stain the mechanism or cause it to malfunction.

Rev.A 6-3

Page 41

Maintenance EPSON Stylus COLOR 500 Service Manual

1

4

2

5

16

8

3

6

7

6

M/B Shield Plate

10

Carriage Unit

9

11

PG Lever

12

Base Frame

Figure 6-1. Lubrication Points and Adhesive Points (1)

6-4 Rev.A

Page 42

(2)

(1)

13

14

15

13

Carriage Unit

Base Frame

EPSON Stylus COLOR 500 Service Manual Maintenance

Figure 6-2. Lubrication Points and Adhesive Points (2)

Rev.A 6-5

Page 43

CN1

CN2

CN1

CN5

CN11

CN9

CN8

CN7

CN6

CN10

CN

CN

CN2

CN3

CN4

AC Input

C160 PSB/PSE

C161 MAIN

(C198 MAIN)

Carriage Unit

Color

Black

PF Motor

CR Motor

HP Sensor

PE Sensor

PS Sensor

C161 PNL

Parallel I/F

Serial I/F

Printer Mechanism

EPSON Stylus COLOR 500 Service Manual Appendix

A.1 CONNECTOR SUMMARY

The figure below shows the interconnection between the major components of the EPSON Stylus COLOR

500.

Figure A-1. Interconnection of Main Components

Rev.B A-1

Page 44

EPSON Stylus COLOR 500 Service Manual Appendix

GND

GND

+5V/0.5A

+42V/0.5A

CN2

+42V

1

2

5

4

3

FG

D51

11

FMB-G19L

T1 PT-63

2

C15

ZD51

HZS5C-3

2200P/1.2KV

ZD81

HZS6C-3

Q1

L51

IC51 L4962E

ZD82

HZS5C-3

3

K2182

PI10-471K

1234567

ZD83

C51

2200U/50V

C14

D55

HZS6C-3

R18

11EQS06

ZD84

4

240K/0.5W

4700P

R58

HZS5C-3

C54

C82

4.3K

15K

ZD85

6.3V

470U

2.2U

R63

HZS6C-3

R11

C13

50V

C58

ZD86

5

2200P

C81

0.033U

HZS5C-3

390/0.5W

0.01U

R56

D1

11EQS06

150

Q2

10

Q3

2PA1015Y

R15

C4408

9

510

R13

C55

4.7K

R16

C56

C12

270

33U/35V

R55

0.1U/50V

R14

15K

25V/100U

510

D81

IC1

R54

TL431

GMB01

10K

D52

8

2

1

3

Q81

DTA124ES

R70

AG01Z

1.2K

6

ZD52

R57

2

PC1

3

R20

R21

ZD53

HZS6B-1

HZS24-1

150

1

4

3K

10K

ZD87

Q82

DTC124ES

HZS24-1

PC2

TLP521-1GB

D4

AG01A

R81

R69

4

750

100

R68

2

3K

5

1

6

R25

TLP541G

27K

C18

0.01U

R1

R26

1M/0.5W

2.5A/125V

F1

100K/0.5W

or 250V

CN1

12

LN

100-120VAC

C11

220U/200V

3

C8

R12

D2

0.91/2W

2

4

DB1

S1VBA60

1

FG

1000P

SW1

R19

11EQS04

20K

R2

3.9/5W

C4

C3

3

4

FG

2200P

C1

2

1

2200P

L1

HF2022-103Y0R7

0.1U

Figure A-4. C160 PSB Board Circuit Diagram

Rev.B A-7

Page 45

Appendix EPSON Stylus COLOR 500 Service Manual

GND

GND

+5V/0.5A

+42V/0.5AT1 PT-64

CN2

+42V

1

2

3

4

5

FG

D51

11

1

ZD51

HZS5C-3

FMB-G19L

C15

1000P/1.5KV

ZD81

2

HZS6C-3

Q1

L51

IC51 L4962E

ZD82

HZS5C-3

3

K1603

R12

PI10-471K

ZD83

C51

C14

2/1W

D55

1234567

HZS6C-3

2200U/50V

R28

R18

2200P

11EQS06

ZD84

4

300K/0.5W

300K/0.5W

D2

HZS5C-3

C54

C82

R63

4.3K

R58

15K

ZD85

HZS6C-3

R19

11EQS04

6.3V50V

470U

2.2U

5

R11

C13

C58

2200P

C81

0.033U

ZD86

HZS5C-3

1.1K

4700P

20K

R56

D1

150

11EQS06

Q3

Q2

C4408

10

9

2PA1015Y

R15

510

R13

4.7K

R16

C56

C55

270

33U/35V

R55

0.1U/50V

C12

R14

15K

25V/100U

510

IC1

D81

R54

TL431

GMB01

10K

D52

8

21

3

Q81

R70

AG01Z

DTA124ES

1.2K

6

ZD52

R57

150

2

PC1

3

R20

R21

ZD53

HZS6B-1

HZS24-1

Q82

1

4

3K

10K

R81

750

R69

100

ZD87

HZS24-1

DTC124ES

R68

2

PC2

4

TLP721F(D4-GB)

D4

AG01A

R26

R27

3K

5

1

6

TLP747JF(D4)

R25

27K

100K/0.5W

100K/0.5W

C18

0.01U

F1

T1.25AH/250V

CN1

12

LN

220-240VAC

C11

3

56U/400V

C8

R2

C4

C3

FG

2200P

0.1U

C2

2200P

3

4

2

L1

C1

1

HF2022-253Y0R4

0.22U

R1

1M/0.5W

2

4

DB1

S1VBA60

1

FG

1000P

10/5W

SW1

Figure A-5. C160 PSE Board Circuit Diagram

A-8 Rev.A

Page 46

EPSON Stylus COLOR 500 Service Manual Appendix

GND

GND

+5V/0.5A

+42V/0.5A

CN2

+42V

1

2

3

4

5

FG

C54

11EQS06

C82

4.3K

R58

470U

2.2U

R63

15K

6.3V50V

C58

C81

ZD53

HZS6B-1

R81

750

R69

Q82

ZD87

HZS24-1

DTC124ES

100

2200P

0.033U

C56

33U/35V

R55

15K

D81

GMB01

R54

10K

Q81

R70

DTA124ES

1.2K

ZD52

HZS24-1

L51

PI10-471K

D55

IC51 L4962E

1234567

D51

11

T1 PT-64

1

C15

ZD51

HZS5C-3

FMB-G19L

1000P/1.5KV

ZD81

2

HZS6C-3

Q1

ZD82

HZS5C-3

3

K1603

R12

ZD83

C51

C14

2/1W

ZD84

HZS6C-3

2200U/50V

4

ZD1

R18

2200P

D2

HZS5C-3

RD120E

390K/0.5W

ZD85

R19

11EQS04

HZS6C-3

R11

C13

ZD86

5

13K

HZS5C-3

1.1K

4700P

R56

D1

150

11EQS06

Q3

2PA1015Y

Q2

C4408

10

R15

9

510

R13

C55

4.7K

R16

270

0.1U/50V

C12

R14

25V/100U

510

IC1

R68

PC2

4

TLP721F(GB)

R32

390K/0.5W

2

R26

R27

3K

5

1

6

R25

100K/0.5W

100K/0.5W

TLP747JF

27K

C18

0.01U

R57

150

D52

AG01Z

8

2

1

3

TL431

1

2

PC1

4

3

6

R20

3K

10K

R21

D4

AG01A

F1

T1.25AH/250V

CN1

12

220VAC

LN

C11

3

56U/400V

C8

R2

C4

C3

FG

2200P

0.1U

C2

2200P

3

4

2

L1

C1

1

HF2022-253Y0R4

0.22U

R1

1M/0.5W

2

4

DB1

S1VBA60

1

FG

1000P

10/5W

SW1

Figure A-6. C160 PSE (Korean) Board Circuit Diagram

Rev.B A-9

Page 47

LED0

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LED9

LED10

LED11

SW0

SW1

SW2

SW3

SW4

GREEN

RED

RED

RED

NOT MOUNTED

NOT MOUNTED

MOUNTED

MOUNTED

MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

NOT MOUNTED

20

5

3

1

7

9

14

16

18

15

13

11

19

17

8

6

4

2

10

12

+5 V

+5 V

+5 V

LED11

LED10

LED9

LED8

LED7

LED6

LED5

LED4

LED3

LED2

LED1

LED0

SW4

SW3

SW2

SW1

SW0

GND

CN1

Appendix EPSON Stylus COLOR 500 Service Manual

Figure A-7. C161 PNL Board Circuit Diagram

A-10 Rev.A

Page 48

433

2

3

3

.

5

156.2

Units : mm

EPSON Stylus COLOR 500 Service Manual Appendix

A.3 EXPLODED DIAGRAMS

Figure A-8. EPSON Stylus COLOR 500 Outline Drawing

Rev.B A-11

Loading...

Loading...